Patents

Literature

36results about How to "Shorten desorption time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for activated carbon fiber variable voltage desorption gas

InactiveCN101444693AShorten desorption timeSave energyOther chemical processesDispersed particle separationFiberActivated carbon

The method for activated carbon fiber variable voltage desorption gas relates to a method of desorption gas by using activated carbon fiber. The method solves the problem of high energy consumption in the prior art. The method comprises: the two ends of an adsorbent bed are sequentially switched on 4-6V of alternating voltage to be heated for 28-32s, 8-12V of alternating voltage to be heated for 28-32s, 13-17 V of alternating voltage to be heated for 28-32s, 18-22 V of alternating voltage to be heated for 28-32s and 13-17 V of alternating voltage, and is then continuously heated by changing the 13-17 V of alternating voltage into 4-6V of alternating voltage when the temperature reaches 70-72 DEG C; the temperature of the carbon fiber is kept within the range of 69-71 DEG C for 8-12min, and the gas with the mass percent of 90-99% can be obtained by desorption. The method has short desorption time, low energy consumption, and simple operation and technique.

Owner:HARBIN INST OF TECH

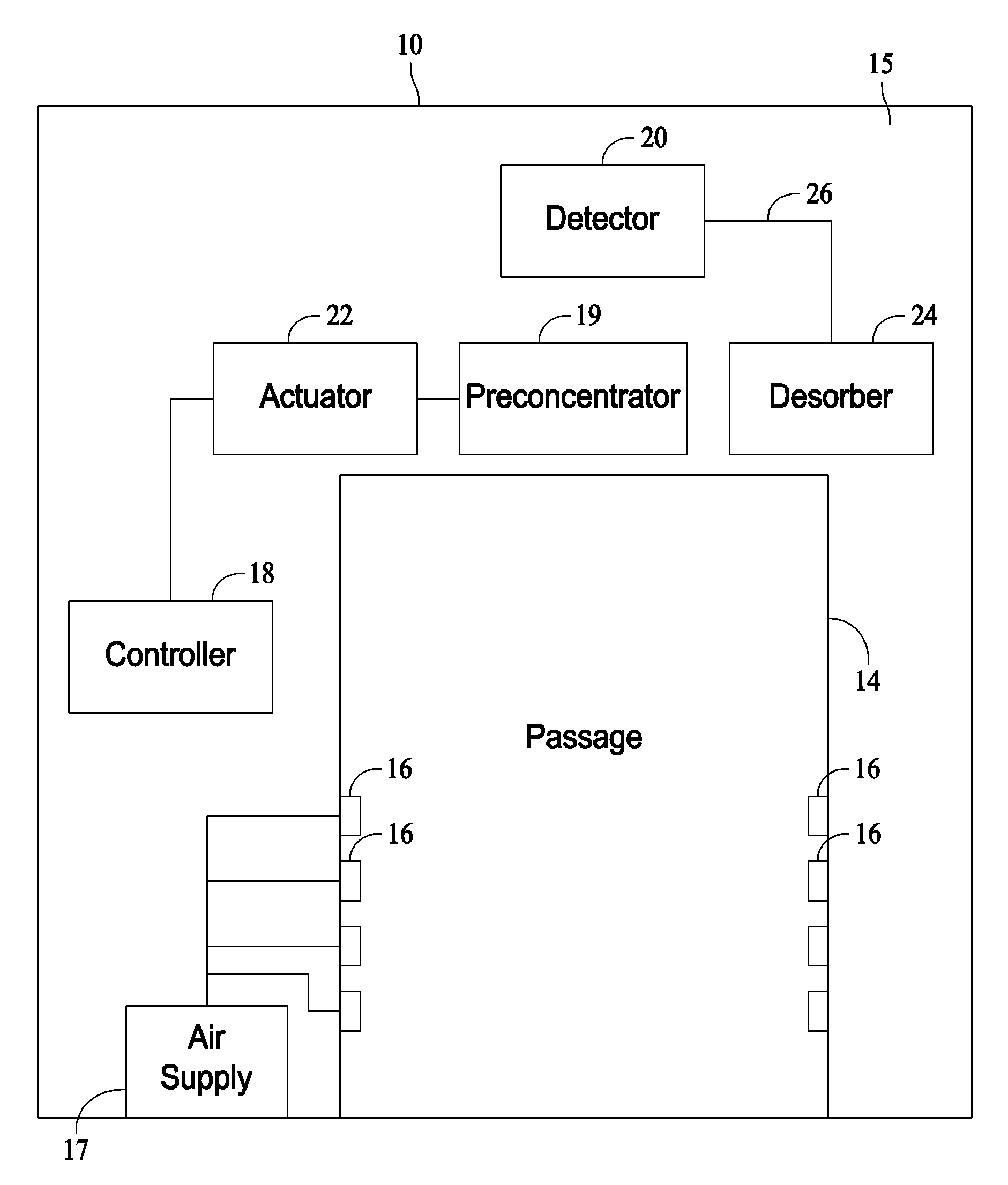

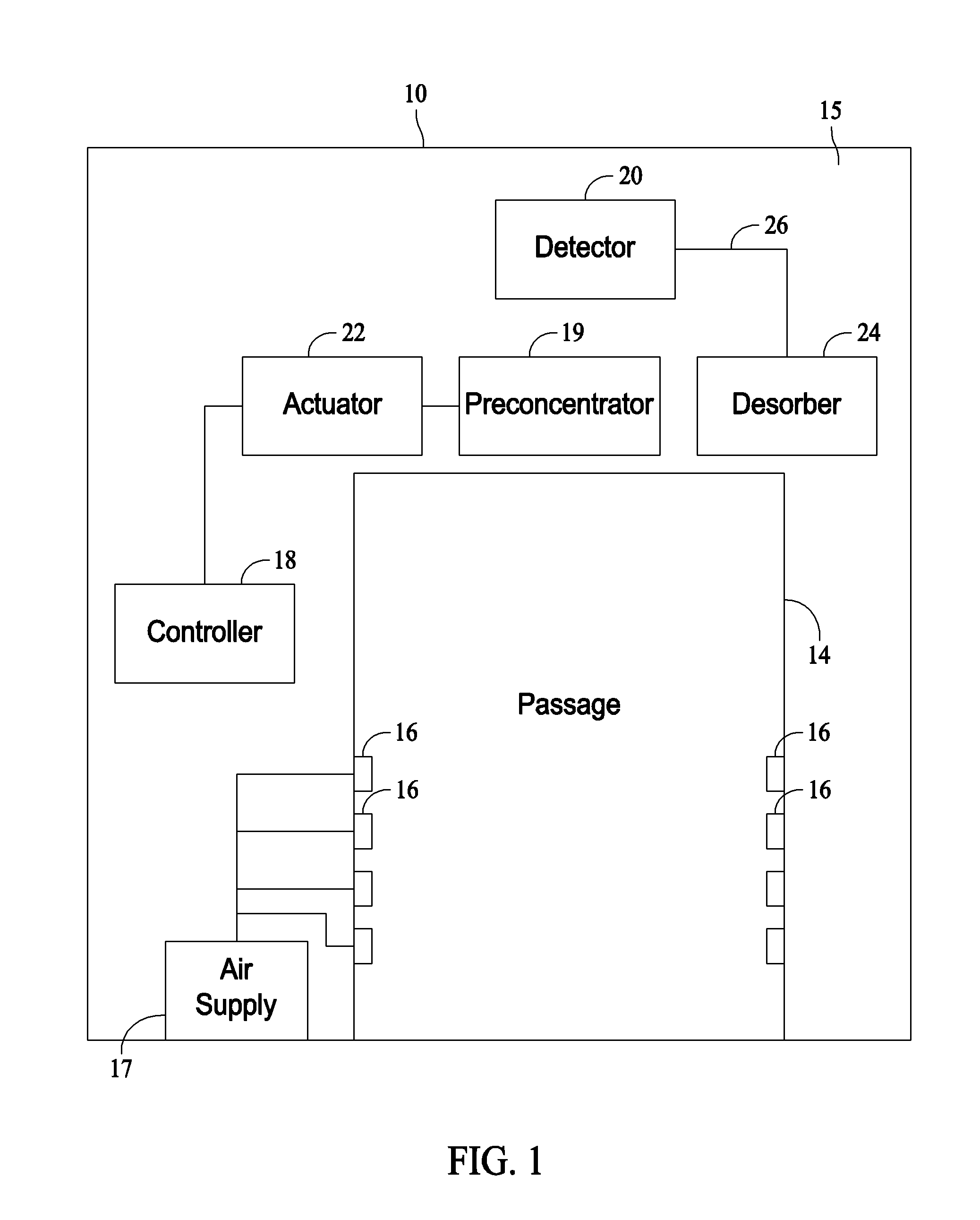

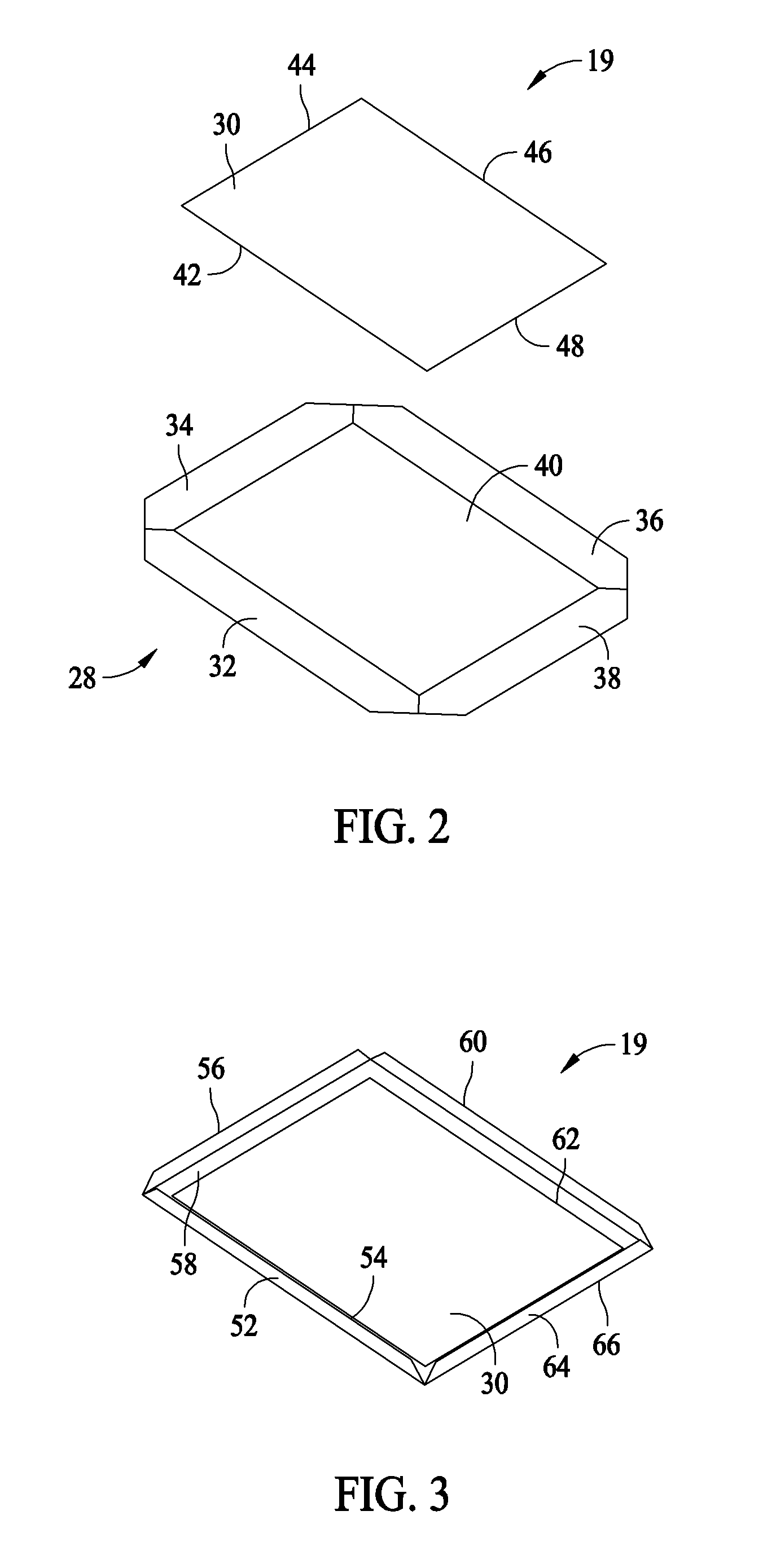

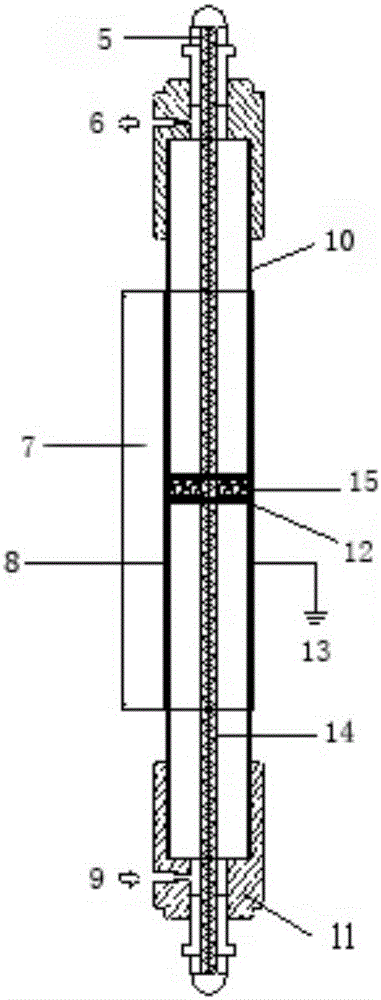

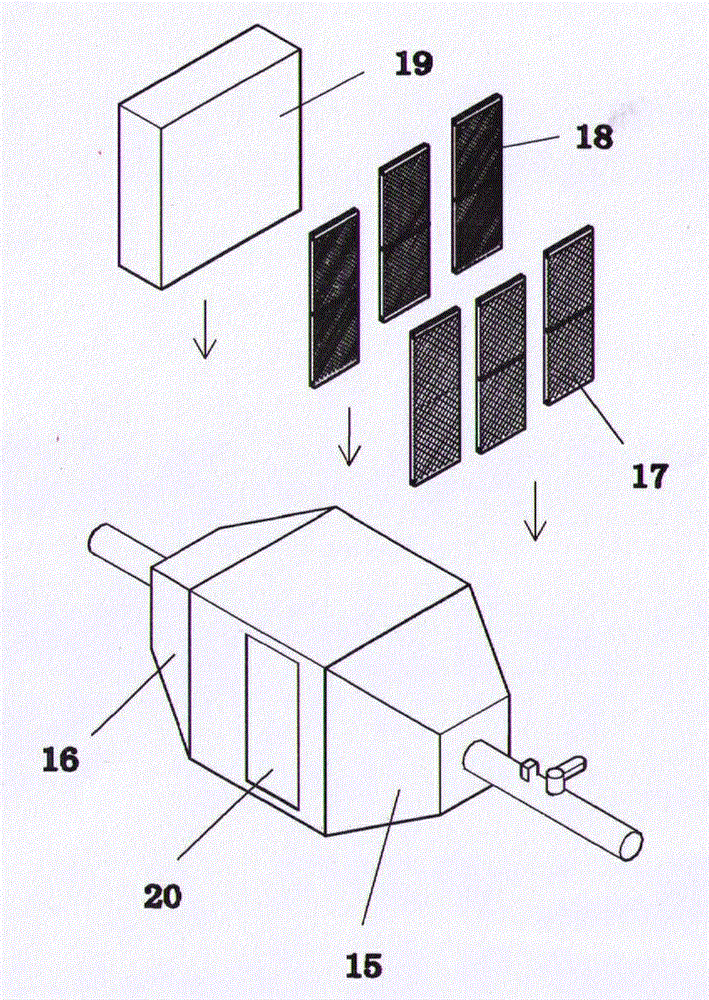

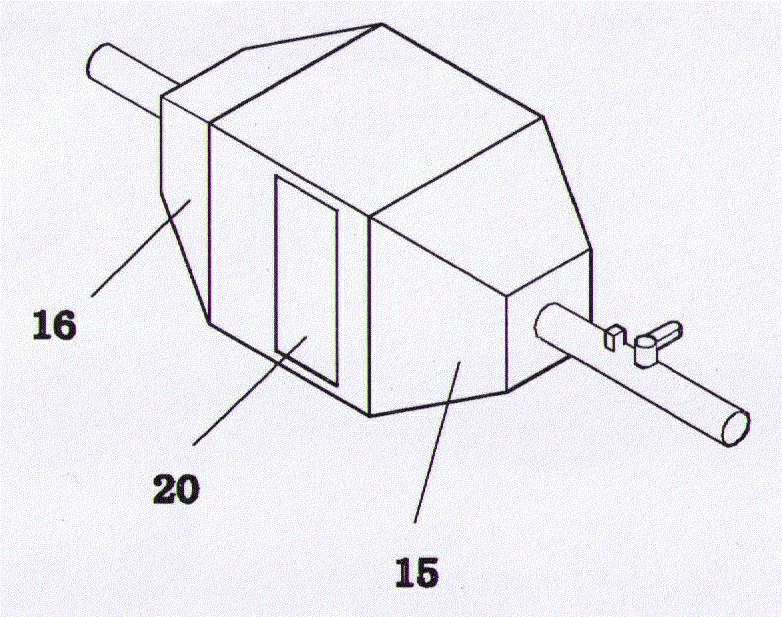

Systems and methods for detecting particles

ActiveUS7721588B2Increase particle concentrationQuickly accurately efficiently identifyDispersed particle filtrationWithdrawing sample devicesEngineeringExplosive material

A method of detecting particles during inspection is provided. The method includes establishing a security checkpoint including a detection system, wherein the detection system includes a chamber defining a passage and includes a plurality of jets. The method also includes passing an individual through the passage, enhancing a convection plume including particles from the individual by blowing air through at least one of the plurality of jets, and absorbing the particles in a preconcentrator including a filter encased in a frame having a high thermal conductivity. Moreover, the method includes evaporating the particles absorbed in the preconcentrator and using a detector to determine whether the particles are from at least one of an explosive material and a narcotic substance.

Owner:RAPISCAN SYST INC (US)

