Method for treating glyphosate waste water

A technology of glyphosate wastewater and a treatment method, which is applied in the field of glyphosate wastewater treatment, can solve the problems of waste of resources, difficult to control, slow treatment speed and the like, and achieves the effects of simple process operation, improved competitiveness and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

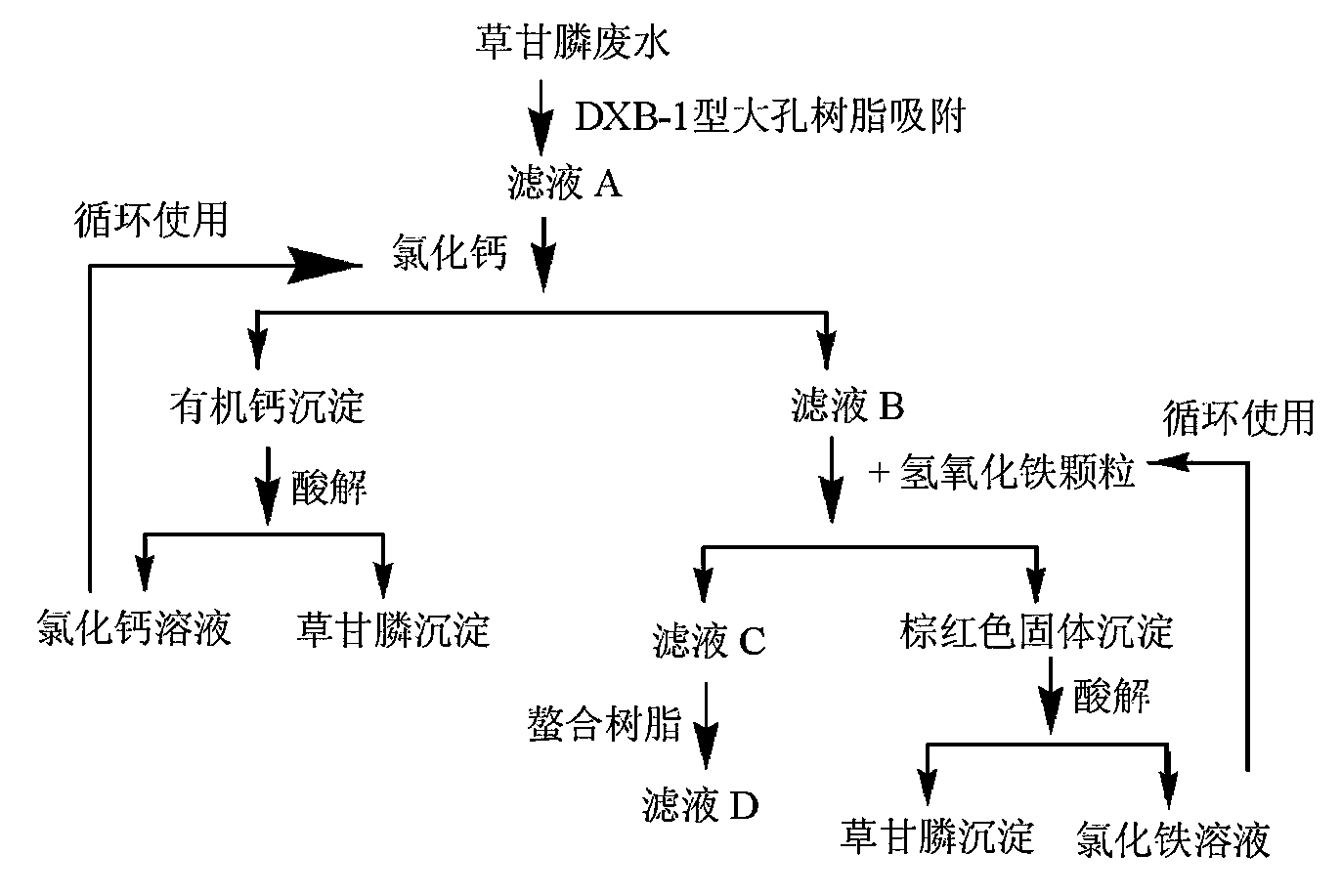

[0022] Cooperate figure 1 Shown, the present invention discloses a kind of processing method of glyphosate waste water, its specific operation steps:

[0023] Step 1. Use hydrochloric acid to adjust the pH value of the solution to about 1.0 with 10L of brown-red glyphosate wastewater, and then absorb it through DXB-1 macroporous resin to obtain a clear and transparent filtrate A;

[0024] Step 2, then add 0.5 kg of calcium chloride, control the pH value of filtrate A to be greater than 8.0, stir for 1 hour, filter, and separate the organic calcium precipitate and filtrate B;

[0025] Step 3, then use hydrochloric acid to adjust the pH value of the obtained filtrate B to 4.0-5.0, then add 0.08 kg of ferric hydroxide particles, stir at room temperature for half an hour, filter, and separate the brownish yellow solid precipitate and filtrate C;

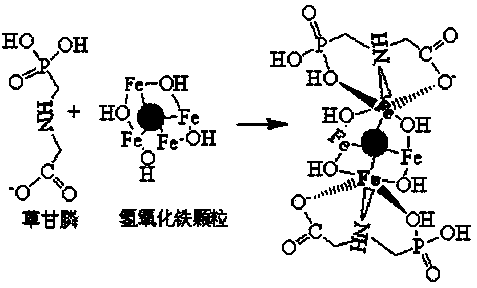

[0026] Here, the treatment principle of iron hydroxide particles to glyphosate is as follows:

[0027]

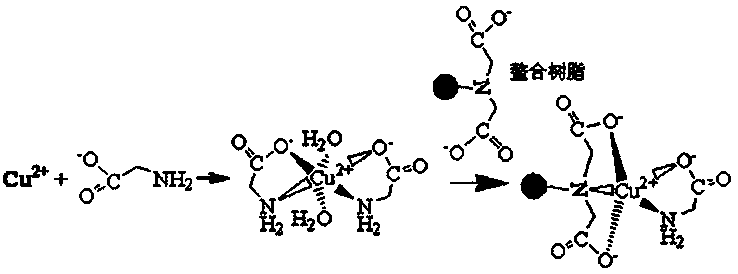

[0028] Step 4, finally ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com