Patents

Literature

32results about How to "Fully oxidative decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Activated carbon regeneration method

InactiveCN105080521AHigh recovery rateHigh regeneration rateOther chemical processesCombustible gas purificationFiltrationDesorption

The invention discloses an activated carbon regeneration method. Waste activated carbon and a desorption solution are mixed and pulped to obtain slurry, post treatment is conducted on the slurry to obtain regenerated activated carbon, and the desorption solution contains an organic solvent and water. The post treatment is performed in the mode (a) that the slurry performs catalyzed wet oxidation reaction, and the regenerated activated carbon and an oxidation filtrate serving as the desorption solution to be repeatedly used are obtained through filtration; or the mode (b) that the slurry performs desorption regeneration reaction, the regenerated activated carbon and a desorption filtrate are obtained through filtration, and then the desorption filtrate performs catalyzed wet oxidation reaction to obtain a reaction solution serving as the desorption solution to be repeatedly used. The catalyst adopted for the catalyzed wet oxidation reaction is one or more of copper salt, rhodium salt and palladium salt. The waste activated carbon is regenerated by means of the activated carbon regeneration method, the activated carbon regeneration rate is high, the losses of the activated carbon and the desorption solution are small, the reaction conditions in the regeneration process are moderate, and energy consumption is lower.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

