Patents

Literature

169 results about "Gliphosate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Use of a supplemental promoter in conjunction with a carbon-supported noble-metal-containing catalyst in liquid phase oxidation reactions

InactiveUS6963009B2Promote oxidationHigh activityBiocideGroup 5/15 element organic compoundsTe elementMethyl group

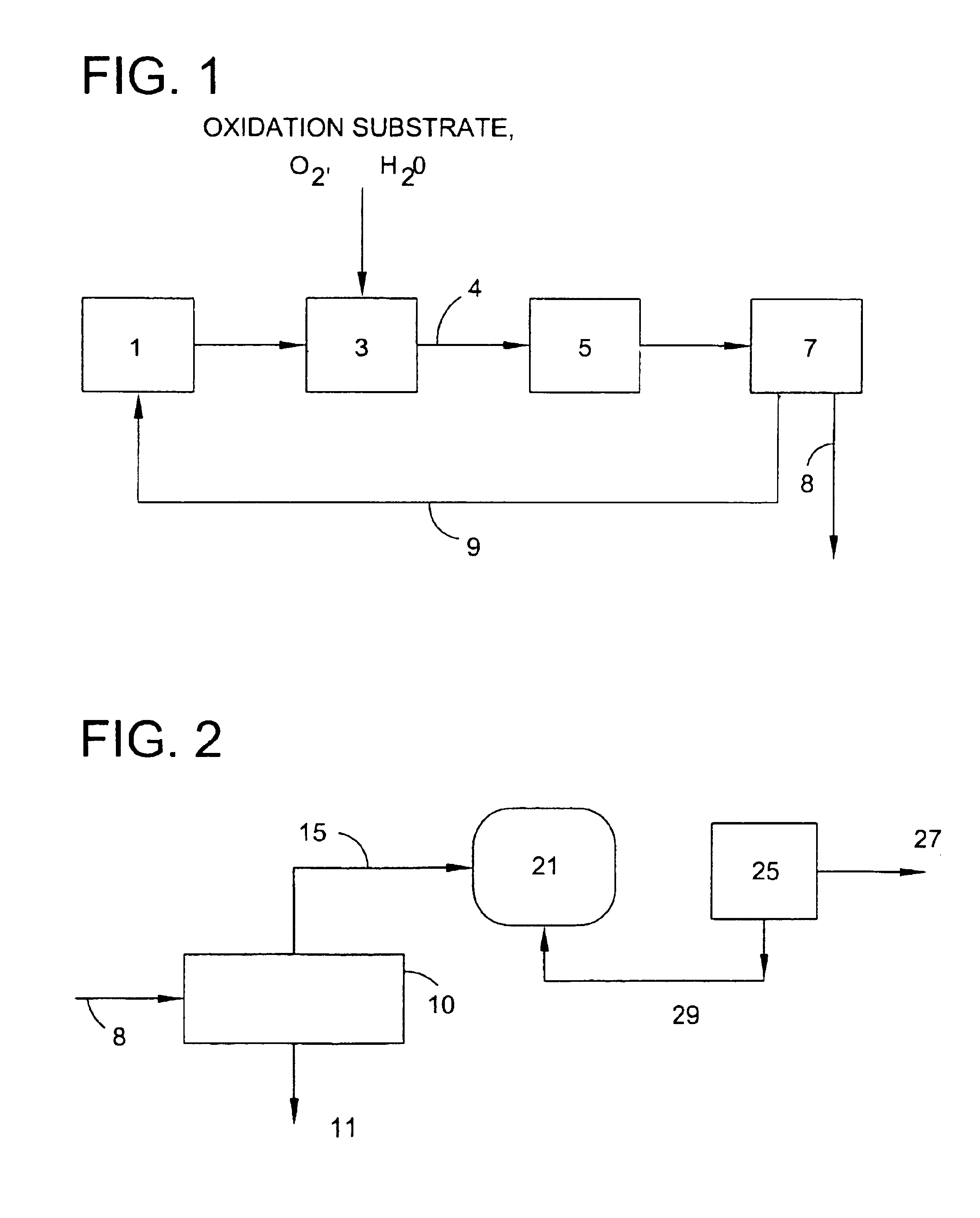

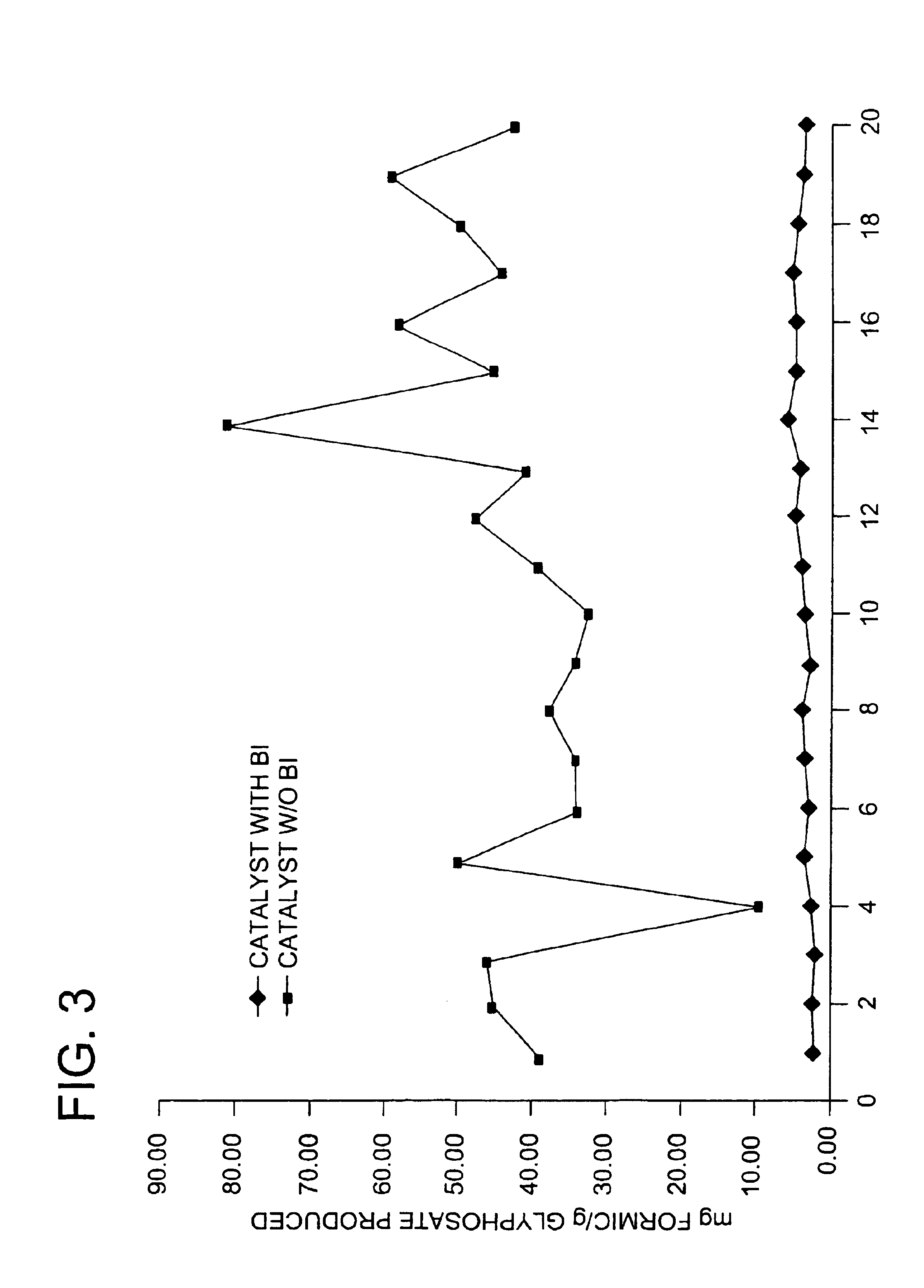

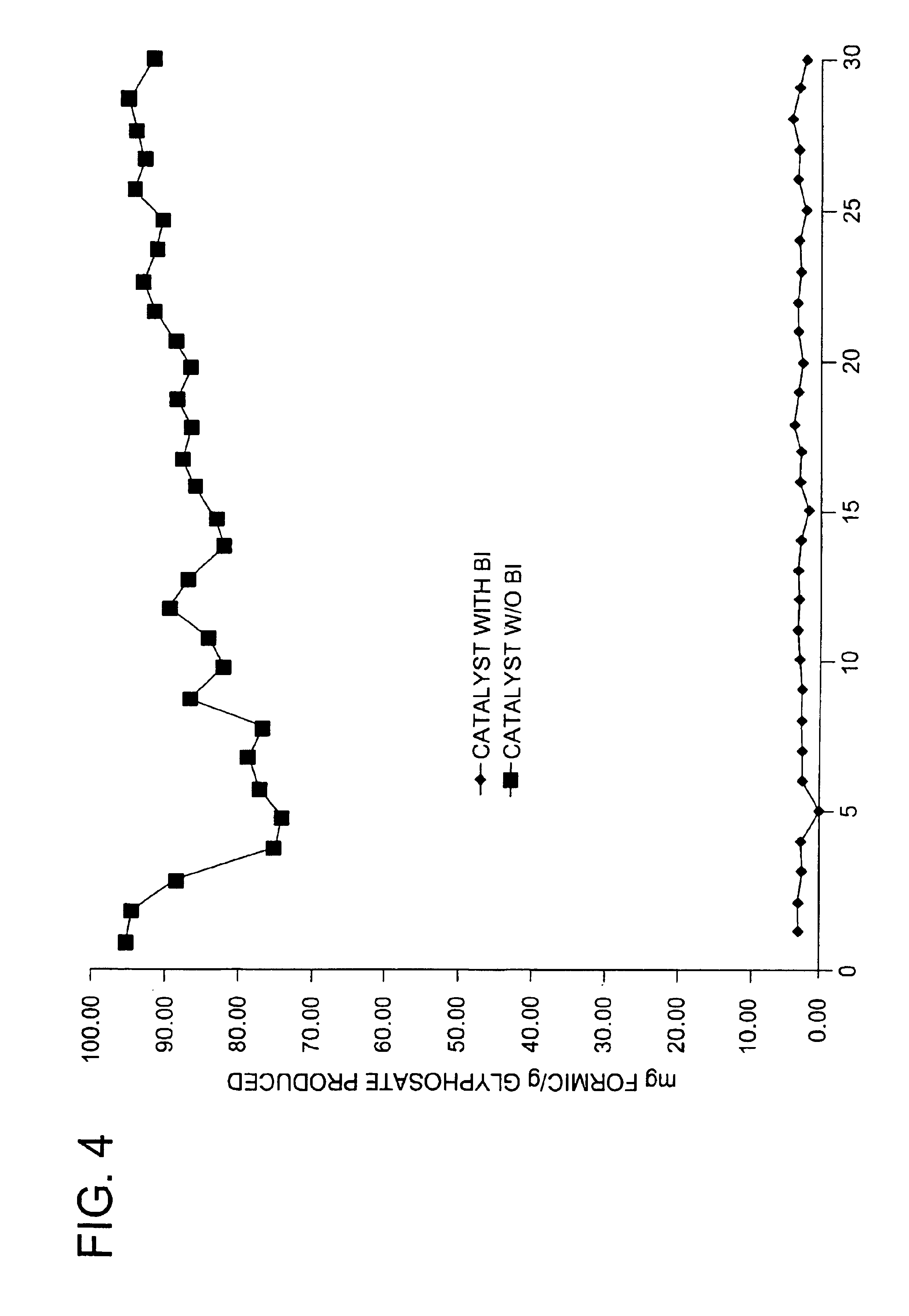

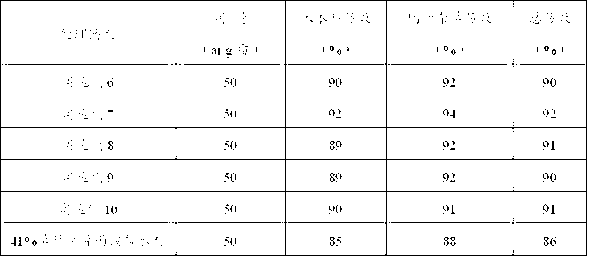

This invention relates to the use of a supplemental promoter in conjunction with a noble-metal-containing catalyst comprising a carbon support in catalyzing liquid phase oxidation reactions.In a particularly preferred embodiment, a supplemental promoter (most preferably bismuth or tellurium) is used in conjunction with a noble-metal-containing catalyst comprising a carbon support in a liquid phase oxidation process wherein N-(phosphonomethyl) iminodiacetic acid (i.e., “PMIDA”) or a salt thereof is oxidized to form N-(phosphonomethyl)glycine (i.e., “glyphosate”) or a salt thereof. The benefits of such a process include oxidation of the formaldehyde and formic acid by-products, and, consequently, decreased final concentrations of those by-products as well as other undesirable by-products, most notably N-methyl-N-(phosphonomethyl)glycine (i.e., “NMG”).

Owner:MONSANTO TECH LLC

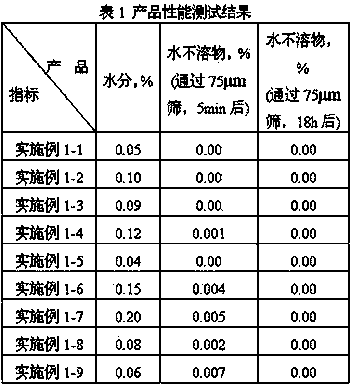

Soluble granule of glyhosate ammonium and preparation method

ActiveCN101564044ANot easy to agglomerateNot easy to thinBiocideAnimal repellantsPhosphatePolluted environment

The invention provides a formula of soluble granule (WSG) of glyhosate ammonium and a preparation method. The formula includes 50-95 percent of glyhosate ammonium, 0.5-25 percent of glyphosate synergistic agent, 0.27-40 percent of phosphate, 0-10 percent of filler, 0.1-0.5 percent of xanthan gum and water. The product is stable in property and not prone to absorb moisture, and the production process is simple and smooth, does not pollute the environment and meets environment-protective requirements.

Owner:SHANGHAI XIANGLIN AGRI TECH CO LTD

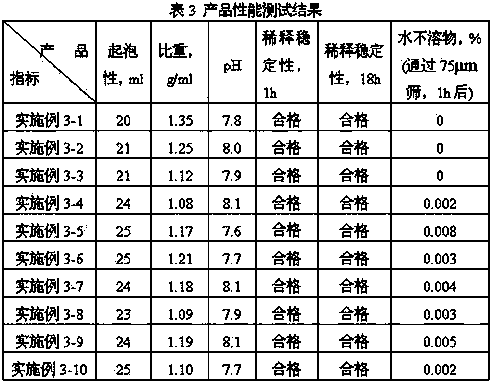

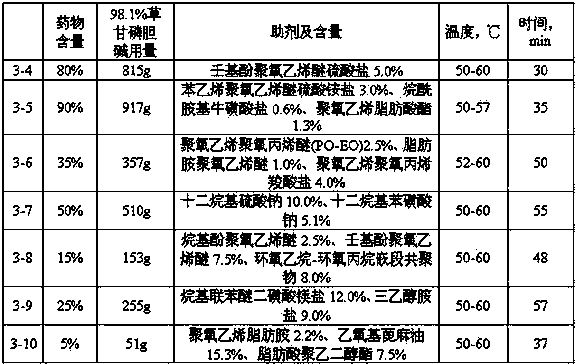

Agricultural thickening synergist and application thereof

ActiveCN103210915AGood wetting and synergistic effectImprove performanceBiocideAnimal repellantsAgricultural scienceActive agent

The invention discloses an agricultural thickening synergist. The agricultural thickening synergist comprises the following components by mass percent: 1-40% of fatty alcohol polyoxyethylene ether sulfate, 0-30% of alkyl glycoside, 5-15% of sodium lauroyl sarcosinate, 5-10% of sodium alkyl benzene sulfonate, 5-15% of ammonium sulfate and the balance of water. The invention also discloses an application of the agricultural thickening synergist in a glyphosate isopropamide salt water agent and a glyphosate salt water agent. The agricultural thickening synergist has the characteristics of better wetting synergy effect, more stable performance and better thickening synergy effect; by using the glyphosate salt water agent, the agricultural thickening synergist has high viscosity, the adhesive force and moisture property of the liquid medicine are improved, the internal absorption and conductivity of the glyphosate are realized, and the pharmacological function can be fully realized. Besides, the agricultural thickening synergist has excellent biological degradability, has high safety to the environment and organisms, and meets the development requirement of the agricultural surface active agent in the future.

Owner:范强

Glyphosate wastewater treatment method

ActiveCN102001792ALow costEasy to put inMultistage water/sewage treatmentNature of treatment waterGliphosateOxidizing agent

The invention relates to an improvement of a method for treating wastewater generated during glyphosate production, which is characterized in that the improved method comprises the following steps: firstly, adding water to dilute the wastewater until the content of salt is less than or equal to 4%; adjusting the pH to 7.5-9.5; carrying out anaerobic biochemistry in the presence of drimophilousbacteria to destroy the structure of organics difficult to dissolve; adjusting effluent to acidity to carry out Fe-C micro-electrolysis reaction; adding alkali up to neutrality or alkalinity, adding drugs to coagulate and precipitate; adding oxidizer into effluent to carry out aeration strong oxidation reaction; and adjusting the pH of effluent to 7-9 to carry out aerobic biochemistry in the presence of drimophilousbacteria. In the invention, the anaerobic biochemistry, materialization and aerobic biochemistry treatment processes are adopted, thereby providing a process route which has simple and practical process and low cost and is high efficient and reliable, and simultaneously has dual effects on lowering treatment cost and improving treatment effect; and the treated effluent can reach the ''National Integrated Wastewater Discharge Standard'' (GB-8978-1996).

