Patents

Literature

30results about How to "Reduce dioxin content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

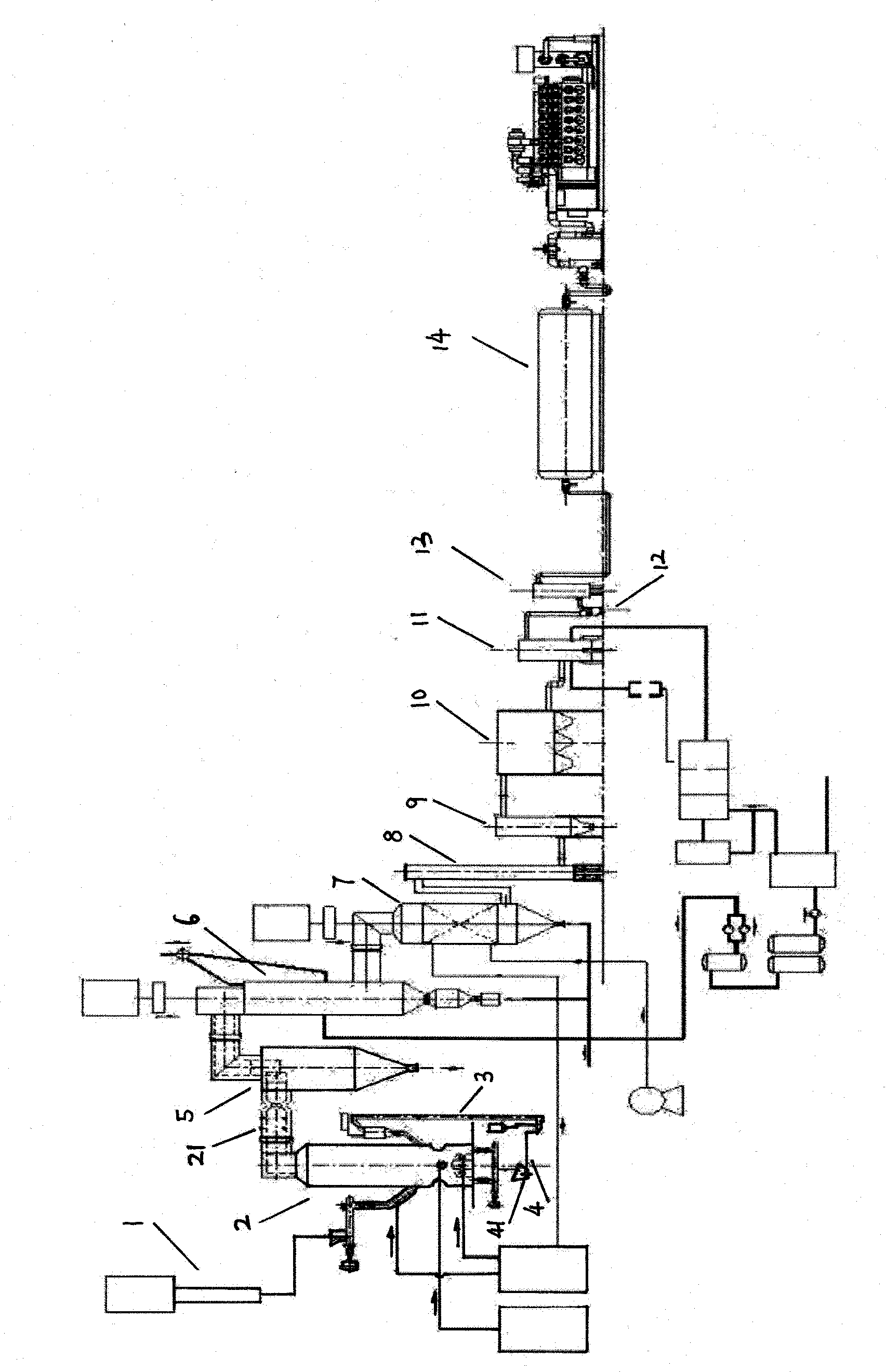

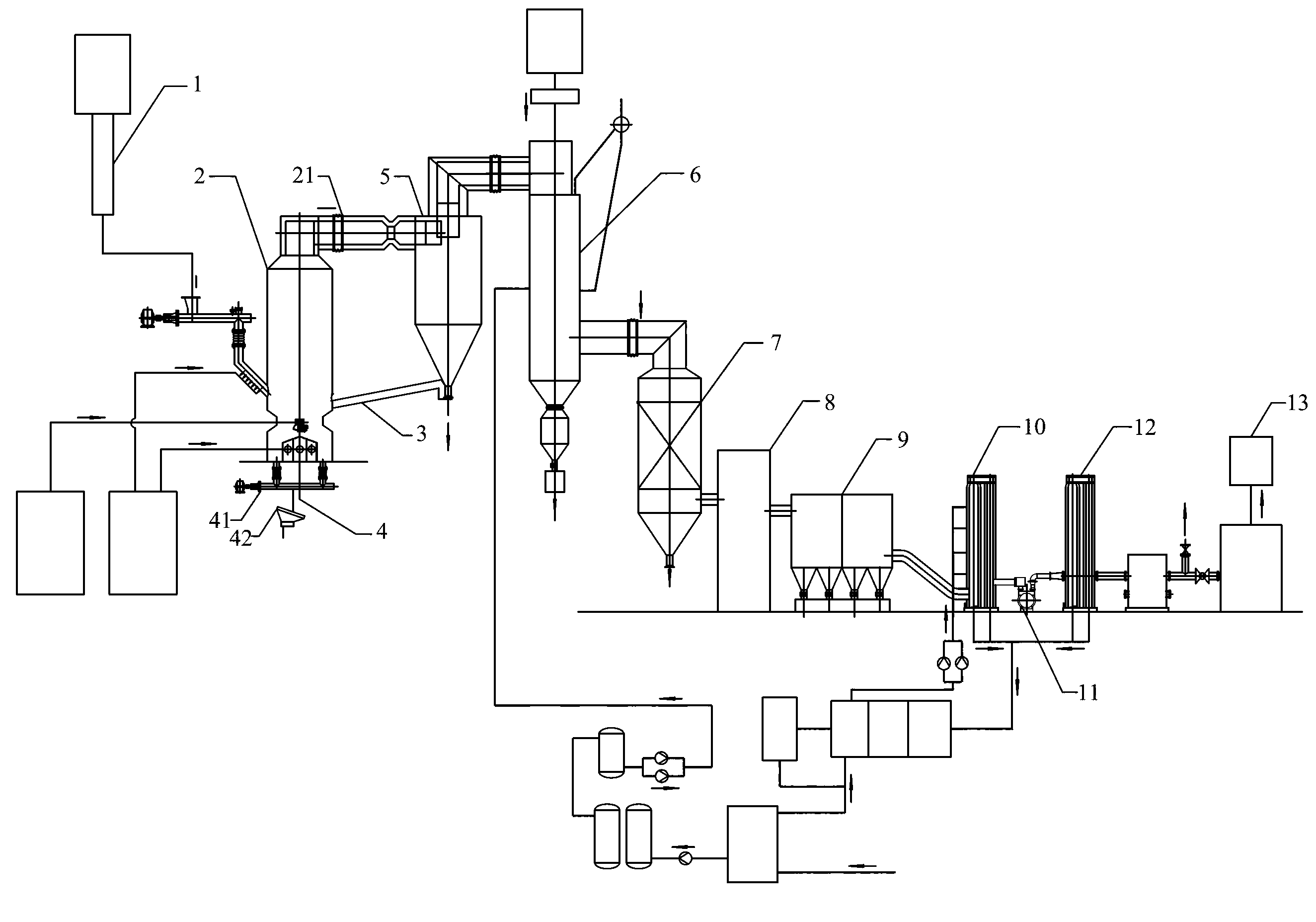

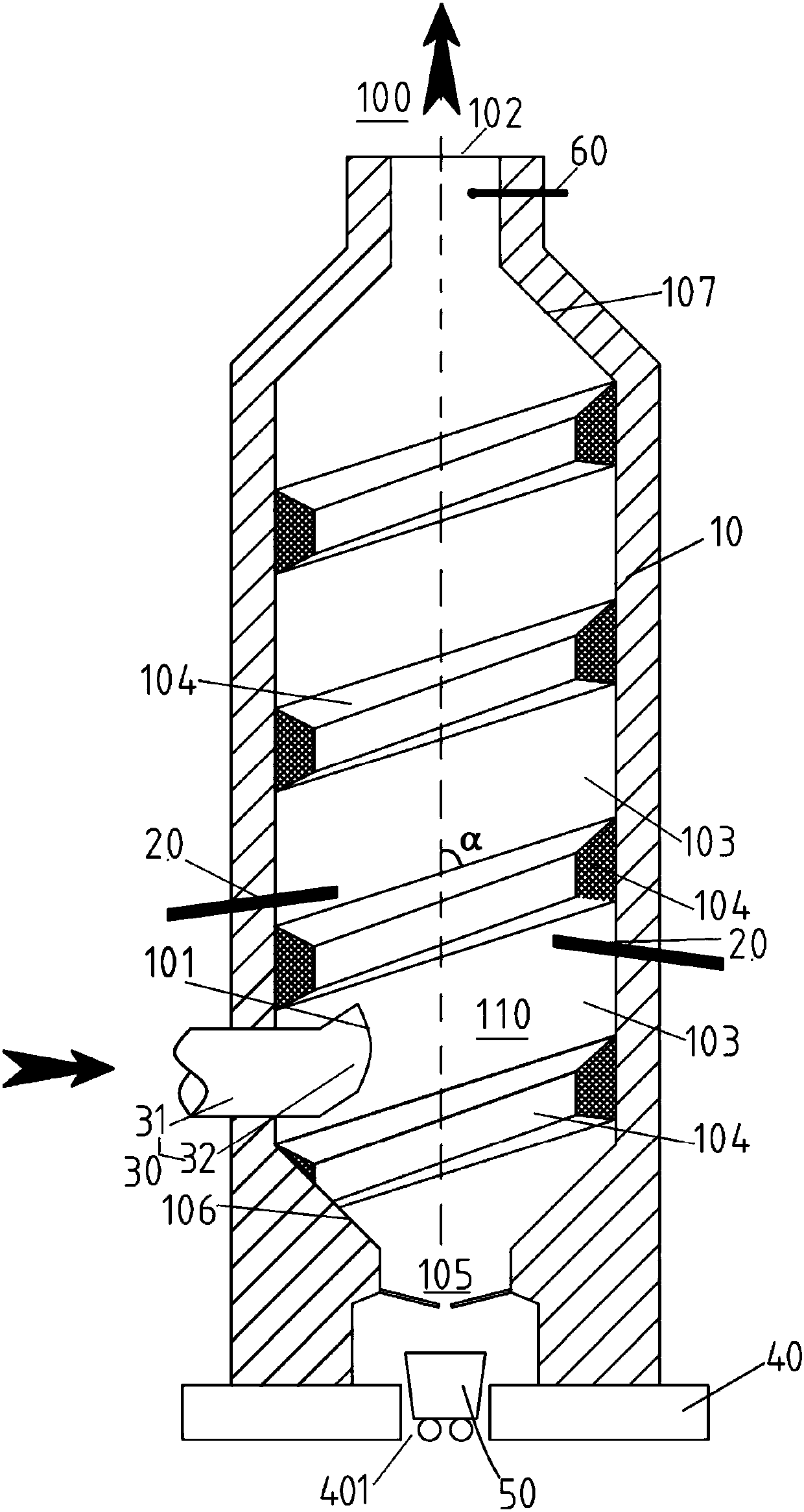

Fluidized bed plasma garbage-gasifying equipment and gasifying process thereof

InactiveCN102627983AImprove gasification efficiencyImprove throughputGranular/pulverulent flues gasificationSlagQuenching

