Testing table for detecting the relaxation of high voltage breaker closing spring stress

A closing spring and stress relaxation technology, applied in the field of spring stress relaxation detection test platform, can solve problems such as electric sparks, hidden dangers, high-voltage circuit breakers cannot be closed, etc., to achieve reliable experimental results and eliminate processing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

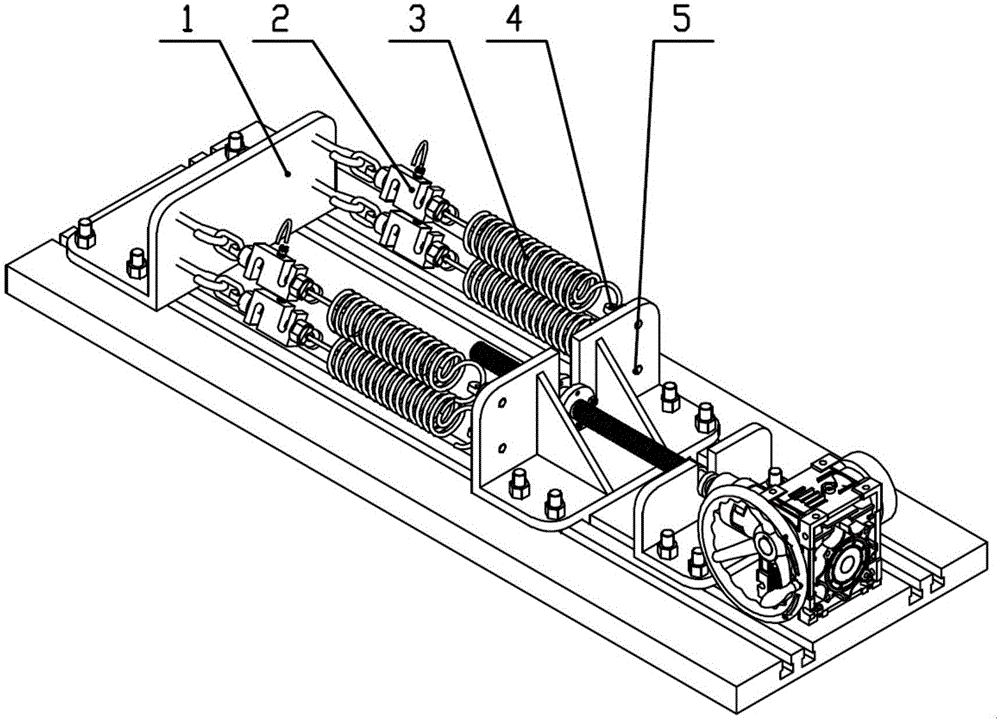

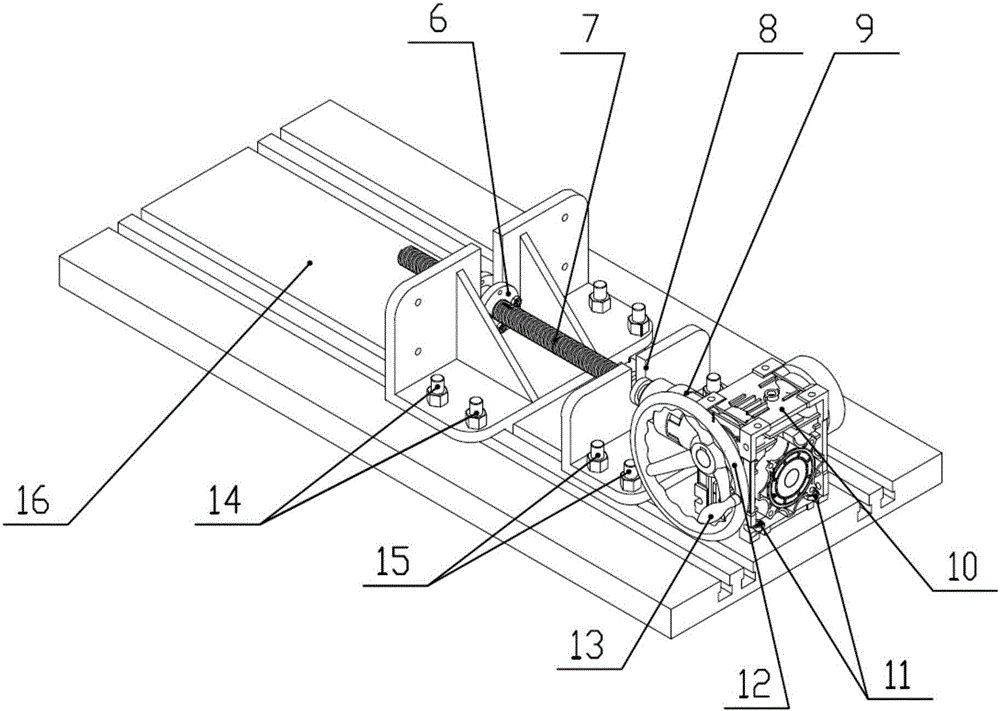

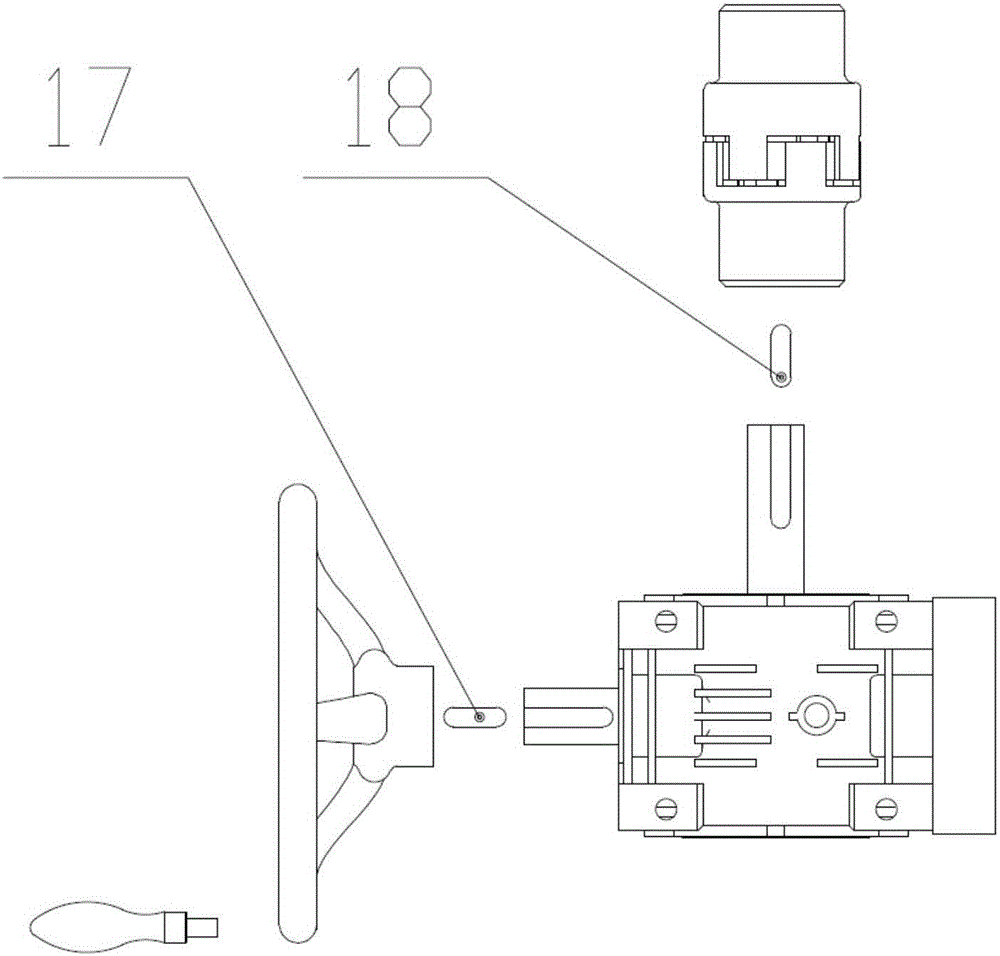

[0024] Such as Figure 1 to Figure 6 As shown, a test bench for detecting the stress relaxation of the closing spring of a high-voltage circuit breaker, the test device in this embodiment includes a spring fixing plate 1, a tension and pressure sensor 2, a spring 3, an eyebolt screw 4, and a spring moving platform 5, Transmission nut 6, trapezoidal transmission screw 7, screw fixing plate 8, plum blossom coupling 9, reducer 10, screw 11, hand wheel 12, handle 13, T-shaped bolts 14, 15, base plate 16, keys 17, 18, 19 . The coupling in this embodiment adopts the plum blossom coupling 9, and the transmission screw adopts the trapezoidal transmission screw 7; the base plate 16 is processed with a T-shaped groove track and threaded holes, the threaded holes are used to install the reducer 10, and the screws 11 are installed on the in the threaded hole. The spring fixing plate 1, the spring moving platform 5, the screw fixing plate 8 are fixed in the T-shaped groove track of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com