Owner:JIANGSU LASON CHEM ENVIRONMENTAL PROTECTION

Process for preparing disodium hydrogen phosphate from glyphosate mother liquor

The invention relates to a process for preparing disodium hydrogen phosphate from a glyphosate mother liquor. The process comprises an oxidization step, a crystallization step and a separation step, wherein the oxidization step comprises oxidizing organic phosphorus compounds and phosphorous acid in the glyphosate mother liquor wastewater into positive phosphate ions under the reaction conditions of a temperature ranging from 240 to 320 DEG C and pressure ranging from 6.0 to 15.0 Mpa by taking the oxygen in the air as an oxidizing agent, wherein the oxygen supply amount is 0.7 to 1.3 times of the total amount of COD (Chemical Oxygen Demand) of the glyphosate mother liquor; the crystallization step comprises cooling the oxidized liquid obtained in the oxidization step to the range from minus 5 to 12 DEG C and generating solid-state disodium hydrogen phosphate dodecahydrate crystals under the condition that pH ranges from 7.0 to 10.5; the separation step comprises performing solid-liquid separation on the oxidized liquid crystallized in the crystallization step.

Owner:杭州深瑞净水技术有限公司

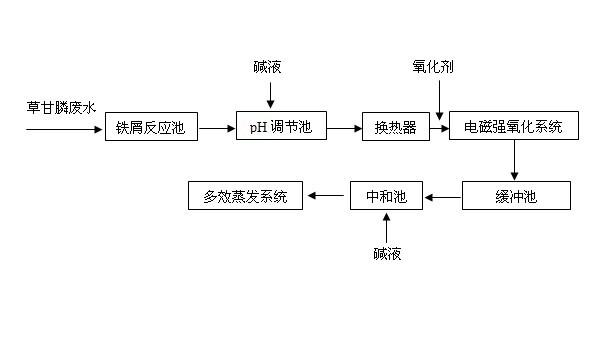

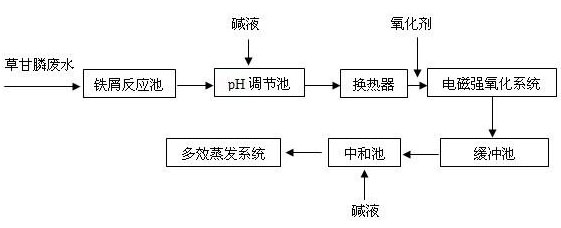

Novel process for zero discharge of glyphosate production waste water

InactiveCN102079605AAchieve "zero emission" effectPhosphatesMultistage water/sewage treatmentChemical oxygen demandO-Phosphoric Acid

The invention discloses a novel process for zero discharge of glyphosate production waste water. Aiming at the characteristics that chemical oxygen demand (COD) concentration of glyphosate mother liquor is high, and the glyphosate mother liquor is difficult to degrade, a process of combing electromagnetism strong oxidization and multiple-effect evaporation concentration is adopted to carry out high-strength oxidation on glyphosate waste water under the action of an electromagnetic field, so that organophosphorus in the glyphosate production waste water is converted into orthophosphate, oxidized waste water is subjected to evaporation concentration, thereby recycling high value-added orthophosphate. By using the process, the zero discharge of the glyphosate production waste water can be reached, which meets the environment-friendly requirement.

Owner:BEIJING TUOFENG TECH DEV

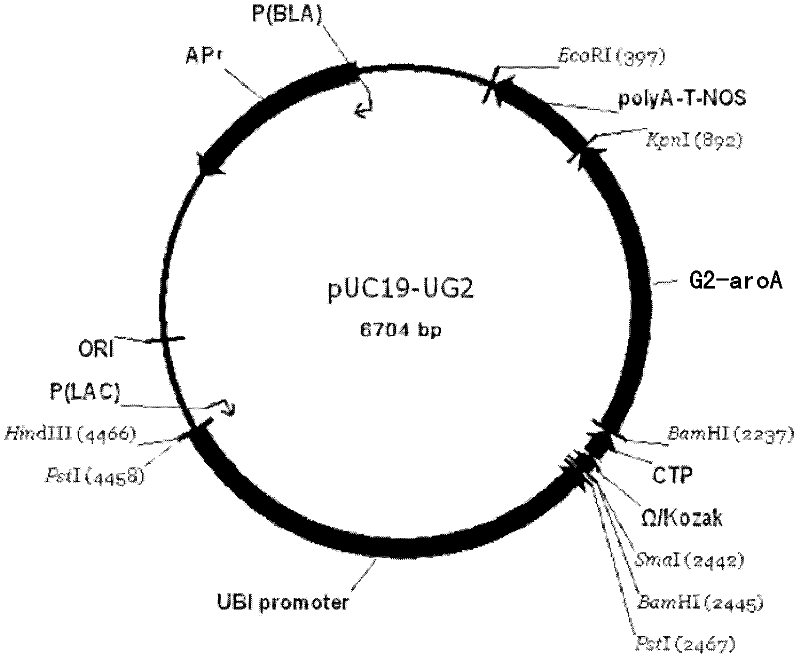

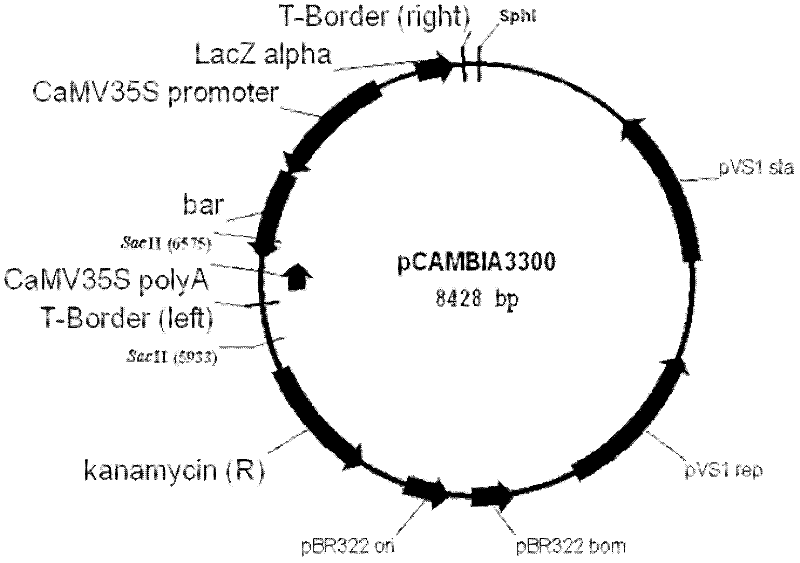

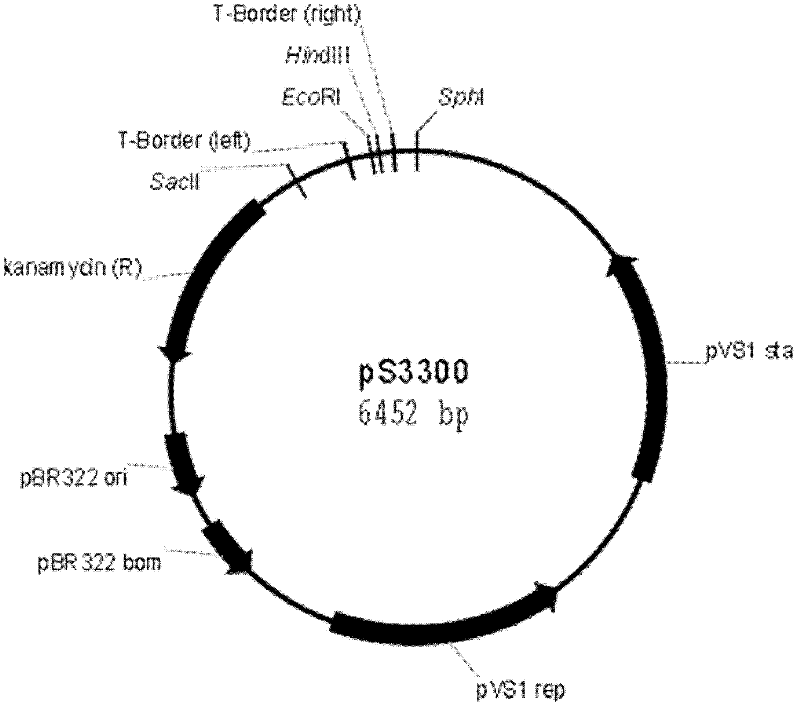

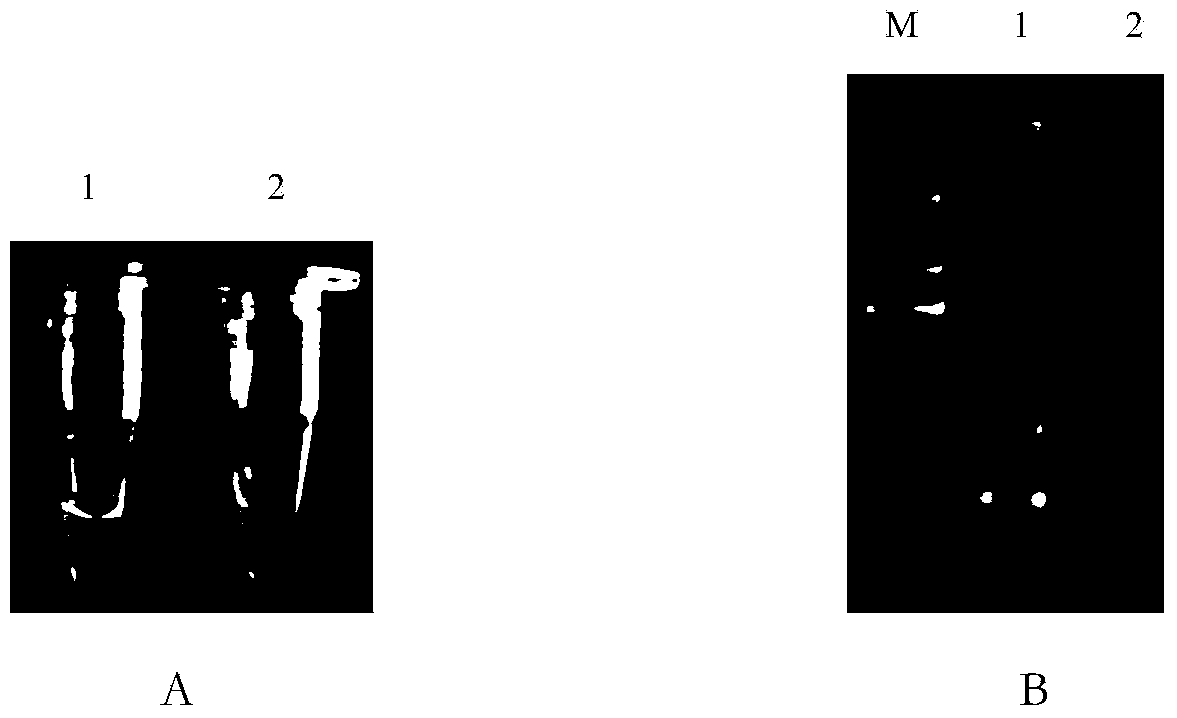

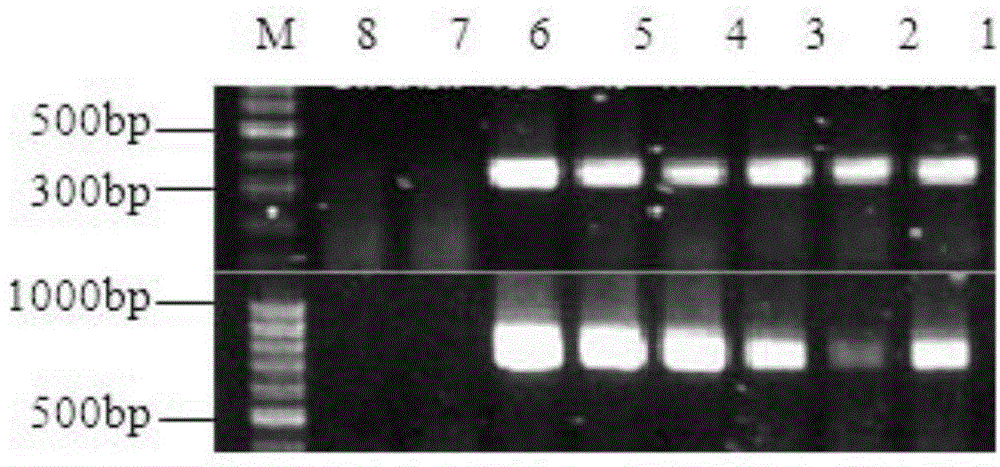

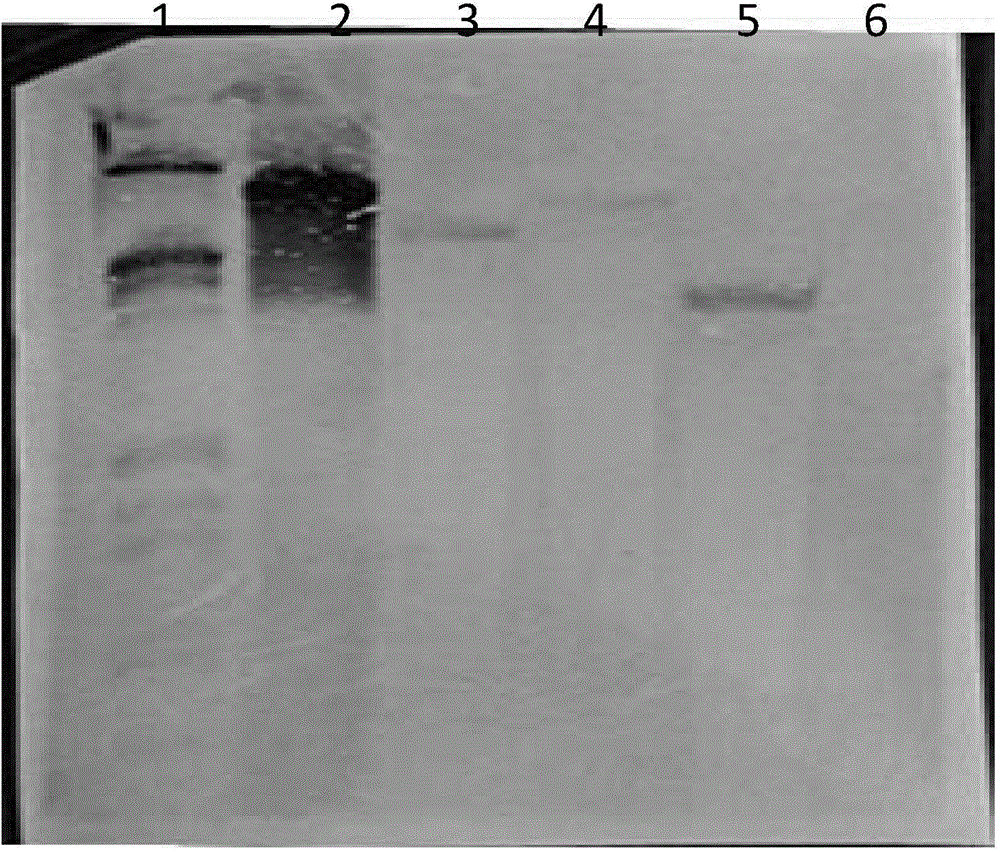

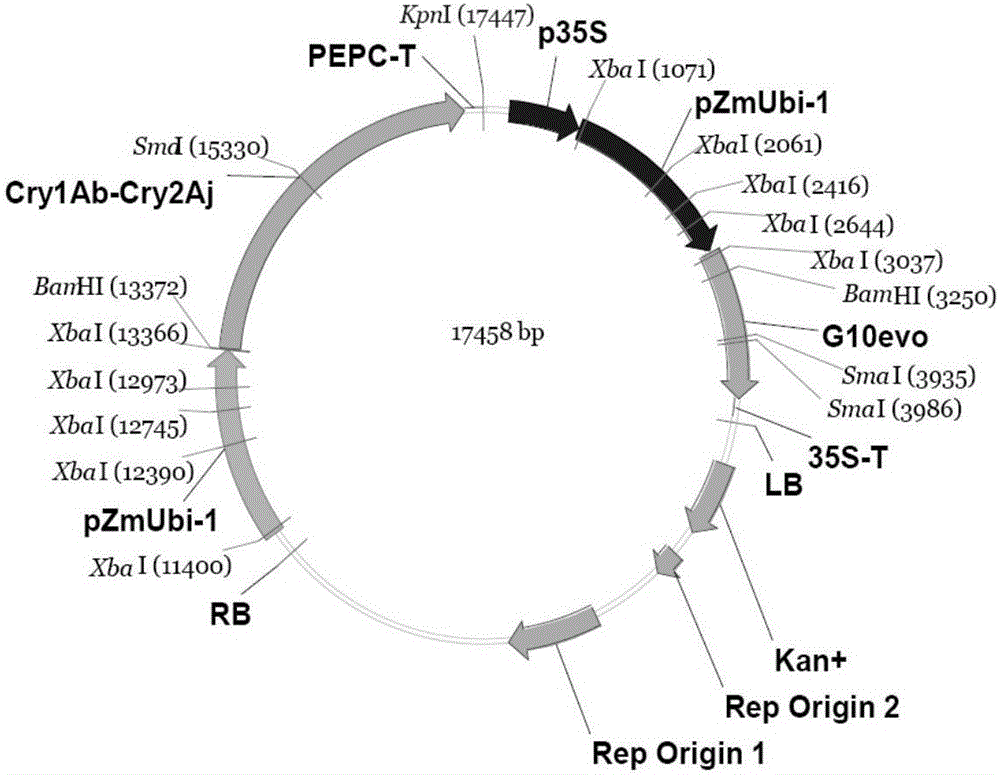

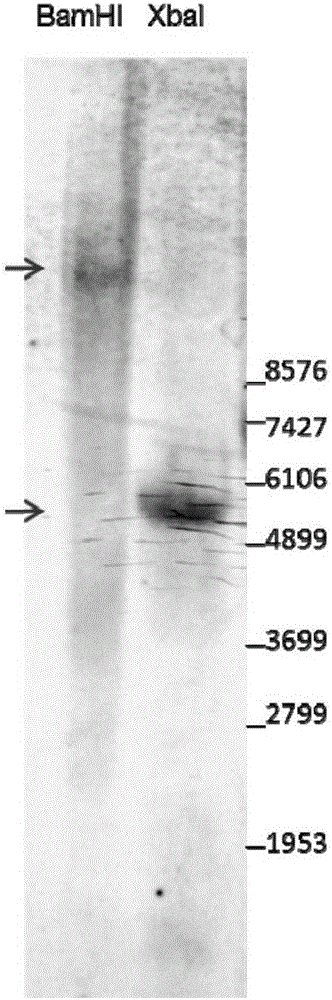

Recombinant DNA (deoxyribonucleic acid) fragment containing roundup ready gene and application thereof