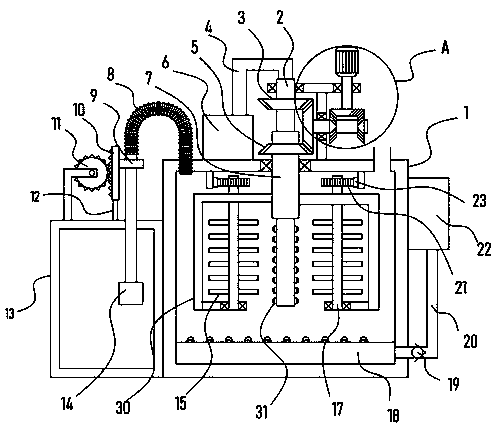

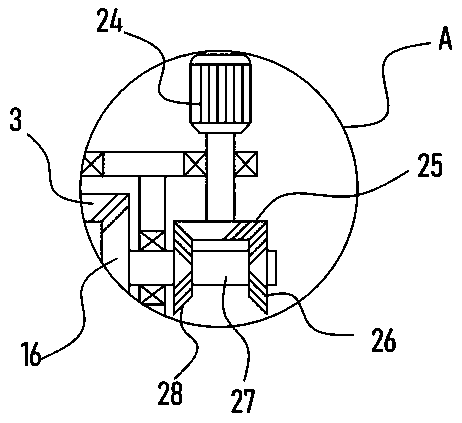

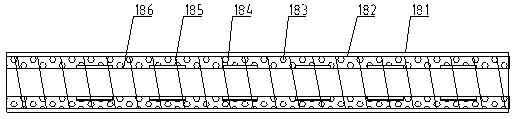

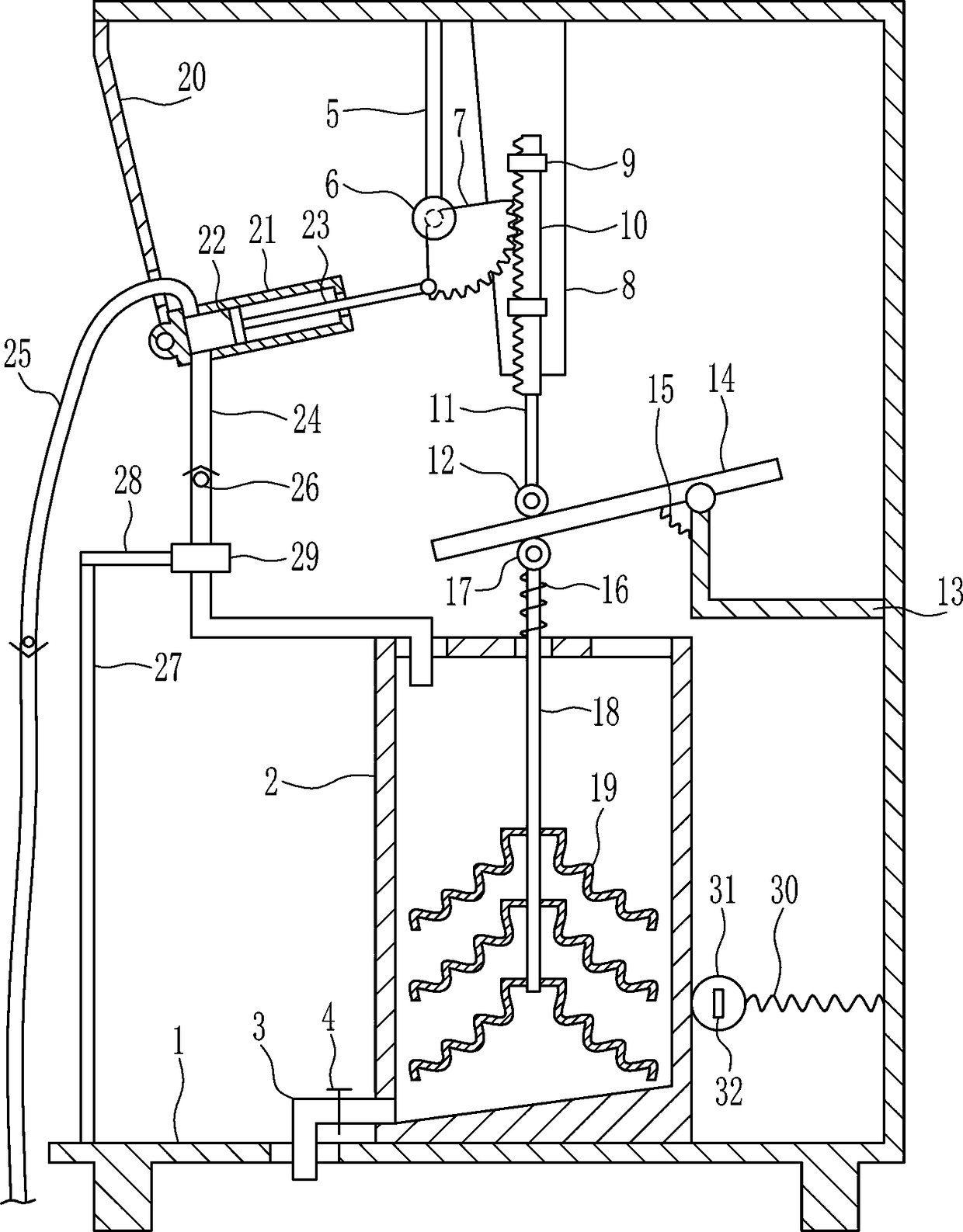

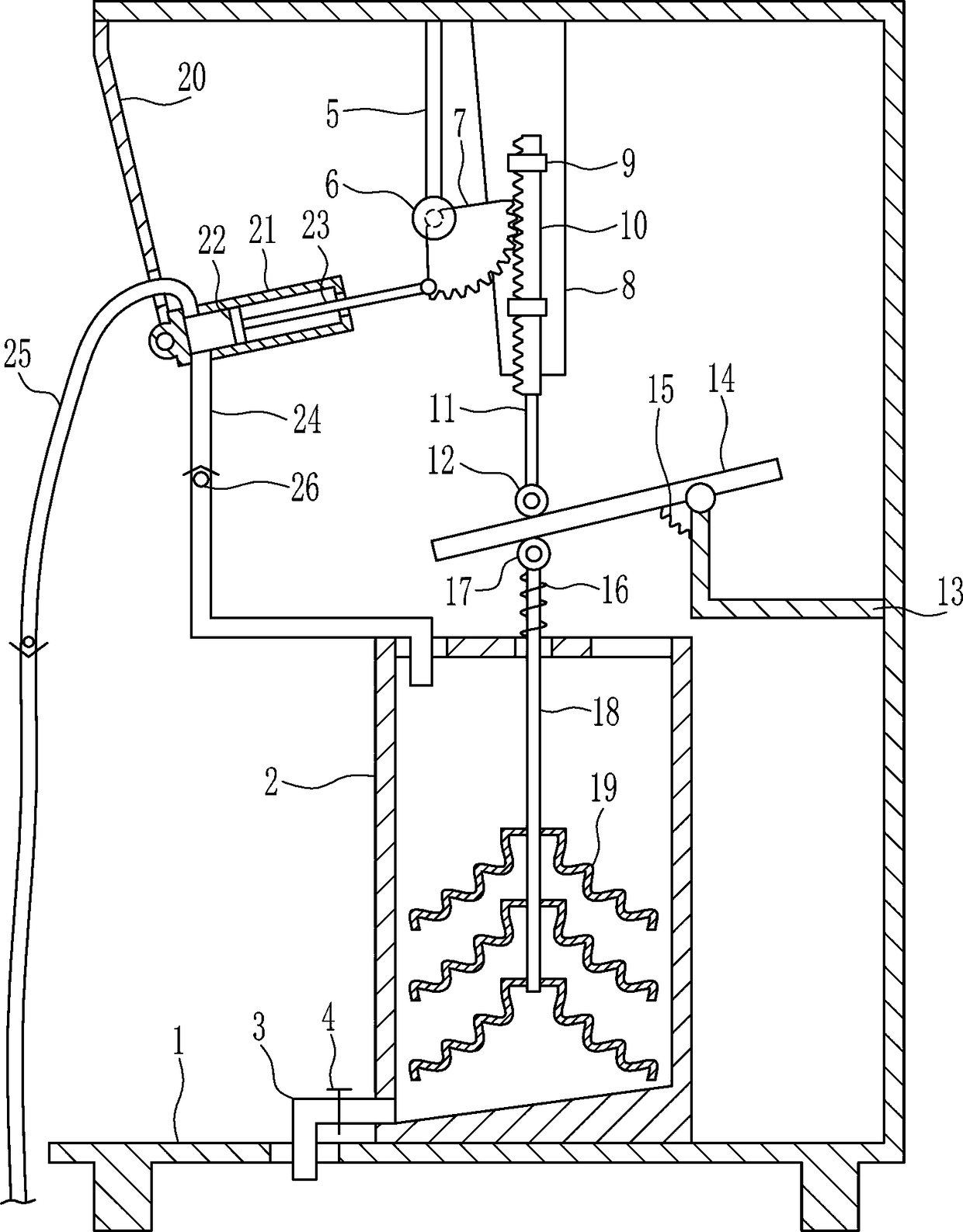

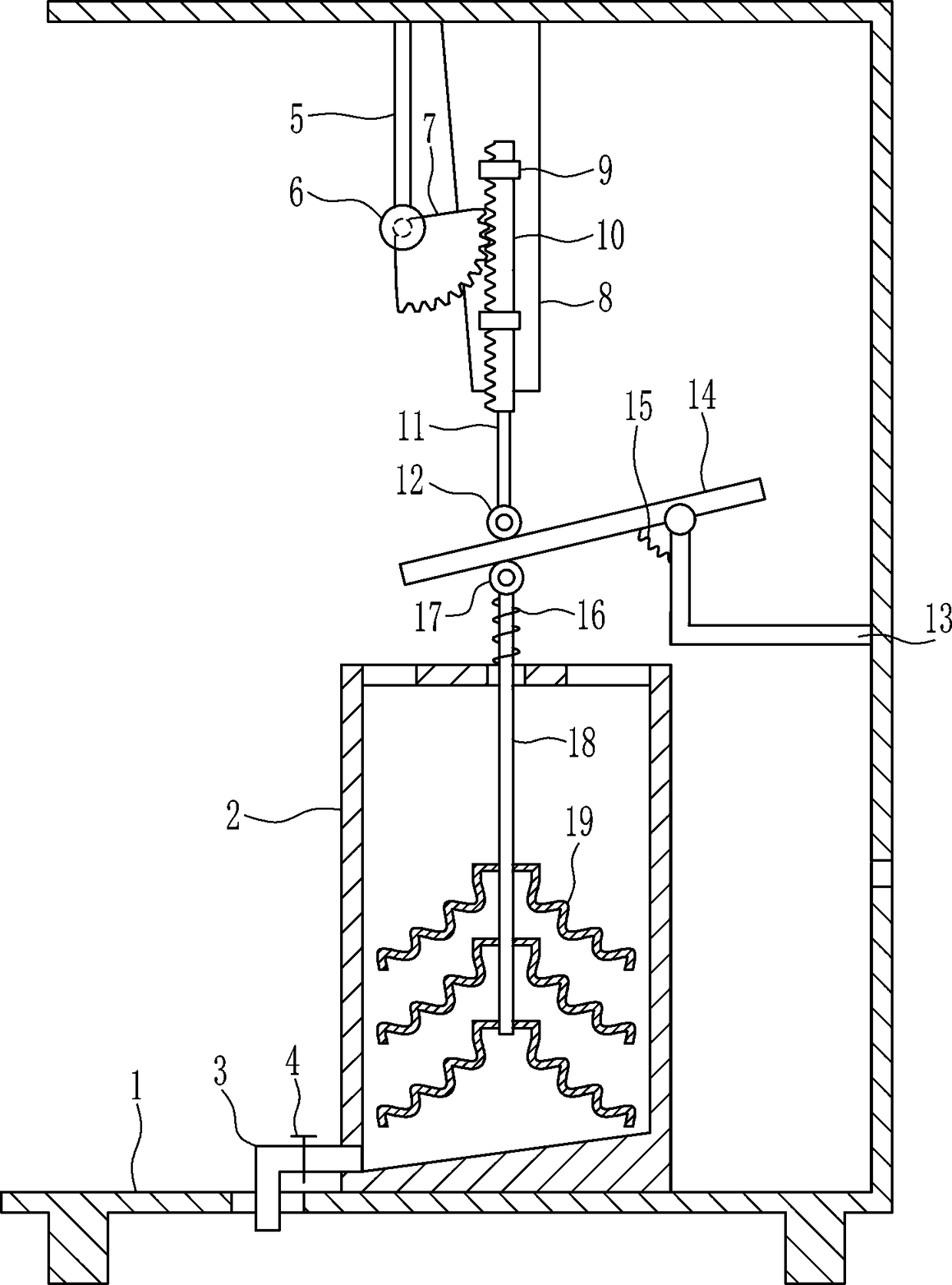

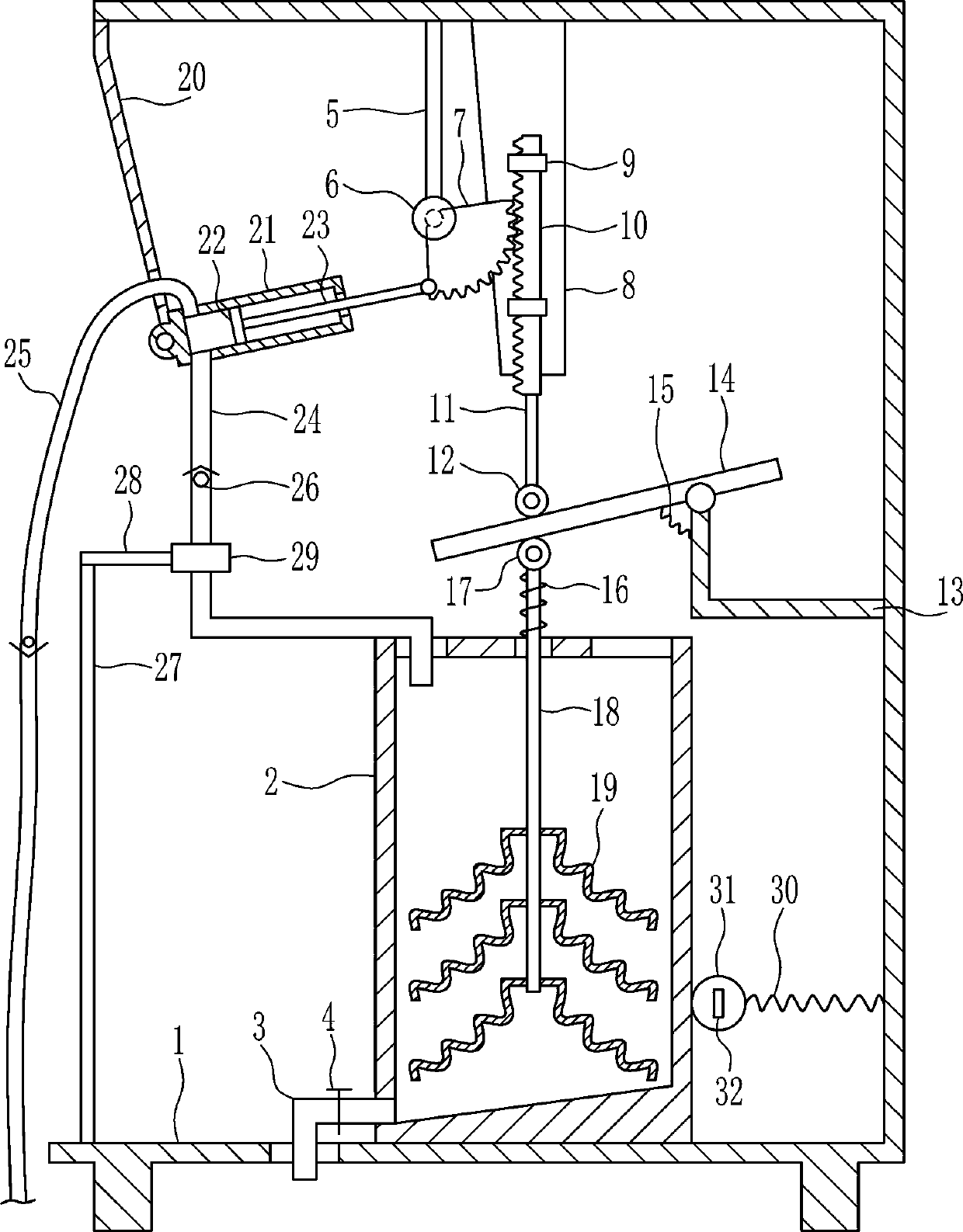

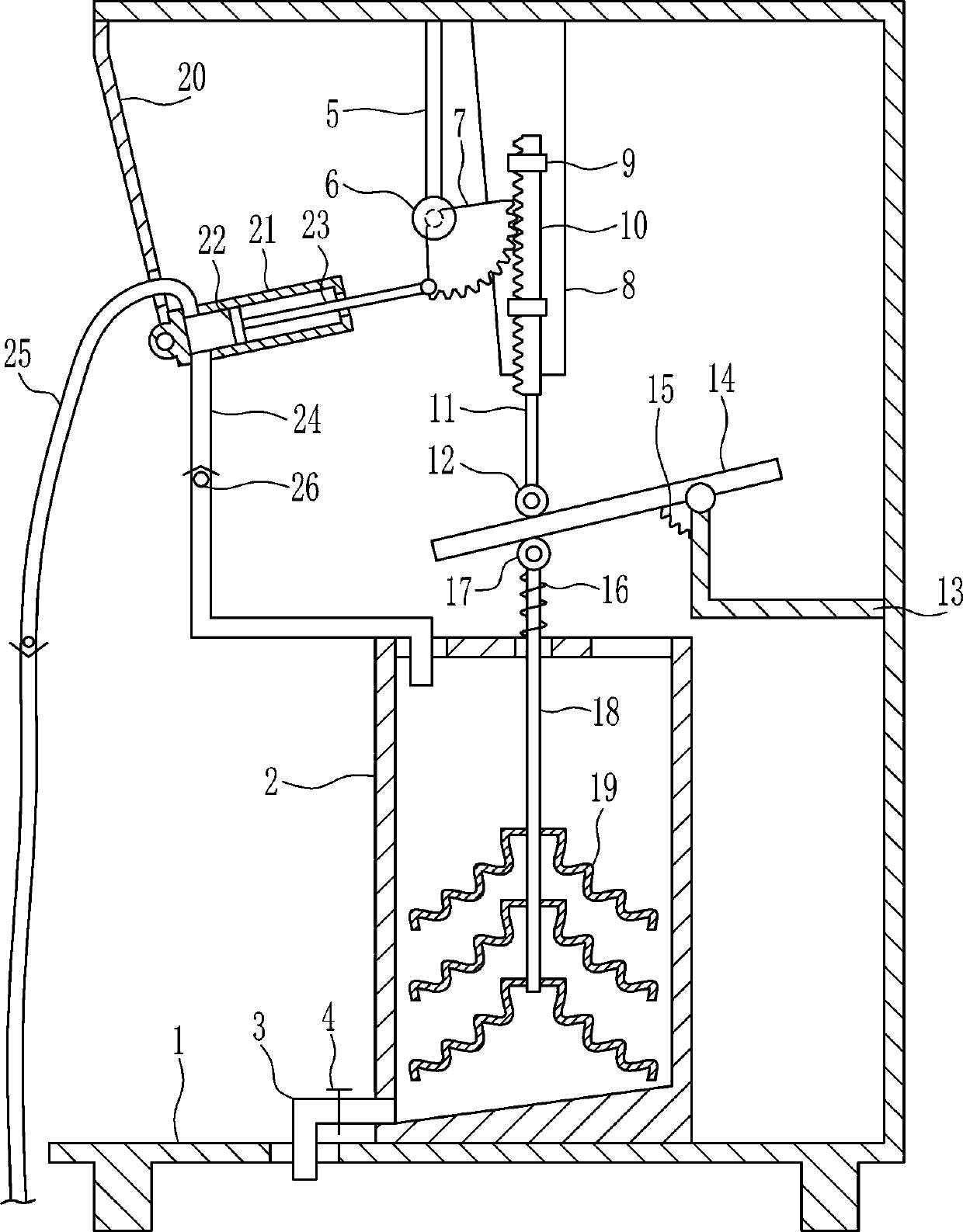

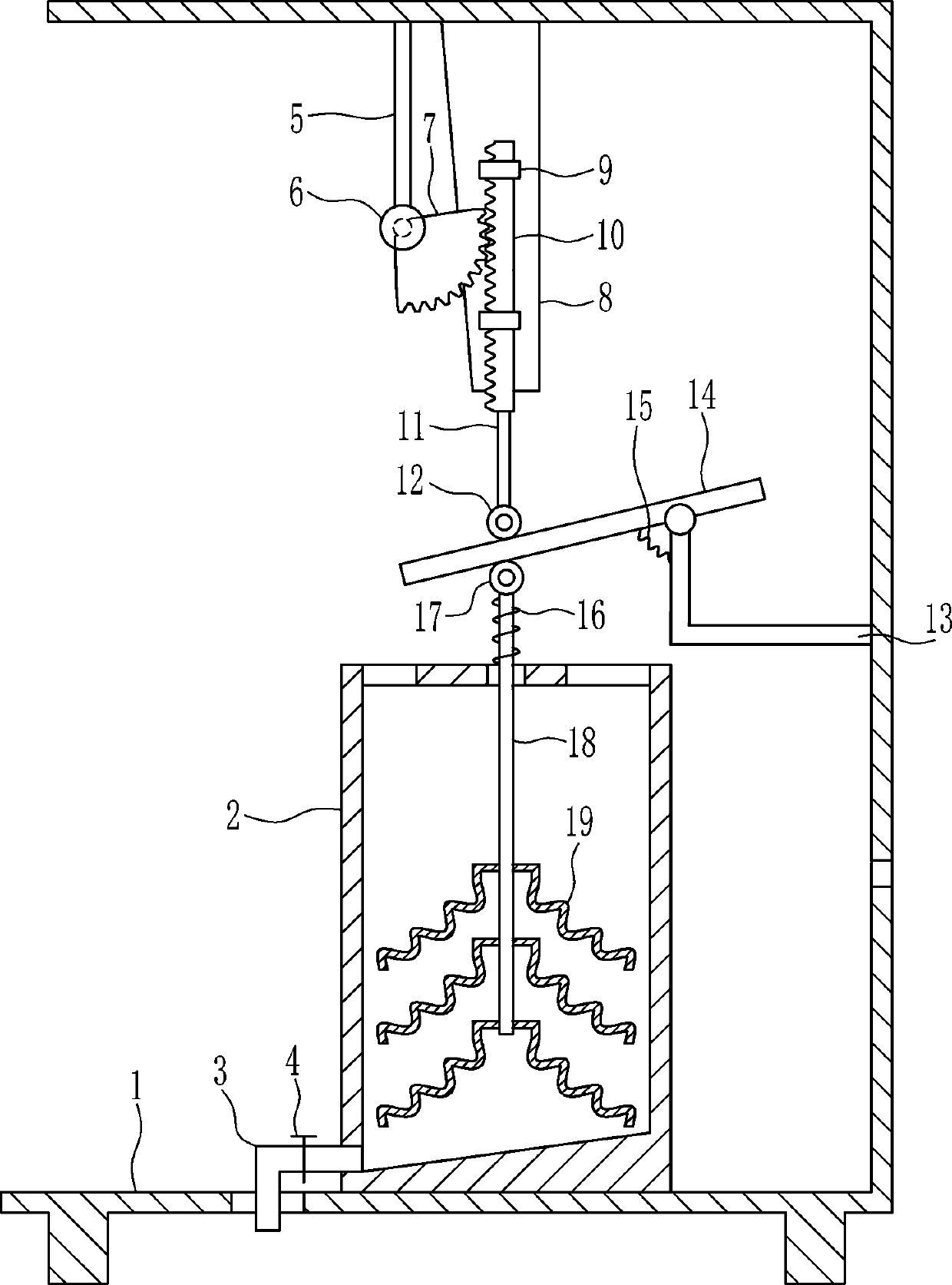

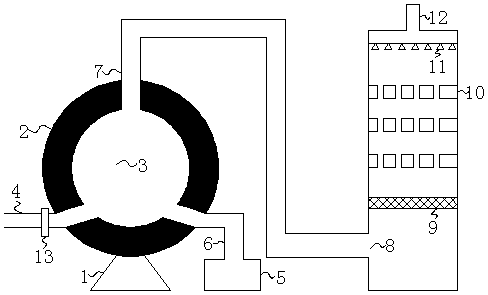

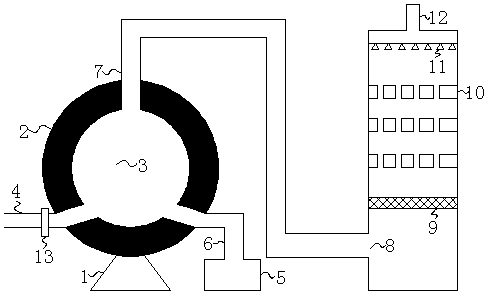

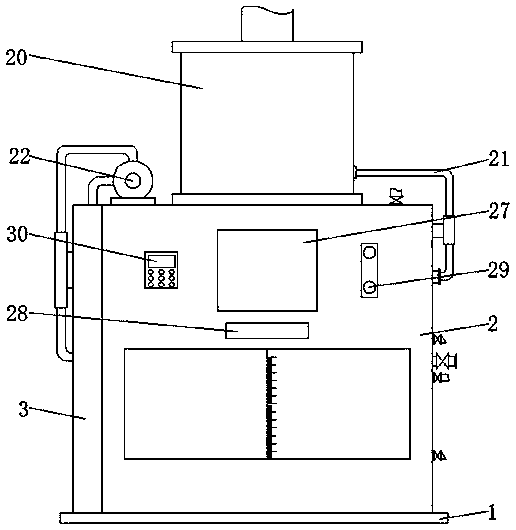

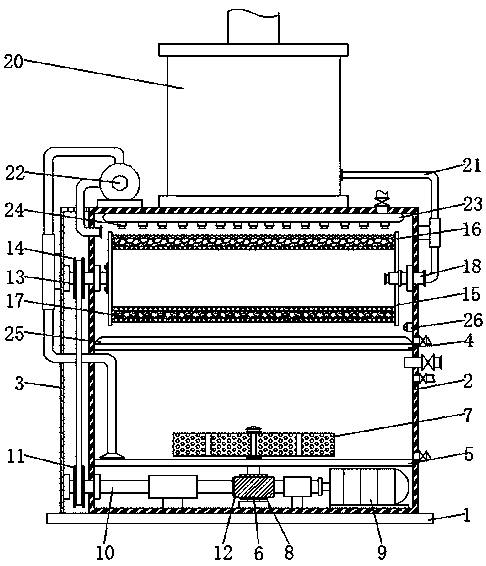

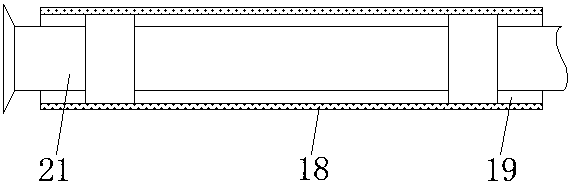

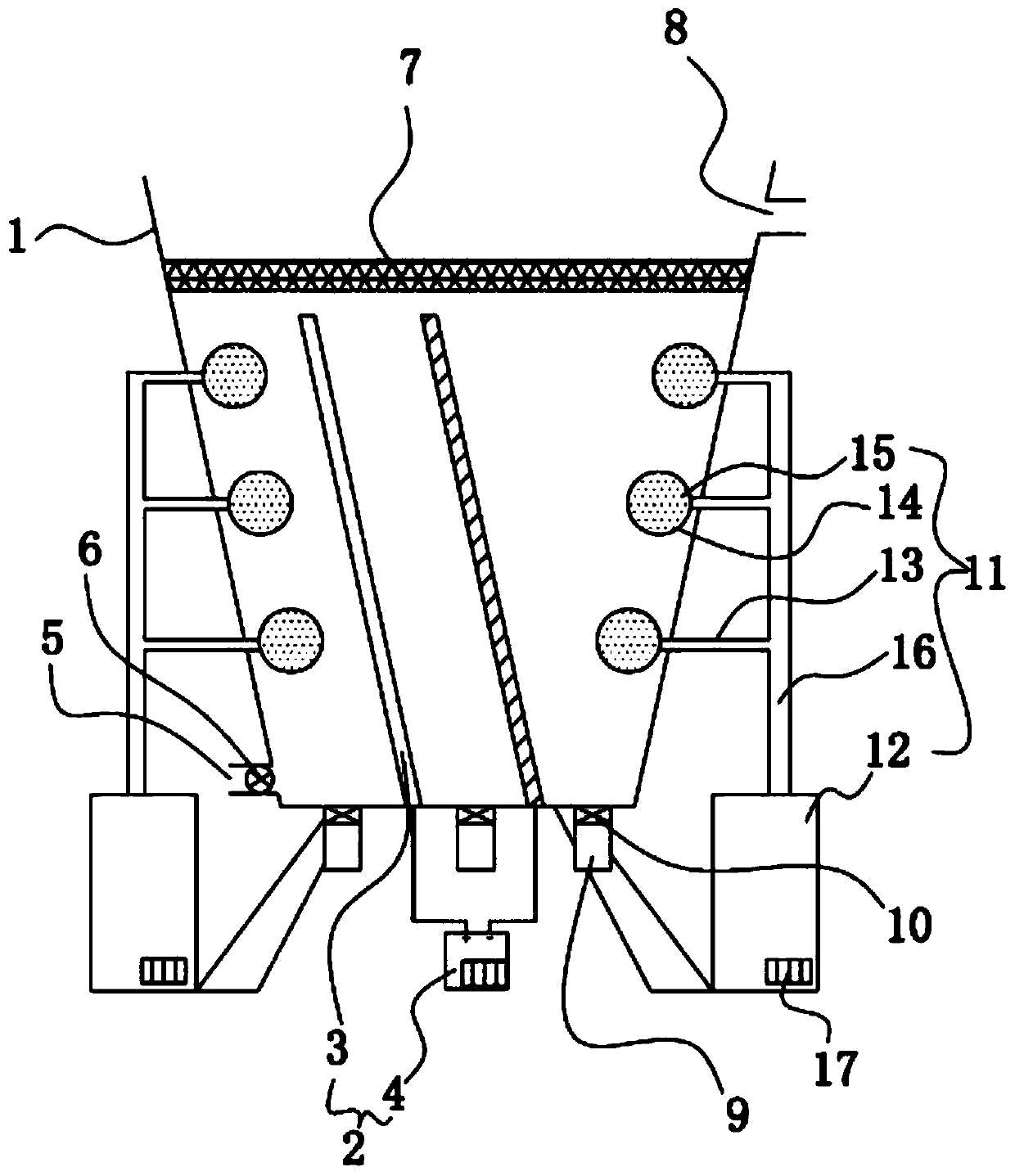

Highly-efficient aeration device for sewage purification treatment

InactiveCN111362433AFully oxidative decompositionWell mixedTreatment using aerobic processesRotary stirring mixersMicroorganismAir pump

The invention discloses a highly-efficient aeration device for sewage purification treatment, and relates to the technical field of forestry machinery. The highly-efficient aeration device comprises an aeration box and a settling box connected with the aeration box, wherein a rotating frame is fixedly arranged on a rotating sleeve pipe in a sleeving mode; a hollow shaft extending into the aerationbox is rotatably arranged in the rotating sleeve pipe; and an air delivery pipe I extending into the hollow shaft is arranged at the outlet end of an air pump I. According to the invention, through arrangement of the air pump I and an air pump II, external air can respectively enter the aeration box through spray heads and an air spray disc; through arrangement of a stirring mechanism, sewage andair in the aeration box can realize aeration under the action of stirring, so the content of oxygen in water is greatly improved, and full oxidation and decomposition of microorganisms to organic matters are promoted; through arrangement of a reversing mechanism, the stirring mechanism can be driven to alternately rotate forwards and backwards, so the stirring efficiency is significantly improved; and through arrangement of stirring plates which can rotate around rotating shafts and can rotate around the rotating sleeve pipe at the same time, sufficient mixing of oxygen and sewage is greatlypromoted, and the aeration effect is significantly improved.