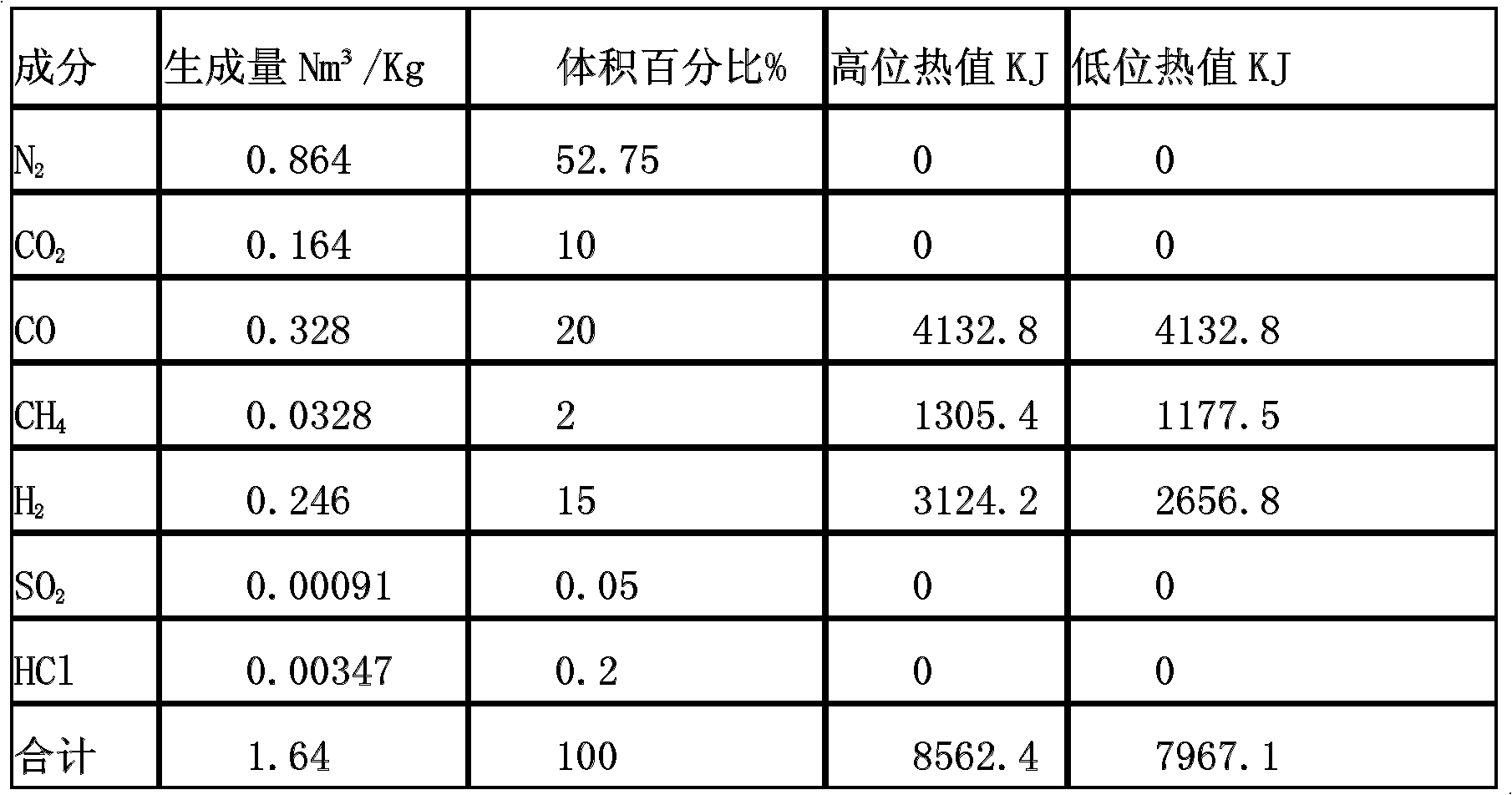

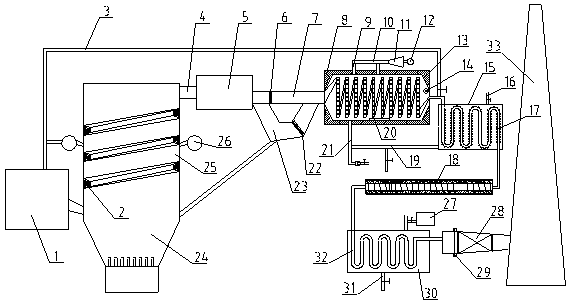

The invention relates to fluidized bed plasma garbage-gasifying equipment and a gasifying process thereof. A gasifying furnace of the gasifying equipment is a plasma gasifying fluidized bed. The gasifying equipment comprises a fluidized bed gasifying furnace, wherein a plasma torque is arranged at a smoke outlet at the top of the fluidized bed; the inner layer of the wall of the fluidized bed gasifying furnace is a corundum cast material layer; an ash plasma processing cabin is arranged on the tail part of a slag discharging system; and the inner layer of the fluidized bed gasifying furnace is a corundum cast material layer. The gasifying process comprises the following steps of: (a) generating mixed gas; (b) discharging slag and returning the materials; and (c) purifying and filtering gas. In the process, the mixed gas generated in the fluidized bed furnace is re-heated to more than 1,000 DEG C through plasma to perform tar recombination and eliminate dioxin on the surface of a part of ash, and the mixed gas is cooled from 800 DEG C to 180 DEG C within 0.6 second under the action of quenching, so a re-polymerization interval of the dioxin is completely avoided. The fluidized bed plasma garbage-gasifying equipment has the characteristics of harmlessness, environment friendliness, energy conservation and consumption reduction.

Owner:大连鑫宝生物质能有限公司

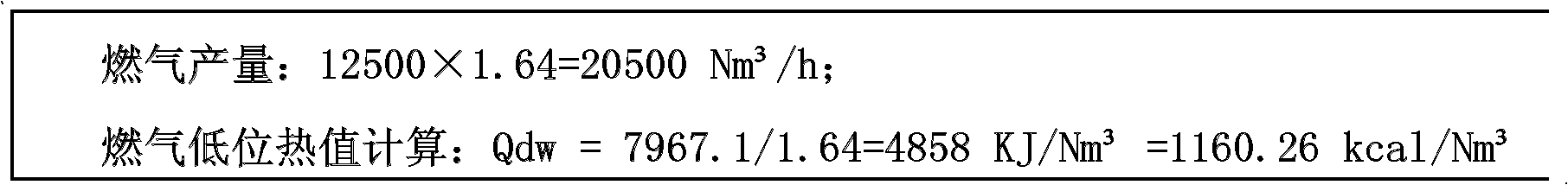

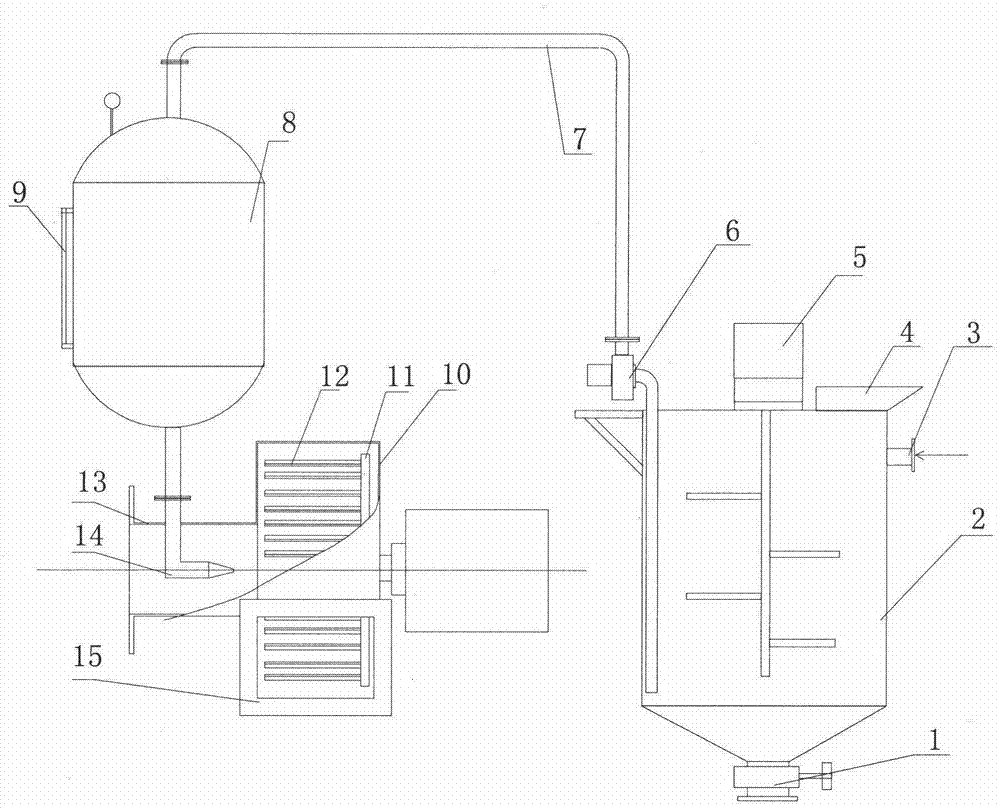

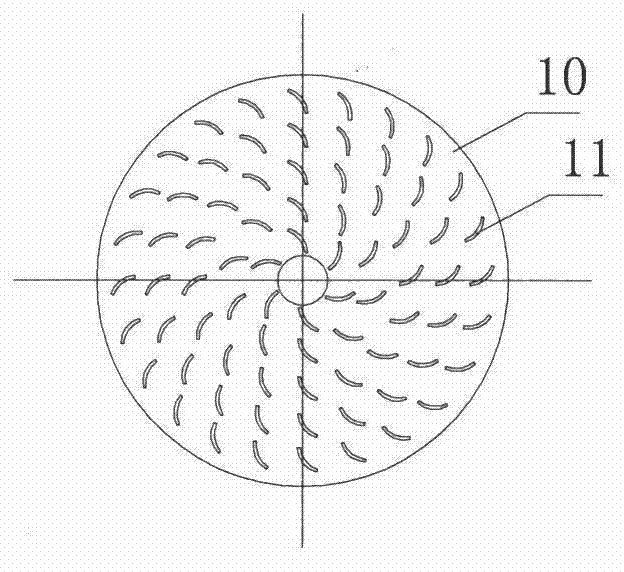

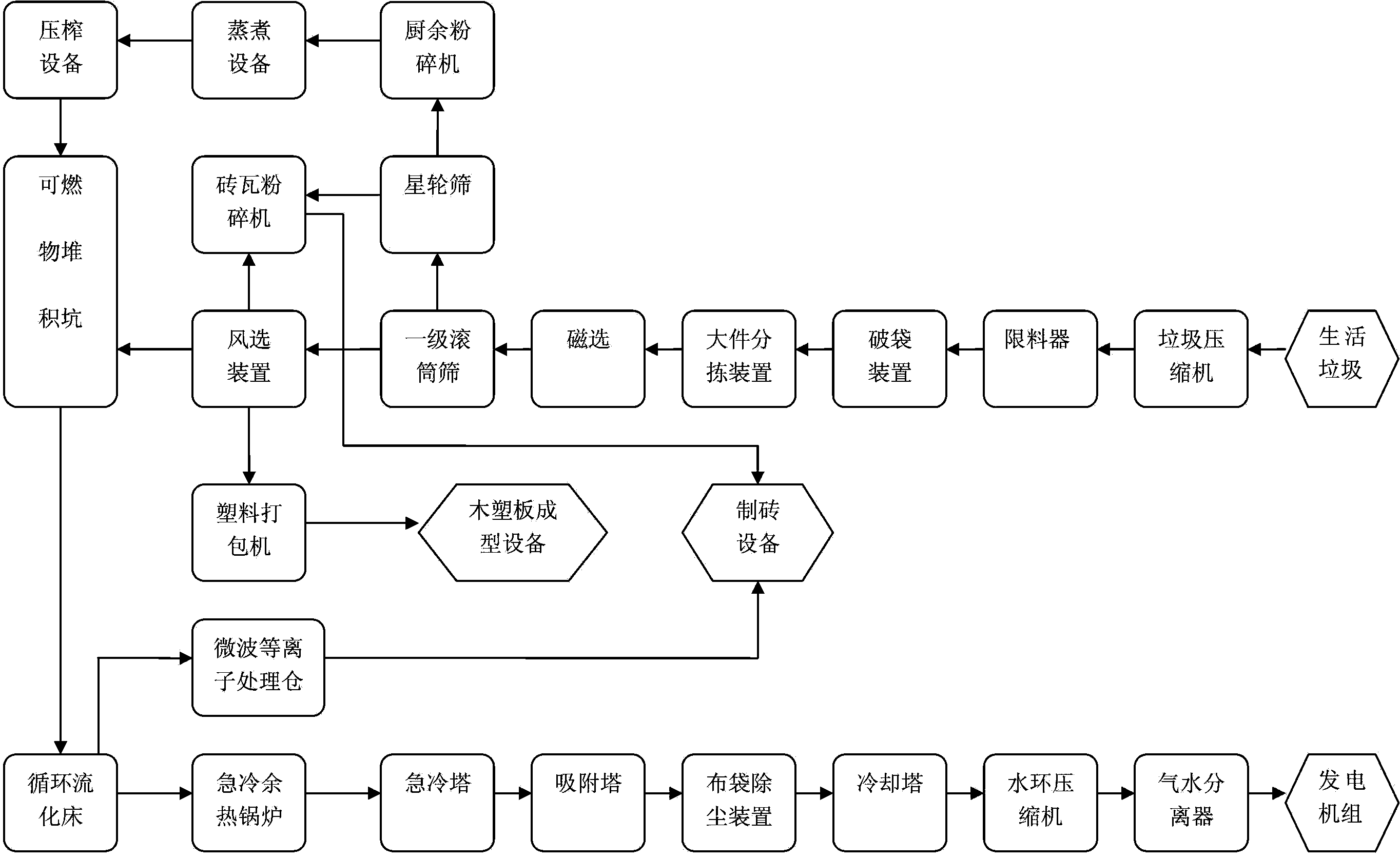

Method for treating household garbage

InactiveCN102836862AGood hygieneReduce odorSolid waste disposalFurniture waste recoveryWaste treatmentElectricity

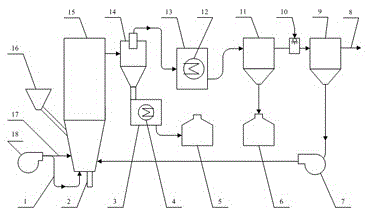

The invention discloses a method for treating household garbage, which comprises a pre-treating step, a plastic product treating step, a sand treating step and a combustible material treating step, wherein, according to the method, the household garbage is divided into five kinds of material, namely ferromagnetic material, plastic products, sands, light combustible material and kitchen waste; the five kinds of material are used for manufacturing wood-plastic boards, bricks and generating electricity by gasification and the like, respectively; the method disclosed by the invention has the advantages of simple operation, strong practicability, high automatic degree, safe and controllable use; a circular fluidized bed with relatively high gasification efficiency is used for light combustible material and kitchen waste treatment; the circular utilization degree of the household garbage such as gasified mixing gas treatment and the like except dioxin is increased; secondary pollution is avoided; and the method can be widely suitable for household garbage treatment of all scales.

Owner:张建超 +1

Device for reducing dioxins discharge during steel smelting in electric furnace and method thereof

InactiveCN101274212ABurn fullyDecomposition maximizationDispersed particle separationProcess efficiency improvementSteelmakingElectric arc furnace

The invention discloses a device and a method used for reducing the exhaust of electric furnace steelmaking dioxin, comprising a bag-typed deduster which is communicated with the electric furnace by a flue gas pipeline and a loading device. The invention is characterized in that the pipeline between the electric furnace and the bag-typed deduster is sequentially communicated with a combustion settlement chamber and a temperature reduction device. The method comprises the steps as follows: the electric furnace adopts the molten iron hot charging technique; the steelmaking flue gas enters the combustion settlement chamber for sufficient combustion, then enters the temperature reduction device, with the temperature reduced from 800 to 1000 DEG C at the inlet to below 200 DEG C at the outlet within 1 to 3 seconds, and is finally exhausted after being disposed by the bag-typed deduster; wherein, the content of the dioxin is not more than 0.2ngTEQ / m<3>. The device and the method of the invention reduce the content of the dioxin, generate a plurality of saturated steam at the same time and have the advantages of saving energy and reducing the steelmaking cost.

