Integrated beam-slab-column formwork structural system and construction method

A construction method and technology of column formwork, which are applied in the direction of building structure and construction, can solve the problem that the connection effect of beam-column joints is difficult to reach the degree of cast-in-place, the plastering layer and the concrete surface are not firmly bonded, and the quality of components is greatly affected, etc. problems, to achieve the effect of firm splicing construction method, strong frame structure integrity, and improved force transmission performance of beam-column joints

Active Publication Date: 2015-05-06

JINAN RAILWAY TRANSPORT GRP CO LTD

View PDF7 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The traditional construction sequence of the frame structure is to tie the steel bars-support the formwork-pour the concrete-remove the formwork. This process is not only labor-intensive and material-intensive, but also the construction is relatively complicated. The quality of the components is greatly affected when the formwork is removed. Decoration, the plaster layer and the concrete surface are not bonded firmly, and hollowing cracks are easy to occur, which takes a long time and costs a lot. For large-scale steel formwork pouring, large-scale hoisting equipment must be used for its installation and removal, and the safety risk factor is high. ;The emergence of prefabricated components has brought factoryization into the construction field, shortening the construction period, but the connection effect of beam-column joints is difficult to reach the level of cast-in-place, which affects the seismic performance of the entire structure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

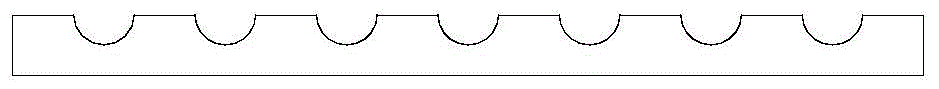

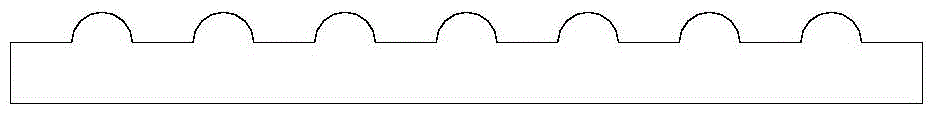

[0056] The beam formwork in embodiment 2 is composed of a formwork unit (such as Figure 13 As shown), the two ends are spliced with the formed beam-column joint formwork through concave-convex grooves, and the upper part of the side wall has a pair of tie rods 121. The rest of the construction steps are similar to those in Embodiment 1 and will not be described again.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

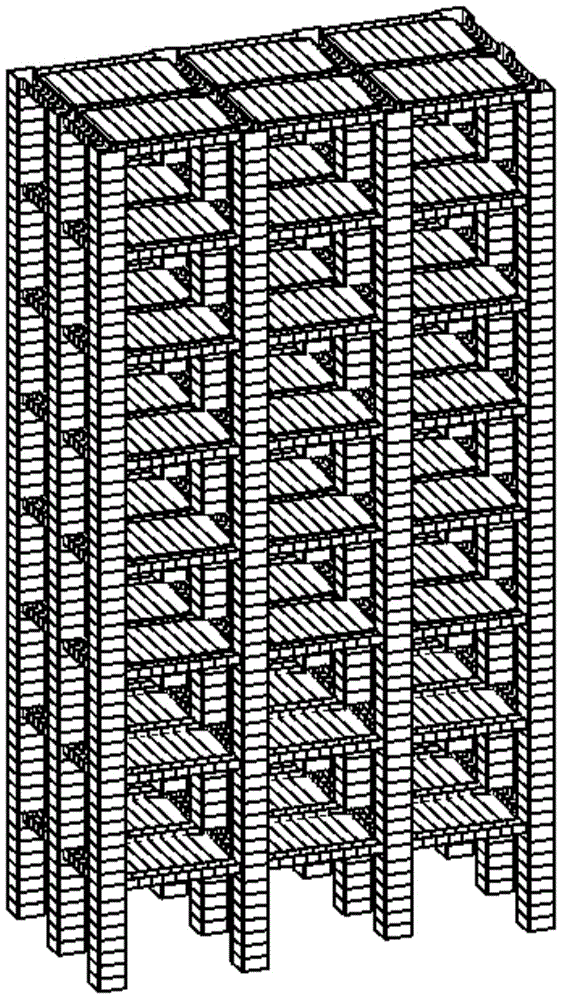

The invention relates to the technical field of constructional engineering, in particular to an integrated beam-slab-column formwork structural system and a construction method. The structural system is a frame structure formwork system composed of a non-dismantling column formwork, a beam formwork, a beam-column joint formwork and a slab formwork which are connected to each other; the column formwork, the beam-column joint formwork, the beam formwork and the slab formwork are respectively composed of corresponding formwork units by means of splicing; a non-dismantling formwork unit is made of a thin-wall shell structure and used as a formwork when pouring concrete, and also used as finishing material in the later stage, wherein one side of the non-dismantling formwork unit is processed into a rough surface and the other side is smooth; the splicing parts of the formwork units are built in by adopting a form of concave-convex groove and tongue; an outer side of the non-dismantling formwork is fastened by using a fastening hoop to resist the cast-in-situ concrete side pressure; the beam-column joint formwork makes the integrated beam-slab-column formwork structural system applicable to a preformed structural member, and also applicable to cast-in-situ; the preformed member is spliced or concrete is casted in situ to the preformed member to form one building unit of the frame structure, and a plurality of building units form a multilayer or a high-rise frame structure.

Description

technical field [0001] The invention relates to the technical field of construction engineering, in particular to a frame beam-slab-column formwork structure system and a construction process that apply an industrialization model to the field of building structures. Background technique [0002] The traditional construction sequence of the frame structure is to tie the steel bars-support the formwork-pour the concrete-remove the formwork. This process is not only labor-intensive and material-intensive, but also the construction is relatively complicated. The quality of the components is greatly affected when the formwork is removed. For decoration, the bond between the plaster layer and the concrete surface is not strong, and hollow cracks are easy to occur, which takes a long time and costs a lot. For large-scale steel formwork pouring, large-scale hoisting equipment must be used for its installation and removal, and the safety risk factor is high. The emergence of prefabri...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04B1/16

Inventor 王国富王威汐

Owner JINAN RAILWAY TRANSPORT GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com