Connecting structure for steel tube concrete beam and column node

A technology for CFST column and CFST, which is applied in building structures, buildings, etc., can solve the problems of complex construction, limited rigidity, increased structural self-weight, etc., to improve the shear and flexural bearing capacity of nodes and good mechanical performance. , The effect of improving force transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

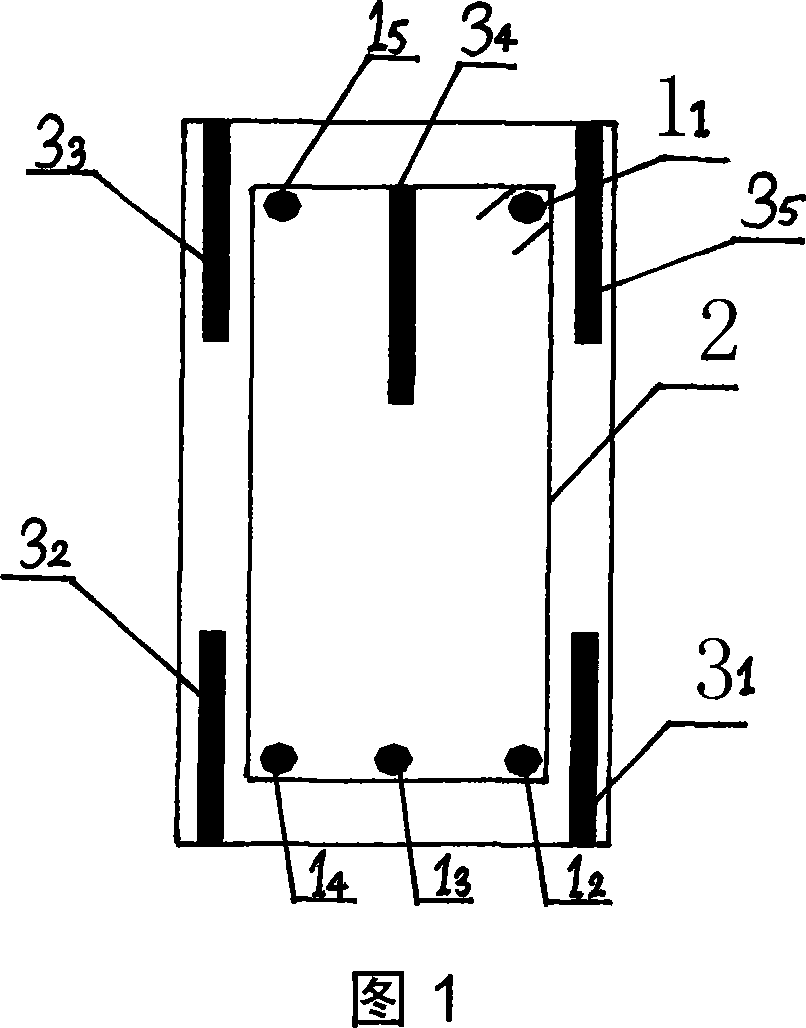

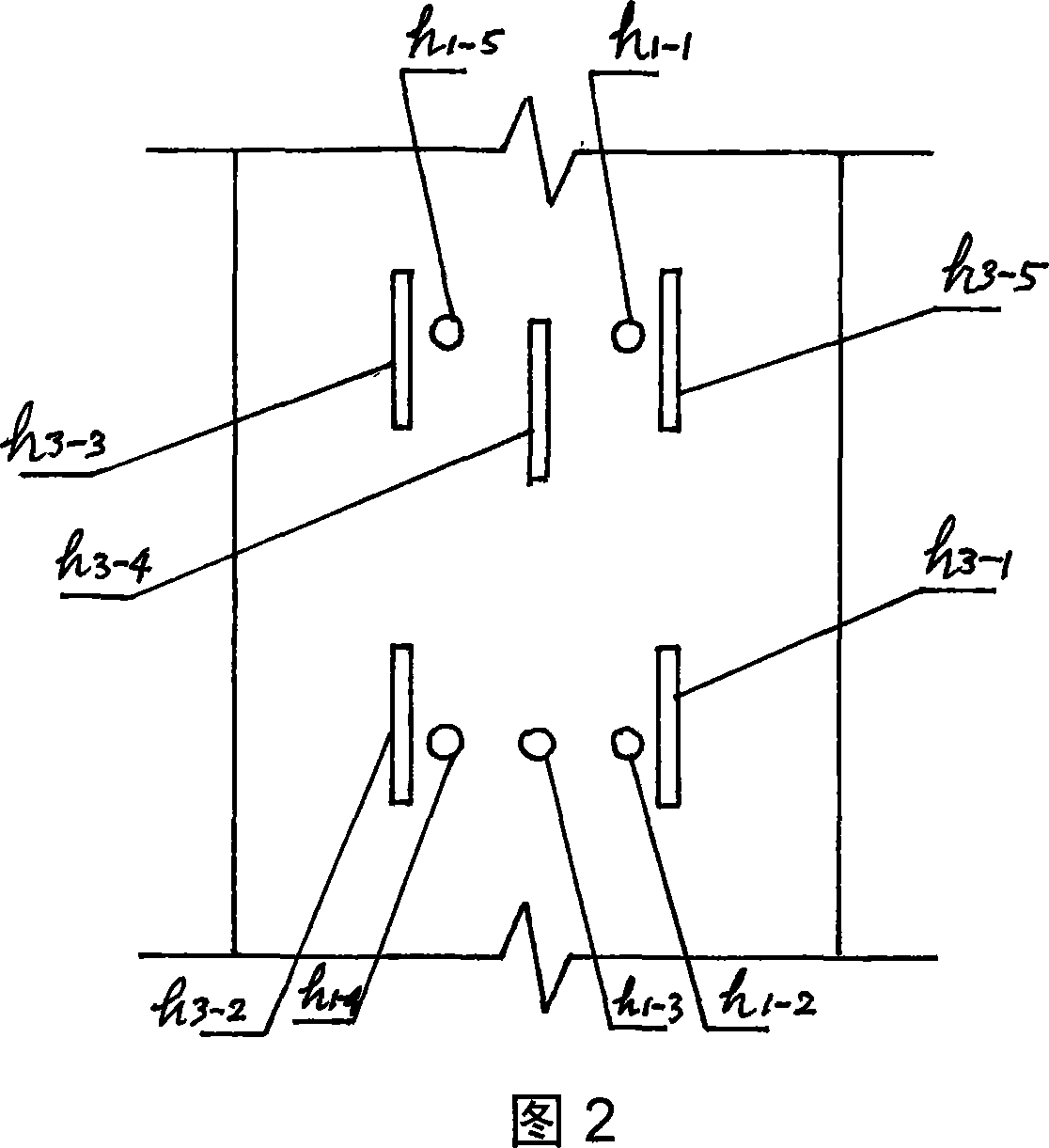

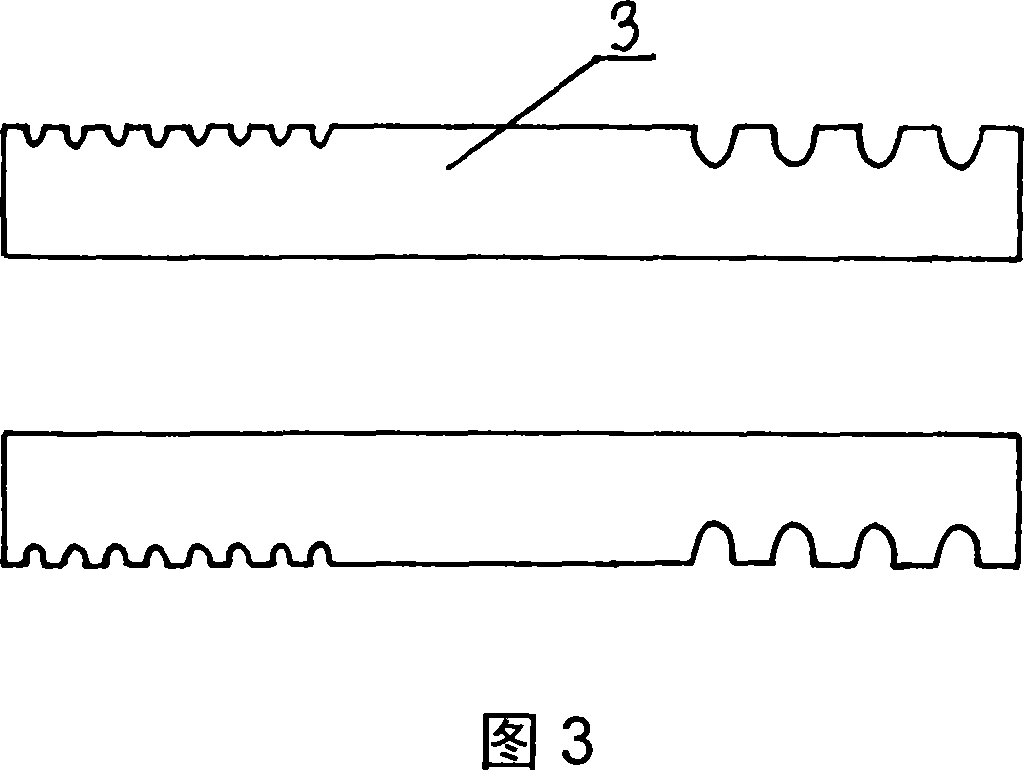

[0007] Figure 1 shows the cross-sectional structure of the beam at the concrete-filled steel tube beam-column joint. There are 5 steel plates in the beam 3 1 , 3 2 , 3 3 , 3 4 , 3 5 And 5 steel bars 1 1 ,1 2 ,1 3 ,1 4 ,1 5 , Use stirrup 2 to fix. As shown in Figure 4c, the cross section of the steel tube 4 in the concrete-filled steel tube column is a rectangle, which can be welded by four steel plates. As shown in Figure 2, the steel pipe 4 corresponds to the beam 3 1 , 3 2 , 3 3 , 3 4 , 3 5 And 5 steel bars 1 1 ,1 2 ,1 3 ,1 4 ,1 5 There are rectangular holes h 3-1 , H 3-2 , H 3-3 , H 3-4 , H 3-5 And round hole h 1 , H 2 , H 3 , H 4 , H 5 . As shown in Figure 3, the steel plate 3 in the beam 1 , 3 2 , 3 3 , 3 4 , 3 5 There are 8 to 16 semi-circular holes at both ends of the machine. On steel plate 3 1 , 3 2 , 3 3 , 3 4 , 3 5 There are 8 semi-circular holes with a diameter of 20mm at both ends, or in the steel plate 3 1 , 3 2 , 3 3 , 3 4 , 3 5 Four semi-circular holes with a diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com