Patents

Literature

33results about How to "Reduce volume shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal-containing composite materials

InactiveUS20060167147A1Robust processingStable materialPowder deliveryInorganic active ingredientsMetallic materialsMaterials science

The present invention relates to a process for the manufacture of metal-containing materials or composite materials, the process comprising the steps of encapsulating at least one metal-based compound in a polymeric shell, thereby producing a polymer-encapsulated metal-based compound and / or coating a polymeric particle with at least one metal-based compound; forming a sol from suitable hydrolytic or non-hydrolytic sol / gel forming components; combining the polymer-encapsulated metal-based compound and / or the coated polymeric particle with the sol, thereby producing a combination thereof; and converting the combination into a solid metal-containing material. The present invention further relates to metal-containing materials produced in accordance with the above process.

Owner:CINVENTION AG

Monomer formulations and methods for 3D printing of preceramic polymers

ActiveUS20180148380A1Prevent degradationGood compatibilityAdditive manufacturing apparatusInks3d shapesFree form

This invention provides resin formulations which may be used for 3D printing and pyrolyzing to produce a ceramic matrix composite. The resin formulations contain a solid-phase filler, to provide high thermal stability and mechanical strength (e.g., fracture toughness) in the final ceramic material. The invention provides direct, free-form 3D printing of a preceramic polymer loaded with a solid-phase filler, followed by converting the preceramic polymer to a 3D-printed ceramic matrix composite with potentially complex 3D shapes or in the form of large parts. Other variations provide active solid-phase functional additives as solid-phase fillers, to perform or enhance at least one chemical, physical, mechanical, or electrical function within the ceramic structure as it is being formed as well as in the final structure. Solid-phase functional additives actively improve the final ceramic structure through one or more changes actively induced by the additives during pyrolysis or other thermal treatment.

Owner:HRL LAB

Formulations and methods for 3D printing of ceramic matrix composites

ActiveUS20180148379A1Prevent degradationGood compatibilityAdditive manufacturing apparatusInks3d shapesFree form

This invention provides resin formulations which may be used for 3D printing and pyrolyzing to produce a ceramic matrix composite. The resin formulations contain a solid-phase filler, to provide high thermal stability and mechanical strength (e.g., fracture toughness) in the final ceramic material. The invention provides direct, free-form 3D printing of a preceramic polymer loaded with a solid-phase filler, followed by converting the preceramic polymer to a 3D-printed ceramic matrix composite with potentially complex 3D shapes or in the form of large parts. Other variations provide active solid-phase functional additives as solid-phase fillers, to perform or enhance at least one chemical, physical, mechanical, or electrical function within the ceramic structure as it is being formed as well as in the final structure. Solid-phase functional additives actively improve the final ceramic structure through one or more changes actively induced by the additives during pyrolysis or other thermal treatment.

Owner:HRL LAB

Polyorganosiloxane composition

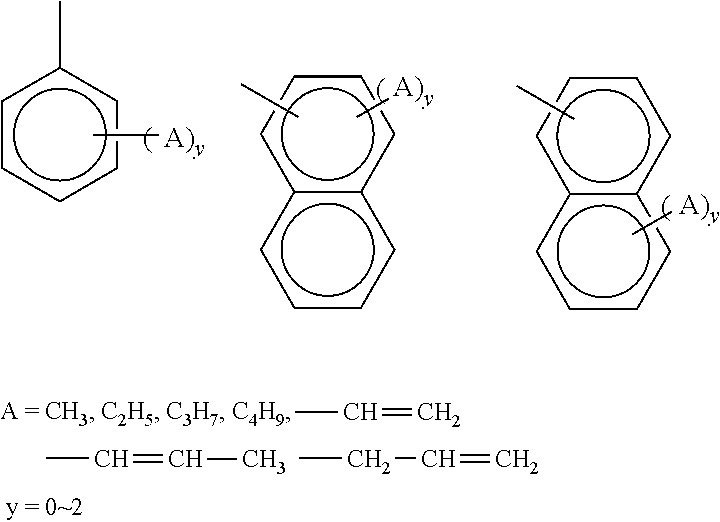

InactiveUS20100019399A1Excellent in photosensitive characteristicReduce volume shrinkageSemiconductor/solid-state device detailsSolid-state devicesChemistryChemical formula

Disclosed is a polyorganosiloxane composition containing the following components (a)-(c). (a) 100 parts by mass of a polyorganosiloxane obtained by mixing at least one silanol compound represented by the general formula (1) below, at least one alkoxysilane compound represented by the general formula (2) below, and at least one catalyst selected from the group consisting of compounds represented by the general formula (3) below, compounds represented by the general formula (4) below and Ba(OH)2, and polymerizing the mixture without actively adding water thereinto [chemical formula 1] R2Si(OH)2 (1) [chemical formula 2] R′Si(OR″)3 (2) (chemical formula 3] M(OR′″)4 (3) [chemical formula 4] M′(OR″″)3 (4) (b) 0.1-20 parts by mass of a photopolymerization initiator (c) 1-100 parts by mass of a compound other than the component (a) having two or more photopolymerizable unsaturated bonding groups.

Owner:ASAHI KASEI ELECTRONICS CO LTD

Cationic UV and heat dual deeply-curing adhesive and preparation method thereof

InactiveCN105199643ARapid responseDeep curing fastNon-macromolecular adhesive additivesEpoxy resin adhesivesPhotosensitizerOligomer

A cationic UV and heat dual deeply-curing adhesive and its preparation method relate to a curing adhesive and its preparation method. The invention aims to solve the problem that an existing UV curing adhesive cannot achieve rapid deep curing and still needs subsequent heating after UV-irradiation. The UV and heat dual deeply-curing adhesive is prepared from, by weight, 60-100 parts of an oligomer resin mixture containing an epoxy group, 5-30 parts of a diluent, 5-15 parts of a coupling agent, 0.75-3 parts of a photoinitiator, 0.75-3 parts of a photosensitizer, 0.075-0.5 part of a thermal initiator and 0-0.2 part of a heat stabilizer. The method comprises the following steps: 1, weighing; and 2, mixing to obtain the cationic UV and heat dual deeply-curing adhesive. According to the invention, a cationic UV and heat dual deeply-curing adhesive and its preparation method can be obtained.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Mortar preparation method

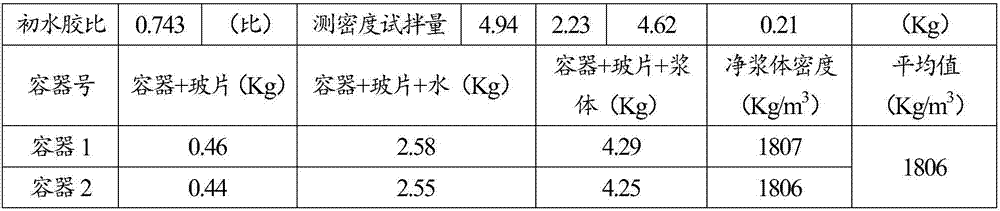

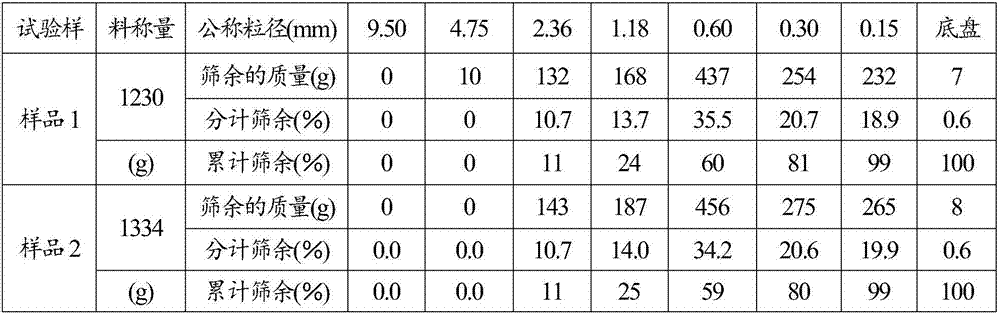

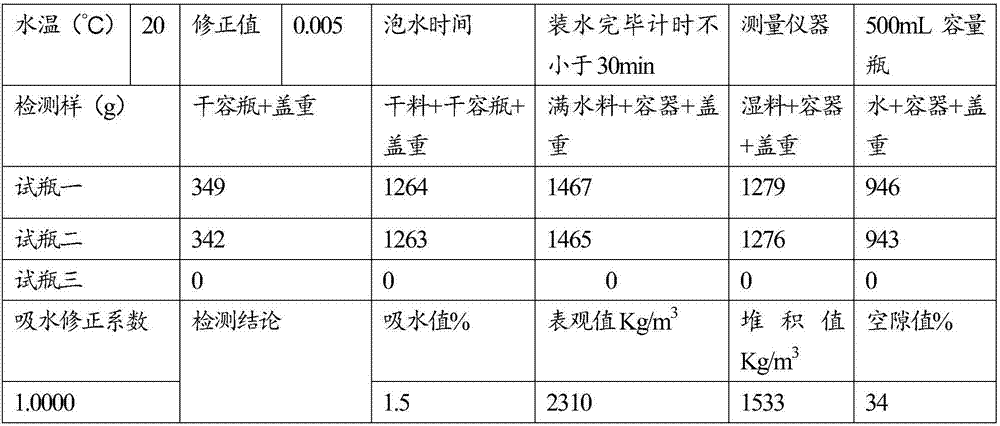

The invention discloses a mortar preparation method. The method comprises the steps as follows: (1) the neat slurry amount is determined initially and the density is measured; (2) fine aggregate and the amount are determined; (3) the initial standard mix proportion of mortar is determined; (4) premixing is performed according to the initial standard mix proportion and the workability is detected; (5) the production mix proportion is determined and premixing detection is performed. Fine aggregate and neat slurry are mixed, local materials are used according to fluctuation of raw materials as well as influence of production and construction links, actual raw material detection data are based, divorcing from reality due to the use of empirical data is avoided, and the effects that the quality is controllable, the cost is reduced and the resources are saved can be realized.

Owner:四川省三台县波特兰商品砼有限公司

Formulations with active functional additives for 3D printing of preceramic polymers, and methods of 3D-printing the formulations

ActiveUS20180148585A1Good compatibilityImprove solubilityAdditive manufacturing apparatusInks3d shapesThermal treatment

This invention provides resin formulations which may be used for 3D printing and pyrolyzing to produce a ceramic matrix composite. The resin formulations contain a solid-phase filler, to provide high thermal stability and mechanical strength (e.g., fracture toughness) in the final ceramic material. The invention provides direct, free-form 3D printing of a preceramic polymer loaded with a solid-phase filler, followed by converting the preceramic polymer to a 3D-printed ceramic matrix composite with potentially complex 3D shapes or in the form of large parts. Other variations provide active solid-phase functional additives as solid-phase fillers, to perform or enhance at least one chemical, physical, mechanical, or electrical function within the ceramic structure as it is being formed as well as in the final structure. Solid-phase functional additives actively improve the final ceramic structure through one or more changes actively induced by the additives during pyrolysis or other thermal treatment.

Owner:HRL LAB

Preparation method of cationic ultraviolet light and heat dual deep curing adhesive

InactiveCN106928893ARapid responseDeep curing fastNon-macromolecular adhesive additivesEpoxy resin adhesivesPhotosensitizerAdhesive

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

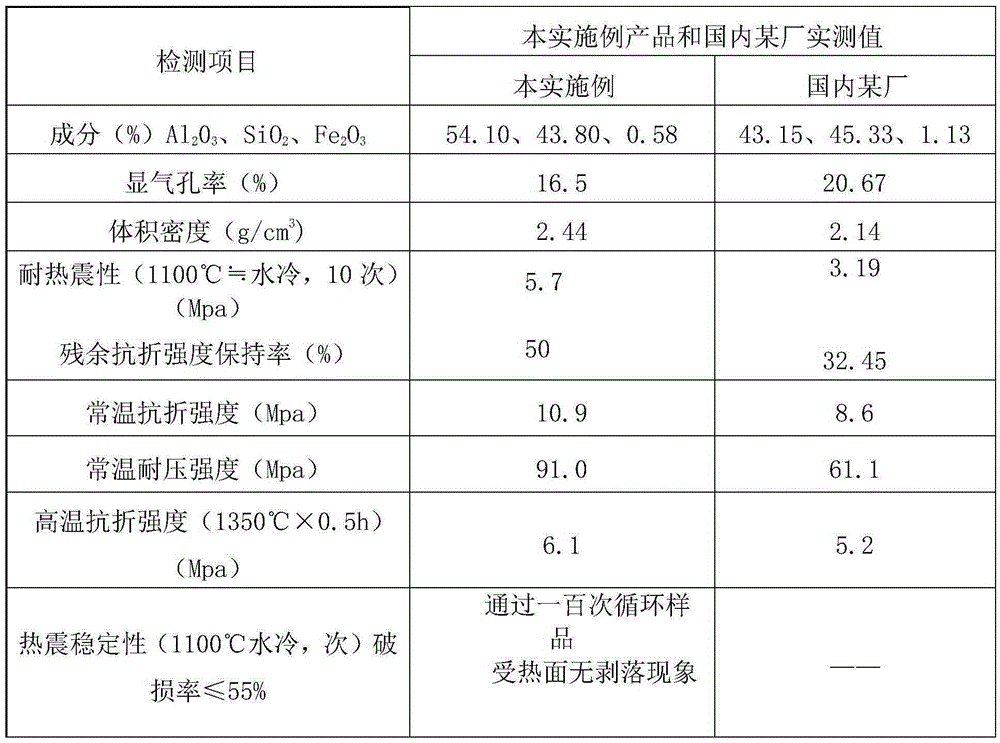

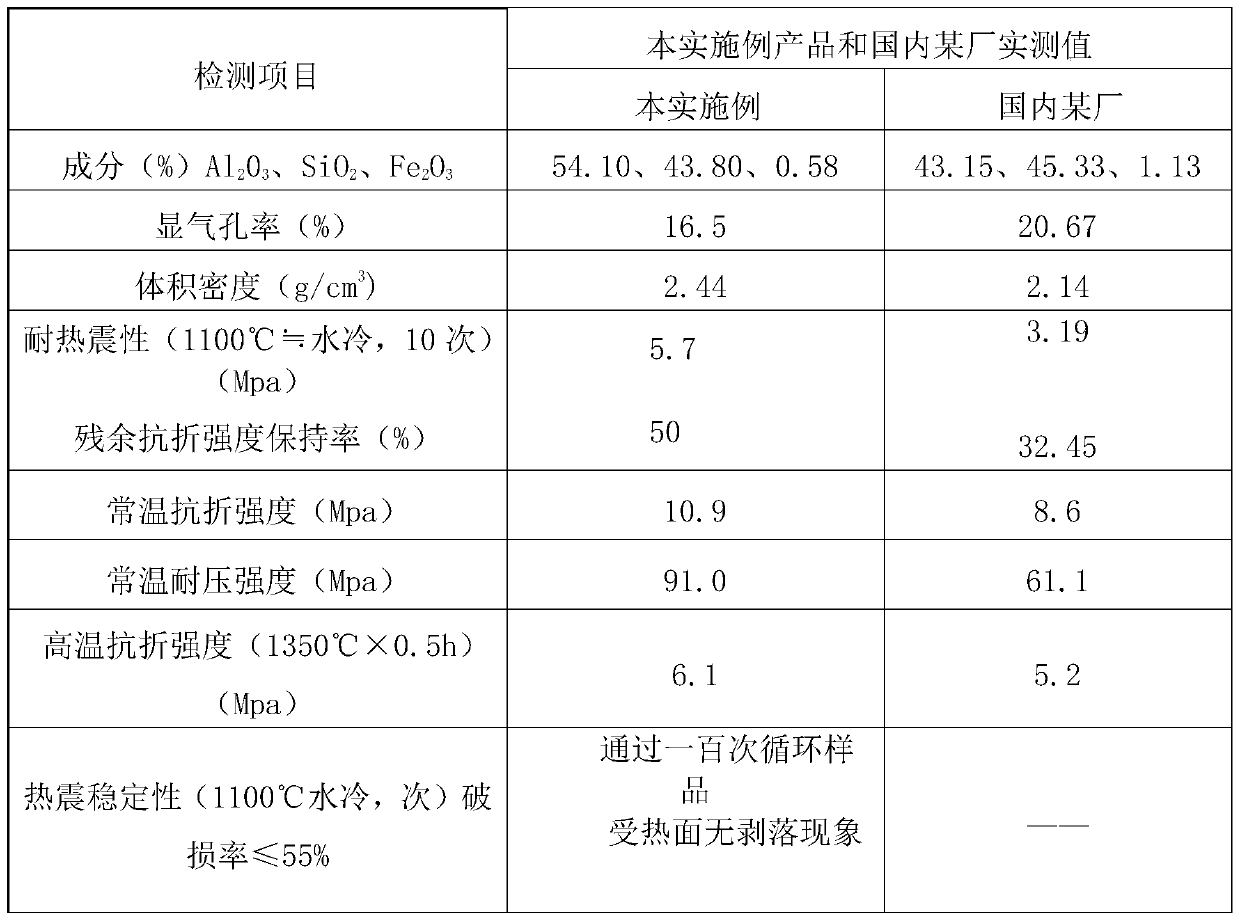

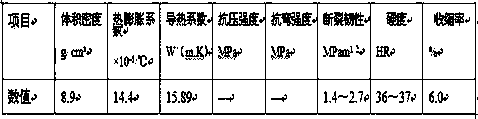

High strength thermal shock resistance push plate

The invention discloses a high strength thermal shock resistance push plate, which comprises components with parts by weight: 3-0.5mm mullite particles 20-30 parts, 1-0.5mm alundum particles 15-20 parts, 0.5-0.1mm quartz particles 10-15 parts, 320 meshes andalusite fine powder 15-20 parts, 220 meshes mullite fine powder 25-30 parts, 2Mumalumina micro powder 8-12 parts, 320 meshes alundum fine powder 5-10 parts, silica powder 5-15 parts, zirconite 5-10 parts, cerium oxide 0.5-2 parts, cerium oxide 2-10 parts, aluminum 5-10 parts, silicon 10-15 parts, white mud 10-15 parts and external binders 1-3 parts. The invention further discloses a method for preparing the high strength thermal shock resistance push plate. The high strength thermal shock resistance push plate is excellent in thermal shock resistance, high in mechanical strength, simple in preparation method and convenient for actual operation.