The invention discloses a recombinant DNA (deoxyribonucleic acid) fragment containing a roundup ready gene and application thereof. The recombinant DNA fragment provided by the invention comprises the following components from 1) to 3): 1) a promoter; 2) the roundup ready gene which is promoted by the promoter to be transcribed, the nucleotide sequence of the roundup ready gene is a) or b), wherein a) represents a sequence 2 in a sequence table, and b) represents a protein which has at least 98% of identity with the sequence 2 in the sequence table and is shown by a coding sequence 9; and 3) tanscription termination sequence. Compared with the transgenic corn which contains the recombinant DNA fragment in which prokaryote roundup ready gene G2-aroA is transplanted, the transgenic corn which is transplanted with the recombinant DNA fragment provided by the invention is obviously higher in the expression quantity of G2-aroA protein; and the transgenic corn is also obviously higher in the glyphosate tolerance.

Owner:BEIJING ORIGIN SEED TECH

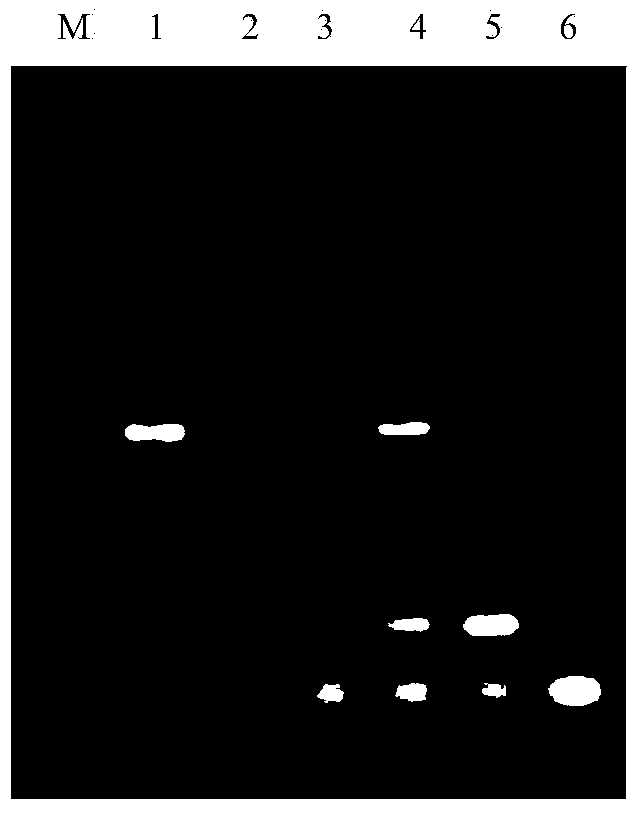

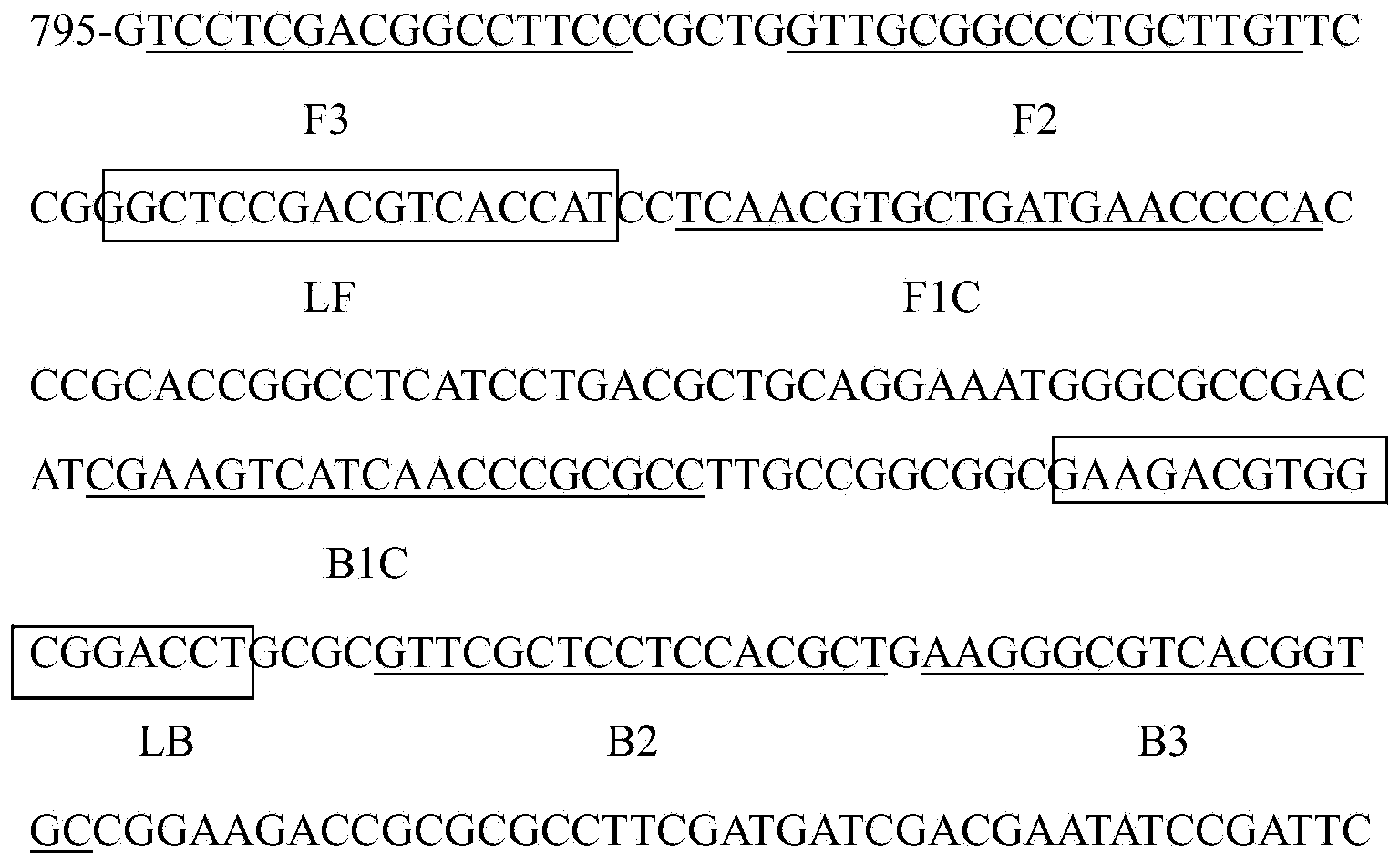

LAMP (Loop-Mediated Isothermal Amplification) rapid detection method and application of glyphosate-resist transgenic soybean

InactiveCN103642918AEasy to operateHigh sensitivityMicrobiological testing/measurementResistGene flow

The invention relates to an LAMP (Loop-Mediated Isothermal Amplification) rapid detection method and application of a glyphosate-resist transgenic soybean. The method comprises the following steps: designing and selecting 6 LAMP primers F3, B3, FIP, BIP, LB and LF according to the specificity of a CP4-EPSPS gene sequence; and preparing and optimizing an LAMP reaction system. The glyphosate-resist transgenic soybean can be rapidly detected through DNA extraction of the glyphosate-resist transgenic soybean, loop-mediated isothermal amplification, amplification output color development and observation. According to the detection method, the specificity is strong, the sensitivity is high, the detection is rapid, the cost is low, the operation is convenient, and application values in rapid detection of transgenic soybean and processed goods and field monitoring of gene flow of the transgenic soybean are high.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

Polycaprolactone polyol as well as preparation method and application thereof

The invention relates to polycaprolactone polyol as well as a preparation method and application thereof. The method comprises the following steps that S1, under the protection of the water-free and oxygen-free conditions and inert gas, an initiator, a catalyst, an inhibitor and caprolactone are uniformly mixed; and S2, a system obtained in the step S1 is heated to 120-230 DEG C for reaction for 10-180 minutes so as to carry out ring-opening polymerization reaction, vacuum defoamation is carried out, and cooling and discharging are carried out so as to obtain the polycaprolactone polyol, wherein the inhibitor is one or more of organic phosphine, glyphosate-sodium, ethyldiphenylphosphine or tribenzylphosphine. According to the preparation method, the specific side reaction inhibitor is added, so that the polycaprolactone polyol which is controllable in molecular weight, low in acid value, few in metal residues, narrow in polymer molecular weight distribution and capable of keeping the original excellent physicochemical properties is obtained, and the acid value of the polycaprolactone polyol prepared through the preparation method is less than 0.5 mg KOH / g.

Owner:GUANGDONG BOSSIN NOVEL MATERIALS TECH CO LTD

Method for recycling methylal in glyphosate wastewater

ActiveCN103288606AReduce security risksEfficient recyclingOrganic chemistryOrganic compound preparationAlcoholDistillation

Owner:HUBEI TAISHENG CHEM

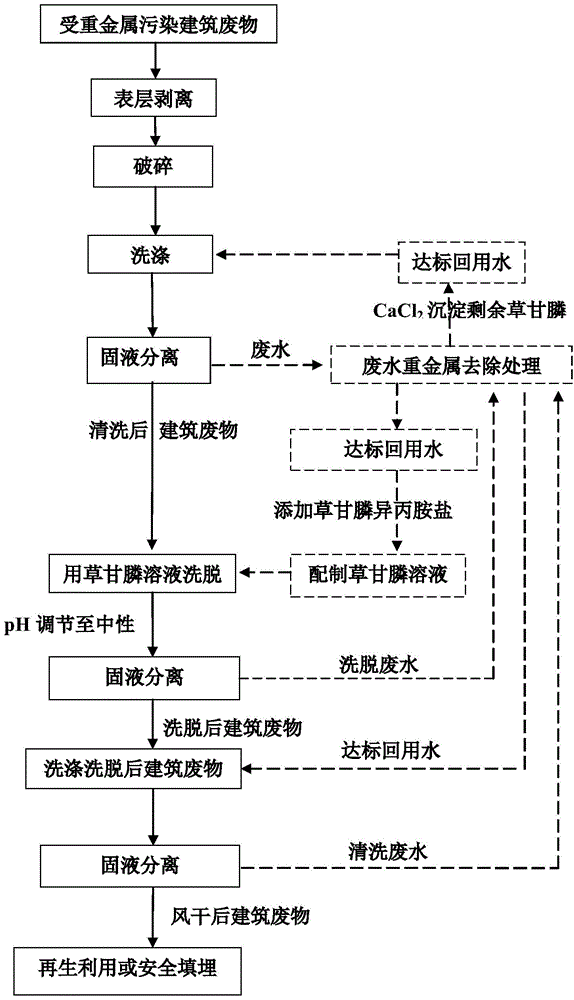

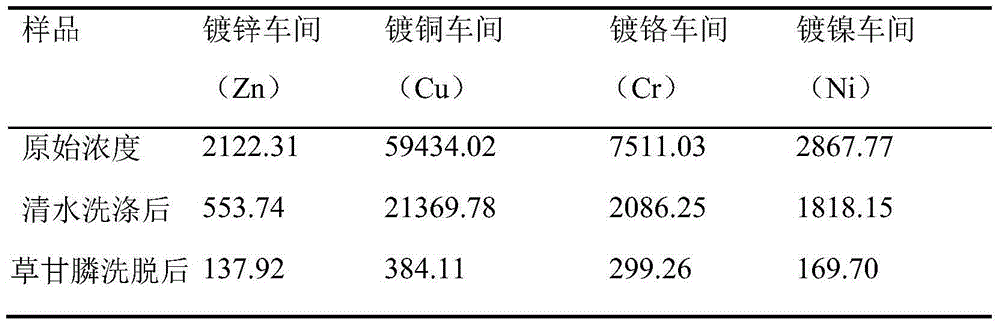

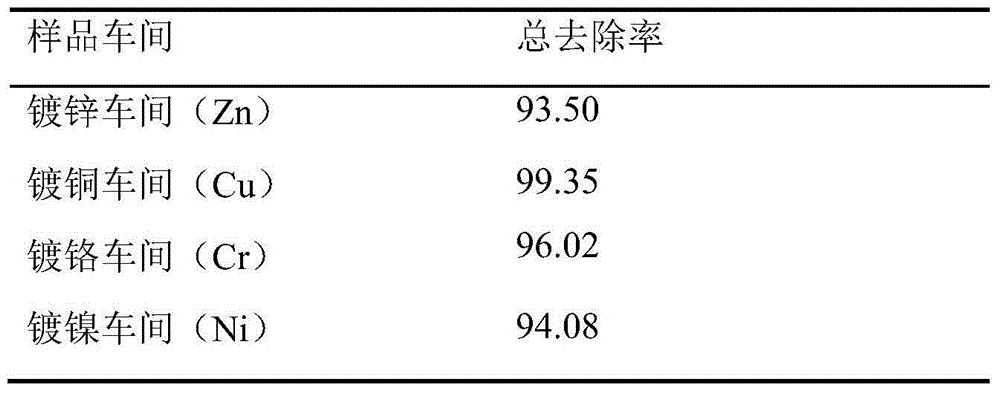

Treating method of high-concentration heavy metal polluted building waste

InactiveCN103978013AEliminate hazardsRealize waste treatmentConstruction waste recoverySolid waste disposalThree levelHigh concentration

The invention relates to a treating method of high-concentration heavy metal polluted building waste. The method includes: stripping surfaces of the building waste, smashing, washing, separating solid and liquid to obtain the cleaned building waste the water-soluble heavy metal of which is removed, adding an isopropylamine glyphosate solution into the cleaned building waste, eluting to remove the heavy metals, adjusting the pH value to be neutral, separating solid and liquid, washing the waste after elution with water and separating solid and liquid. The heavy metal contents in the building waste after air drying are lower than the three-level standard thresholds of the environmental quality standards (GB15618-1995). The building waste after air drying is subjected to a leaching test by utilization of an HJ / T229 leaching method, and the heavy metal contents in the leachate are lower than the thresholds of the standards for hazardous wastes (GB5085.3-2007). The building waste after air drying can be directly buried and stacked without pollution to the soil, and can be used as a regenerated roadbed material and a concrete aggregate. The method is simple in process and capable of completely eliminating the hazard of the polluted building waste, and has good environmental benefit, economic benefit and social benefit.

Owner:TONGJI UNIV

Method for treating glyphosate waste water and reducing the emission of carbon dioxide

ActiveCN101591084ARealize resourcesEmission reductionOrganic chemistryWater/sewage treatment bu osmosis/dialysisHexamethylenetetramineFormate

The invention relates to a method for treating glyphosate waste water and reducing the emission of carbon dioxide. The glyphosate waste water is obtained by extracting glyphosate after the N-phosphonomethyliminodiacetic acid is oxidized in the process of preparing the glyphosate by using an iminodiacetic acid method. Urotropine finished products are prepared by the following steps: (1) adding alkali into the glyphosate waste water, and adjusting and controlling the pH value to between 3 and 5 to obtain corresponding formate solution; (2) performing condensing separation on the solution of the step (1) by a film integration method to obtain 5 to 25 percent formate solution and 0.5 to 5 percent obenzaldehyde water solution (1); (3) performing evaporating, dehydration and solid-liquid separation on the formate solution of the step (2) to obtain formate wet powder and 0.5 to 5 percent benzaldehyde water solution (2), and drying the formate wet powder to obtain the finished product; (4) adding ammonia accounting for 1.5 to 3 percent the benzaldehyde water solution (1) and the benzaldehyde water solution (2) to obtain 0.3 to 4 percent urotropine water solution, and improving the concentration of the urotropine to between 10 and 25 percent by film separation; and (5) evaporating, separating and drying the urotropine solution to obtain the urotropine finished product.

