Composite bulletproof armor plate and preparation method thereof

A bulletproof armor and deck technology, which is applied to the structure of armor plates, chemical instruments and methods, lamination devices, etc., can solve the problems of introducing fiber metal laminates and porous metal sandwich panels at the same time, so as to improve the resistance to multiple strikes Ability, evenly spaced, beneficial for evenly distributed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

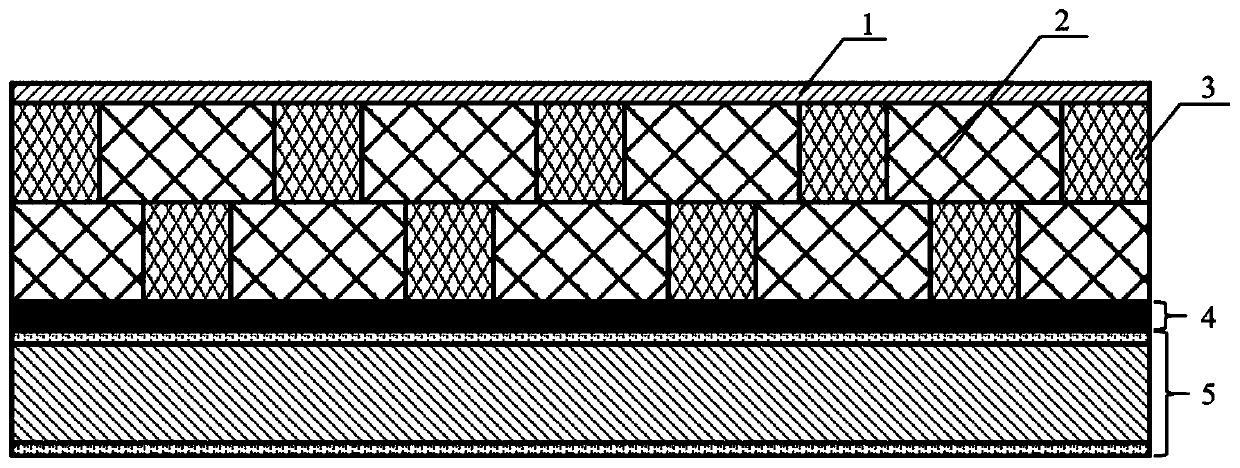

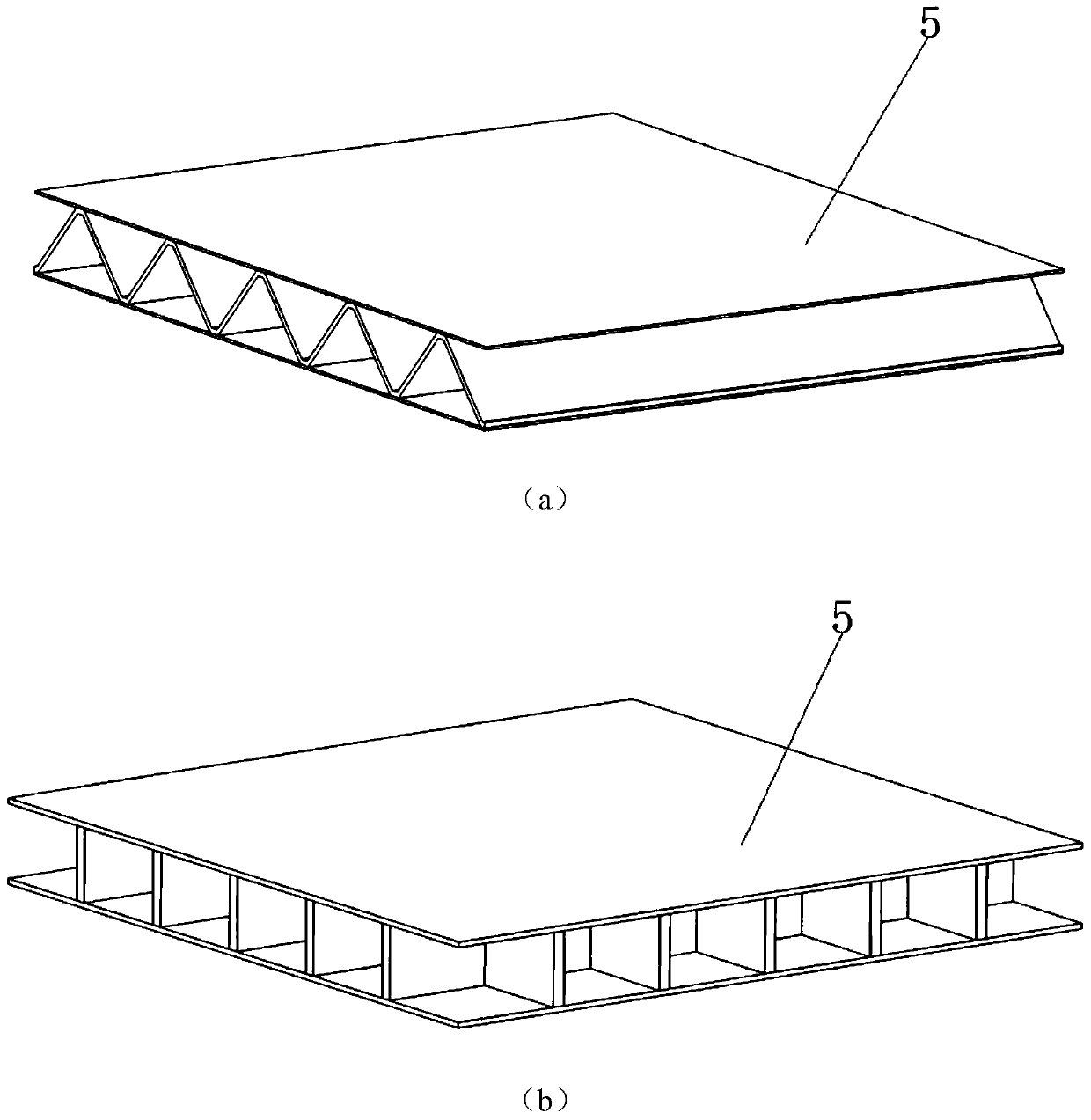

[0047] A preparation method for a composite bulletproof armor plate, comprising the following steps:

[0048] S1. Take a piece of metal or fiber-reinforced composite material plate to prepare a protective cover plate;

[0049] S2, preparing the ceramic disc 2, grinding the surface of the ceramic disc 2 to make its surface roughness R a ≤3.2μm; laser cutting is used to make a round hole on the metal constraining plate 3, and the surface roughness R of the inner hole is controlled during the cutting process a ≤3.2μm; put the metal constraining plate 3 into the muffle furnace, raise the temperature at a rate of 10-50°C / min, and keep it warm for 1-3min when the temperature reaches 600-900°C; then place the room temperature in the muffle furnace The lower ceramic disc 2 is filled into the hole after the high temperature expansion of the metal constraining plate 3; the muffle furnace is closed, and after the temperature in the muffle furnace drops to room temperature, the assembly ...