Owner:ANHUI NINGHUO NEW MATERIAL

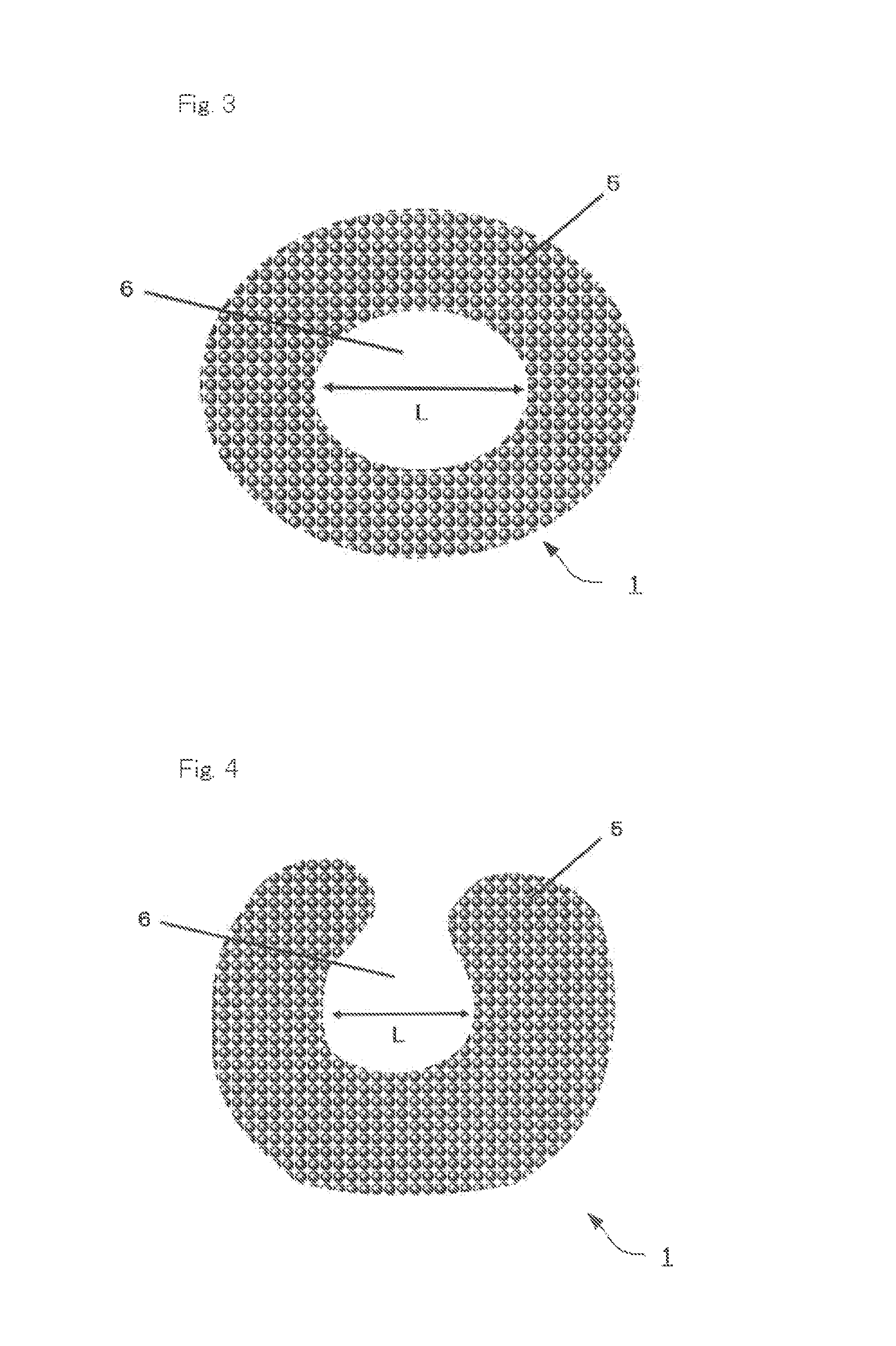

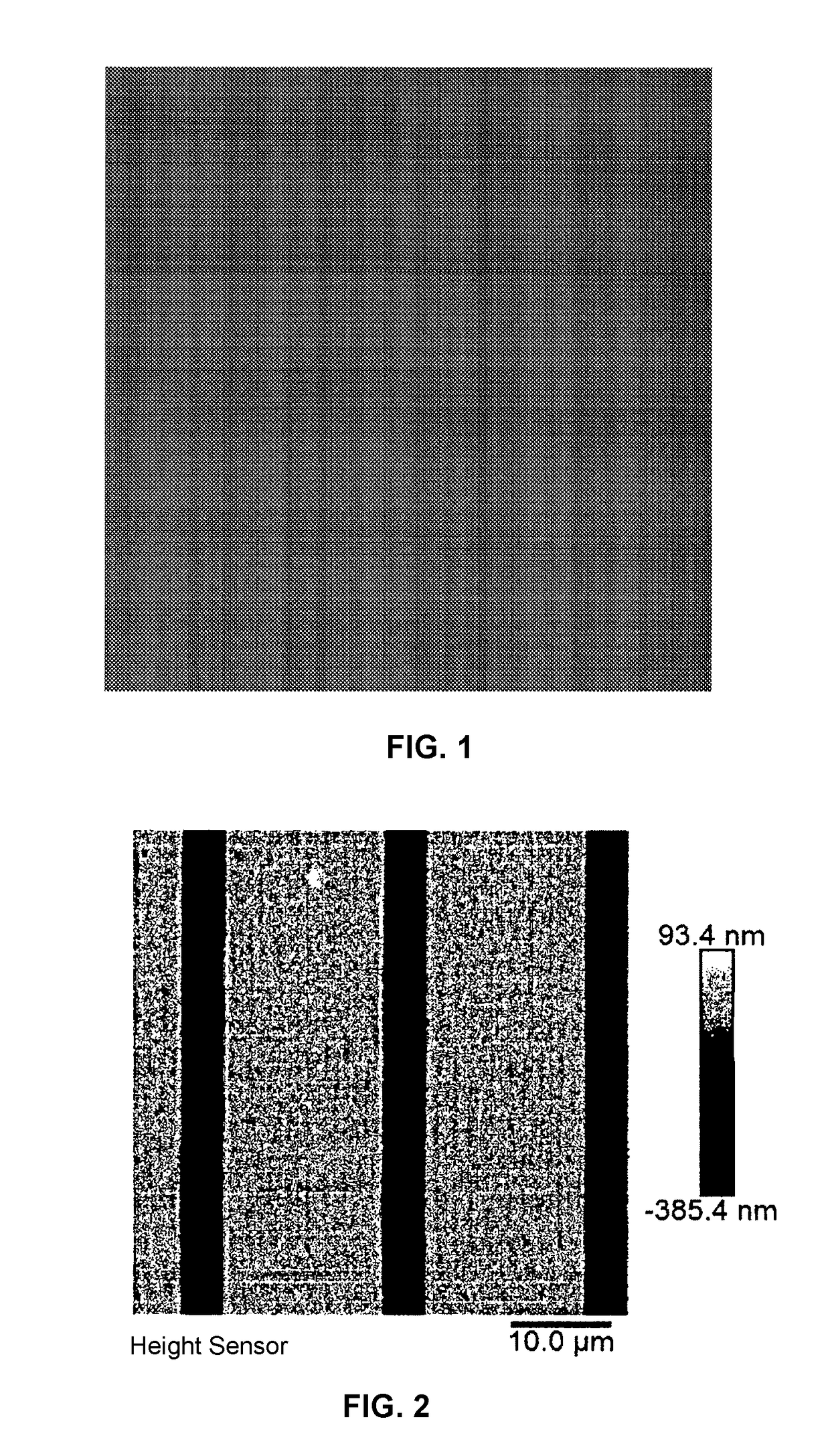

Organic-inorganic composite filler, and method for producing the same

ActiveUS20140213687A1Improve handling propertyReduction of volume shrinkageImpression capsPretreated surfacesPore diameterOrganic inorganic

An organic-inorganic composite filler contains: inorganic aggregate particles formed by aggregation of inorganic primary particles with an average particle diameter of 10 to 1000 nm; an organic resin phase including a cured polymer of a polymerizable monomer covering surfaces of the inorganic primary particles and bonding the inorganic primary particles to each other, and a water absorbing resin; and aggregation gaps with a volume of micropores formed between parts of the organic resin phase of 0.01 to 0.30 cm3 / g in pore volume measurement within a pore diameter range of 1 to 500 nm, as measured by a mercury intrusion technique. In a cross section passing through the centers of the inorganic aggregate particles, based on 100 measured inorganic particles, there are 10 or less inorganic aggregate particles having a macro void with a maximum width of at least 1 μm.

Owner:TOKUYAMA DENTAL CORP

Organic-inorganic composite filler, and method for producing the same

ActiveUS10004667B2Easy to operateReduce volume shrinkageImpression capsDentistry preparationsInorganic particlePore diameter

An organic-inorganic composite filler contains: inorganic aggregate particles formed by aggregation of inorganic primary particles with an average particle diameter of 10 to 1000 nm; an organic resin phase including a cured polymer of a polymerizable monomer covering surfaces of the inorganic primary particles and bonding the inorganic primary particles to each other, and a water absorbing resin; and aggregation gaps with a volume of micropores formed between parts of the organic resin phase of 0.01 to 0.30 cm3 / g in pore volume measurement within a pore diameter range of 1 to 500 nm, as measured by a mercury intrusion technique. In a cross section passing through the centers of the inorganic aggregate particles, based on 100 measured inorganic particles, there are 10 or less inorganic aggregate particles having a macro void with a maximum width of at least 1 μm.

Owner:TOKUYAMA DENTAL CORP

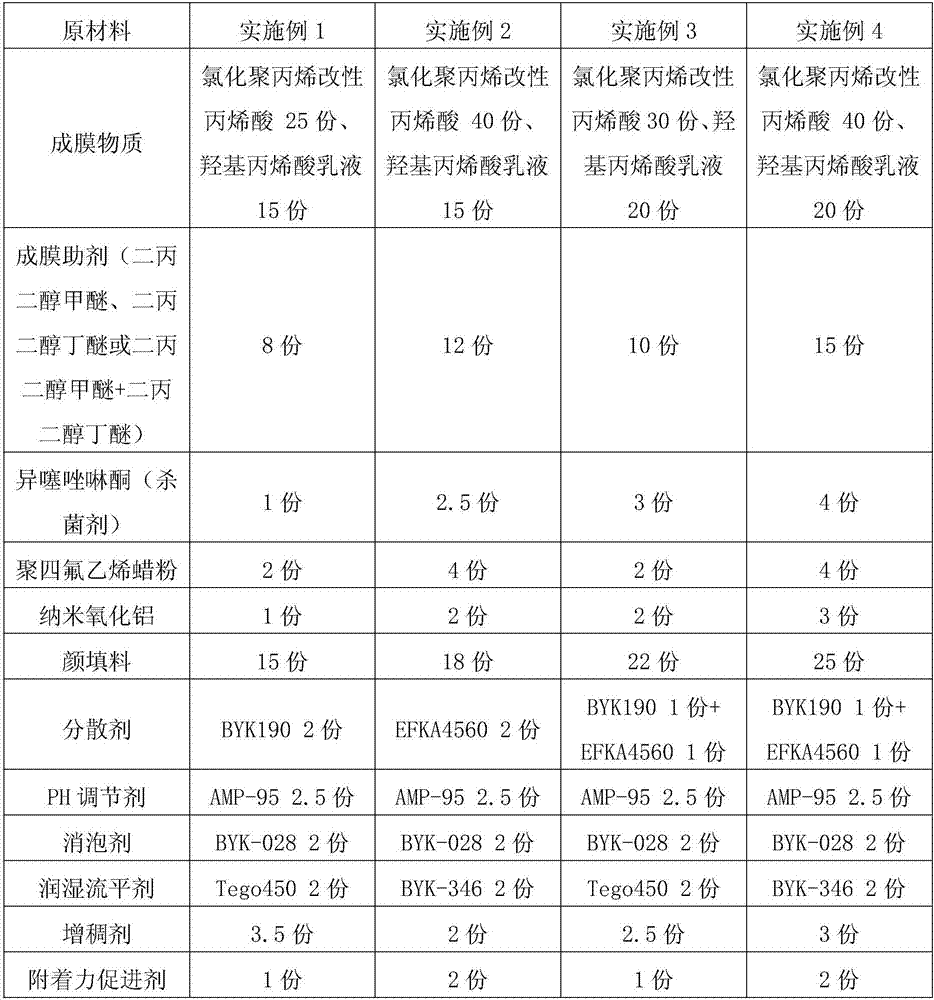

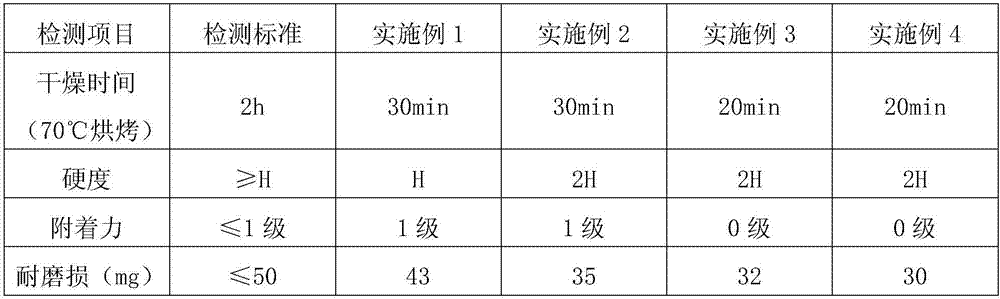

Keyboard water paint with high wear resistance and high hardness and preparation method thereof

ActiveCN107141913ALow VOCSmall smellAntifouling/underwater paintsPaints with biocidesHigh resistancePolymer science

The invention discloses keyboard water paint with high wear resistance and high hardness and a preparation method thereof. The water paint consists of the following components in parts by weight: 40-60 parts of a film forming matter, 8-15 parts of a film forming auxiliary, 1-4 parts of a bactericide, 2-4 parts of wax powder, 1-3 parts of nano-aluminum oxide, 15-25 parts of pigment and filler and a cosolvent; the cosolvent contains 2-5 parts of a dispersant, 1-3 parts of a pH regulator, 1-4 parts of a defoamer, 1-3 parts of a wetting and leveling agent, 2-5 parts of a thickening agent and 1-2 parts of an adhesion promoter; and counted by percentage by weight, the film forming matter consists of 50-75% of thermoplastic chlorinated polypropylene modified acrylic resin and 25-50% of a thermoplastic hydroxy acrylic acid emulsion. The film forming matter adopted by the invention is chlorinated polypropylene modified acrylic resin, and has the advantages of low VOC, low odor, conformance to the green environmental requirements, acid and alkali resistance, oxidation resistance, high drying speed, strong adhesion of paint film and excellent weather resistance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