Owner:HANGZHOU TIAN CHUANG ENVIRONMENTAL TECH

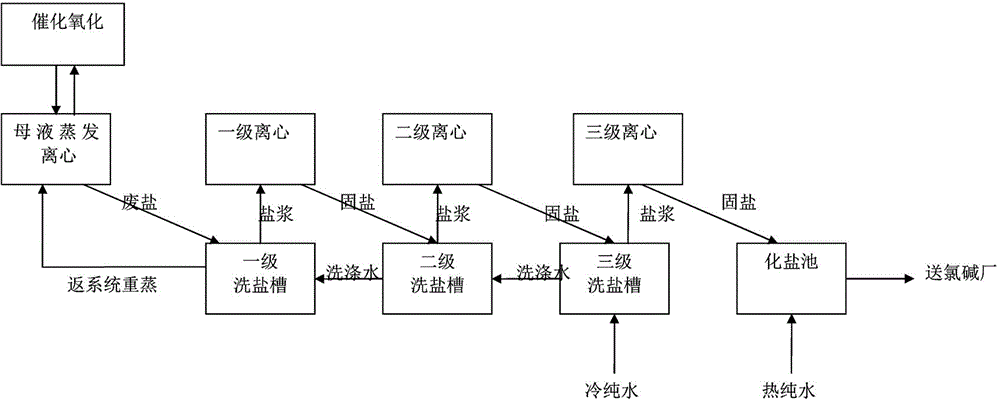

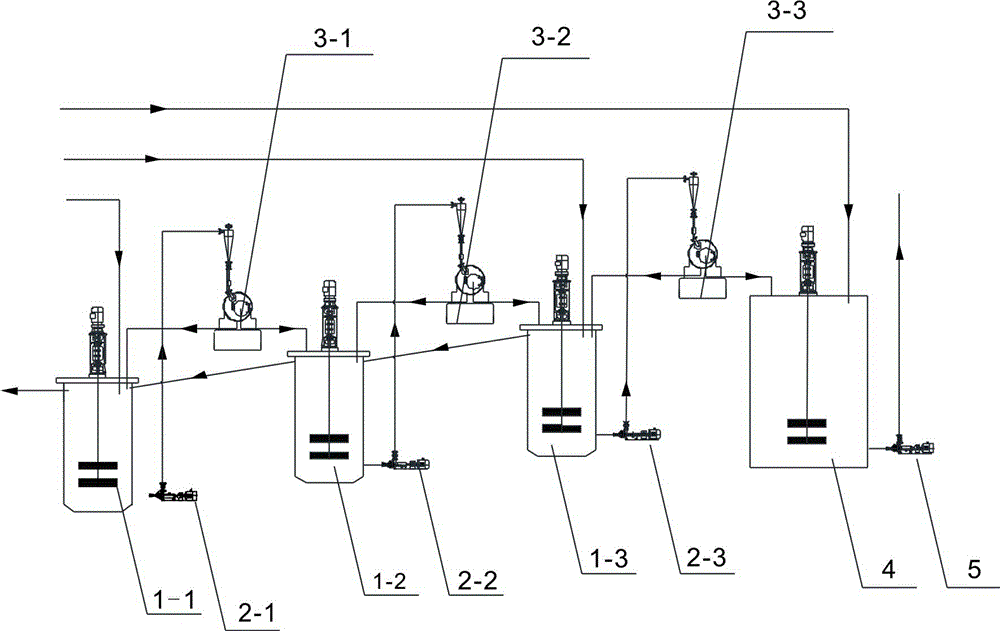

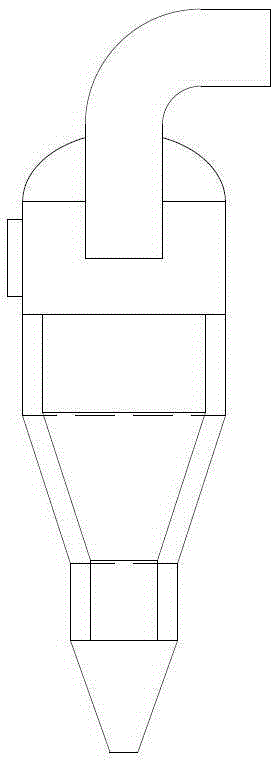

Purification device and purification process for waste salt in by-product of glyphosate

ActiveCN104098113AAchieve reuseSolve the narrow scope of useAlkali metal halide purificationMelting tankSaline water

The invention relates to a purification device of waste salt in a by-product of plyphosate. A first-stage salt cleaning tank is connected with a first-stage slurry pump through route pipelines first, then the first-stage slurry pump is connected with a first-stage centrifuge; the first-stage centrifuge is connected with a second-stage salt cleaning tank through the route pipelines; after three stages of circulating connection of the salt cleaning tanks, the slurry pumps and the centrifuges, a three-stage centrifuge is connected with a salt melting tank through the route pipelines, and the salt melting tank is connected with a salt water delivery pump. The waste salt from an evaporation system is conveyed to the first-stage salt cleaning tank, and mixed with water obtained from the centrifuge of the previous stage to obtain salt slurry with the solid content rate of 25%; after being uniformly stirred, the salt slurry is pumped into the first-stage centrifuge utilizing the first-stage slurry pump; the centrifuged solid salt is conveyed to the second-stage salt cleaning tank, and the salt cleaning water returns to the second-stage salt cleaning tank. The purified refined salt cleaned through three stages adopting the same method has the solid content rate of 60-70%; through the adoption of the process, waste salt is converted into raw materials capable of being used in the downstream chlor-alkali industry, and improves the economic benefit of waste salt treatment; meanwhile, in virtue of great raw material demand in the chlor-alkali industry, the defects of narrow application range and small demand for the conventional waste salt are completely overcome.

Owner:HUBEI TAISHENG CHEM

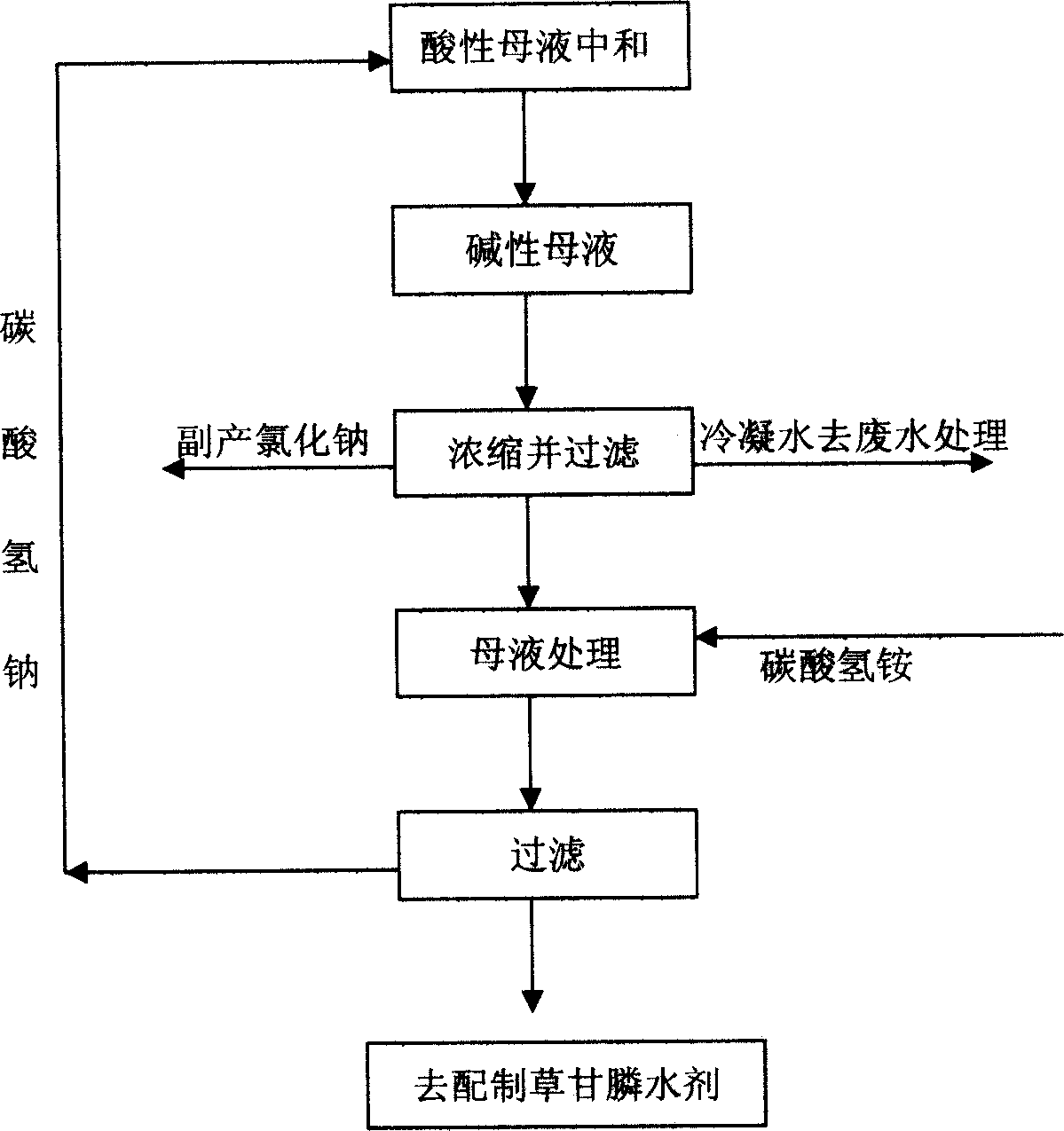

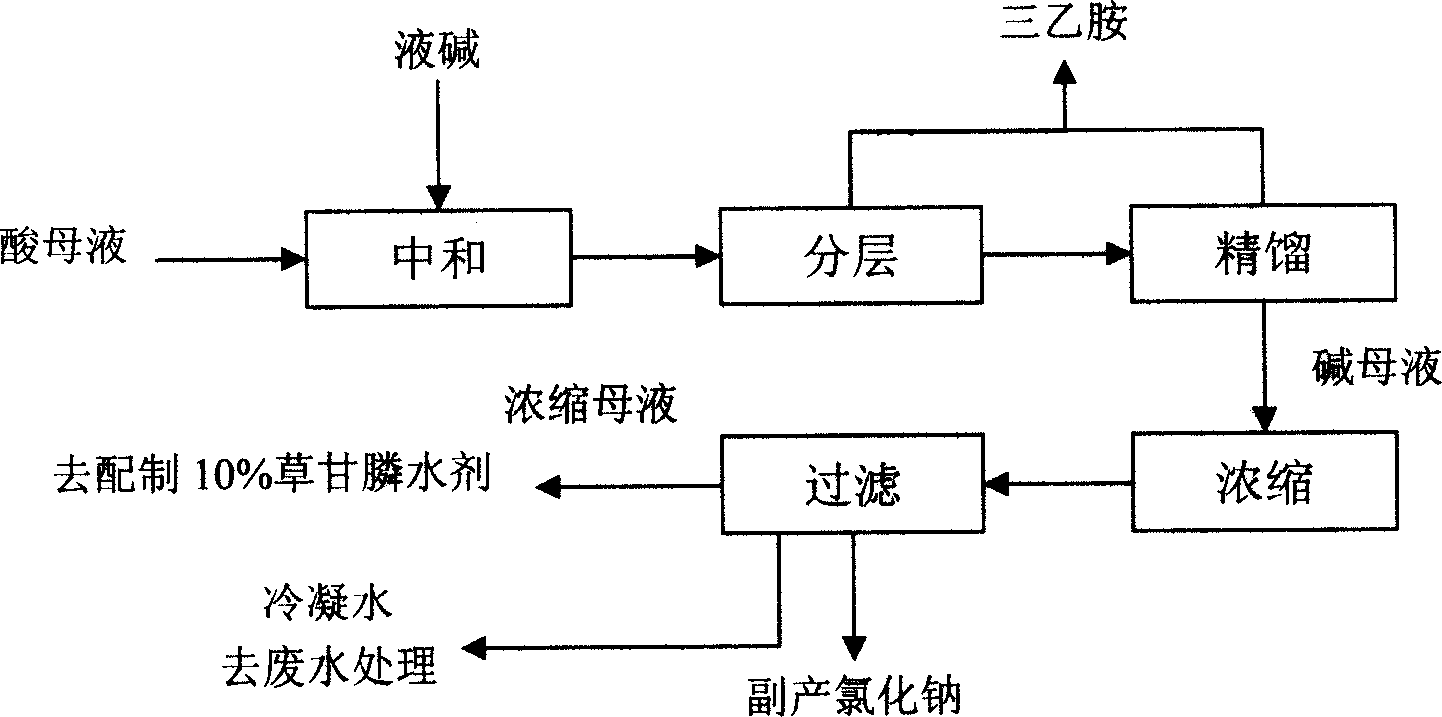

Glyphosate mother liquid treating method

ActiveCN1676527AImprove weed control effectEliminate pollutionGroup 5/15 element organic compoundsEnergy consumptionChloride sodium

This invention relates to a treatment method of mother liquid from alkyl esterification composing glyphosate. This method mainly reclaims TEA, condenses alkali mother liquid to get off large amount of byproduct soldium chloride, after which adds ammonium bicarbonate in the alkali mother liquid, fully reacts, filters to collocate glyphosate solution. This invention can not only get rid of the alkalization problem cause by too much sodium chloride in glyphosate, and also improves the medical effect of this solution collocated by this method, and lower the cost and save the energy consumption.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

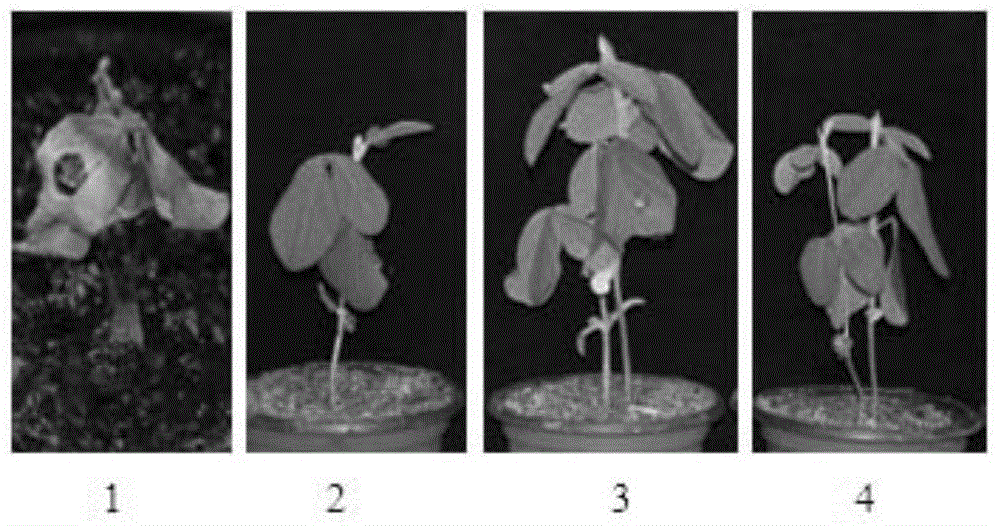

Transgenic glyphosate-resistant soybeans as well as preparation method and application thereof

ActiveCN104450775AMicrobiological testing/measurementVector-based foreign material introductionChromatophoreHigh doses

The invention discloses transgenic glyphosate-resistant soybeans as well as a preparation method and application thereof. The invention provides a method of cultivating transgenic soybeans. The method comprises the following step: inserting a foreign DNA fragment in a range from a 7980527th position to a 7982541st position of chromosome 17 of a target soybean genome to obtain the transgenic soybeans. The transgenic soybeans have tolerance to high-dose glyphosate and can be further improved by being hybridized with an excellent soybean strain so as to optimize other agronomic characters including quality and yield. The detection method is capable of identifying a combined region of an inserted T-DNA and a plant genome DNA and further identifying cells, tissues, organs, products and the like of the transgenic soybeans and progenies of the transgenic soybeans.

