Wind power generation tower prestress anchor bolt cage

An anchor bolt cage and prestressing technology, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve problems affecting the normal operation of wind turbines, foundation ring anchorage failure, weak force integrity, etc., and achieve improved contact Environment and force transmission performance, lower foundation cost, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

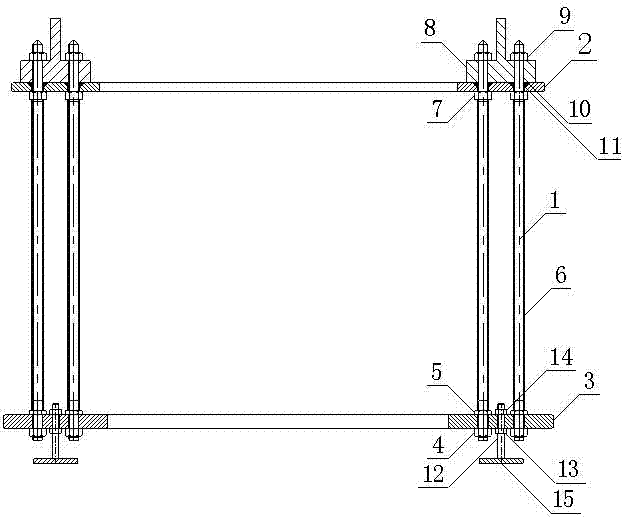

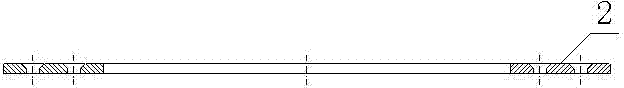

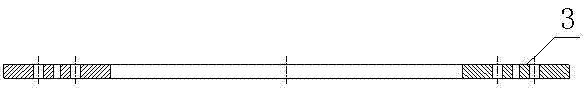

[0029] The present invention includes an anchor bolt 1 , an upper flange 2 and a lower flange 3 . Anchor bolt 1 passes through anchor nut 4, lower flange 3, positioning nut 5, anchor bolt sleeve 6, adjusting nut 7, upper flange 2, T-shaped flange 8 at the bottom of the wind power tower and locking bolt from bottom to top. Nut 9. The upper flange 2 is a ring-shaped steel plate, and the evenly distributed anchor bolt holes on it are inverted taper holes 10, which are supported by several uniformly distributed circumferential and plastic-made adjusting nuts 7 located below the upper flange 2, and their level can be adjusted. The connection between the inverted taper hole 10 of the upper flange and the anchor bolt 1 is filled with a sealing material 11 . The lower flange 3 is an annular steel plate, the lower flange support bolts 12 and the support nuts 13 bear the weight of the lower flange 3, and its levelness can be adjusted, the lower flange 3 is fixed by the compression nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com