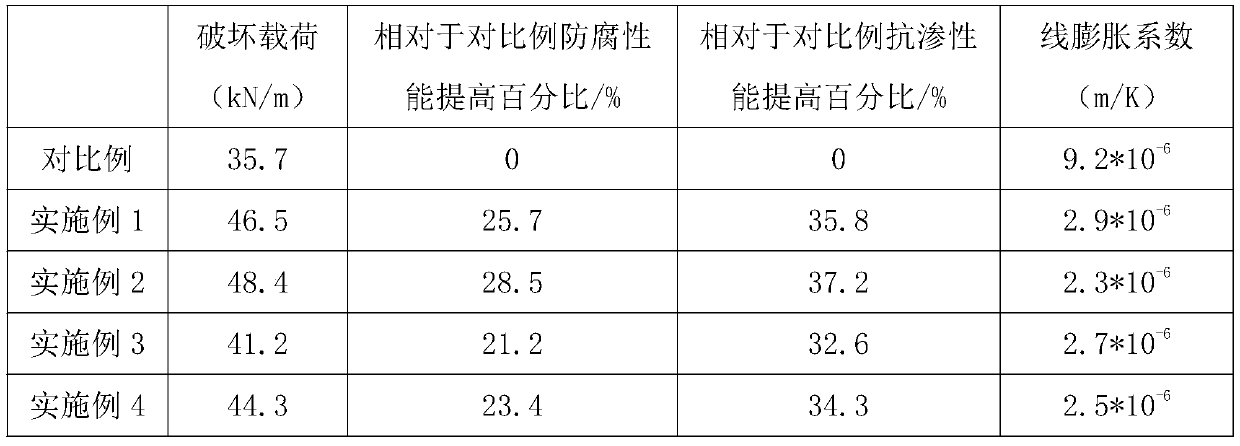

Road inspection well and manufacturing process and construction method thereof

InactiveCN111268963AReduces the chance of microcracksImprove crack resistanceArtificial islandsSewerage structuresSuper absorbentSilicate Cement

The invention relates to the technical field of road inspection well construction, in particular to a road inspection well and a manufacturing process and a construction method thereof. The concrete is prepared from the following raw materials: Portland cement, medium sand, super absorbent resin, pebbles, a fiber mixture, fly ash, an expanding agent, a polycarboxylate superplasticizer, gravel-typegranules, montmorillonite powder, attapulgite, a retarder, an early strength agent and water. The fiber mixture is used as a raw material for preparing the road inspection well, wherein the fiber mixture is formed by mixing polypropylene fibers and steel fibers according to a certain proportion, as a result, the polypropylene fibers and the steel fibers are matched with each other to effectivelyreduce the volume shrinkage phenomenon of the road inspection well in the early stage, and the anti-cracking performance of the road inspection well is improved; and moreover, proper vibration compaction treatment is carried out on the concrete during pouring, so that the compactness and the uniformity of the concrete are improved and guaranteed, the crack resistance and the bearing capacity of the road inspection well are remarkably improved, and the service life of the road inspection well is effectively prolonged.

Owner:漳州明威建材发展有限公司

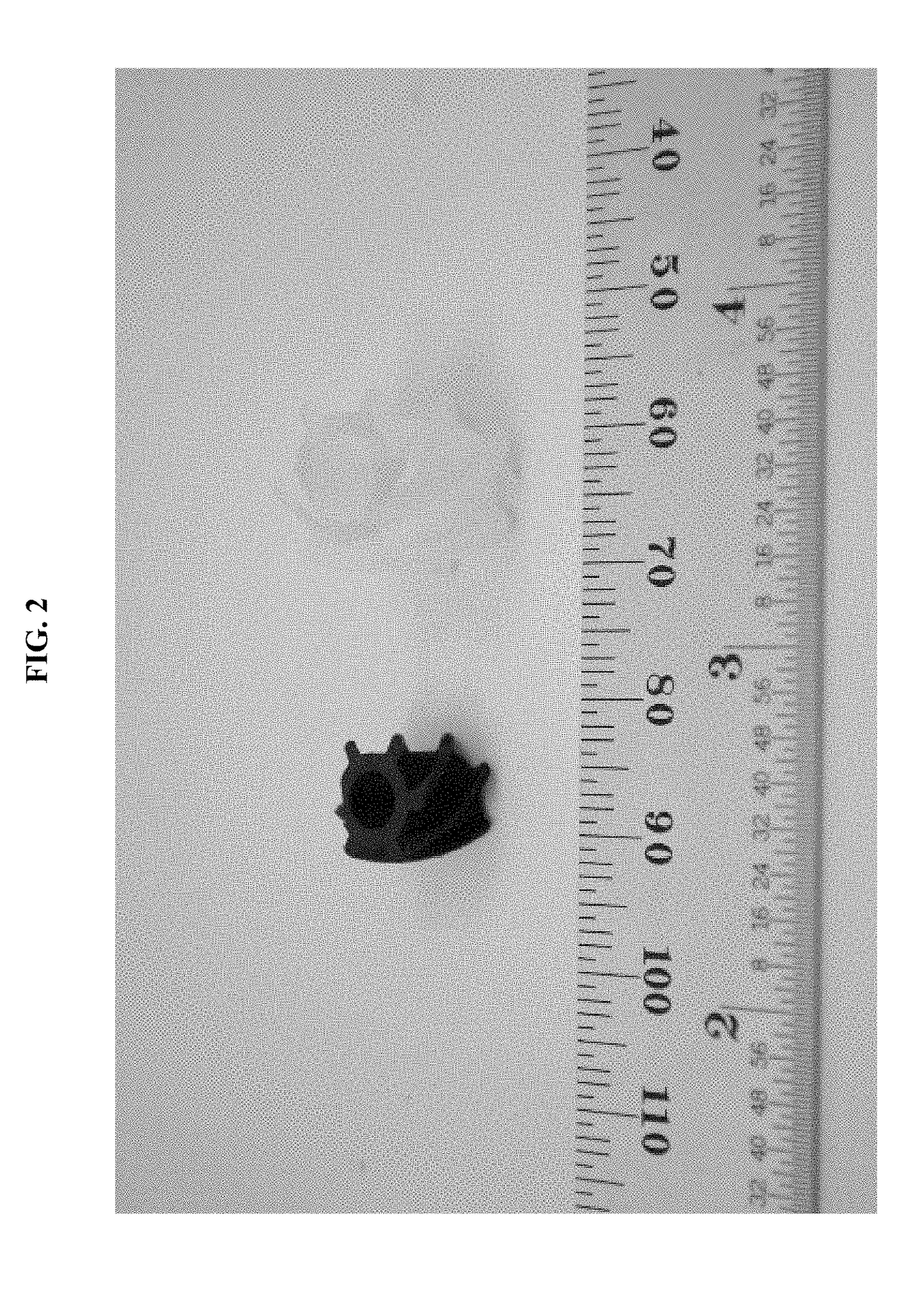

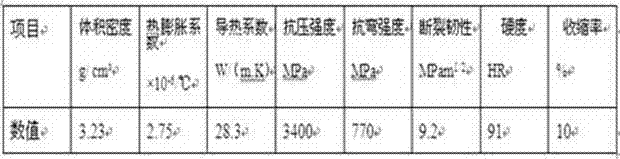

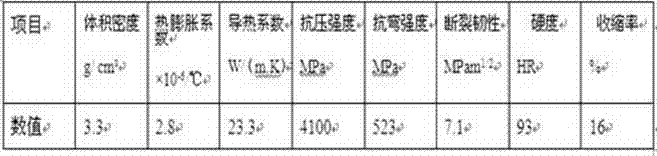

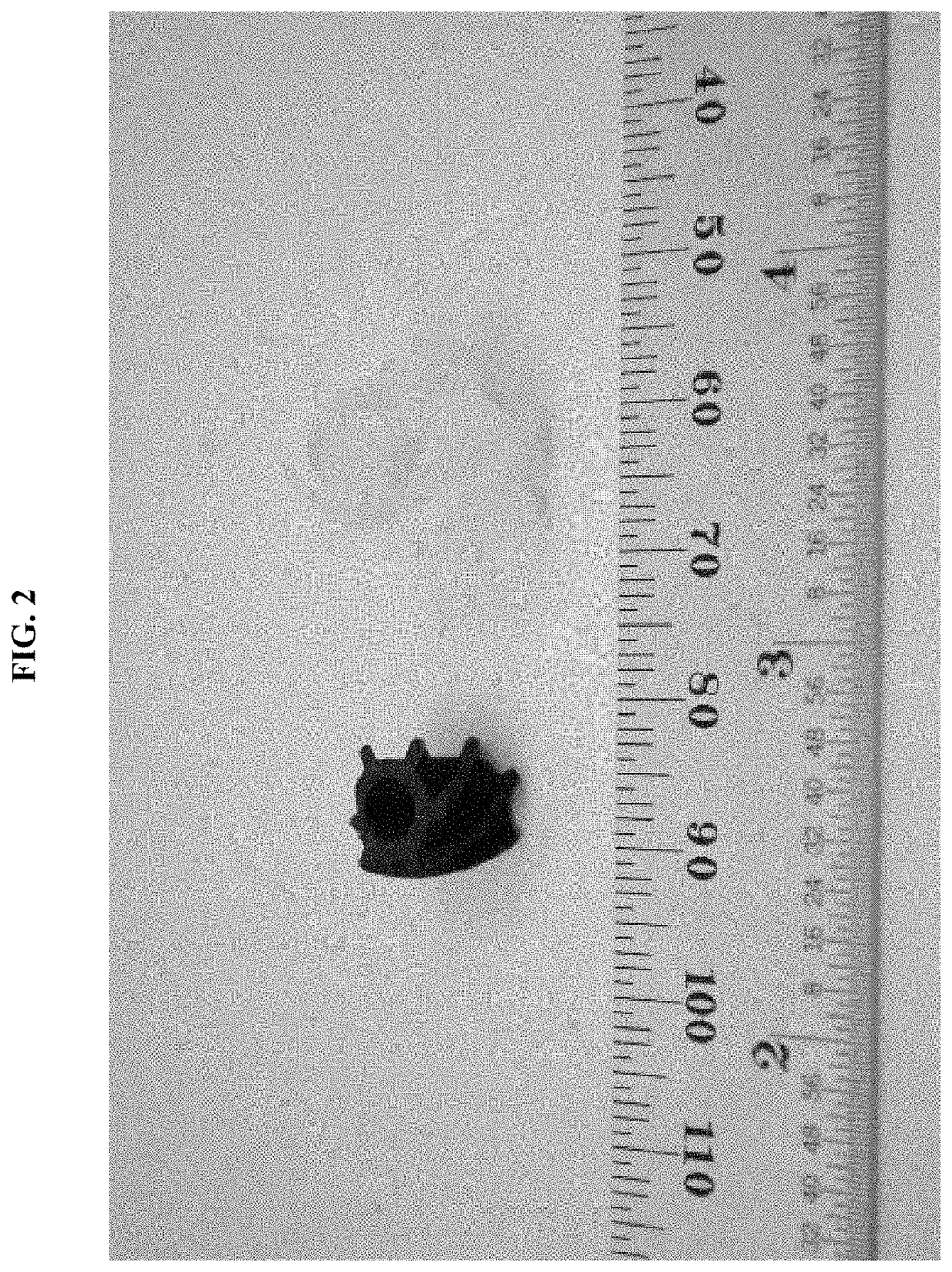

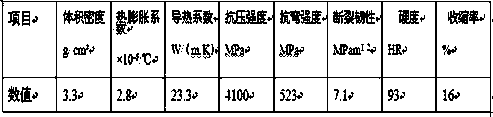

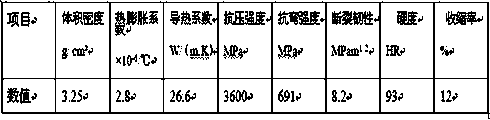

Material for preparing turbine rotor of pressurizer and method for preparing turbine rotor by material

InactiveCN102765957AHigh hardnessHigh strengthBlade accessoriesMachines/enginesGas pressure sinteringInjection moulding

The invention belongs to the technical field of manufacturing of turbine rotor of a pressurizer, in particular to a material for preparing a turbine rotor of the pressurizer and a method for preparing the turbine rotor by the material. The material for preparing the turbine rotor of the pressurizer comprises the components in parts by weight as follows: 85-90 parts of silicon nitride powder, 1-8 parts of boron nitride nanotube powder, 2-4 parts of aluminite powder, 2-4 parts of silicon powder and 3-5 parts of zirconium oxide powder. The method for preparing the turbine rotor by the material comprises the steps of: (1) preparing a raw material; (2) preparing a paste material; (3) injection moulding; (4) setting and drying; and (5) gas pressure sintering of mould constraint. The turbine rotor of the pressurizer prepared by the material is light in weight, good in toughness, high in strength, low in specific gravity and good in proportionality, and small in lag proportionality, small in deformation, small in accumulated carbon and long in service life under supernormal work conditions such as high temperature, high pressure and high speed. Meanwhile, the method for preparing the turbine rotor by the material is simple in steps, convenient to operate and is beneficial for industrialized production in a large scale.

Owner:UNIV OF JINAN

Formulations and methods for 3D printing of ceramic matrix composites

ActiveUS10737984B2Good compatibilityImprove solubilityAdditive manufacturing apparatusInks3d shapesThermal treatment

This invention provides resin formulations which may be used for 3D printing and pyrolyzing to produce a ceramic matrix composite. The resin formulations contain a solid-phase filler, to provide high thermal stability and mechanical strength (e.g., fracture toughness) in the final ceramic material. The invention provides direct, free-form 3D printing of a preceramic polymer loaded with a solid-phase filler, followed by converting the preceramic polymer to a 3D-printed ceramic matrix composite with potentially complex 3D shapes or in the form of large parts. Other variations provide active solid-phase functional additives as solid-phase fillers, to perform or enhance at least one chemical, physical, mechanical, or electrical function within the ceramic structure as it is being formed as well as in the final structure. Solid-phase functional additives actively improve the final ceramic structure through one or more changes actively induced by the additives during pyrolysis or other thermal treatment.