Owner:INST OF CROP SCI CHINESE ACAD OF AGRI SCI

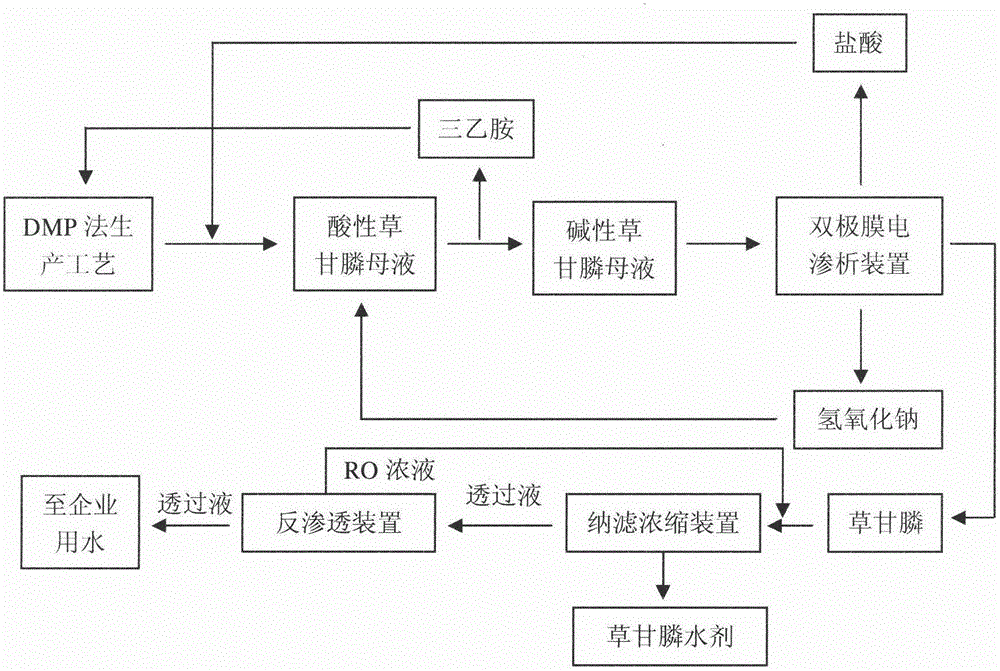

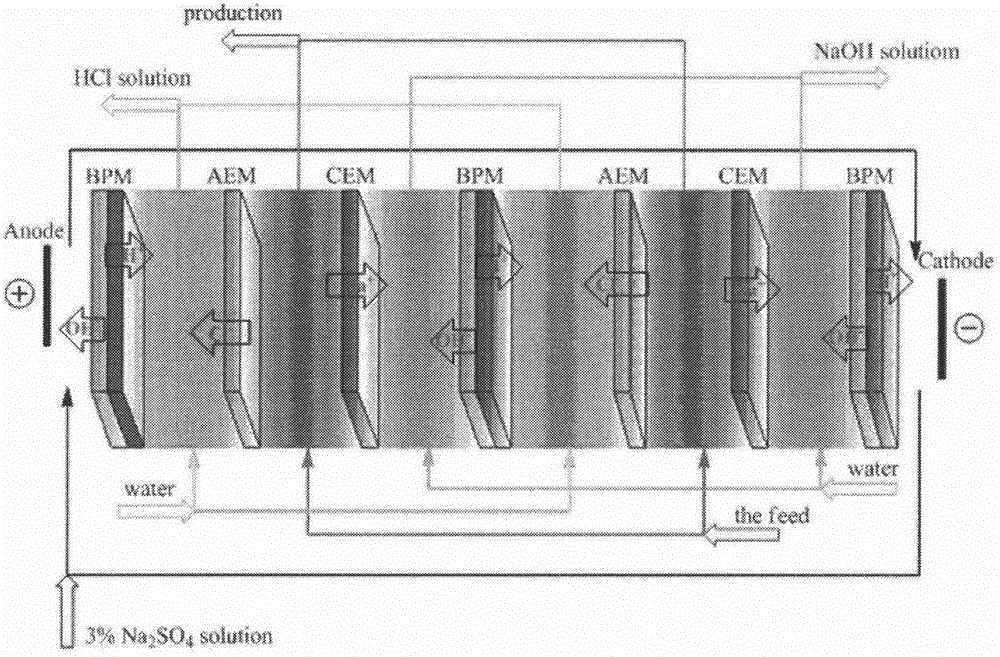

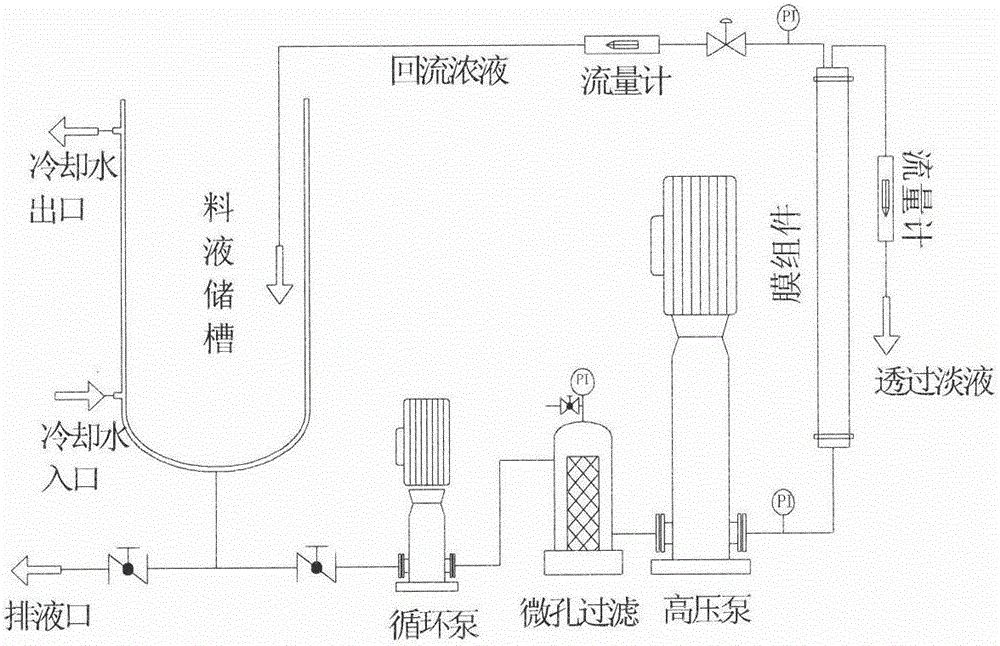

Method and apparatus for resourceful treatment of glyphosate mother liquor by bipolar membrane electrodialysis integrated nanofiltration and reverse osmosis technology

InactiveCN103949160AImprove pollutionAchieve resource recyclingChlorine/hydrogen-chlorideBiocideReverse osmosisHydrolysis

The invention discloses a method and apparatus for resourceful treatment of glyphosate and neutralization of mother liquor by integrated membrane electrodialysis integrated nanofiltration and reverse osmosis technology. The bipolar membrane electrodialysis technology is used for treating glyphosate and neutralizing mother liquor; sodium ions in the mother liquor enter into an alkali chamber through a cation exchange membrane, and combine with hydroxyl ions produce by the bipolar membrane to produce sodium hydroxide; and chloride ions enter into an acid chamber through an anion exchange membrane, and combine with the hydrogen ions generated by the bipolar membrane to form hydrochloric acid. When the conductance in the mother liquor is less than 10000, the desalinated mother liquor is subjected to desalination concentration and reverse osmosis concentration by the nanofiltration membrane, so as to recover glyphosate. The concentration of acid and alkali obtained by the invention is above 2 mol / L, the obtained hydrochloric acid can be used for hydrolysis of esterification reaction in a production process, sodium hydroxide can be used for recycling tri ethylamine, and the concentrated glyphosate has concentration more than 10%. The invention achieves glyphosate mother liquor cleaning technology with zero discharge and can be widely applied to treatment of the glyphosate mother liquor with high salt content.

Owner:ZHEJIANG CIRCLE TECH MEMBRANE TECH +1

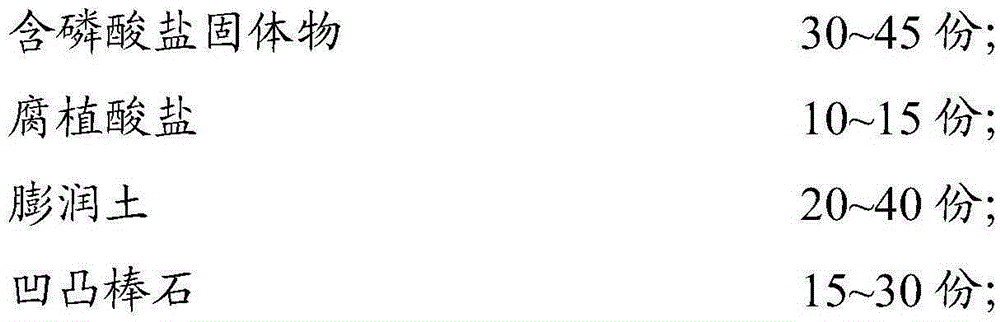

Acidic soil conditioner and preparation method thereof

ActiveCN105255501AImprove aggregate structureIncrease available phosphorus contentOther chemical processesOrganic fertilisersPhosphatePotassium

The invention relates to an acidic soil conditioner and a preparation method thereof. The method comprises the following steps: preparation of a phosphate-containing solid from glyphosate waste liquid; preparation of a soil conditioner; granulation; drying; etc. Compared with CK, the pH value, effective phosphorus content and rapidly-available potassium content in soil of a capsicum area where the acidic soil conditioner is applied are increased by 0.44 unit, 21.60% and 33.87%, respectively; as for disease resistance, the incidence of capsicum anthracnose and the incidence of capsicum phytophthora blight are reduced by 17.83% and 26.21% compared with a control group, respectively; moreover, the contents of cadmium, lead, total mercury and total arsenic in capsicum fruit are reduced by 24.21%, 23.37%, 31.58% and 17.39%, respectively. According to the invention, recycling sustainable utilization of high-pollution waste water in production of glyphosate is realized; the pH value of acidic soil is increased; and disease resistivity and harmful heavy metal ion absorbing capacity of plants are improved.

Owner:JIANGSU GOOD HARVEST WEIEN AGROCHEM

Glyphosate-resistant transgenic soybean as well as preparation method and application thereof

The invention discloses glyphosate-resistant transgenic soybean as well as a preparation method and application thereof. The invention provides a method for cultivating transgenic soybean. In the method, an exogenous DNA fragment is inserted between the 50543767th site-50543792nd site of the chromosome No.19 of the target soybean genome to obtain transgenic soybean. The transgenic soybean disclosed by the invention is tolerant to high-dose glyphosate, and the transgenic soybean can be further hybridized with a good soybean strain so as to improve and optimize other agronomic characters such as yield and quality. A detection method provided by the invention can be used for identifying the binding domain between the inserted T-DNA and plant genome DNA and further identifying the cells, tissues, organs, products and the like of the transgenic soybean and progenies thereof.

Owner:INST OF CROP SCI CHINESE ACAD OF AGRI SCI

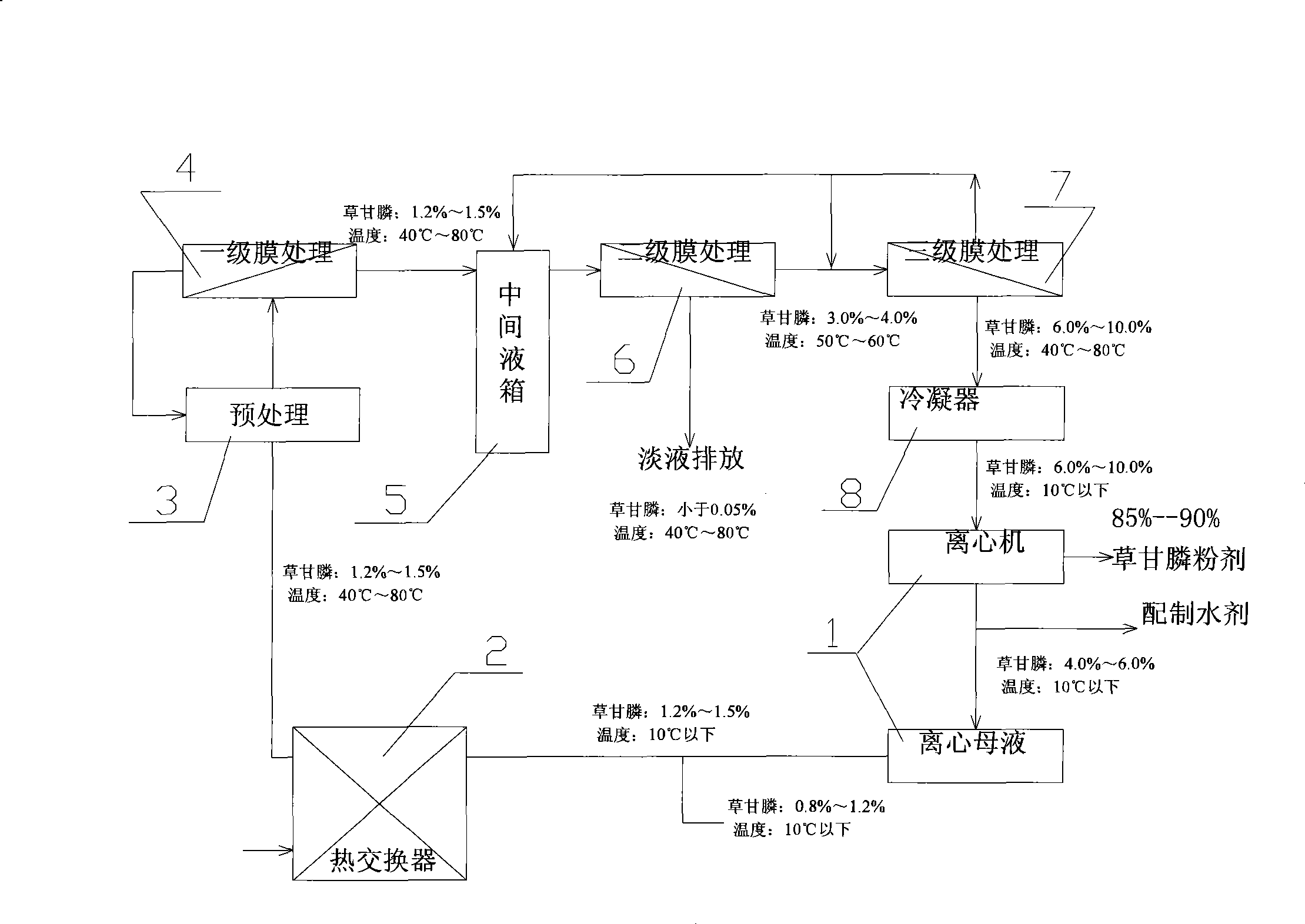

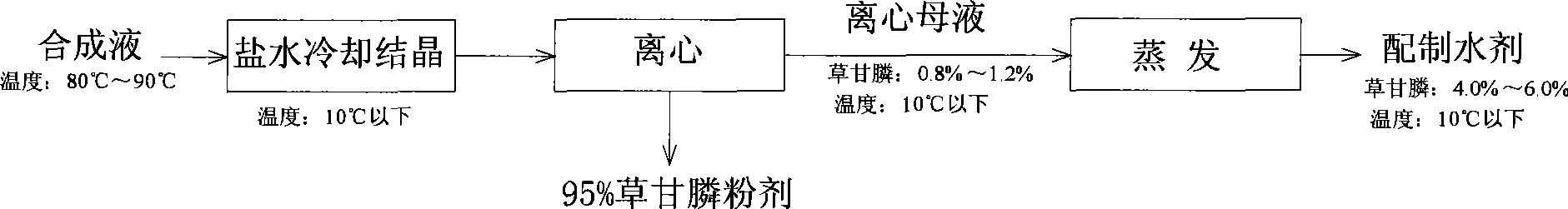

Power extraction system and process for glyphosate mother liquor by IDA method

InactiveCN101434620ANo foulingHigh economic valueGroup 5/15 element organic compoundsEngineeringPower extraction

The invention relates to a system and a technique for extracting powder from glyphosate mother liquid by an IDA method, wherein, the glyphosate mother liquid flows from a discharge port of a centrifuge to a heat exchanger, from a discharge port of the heat exchanger to the inlet of a preprocessing device, the outlet of the preprocessing device, the inlet of a primary membrane processor and the outlet of the primary membrane processor in sequence; and then, the glyphosate mother liquid is divided into two paths, one path of the glyphosate mother liquid returns to the inlet of the preprocessing device and the other path of the glyphosate mother liquid flows to the inlet of a secondary membrane processor, the outlet of the secondary membrane processor, the inlet of a tertiary membrane processor, the outlet of the tertiary membrane processor, the inlet of a condenser, the outlet of the condenser and the inlet of the centrifuge in sequence. The system and the technique have the advantages that: firstly, membrane concentration is carried out under high temperature ranging from 50 DEG C to 80 DEG C so that the glyphosate mother liquid is crystallized outside a membrane component system, thus avoiding the blockage of the membrane; secondly, the heat energy of a synthetic solution and the glyphosate mother liquid are utilized effectively; thirdly, the glyphosate mother liquid is circulated for powder extraction, thereby reducing the total quantity of the glyphosate mother liquid and greatly reducing pollution emission and pressure of environmental protection; and fourthly, the glyphosate mother liquid is concentrated to extract the powder, thus significantly increasing the economic value of the glyphosate mother liquid.