Owner:JIANGSU SHAGANG GROUP HUAIGANG SPECIAL STEEL CO LTD

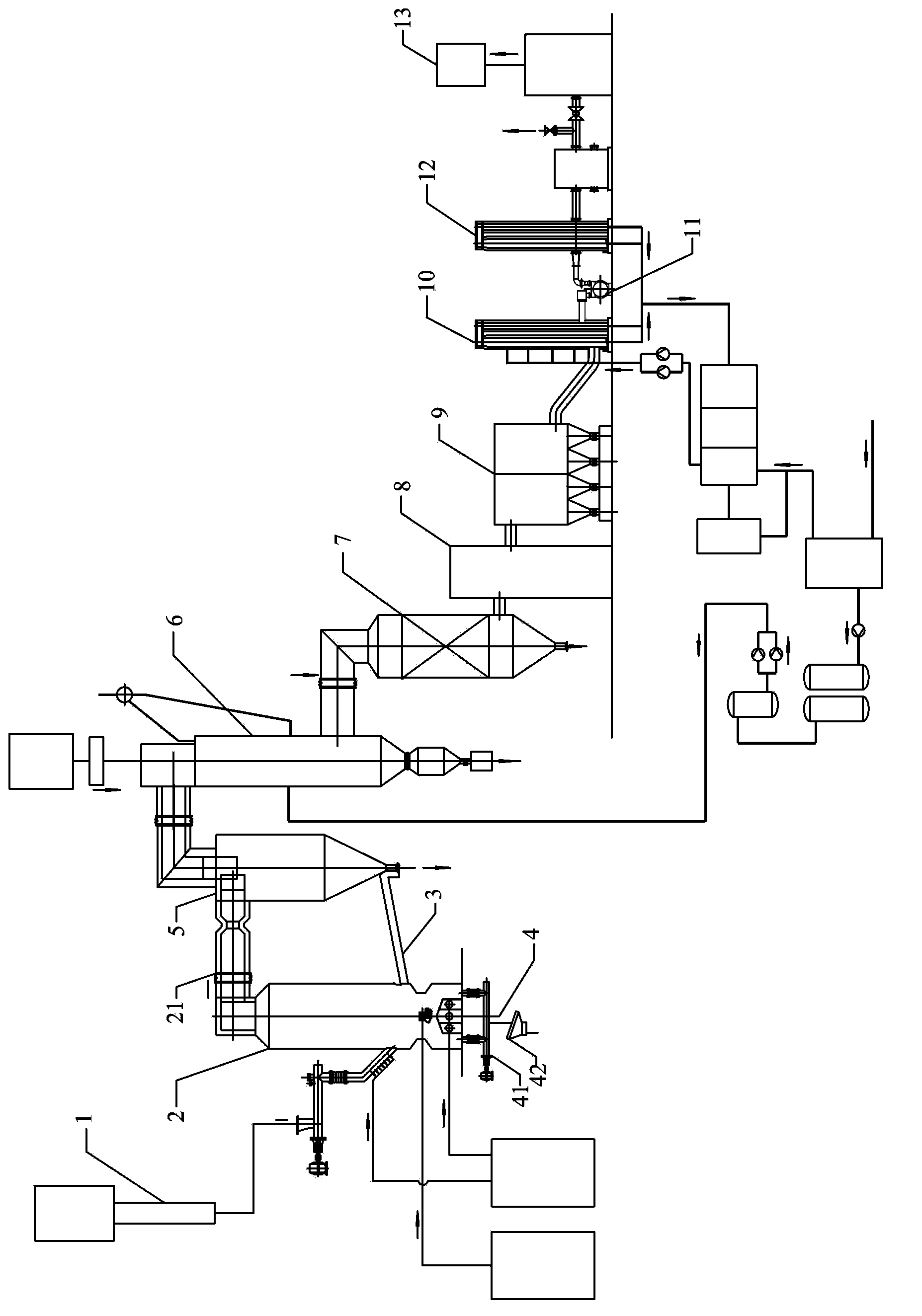

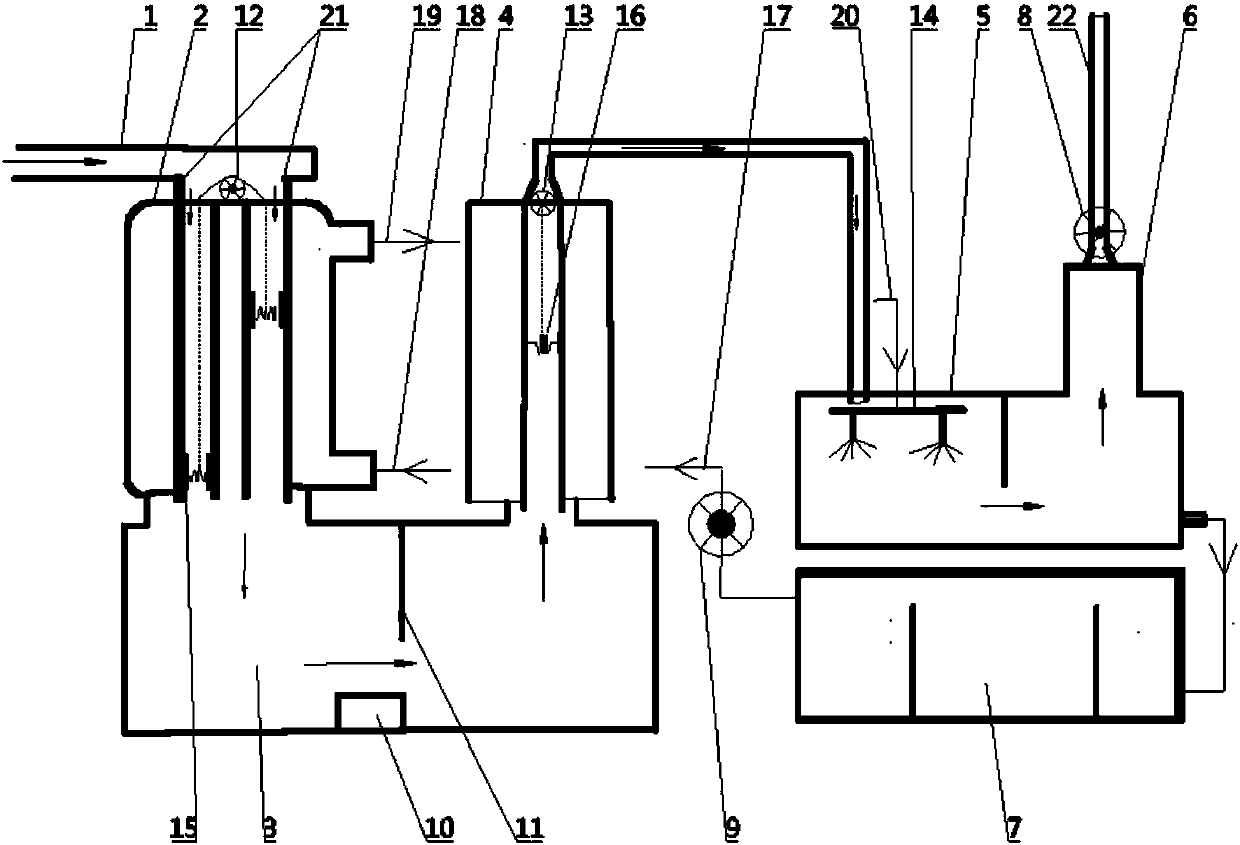

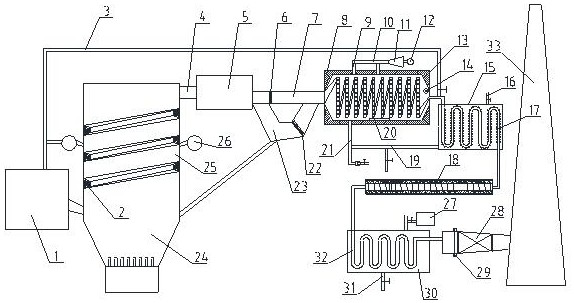

Household garbage pyrolysis and gasification processing system

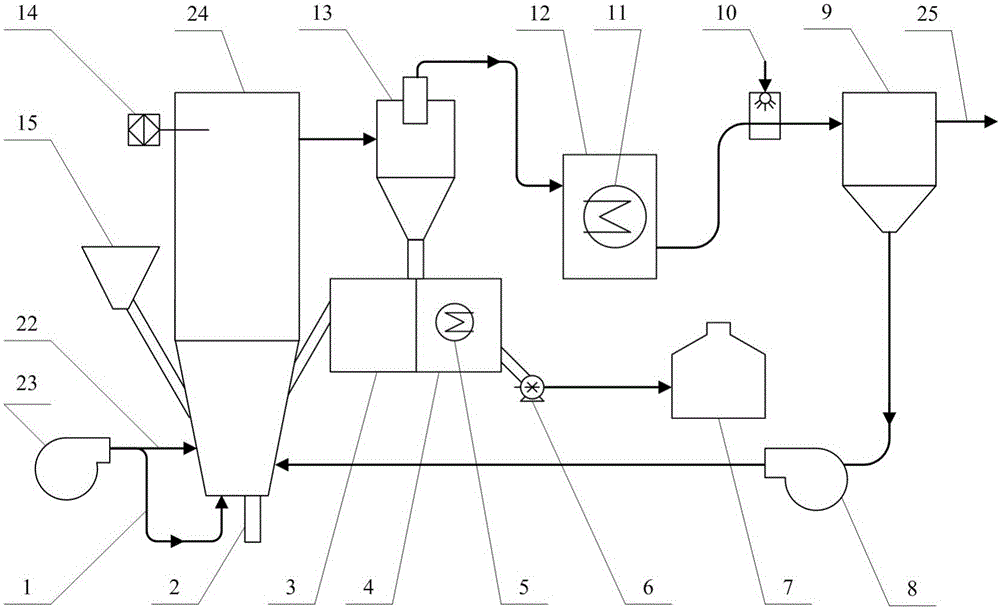

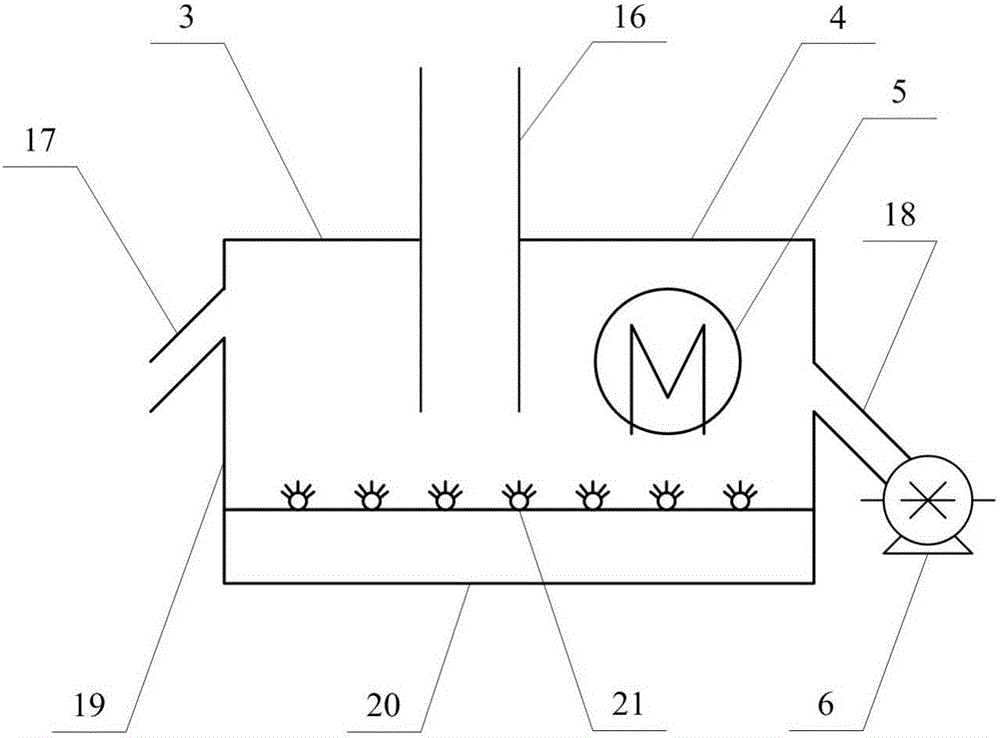

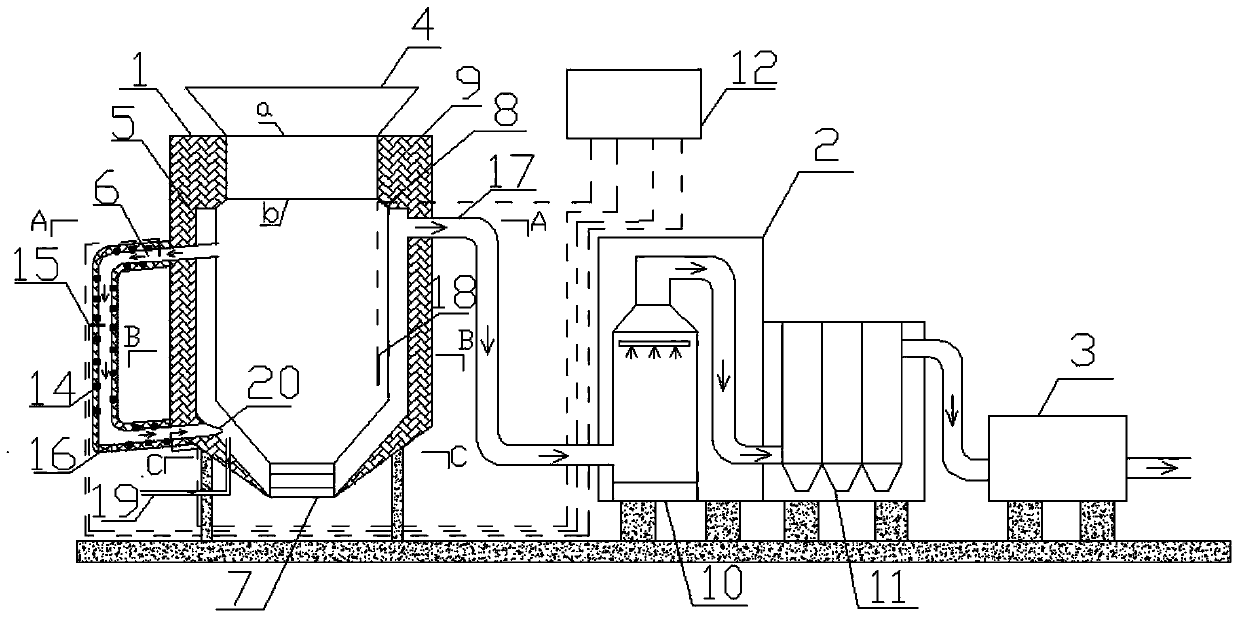

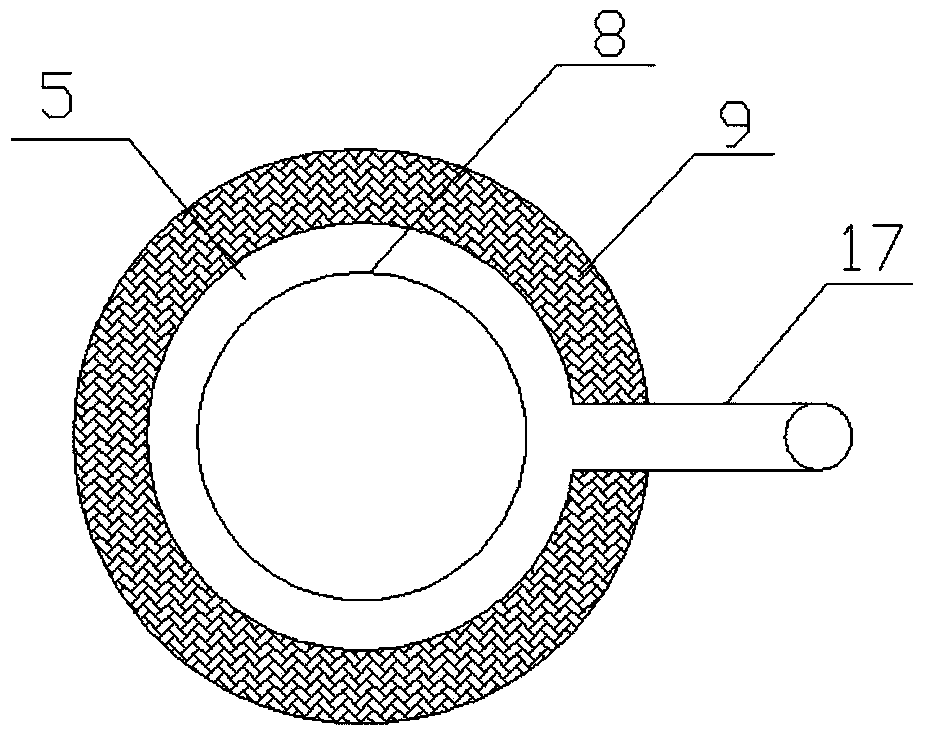

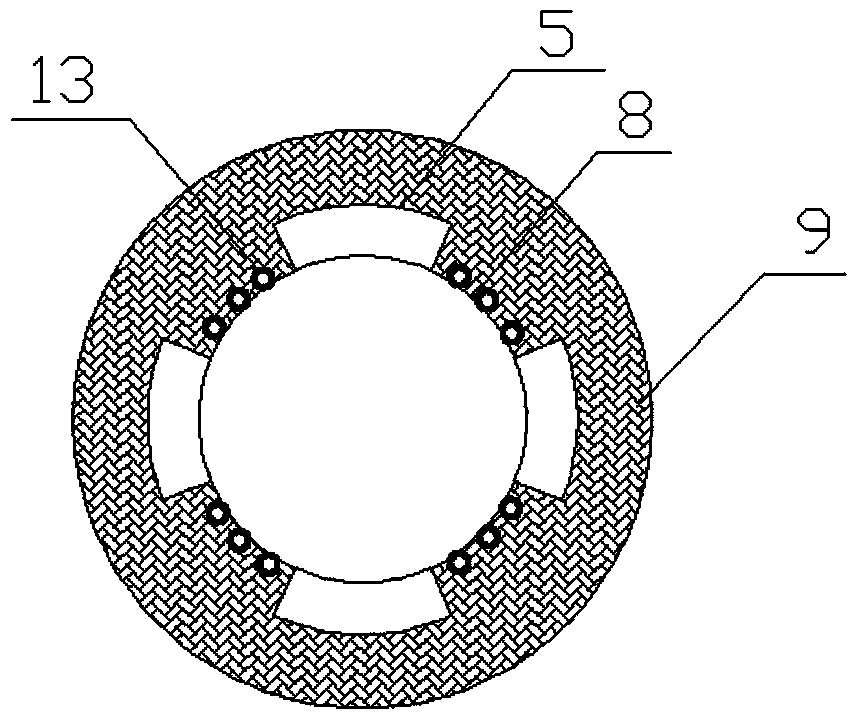

InactiveCN106338068AImprove heat utilization efficiencyImprove operational efficiencyGasification processes detailsIncinerator apparatusSlagEngineering

The invention discloses a household garbage pyrolysis and gasification processing system. A pyrolysis and gasification furnace is included. A smoke exhaust pipeline is arranged on the middle upper portion of the pyrolysis and gasification furnace and communicates with exhaust gas processing equipment. The exhaust gas processing equipment is connected with an induced draft fan. The upper portion of the pyrolysis and gasification furnace communicates with a furnace bottom through a pyrolysis gas pipeline. An electric air valve is arranged on the pyrolysis gas pipeline, the pyrolysis gas pipeline is connected with a condenser, and the condenser is connected with a gas storage tank. The pyrolysis and gasification furnace adopts fuel as an auxiliary drive heat source, and generated pyrolysis gasified gas serves as a main heat source. By utilizing the pyrolysis and gasification system for processing household garbage, the garbage volume and quantity are remarkably reduced, the performance of ash and slag is stable, the dioxin content of generated exhaust gas is extremely low, then the exhaust gas is further processed so that harmlessness of the exhaust gas can be achieved, and environmental pollution caused by garbage incineration is effectively avoided. The two heat sources are combined, so that the problem that a heat source is additionally arranged for external heating type pyrolysis and gasification of garbage is solved, and dependency on conventional energy such as coal and electricity is reduced; and besides, combustible gas can be supplied externally, and the economic benefit of the system is increased.

Owner:TIANJIN UNIV

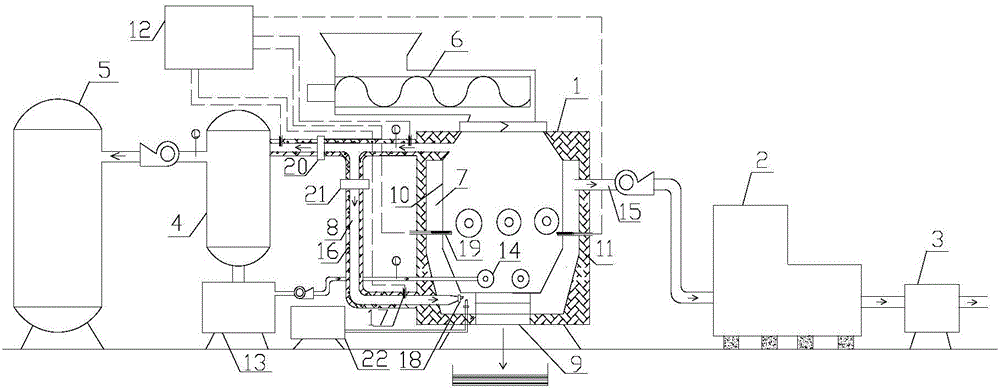

Smoke purifying and waste heat utilizing system of waste incineration power plant

ActiveCN109395496AIncrease temperatureLow costGas treatmentDispersed particle filtrationDecomposerWaste heat recovery unit

The invention discloses a smoke purifying and waste heat utilizing system of a waste incineration power plant. The smoke purifying and waste heat utilizing system comprises an incinerator body, a steam turbine, a power generator, a smoke purifying treatment device and a smoke discharge chimney. The smoke purifying treatment device comprises a pipeline combustor, a steam generator, a waste heat recoverer, a smoke decomposer, a washing tank and an adsorption purifier which are sequentially arranged from a high-temperature smoke outlet and the smoke discharge chimney. The smoke discharge pipe isarranged between the pipeline combustor and the steam generator. A particle collecting pipe is arranged on the lower side of the smoke discharge pip. A spiral smoke pipe is arranged in the steam generator. A heat pipe is arranged in the waste heat recoverer. An outer cylinder, an inner cylinder and a decomposition ball are arranged in the smoke decomposer. An inner electrode is arranged on the inner side of the inner cylinder. An outer electrode is wound on the outer surface of the outer cylinder. A washing pipe is arranged in the washing tank. The adsorption purifier is filled with adsorptionfiller. By means of the system, the combustion state is improved, combustion efficiency is improved, the dioxin content is reduced, and the waste heat recovery efficiency is improved.

Owner:QUJING YUNDIAN TOUXIN ENERGY POWER GENERATION

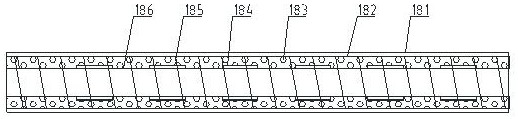

Fluidized bed waste incineration treatment system

PendingCN105823059ALow concentration of dioxinsLow toxicityEmission preventionIncinerator apparatusFlueActivated carbon

The invention provides a fluidized bed waste incineration treatment system. Waste is combusted in a fluidized bed waste incineration furnace. Bed materials are carried by smoke to leave a hearth, and enter a cyclone separator. One part of the bed materials are gathered by the cyclone separator and sent into a receiver. The other part of the bed materials leave the cyclone separator along with the smoke, pass through a tail flue and enter a dust remover. Active carbon is sprayed into an inlet of the dust remover so as to adsorb dioxin in the smoke. The active carbon and the bed materials are gathered by the dust remover and sent back into the hearth. The dioxin adsorbed by the active carbon is decomposed in the hearth at the high temperature, thereby losing toxicity. One part of the bed materials entering the receiver are sent back to the hearth, and the other part of the bed materials are discharged outwards after being cooled. The discharged bed materials do not pass through a dioxin low-temperature resynthesis area of the tail flue, so that the dioxin content is low. By the adoption of the fluidized bed waste incineration treatment system, the emission of dioxin in the discharged smoke and discharged dust of waste incineration is reduced, and thus the negative influences of waste incineration on the environment are reduced.