Owner:HRL LAB

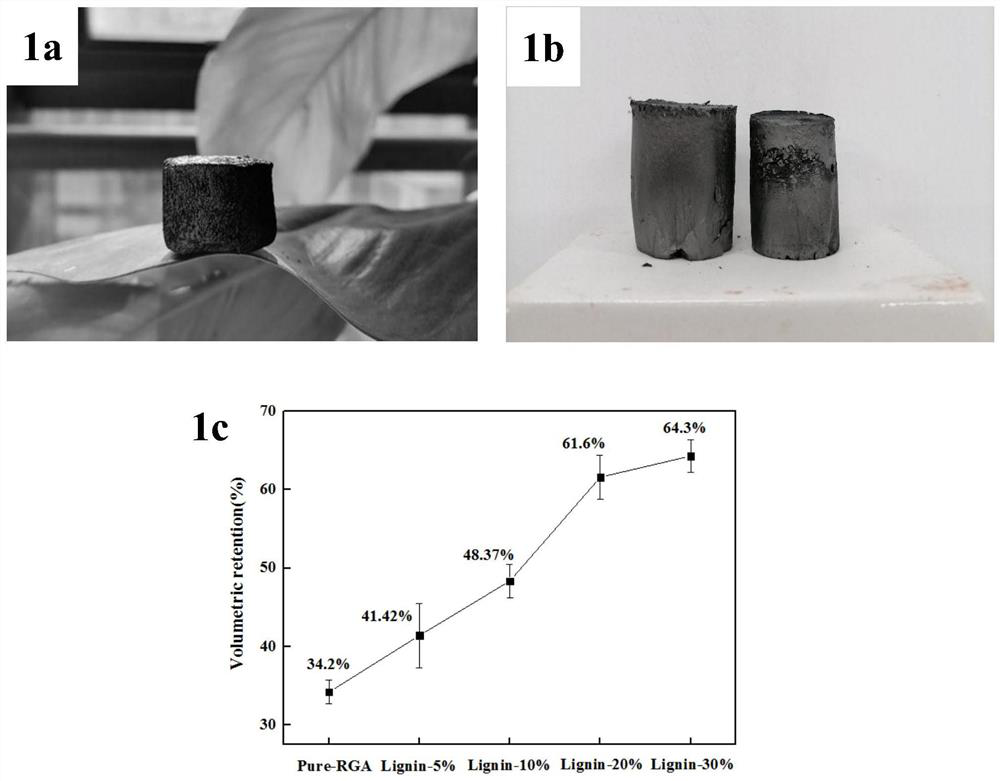

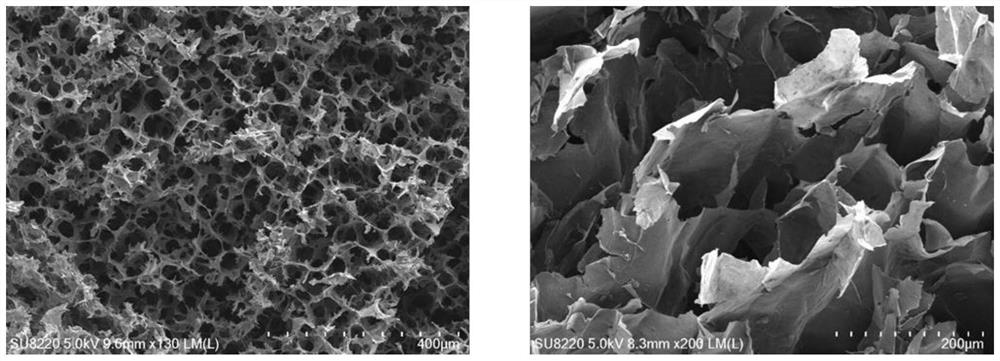

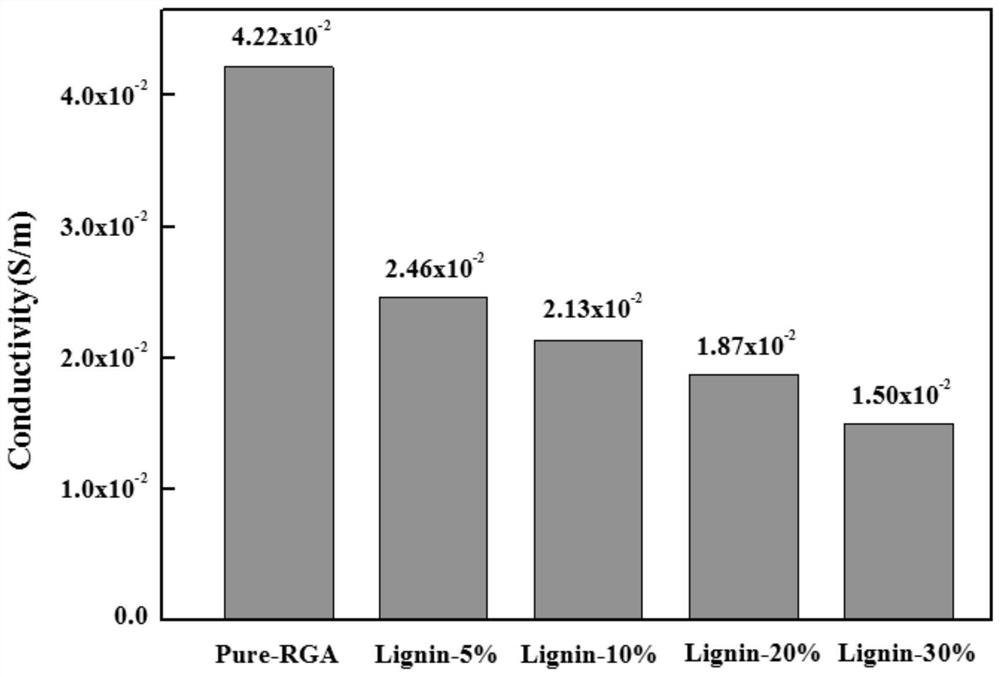

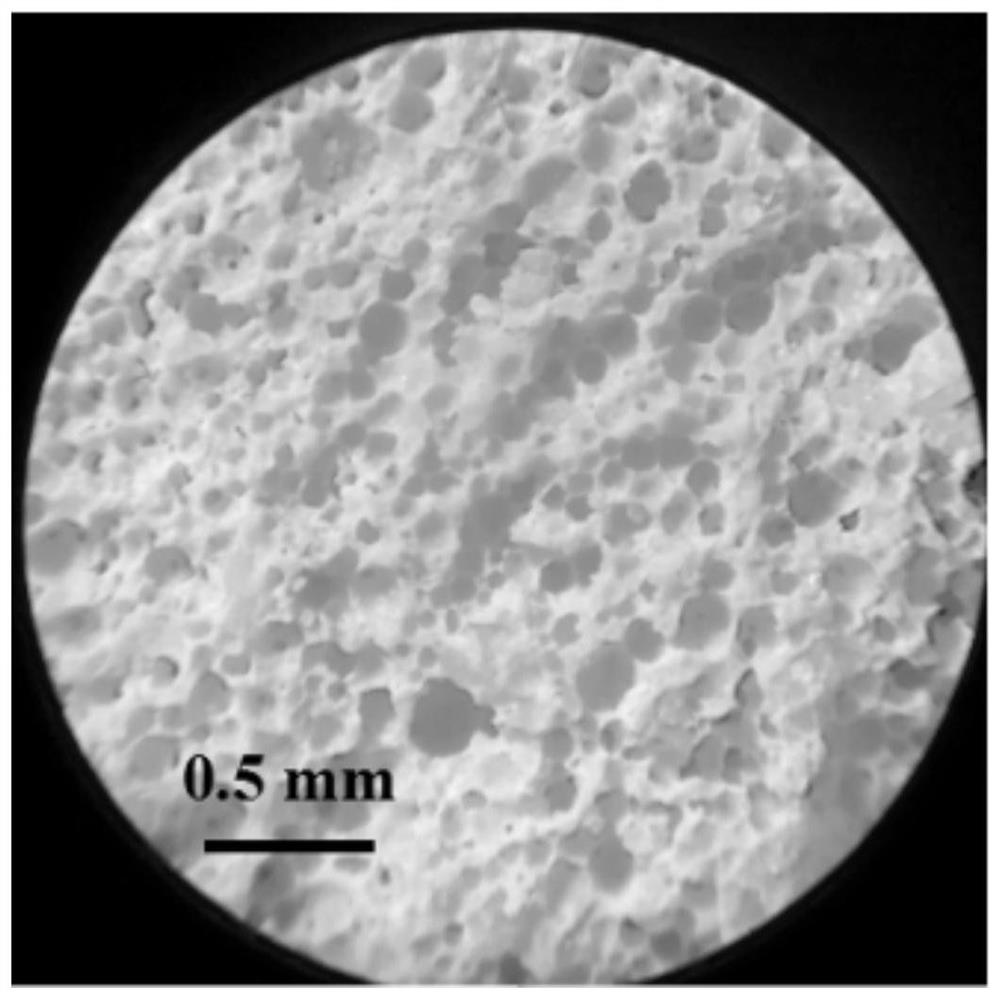

Lignin/reduced graphene oxide carbon aerogel electromagnetic shielding material as well as preparation method and application thereof

PendingCN112919445AGood dispersionIncrease the direction of propagationMagnetic/electric field screeningGrapheneAviationUltrasonic cavitation

The invention discloses a lignin / reduced graphene oxide carbon aerogel electromagnetic shielding material as well as a preparation method and application thereof. Carbonized lignin is used as a conductive skeleton, polarization loss and conductive loss are improved, graphene oxide is introduced as a conductive filler, and the composite carbon aerogel which can resist volume shrinkage and is of a directional pore channel network structure is constructed through ultrasonic cavitation, oxidation reduction, freeze drying and high-temperature carbonization treatment. The preparation of the hydrophobic electromagnetic shielding material with high electromagnetic shielding effectiveness, low density and high conductivity is realized. The raw materials are wide in source and environmentally friendly, the solvent system is non-toxic and cheap, the material preparation process is simple, and the production cost is low. The electromagnetic shielding material with wide frequency and high efficiency is widely applied to military equipment, space flight and aviation, microwave darkrooms, electromagnetic information leakage protection, portable mobile equipment and the like.

Owner:SOUTH CHINA UNIV OF TECH

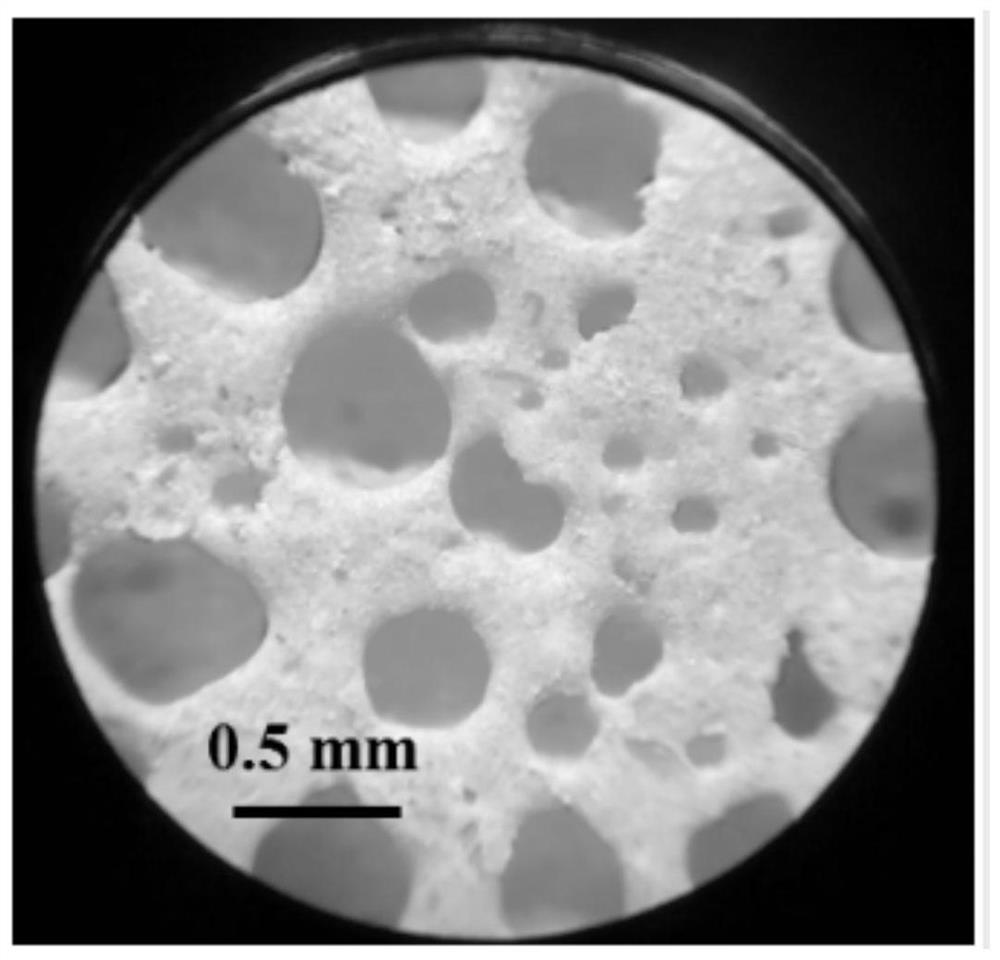

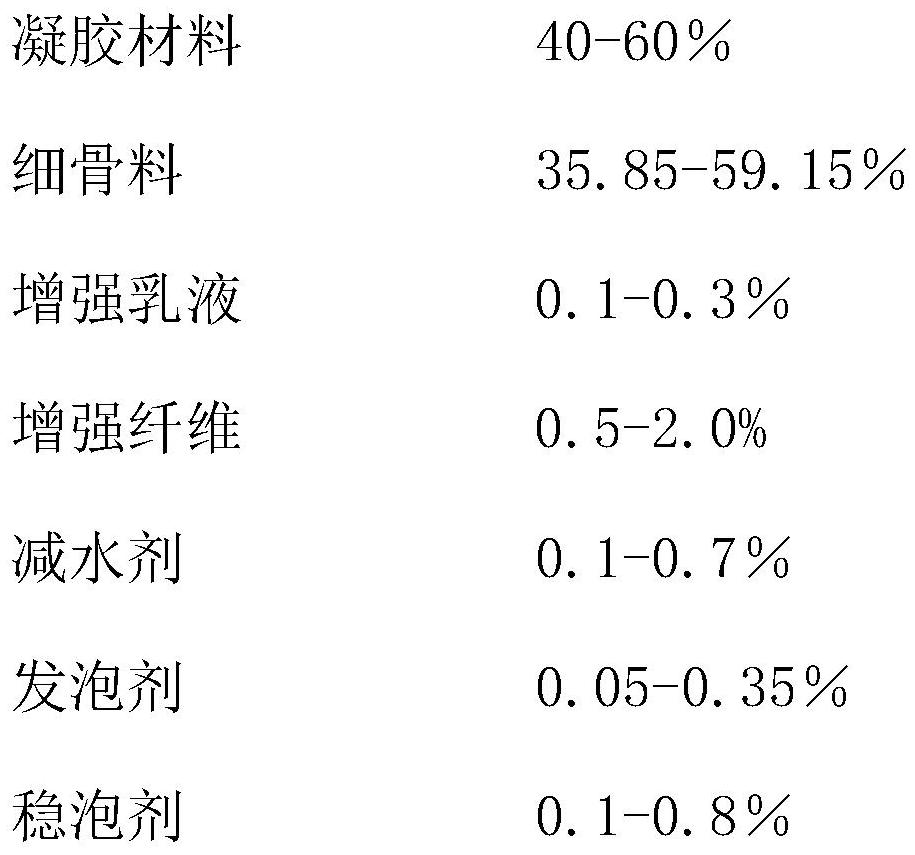

Lightweight waterproof high-strength foam concrete and preparation method thereof

The invention provides lightweight waterproof high-strength foam concrete and a preparation method thereof. The lightweight waterproof high-strength foam concrete is prepared from the following components in percentage by weight: 40 to 60 percent of gel material, 35.85 to 59.15 percent of fine aggregate, 0.1 to 0.3 percent of reinforced emulsion, 0.5 to 2.0 percent of reinforced fiber, 0.1 to 0.7 percent of water reducing agent, 0.05 to 0.35 percent of foaming agent and 0.1 to 0.8 percent of foam stabilizer. According to the lightweight waterproof high-strength foam concrete provided by the invention, the foam which is small in size, uniform and densely distributed is formed, so that the distribution of a concrete material is more uniform, the stress is more uniform correspondingly, the risk of material fracture caused by overlarge local stress is reduced, and the strength of the material is improved.