Embodiment 1

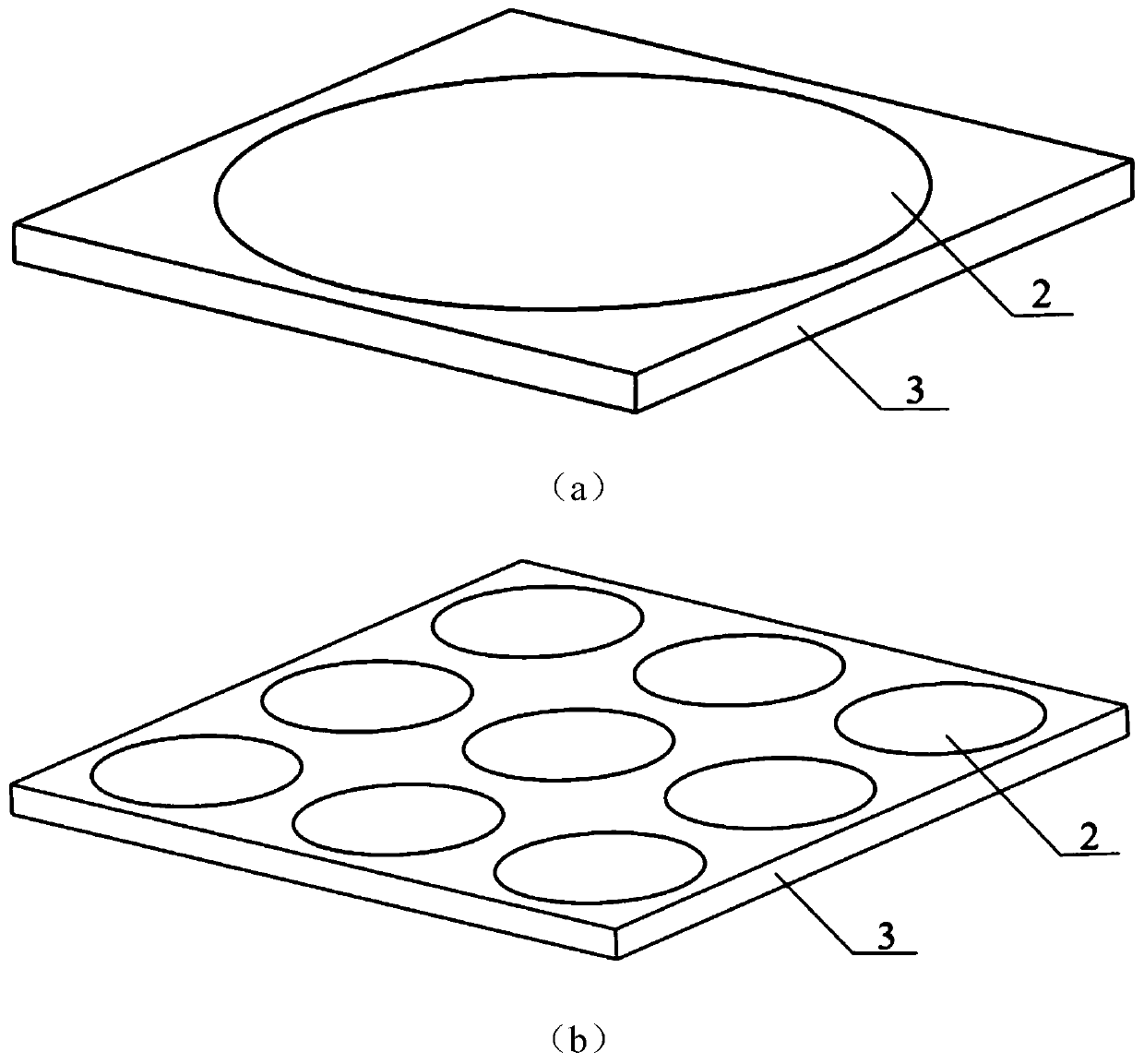

[0056] (1) Prepare a TC4 titanium alloy plate with a thickness of 1mm and a side length of 120mm as a protective cover;

[0057] (2) Prepare a boron carbide ceramic plate with a thickness of 6 mm and a diameter of 100 mm, and grind the surface of the ceramic plate to make its surface roughness R a ≤3.2μm; prepare a TC4 titanium alloy constraining plate with a thickness of 6mm and a side length of 120mm, and use laser cutting to make a circular hole on the TC4 titanium alloy constraining plate. The hole size is 0.4mm smaller than the ceramic diameter, and the cutting process controls the surface roughness of the inner hole R a ≤3.2μm; put the TC4 titanium alloy constraining plate into the muffle furnace, raise the temperature at a rate of 10°C / min, and keep it warm for 1-3min when the temperature reaches 600°C; Fill the boron ceramic plate into the hole after the high temperature expansion of the TC4 titanium alloy constrained plate; close the muffle furnace, and take out the ...

Embodiment 2

[0062] (1) prepare a thickness of 1mm, an ultra-high molecular weight polyethylene fiber composite material plate with a side length of 150mm as a protective cover;

[0063] (2) Prepare 9 silicon carbide ceramic plates with a thickness of 6 mm and a diameter of 40 mm, and grind the surface of the ceramic plate to make the surface roughness R a ≤3.2μm; prepare a TC4 titanium alloy constraining plate with a thickness of 6mm and a side length of 150mm, and use laser cutting to drill 9 evenly distributed holes on the TC4 titanium alloy constraining plate. , the cutting process controls the surface roughness R of the inner hole a ≤3.2μm; put the TC4 titanium alloy constraining plate into the muffle furnace, raise the temperature at a rate of 25°C / min, and keep it warm for 1-3min when the temperature reaches 800°C; then place the 9 A silicon carbide ceramic plate is filled into the hole after high temperature expansion of the TC4 titanium alloy constrained plate; close the muffle f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com