Cold-formed thin-walled steel-structure house outer wall structure system

A technology for cold-formed thin-walled section steel and houses, which is applied in building structure, construction, etc., can solve the problems of limited promotion and application, difficult installation of external wall panels, etc., to increase the weight of the house, increase the comprehensive cost of the house, and reduce the weight of the house. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings.

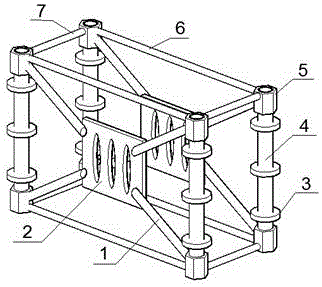

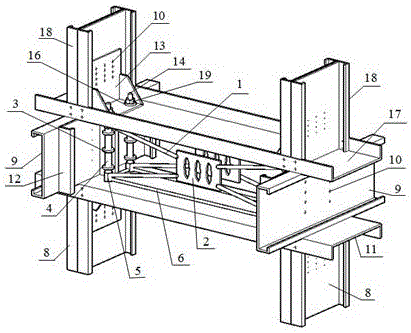

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a cold-formed thin-walled steel structure building exterior wall structure system, including beams and columns that cooperate with each other, is characterized in that:

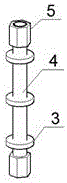

[0041] The column is composed of two C-shaped steels that are attached back to back and fixed with self-tapping screws 10, including the lower column 8 and the upper column 18;

[0042] The beams include a C-shaped steel floor beam 9, which connects the U-shaped steel top beam 11 of the lower building with the opening downwards of two adjacent columns and the U-shaped steel bottom beam 17 of the upper building with the opening upward;

[0043] And: there is an anti-pull piece 13 consisting of a bottom plate, a back plate and a side plate, the bottom plate is provided with bolt holes 15, and the back plate is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com