Owner:武汉来道建材科技有限公司

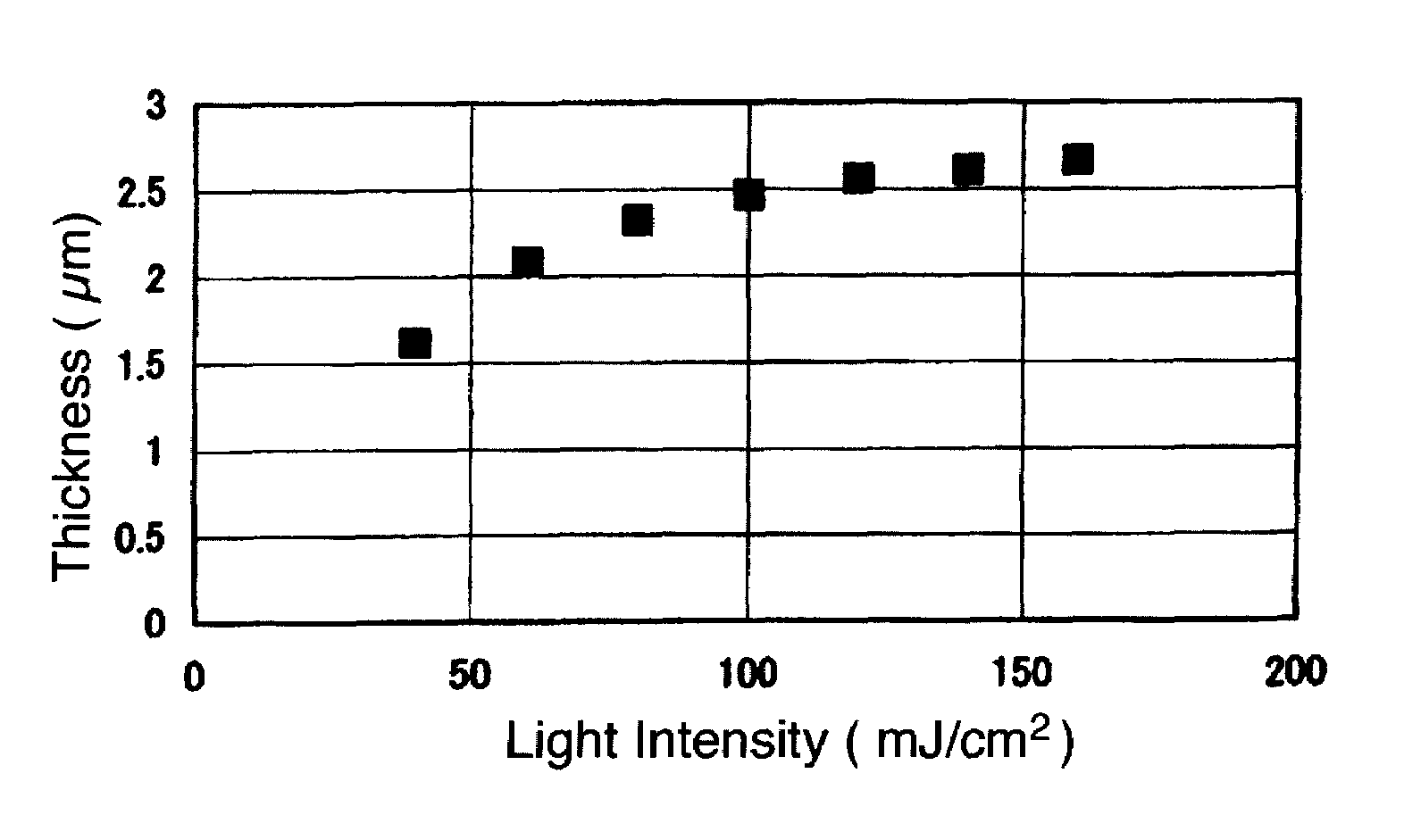

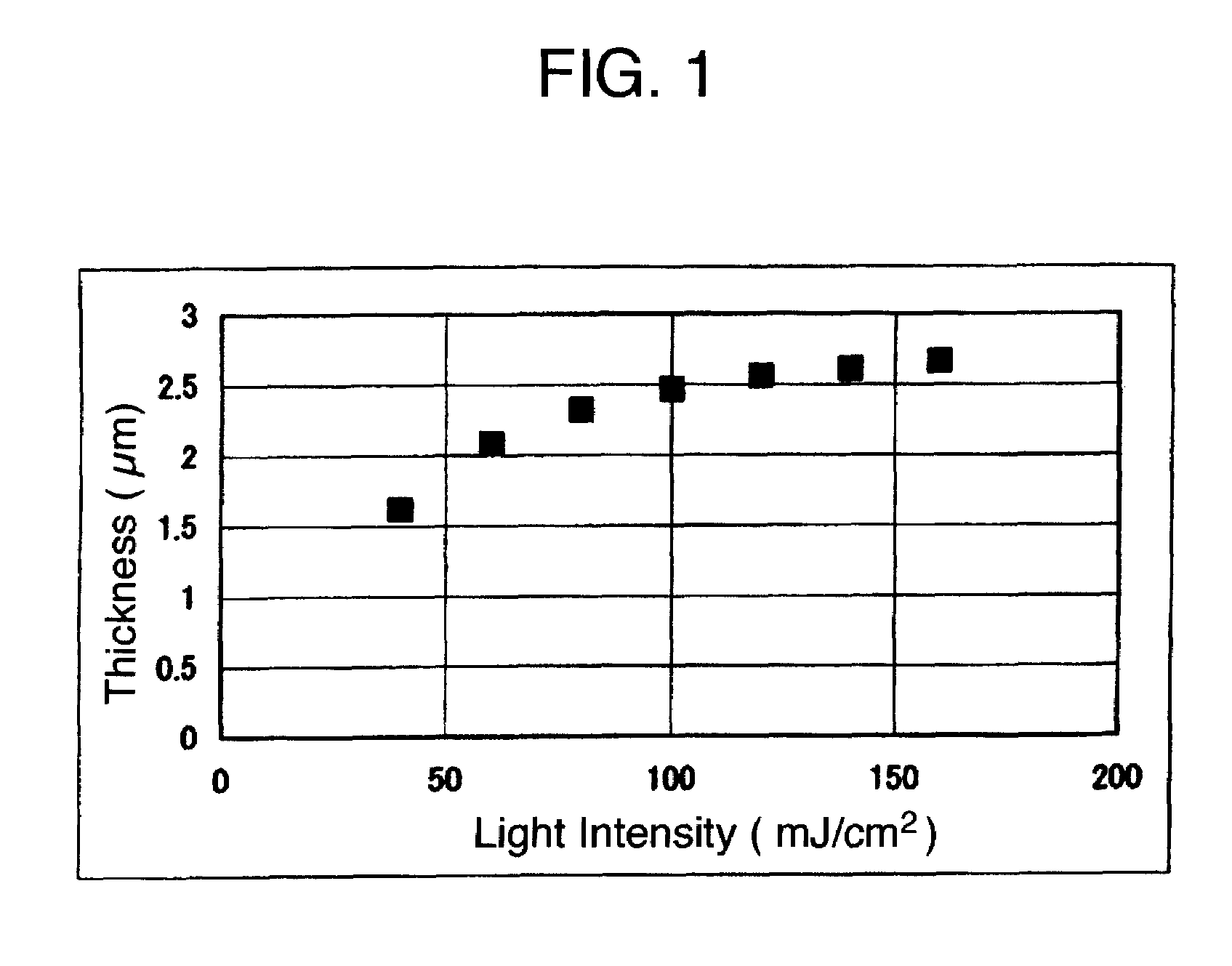

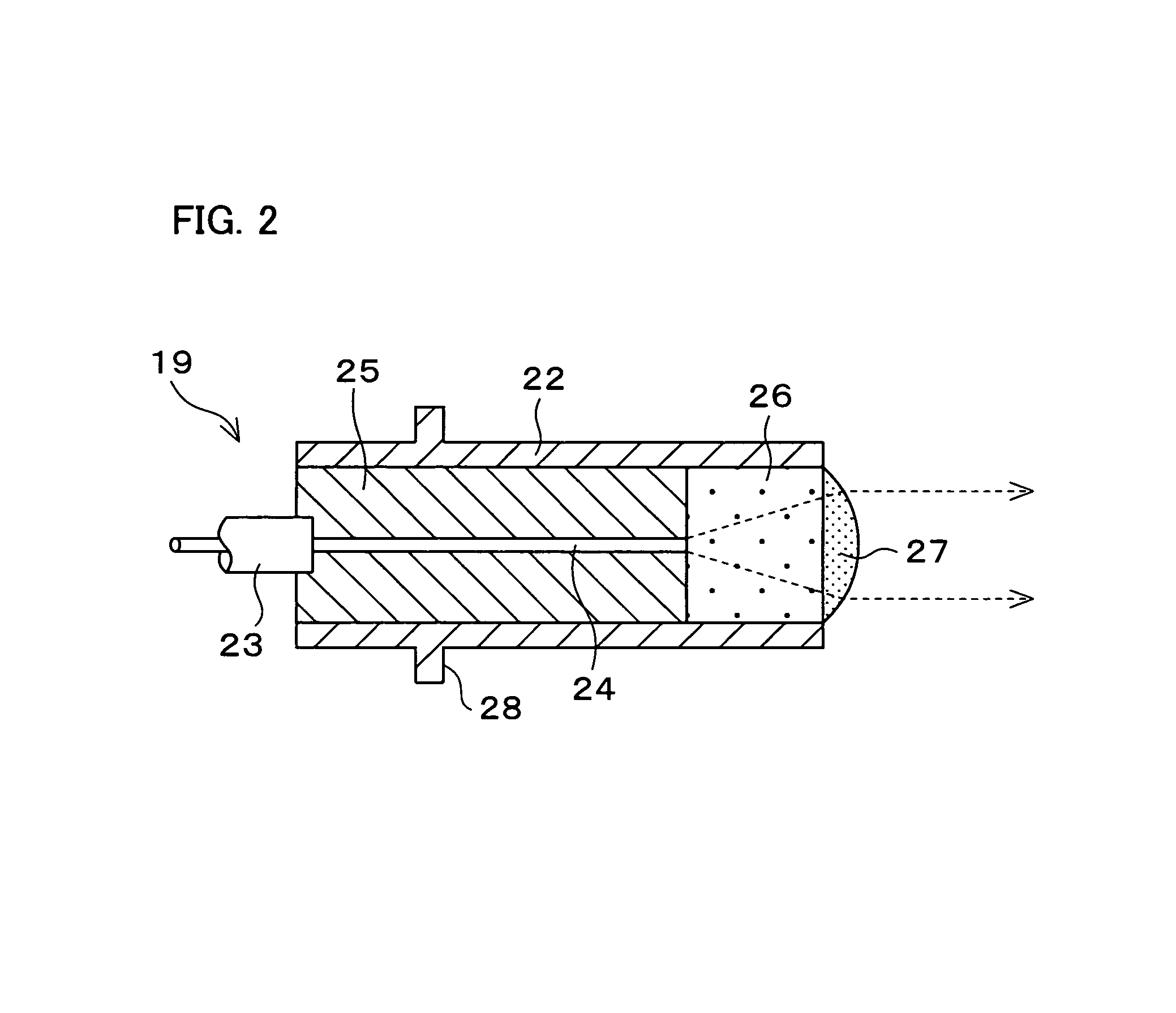

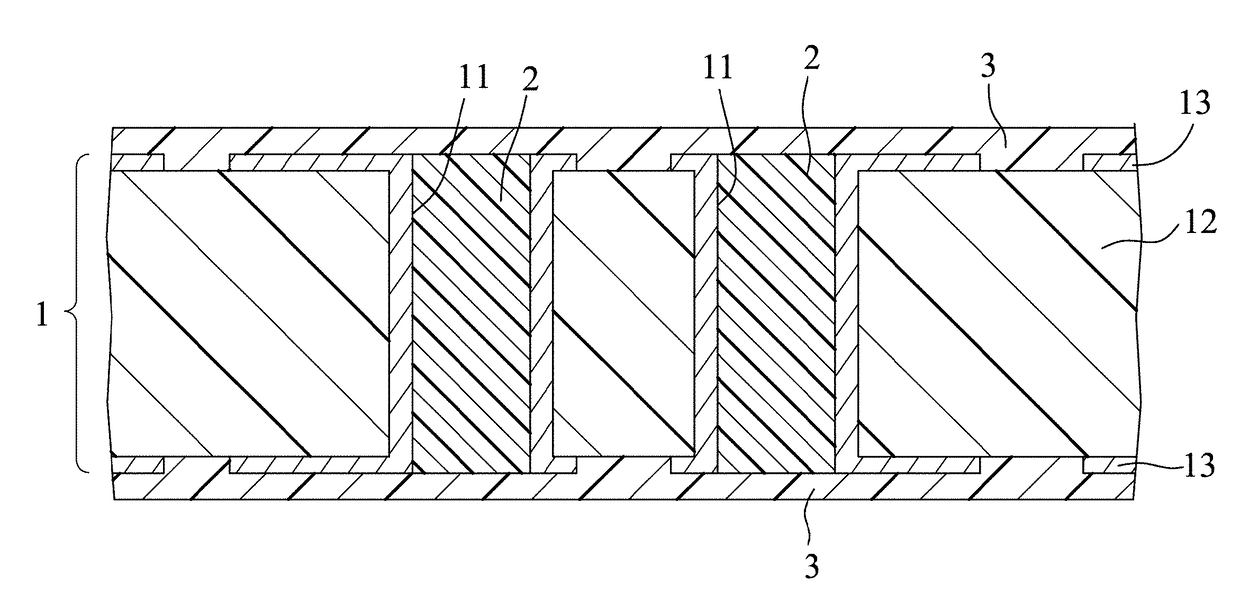

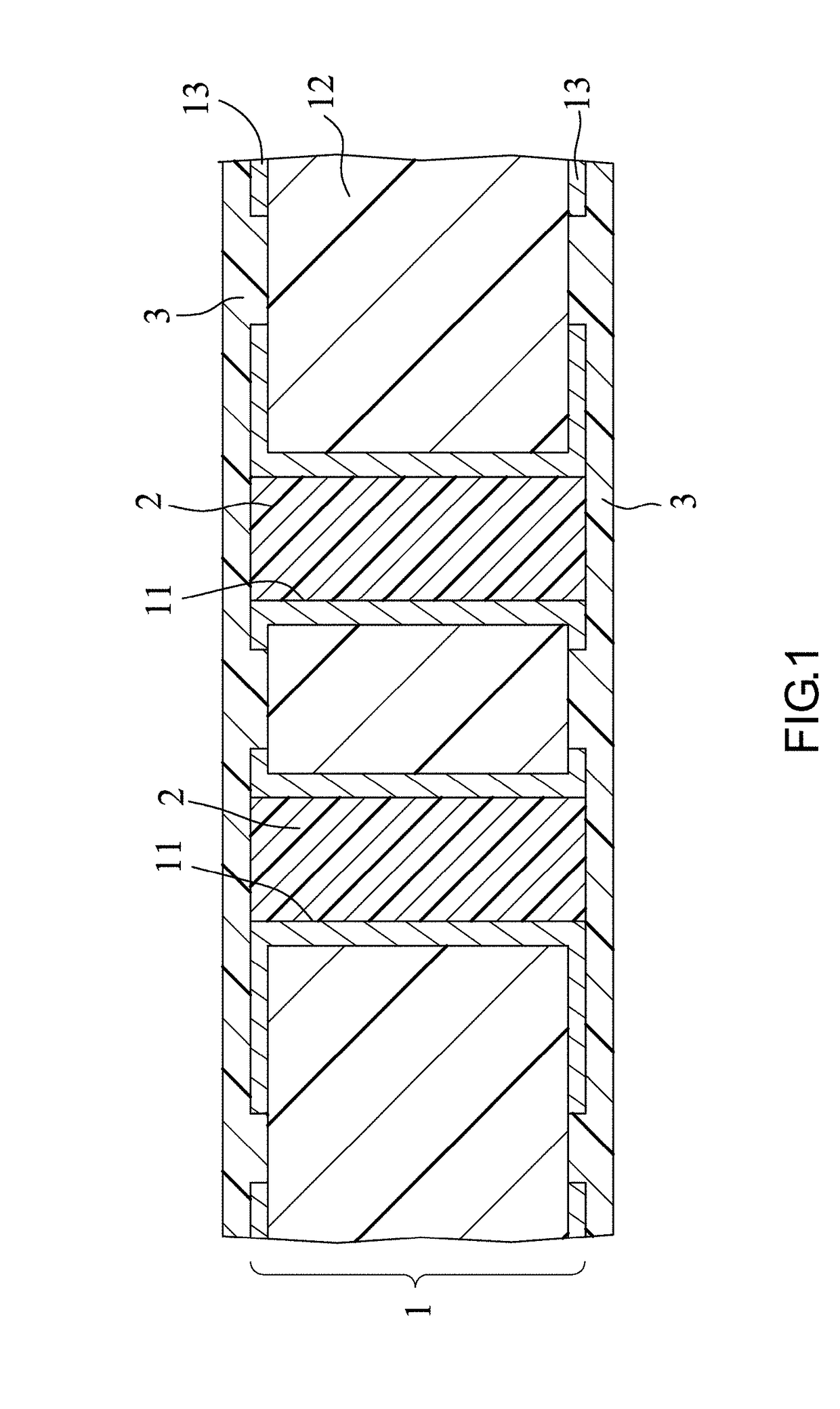

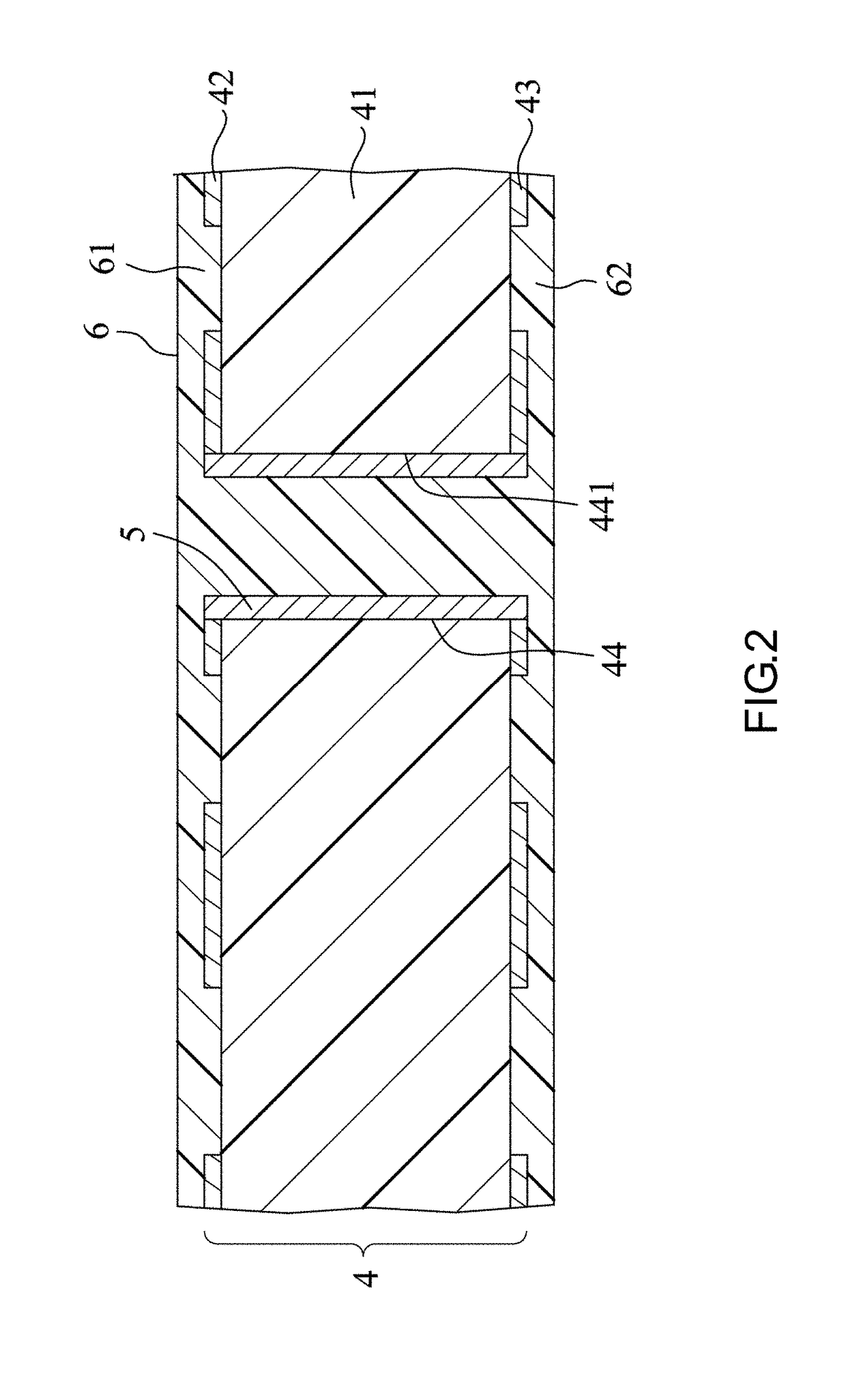

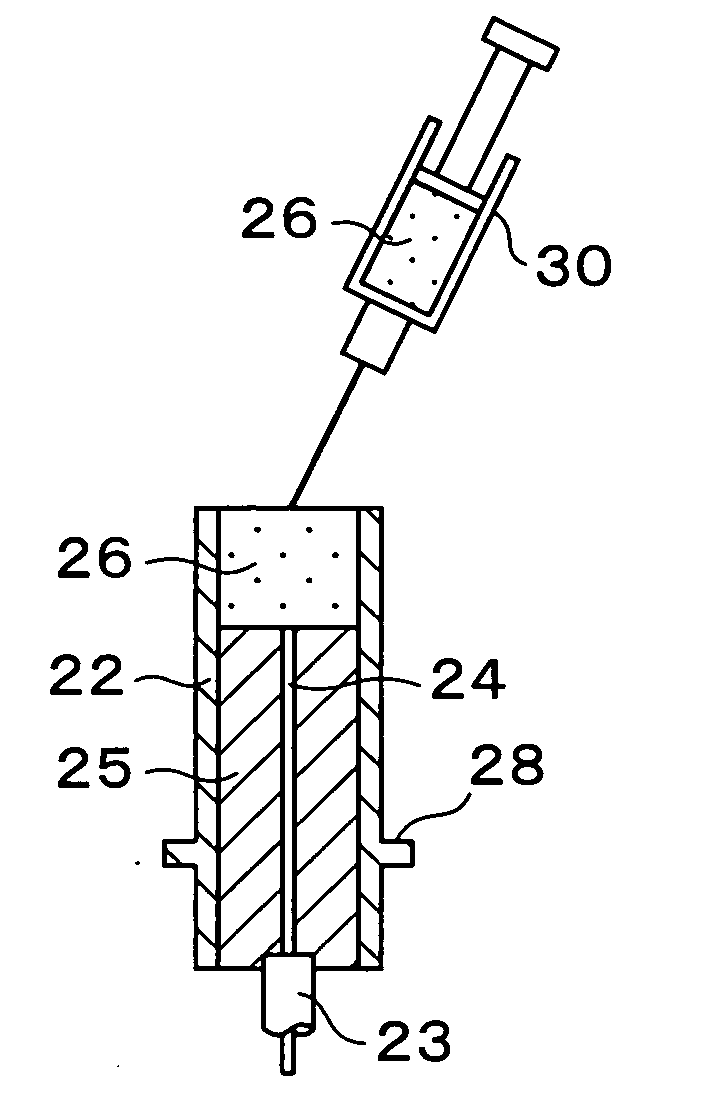

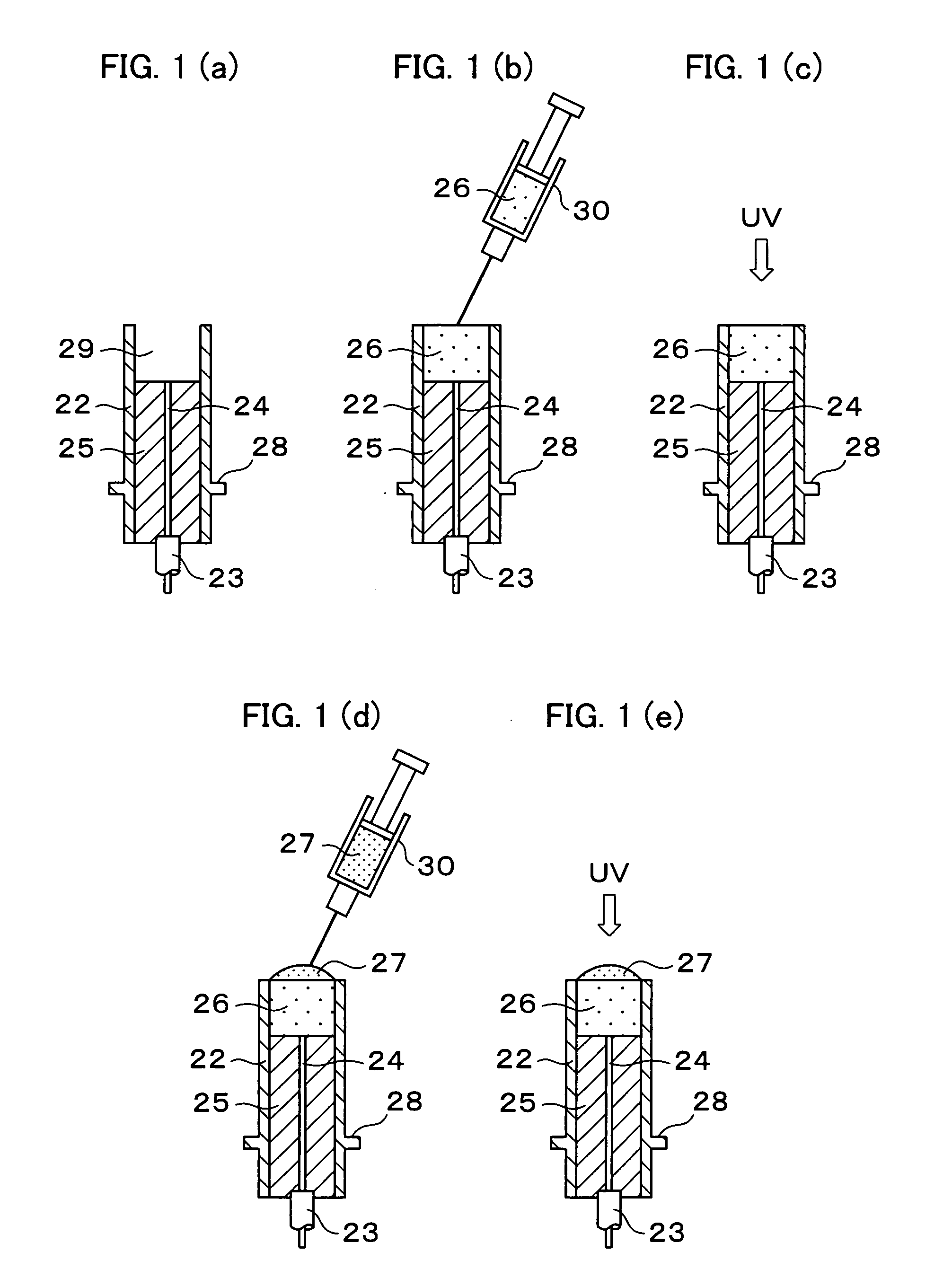

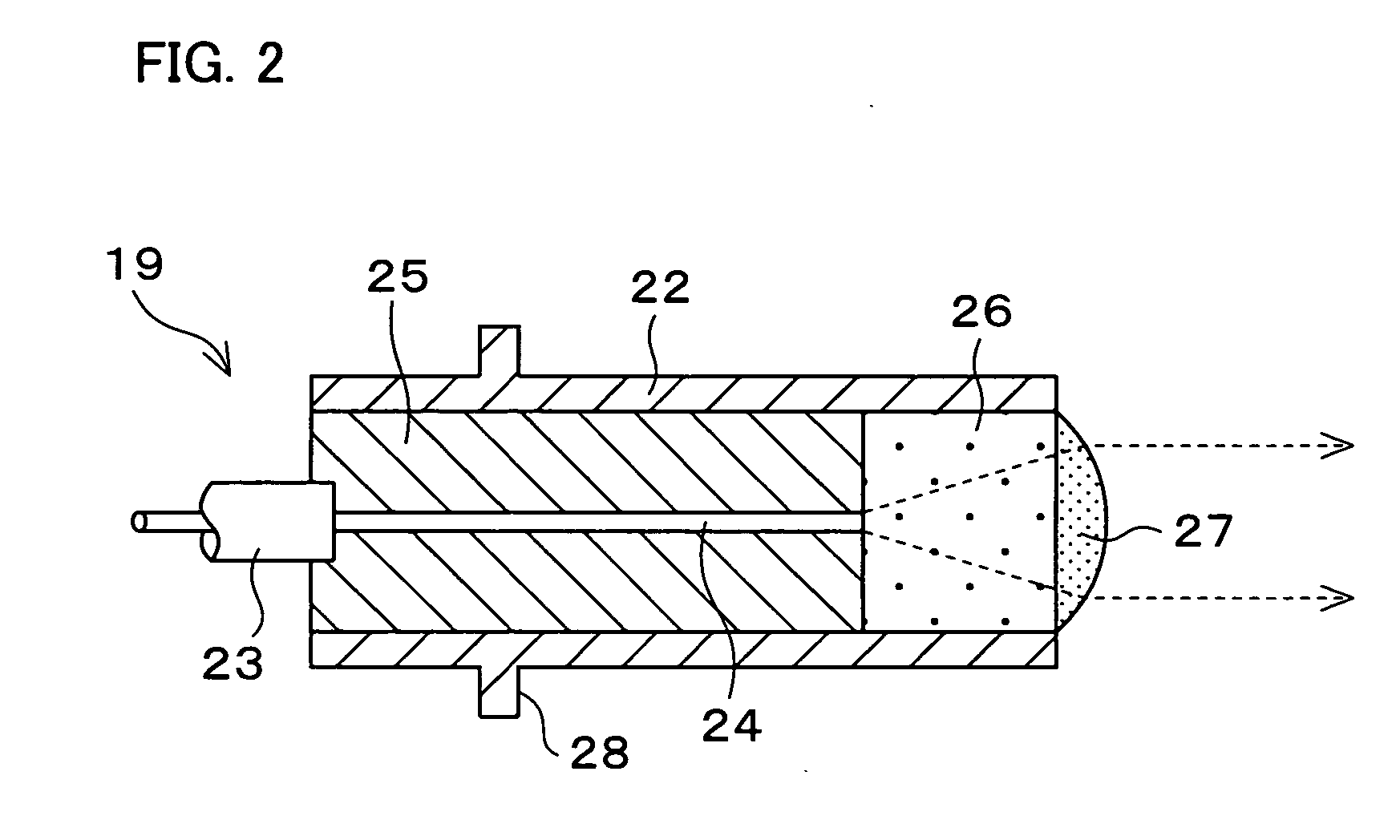

Production method for optical lens and production method for optical fiber connector

InactiveUS7170685B2Reduce impactEasy to adjustCladded optical fibreOptical articlesOptical fiber connectorComposite material

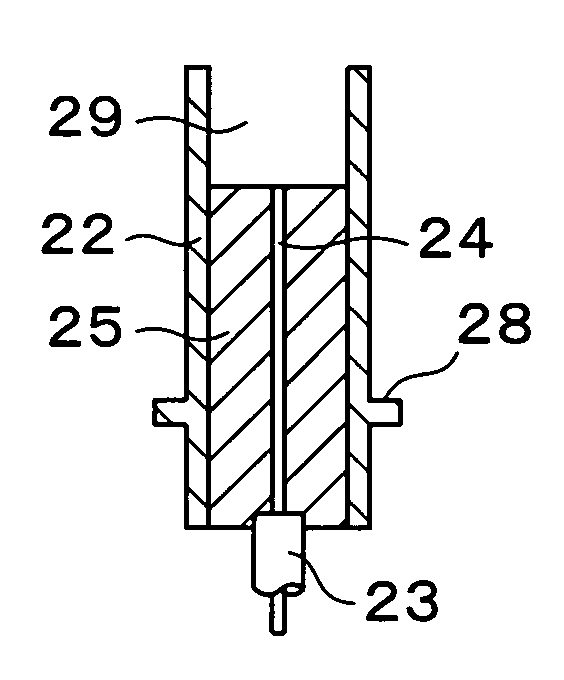

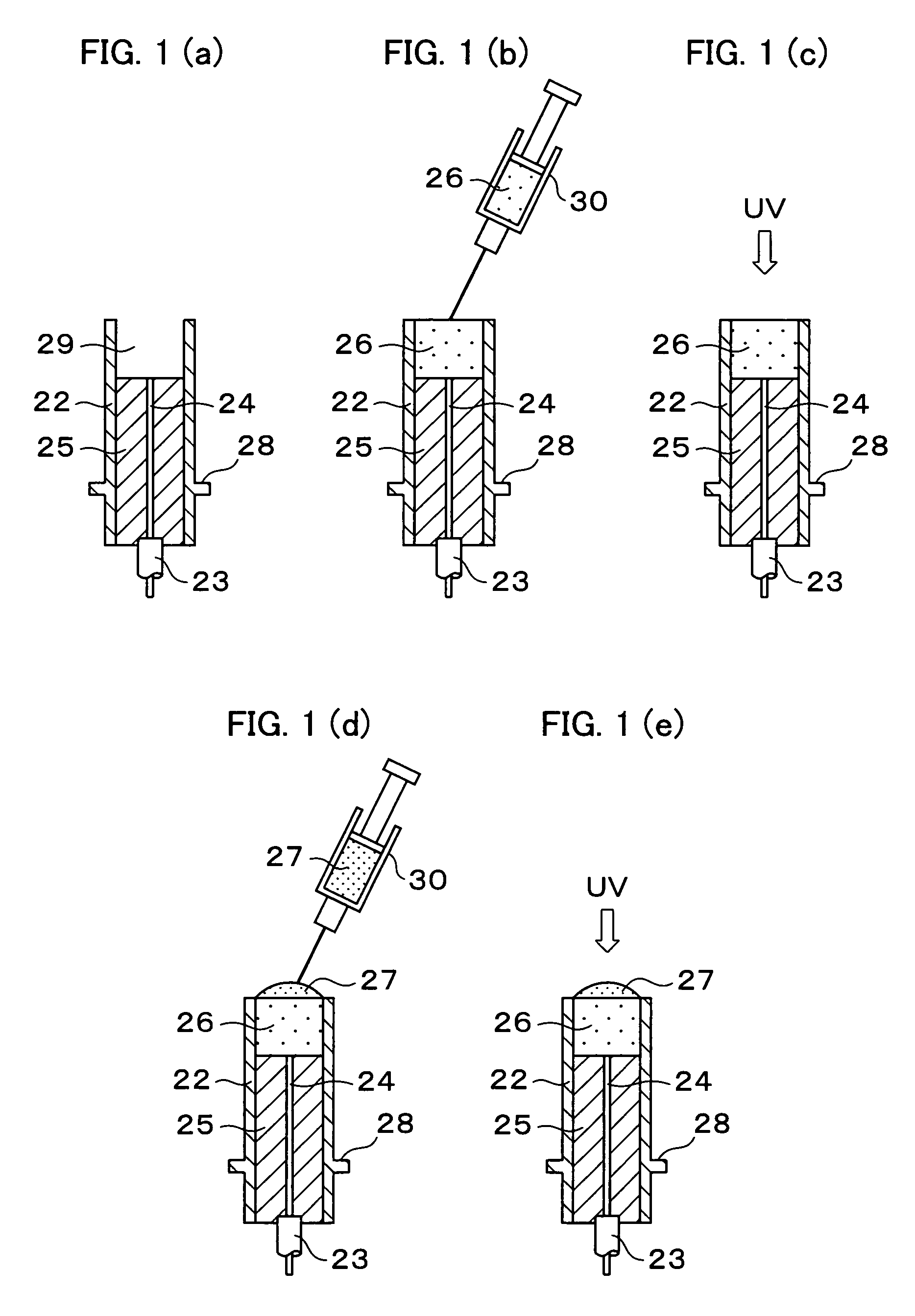

The production method for an optical fiber connector includes the steps of: injecting and hardening a first resin (26) into a resin-injection portion (29) of a connector body (22), the first resin (26) being a light hardening resin or a heat hardening resin; forming a pre-lens by further injecting a second resin (27) on the hardened first resin (26), the second resin (27) being the light hardening resin or the heat hardening resin; and forming a lens by hardening the second resin (27). In this way, it is possible to provide a production method for an optical lens by which influences by volume shrinkage of a resin are decreased, a lens surface can be formed with high accuracy and the product can be made with high quality.

