Glyphosate wastewater purifying device and purifying method

A glyphosate wastewater and purification device technology, applied in chemical instruments and methods, inorganic chemistry, ammonia compounds, etc., can solve problems such as waste of raw materials and difficult treatment, and achieve the effects of optimizing the environment, stabilizing performance, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

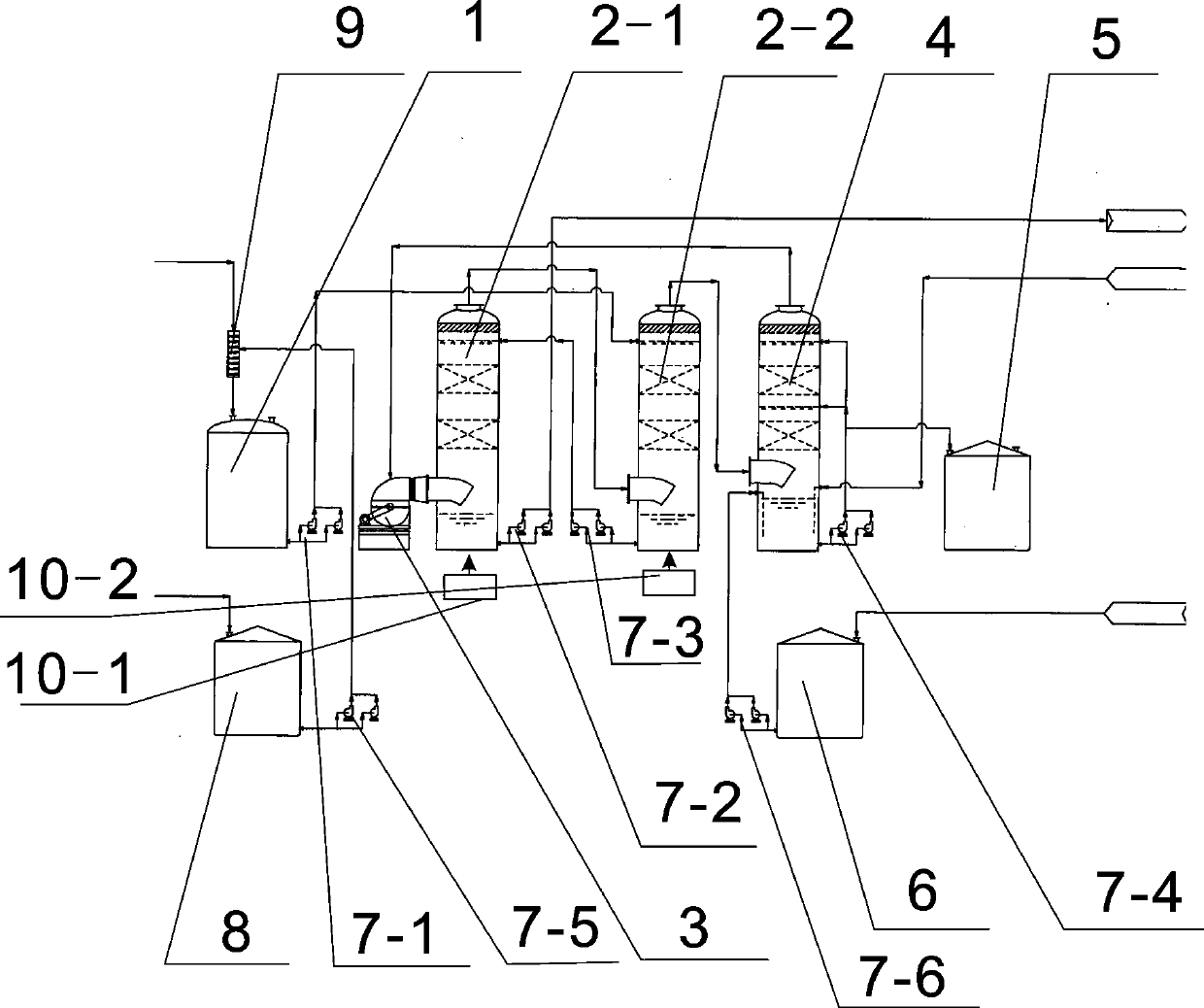

[0029] A glyphosate wastewater purification device, the liquid alkali storage tank 8 is connected to the flow control valve 9 of the upper pipeline of the pH adjustment tank 1 through the liquid alkali pump 7-5;

[0030] The bottom of the pH adjustment tank 1 is connected to the spray layer at the upper end of the stripping tower 2-2 via the stripping pump 7-1, and the bottom of the stripping tower 2-2 is connected to the top of the stripping tower 2-1 via the stripping pump 7-3 The spray layer is connected, the stripping tower 2-1 top is connected with the inlet at the bottom of the stripping tower 2-2 through the line pipeline, the top of the stripping tower 2-2 is connected with the bottom inlet of the absorption tower 4 through the line pipeline, and the top of the absorption tower 4 is connected with the bottom inlet of the absorption tower 4 through the line pipeline. The line pipeline is connected with the blowing blower 3 and then connected with the blowing tower 2-1; ...

Embodiment 2

[0037] A method for purifying glyphosate wastewater, comprising the steps of:

[0038]1) Send the glyphosate wastewater to the pH adjustment tank 1, the total nitrogen concentration in the glyphosate wastewater is 5000mg / L, adjust the pH of the wastewater to 11, adjust the wastewater to a temperature of 45°C, and then pump it into the blower The spray layer at the top of the stripping tower 2-2 is fed with steam to the bottom of the stripping tower 2-2, and the waste water is sprayed and scattered on the packing, and denitrified by the denitrification agent on the packing, and the denitrified The gas rises through the top of the stripping tower 2-2 and passes into the absorption tower 4 to complete a stripping;

[0039] 2) The waste water after denitrification falls through the packing material in the upper part of the stripping tower 2-2 and is pumped by the stripping pump 8-3 to the spray layer at the top of the stripping tower 2-1, and then to the bottom of the stripping to...

Embodiment 3

[0042] A method for purifying glyphosate wastewater, characterized in that it comprises the steps of:

[0043] 1) Send the glyphosate wastewater to the pH adjustment tank 1, the total nitrogen concentration in the glyphosate wastewater is 800mg / L, adjust the pH of the wastewater to 12, adjust the wastewater to a temperature of 50°C, and then pump it into the blower The spray layer at the top of the stripping tower 2-2, the waste water is sprayed and scattered onto the packing, and the denitrification agent on the packing is denitrified, and the gas after denitrification rises through the top of the stripping tower 2-2 and passes into the Absorption tower 4 completes a stripping;

[0044] 2) The waste water after denitrification falls through the filling material in the upper part of the stripping tower 2-2 and is pumped by the stripping pump 8-3 to the spray layer at the top of the stripping tower 2-1, and the blowing blower 3 is turned on for blowing The waste water is spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com