Method for recycling distillate water at top of alkali mother liquor rectifying tower in glyphosate production process

A mother liquor rectification tower and production process technology, applied in the field of recovery and utilization of distillate water at the top of the alkali mother liquor rectification tower in the glyphosate production process, can solve the problem of not having discharge conditions, affecting the pressure stability of the rectification tower, and the yield of glyphosate Reduce and other problems, achieve the effect of reducing equipment cost and operating cost, simplifying process steps, and avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further illustrated below by detail below:

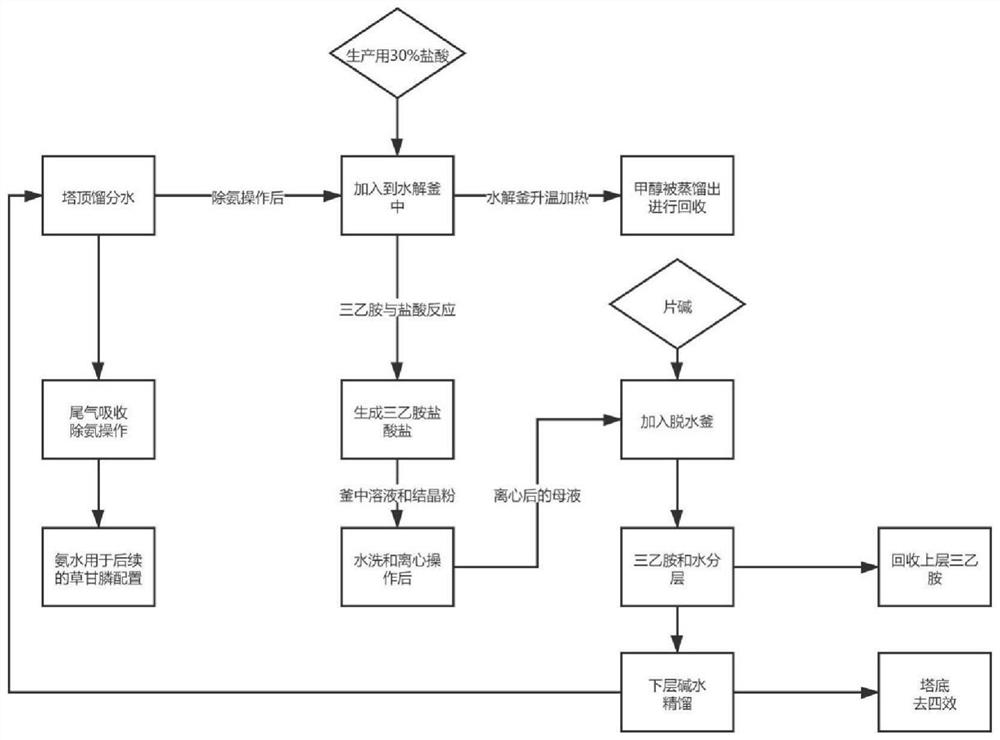

[0023] Glyphosate production in the process of glyphosate was produced in a triethylamine dehydrate, and triethylamine was replaced by reactive in the kettle.

[0024] After treatment, the alkali-liquid obtained, rectified in the triethylamine rectification column, condensed, recovered methanol, triethylamine, and water as a recovery liquid; the ammonia in the fraction was released to the exhaust gas absorption tower. Water is absorbed to absorb ammonia and obtain ammonia water;

[0025] The fraction feedstock samples come from triethylamine rectification column, and the weight of the component is methanol (content of 30% -40%), triethylamine (content of 3% -5%), ammonia (content of 8% to 10%) and Water (content 45% -59%).

[0026] The fraction feedstock passes through triethylamine rectification column, ammonia is discharged into the absorption tower from the exhaust gas, and the amount of exhaust is 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com