Owner:JIMEI UNIV +1

Preparation method of capsanthin feed additive with low dioxin content

InactiveCN103271226AImprove feeding safetySimple methodAnimal feeding stuffChemistryAgricultural science

The invention discloses a preparation method of a capsanthin feed additive with low dioxin content. According to the preparation method, commercially available capsanthin factice is further saponified, and then an acetone solvent is used for extracting, so that the dioxin content in the capsanthin factice is effectively reduced; and then the capsanthin factice and a feeding carrier are mixed uniformly, thus obtaining the capsanthin feed additive with low dioxin content. Therefore, the feeding safety of capsanthin can be improved. The preparation method fills up the research blank of the capsanthin feed additive with low dioxin content, is simple and effective and can adapt to demands of industrial production.

Owner:FOSHAN LEADER BIO TECH +1

Secondary combustion device used for treating flue gas containing dioxin

The invention discloses a secondary combustion device used for treating flue gas containing dioxin. The secondary combustion device comprises a furnace body and injection type combustors, and a furnace cavity is limited in the furnace body. The upper end of the furnace body is provided with a secondary flue gas outlet communicating with the furnace cavity. Trapezoidal protruding ribs are arrangedon the inner circumferential wall faces of the furnace cavity, and the trapezoidal protruding ribs extend spirally in the axial direction of the furnace cavity to form a spiral flow guide groove. A primary flue gas inlet communicating with a primary flue gas outlet of a primary combustion device is formed in the lower portion of the spiral flow guide groove. A combustion sprayer of each injectiontype combustor stretches in the furnace cavity, wherein the combustion sprayer is arranged in the flow guide groove. The combustion sprayer adjacent to the primary flue gas inlet is located on the downstream part, in the extending direction of the spiral flow guide groove, of the primary flue gas inlet, wherein the shortest distance between the combustion sprayer and the primary flue gas inlet islarger than or equal to one time of the caliber of the primary flue gas inlet. According to the secondary combustion device used for treating flue gas containing dioxin in the embodiment, flue gas canbe mixed and burnt sufficiently, the dioxin burning-down rate is higher, decomposing is thorough, and the treatment effect is better.

Owner:CHINA NERIN ENG

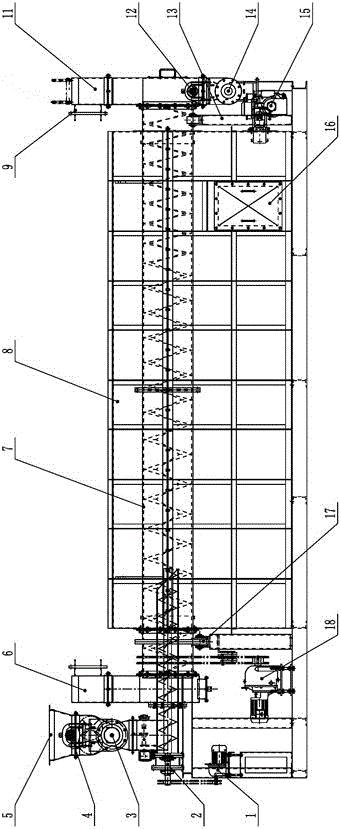

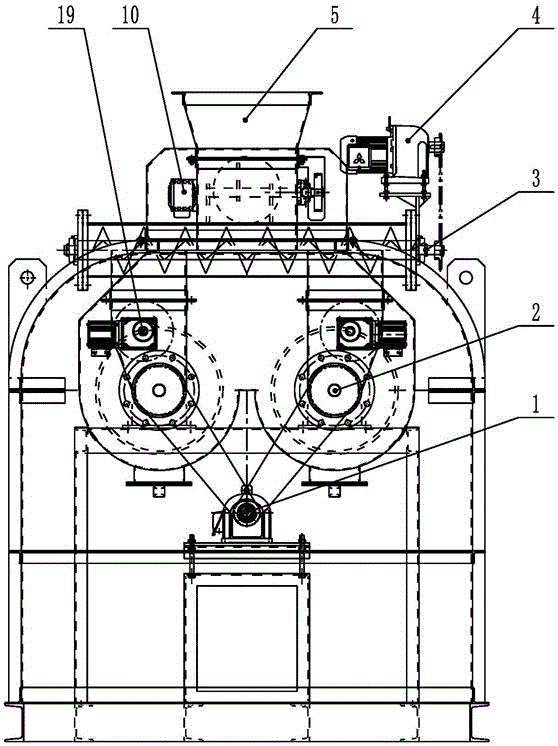

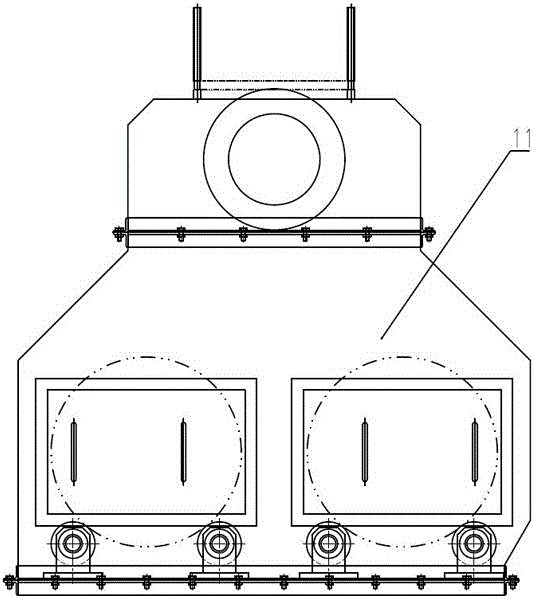

Screw propelling type solid waste continuous carbonization equipment and continuous carbonization method

The invention provides screw propelling type solid waste continuous carbonization equipment and a continuous carbonization method. The screw propelling type solid waste continuous carbonization equipment is characterized by comprising a feeding system, a material distributing system, a carbonization system, a product collecting system and a discharging system which are successively connected with one another, wherein a sealed connected screw propelling material channel is formed from a feeding opening of the feeding system to a discharging opening of the discharging system; and the carbonization system is connected with a deodorization system. The feeding system comprises a feeding screw conveyer, a feeding gear motor, a first stirring motor and the feeding opening, the feeding opening of the feeding system is an inverted-cone-shaped feeding hopper, the first stirring motor drives a stirring shaft to rotate, blades are mounted on the stirring shaft, and the stirring shaft is positioned in the inverted-cone-shaped feeding hopper of the feeding system. The screw propelling type solid waste continuous carbonization equipment is high in universality, the generated carbonization products are used extensively, and secondary pollution is avoided. The screw propelling type solid waste continuous carbonization equipment is reasonable and compact in structure, good in airtightness, relatively low in manufacturing cost, high in degree of automation and high in working efficiency.