Owner:HANGZHOU TIAN CHUANG ENVIRONMENTAL TECH

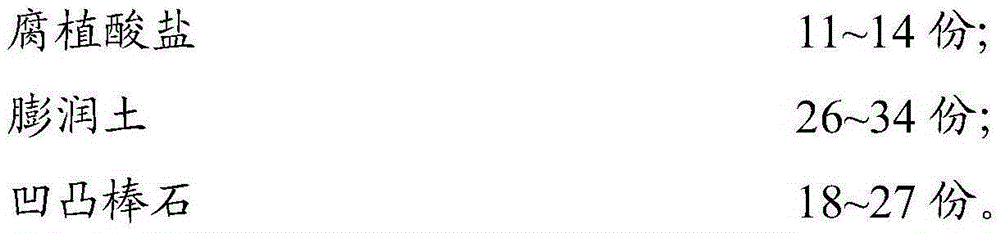

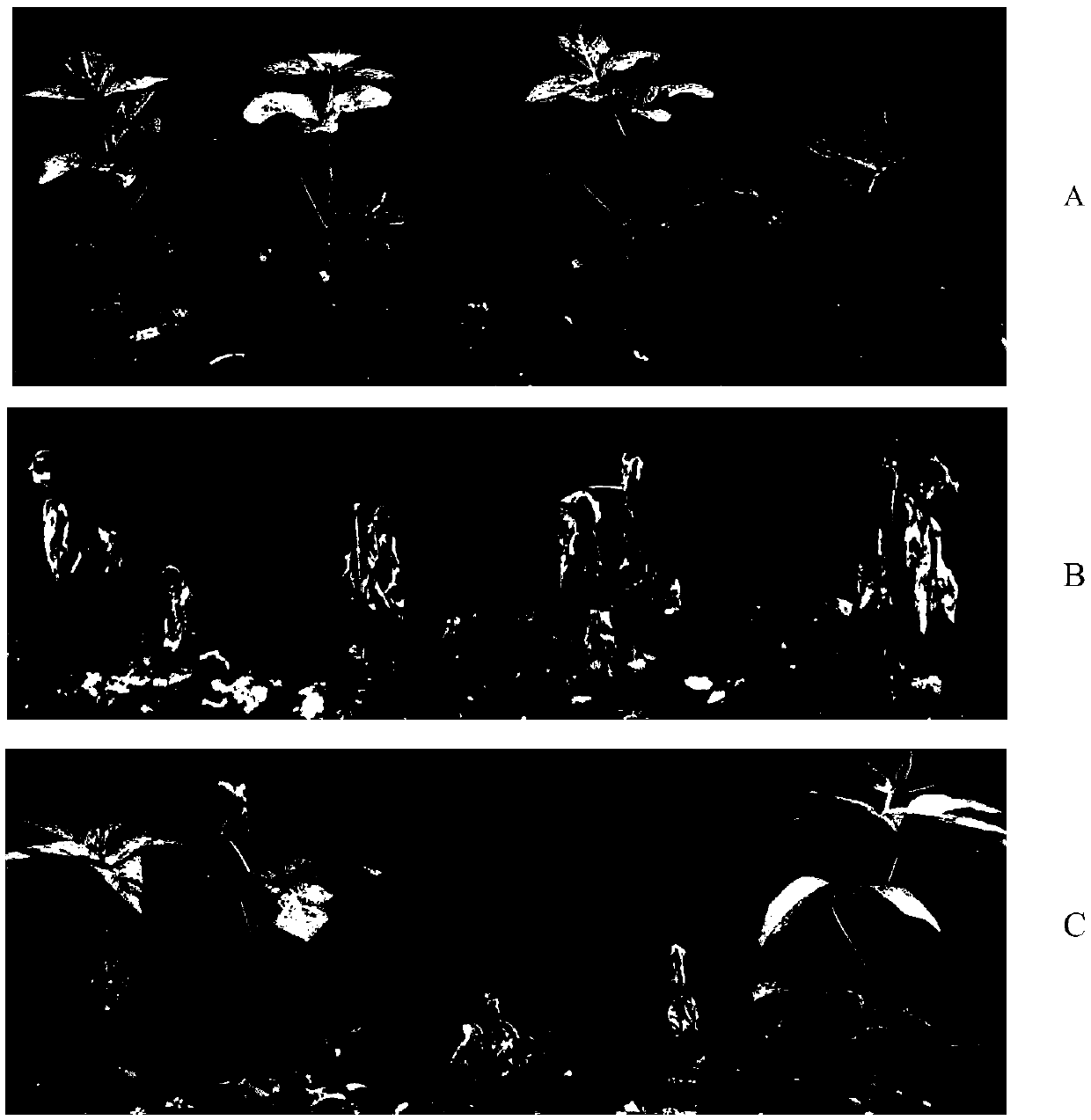

Maize transformation event and specificity identification method and application thereof

PendingCN106167818AEffect of agronomic traitsGenetic stabilityAntibody mimetics/scaffoldsMicrobiological testing/measurementBiotechnologyResistant genes

Owner:HANGZHOU RUIFENG BIOTECH LIMITED

Treatment method for phosphor-containing wastewater produced in glyphosate production process

ActiveCN104058516AAccelerate the speed of photocatalytic reactionThorough responseMultistage water/sewage treatmentNature of treatment waterPtru catalystPhoto catalytic

The invention relates to a treatment method for phosphor-containing wastewater produced in a glyphosate production process. Perovskite type nano LaFeO3 rear-earth composite compound is taken as a catalyst, the catalyst is applied to photocatalysis treatment of glyphosate phosphor-containing wastewater, a flocculating agent for flocculation treatment is added in wastewater treated by the photocatalysis in the first step, and content of total phosphor of the wastewater treated in the second step is less than 20mg / L. The treatment method disclosed by the invention is simple and quick, efficient and pollution-free; moreover, the rear-earth composite compound can be recycled and re-utilized, is low in economic cost, high in utilization rate, good in treatment effect; and the flocculated and deposited sludge can be used as the raw material for producing a phosphor fertilizer.

Owner:ANHUI COSTAR BIOCHEM CO LTD

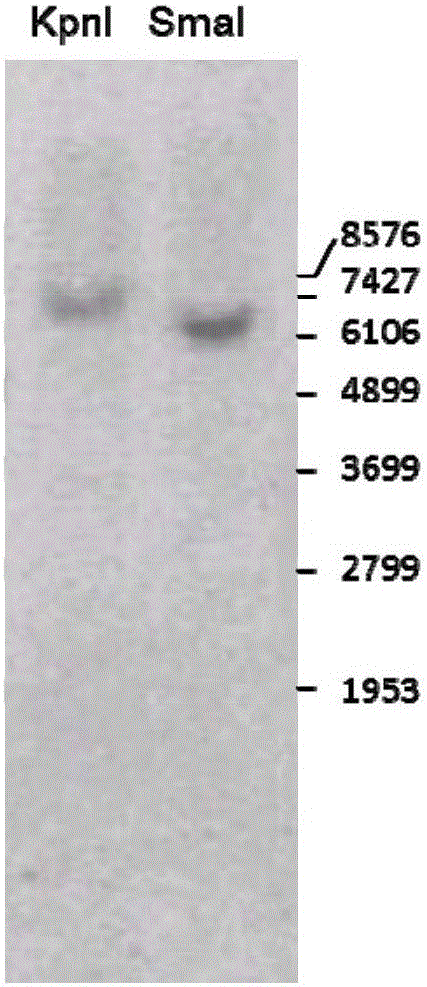

Glyphosate mother liquor resource utilization system

ActiveCN105236376AAchieve reductionRealize harmless treatmentEnergy inputPhosphorus compoundsFlue gasExhaust fumes

The invention discloses a glyphosate mother liquor resource utilization system, and relates to the environmental protection technical field of treating the three wastes of waste liquid, waste gas and solid waste. The system mainly comprises a mother liquor concentration system, a thermal oxidation reaction system, a residual heat recovery system, a flue gas environment-friendly treatment system, and a solid product recovery system. The mother liquor concentration system is respectively communicated with the thermal oxidation reaction system and the residual heat recovery system. The thermal oxidation reaction system is communicated with the residual heat recovery system and the solid product recovery system. The residual heat recovery system is communicated with the flue gas environment-friendly treatment system and the solid product recovery system. The flue gas environment-friendly treatment system is communicated with the solid product recovery system. With the system provided by the invention, chemical engineering waste liquid can be treated with an environment-friendly manner. The chemical engineering waste can be subjected to a thermal oxidation reaction, such that valuable chemical engineering products can be produced, and a purpose of resource utilization is achieved. Also, waste heat is fully utilized, such that energy can be saved.

Owner:大连科林能源工程技术开发有限公司

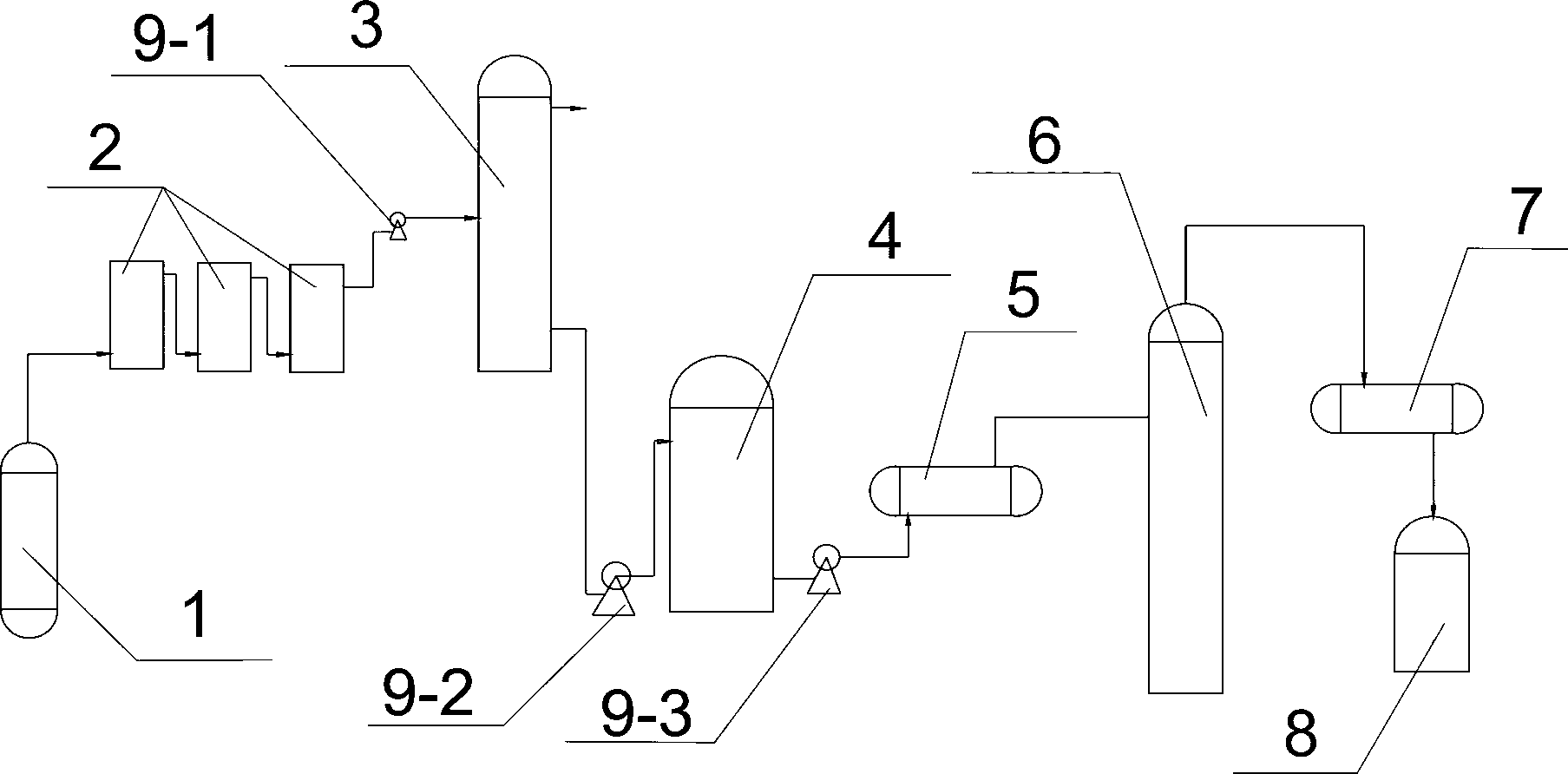

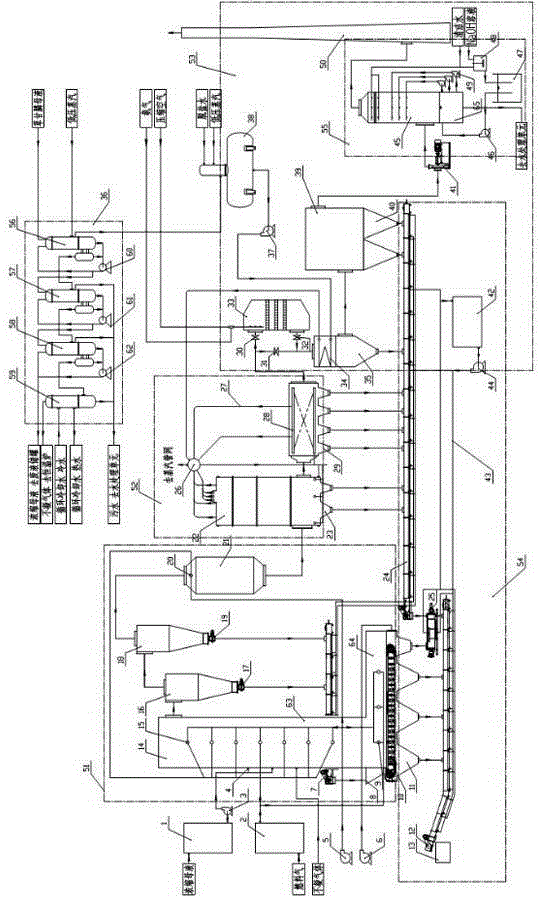

Glyphosate wastewater purifying device and purifying method

InactiveCN104176851AImprove purification rateImprove stripping efficiencyMultistage water/sewage treatmentNature of treatment waterGliphosateAmmonia gas

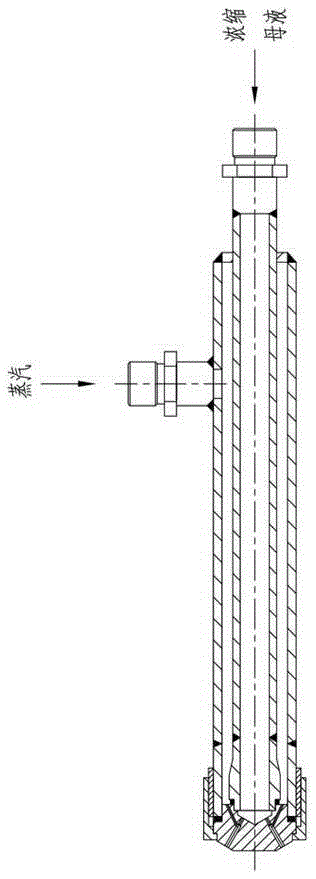

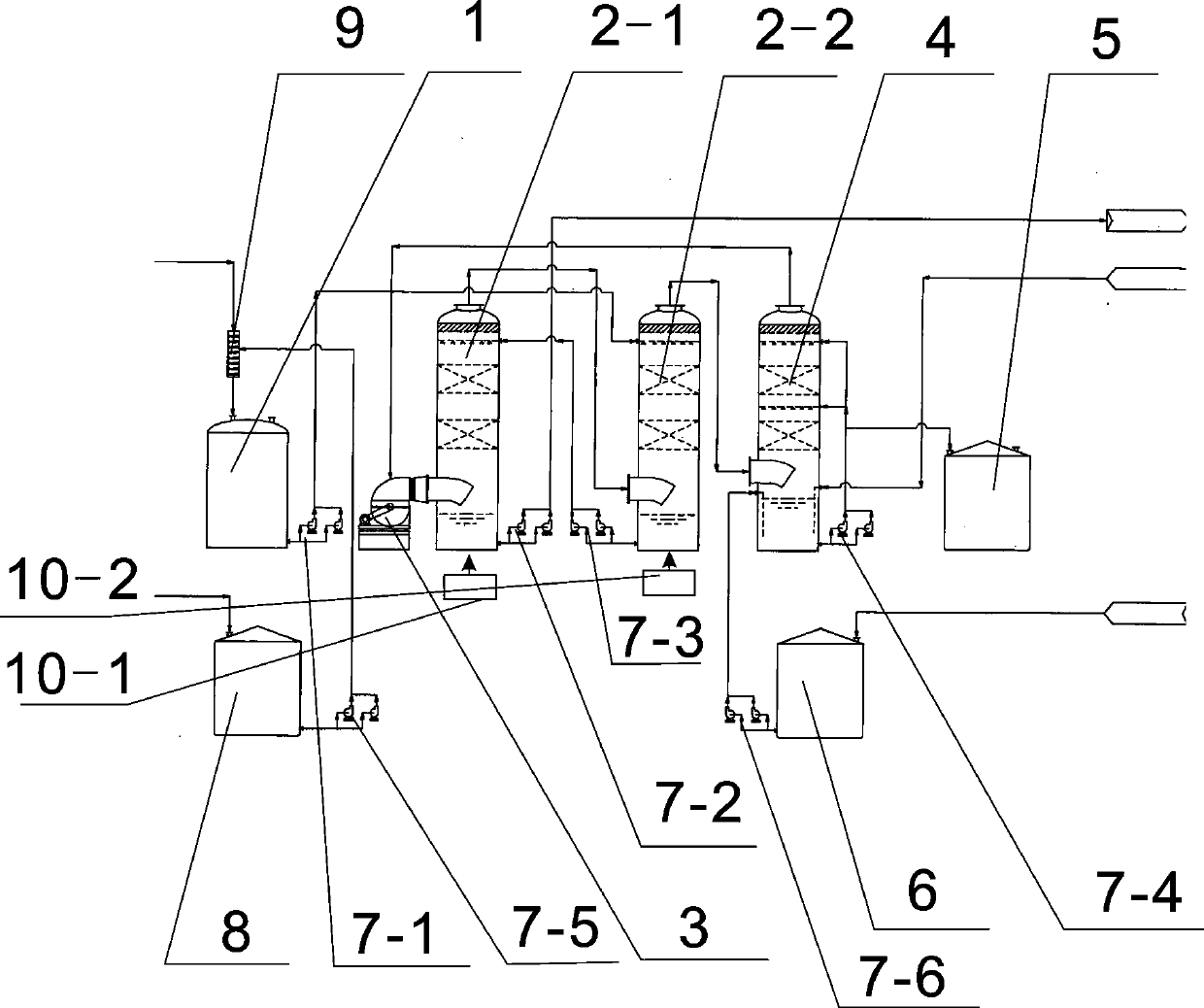

The invention relates to a glyphosate wastewater purifying device. According to the device, a pH regulating tank is connected with a spraying layer of an air stripping tower (2-2) through an air stripping pump (7-1); the air stripping tower (2-2) is connected with a spraying layer at the upper end of an air stripping tower (2-1) via an air stripping pump (7-3); the top end of the air stripping tower (2-1) is connected with the bottom of the air stripping tower (2-2); the top end of the air stripping tower (2-2) is connected with an inlet in the bottom of an absorption tower (4); and the top of the absorption tower (4) is connected with the air stripping tower (2-1) after being connected with an air stripping fan (3). Ammonia gas obtained through first-level and second-level air stripping by adopting the equipment is neutralized via sulfuric acid to prepare ammonium sulfate for being used in the next step. The device has the advantages that the device is high in purifying rate, the air stripping efficiency of the purifying method is far higher than that of a traditional air stripping method and the ammonia gas air stripping efficiency can be up to 98%; the ammonia gas with large wastewater quantity and high concentration can be recycled; and an absorption and purification tower adopts second-level reverse spraying, the specific surface area of padding is large, the performance stability is guaranteed through the gas liquid ratio confirmed by experimental researches and the ammonia gas absorbing efficiency can be up to 95%.