Owner:JAPAN SCI & TECH CORP +2

Preparation method of stain-resistant high-hardness real stone paint

PendingCN110591532AImprove hardness and wear resistanceImprove impact resistancePolyurea/polyurethane coatingsEpoxy resin coatingsEmulsionHardness

The invention relates to the technical field of real stone coatings, in particular to a preparation method of a stain-resistant high-hardness real stone paint. The preparation method comprises a primer, a finish paint and a finish-coat paint, wherein the finish-coat paint comprises the following components in parts by mass: 10-20 parts of polyurethane emulsion, 0.6-2.4 parts of a hardening scratch-resistant agent, 10-12 parts of fumed silica, 0.15-0.3 part of an amide defoaming agent, 0.07-0.15 part of a preservative and 0.16-0.32 part of a nano additive. The finish paint comprises the following components in parts by mass: 10-20 parts of styrene-acrylic emulsion, 8-16 parts of polyurethane modified epoxy resin, 40-60 parts of fine aggregates, 2-4 parts of a thickening agent and 1.2-1.8 parts of a toughening agent. According to the preparation method, the hardening agent is added into the finish-coat paint, so that the coating layer of the finish-coat paint is reinforced, the hardnessand the wear resistance of the coating layer are improved, the hardness is improved along with the increase of the addition amount, the impact resistance of the coating can be improved, the adhesion force and the transparency of the coating layer of the coating are not influenced by the hardening agent, volume shrinkage of the coating layer during curing can be relieved by addition of the hardening agent, and the adhesion force between the coating layer and a substrate is improved; and therefore, the hardness of the real stone paint is improved.

Owner:Jiangsu Jiunuo Architectural Materials Technology Co Ltd

Photosensitive and via-forming circuit board

ActiveUS20180263122A1Increase flexibilityImprove heat resistanceResist coatingPrinted circuit aspectsEpoxyElectrical conductor

A photosensitive and via-forming circuit board comprising a laminate unit, a conductor unit, and a cover layer unit is provided. The laminate unit includes an insulating layer, a first conductive wiring layer and a second conductive wiring layer formed at two opposite sides of the insulating layer, respectively, and at least one through-hole surface defining a through hole extending from the upper surface of the first conductive wiring layer through the insulating layer to the lower surface of the second conductive wiring layer. The conductor unit is formed on the at least one through-hole surface. The cover layer unit is formed from a photosensitive composition comprising an epoxy group-containing compound and a photosensitive polyimide capable of reacting with the epoxy group of the epoxy group-containing compound, and includes a first cover layer formed on the first conductive wiring layer and extending into and filling the through hole.

Owner:MICROCOSM TECH

Production method for optical lens and production method for optical fiber connector

InactiveUS20050163441A1Reduce the impactEasily and finely be adjustedCladded optical fibreOptical articlesOptical fiber connectorComposite material

The production method for an optical fiber connector includes the steps of: injecting and hardening a first resin (26) into a resin-injection portion (29) of a connector body (22), the first resin (26) being a light hardening resin or a heat hardening resin; forming a pre-lens by further injecting a second resin (27) on the hardened first resin (26), the second resin (27) being the light hardening resin or the heat hardening resin; and forming a lens by hardening the second resin (27). In this way, it is possible to provide a production method for an optical lens by which influences by volume shrinkage of a resin are decreased, a lens surface can be formed with high accuracy and the product can be made with high quality.

Owner:JAPAN SCI & TECH CORP +2

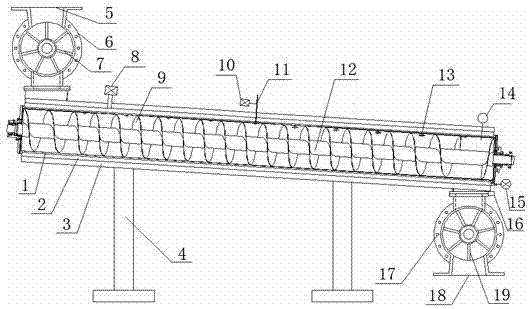

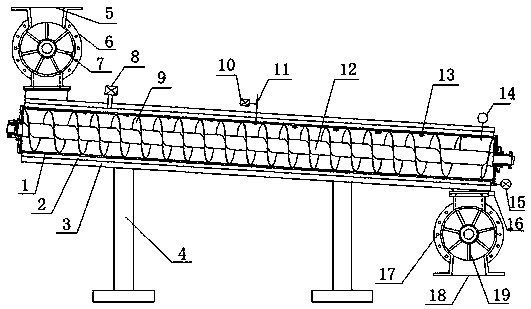

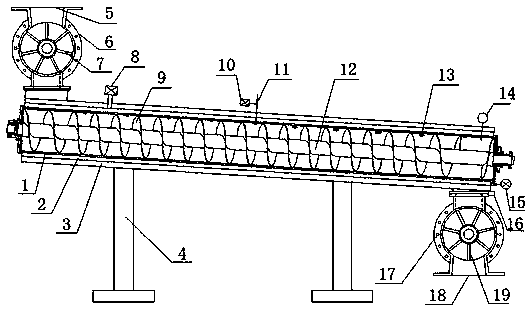

Volume control device for improving processability of microwave expansion tobacco stems

ActiveCN107259633AReduce volume shrinkageFacilitate subsequent slicingTobacco treatmentMicrowaveHelical blade

The invention discloses a volume control device for improving the processability of microwave expansion tobacco stems, aiming at providing the volume control device for improving the processability of the microwave expansion tobacco stems, which is simple in structure. The device comprises a barrel, a bracket, a rotating shaft, a helical blade, a steam jacket, a drain valve, a heat preservation layer, a compressed air pipeline and a plurality of compressed air nozzles, wherein a feeding opening is formed in one end of the barrel, a discharging opening is formed in the other end of the barrel, the bracket is used for supporting the barrel, the rotating shaft is rotatably arranged in the barrel, the helical blade is fixedly arranged on the rotating shaft, the steam jacket sleeves the outer wall of the barrel, the drain valve is arranged on the steam jacket, the heat preservation layer is arranged on the outer wall of the steam jacket, the compressed air pipeline penetrates into the barrel, and the plurality of compressed air nozzles are located in the barrel and communicate with the compressed air pipeline; a feeding cross valve is arranged on the feeding opening of the barrel, a discharging cross valve is arranged on the discharging opening of the barrel, and a pressure gauge and a humidity eliminating hole are arranged on the barrel. With the volume control device, the volume shrinkage degree of the microwave expansion tobacco stems after moisture regaining treatment can be greatly reduced, and thus the subsequent slicing processing is facilitated.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

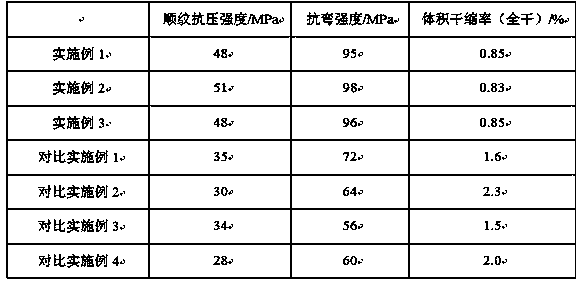

Treatment method capable of improving mechanical performance of mongolian scotch pine wood

InactiveCN110076866AGuaranteed dimensional stabilityGood dimensional stabilityRadiation/waves wood treatmentWood treatment detailsFiberPolyvinyl alcohol

The invention discloses a treatment method capable of improving mechanical performance of mongolian scotch pine wood. The mongolian scotch pine wood treated with the method has the advantages that notonly are compressive strength and bending strength improved, but also the volume dry shrinkage rate is reduced and dimensional stability is guaranteed. The mongolian scotch pine wood is watered withhot water firstly and then is irrigated with cold water at 1-5 DEG C, so that gaps among wood fibers can be opened sufficiently, and follow-up active substance intervention is facilitated; a treatingliquid is prepared from urea, sodium laureth sulfate, acrylamide and polyvinyl alcohol and used for treating the wood, impurities such as protein, grease and the like in the wood can be removed, the mechanical performance of the wood is enhanced, and meanwhile, the dimensional stability of the wood is improved; the wood is treated by carbon dioxide gas, and internal grease can be further removed under cooperation with urea, sodium laureth sulfate, acrylamide and polyvinyl alcohol.

Owner:FUNAN HUIFENG HOUSEHOLD CRAFT

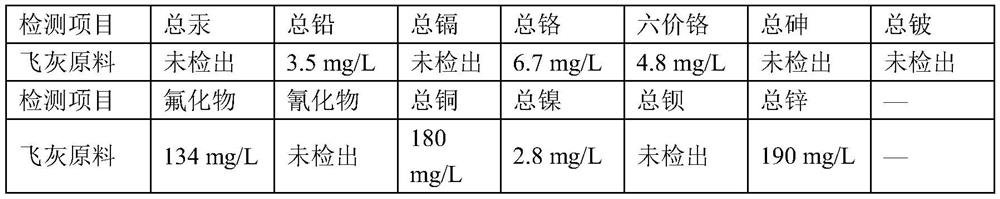

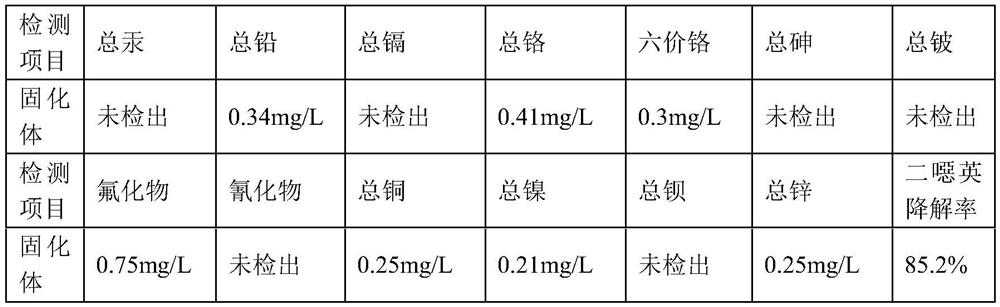

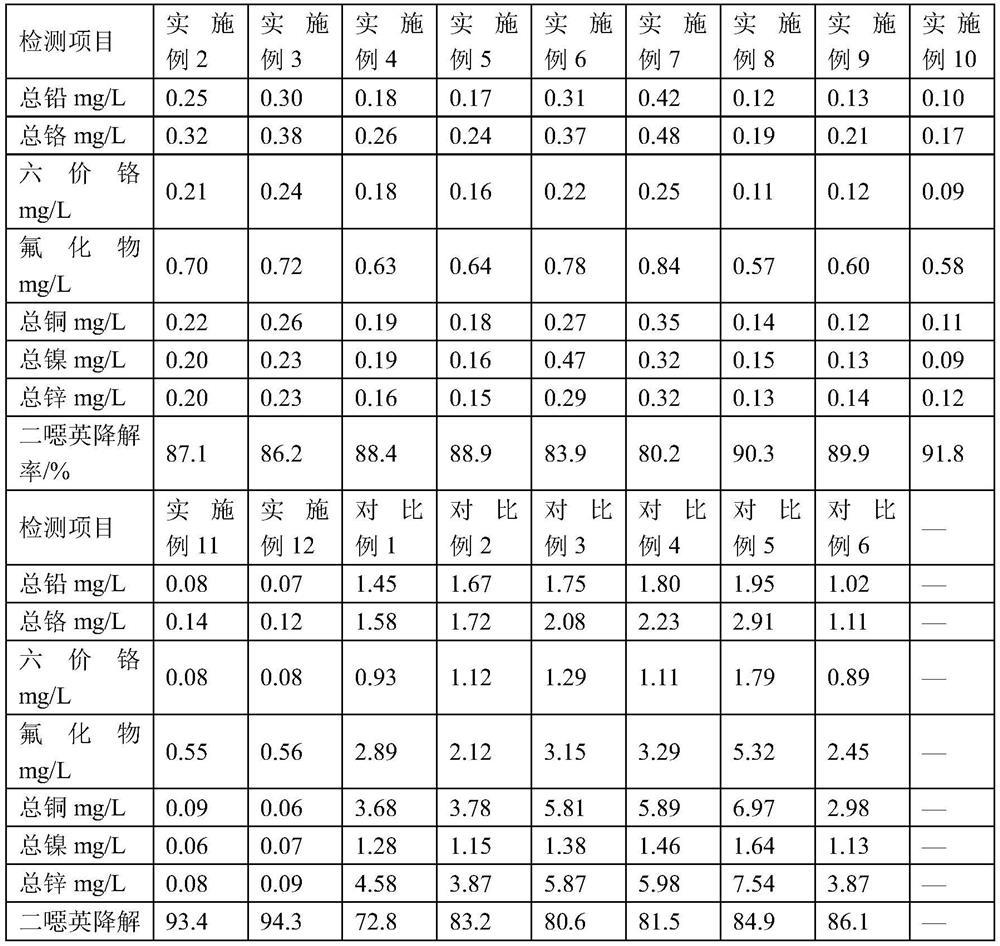

Waste incineration treatment process

PendingCN114321939ALow heavy metal leaching rateReduce dioxin contentOther chemical processesDispersed particle separationActivated carbonHydrotalcite

The invention relates to the field of waste incineration, and particularly discloses a waste incineration treatment process which comprises the following steps: waste incineration: performing waste incineration, and introducing oxygen in the incineration process; after the incineration flue gas is adsorbed by activated carbon and sprayed and deacidified by lime slurry, discharged flue gas and incineration fly ash are obtained; the incineration fly ash and a treatment agent are mixed and stirred under the condition of a mercury lamp or ultraviolet light, then a binding material is added, finally, water is added for stirring, building blocks are formed, and a solidified body is obtained; wherein the treatment agent is prepared by mixing the following raw materials in parts by weight: 15-25 parts of a chelating agent, 6-15 parts of hydrotalcite, 5-12 parts of nano titanium dioxide and 28-35 parts of graphene oxide loaded biochar. The device has the advantage that heavy metal and dioxin in the fly ash generated by waste incineration can be more effectively treated.