Owner:CHENGHE ENVIRONMENTAL PROTECTION SCIEN TECH CO LTD

Waste incineration treatment system with high-temperature dust remover

InactiveCN105605586ALow concentration of dioxinsMeet the requirements for non-hazardous wasteIncinerator apparatusActivated carbonFlue gas

The invention provides a waste incineration treatment system with a high-temperature dust remover. Flue gas produced by waste incineration is exhausted after being subjected to multistage dust removal purification, first-stage dust removal is completed by the high-temperature dust remover, and collected fly ash is less in dioxin content and capable of being recycled; low-temperature dust removal is adopted by second-stage dust removal and third stage dust removal, the dust removal efficiency is high due to the combination of the second-stage dust removal and the third-stage dust removal, the dust content and dioxin content of the exhausted flue gas are low, and the flue gas is cleaner; activated carbon is sprayed into the flue gas at an inlet of a third-stage remover, dioxin in the flue gas is adsorbed, activated carbon is collected by the third-stage remover and sent back to f hearth of an incinerator, dioxin adsorbed by the activated carbon is disintegrated at high temperature, and the toxicity is removed. The waste incineration treatment system with the high-temperature dust remover has the advantages that the fly ash collected through high-temperature dust removal can be recycled, dioxin adsorbed by the activated carbon is disintegrated at high temperature after being sent back to the hearth, the total quantity of dioxin exhausted from waste incineration is effectively reduced, and the adverse effect of waste incineration on the environment is reduced.

Owner:JIMEI UNIV +1

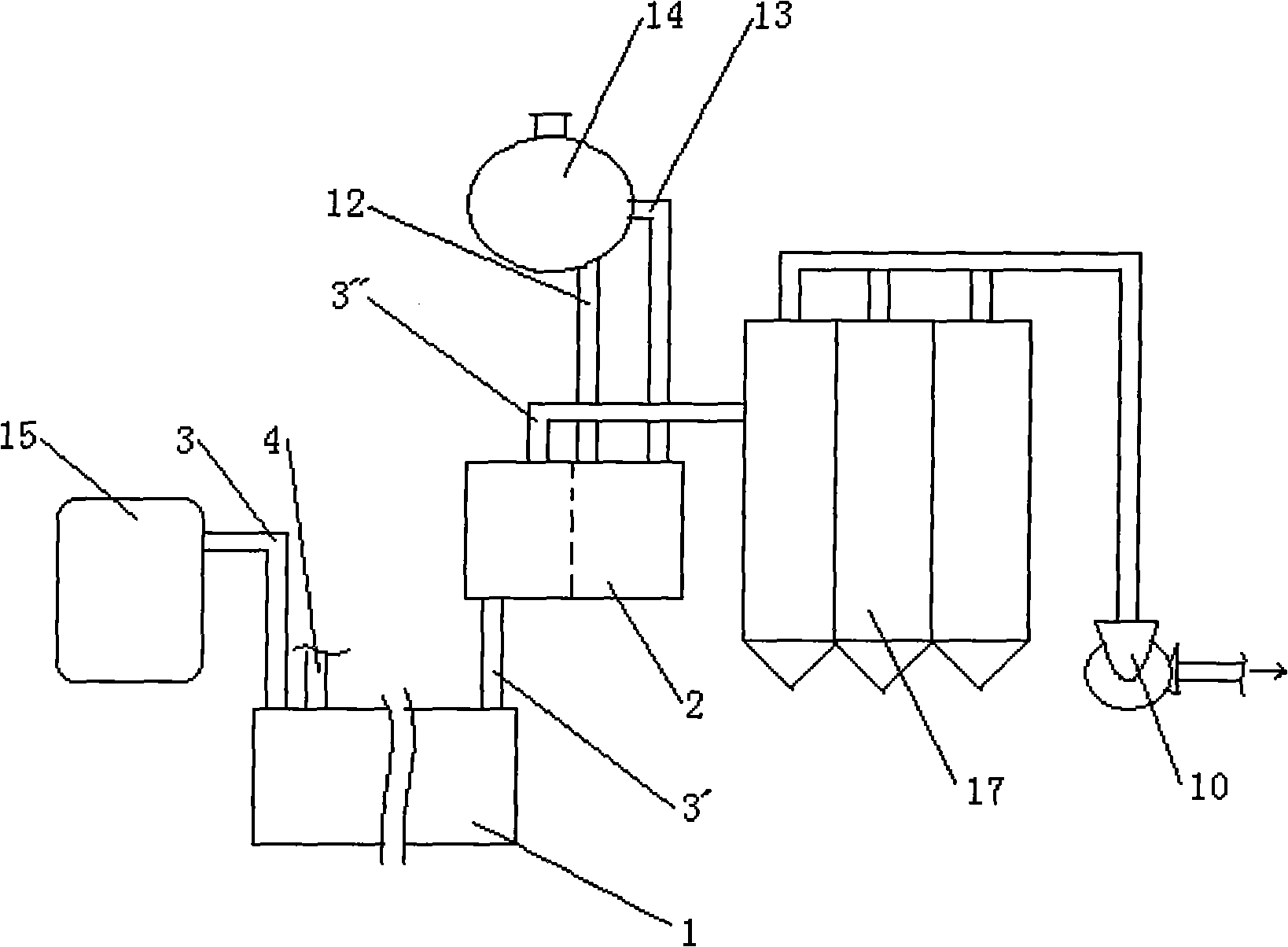

Pyrolysis-gas-recyclable medical waste pyrolysis treatment device

InactiveCN103697481AImprove heat utilization efficiencyImprove operational efficiencyIncinerator apparatusEngineeringPollution

The invention discloses a pyrolysis-gas-recyclable medical waste pyrolysis treatment device which comprises a pyrolysis furnace, accessory equipment and an induced draft fan. The pyrolysis furnace comprises a furnace body, a feed device, a flue gas passage, a pyrolysis gas pipeline, an ash discharging gear and temperature measurement and control systems, and each temperature measurement and control system mainly comprises a temperature sensor, a temperature display instrument and an automatic controller. The accessory equipment comprises a half-dry type scrubber and a bag type dust collector. By reasonable design of the furnace body structure, automatic measurement and control of the furnace hearth temperature is realized, generated pyrolysis gas enters the furnace bottom to be combusted through the pipeline designed specially, and efficiency of the pyrolysis furnace is improved; meanwhile, the problem of inherent tar in pyrolysis equipment is solved, flue gas generated by combustion of the pyrolysis gas is purified prior to being discharged, and harmlessness, reduction and stabilization of treatment of medical waste are realized. In-situ treatment of the medical waste is realized, and secondary pollution caused by transportation is also avoided.

Owner:TIANJIN UNIV

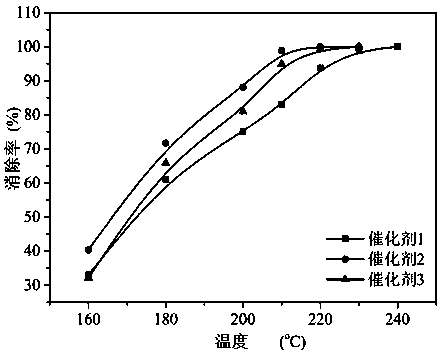

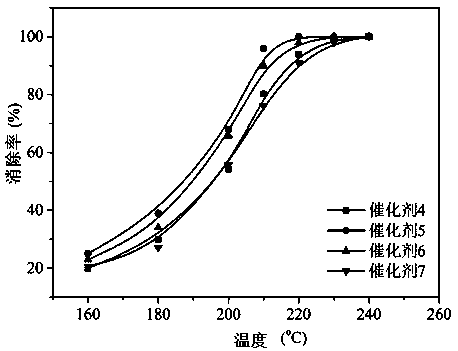

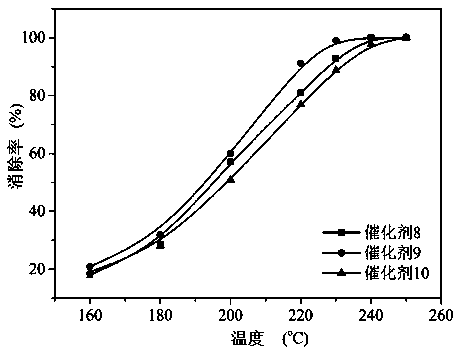

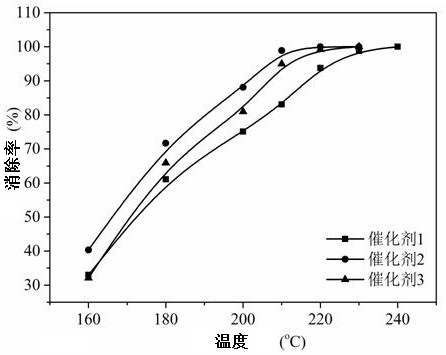

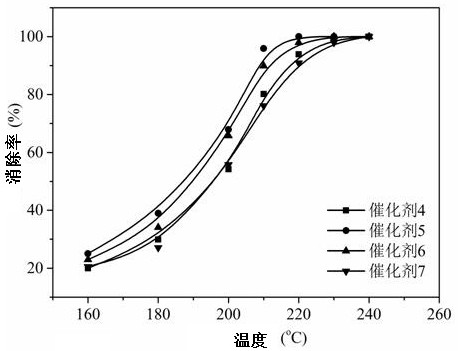

Catalyst for removing dioxin in kiln flue gas through catalytic oxidation and preparation method of catalyst

ActiveCN110586073AHigh surface areaImprove thermal stabilityGas treatmentHeterogenous catalyst chemical elementsDecompositionCatalytic oxidation

The invention provides a catalyst for catalytic oxidation elimination of dioxin pollutants in flue gas and waste gas from garbage incinerators, hazardous waste incinerators, medical waste incinerators, steel sintering furnaces, coal-fired power plants, funeral parlors and chemical plants, and a preparation method of the catalyst. According to the catalyst, industrial titanium dioxide is used as acarrier, SnO2-V2O5-WO3 composite oxide is used as an active component, and La2O3, MoO3, CeO2, Nb2O5, CuO, Pr6O11 and Sb2O3 are used as auxiliaries. According to the catalyst, the active components areuniformly dispersed on the surface of the carrier under the complexing action of an organic amine, and the catalyst auxiliaries are uniformly precipitated on the surface of the carrier under the condition of ammonia water, so that the catalyst is high in specific surface area, high in thermal stability and high in chlorine poisoning resistance, can continuously operate for a long time without activation, and is low in activation temperature and high in dioxin decomposition efficiency in dioxin pollutant elimination.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