Owner:中车环境科技有限公司

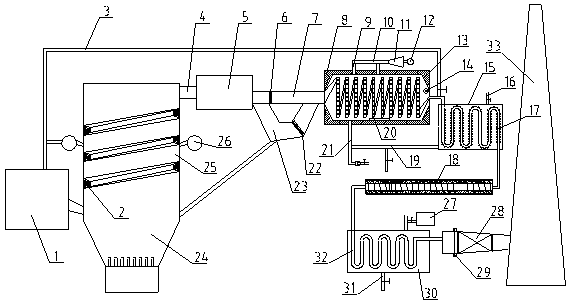

Smoke purifying and waste heat utilizing system of waste incineration power plant

ActiveCN109395496AIncrease temperatureLow costGas treatmentDispersed particle filtrationDecomposerWaste heat recovery unit

The invention discloses a smoke purifying and waste heat utilizing system of a waste incineration power plant. The smoke purifying and waste heat utilizing system comprises an incinerator body, a steam turbine, a power generator, a smoke purifying treatment device and a smoke discharge chimney. The smoke purifying treatment device comprises a pipeline combustor, a steam generator, a waste heat recoverer, a smoke decomposer, a washing tank and an adsorption purifier which are sequentially arranged from a high-temperature smoke outlet and the smoke discharge chimney. The smoke discharge pipe isarranged between the pipeline combustor and the steam generator. A particle collecting pipe is arranged on the lower side of the smoke discharge pip. A spiral smoke pipe is arranged in the steam generator. A heat pipe is arranged in the waste heat recoverer. An outer cylinder, an inner cylinder and a decomposition ball are arranged in the smoke decomposer. An inner electrode is arranged on the inner side of the inner cylinder. An outer electrode is wound on the outer surface of the outer cylinder. A washing pipe is arranged in the washing tank. The adsorption purifier is filled with adsorptionfiller. By means of the system, the combustion state is improved, combustion efficiency is improved, the dioxin content is reduced, and the waste heat recovery efficiency is improved.

Owner:QUJING YUNDIAN TOUXIN ENERGY POWER GENERATION

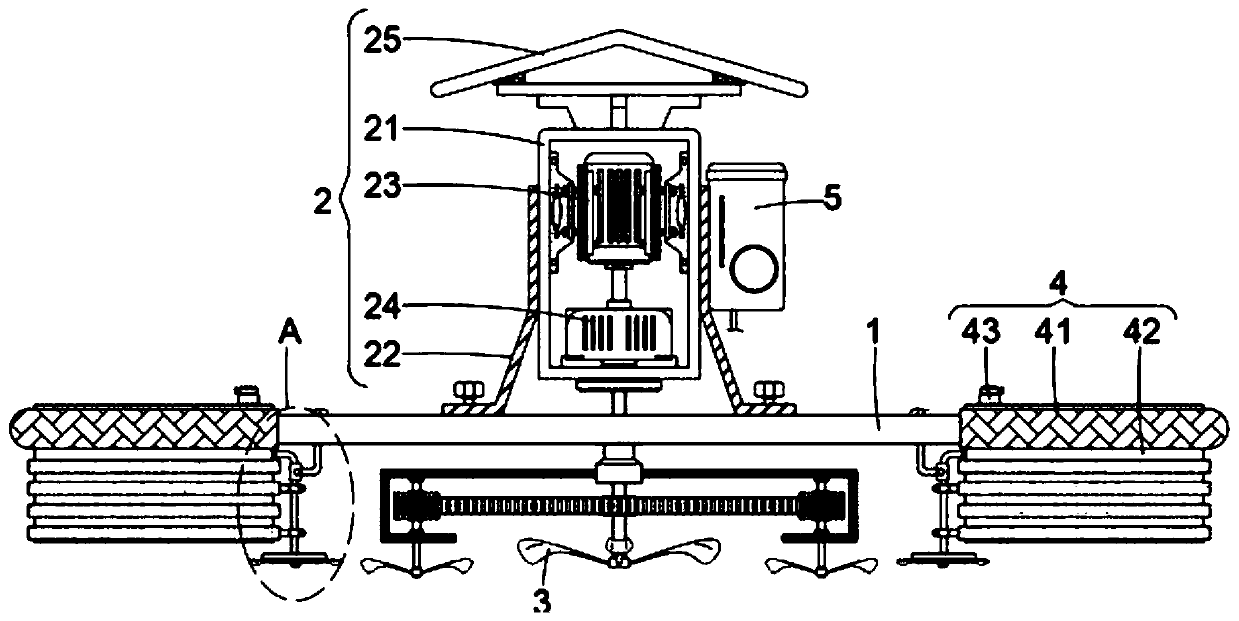

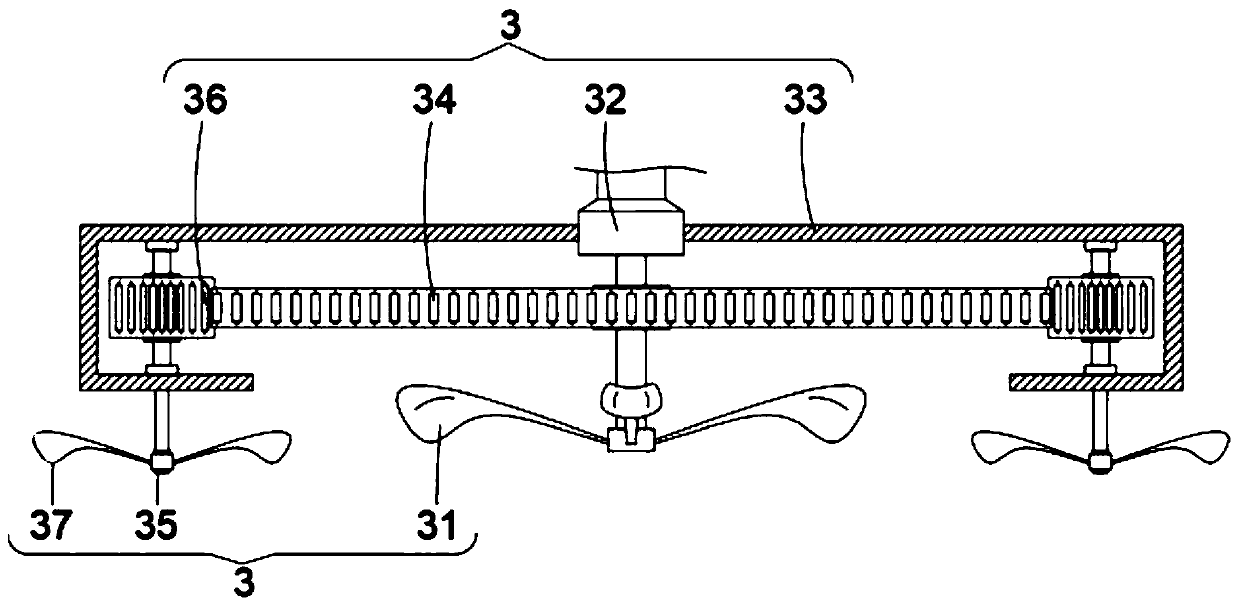

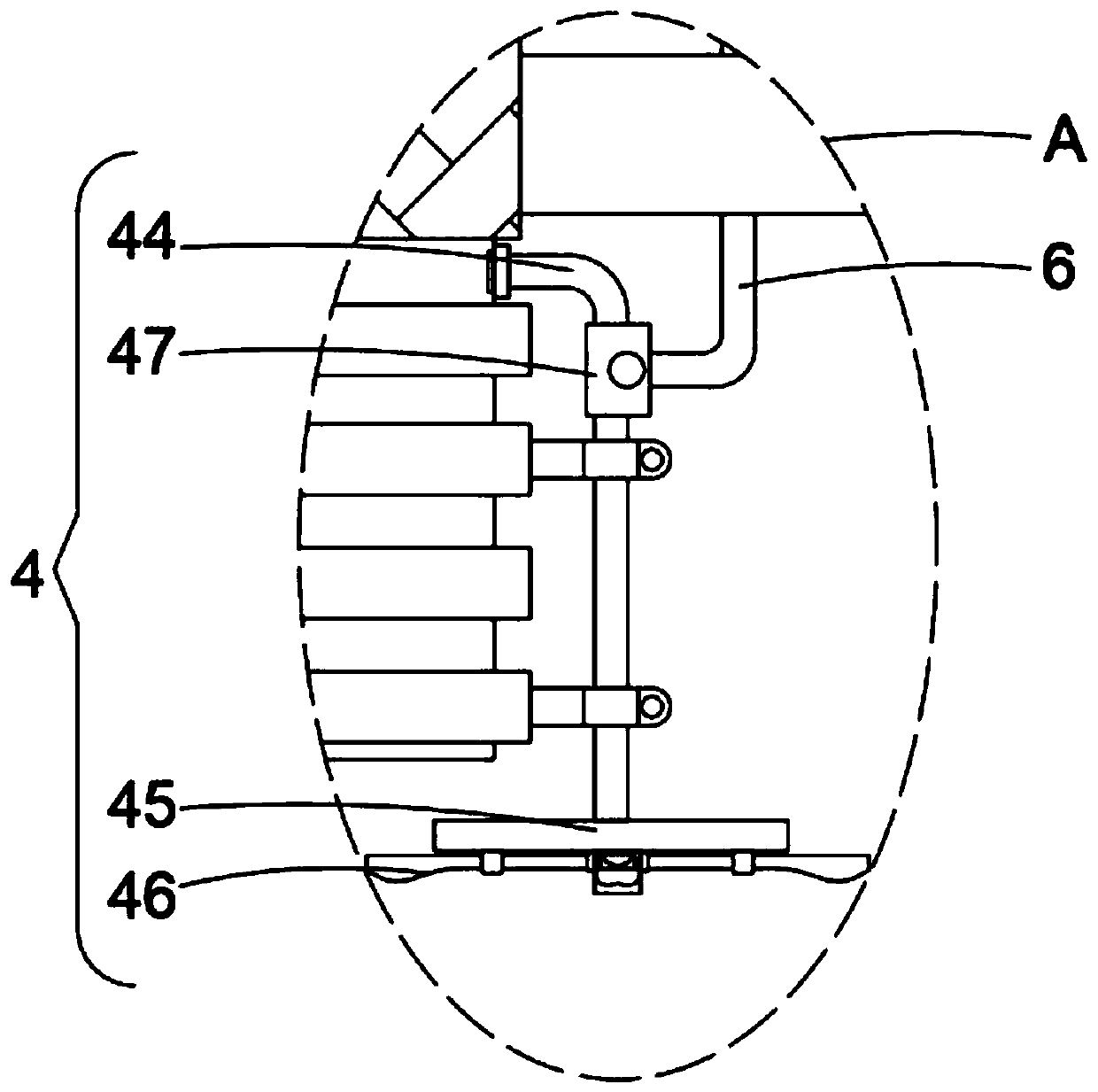

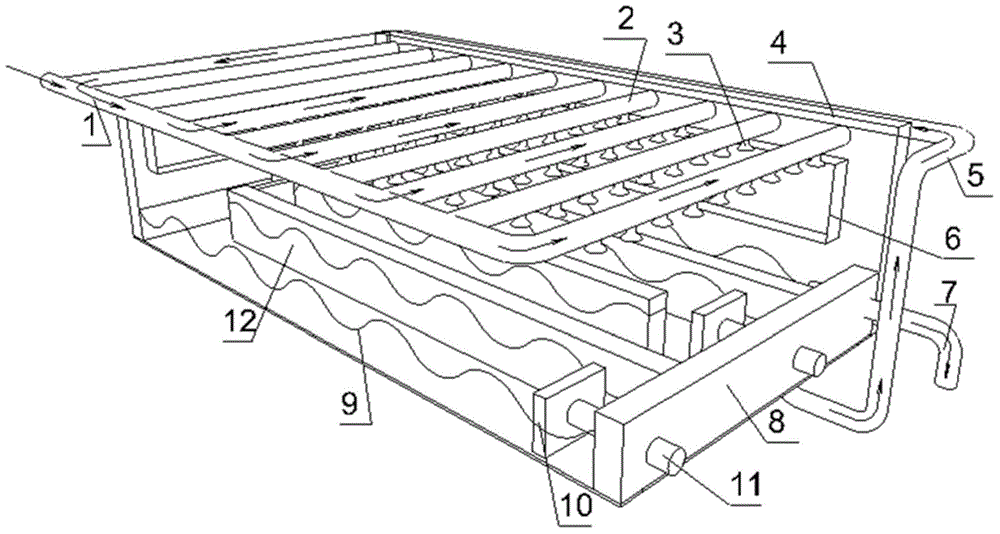

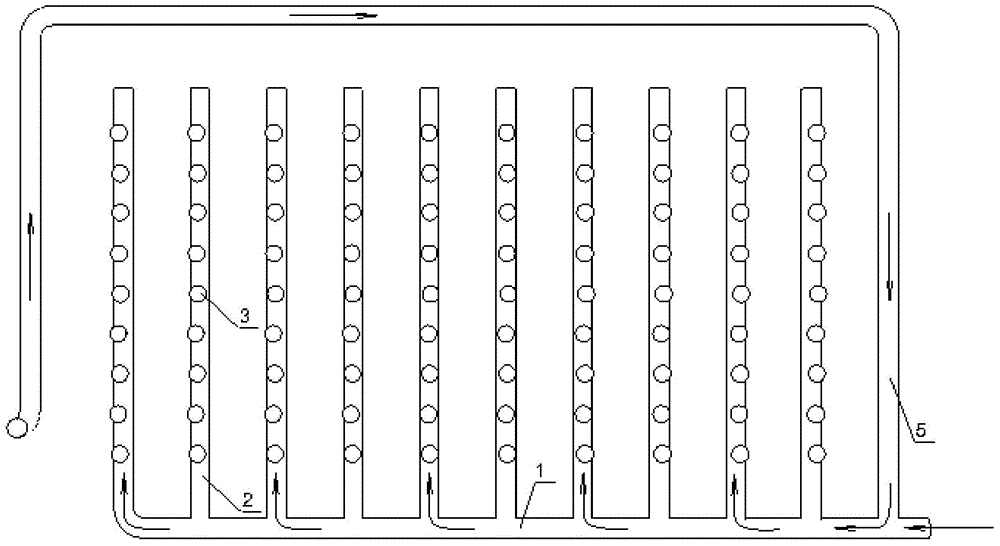

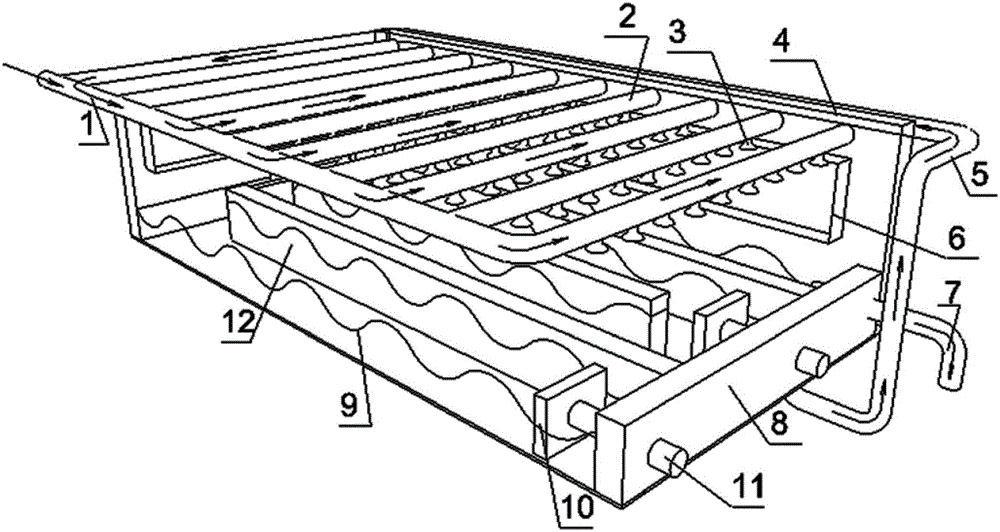

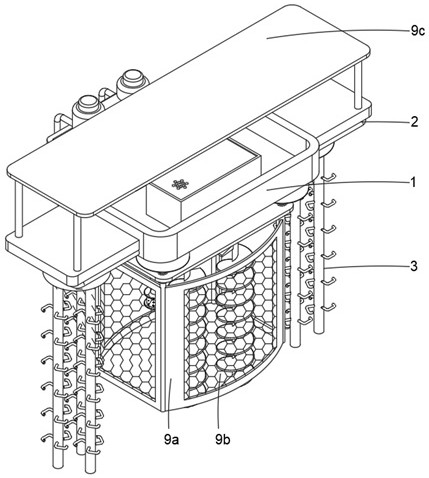

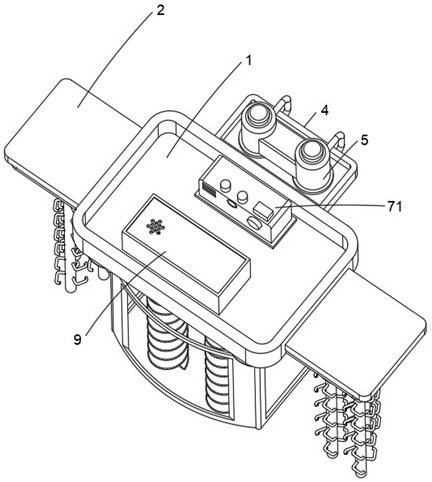

Unmanned aquaculture oxygenation workstation and oxygenating method

InactiveCN111066718AIncrease dissolved oxygen levelsReduce dissolved oxygenWaste water treatment from animal husbandryPisciculture and aquariaOxygen enhancedEngineering