Owner:北京北控绿海能环保有限公司

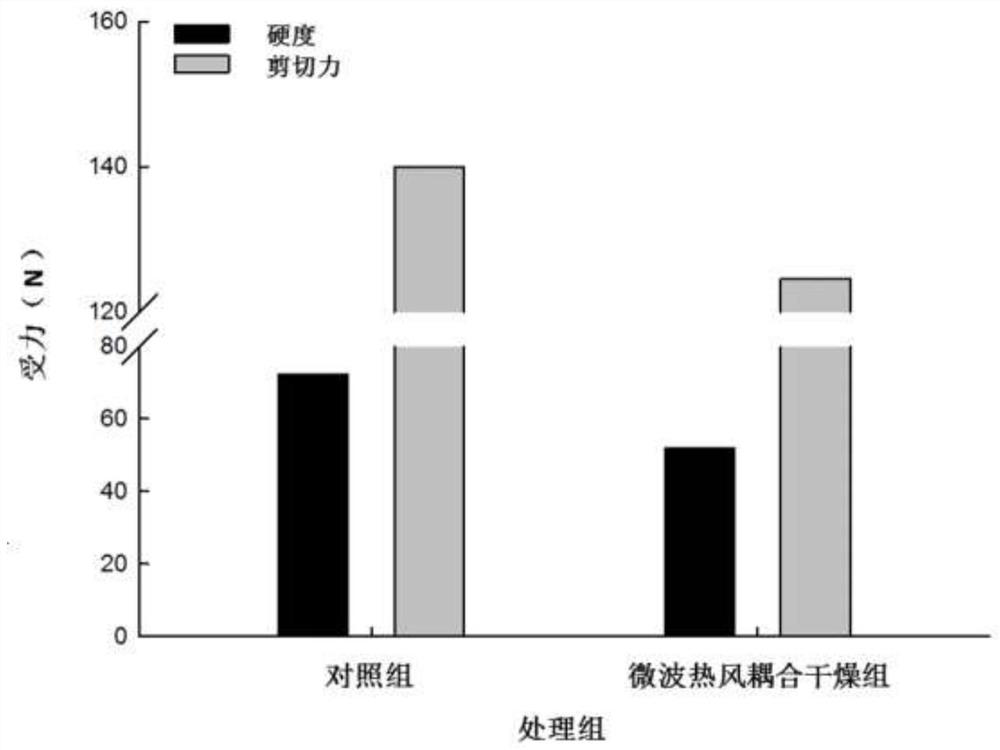

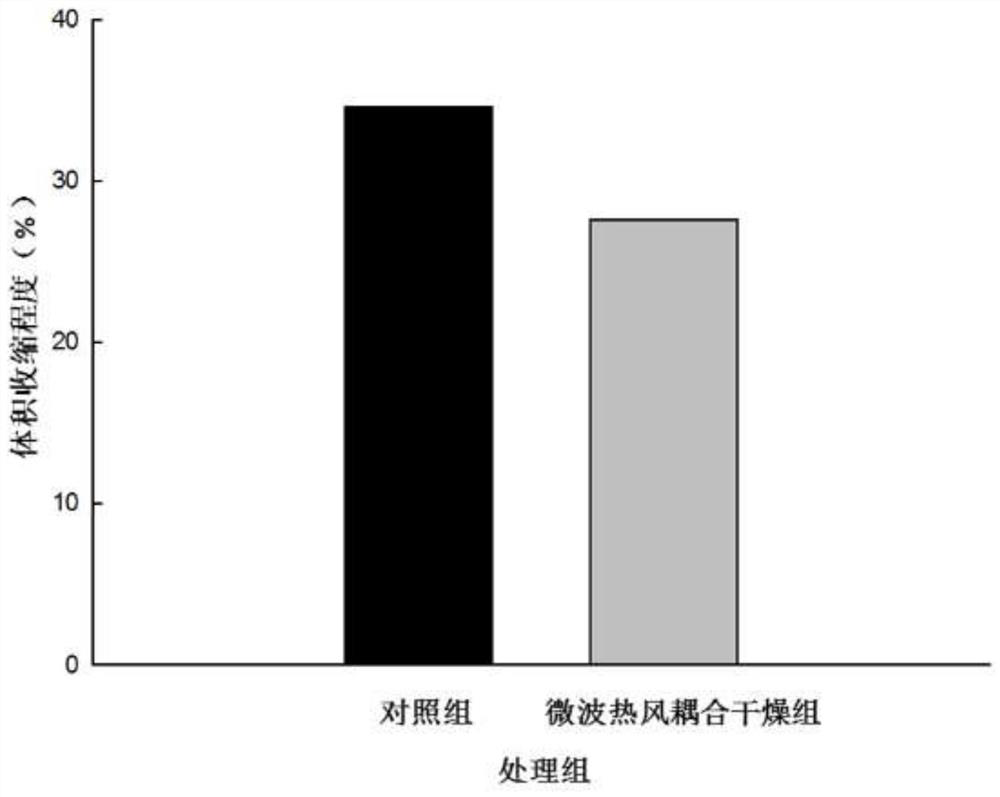

Microwave-hot air coupled dried beef jerky production method

The invention relates to the technical field of beef jerky processing, and discloses a microwave-hot air coupled dried beef jerky production method, which comprises the following steps: S1, preparingraw materials: unfreezing fresh hind leg meat, and removing visible fascia and fat; S2, burdening: respectively taking beef, salt, sugar, ginger, light soy sauce, dark soy sauce, cooking wine, maturevinegar, amomum tsao-ko, star anise, myrcia, cinnamon, Chinese prickly ash and chili for later use according to the parts by weight; S3, performing primary boiling: adding 3-5g of fresh ginger and 20ml of cooking wine, putting the cut meat samples into the mixture, performing primary boiling for 15-25min, and removing blood water and floating foam at the boiling power of 160W; compared with a traditional beef jerky making method, the making method has the advantages that the tenderness of the beef jerky can be effectively improved, the hardness is reduced, the volume shrinkage degree of the beef jerky is reduced, the yield is increased, moisture distribution is uniform, the problem of surface hardening caused by uneven drying is effectively solved, and besides, on the basis that the original flavor is kept, the beef jerky can be endowed with relatively good roasting fragrance.

Owner:YANGZHOU UNIV

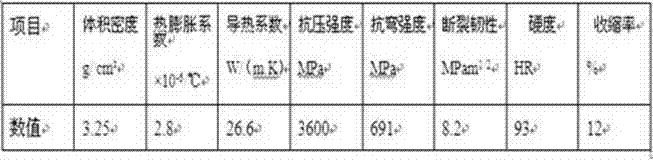

A high-strength heat-shock resistant push plate and its preparation method

The invention discloses a high-strength heat-resistant shock-resistant push plate. The raw materials include the following components by weight: 20-30 parts of 3-0.5mm mullite particles, 15-20 parts of 1-0.5mm corundum particles, 0.5-0.1 mm quartz particles 10‑15 parts, 320 mesh andalusite fine powder 15‑20 parts, 220 mesh mullite fine powder 25‑30 parts, 2μm alumina fine powder 8‑12 parts, 320 mesh corundum fine powder 5‑10 parts, Silica powder 5‑15 parts, zircon 5‑10 parts, cerium oxide 0.5‑2 parts, aluminum fluoride 2‑10 parts, aluminum 5‑10 parts, silicon 10‑15 parts, white clay 10‑15 parts, plus 1‑3 parts of binder. The invention also discloses a preparation method of the high-strength heat-shock-resistant push plate. The product of the invention has good thermal shock resistance, high mechanical strength, simple preparation method and convenient practical operation.

Owner:ANHUI NINGHUO NEW MATERIAL

A volume control device for improving the processability of microwave-expanded tobacco stems

ActiveCN107259633BReduce volume shrinkageFacilitate subsequent slicingTobacco treatmentMicrowaveHelical blade

The invention discloses a volume control device for improving the processability of microwave expansion tobacco stems, aiming at providing the volume control device for improving the processability of the microwave expansion tobacco stems, which is simple in structure. The device comprises a barrel, a bracket, a rotating shaft, a helical blade, a steam jacket, a drain valve, a heat preservation layer, a compressed air pipeline and a plurality of compressed air nozzles, wherein a feeding opening is formed in one end of the barrel, a discharging opening is formed in the other end of the barrel, the bracket is used for supporting the barrel, the rotating shaft is rotatably arranged in the barrel, the helical blade is fixedly arranged on the rotating shaft, the steam jacket sleeves the outer wall of the barrel, the drain valve is arranged on the steam jacket, the heat preservation layer is arranged on the outer wall of the steam jacket, the compressed air pipeline penetrates into the barrel, and the plurality of compressed air nozzles are located in the barrel and communicate with the compressed air pipeline; a feeding cross valve is arranged on the feeding opening of the barrel, a discharging cross valve is arranged on the discharging opening of the barrel, and a pressure gauge and a humidity eliminating hole are arranged on the barrel. With the volume control device, the volume shrinkage degree of the microwave expansion tobacco stems after moisture regaining treatment can be greatly reduced, and thus the subsequent slicing processing is facilitated.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

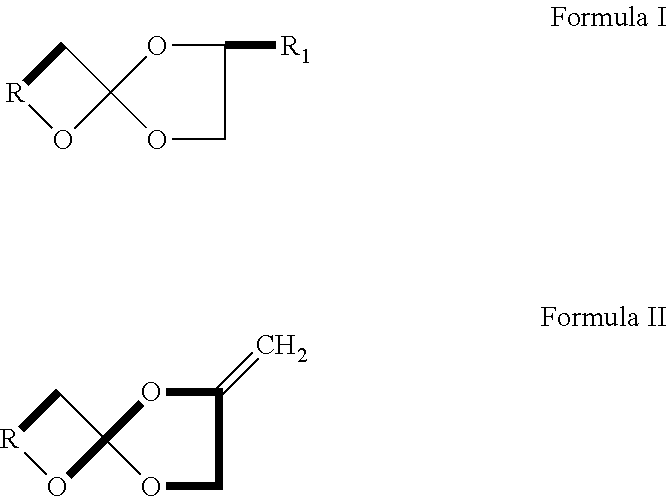

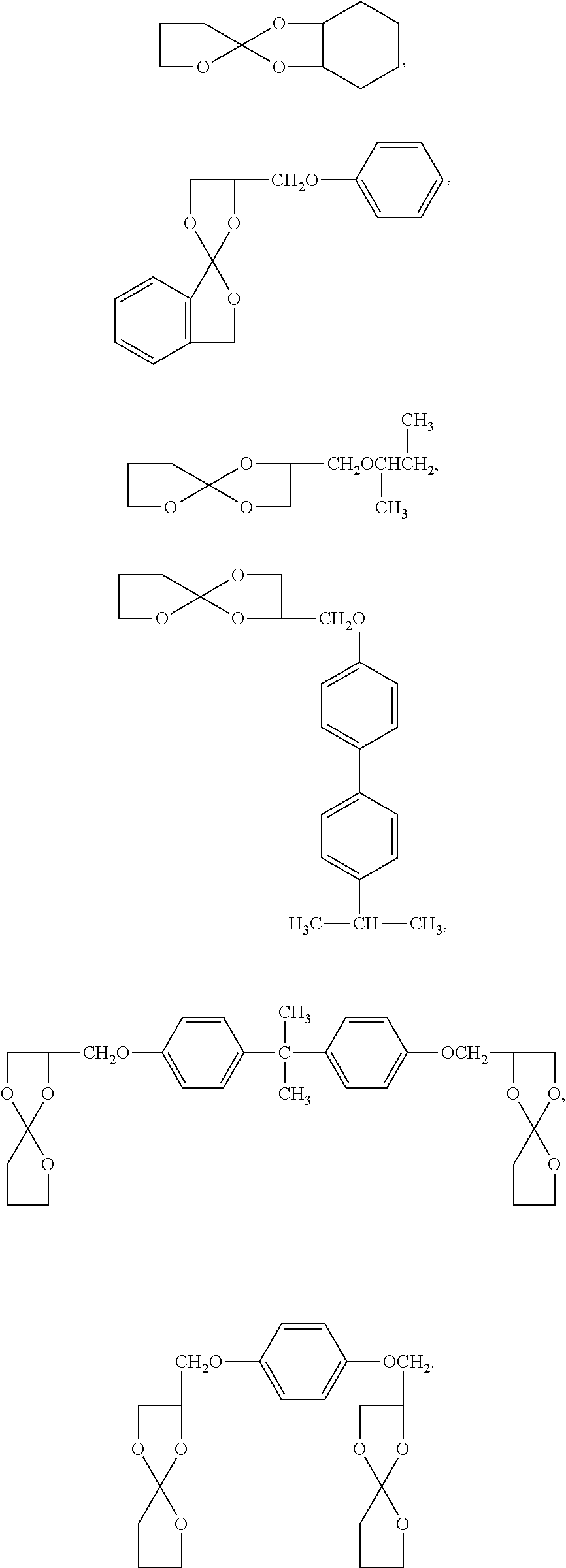

Expansion polymerization imprinting glue for nano-printing

InactiveUS20190056663A1Low curing shrinkageEasy to demouldPhotomechanical apparatusMicro nanoPolymer science

An expansion polymerization imprinting glue for nano-imprinting. Raw materials required for the preparation of the expansion polymerization imprinting glue comprise a low polymer and an expansion monomer. Compared with the prior art, after the expansion monomer is introduced into the expansion polymerization imprinting glue for nano-imprinting, the expansion monomer can be polymerized with the low polymer, the volume change of the imprinting glue after polymerization can be adjusted, and accordingly the volume shrinkage after the imprinting glue is cured is reduced or even eliminated; and the imprinting glue having zero curing shrinkage or volume expansion can be obtained by adjusting the content of the expansion monomer. The imprinting glue can effectively reduce the residual stress in a micro-nano pattern, and the generation of pattern defects in the nano-imprinting demolding process caused by the residual stress is reduced while accurate pattern copying is implemented.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Material for preparing turbine rotor of pressurizer and method for preparing turbine rotor by material

InactiveCN102765957BHigh hardnessHigh strengthBlade accessoriesMachines/enginesGas pressure sinteringInjection moulding

The invention belongs to the technical field of manufacturing of turbine rotor of a pressurizer, in particular to a material for preparing a turbine rotor of the pressurizer and a method for preparing the turbine rotor by the material. The material for preparing the turbine rotor of the pressurizer comprises the components in parts by weight as follows: 85-90 parts of silicon nitride powder, 1-8 parts of boron nitride nanotube powder, 2-4 parts of aluminite powder, 2-4 parts of silicon powder and 3-5 parts of zirconium oxide powder. The method for preparing the turbine rotor by the material comprises the steps of: (1) preparing a raw material; (2) preparing a paste material; (3) injection moulding; (4) setting and drying; and (5) gas pressure sintering of mould constraint. The turbine rotor of the pressurizer prepared by the material is light in weight, good in toughness, high in strength, low in specific gravity and good in proportionality, and small in lag proportionality, small in deformation, small in accumulated carbon and long in service life under supernormal work conditions such as high temperature, high pressure and high speed. Meanwhile, the method for preparing the turbine rotor by the material is simple in steps, convenient to operate and is beneficial for industrialized production in a large scale.

Owner:UNIV OF JINAN

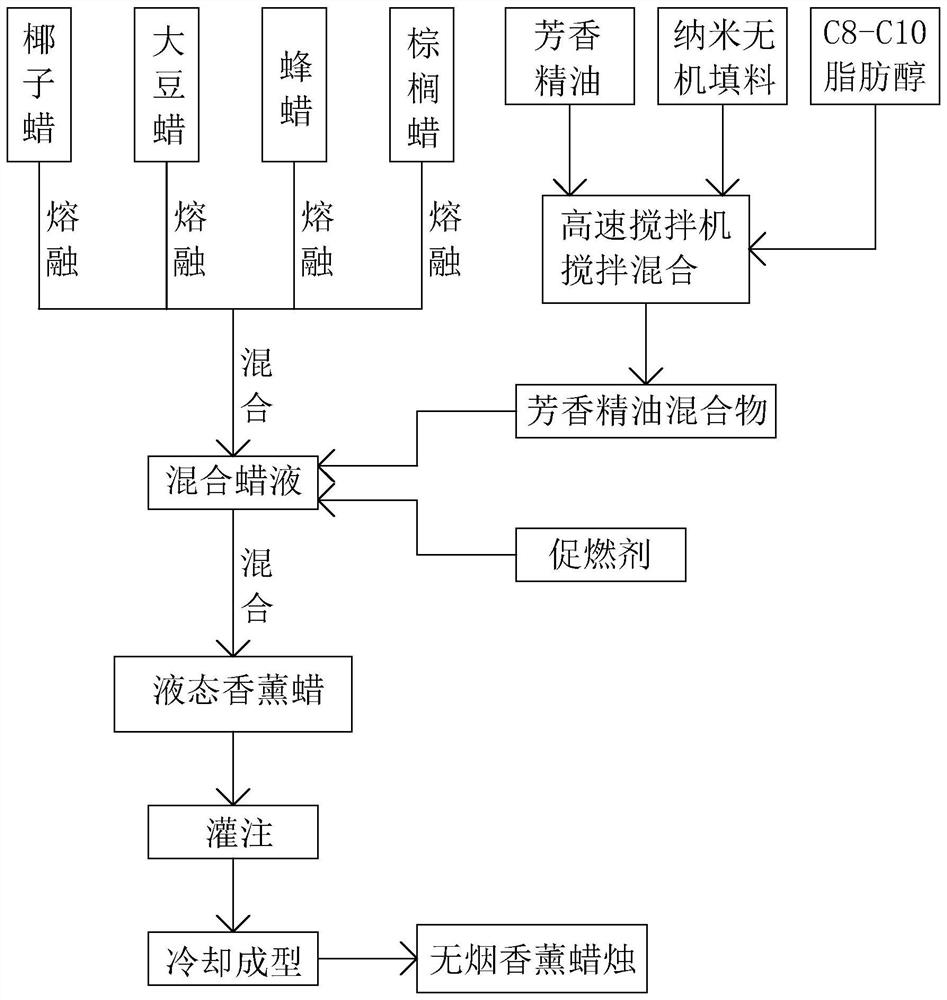

A smokeless scented candle and its manufacturing process

The invention discloses a smokeless scented candle, which belongs to the technical field of candles. The key point of the technical scheme is that it is prepared from the following raw materials in parts by weight: 80-100 parts of coconut wax, 50-80 parts of soybean wax, beeswax 0-30 parts, palm wax 0-15 parts, aromatic essential oil 1-5 parts, nano inorganic filler 1-5 parts, combustion accelerator 1-3 parts, C8-C10 fatty alcohol 1-3 parts. The smokeless aromatherapy candle of the present invention burns completely, produces less harmful substances such as smoke, and has good storage stability. The invention correspondingly discloses a manufacturing process of a smokeless scented candle, including the steps of mixed wax preparation, essential oil pretreatment, mixing, filling and molding. The smokeless scented candle produced has the advantages of low combustion smoke and environmental protection.

Owner:蔓莎(苏州)工艺制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com