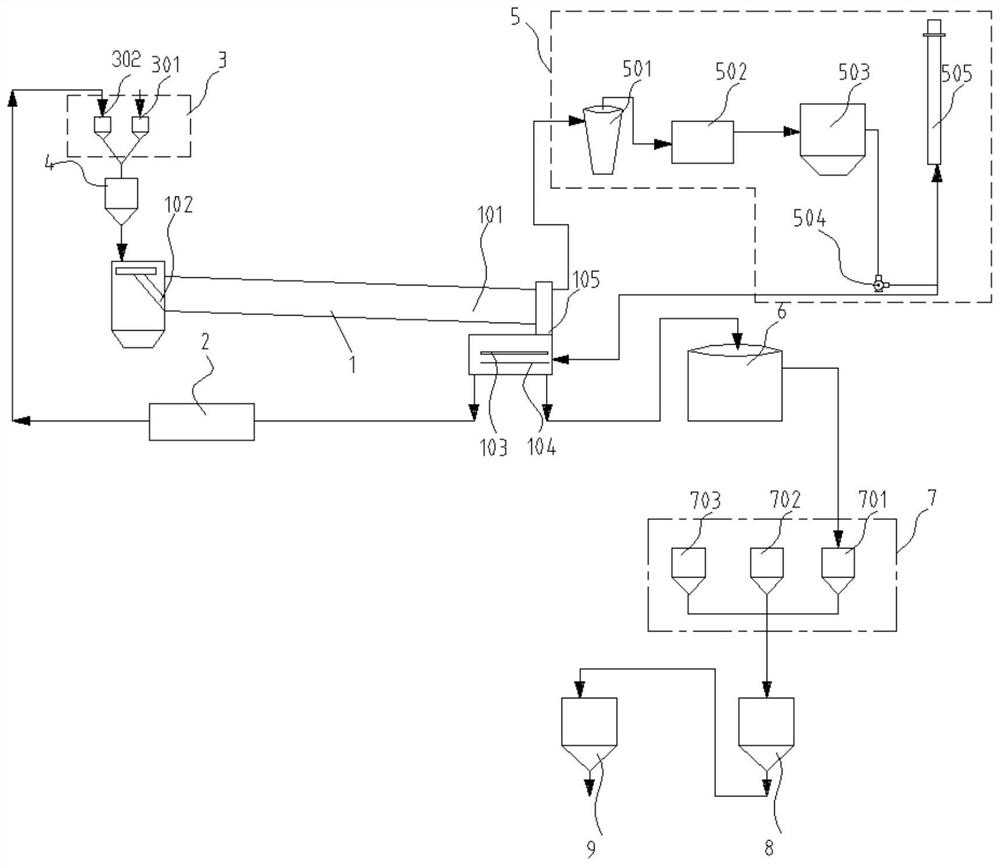

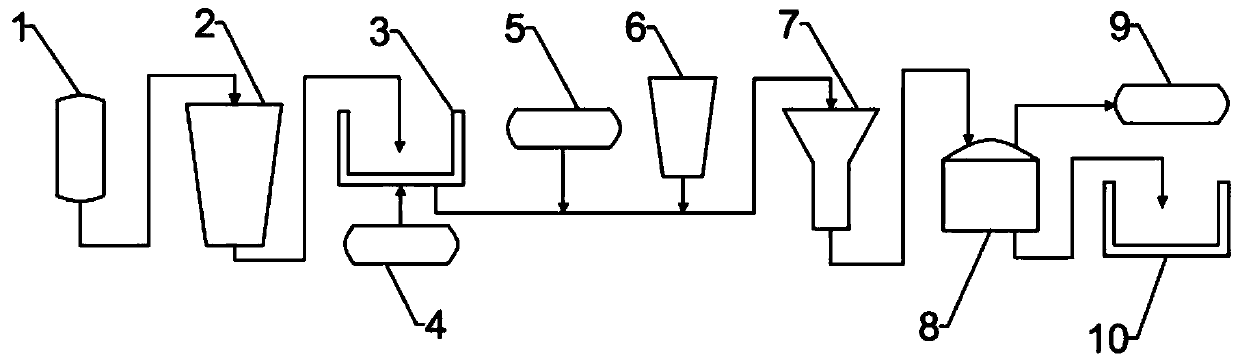

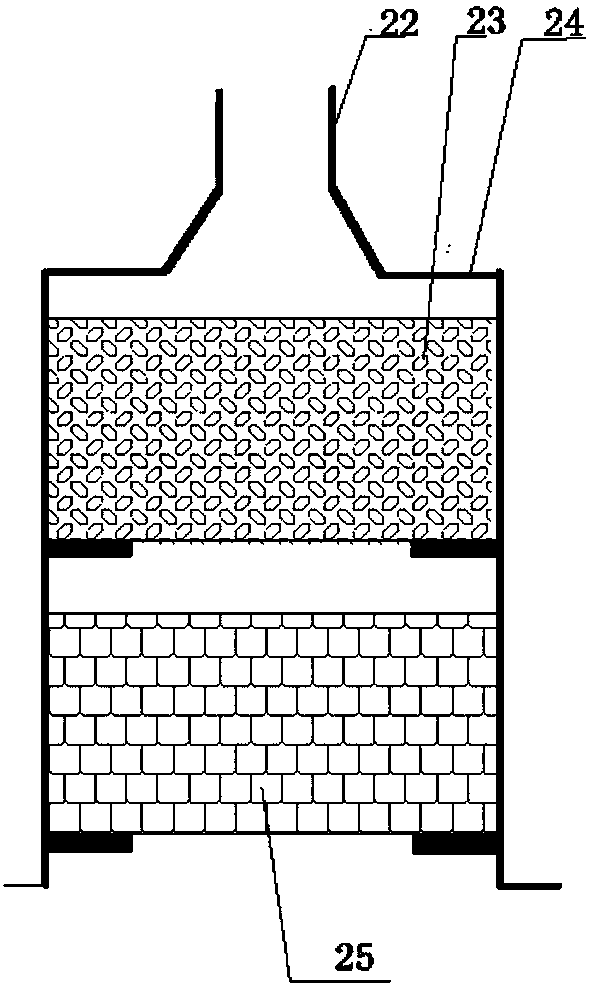

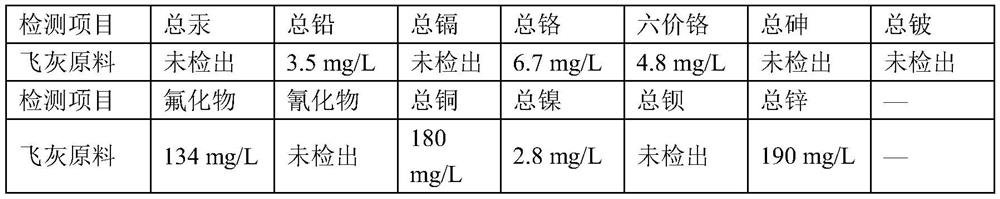

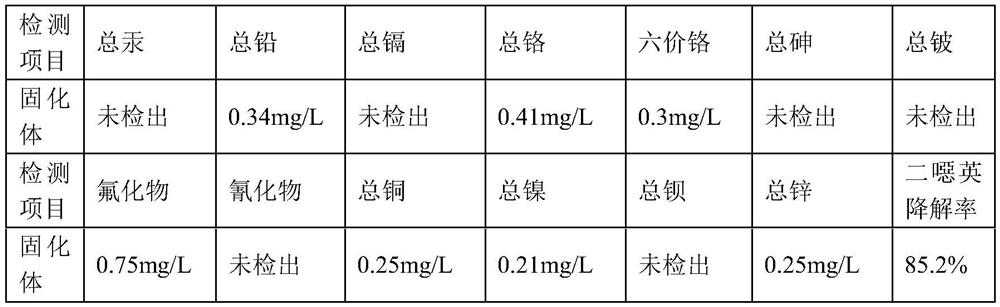

Novel fly ash efficient resource utilization system and method

ActiveCN114349452AImprove heating uniformityImprove single furnace processing capacitySlagProcess engineering

The invention relates to the technical field of environmental protection, in particular to a novel fly ash efficient resource utilization system and method.The method comprises the steps that fly ash is subjected to heat treatment, and a fly ash product obtained after heat treatment is mixed with slag and desulfurized gypsum to prepare a solid waste-based cementing material. The novel fly ash efficient resource utilization system comprises a back-mixing pyrolysis reactor, a preheater, a feeding bin, a mixing bin, a gas purification system, a finished product bin, a solid waste-based cementing material mixing device, a solid waste-based cementing material preparation device and a solid waste-based cementing material finished product bin. The invention provides a novel fly ash efficient resource utilization system which can greatly improve the cracking efficiency of organic compounds, reduce equipment faults, reduce the occupied area of equipment, thoroughly solve the problem of non-uniform local pyrolysis caused by non-uniform heating of materials, greatly reduce energy consumption and prolong the service life of the equipment.

Owner:北科蕴宏环保科技(北京)有限公司 +1

Method for reducing content of dioxin in capsanthin ointment

The invention discloses a method for reducing the content of dioxin in capsanthin ointment. According to the method, the saponification and the solvent extraction are carried out on the commercially available capsanthin ointment to ensure that the dioxin content in capsanthin ointment products is effectively reduced and the content of capsanthin in the ointment basically remains unchanged at the same time, and therefore, the food safety is increased. The method disclosed by the invention is simple and effective and can be adapted to the requirements of industrial production.

Owner:FOSHAN LEADER BIO TECH +1

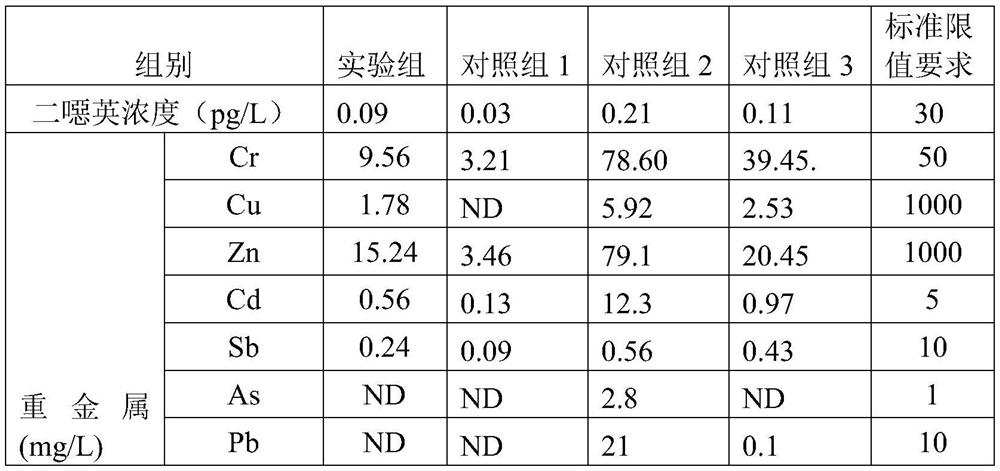

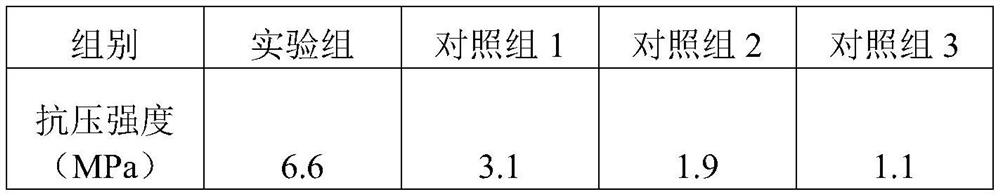

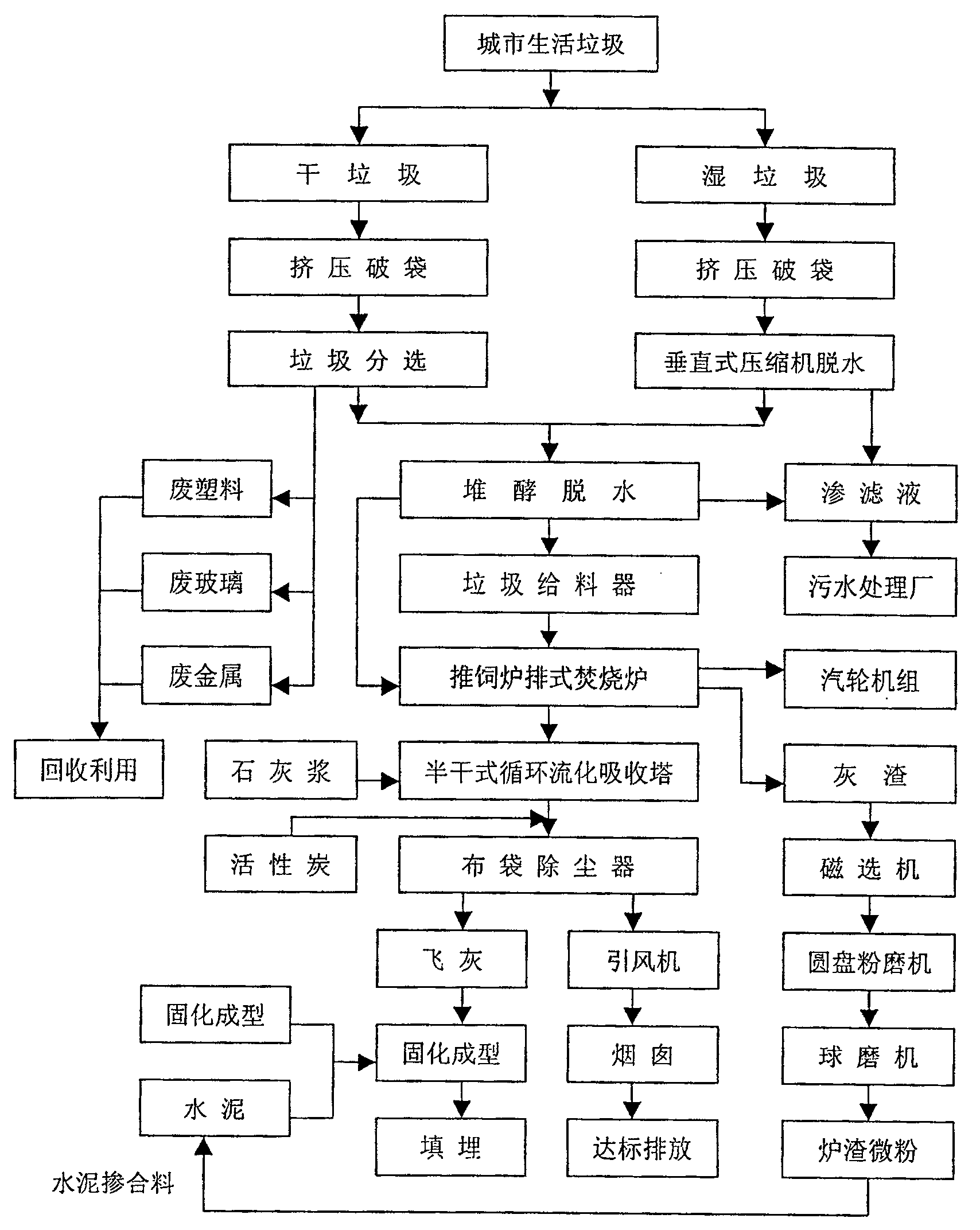

A comprehensive treatment process for urban domestic garbage

InactiveCN100548517CReduce moisture contentHigh calorific valueSolid waste disposalTotal efficiencySlag

The invention relates to an integrated method for processing municipal life waste, which comprises: collecting and classifying, separating, mechanically dewatering, fermenting and dewatering, burning, treating smoke, and collecting the slag to be used. Wherein, the dry waste after classifying and collecting can be separated into waste metal, waste glass and waste plastic, to be directly used; the wet waste via dewatered by compressing vehicle, mechanically compressed dewatered and fermenting dewatered can reach more 25% of dewatering total efficiency; the low-level caloricity of waste wet base is improved to 5990kg / kJ; the burning temperature is kept at 950-1050Deg. C, with high caloricity recycle rate; and the burning smoke has lower contents of dust, hydrochloride, heavy metal and dioxins; the smoke processing system has lower cost; and the slag has stable property, which can be used as cement blending material after magnetically selection and secondary grinding, or replace some cement. The invention can realize the integrated utilization of slag.