The invention provides an unmanned aquaculture oxygenation workstation and an oxygenating method. The unmanned aquaculture oxygenation workstation comprises a floating plate, a driving mechanism, an oxygenation mechanism and an oxygen injection mechanism, wherein the driving mechanism is arranged on the upper surface of the floating plate; the oxygen injection mechanism is annularly arranged on the periphery of the floating plate, and comprises a rubber water ring, a floating bucket, a valve, an air guide pipe, an assembly plate, exhaust duckbills and a three-way valve; the rubber water ring is fixedly arranged on the side wall of the floating plate, and the floating bucket is fixedly arranged in the rubber water ring; the oxygen outlet formed in the side wall of the floating bucket is fixedly connected with the oxygen inlet of the assembly plate through the air guide pipe; four exhaust duckbills which are arranged in an annular shape are fixedly arranged at the bottom of the assemblyplate, and each exhaust duckbill is fixedly connected with the oxygen vent formed in the bottom of the assembly plate; and the three-way valve is arranged on the air guide pipe. The unmanned aquaculture oxygenation workstation and oxygenating method have the advantage of increasing the mixing contact area of air and a water body.

Owner:ZHEJIANG OCEAN UNIV

Efficient energy-saving coal-firing additive

The invention relates to high efficiency energy preserving coal additive that the weight ratio of constituents is benzene dregs: NaCl: potassium permanganate: rare earth chloride: CaCO3 or Na2CO3 =4.7-6:3-4.5:0.5:0.5:3-5. The additive added into coal could make it fast fire, long time burning, no smoke, etc. The coal save quantity could reach to 40%.

Owner:何永亮

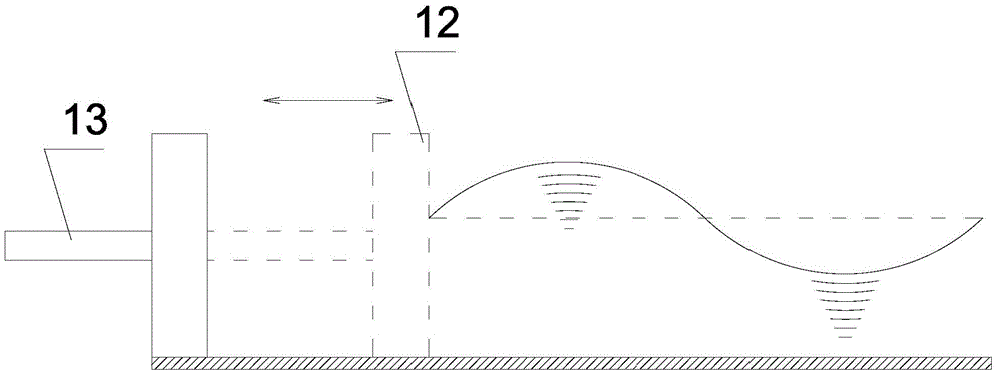

1,2-dichloropropane separation system and separation technique

InactiveCN104671332AImprove processing efficiencyImprove removal effectWater contaminantsWater/sewage treatment with mechanical oscillationsAutomatic control1,2-Dichloropropane

The invention discloses a 1,2-dichloropropane separation system and separation technique. The separation system comprises a bottom with vibration surge tanks and a top with a nozzle head, wherein a water channel is divided into the plurality of vibration surge tanks by the tank body. The separation technique is implemented in a way that: under the action of the vibration surge tanks, 1,2-dichloropropane-containing underground water flows according to a S-shaped route; the reflux quantity is controlled at 80 m<3> / minute, the water level is controlled at 80cm, the vibration surge period is controlled at 20 times / minute, and the vibration surge plate stroke is controlled at 600mm; and a continuous spray mode is adopted. The separation technique has the characteristics of high environment friendliness, high resource utilization ratio, high treatment effect and high impact resistance, and implements full-automatic control.

Owner:XUZHOU UNIV OF TECH

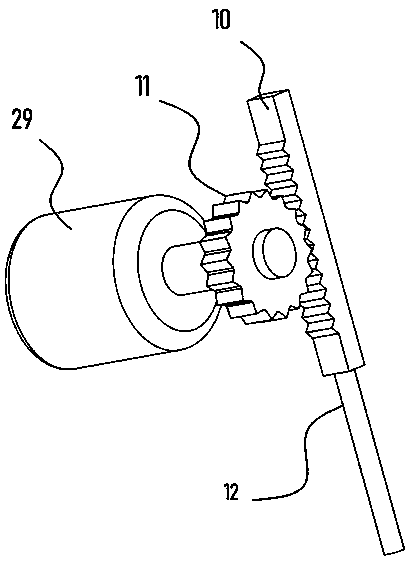

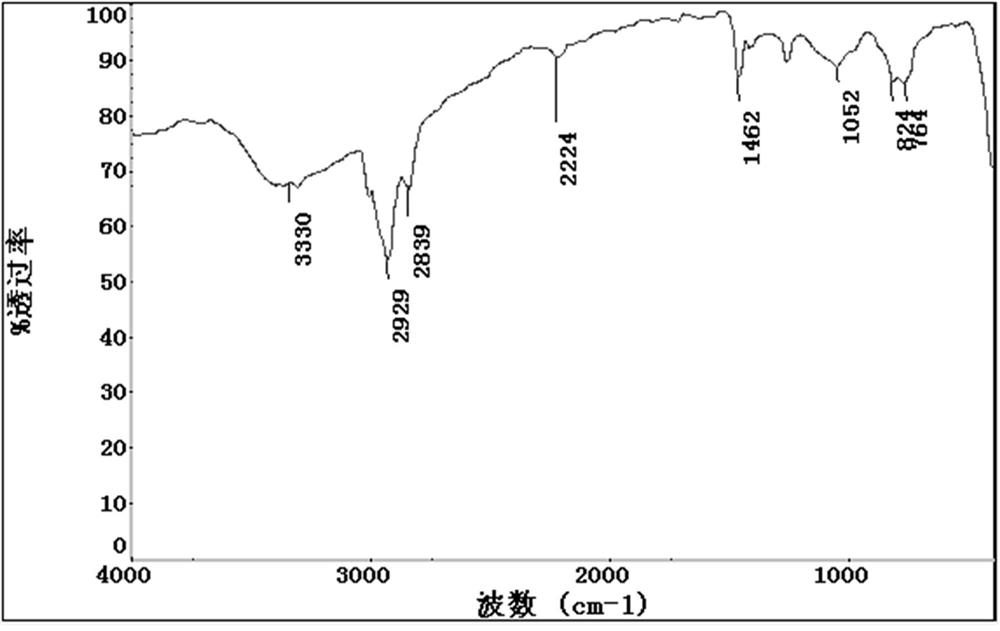

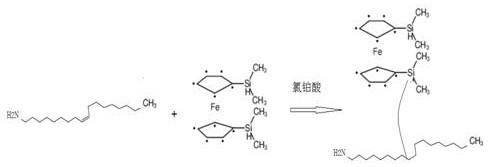

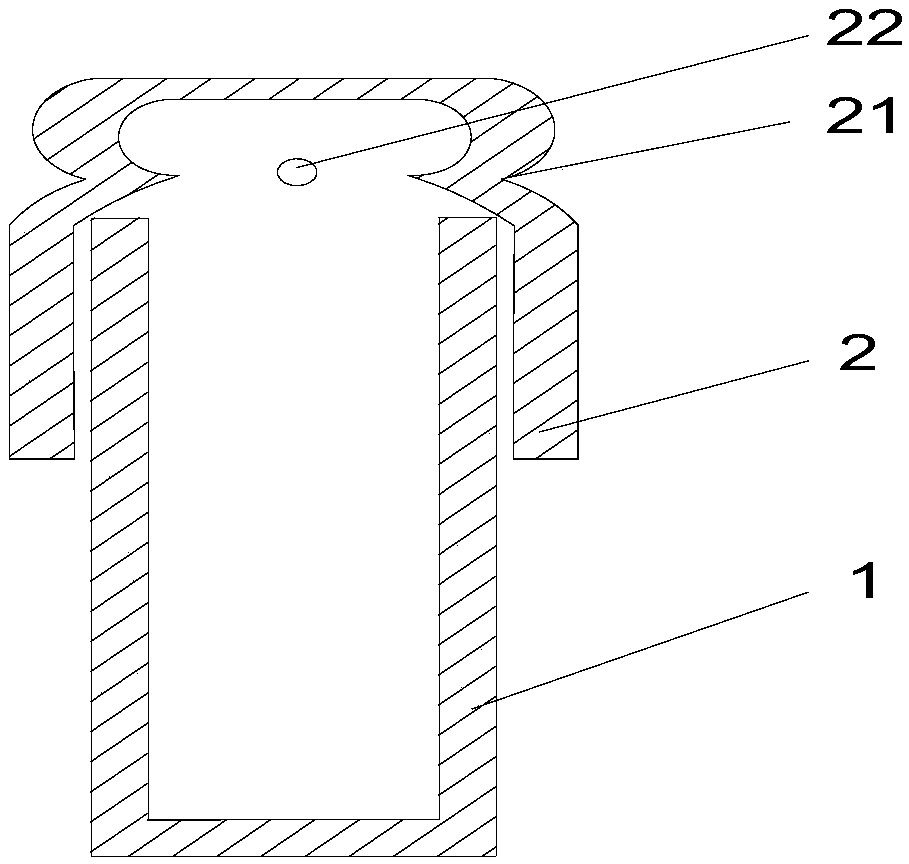

Material mixing machine for rare earth ore powder and hydrochloric acid

ActiveCN108330280AFully oxidative decompositionSave human effortProcess efficiency improvementMetallurgyDecomposition

The invention relates to a material mixing machine, in particular to a material mixing machine for rare earth ore powder and hydrochloric acid. The material mixing machine for the rare earth ore powder and the hydrochloric acid aims to achieve the technical effects that manual feeding of the hydrochloric acid is not needed, the decomposition rate can be improved, and waste of the hydrochloric acidis avoided. The material mixing machine for the rare earth ore powder and the hydrochloric acid comprises an installation frame, a box, a discharging pipe, a valve, a support rod, a servo motor, a sector gear and the like. The box is installed in the middle of the inner wall of the lower side of the installation frame. The discharging pipe is connected with the lower portion of the left wall of the box. The discharging pipe penetrates through the left portion of the lower wall of the installation frame. The material mixing machine for the rare earth ore powder and the hydrochloric acid achieves the technical effects that manual feeding of the hydrochloric acid is not needed, the decomposition rate can be improved, and waste of the hydrochloric acid is avoided. Through the arrangement of acylinder block and a piston, hydrochloric acid liquid flows into the box intermittently, so that the rare earth powder can be fully oxidized and decomposed, and the effect of improving the decomposing efficiency is achieved.

Owner:嘉兴华雯化工股份有限公司

A treatment process for resource utilization of medical waste salt by medium-temperature pyrolysis

ActiveCN111468516BFully oxidative decompositionLow organic residueSolid waste disposalTransportation and packagingInorganic saltsAnticaking agent

The present invention relates to the field of environmental protection, and specifically relates to a treatment process for resource utilization of medical waste salt at medium temperature pyrolysis; the present invention provides a process for resource utilization of waste medical salt at medium temperature pyrolysis. The principle is to use lower temperature to fully oxidize and decompose organic pollutants from the waste salt that has removed volatile substances, so as to achieve the purpose of harmless treatment of waste salt and then resource utilization; the invention adds an inorganic salt anti-caking agent, It can effectively prevent the waste salt from agglomerating in the fluidized bed reactor and ensure the sufficient oxidation and decomposition of organic pollutants, which is the key to the process; the waste salt obtained by the treatment method of medical waste salt of the present invention has extremely low organic residues and no agglomeration phenomenon. The organic matter is fully oxidized, and the energy saving is significantly reduced. The effective treatment of medical waste salt can not only protect the environment, but also reuse the main component sodium chloride salt to make up for the market gap, which has high economic value.

Owner:浙江红狮环保股份有限公司

Waste toluene recovery method in chemical production

InactiveCN105601461ASolve the problem of recycling and reusing in productionReduce pollutionHydrocarbon purification/separationHydrocarbonsRecovery methodDistillation

The present invention discloses a waste toluene recovery method in chemical production. The method comprises the steps of: A, adjusting the pH value of the waste toluene by acid to 2-4, and then stirring; B, adding deionized water, continuing stirring, washing, standing for stratification and extracting a supernatant; C, repeating the step B; and D, recovering toluene by distillation. The method of the present invention can sufficiently remove waste toluene impurities in chemical production, has simple operation and good effect, and solves the problems of waste toluene recycling and reuse in chemical production.

