1,2-dichloropropane separation system and separation technique

A dichloropropane and separation system technology, which is applied in heating water/sewage treatment, polluted groundwater/leachate treatment, mechanical oscillation water/sewage treatment, etc., can solve the problem of poor pollutant treatment effect and high energy consumption of equipment , complex geological structure and other issues, to achieve the effects of increasing contact time, high treatment efficiency, and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

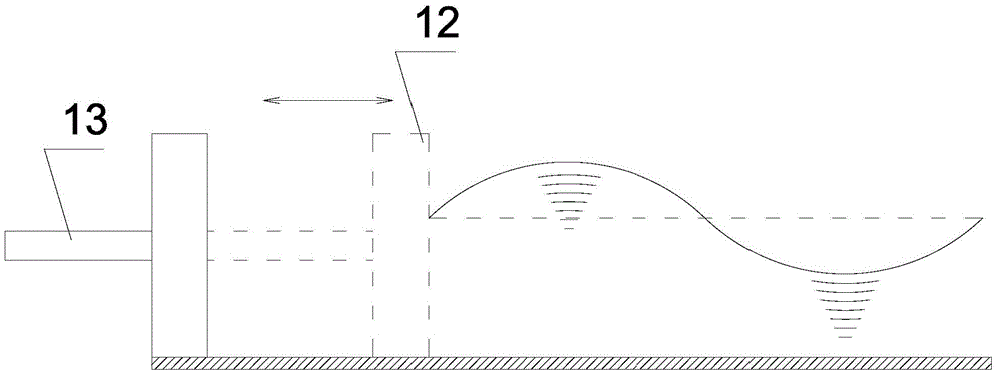

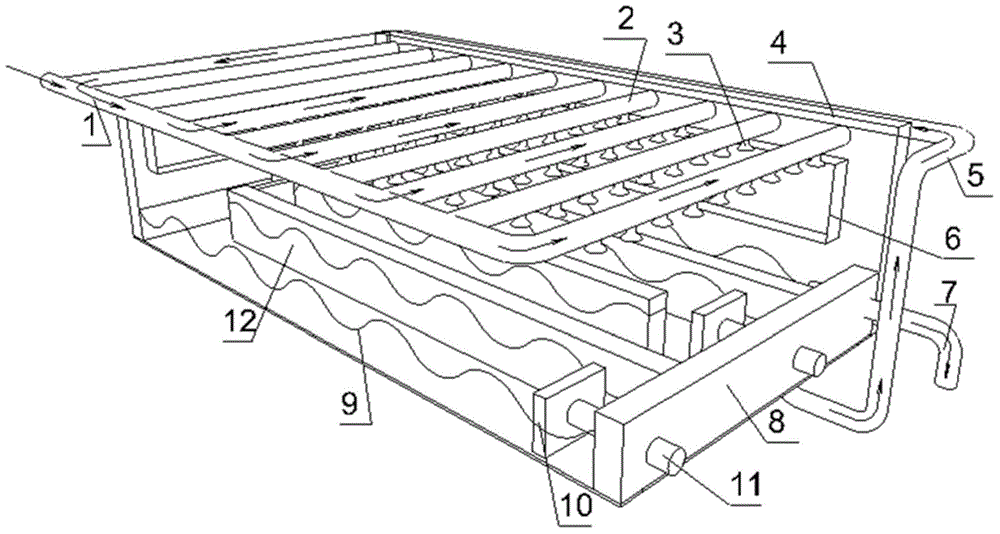

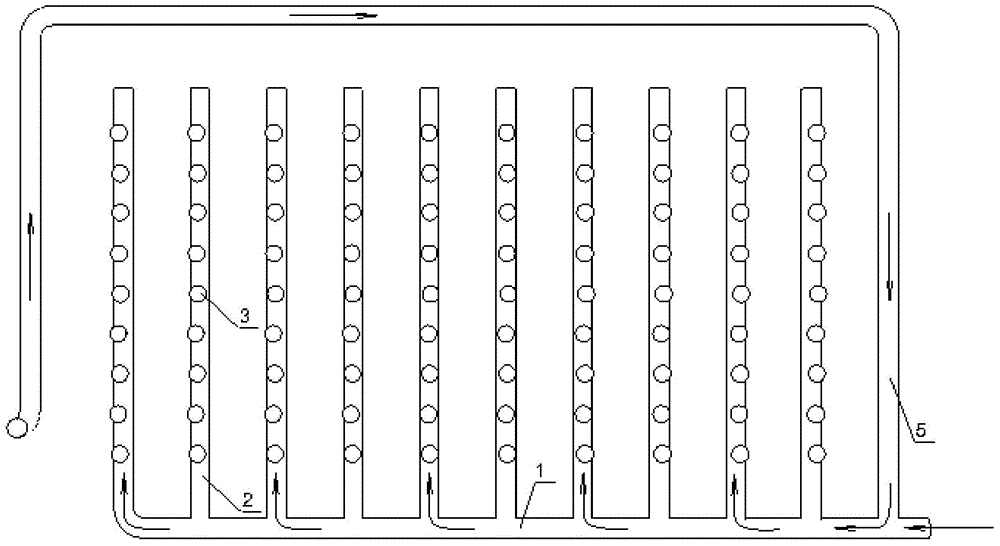

[0051] Such as figure 2 As shown, the three-dimensional schematic diagram of the 1,2-dichloropropane treatment system provided by the present invention can be seen, including the bottom containing the shock surge pool 8 and the top with the spray nozzle 3, wherein the inside of the shock surge pool 8 The installation is divided into multiple oscillating surge corridors by multiple partitions 12, and the multiple oscillating surge corridors are arranged in parallel and misplaced, and connected from head to tail to form an S-shaped channel. One end of each oscillating surge channel is provided with an oscillating surge device, which is composed of a oscillating surge plate 10 and a reciprocating rod 11 slidingly connected; Water outlet pipe 7 is provided.

[0052] The top spray system is connected with the bottom oscillating surge pool 8 through the return pipe 5 arranged on the side of the outlet pipe 7 at the bottom of the oscillating surge pool 8, and the water that reaches...

Embodiment 2

[0067] In order to test the rationality of the design and make it achieve the best treatment effect, the 1,2-dichloropropane removal rate test and the influencing factors were carried out through the above 1,2-dichloropropane separation system. The test results are as follows:

[0068] 1. The effect of the stroke of the oscillating surge plate on the removal of 1,2-dichloropropane

[0069] In the simulated 1,2-dichloropropane separation system, add 1,2-dichloropropane at a concentration of 100 μg / L, control the stroke of the oscillating surge plate in the simulated system to 400mm, 500mm, and 600mm, and record the travel conditions of each oscillating surge plate, 1 , 2-dichloropropane removal rate, such as Figure 6As shown, it is the characteristic curve of the removal of 1,2-dichloropropane by the above system, and the change curve of 1,2-dichloropropane removal rate and time reflects and expresses the removal rate and time of 1,2-dichloropropane relation. Wherein the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com