Owner:ZHEJIANG UNIV

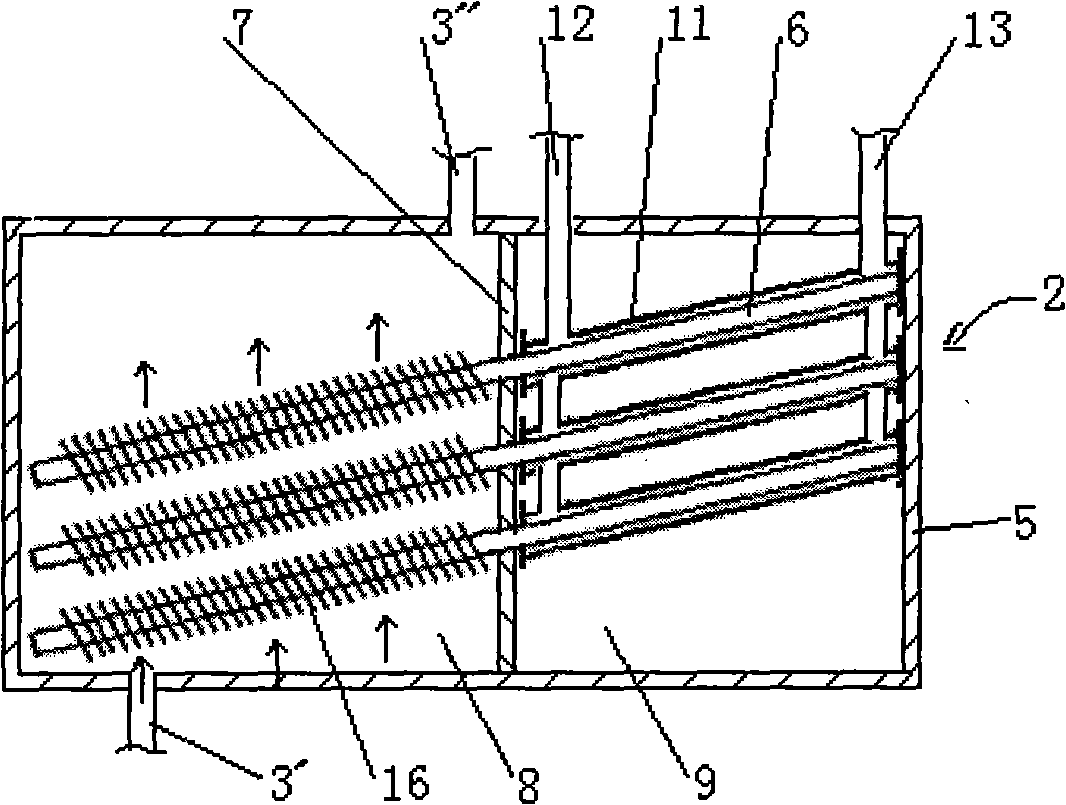

Superheater for waste heat boiler of waste incineration system

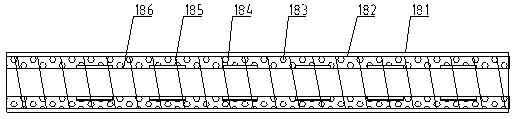

InactiveCN106678832AReduce dioxin contentReduce difficultySteam superheatersIncinerator apparatusFlue gasSteam power

The invention discloses a superheater for a waste heat boiler of a waste incineration system. A superheater body is arranged in a vertically arranged flue; a superheater pipeline is transversely arranged, an input end of the superheater pipeline is connected with a steam pocket, and an output end of the superheater pipeline is used for outwards outputting steam; the superheater body consists of a first superheater, a second superheater and a third superheater; an inlet header of the first superheater is connected with a saturated steam output pipeline of the steam pocket; an outlet header of the first superheater is connected with an inlet header of the second superheater through a first desuperheater; an outlet header of the second superheater is connected with an inlet header of the third superheater through a second desuperheater; and an outlet header of the third superheater is connected with a main steam pipeline. The superheater disclosed by the invention has the advantages of being capable of effectively reducing content of dioxin in flue gas, being beneficial for reducing difficulty of treating flue gas at a later period; and the superheater is energy-saving, efficient, can effectively improve thermal conversion efficiency, and ensures steam supply amount of steam power generation.

Owner:ANHUI CONCH KAWASAKI ENG +2

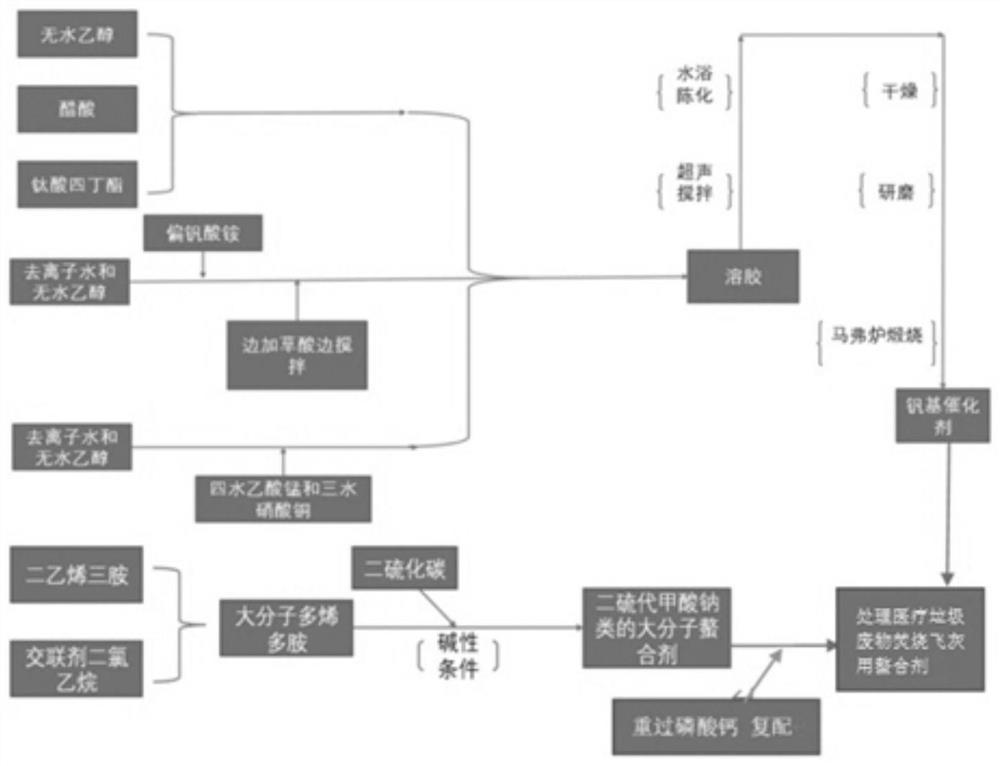

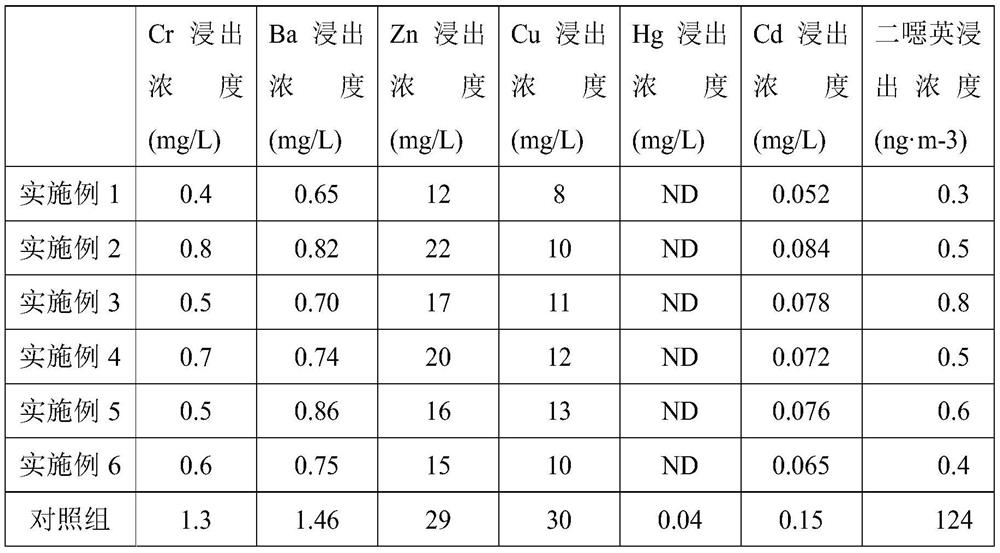

Chelating agent for treating medical waste incineration fly ash and preparation method thereof

InactiveCN112169245ASafe and efficient handlingEnvironmental protectionChemical protectionPtru catalystThio-

The invention discloses a chelating agent for treating medical waste incineration fly ash and a preparation method thereof, the chelating agent is composed of the following components by mass: 15-35 parts of an organic chelating agent, 5-15 parts of an inorganic chelating agent, and 10-20 parts of a vanadium-based catalyst, the organic chelating agent is sodium dithioformate, and the inorganic chelating agent is triple superphosphate. In the preparation process, the organic chelating agent and the vanadium-based catalyst can be separately prepared and then compounded, the preparation method issimple, and the preparation method is suitable for industrial popularization. The chelating agent for treating the medical waste incineration fly ash can react with heavy metal ions and dioxin to form a complex, and the effect of safely, rapidly and efficiently treating the medical waste incineration fly ash is achieved.

Owner:HUNAN UNIV OF TECH

Handling method for lowering dioxins and dust content in industrial flue gas by control wet method

InactiveCN110585847AAvoid harmReduce dioxin contentCombination devicesGas treatmentAutomatic controlQuenching

The invention discloses a handling method for lowering dioxins and the dust content in industrial flue gas by a control wet method. By automatically controlling heating of the flue gas, the flue gas reaches and is kept in the temperature interval of 750 DEG C to 850 DEG C, the dioxins in the flue gas can be further eliminated by the temperature interval, meanwhile, through quenching of a quench tower, the cooling water spray volume is automatically controlled so as to lower the temperature of the flue gas to 200 DEG C to 250 DEG C within 2.5 s, the temperature interval can inhibit production of the dioxins, and finally, the content of the dioxins in the flue gas is greatly lowered.

Owner:无锡雷顿电器有限公司

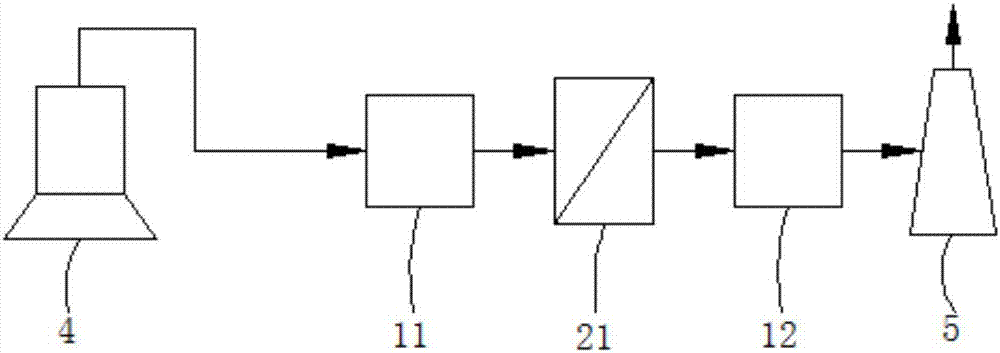

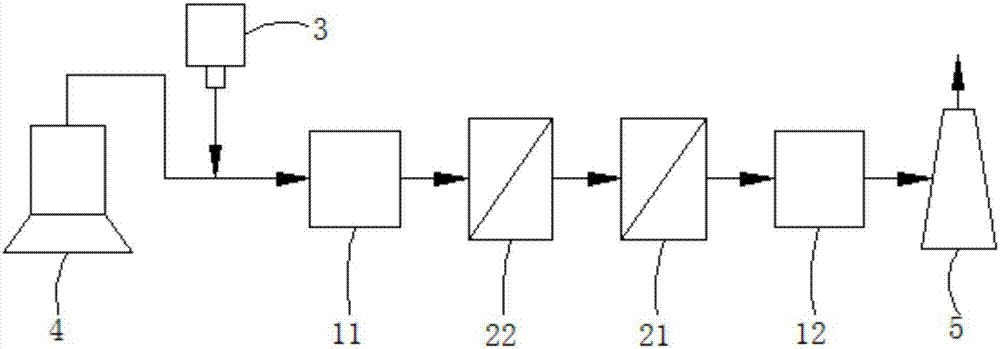

Method and equipment for reducing dioxin in smoke emitted in waste incineration

PendingCN107965775AStrong corrosion resistanceReduce energy consumptionMembrane filtersCombustion technology mitigationFilter materialEngineering

The invention discloses a method and equipment for reducing dioxin in smoke emitted in waste incineration. The method comprises the following steps: (1) reducing the temperature of the smoke to 450 to800 DEG C by adopting first afterheat recycling equipment, and treating the smoke by using the first afterheat recycling equipment to obtain first smoke; (2) filtering the first smoke at a temperature larger than or equal to 350 DEG C by adopting first filtration equipment, and making the first smoke pass through a filter material of the first filtration equipment to obtain second smoke of whichthe flying dust content is smaller than or equal to 20 mg / Nm<3>; and (3) reducing the temperature of the second smoke to 200 DEG C or below 200 DEG C by adopting second afterheat recycling equipment,and treating the second smoke by using the second afterheat recycling equipment to obtain exhaust smoke which can be directly exhausted, wherein the filter material of the first filtration equipment is a sheet composed of a metal porous material which takes a metal element of solid solution alloy and a face-centered cubic structure or the metal element of a body-centered cubic structure as a matrix phase.

Owner:CHENGDU INTERMENT TECH

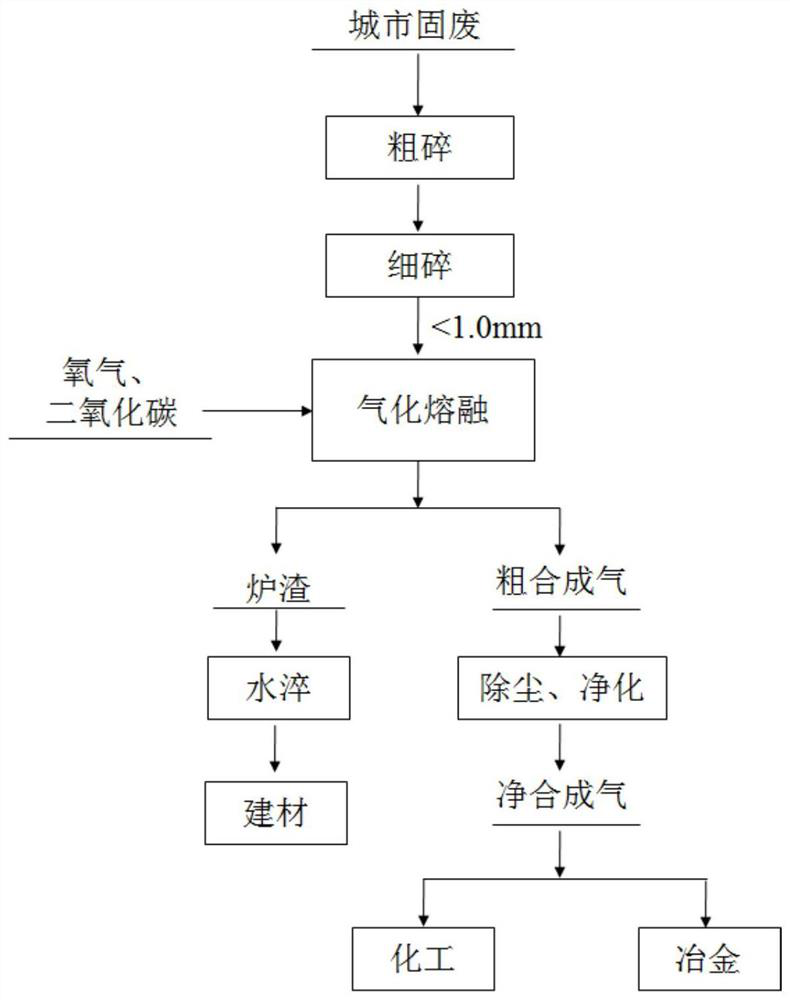

A method for co-resource utilization of urban solid waste and carbon dioxide

ActiveCN113025388BReduce difficultyRealize safe resource utilizationGasification processes detailsGas purification by non-gaseous materials condensationSlagMixed gas

The invention relates to the technical field of resource utilization of urban solid waste, in particular to a method for co-resource utilization of urban solid waste and carbon dioxide, in which oxygen-carbon dioxide mixed gas is used as an oxidant to carry out parallel combustion and gasification with finely crushed urban solid waste The reaction produces slag and synthesis gas, thereby realizing the co-resource utilization of urban solid waste and carbon dioxide. Municipal solid waste is put into the furnace in the state of fine powder for gasification, which improves the reaction rate, ensures the stability of the reaction in the furnace, and reduces the generation of dioxins. At the same time, through high temperature and high pressure operation, the inorganic substances in urban solid waste It melts into slag and forms a glass state after quenching, which realizes the solidification of heavy metals, reduces the leaching rate of heavy metal elements, and provides the possibility for the resource utilization of residues.