Owner:安徽泰格生物技术股份有限公司

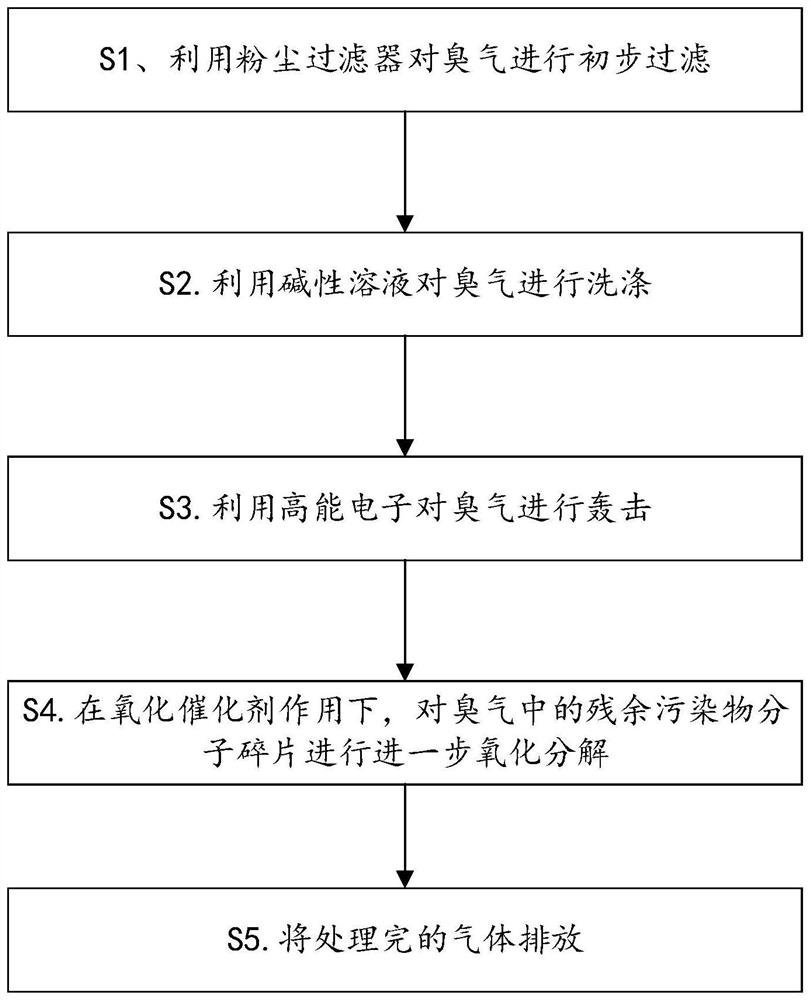

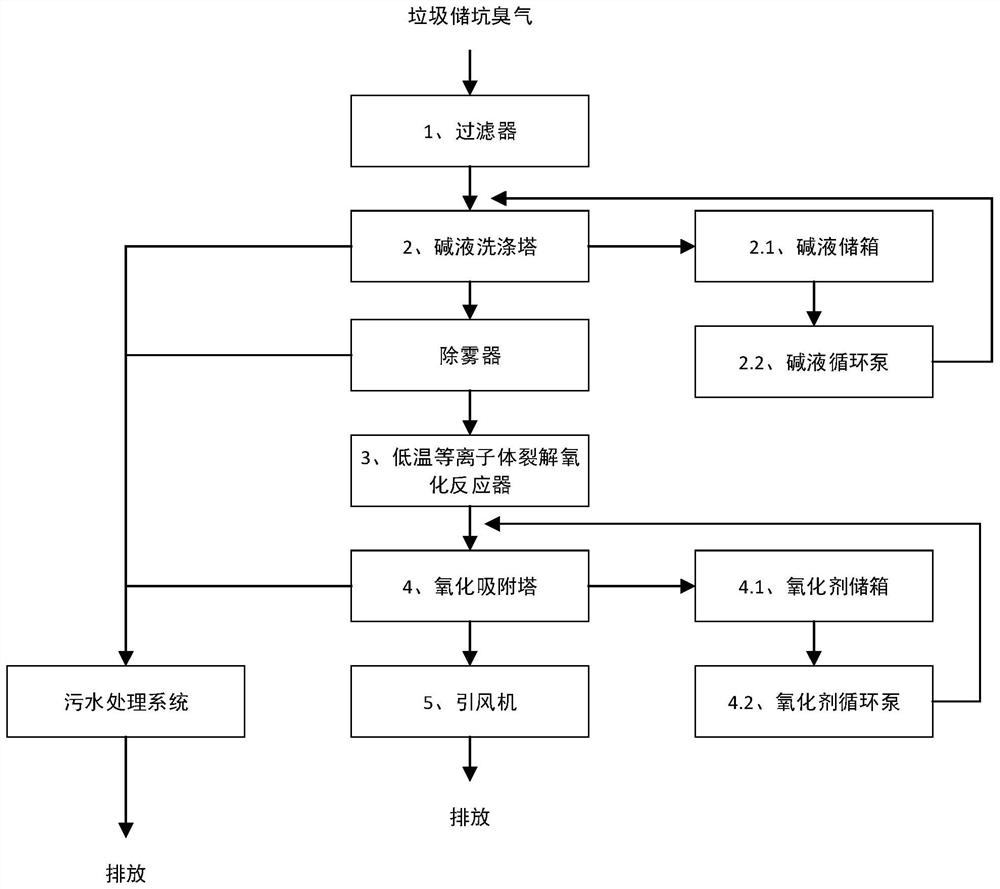

Garbage deodorization method and device

PendingCN113440996AImprove processing rateCompletely decompose and oxidizeCombination devicesPtru catalystWastewater

The invention discloses a garbage deodorization method. The garbage deodorization method comprises the following steps: S1, primarily filtering odor by using a dust filter; S2, washing the odor by using an alkaline solution to remove acidic substances and water-soluble gas components in the odor; S3, degrading pollutants with relatively high bond energy in the odor by utilizing high-energy electrons; S4, further oxidizing and decomposing residual molecular fragments of the pollutants in the odor under the action of an oxidation catalyst; and S5, discharging treated gas. The method has the advantages of good deodorization effect, low energy consumption, less generated wastewater and the like. The invention further discloses a garbage deodorization device.

Owner:烟台润达垃圾处理运营有限公司

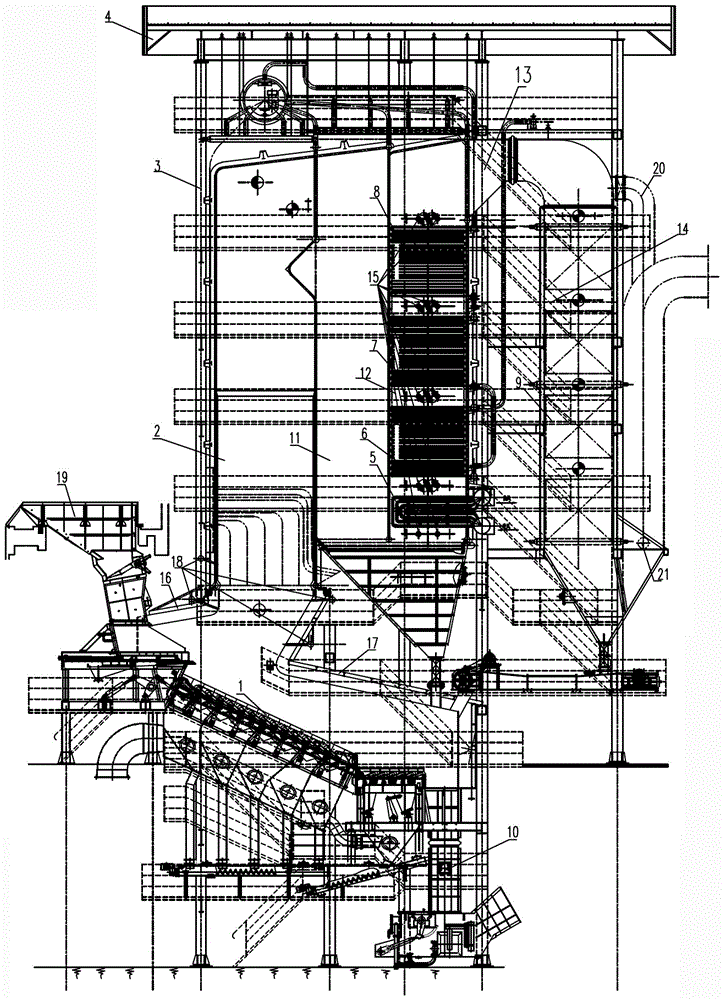

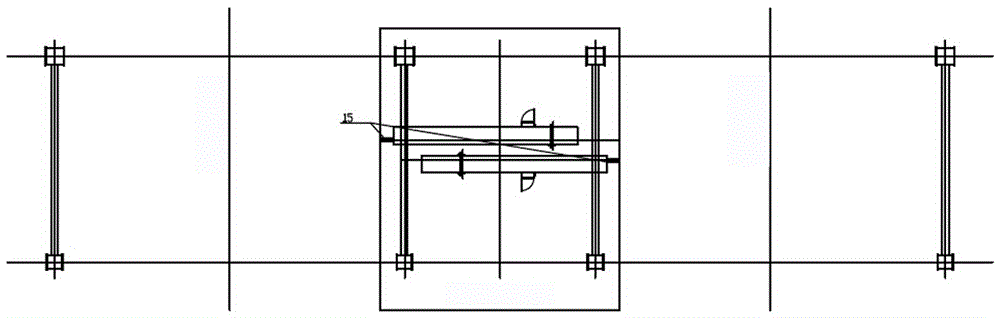

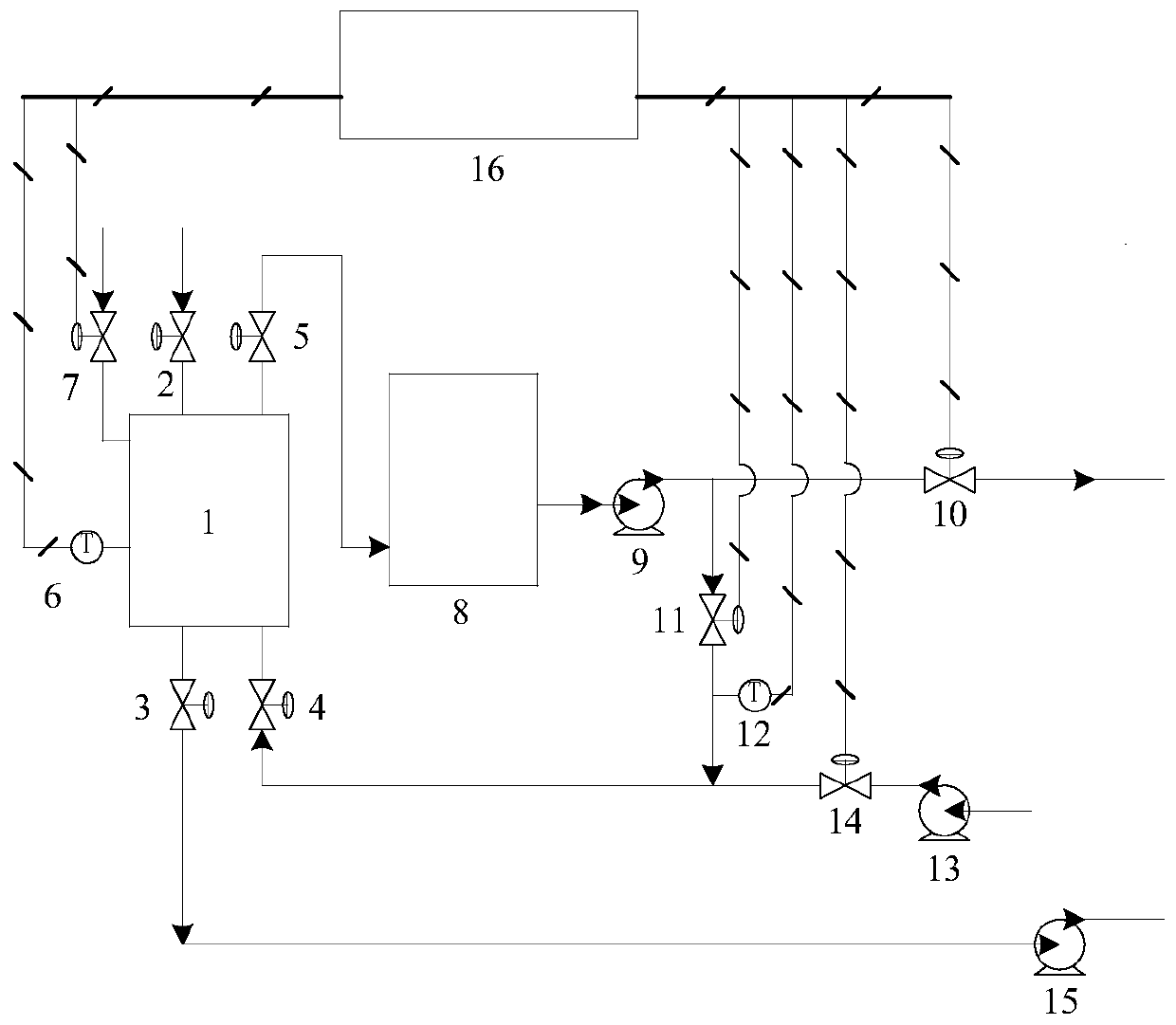

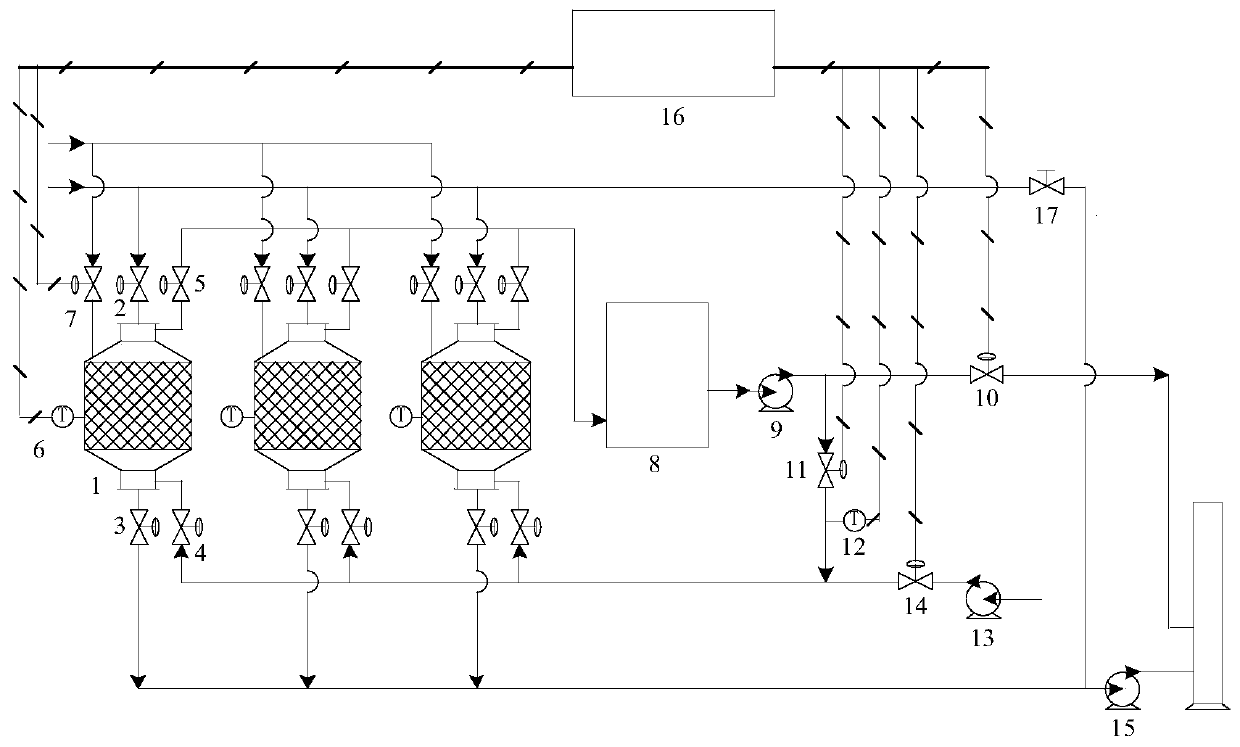

Straw and household garbage co-combustion boiler

InactiveCN105927987ASave spaceSave civil investmentSteam generation using pressureIndirect carbon-dioxide mitigationProcess engineeringSteel frame

The invention discloses a straw and household garbage co-combustion boiler arranged in a semi-outdoor manner. The straw and household garbage co-combustion boiler comprises a steel frame, a canopy, a boiler chamber, a feed device, a fire grate and a slag and ash discharge device, and is characterized in that the boiler chamber is installed on the steel frame; the canopy is directly borne on a top plate of the steel frame; the fire grate is arranged below the boiler chamber; the slag and ash discharge device is arranged on the lower portion of the fire grate; the boiler chamber is composed of a hearth, a burnout chamber and three flues; the connection flue and the tail flue are arranged behind the boiler chamber; and the boiler chamber, the connection flue and the tail flue form an n shape. The feed device is arranged at the front of the boiler chamber; the bypass flue is installed at the position of an inlet of the tail flue; and a smoke recirculation pipeline is arranged at the position of an outlet.

Owner:ZHEJIANG WEIMING ENVIRONMENT PROTECTION

Graded desorption method for volatile organic compound adsorbed active carbon

PendingCN111185142AHigh desorption rateAvoid problems exceeding emission standardsGas treatmentDispersed particle separationActivated carbonExhaust fumes

The invention discloses a graded desorption method for volatile organic compound adsorbed active carbon. The graded desorption method comprises the following steps: carrying out time-phased stepped heating desorption on the volatile organic compound adsorbed active carbon, and according to factors like types, concentrations and properties of volatile organic compounds in waste gas, determining thenumber of time periods and desorption temperature and time of each time period. According to the invention, active carbon is fully and thoroughly desorbed; meanwhile, the concentration of desorbed waste gas can be more balanced; the impact caused by large concentration change on a treatment system is avoided; and the problems of mismatching between a desorption process and a combustion process, incomplete desorption, large fluctuation of the concentration of the volatile organic compounds in desorbed gas, excessive exhaust and high operation and maintenance cost can be solved.