Owner:HUBEI TAISHENG CHEM

Method for recycling and treating wastewater from glyphosate production

InactiveCN102583825ASimple operation processMild conditionsBiocideMultistage water/sewage treatmentActivated carbonFiber

The invention discloses a method for recycling and treating wastewater from glyphosate production,. The method comprises the following steps: firstly pre-treating the required alkaline ion exchange fiber, ion exchange resin and activated carbon, then packing the pre-treated ion exchange fibre, ion exchange resin and activated carbon via wet packing method to obtain two packed columns, infusing the pre-treated production wastewater of glyphosate to the column packed with basic ion exchange fibre and the column packed with activated carbon and ion exchange resin in sequence adsorption, desorbing the two packed columns by NaOH solution after adequate adsorption, treating the recycled liquid obtained after desorption to obtain 30% original glyphosate, and recycling glycine therein. Through the technical scheme provided by the invention, glyphosate and glycine in wastewater can be recycled at normal temperature and the adsorption rate and desorption rate of glyphosate and glycine can both reach above 90%. The technical scheme provided by the invention not only realizes recycling of effective components, but also reduces the difficulty in subsequent treatment of the glyphosate wastewater so as to reduce the environmental pollution.

Method for treating glyphosate waste water

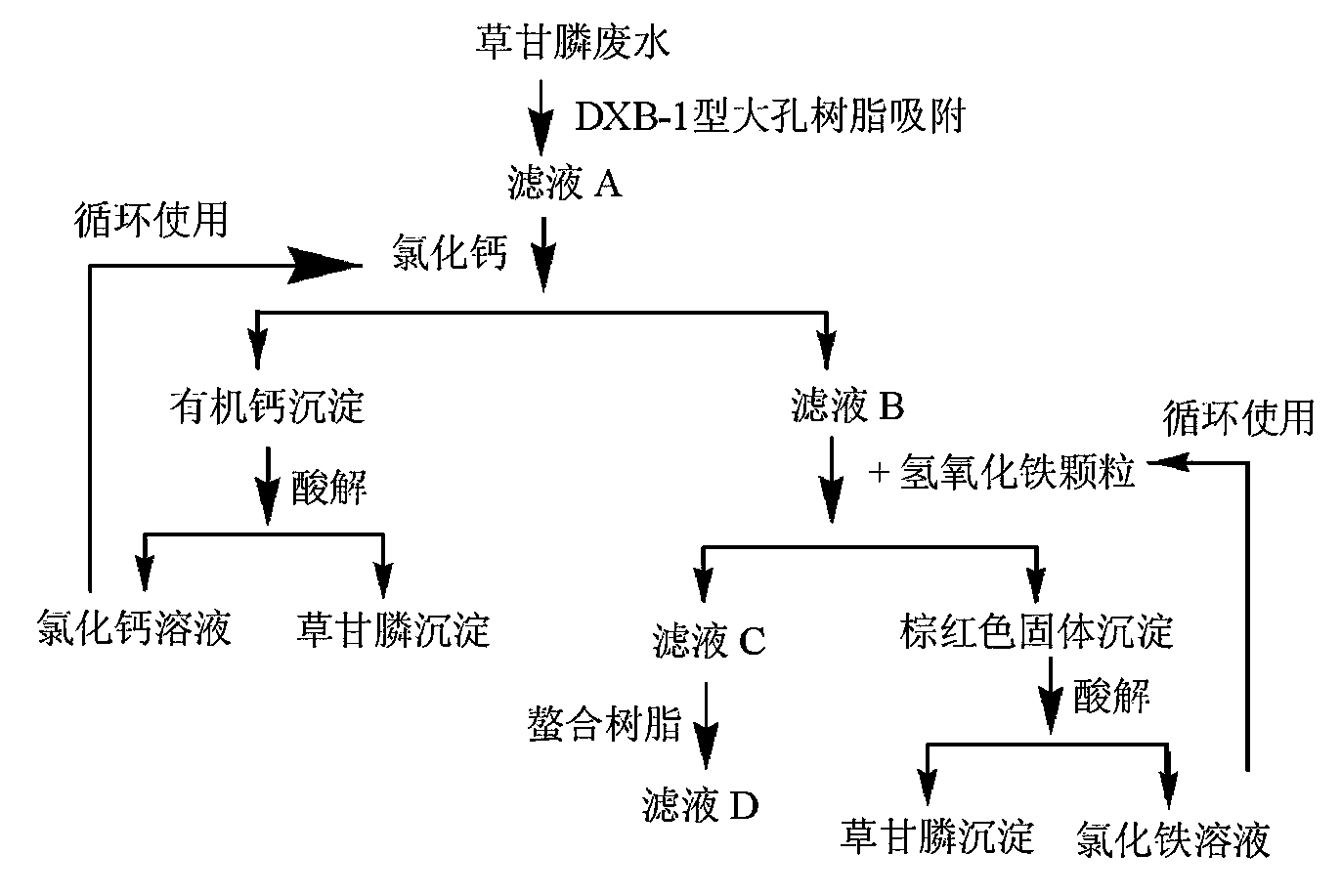

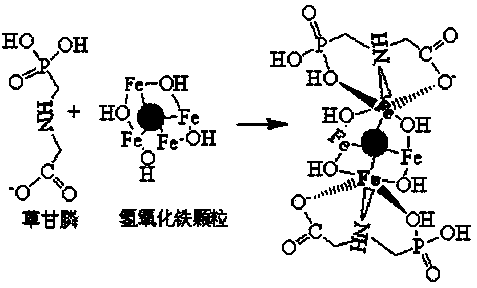

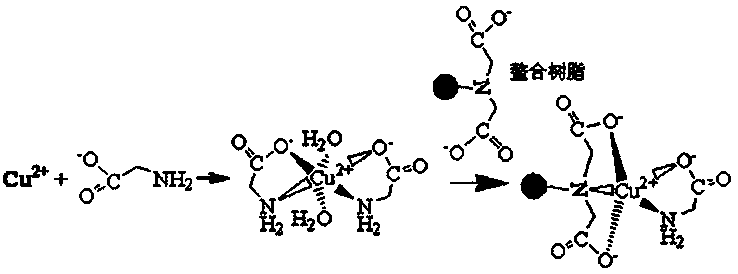

InactiveCN103351070ASolve processing problemsAddress the effects of processingGroup 5/15 element organic compoundsMultistage water/sewage treatmentFerric hydroxideChelating resin

The invention discloses a method for treating glyphosate waste water. The method comprises the follow steps: firstly, adjusting the pH value of the glyphosate waste water to 1.0 with hydrochloric acid, and then obtaining a clear and transparent filter liquor through an adsorption method; secondly, adding calcium chloride to the filter liquor to control the pH valve of the filter liquor is larger than 8.0, and filtering the filter liquor to separate an organic calcium sediment; then, adjusting the pH value of the obtained filter liquor to 4.0-5.0, adding ferric hydroxide particles to the filter liquor, and filtering the filter liquor to separate a brown-orange solid sediment; finally, adjusting the pH value of the filter liquor to 7.0-8.0 with sodium hydroxide, adding transitional metal ions to the filter liquor, and obtaining the completely treated glyphosate waste water through chelate resin. The method has the advantages that the operation of the whole process is simple; the cost is low; the feasibility is high. Especially, a small amount of glyphosate is subjected to complexing precipitation through the ferric hydroxide particles; on the basis of the complexing principle, a small quantity of organic matters are subjected to adsorption treatment through the chelate resin, so that in the completely treated glyphosate waste water, the phosphorus content is lower than 1.0 mg / L, the carbon content is lower than 100 mg / L, the nitrogen content is lower than 20 mg / L; the COD (Carbon Doped Oxide) content is lower than 200 mg / L.

Owner:MINNAN NORMAL UNIV

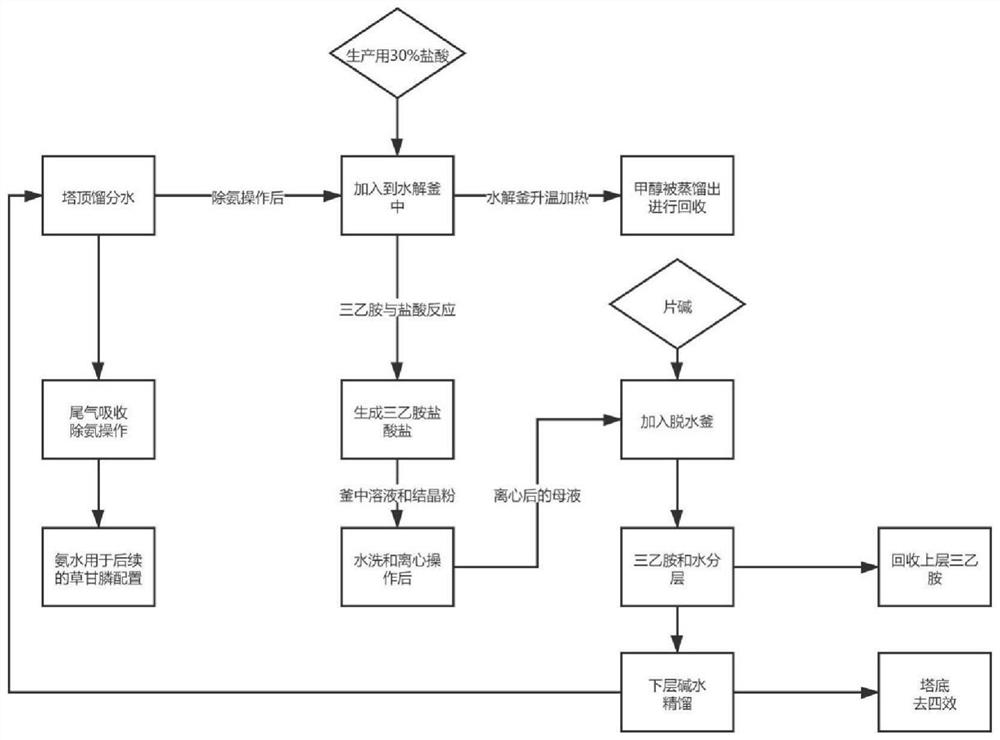

Method for recycling distillate water at top of alkali mother liquor rectifying tower in glyphosate production process

PendingCN113827992AReduce adverse effectsThe process steps are simpleGas treatmentGroup 5/15 element organic compoundsPulp and paper industryIndustrial water

The invention relates to a technology for producing glyphosate by a glycine method, and relates to a method for recycling distillate water at the top of an alkali mother liquor rectifying tower in a glyphosate production process. The method sequentially comprises the following steps: a) adding alkali to neutralize the acid mother liquor in the glyphosate process, and replacing triethylamine in a layering manner; b) rectifying the treated alkali mother liquor; condensing the fractions to recover methanol, triethylamine and water as recovery liquid; emptying ammonia to a tail gas absorption tower to obtain ammonia water; c) adding the recovery liquid into a hydrolysis kettle in the glyphosate production process by a glycine method to serve as industrial water; in the heating process of the hydrolysis procedure, methanol is distilled and recycled; and d) forming an acid mother liquor after the subsequent glyphosate production crystallization and solid-liquid separation processes of the remaining triethylamine hydrochloride along with the mother liquor are completed, and returning to the step a). The method has the advantages that the process steps are simplified, the equipment cost and the operation cost are reduced, and the adverse effect of fraction accumulation on glyphosate production is effectively avoided.

Owner:ZHENJIANG JIANGNAN CHEM

IDA method glyphosate wastewater resource treatment method

ActiveCN104591424AAchieving zero emissionsEasy to handleOrganic compound preparationGroup 5/15 element organic compoundsFormatePhosphate

The present invention discloses an IDA method glyphosate wastewater resource treatment method, which comprises: making glyphosate wastewater obtained through the IDA method pass through a reverse osmosis membrane, separating the glyphosate to obtain a glyphosate concentrated liquid and a formaldehyde light liquid, filtering the concentrated liquid, recovering the glyphosate, adjusting the pH value of the remaining filtrate and burning to obtain a pyrophosphate, adopting an oxidation method to oxidize the formaldehyde in the light liquid into formic acid in a directed manner, concentrating the formic acid in the light liquid, and reacting to produce formate. According to the present invention, the glyphosate, the formaldehyde and the formic acid in the glyphosate wastewater are effectively treated and recovered, the treated wastewater can be completely used for production so as to achieve zero emission, and the recovered glyphosate, the recovered pyrophosphate and the recovered formate can be directly sold so as to provide a certain benefit, retrieve the investment and the operation cost, and provide great environmental protection and economic values.

