An Independent Suspension with Elastic Elements and Reversing Mechanism

A technology of reversing mechanism and elastic components, which is applied in the direction of elastic suspensions, suspensions, vehicle components, etc., can solve the problems of adjustable suspension stiffness and adjustable height from the ground, so as to expand the scope of road application and ensure Driving comfort, effect of changing ground clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0022] This embodiment provides an independent suspension with an elastic element and a reversing mechanism, which can solve the problem that the traditional vehicle wheel structure is too complicated, it is not easy to shape the body and frame, and the vehicle passability and ride comfort cannot be adjusted. Small and other issues.

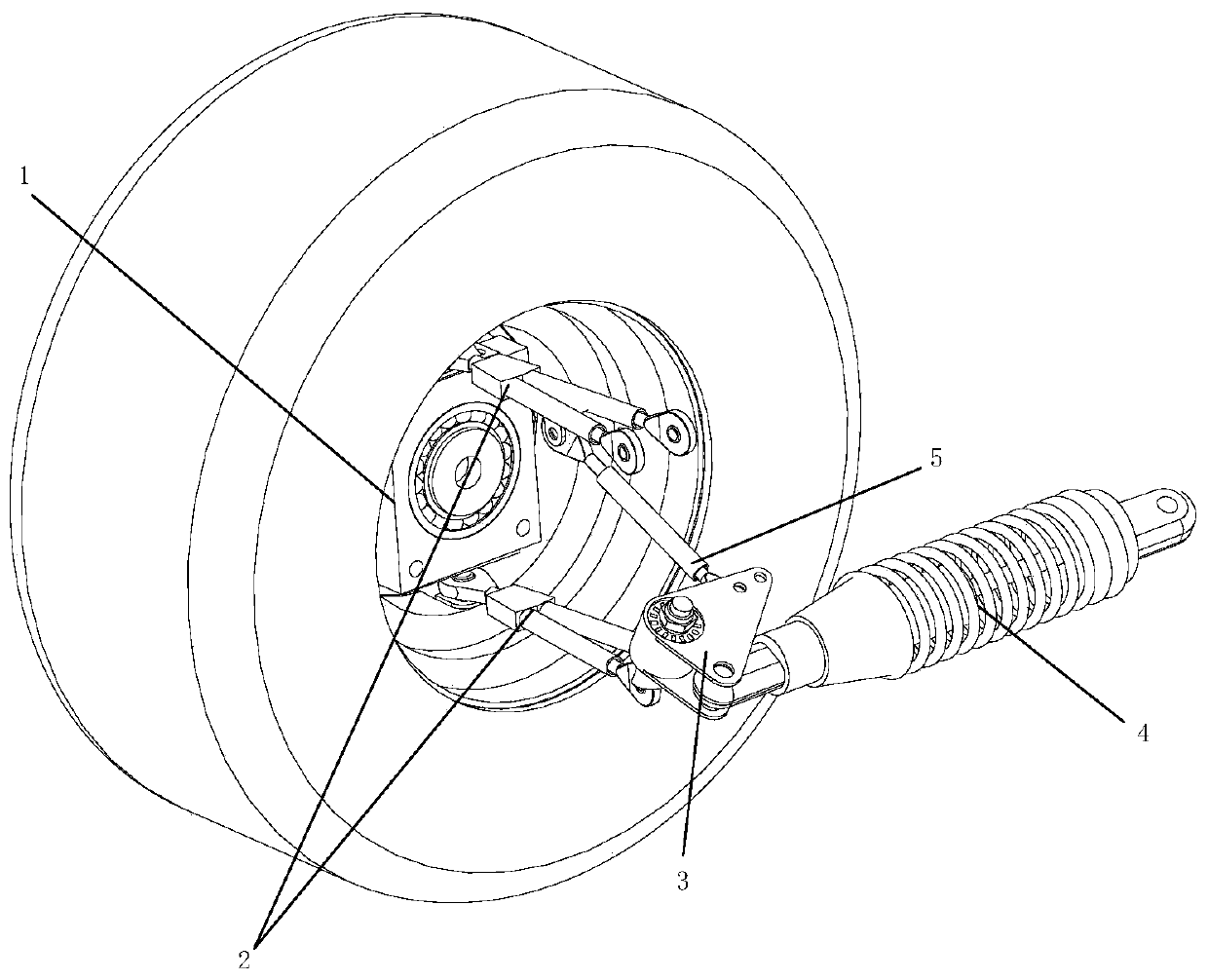

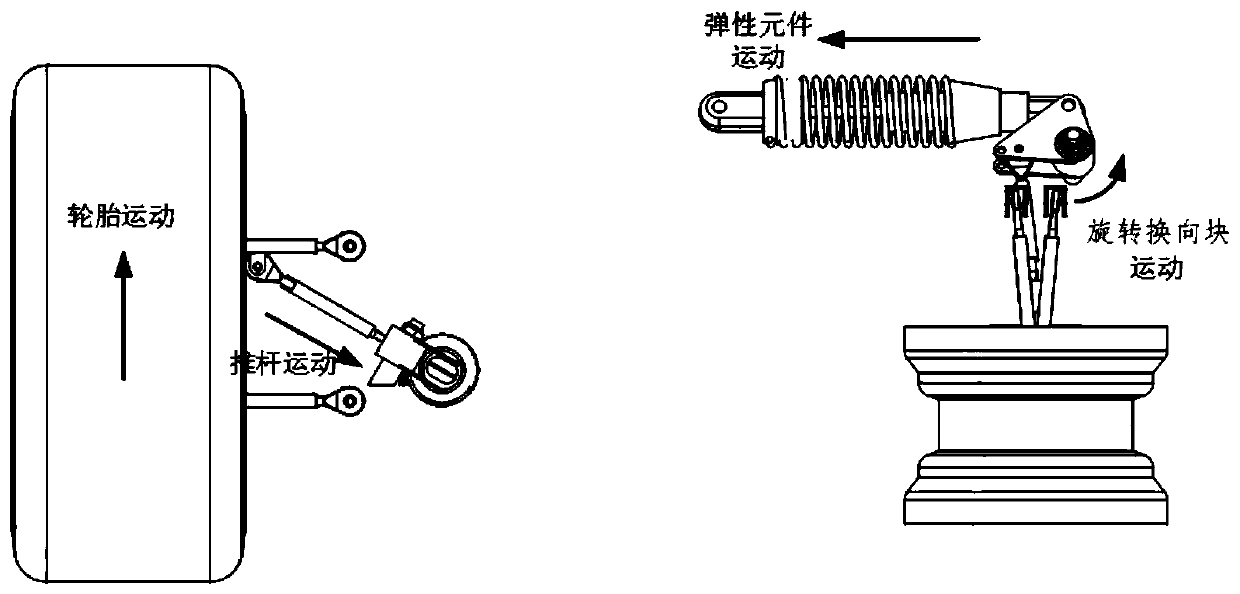

[0023] Such as figure 1 As shown, the independent suspension includes: an elastic element 4, a push rod 5, a reversing mechanism 3, a guiding mechanism 2 and a wheel rim system 1; wherein the elastic element 4 serves as a shock absorber; the guiding mechanism 2 is two sets of transverse arms.

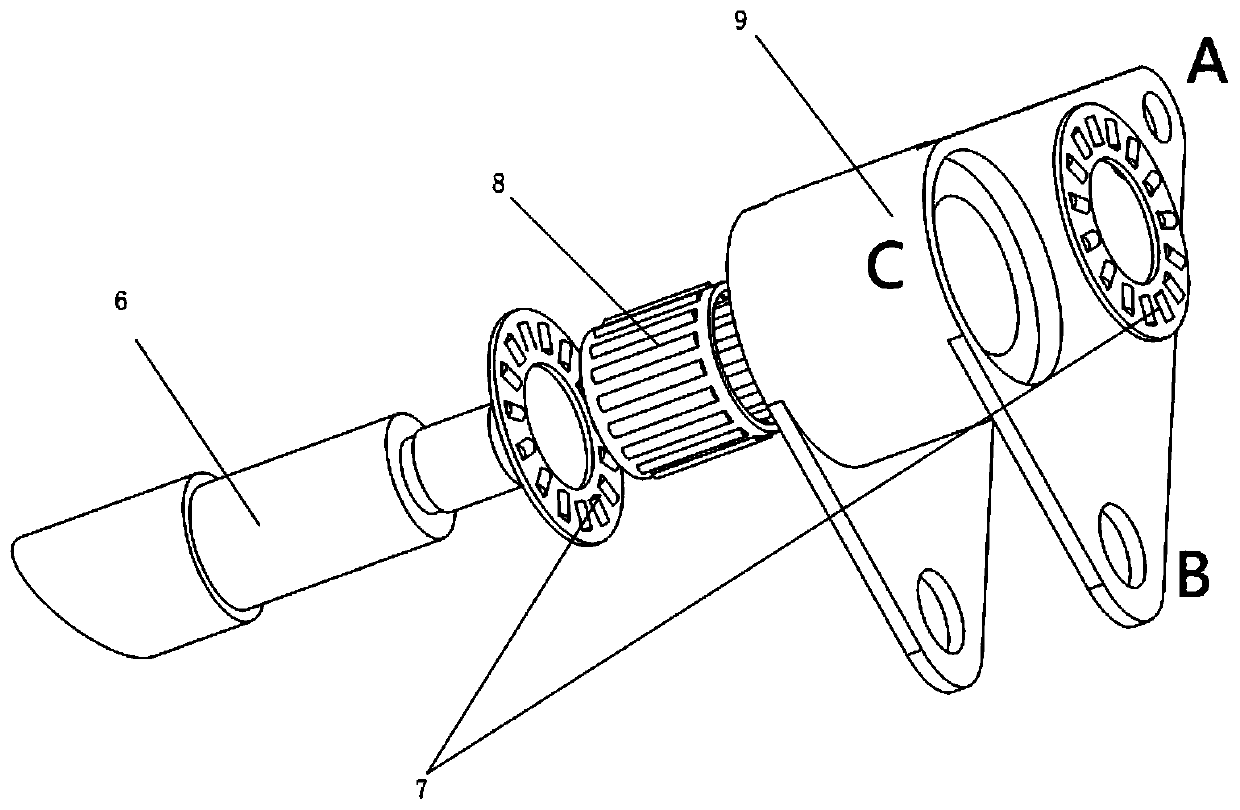

[0024] Reversing mechanism 3 such as figure 2 As shown, it includes: a rotating shaft 6, a needle bearing 8, a thrust bearing 7 and a rotation reversing block 9, wherein the rotation reversing block 9 is a triangular structure, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com