However, the two-stage

incineration device and

incineration system described in this patent has the following disadvantages: (1) The outlet of the vertical furnace is directly connected to the secondary

combustion settling chamber, and a large amount of salt-containing solid particles carried in the

flue gas are heated again, making it When it becomes molten, the settled

molten salt-containing solid particles will block the

slag discharge hole of the secondary

combustion settling chamber, and the

molten salt-containing solid particles brought into the heat exchange unit will stick to the heat exchange tube, resulting in The

thermal efficiency is reduced, and even the

flue gas channel is blocked; (2) The front of the scale circulating grate is equipped with a hopper, which cannot return the unburned solid particles containing salt to the horizontal furnace for further

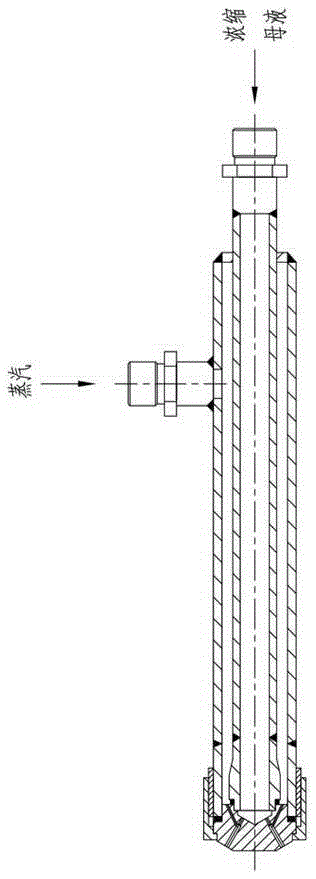

incineration. The impurities of chemical raw materials produced during the incineration process (3) The waste liquid atomizing spray gun is a two-fluid structure atomizing gun, and the outer layer is a

compressed air pipeline. According to experience, the glyphosate mother liquor has a high

viscosity at

room temperature, and it needs to be heated to reduce its

viscosity coefficient, while

compressed air is mostly At

room temperature, using

compressed air as the atomization medium will cool the glyphosate mother liquor, the

viscosity coefficient will increase, the

nozzle will be blocked, and the atomization effect will be affected, and the atomization effect is an important factor affecting the

combustion efficiency; (4) vertical furnace , The horizontal furnace and the secondary combustion

settling chamber do not limit the incineration temperature. From the collection of solid materials, it can be seen that although it is two-stage combustion, it is basically low-temperature combustion, and the

organic matter in the waste liquid cannot be completely incinerated. It also cannot meet the national "

Pollution Control Standards for

Hazardous Waste Incineration"; (5) The glyphosate mother liquor sprayed into the vertical furnace through the waste liquid atomization spray gun has not been concentrated, and the glyphosate mother liquor contains a large amount of water, which makes this A large amount of auxiliary fuel is consumed for part of the water to reach the combustion temperature of the furnace, resulting in a waste of energy

However, the method and device for producing

sodium pyrophosphate by constant-temperature

calcination of glyphosate mother liquor described in this patent has the following disadvantages: (1) The three inlets of the incinerator are respectively glyphosate mother liquor pipeline and combustion air from bottom to top Pipelines and

natural gas pipelines are all supplied in a centralized manner, and the combustion area is relatively concentrated, resulting in excessive local temperature, which will generate more thermal

NOx, and there is no

denitrification device at the rear, and the

environmental protection is not up to standard; (2) The three parts of the incinerator The two inlets from bottom to top are glyphosate mother liquor pipeline, combustion air pipeline and

natural gas pipeline, all of which are supplied in a centralized manner, and the combustion area is relatively concentrated, resulting in excessive local temperature and uneven temperature field, so that the glyphosate mother liquor cannot Complete combustion, there are organic residues on the surface of

sodium pyrophosphate solid particles, and the purity of

sodium pyrophosphate is low; (3) The glyphosate mother liquor is directly sprayed into the furnace through a

booster pump, and the droplet

diameter is relatively large, so the

evaporation of the glyphosate mother liquor, The

decomposition and oxidation time will increase correspondingly, which is not conducive to the complete incineration of glyphosate mother liquor; (4) The salt produced during the

combustion process in the incinerator will settle under the action of gravity and then sent to the

slag remover, because the salt produced during the

combustion process If it is in a

molten state, it will stick to the internal transmission device of the

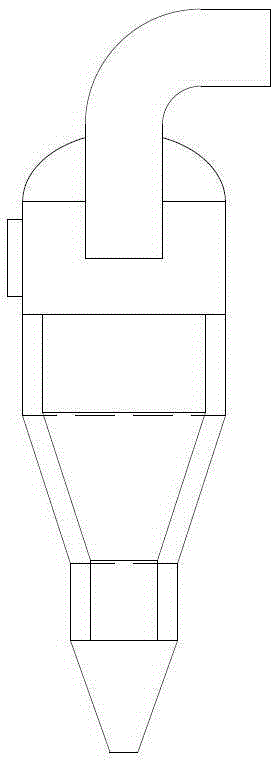

slag remover when it enters the slag remover, which will eventually cause the blockage of the slag remover; (5) There are two combustion chambers in the incinerator, and the

reaction temperature in the second

combustion chamber is controlled at 900 ~ At 1000°C, the

molten salt enters the

cyclone dust collector along with the

flue gas, and the molten salt will bond along the circumferential direction of the

cyclone dust collector, eventually blocking the

cyclone dust collector; Ideally, unseparated molten salt is likely to block the rear heating surface and flue; (7) The glyphosate mother liquor sprayed into the vertical furnace through the waste liquid atomization spray gun has not been concentrated, and the glyphosate mother liquor contains A large amount of water, so that this part of water reaches the combustion temperature of the furnace needs to consume a large amount of auxiliary fuel, resulting in a waste of energy; (8) There are 3 cooling chambers in the

waste heat boiler, and the cooling chambers are generally cavities surrounded by membrane water walls Type heating surface, mainly based on

radiation heat transfer, the

heat transfer effect is good when the flue gas temperature is high, and the

heat transfer effect is not good when the flue gas temperature is low, it is necessary to increase the heating surface to reduce the flue gas temperature, which increases the initial

investment cost of the equipment; (9) The induced draft fan is arranged after the

water washing spray tower, which increases the load of the induced draft fan and increases the

power consumption Login to View More

Login to View More  Login to View More

Login to View More