Method for recycling methylal in glyphosate wastewater

A technology of glyphosate wastewater and methylal, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as environmental pollution, waste, waste and environmental protection, and achieve improved recovery rate, effective recovery, The effect of reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

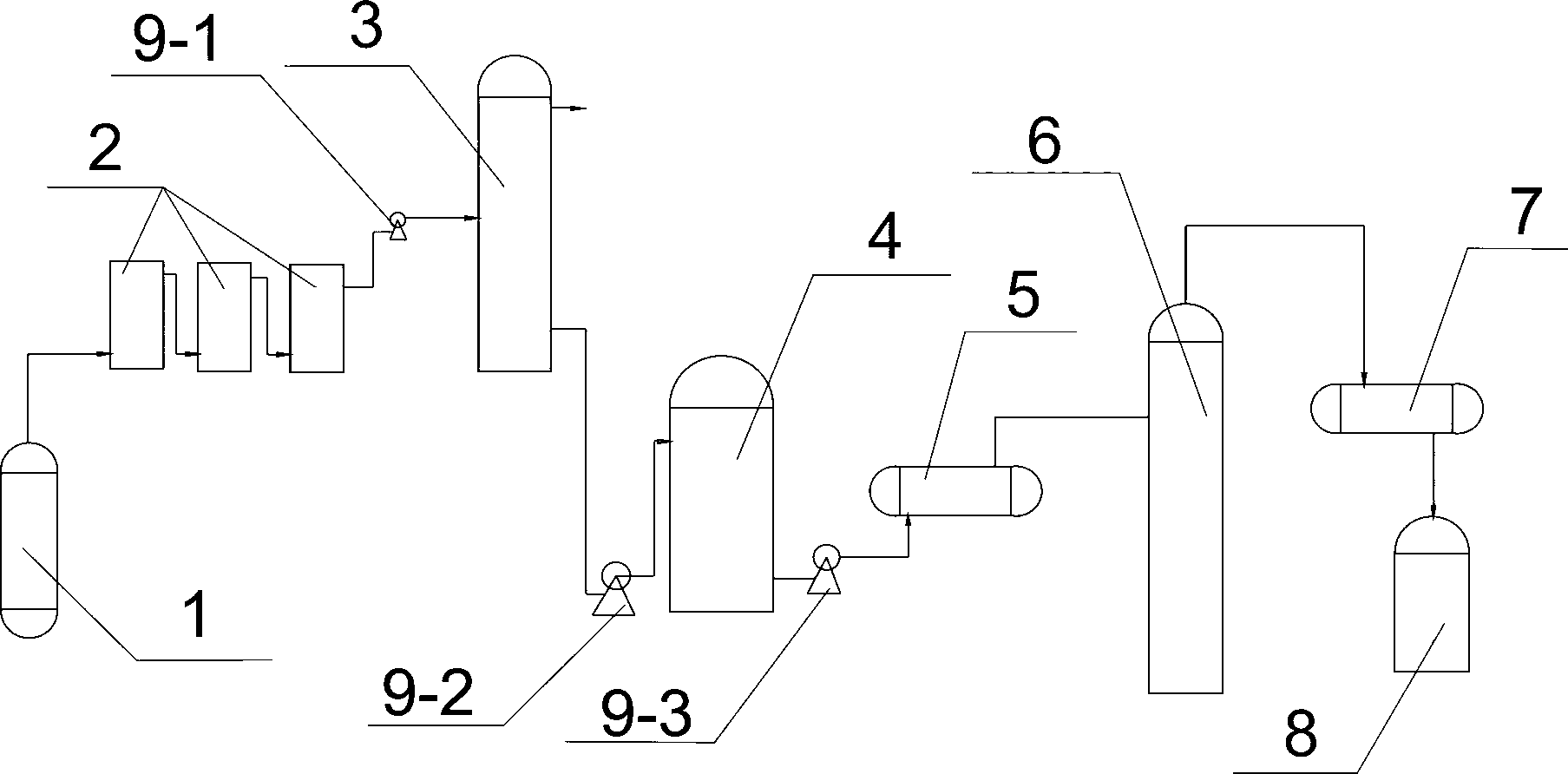

[0010] After deacidification of glyphosate through the dealcoholization tank, the methyl chloride tail gas is condensed in three stages and washed in a multi-stage washing tower, the methyl chloride gas is compressed and recovered, and the condensate enters the dilute methanol storage tank. Wash the condensate with 3.5M 3 The flow rate per hour is poured into a preheating kettle at 50-60°C for 10-15 minutes, and the preheated feed liquid is pumped into a distillation tower through a high-pressure pump for distillation. The temperature at the bottom of the distillation tower is controlled at 103°C, and the temperature in the tower is Control the temperature at 65°C, the temperature at the top of the tower at 60°C, and the pressure of the steam valve at 0.15MPa. The low-boiling point methylal in the obtained product is discharged from the top of the distillation tower, and then enters the condenser to reflux and condense the material, and the reflux flow rate is 1.5M 3 / h, the ...

Embodiment 2

[0012] After deacidification of glyphosate through the dealcoholization tank, the methyl chloride tail gas is condensed in three stages and washed in a multi-stage washing tower, the methyl chloride gas is compressed and recovered, and the condensate enters the dilute methanol storage tank. Wash the condensate with 3.8M 3 The flow rate per hour is poured into a preheating kettle at 50-60°C for 10-15 minutes, and the preheated feed liquid is pumped into a distillation tower for distillation through a high-pressure pump. The temperature at the bottom of the distillation tower is controlled at 104°C, and the temperature in the tower is Control the temperature at 75°C, the temperature at the top of the tower at 63°C, and the pressure of the steam valve at 0.42MPa. The low boiling point methylal in the obtained product is discharged from the top of the distillation tower, and then enters the condenser to reflux and condense the material, and the reflux flow rate is 2.0M 3 / h, the ...

Embodiment 3

[0014] After deacidification of glyphosate through the dealcoholization tank, the methyl chloride tail gas is condensed in three stages and washed in a multi-stage washing tower, the methyl chloride gas is compressed and recovered, and the condensate enters the dilute methanol storage tank. Wash the condensate with 4.5M 3 The flow rate per hour is poured into a preheating kettle at 50-60°C for 10-15 minutes, and the preheated feed liquid is poured into a distillation tower through a high-pressure pump for distillation. The temperature at the bottom of the distillation tower is controlled at 105°C, and the temperature in the tower is The temperature is controlled at 85°C, the temperature at the top of the tower is controlled at 64°C, and the pressure of the steam valve is 0.75MPa. The low boiling point methylal in the obtained product is discharged from the top of the distillation tower, and then enters the condenser to reflux and condense the material, and the reflux flow rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com