Owner:SHANDONG WEIFANG RAINBOW CHEM

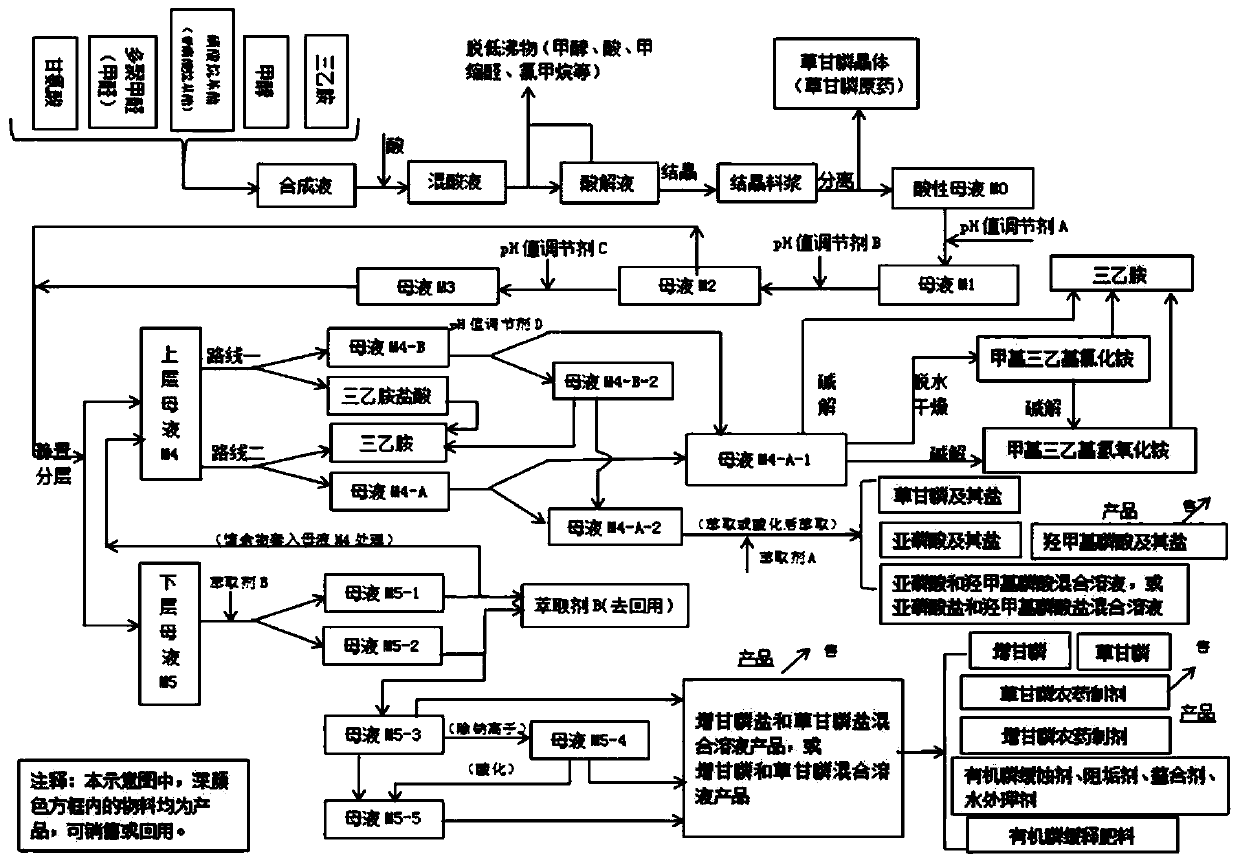

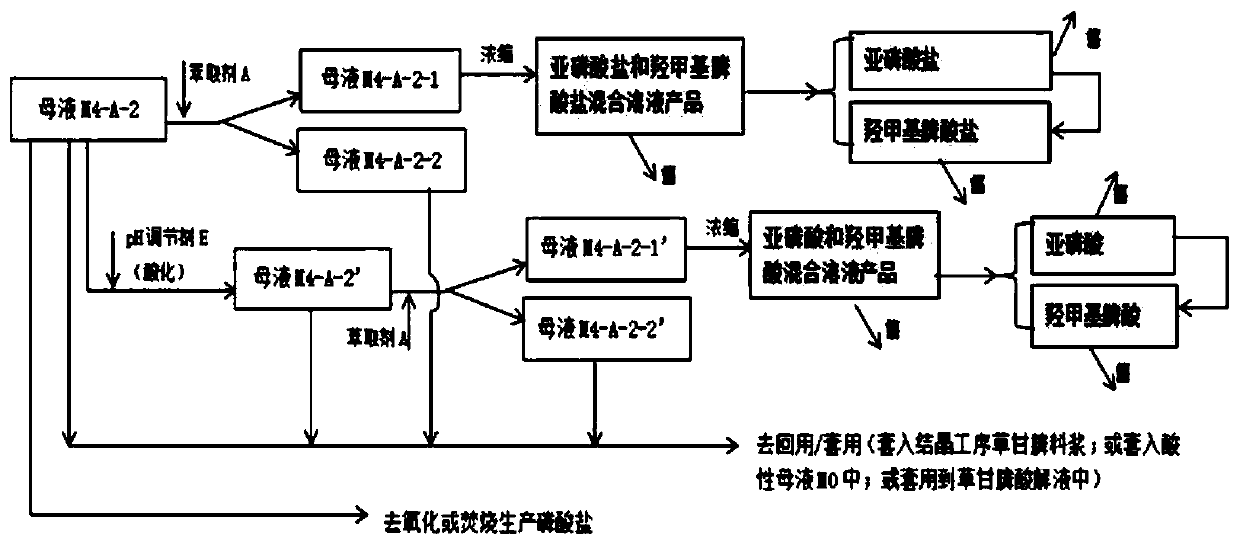

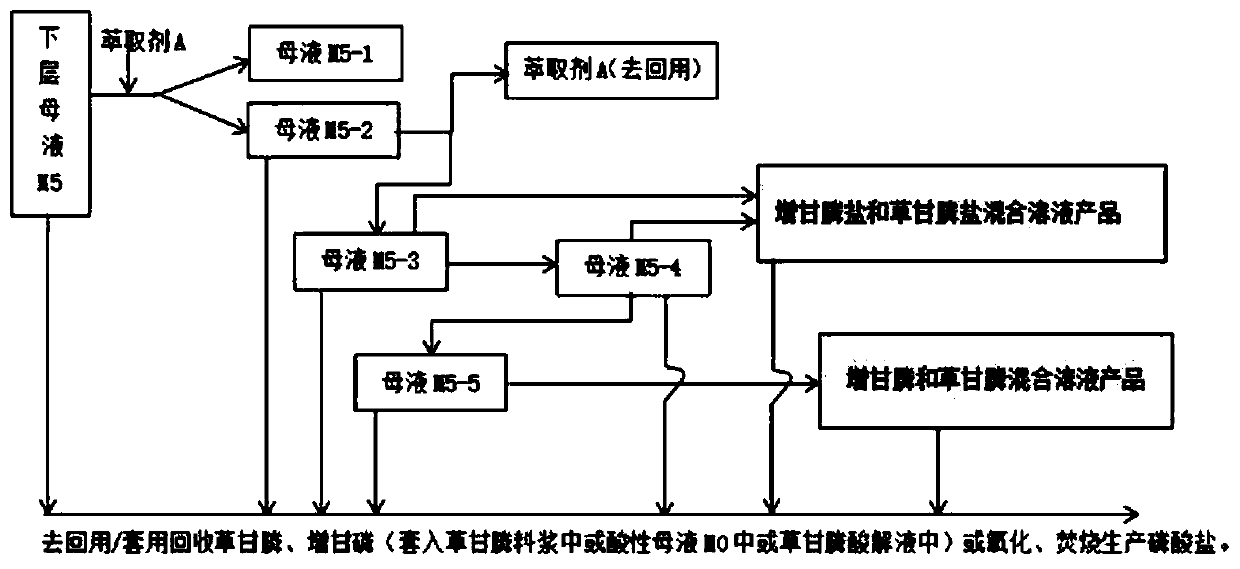

Glyphosate mother liquor comprehensive treatment and resource recycling method

PendingCN111333519AReduce volume and handling costsLess impuritiesAmino compound purification/separationGroup 5/15 element organic compoundsPhosphorous acidPulp and paper industry

The invention discloses a glyphosate mother liquor comprehensive treatment and resource recycling method which comprises the following steps: adding a pH value regulator into acidic mother liquor M0,standing for layering, and separating the solution to obtain mother liquor M4 at the upper layer and mother liquor M5 at the lower layer; the mother liquor M4 and the mother liquor M5 are treated andapplied, triethylamine hydrochloride, triethylamine, chloride salt, methyltriethylammonium chloride, phosphorous acid or salt thereof, hydroxymethylphosphonic acid or salt thereof, glyphosate or saltthereof, glyphosate or salt thereof and glyphosate or salt thereof are recovered from the mother liquor M4 and the mother liquor M5, and are respectively and correspondingly converted into products with higher additional values for utilization. The glyphosate mother liquor comprehensive treatment and resource recycling method has the advantages that the emission is reduced from the source; the method reduces the total amount and treatment load of the glyphosate mother liquor, reduces environmental pollution, realizes reasonable recycling and appreciation of resources, improves economic benefits, is environment-friendly, outstanding in economic benefits and good in technical implementation effect, and is suitable for large-scale industrial application.

Owner:陈兴华

Glyphosate choline active compound and preparation, and preparation method thereof

ActiveCN104277071ASimple processRaw materials are easy to getBiocideOrganic compound preparationDrug contentPhosphonium choline

The invention discloses a glyphosate choline active compound and preparation, and a preparation method thereof. The preparation can be an aqueous solution or water-soluble granules. The content of the glyphosate choline in the preparation is 5-95 wt%, preferably 15-90 wt%, further preferably 35-90 wt%, most preferably 50-90 wt%, further most preferably 55-90 wt% and optimally 80 wt%. The preparation method comprises the following steps: simple technique, has the advantages of, high economy and safety, accessible raw materials and environment friendliness; and the prepared glyphosate choline active compound has the advantages of identical efficacy to glyphosate, environment friendliness and high purity, can be used for preparing different types of preparations, and especially can be used for preparing preparations with high drug content. The active compound and preparation have the advantages of stable physico-chemical properties and high water solubility, and can be used for preparing preparations with high drug content; and the preparation does not deteriorate or deform when being heated or extruded, and thus, has high stability.

Owner:SHANDONG WEIFANG RAINBOW CHEM

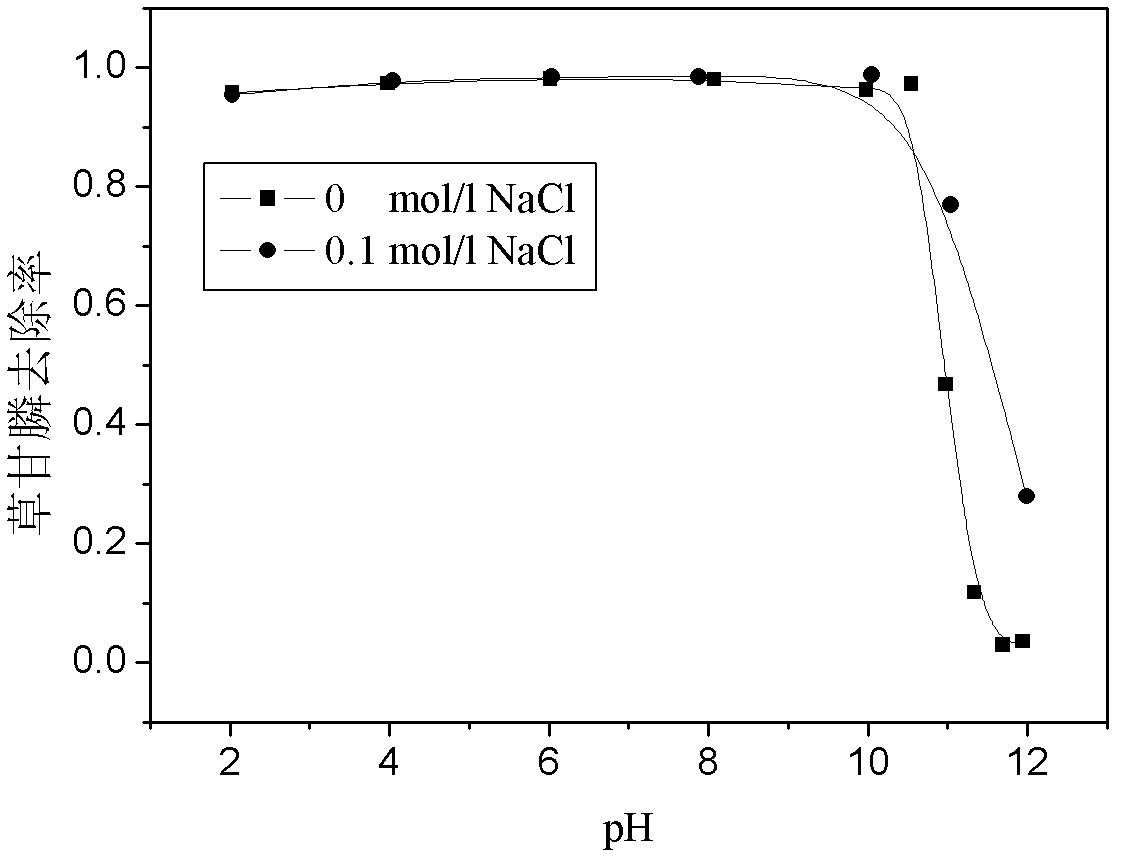

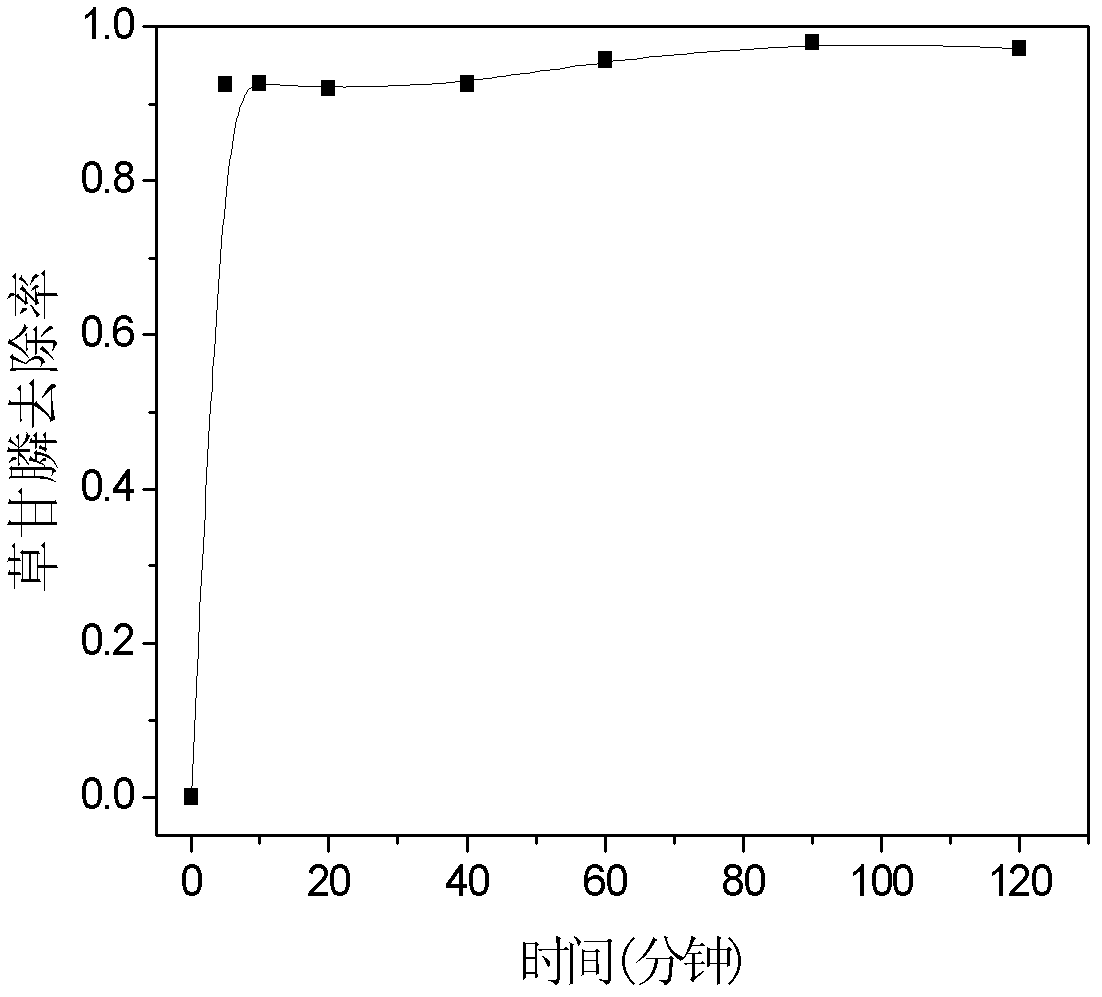

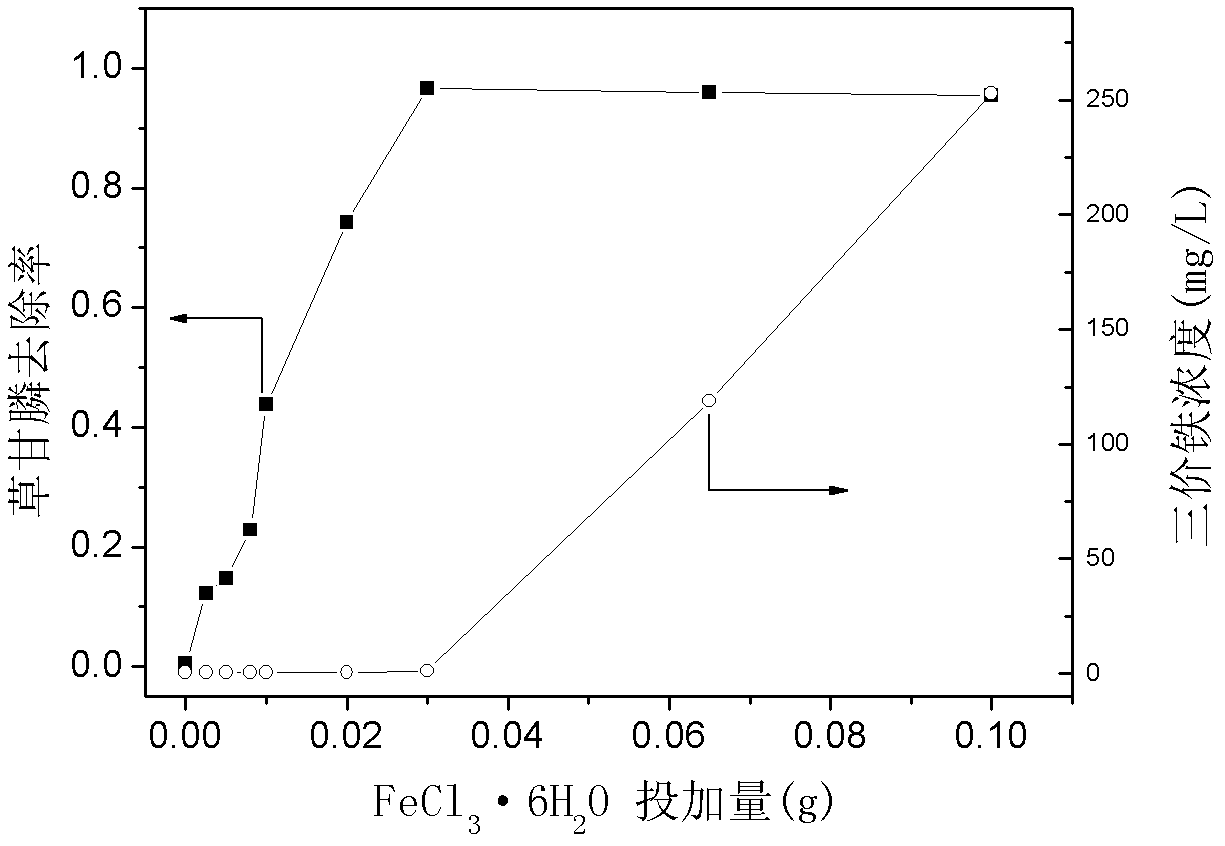

Method for removing glyphosate in water body by using montmorillonite

InactiveCN102583673AAchieve removalImprove adsorption efficiencyWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionMontmorilloniteWastewater

The invention discloses a method for removing glyphosate in water body by using montmorillonite. The method comprises the following steps: grinding and drying montmorillonite, then adding glyphosate wastewater and a ferric salt, mixing evenly, performing solid-liquid separation at the reaction end point when the pH value is 2-4 and finishing the treatment, wherein the dosage of montmorillonite is2-10g / L and the dosage of the ferric salt is 0.3-1g / L. The method disclosed by the invention uses cheap raw material-montmorillonite and ferric chloride and can quickly realize the treatment of the glyphosate wastewater.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com