Owner:秦皇岛格瑞因环境工程有限公司

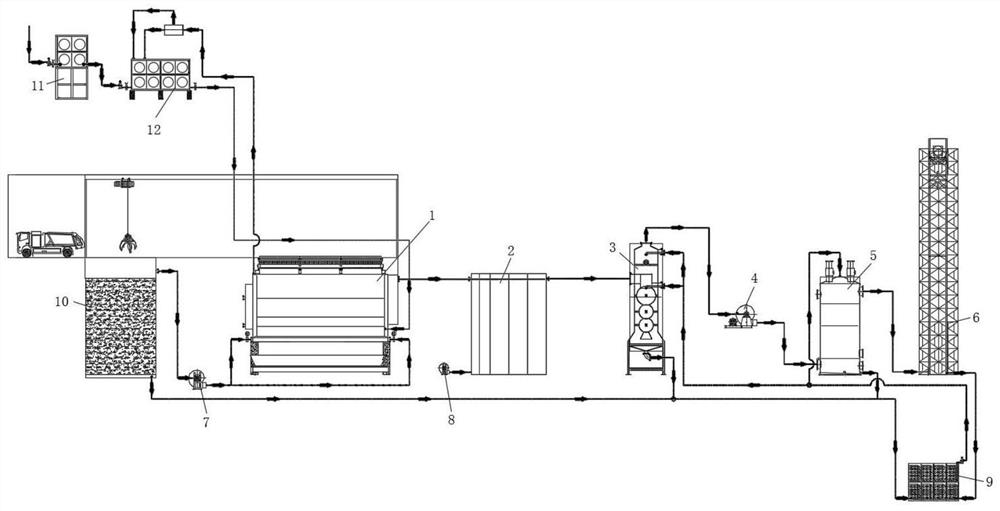

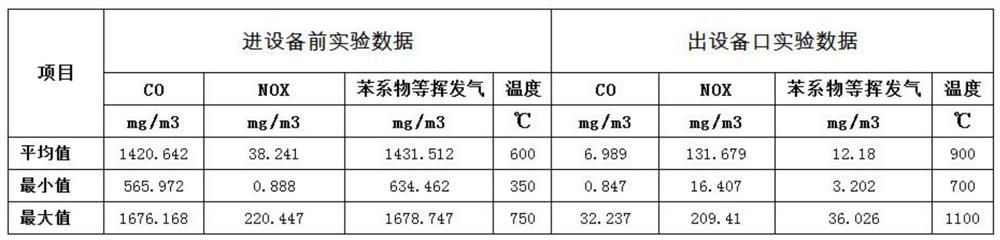

Household garbage pyrolysis gas carbonization treatment system and process thereof

PendingCN114350412AReduce contentReduce secondary generationDispersed particle separationIncinerator apparatusCarbonizationDust control

The invention discloses a household garbage pyrolysis gas carbonization treatment system and a process thereof, and relates to the technical field of household garbage treatment, the household garbage pyrolysis gas carbonization treatment system comprises a pyrolysis gas carbonization device, a turning type multi-stage rotational flow oxidation chamber, a reverse type uniform rotational flow purification device, a low-temperature plasma dust removal device and a chimney. The device is scientific in design and reasonable in process, waste gas generated by garbage combustion in the process of preparing a large amount of household garbage can be fully oxidized, decomposed, combusted and completely utilized, combustion tail gas meets the emission standard, the content of sulfur dioxide, nitric oxide, carbon monoxide and nitride in the tail gas can be greatly reduced, and the environment is protected. Secondary generation of dioxin is reduced, and the difficult problem that tail gas reaches the standard in the household garbage gas carbonization process in the prior art and the problem that pipelines in the whole treatment system are blocked by tar in the technical field can be solved.

Owner:湖南未名环保科技有限公司

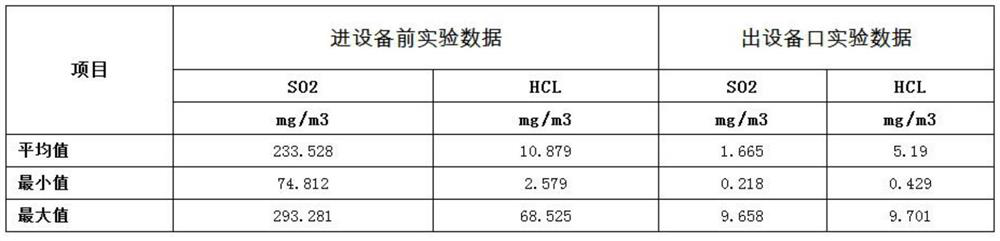

High-concentration cymoxanil wastewater treatment system and method

InactiveCN113087250AFully oxidative decompositionEasy to handleWater contaminantsWater/sewage treatmentPtru catalystTreatment system

The invention provides a high-concentration cymoxanil wastewater treatment system and a high-concentration cymoxanil wastewater treatment method using the system. The system comprises a cymoxanil wastewater oxidizer, a micro-interface generator, an evaporation unit and the like; oxygen is broken through a micro-interface generator to form micron-sized bubbles, the micron-sized bubbles have physicochemical properties which conventional bubbles do not have, and it can be known from a calculation formula of the volume and the surface area of a sphere that the total surface area of the bubbles is inversely proportional to the diameter of a single bubble under the condition that the total volume is not changed; therefore, the total surface area of the micron-sized bubbles is huge, so that the micron-sized bubbles are mixed with the cymoxanil wastewater to form a gas-liquid mixture, the contact area of a gas phase and a liquid phase is increased, the cymoxanil wastewater is fully oxidized and decomposed under a relatively low preset condition, the treatment effect of the high-concentration cymoxanil wastewater is optimized, meanwhile, as no catalyst is used, the treatment cost of the high-concentration cymoxanil wastewater is reduced.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

A batching machine for rare earth ore powder and hydrochloric acid

ActiveCN108330280BNo wasted effectFully oxidative decompositionProcess efficiency improvementDecompositionMetallurgy

The invention relates to a material mixing machine, in particular to a material mixing machine for rare earth ore powder and hydrochloric acid. The material mixing machine for the rare earth ore powder and the hydrochloric acid aims to achieve the technical effects that manual feeding of the hydrochloric acid is not needed, the decomposition rate can be improved, and waste of the hydrochloric acidis avoided. The material mixing machine for the rare earth ore powder and the hydrochloric acid comprises an installation frame, a box, a discharging pipe, a valve, a support rod, a servo motor, a sector gear and the like. The box is installed in the middle of the inner wall of the lower side of the installation frame. The discharging pipe is connected with the lower portion of the left wall of the box. The discharging pipe penetrates through the left portion of the lower wall of the installation frame. The material mixing machine for the rare earth ore powder and the hydrochloric acid achieves the technical effects that manual feeding of the hydrochloric acid is not needed, the decomposition rate can be improved, and waste of the hydrochloric acid is avoided. Through the arrangement of acylinder block and a piston, hydrochloric acid liquid flows into the box intermittently, so that the rare earth powder can be fully oxidized and decomposed, and the effect of improving the decomposing efficiency is achieved.

Owner:嘉兴华雯化工股份有限公司

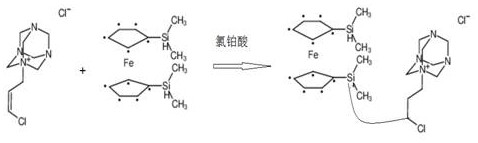

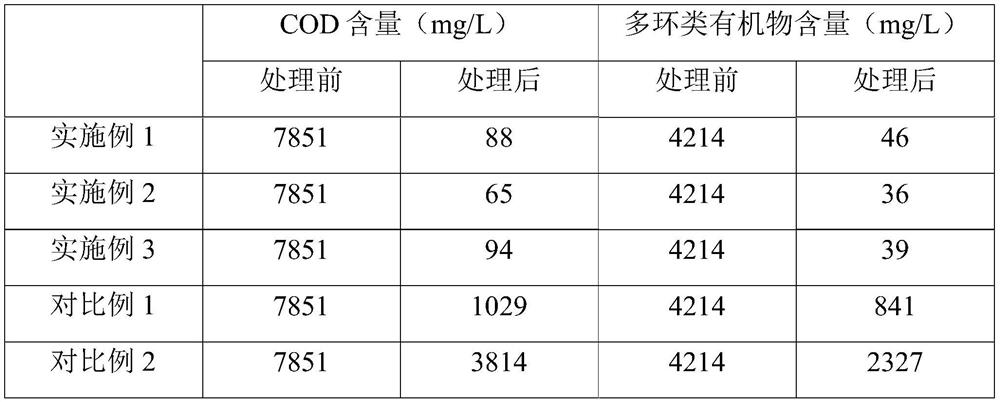

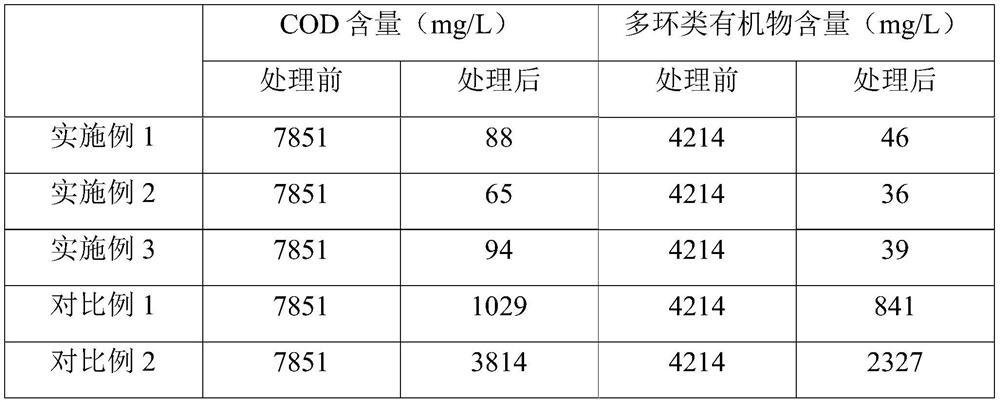

Composition for degrading polycyclic organic matter as well as preparation method and application of composition

ActiveCN112960778AHigh activityIncreased degradation rateWater treatment parameter controlTreatment using aerobic processesPetrochemicalPseudomonas

The invention relates to the technical field of organic pollutant treatment, and particularly discloses a composition for degrading polycyclic organic matter as well as a preparation method and application of the composition. The composition for degrading the polycyclic organic matter comprises biomass charcoal, ferric salt, compound microorganisms, sodium alginate and calcium phosphate, wherein the compound microorganisms comprise bacillus subtilis, pseudomonas and serratia marcescens. The composition for degrading the polycyclic organic matter, provided by the invention, can efficiently degrade the polycyclic organic matter which are difficult to degrade in wastewater, is wide in raw material source, low in cost, free of toxic chemical components and free of secondary pollution, particularly has an excellent treatment effect on petrochemical engineering and coking wastewater, has extremely high application value in the field of wastewater treatment.

Owner:吴奇桐

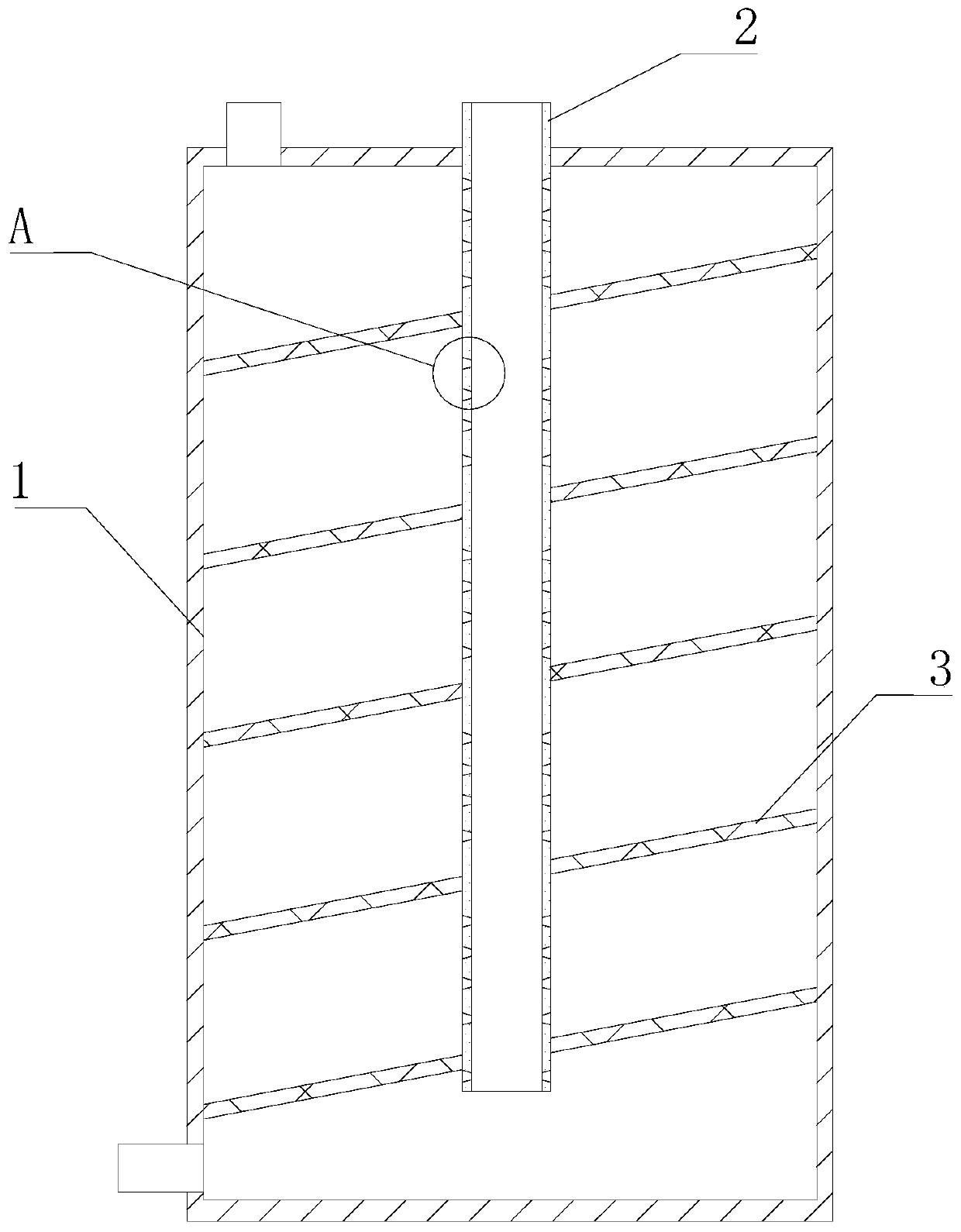

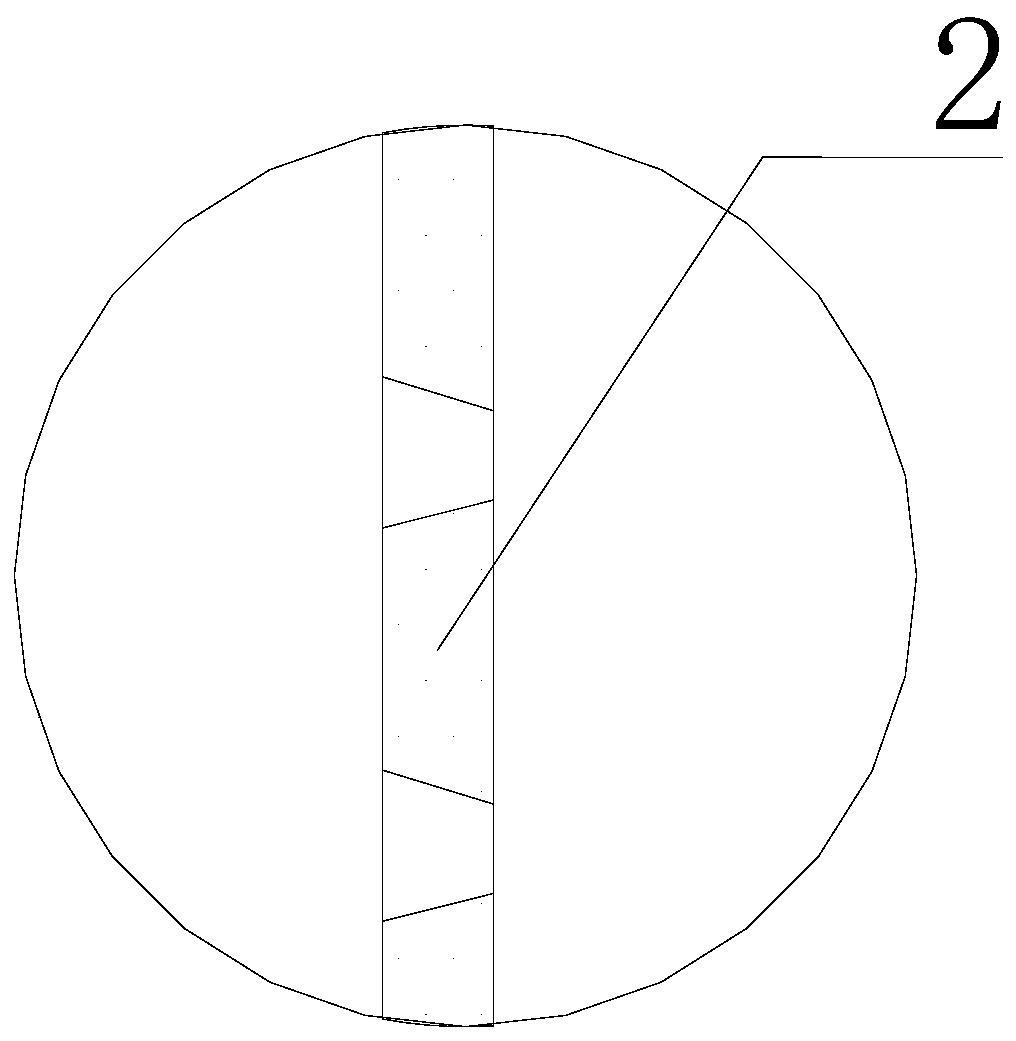

Mixer and high-temperature flue gas treatment device with same

InactiveCN111036104AIncrease contact timeIncrease contact areaGas treatmentFlow mixersEngineeringFlue gas

The invention provides a mixer and a high-temperature flue gas treatment device with the same. The mixer comprises a shell and an isolation column, wherein a first gas inlet connected with a first gassource is formed in the bottom of the shell, a gas outlet is formed in the top of the shell, the isolation column is of a vertically-through hollow structure, one end of the isolation column penetrates through the shell and extends into the shell, a second gas inlet connected with a second gas source is formed in the other end of the isolation column, a plurality of through holes are formed in the isolation column located in the shell, a partition plate spirally wound around the isolation column is arranged in the shell, the inner end of the partition plate is in sealed connection with the isolation column, the outer end of the partition plate is in sealed connection with the inner wall of the shell, the partition plate divides the interior of the shell to form a spiral runner, the bottomend of the spiral runner communicates with the gas inlet, and the top end of the spiral runner communicates with the gas outlet. The contact area and the contact time of the first gas and the secondgas can be effectively increased, so that the second gas is in full contact with the first gas.

