Mortar preparation method

A technology of mortar and mix ratio, which is applied in the field of mortar mix ratio, can solve problems such as difficult control of technical rules, large actual access and large changes in bulk density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0222] Taking the preparation of ordinary M5 mixed masonry mortar as an example, the construction level is average, and the block material is sintered ordinary brick (wet before use). More than 8 hours, compressive strength ≥ 5Mpa, good workability, the proportioning method includes the following steps:

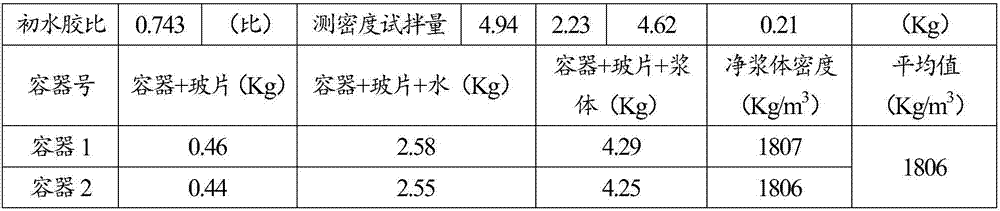

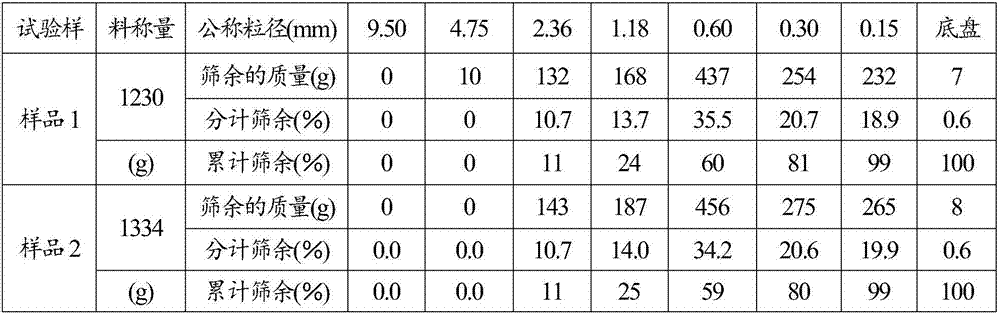

[0223] (1) Initially determine the net slurry and measure the density:

[0224] 1. Select the raw materials for the clean slurry: choose National University 42.5 cement for cement, medium sand and lime paste for sand, and special mortar admixture for admixture.

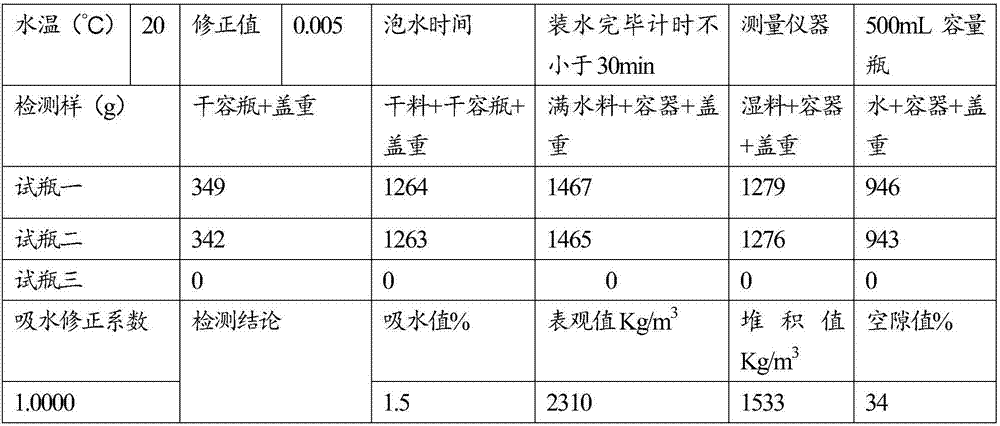

[0225] 2. Determination of raw material indicators: the standard deviation of the mortar strength is not greater than 1.25 according to the specification, and the actual statistical standard deviation is 1.2, which meets the requirements. Cement adequacy coefficient statistics 1.1, test admixture water-reducing rate 23%, admixture test to determine 3%, measured admixture solid content 27%, lime paste consistency tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com