Titanium alloy guide wire for surgical interventional therapy

An interventional therapy, titanium alloy technology, applied in the direction of guide wire, etc., can solve the problems of high cost, complex processing process of titanium alloy guide wire, poor adaptability, etc., and achieves simple processing and manufacturing, good controllability, support force, and performance adjustment large range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

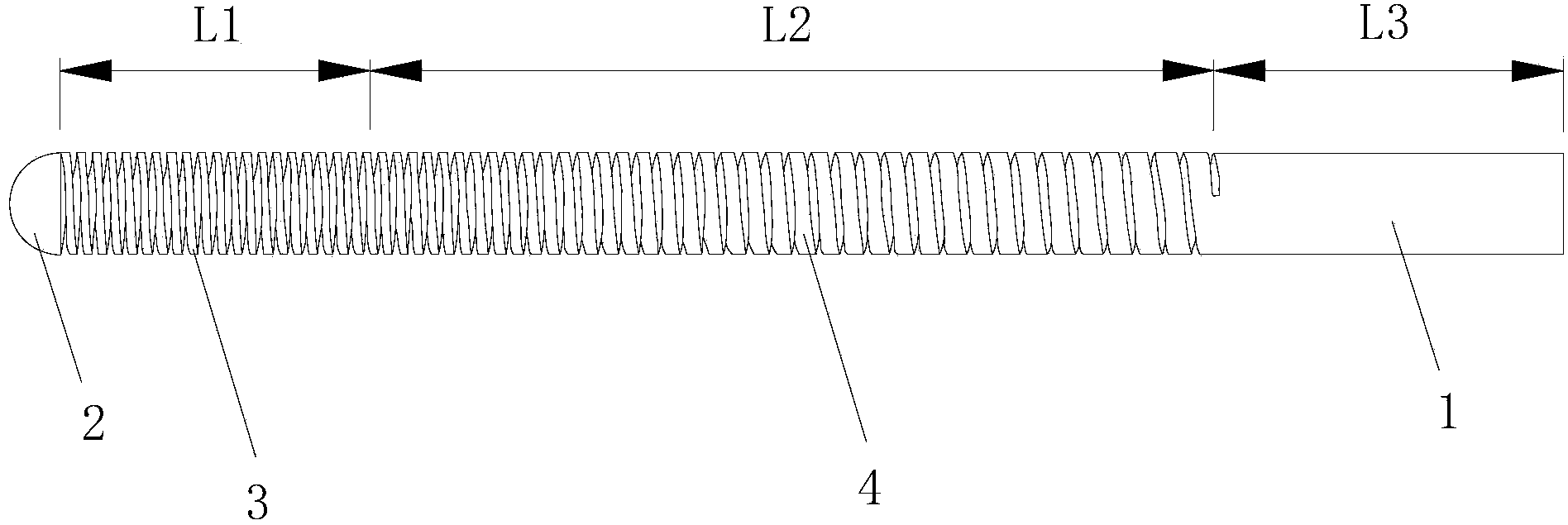

[0029] Such as figure 1 A titanium alloy guide wire for surgical interventional treatment is shown, comprising a titanium alloy thin-diameter thin-walled tubing 1 and a noble metal tip 2 arranged at the distal end of the titanium alloy thin-diameter thin-walled tubing 1, the titanium alloy thin-diameter thin-walled The tube material 1 is divided into three parts from far to near: the distal section of the guide wire, the middle section of the guide wire and the proximal section of the guide wire. The tube wall of the far section of the guide wire has a single helical groove one 3, and the tube wall of the middle section of the guide wire has a single helical groove two 4, and the single helical groove one 3 is an equal-pitch helical groove. The single helical groove two 4 is a variable pitch helical groove, the groove widths of the single helical groove one 3 and the single helical groove two 4 are all the same, the pitch of the single helical groove two 4 gradually increases ...

Embodiment 2

[0038] In this embodiment, the difference from Embodiment 1 is that the material of the noble metal tip 2 is gold, the material of the titanium alloy thin-diameter thin-walled pipe 1 is Ti6Al4V titanium alloy, and the titanium alloy thin-diameter thin-walled pipe 1 is made of gold. 1 has an outer diameter of Φ0.5 mm and a wall thickness of 0.1 mm, the groove widths of the single helical groove 1 and the single helical groove 2 4 are both 0.2 mm, and the pitch of the single helical groove 3 is 0.5 mm. The pitch of the single helical groove 2 4 is a gradual pitch and it increases by 0.3 mm from far to near, the length L1 of the distal section of the guide wire is 10 mm, the length L2 of the middle section of the guide wire is 90 mm, and the length of the guide wire near The length of the segment L3=200mm.

[0039] In this embodiment, the structures of other parts are the same as those in Embodiment 1.

[0040] In this embodiment, the processed and formed titanium alloy guide wi...

Embodiment 3

[0042] In this embodiment, the difference from Embodiment 1 is that the material of the noble metal tip 2 is platinum-iridium alloy, the material of the titanium alloy thin-diameter thin-walled pipe 1 is Ti6Al7Nb titanium alloy, and the thin-diameter thin-walled titanium alloy pipe 1 is Ti6Al7Nb titanium alloy. The outer diameter of the wall pipe material 1 is Φ2mm and its wall thickness is 0.2mm, the groove width of the single helical groove one 3 and the single helical groove two 4 is 0.1mm, and the pitch of the single helical groove one 3 is 0.2mm, The pitch of the single helical groove 2 4 is a gradual pitch and it increases by 0.1 mm from far to near, the length L1 of the distal section of the guide wire is 20 mm, the length L2 of the middle section of the guide wire is 100 mm, and the length of the guide wire near The length of the segment L3=200mm.

[0043] In this embodiment, the structures of other parts are the same as those in Embodiment 1.

[0044] In this embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com