Owner:UNIV OF SCI & TECH BEIJING

Low-cost cooperative treatment and ultra-clean emission process of steel mill sintering flue gas and system thereof

PendingCN112944923AImprove power generation efficiencyIncrease temperatureIncreasing energy efficiencyHandling discharged materialCombustionFlue gas

The invention provides a low-cost cooperative treatment and ultra-clean emission process of steel mill sintering flue gas and a system thereof, and particularly relates to the technical field of waste heat utilization and purification treatment of flue gas. The process comprises the following steps: enabling sintering flue gas in a sintering machine to enter an annular cooler for exchanging heat, heating the sintering flue gas, then enabling the sintering flue gas to enter a reaction furnace for carrying out cooperative combustion with fuel supplemented in the reaction furnace, removing carbon monoxide and dioxin in the flue gas, and preparing the purified flue gas into steam. The problems that a large amount of CO and dioxin are contained in the sintering flue gas of the steel mill in the prior art, the pollution is brought to the environment, desulfurization and denitrification are only concerned generally in the prior art, and the method for effectively removing CO and dioxin in the sintering flue gas of the steel mill is not provided in the prior art are solved.

Owner:彭思尧

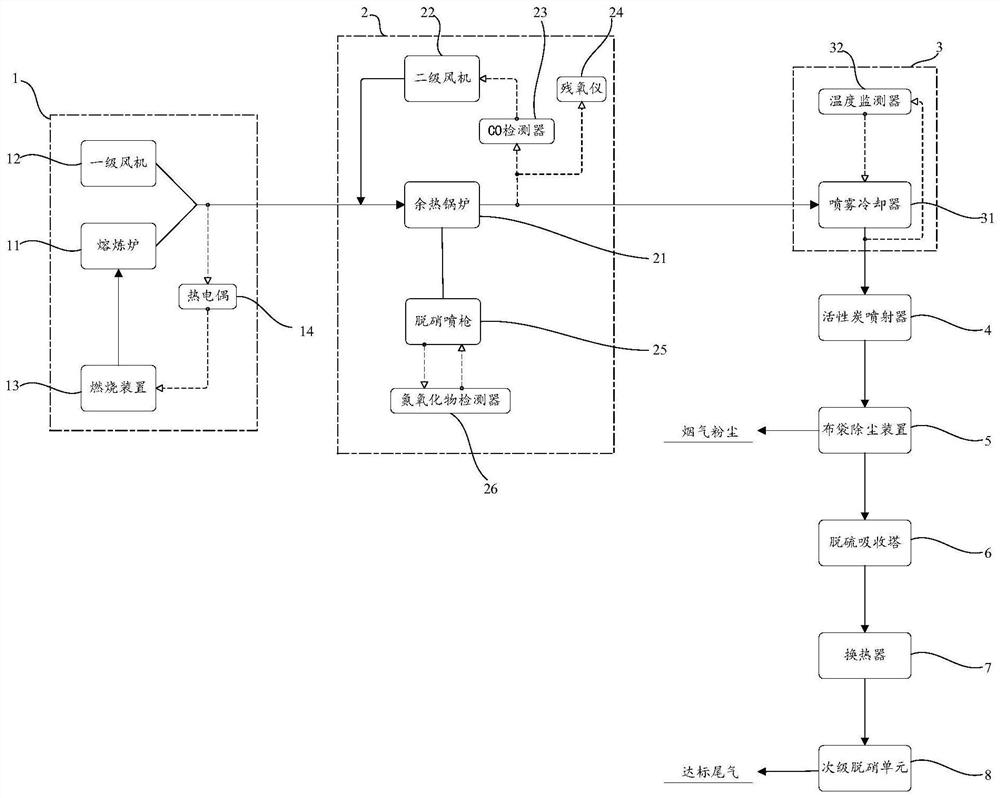

Circuit board smelting organic tail gas treatment system

PendingCN114459253AReduce dioxin contentMeet emission standardsIncreasing energy efficiencyCombustion technology mitigationActivated carbonInjector

The invention discloses a circuit board smelting organic tail gas treatment system which comprises a smelting unit, a waste heat unit, a cooling unit, an activated carbon ejector, a cloth bag dust removal device, a desulfurization absorption tower and a secondary denitration unit, the waste heat unit comprises a waste heat boiler, and the cooling unit comprises a spray cooler and a temperature monitor; the waste heat boiler, the spray cooler, the activated carbon ejector, the cloth bag dust removal device, the desulfurization absorption tower, the heat exchanger and the secondary denitration unit are sequentially communicated in the flowing direction of tail gas generated by the smelting unit, and the tail gas reaching the standard is discharged from a gas outlet of the secondary denitration unit. The temperature of the tail gas at the smelting furnace, the CO concentration at the waste heat boiler and the nitrogen oxide content at the denitration spray gun are monitored and adjusted in real time, and rapid cooling of the spray cooler is matched, so that the dioxin content in the tail gas after circuit board smelting is remarkably reduced, and the treated tail gas meets the emission standard.

Owner:荆门格林循环电子废弃物处置有限公司 +1

A method for reducing dioxin content in capsicum red ointment

The invention discloses a method for reducing the content of dioxin in capsicum red ointment. The commercially available capsicum red ointment is subjected to saponification reaction and solvent extraction to effectively reduce the dioxin content in the capsicum red ointment product. At the same time, the content of capsanthin in the ointment basically remains unchanged, which improves the food safety. The inventive method is simple and effective, and can meet the needs of industrialized production.

Owner:FOSHAN LEADER BIO TECH +1

A waste incineration fly ash recycling system and method coupled with waste incineration

ActiveCN108640543BRealize zero transportation costRealize resource utilizationSolid waste managementCement productionActivated carbonFlue gas

Owner:XI AN JIAOTONG UNIV

A kind of harmful gas dynamic purification reactor and purification method thereof

ActiveCN103566743BReduce dioxin contentImprove clearanceCalcium/strontium/barium chloridesDispersed particle separationPurification methodsDecomposition

The invention discloses a harmful gas dynamic purification reactor and a purification method thereof, wherein saturated whitewash is used as a cleaning agent to react with chlorine elements produced after the decomposition of a chlorine-containing plastic waste in a shell of an induced draft fan and a flue to produce calcium chloride, then the concentration of the chlorine elements for the synthesis of dioxin at the temperature interval of 400-800 DEG C is reduced, the production of dioxin is completely eradicated, the dynamic purification reactor structurally comprises the shell of the induced draft fan, an impeller, blades and a saturated whitewash nozzle, wherein the impeller is arranged in the shell of the induced draft fan, the blades are uniformly arranged on the impeller, the saturated whitewash nozzle is arranged in a smoke inlet of the induced draft fan, the saturated whitewash nozzle is connected with a saturated whitewash pressurization liquid storage tank, the smoke inlet of the induced draft fan is connected with a smoke outlet of a waste incineration furnace, and the smoke outlet is connected with a gas-liquid separator and a calcium chloride concentrating and drying process.

Owner:ENVIRONMENTAL PROTECTION EQUIP CO LTD SHANDONG GIANT ASIA

Method for treating household garbage

InactiveCN102836862BRelieve pressureReduce generationSolid waste disposalFurniture waste recoveryElectricityBrick

The invention discloses a method for treating household garbage, which comprises a pre-treating step, a plastic product treating step, a sand treating step and a combustible material treating step, wherein, according to the method, the household garbage is divided into five kinds of material, namely ferromagnetic material, plastic products, sands, light combustible material and kitchen waste; the five kinds of material are used for manufacturing wood-plastic boards, bricks and generating electricity by gasification and the like, respectively; the method disclosed by the invention has the advantages of simple operation, strong practicability, high automatic degree, safe and controllable use; a circular fluidized bed with relatively high gasification efficiency is used for light combustible material and kitchen waste treatment; the circular utilization degree of the household garbage such as gasified mixing gas treatment and the like except dioxin is increased; secondary pollution is avoided; and the method can be widely suitable for household garbage treatment of all scales.

Owner:张建超 +1

A small domestic waste low-temperature pyrolysis furnace flue gas purification device

The invention discloses a small flue gas purification device for a domestic garbage low-temperature pyrolysis furnace. The small flue gas purification device comprises a tar condenser, a tar collecting case, an electrostatic decoking device, a wet scrubber, an efficient dioxin adsorption bed and a three-stage settling pond; the tar condenser and the electrostatic decoking device are both arranged above the tar collecting case and communicated with the tar collecting case; the electrostatic decoking device is connected with the wet scrubber through a pipeline, the efficient dioxin adsorption bed is arranged at the upper end the wet scrubber and communicated with the wet scrubber, and the lower end of the wet scrubber is communicated with the three-stage settling pond; a flue gas inlet of the tar condenser is connected with a flue gas outlet of the domestic garbage low-temperature pyrolysis furnace, an outlet of the tar condenser is connected with the tar collecting case, and an inlet of the electrostatic decoking device is connected with the tar collecting case. According to the small flue gas purification device for the domestic garbage low-temperature pyrolysis furnace, tar in flue gas is removed first, the problems that the tar plugs and corrodes a flue gas pipeline in existing small domestic garbage pyrolysis treatment on the flue gas are solved, and meanwhile it can be guaranteed that new dioxin cannot be generated again in subsequent treatment of the flue gas by cooling the flue gas first.

Owner:SOUTH CHINA UNIV OF TECH +1

Waste incineration treatment process

PendingCN114321939ALow heavy metal leaching rateReduce dioxin contentOther chemical processesDispersed particle separationActivated carbonHydrotalcite

The invention relates to the field of waste incineration, and particularly discloses a waste incineration treatment process which comprises the following steps: waste incineration: performing waste incineration, and introducing oxygen in the incineration process; after the incineration flue gas is adsorbed by activated carbon and sprayed and deacidified by lime slurry, discharged flue gas and incineration fly ash are obtained; the incineration fly ash and a treatment agent are mixed and stirred under the condition of a mercury lamp or ultraviolet light, then a binding material is added, finally, water is added for stirring, building blocks are formed, and a solidified body is obtained; wherein the treatment agent is prepared by mixing the following raw materials in parts by weight: 15-25 parts of a chelating agent, 6-15 parts of hydrotalcite, 5-12 parts of nano titanium dioxide and 28-35 parts of graphene oxide loaded biochar. The device has the advantage that heavy metal and dioxin in the fly ash generated by waste incineration can be more effectively treated.

Owner:北京北控绿海能环保有限公司

A kind of catalyst used for catalytic oxidation to eliminate dioxin in kiln flue gas and preparation method thereof

ActiveCN110586073BHigh surface areaImprove thermal stabilityGas treatmentHeterogenous catalyst chemical elementsPtru catalystAntichlor

The invention provides a method for catalytic oxidation of dioxin-like pollutants in waste incinerators, hazardous waste incinerators, medical waste incinerators, steel sintering furnaces, coal-fired power plants, funeral homes and chemical plant flue gas and exhaust gases. Eliminated catalysts and methods of preparation. The catalyst is supported by industrial titanium dioxide, SnO 2 -V 2 o 5 -WO 3 Composite oxide is the active component, La 2 o 3 、MoO 3 , CeO 2 , Nb 2 o 5 , CuO, Pr 6 o 11 and Sb 2 o 3 as an auxiliary agent. In the catalyst prepared by the present invention, the active components are uniformly dispersed on the surface of the carrier under the complexation of organic amines, and the catalyst auxiliary agent is uniformly precipitated on the surface of the carrier under the condition of ammonia water, so that the catalyst has a high specific surface area, high thermal stability and comparative Strong anti-chlorine poisoning ability, continuous long-term operation without activation, low operating temperature in the elimination of dioxin-like pollutants, and high dioxin decomposition efficiency.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A flue gas purification and waste heat utilization system of a waste incineration power plant

ActiveCN109395496BFully mixed combustionFully oxidative decompositionGas treatmentDispersed particle filtrationElectric generatorEnvironmental geology

The invention discloses a smoke purifying and waste heat utilizing system of a waste incineration power plant. The smoke purifying and waste heat utilizing system comprises an incinerator body, a steam turbine, a power generator, a smoke purifying treatment device and a smoke discharge chimney. The smoke purifying treatment device comprises a pipeline combustor, a steam generator, a waste heat recoverer, a smoke decomposer, a washing tank and an adsorption purifier which are sequentially arranged from a high-temperature smoke outlet and the smoke discharge chimney. The smoke discharge pipe isarranged between the pipeline combustor and the steam generator. A particle collecting pipe is arranged on the lower side of the smoke discharge pip. A spiral smoke pipe is arranged in the steam generator. A heat pipe is arranged in the waste heat recoverer. An outer cylinder, an inner cylinder and a decomposition ball are arranged in the smoke decomposer. An inner electrode is arranged on the inner side of the inner cylinder. An outer electrode is wound on the outer surface of the outer cylinder. A washing pipe is arranged in the washing tank. The adsorption purifier is filled with adsorptionfiller. By means of the system, the combustion state is improved, combustion efficiency is improved, the dioxin content is reduced, and the waste heat recovery efficiency is improved.

Owner:QUJING YUNDIAN TOUXIN ENERGY POWER GENERATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com