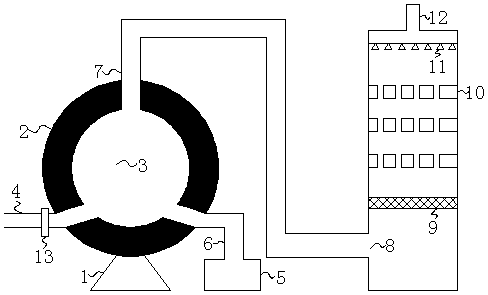

Smoldering type household waste incineration treatment device and use method thereof

A domestic waste incineration and treatment device technology, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve the problems of increasing fuel consumption, high incineration temperature, and not reaching the theoretical air value, so as to reduce fuel consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: (1), domestic garbage is fed into the inner furnace body through the feed channel and through holes, the combustion chamber works, and the air source fills the inner furnace body with air with a flow rate of 4L / min, and the inner furnace body is heated at 10r / min The speed of min is rotated for 5 min; (2), the inner furnace body is rotated at a speed of 6r / min, and the lime water with a concentration of 0.12mol / L is injected into the sprinkler head, and the sprinkler head is opened to spray the lime water downward; ( 3) When the domestic waste is burned, the combustion chamber stops working, and the inner furnace body is rotated so that the three through holes are respectively connected with the feeding channel, the air intake channel and the exhaust port one by one.

Embodiment 2

[0022] Example 2: (1) Household garbage is fed into the inner furnace body through the feed channel and through holes, the combustion chamber works, the gas source fills the inner furnace body with air with a flow rate of 6L / min, and the inner furnace body is heated at 15r / min The speed of min is rotated for 6 min; (2), the inner furnace body is rotated at a speed of 7r / min, and the lime water with a concentration of 0.14mol / L is injected into the sprinkler head, and the sprinkler head is opened to spray the lime water downward; ( 3) When the domestic waste is burned, the combustion chamber stops working, and the inner furnace body is rotated so that the three through holes are respectively connected with the feeding channel, the air intake channel and the exhaust port one by one.

Embodiment 3

[0023] Example 3: (1), domestic garbage is sent into the inner furnace body through the feed channel and through holes, the combustion chamber is working, the gas source is filled with air with a flow rate of 8L / min into the inner furnace body, and the inner furnace body is fed at a rate of 20r / min. The speed of min rotates for 7 minutes; (2), the inner furnace body rotates at a speed of 9r / min, injects lime water with a concentration of 0.16mol / L into the sprinkler head, and the sprinkler head opens to spray lime water downward; ( 3) When the domestic waste is burned, the combustion chamber stops working, and the inner furnace body is rotated so that the three through holes are respectively connected with the feeding channel, the air intake channel and the exhaust port one by one.

[0024] The present invention controls the inner furnace body to start rotating at a speed of 10-20r / min, and fills the inner furnace body with air with a flow rate of 4-8L / min to quickly ignite the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com