Owner:安徽微宇仪器科技有限公司

Smoldering type household waste incineration treatment device and use method thereof

ActiveCN107893997AReduce contentFully oxidative decompositionIncinerator apparatusExhaust gasFlue gas

The invention discloses a smoldering type household waste incineration treatment device and a use method thereof. The smoldering type household waste incineration treatment device comprises an incinerator and a tail gas treatment device communicating with the incinerator. The smoldering type household waste incineration treatment device has the beneficial effects that by the matching of an inner incinerator body and an outer incinerator body, intermittent oxygen supply is adopted, and gas for sustained combustion can be accessed to the inner incinerator body simply when a through hole communicates with a feeding channel, an air inlet channel and a smoke vent, so that the combustion of the inner incinerator body is kept in a smothering stage, fuel consumption and the content of nitrogen oxide in flue gas are reduced; the inner incinerator body, at a set rotational speed, allows air to be fully contacted and mixed with waste and allows the air to be fully contacted and mixed with the flue gas and the disturbance is full, so that noxious substances are subjected to oxygenolysis in a short time; large grain impurities and an irritation smell in the exhausted flue gas are filtered through a filter screen and a deodorization layer, and finally the raising flue gas is subjected to spraying desulfurization by employing a spray head, thus dedusting, deodorization and desulfurization treatment on the flue gas are completed.

Owner:铜陵市宏达家电有限责任公司

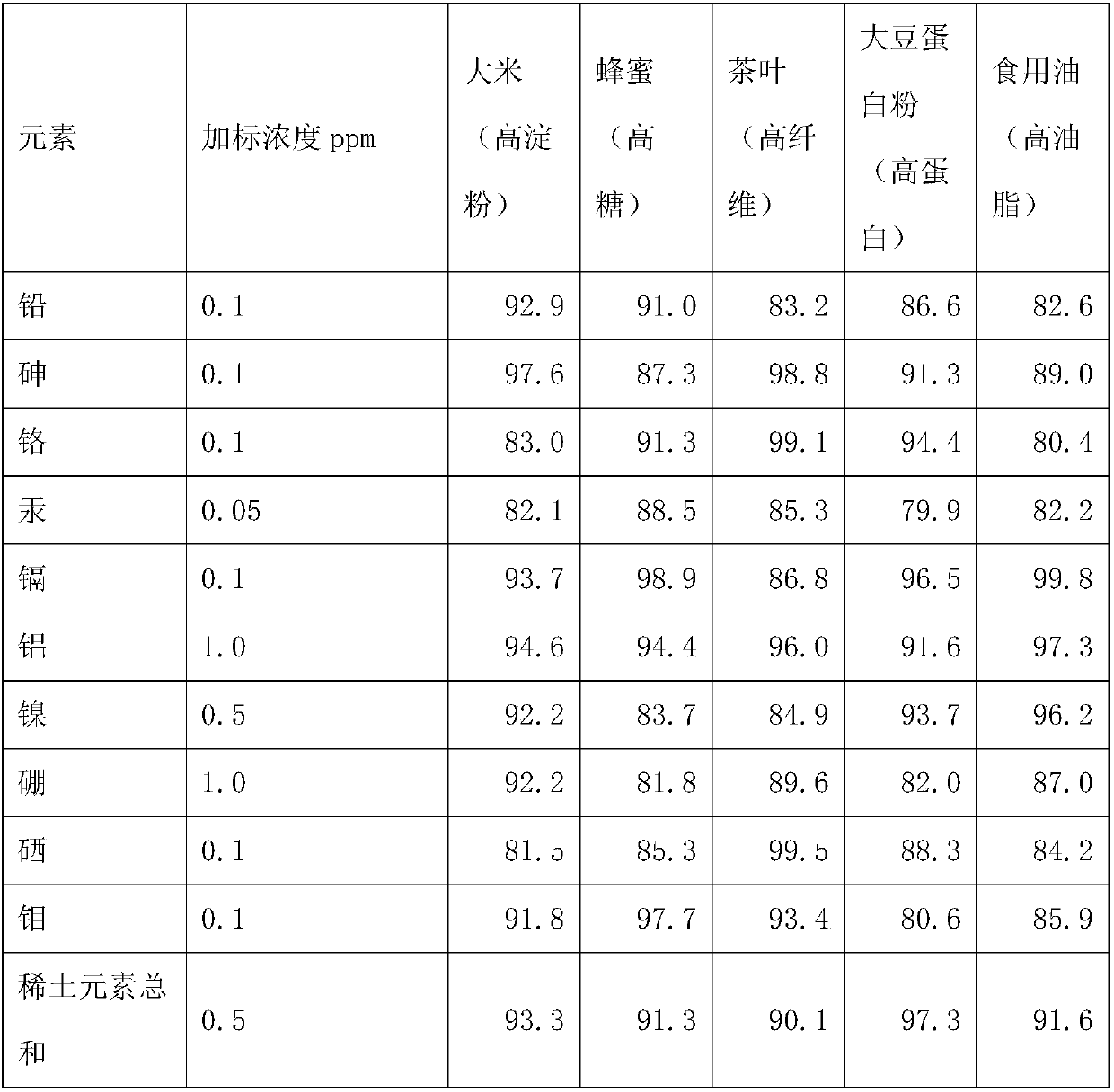

High-throughput super microwave digestion pretreatment method for analyzing multi-element content in food based on icpms and icpoes

ActiveCN107367423BEliminate the acid rinsing stepFully oxidative decompositionPreparing sample for investigationAnalysis by thermal excitationPretreatment methodHigh flux

Owner:GUANGZHOU INSPECTION TESTING & CERTIFICATION GRP CO LTD

An ionic wind -driven air purifier that can handle multiple pollutants

ActiveCN106765566BSpeed up the flowImprove dust removal effectHuman health protectionMechanical apparatusWind drivenElectrical conductor

The invention discloses an ion wind driven air purifier capable of synchronously processing various pollutants, comprising a physical filtering device, a low temperature plasma generating device and an ion wind power device. The physical filtration device adopts conductor mesh, coarse filter mesh, high-efficiency filter mesh and activated carbon filter mesh for physical filtration. The present invention adopts ion pump charging acceleration zone, Low-temperature plasma discharge is carried out around the electrocoagulation device, electrostatic precipitator and oxidation device and anti-corona catalytic zone while targeting fine particulate matter PM 2.5 , microbial aerosols and VOCs, CO, NH 3 and other toxic gaseous pollutants for integrated purification, which can efficiently capture fine particulate matter PM 2.5 , inactivate microbial aerosols, and at the same time deeply oxidize VOCs, CO, NH 3 It is a multi-pollutant compound purification technology that integrates oxidation and oxidation to improve the indoor air purification effect.

Owner:ZHEJIANG UNIV

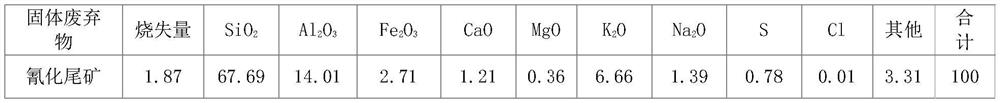

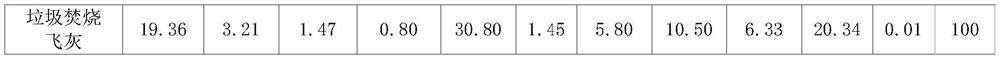

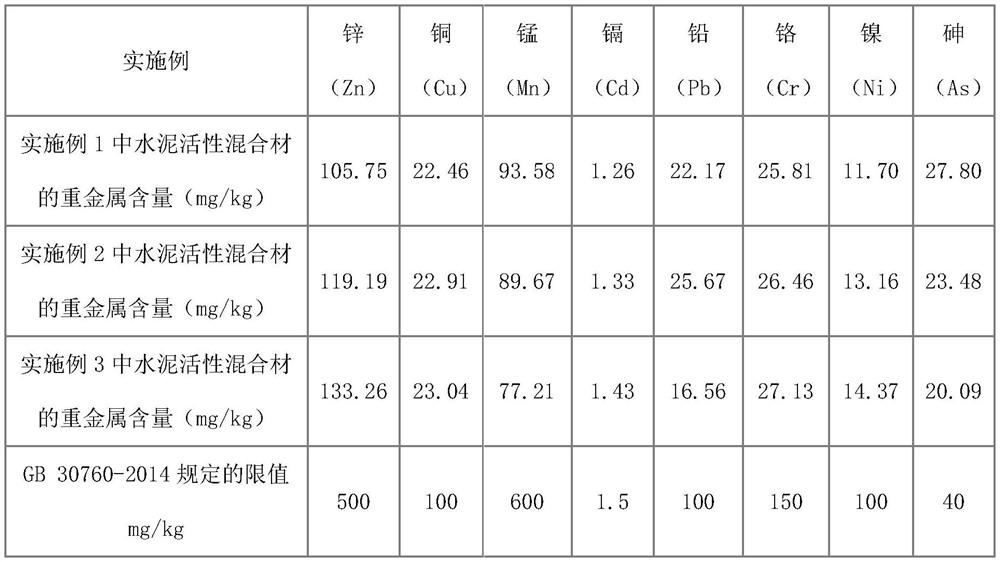

Cement active mixed material prepared from waste incineration fly ash and cyanidation tailings and preparation method of cement active mixed material

PendingCN114804676AFully oxidative decompositionLeaching meetsCement productionIncinerationSocial benefits

The invention discloses a cement active mixed material prepared from waste incineration fly ash and cyanidation tailings and a preparation method thereof.The preparation method comprises the steps that the waste incineration fly ash and the cyanidation tailings are compounded according to a proper proportion to be prepared into granules with the proper size, the granules are sintered in a sintering furnace at the high temperature of 1,100 DEG C or above and quenched to obtain a sintered body, then the sintered body is ground to a certain fineness, and the cement active mixed material is obtained. The problem that the environment is polluted by the waste incineration fly ash and the cyanidation tailings is solved, the complementary and synergistic effects of the two components are utilized, bulk resource utilization of the two solid wastes is achieved, the stable source of the cement active admixture is expanded, and the cement production cost is reduced. The method has remarkable economic benefits, environmental benefits and social benefits.

Owner:BEIJING JINYU MANGROVE ENVIRONMENTAL PROTECTION TECH +1

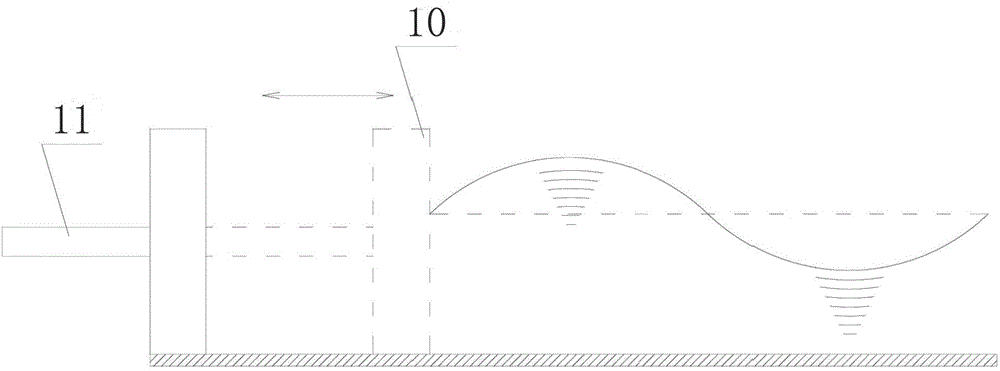

A kind of 1,2-dichloropropane separation system and its separation process

InactiveCN104671332BGood removal effectImprove processing efficiencyWater contaminantsWater/sewage treatment with mechanical oscillationsDichloropropane1,2-Dichloropropane

The invention discloses a 1,2-dichloropropane separation system and separation technique. The separation system comprises a bottom with vibration surge tanks and a top with a nozzle head, wherein a water channel is divided into the plurality of vibration surge tanks by the tank body. The separation technique is implemented in a way that: under the action of the vibration surge tanks, 1,2-dichloropropane-containing underground water flows according to a S-shaped route; the reflux quantity is controlled at 80 m<3> / minute, the water level is controlled at 80cm, the vibration surge period is controlled at 20 times / minute, and the vibration surge plate stroke is controlled at 600mm; and a continuous spray mode is adopted. The separation technique has the characteristics of high environment friendliness, high resource utilization ratio, high treatment effect and high impact resistance, and implements full-automatic control.

Owner:XUZHOU UNIV OF TECH

Smoldering domestic waste incineration treatment device and using method thereof

ActiveCN107893997BReduce contentFully oxidative decompositionIncinerator apparatusInlet channelCombustion

The invention discloses a smoldering type household waste incineration treatment device and a use method thereof. The smoldering type household waste incineration treatment device comprises an incinerator and a tail gas treatment device communicating with the incinerator. The smoldering type household waste incineration treatment device has the beneficial effects that by the matching of an inner incinerator body and an outer incinerator body, intermittent oxygen supply is adopted, and gas for sustained combustion can be accessed to the inner incinerator body simply when a through hole communicates with a feeding channel, an air inlet channel and a smoke vent, so that the combustion of the inner incinerator body is kept in a smothering stage, fuel consumption and the content of nitrogen oxide in flue gas are reduced; the inner incinerator body, at a set rotational speed, allows air to be fully contacted and mixed with waste and allows the air to be fully contacted and mixed with the flue gas and the disturbance is full, so that noxious substances are subjected to oxygenolysis in a short time; large grain impurities and an irritation smell in the exhausted flue gas are filtered through a filter screen and a deodorization layer, and finally the raising flue gas is subjected to spraying desulfurization by employing a spray head, thus dedusting, deodorization and desulfurization treatment on the flue gas are completed.

Owner:铜陵市宏达家电有限责任公司

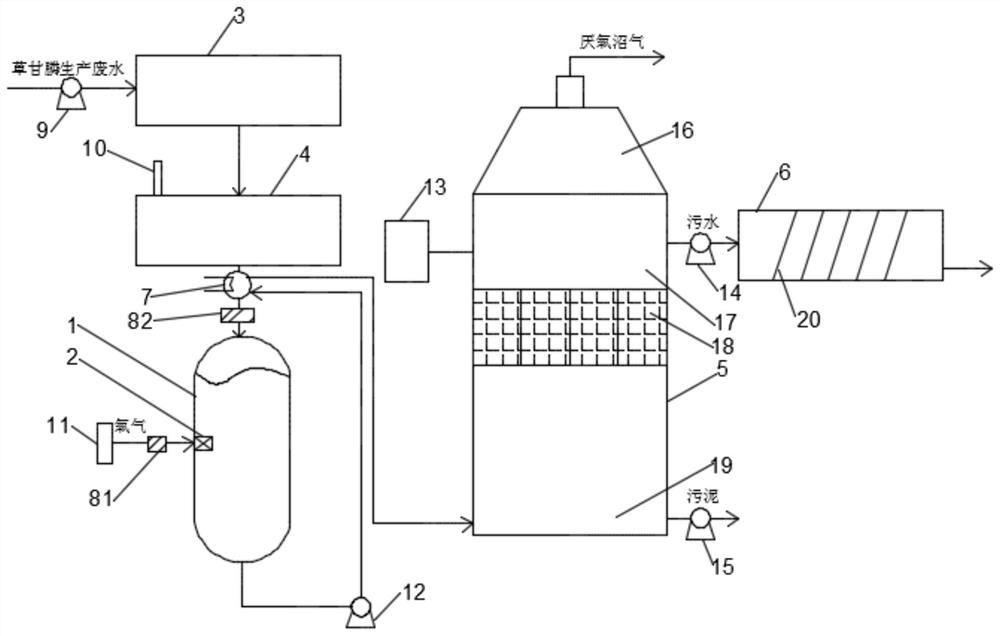

Glyphosate production wastewater treatment system and method

PendingCN113087280AIncrease contact areaReduce the difficulty of industrializationWater treatment parameter controlWater contaminantsEnvironmental chemistryGliphosate

The invention provides a glyphosate production wastewater treatment system and a glyphosate production wastewater treatment method using the system. The glyphosate production wastewater treatment system comprises a glyphosate wastewater oxidizer, a micro-interface generator, a primary filtration sedimentation tank and the like; oxygen is broken through a micro-interface generator to form micron-sized bubbles, the micron-sized bubbles have physicochemical properties which conventional bubbles do not have, and it can be known from a calculation formula of the volume and the surface area of the sphere that the total surface area of the bubbles is inversely proportional to the diameter of a single bubble under the condition that the total volume is not changed; therefore, the total surface area of the micron-sized bubbles is huge, so that the micron-sized bubbles are mixed with the glyphosate wastewater to form a gas-liquid mixture, the contact area of the gas phase and the liquid phase is increased, the glyphosate wastewater is fully oxidized and decomposed under a relatively low preset condition, and the industrialization difficulty of glyphosate production wastewater treatment is effectively reduced.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

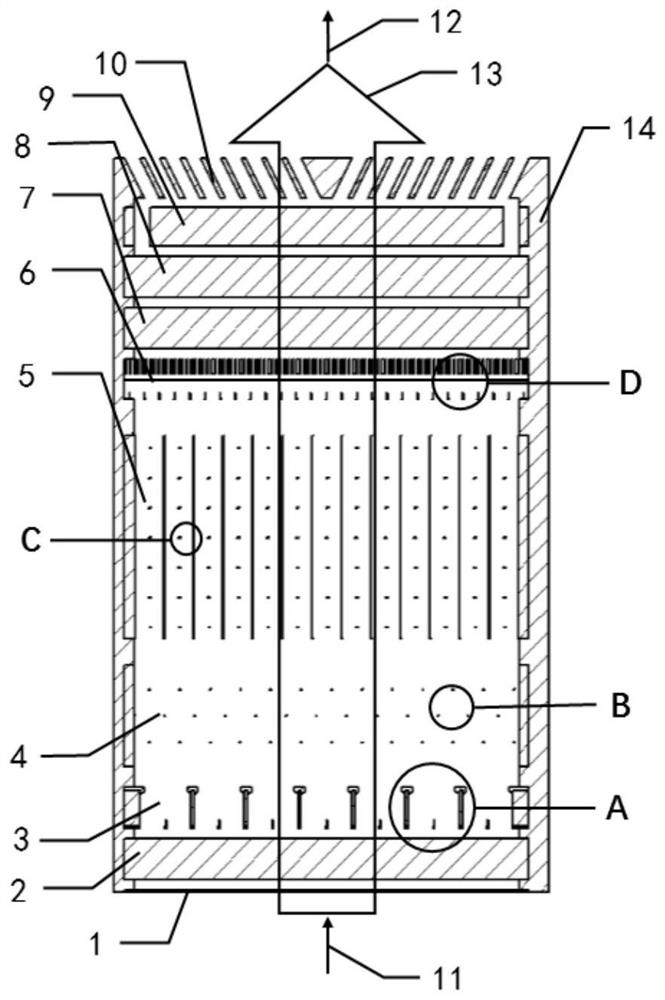

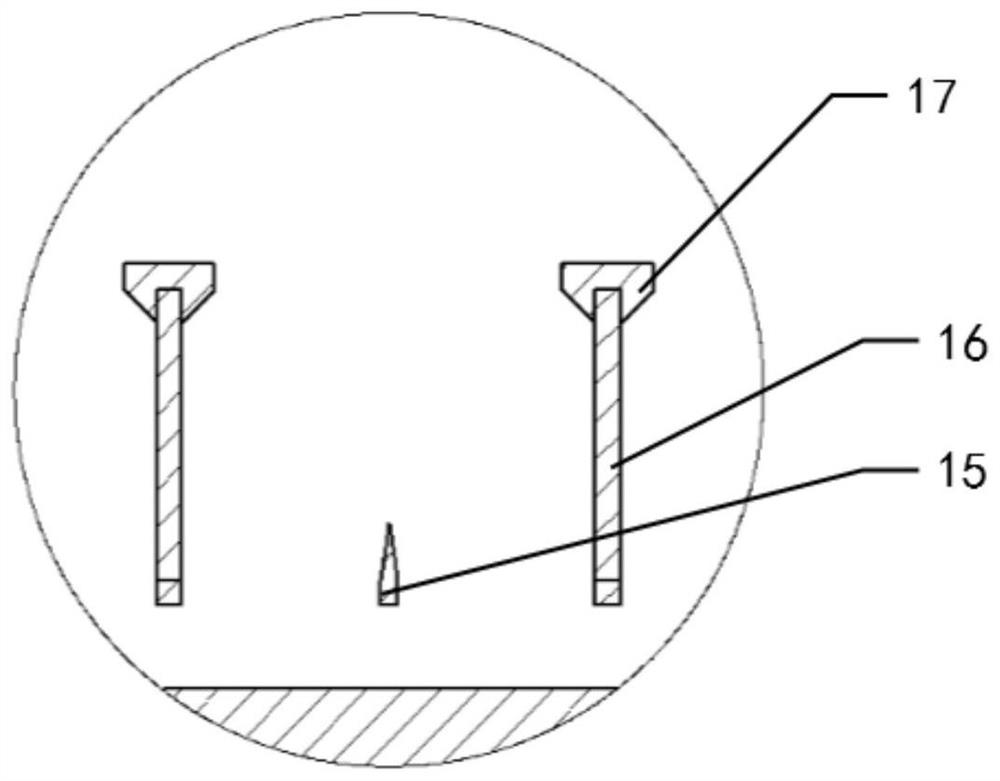

Industrial waste gas treatment system and treatment method

InactiveCN108159882ASufficient adsorption and filtrationFully oxidative decompositionGas treatmentDispersed particle filtrationIndustrial gasHazardous substance

The invention discloses an industrial waste gas treatment system. The industrial waste gas treatment system comprises a bottom plate, wherein the top part of the bottom plate is fixedly connected witha box body; a protection cover is arranged at the top of the bottom plate and is fixedly connected with one side of the box body; a first separation plate and a second separation plate are fixedly connected between two sides of an inner wall of the box body in sequence from top to bottom; the bottom part of the inner wall of the box body is rotatably connected with a stirring shaft through a bearing seat; the top end of the stirring shaft penetrates through the second separation plate and extends to the top part of the second separation plate; the stirring shaft extends to the outer surface of the second separation plate and a stirring head sleeves the outer surface of the stirring shaft. The industrial waste gas treatment system relates to the technical field of industrial waste gas treatment. According to the industrial waste gas treatment system and method, disclosed by the invention, the treatment effect is greatly enhanced and the aim of carrying out multi-grade comprehensive treatment on industrial waste gas is realized, and solid particles, harmful substances and organic gas in the industrial waste gas are completely treated in a graded flow manner, and a condition that pollution to an external air environment is caused by the industrial waste gas is avoided very well.

Owner:车继鲁

Wastewater treatment device

InactiveCN110981042AImprove oxidative decomposition efficiencyImprove processing efficiencyWater contaminantsWater/sewage treatment bu osmosis/dialysisElectrolysisSewage outfall

The invention provides a wastewater treatment device and belongs to the field of wastewater treatment. The problems that a precipitate after electrolysis cannot be directly separated from water in anexisting electrochemical wastewater treatment device and a next procedure needs to be carried out for precipitation separation and the like are solved. The wastewater treatment device comprises a shell and an electrolysis device, the electrolysis device comprises cathode and anode pieces and a control device connected with the cathode and anode pieces; the cathode piece and the anode piece are positioned in the shell; a water inlet is formed in a bottom of the shell; the water inlet is provided with a valve, a top of the shell is provided with a filter membrane and an overflow port, the filtermembrane is used for filtering sediments, filtered water flows out of the overflow port, a bottom of the shell is provided with a drain outlet for discharging the sediments, the drain outlet is provided with a timing electromagnetic valve, and an aeration device is further arranged in the shell and used for aerating wastewater. The wastewater treatment device has the advantages that the precipitated and treated water is directly separated through the filter membrane and the like.

Owner:江西鑫隆泰建材工业有限公司 +1

Composition for degrading polycyclic organic compounds and its preparation method and application

ActiveCN112960778BHigh activityIncreased degradation rateWater treatment parameter controlTreatment using aerobic processesSerratiaIron salts

Owner:吴奇桐

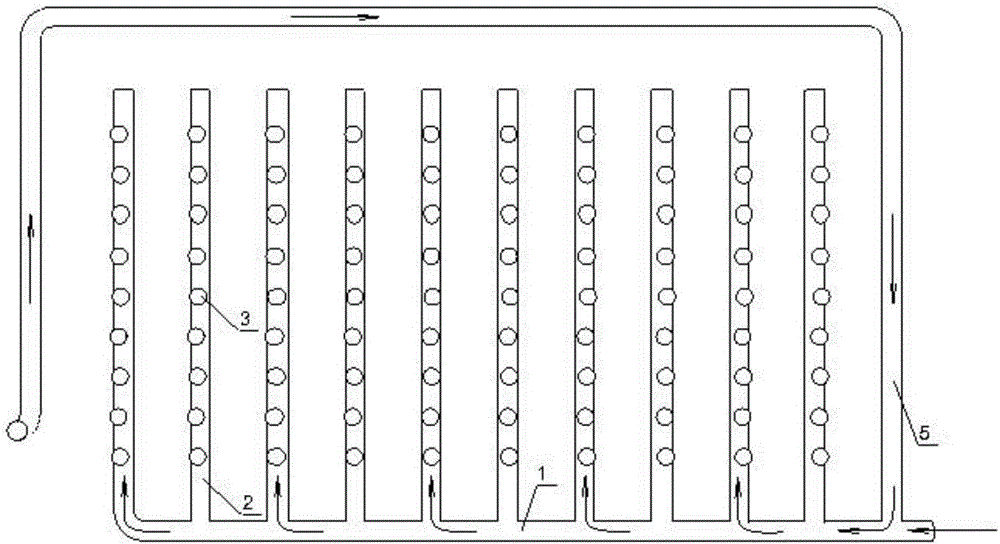

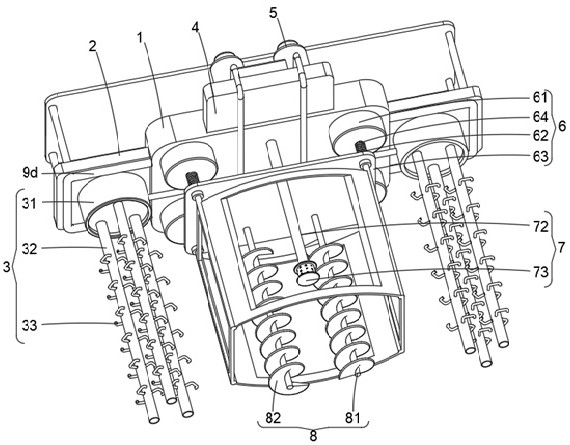

Riverway oxygenation device and oxygenation method thereof

PendingCN112047501AIncrease dissolved oxygenEnhanced mixed contactSpecific water treatment objectivesWater aerationMicroorganismRiver routing

The invention provides a riverway oxygenation device and an oxygenation method thereof. The riverway oxygenation device comprises a floating platform, oxygen injection mechanisms, a sterilization mechanism and an oxygen dissolving mechanism, installation floating plates are fixedly installed on the two sides of the floating platform, a bearing plate is installed on the rear end face of the floating platform, and the floating platform, the installation floating plates and the installation floating plates form a riverway oxygenation base station. One oxygen injection mechanism used for increasing the oxygen content of water liquid in a river channel is installed at the bottom of each installation floating plate, the sterilization mechanism used for reducing the microorganism content of riverwater is installed at the bottom of the floating platform, and the oxygen dissolving mechanism used for increasing the dissolved oxygen content of the water liquid in the river channel is installed at the bottom of the floating platform. The riverway oxygenation device and the oxygenation method thereof have the advantages that the mixing contact area of air and water is increased, and the stability is good.

Owner:陈俭军

High-efficiency energy-efficient fuel additive

The invention provides a high-efficiency energy-efficient fuel additive. The high-efficiency energy-efficient fuel additive comprises benzene residues, sodium chloride, potassium permanganate, rare earth chloride, and calcium carbonate or sodium carbonate in a weight ratio of (4.7-6): (3-4.5): 0.5: 0.5: (3-5). The additive provided by the invention has the advantages of fast fire ignition, long combustion time, little slag, no smoke, no irritant gases, great caloric power, etc.; and the additive allows a coal usage amount (in terms of raw coal) to be reduced by 40% or more, so obvious benefitbenefits are produced.

Owner:绵阳双甘科技有限公司

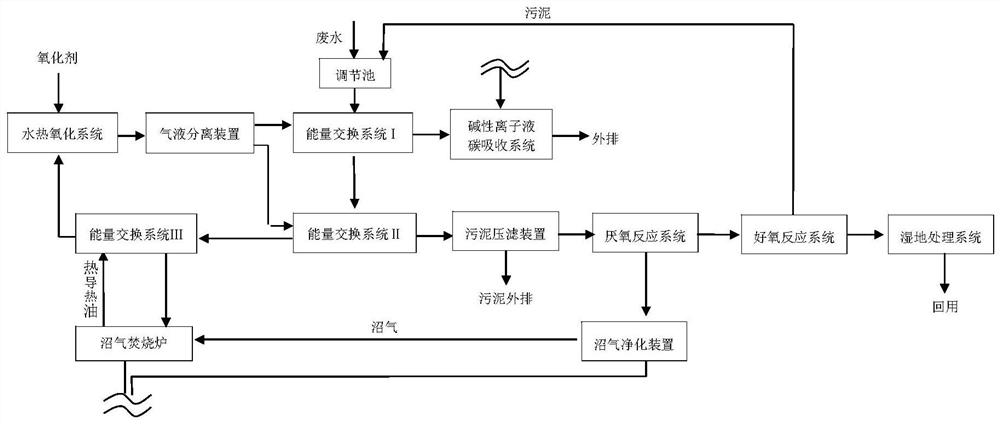

Low-carbon treatment system for high-concentration organic wastewater and method thereof

PendingCN113024038AResidue reductionReduce consumptionSludge treatment by de-watering/drying/thickeningWater treatment parameter controlProcess engineeringEnergy exchange

The invention discloses a low-carbon treatment system and method for high-concentration organic wastewater. The low-carbon treatment system comprises an adjusting tank, an inner pipe of an energy exchange system I, an inner pipe of an energy exchange system II, an inner pipe of an energy exchange system III, a hydrothermal oxidation system, a gas-liquid separation device, an outer pipe of the energy exchange system II, a sludge filter pressing device, an anaerobic reaction system, an aerobic reaction system and a wetland treatment system which are sequentially connected through a liquid pipeline, and finally, discharging to outside is achieved. The gas pipeline is sequentially connected with the hydrothermal oxidation system, the gas-liquid separation device, an outer pipe of the energy exchange system I and an alkaline ionic liquid carbon absorption system, and finally, the discharging to outside is achieved. The gas generated by the anaerobic reaction system is sequentially connected with the biogas purification device, the biogas incinerator and the alkaline ionic liquid absorption system through pipelines, and finally, the discharging to outside is achieved. The sludge generated by the aerobic reaction system flows back to the adjusting tank through a pumping pipeline; and the heat conduction oil circulates between the biogas incinerator and the outer pipe of the energy exchange system III through the pipeline.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com