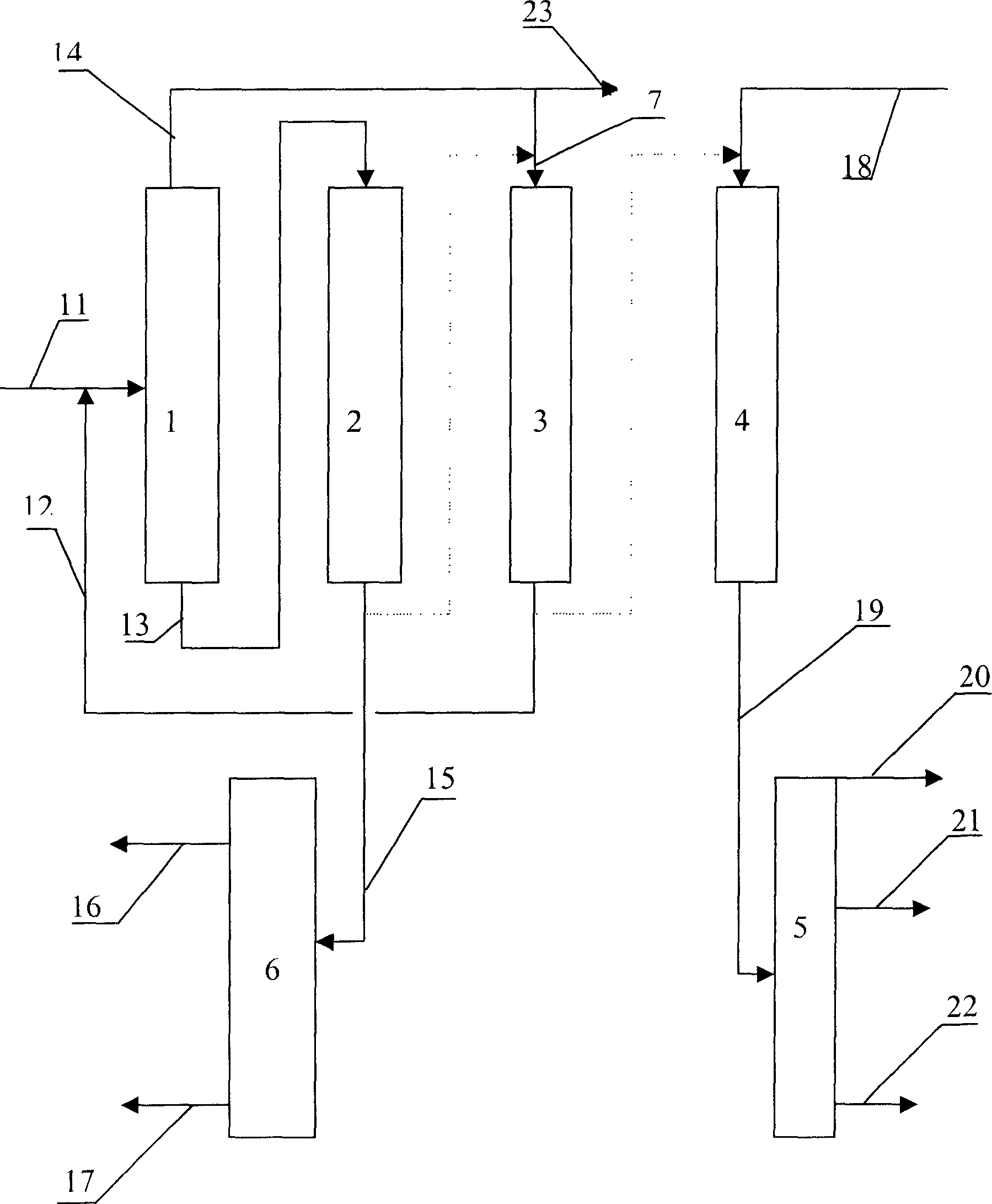

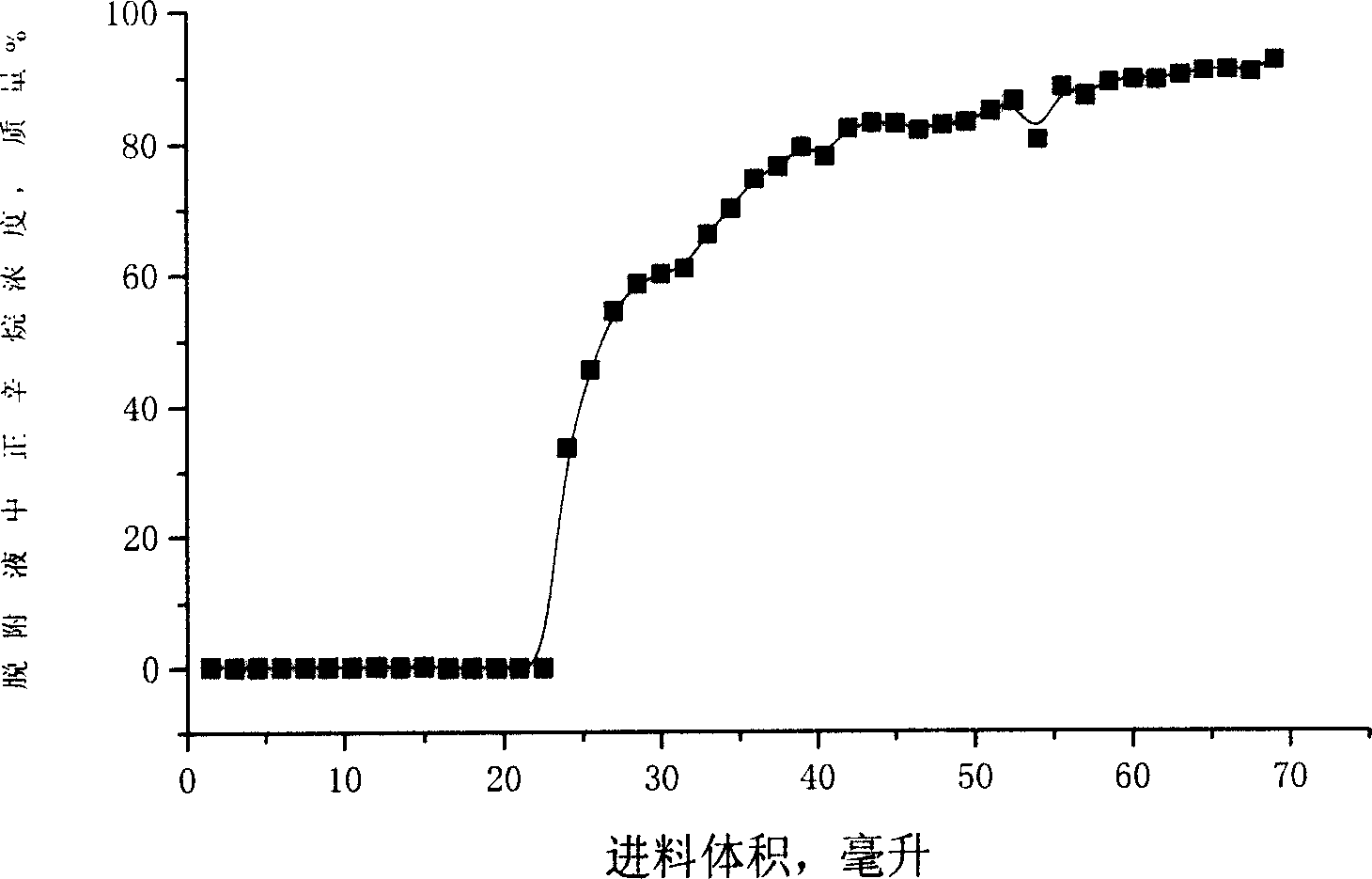

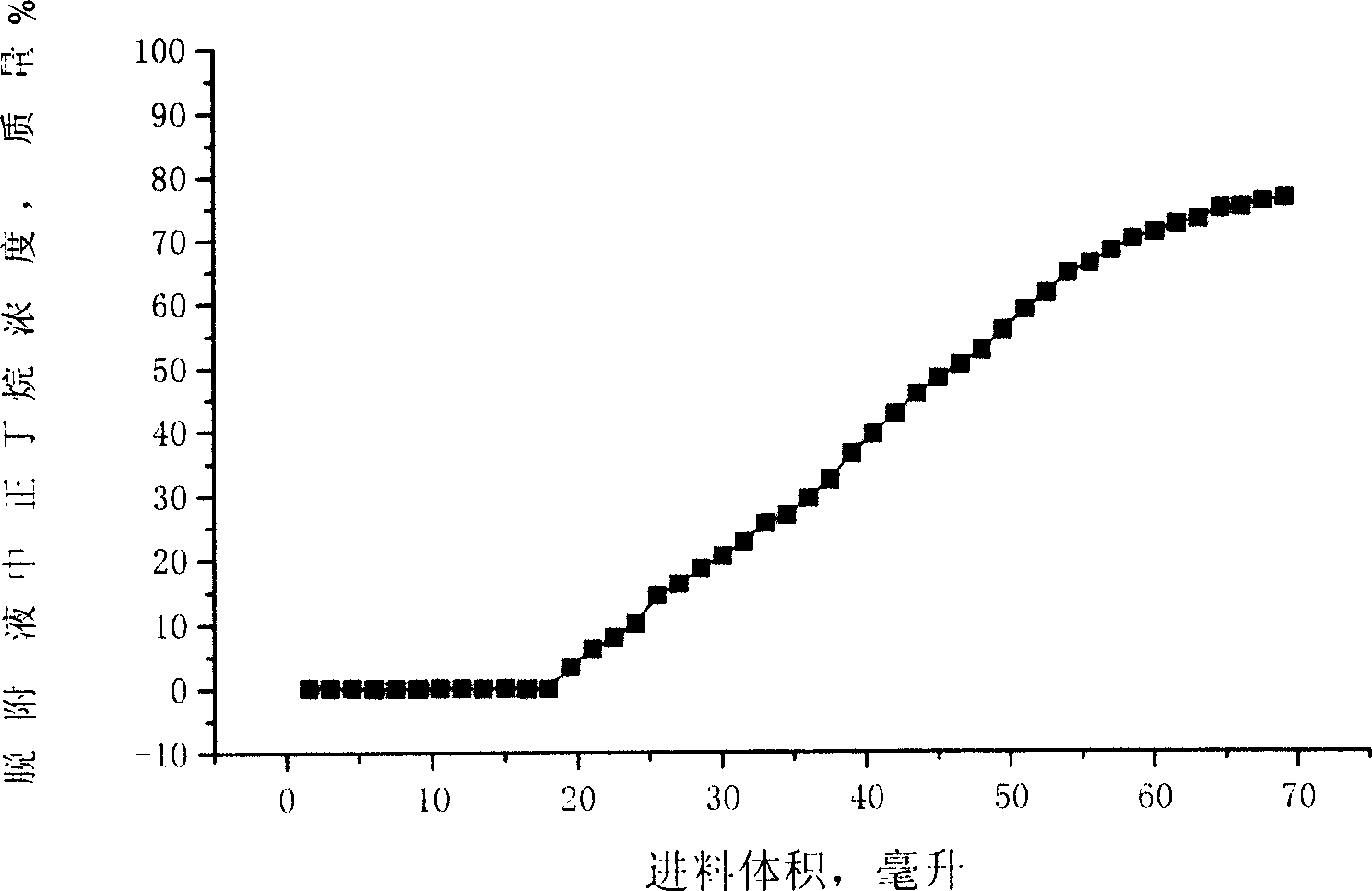

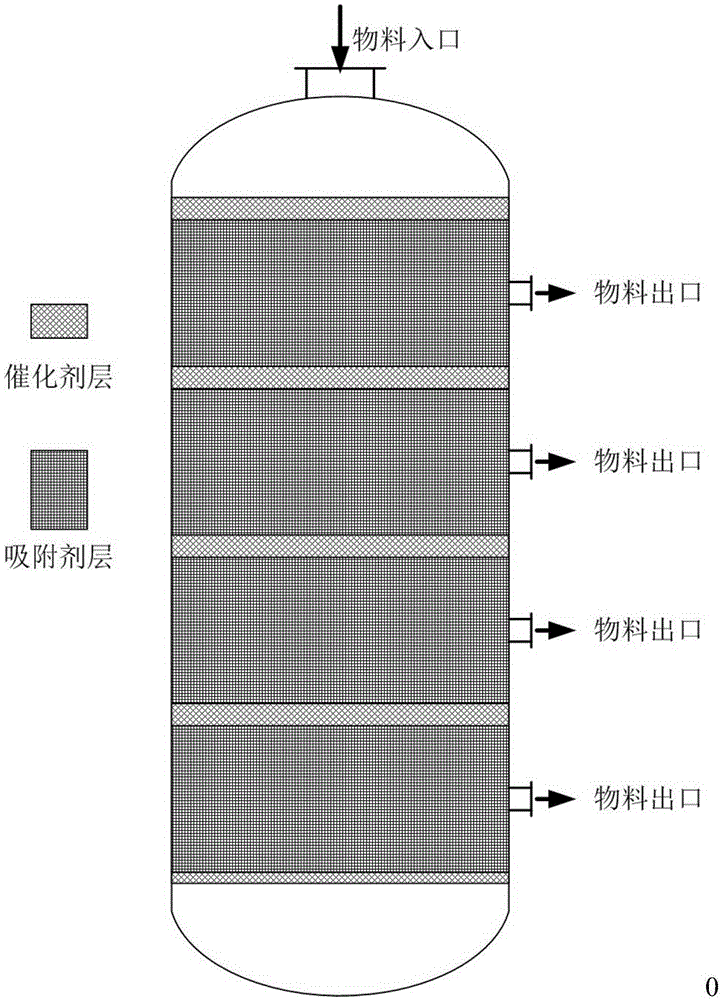

Method for separating n-alkane from C5 to C6 alkane isomerized products

Disclosed is a method for separating normal alkane from C5 to C6 alkane isomerized products. Isopentane is removed from raw materials, and the obtained materials are added into an adsorption separation post to adsorb normal alkane under 2.0-4.0 MPa, 100-150íµ and liquid phase condition, after saturation by adsorption, the adsorption separation post is flushed with flushing agent of isopentene, then desorbed by desorbing agent of C7 to C9 normal alkane. The method can separate normal alkane in light hydrocarbon isomerized products, and the used desorbing agent is less, the desorbing time is short.

Owner:CHINA PETROLEUM & CHEM CORP +1

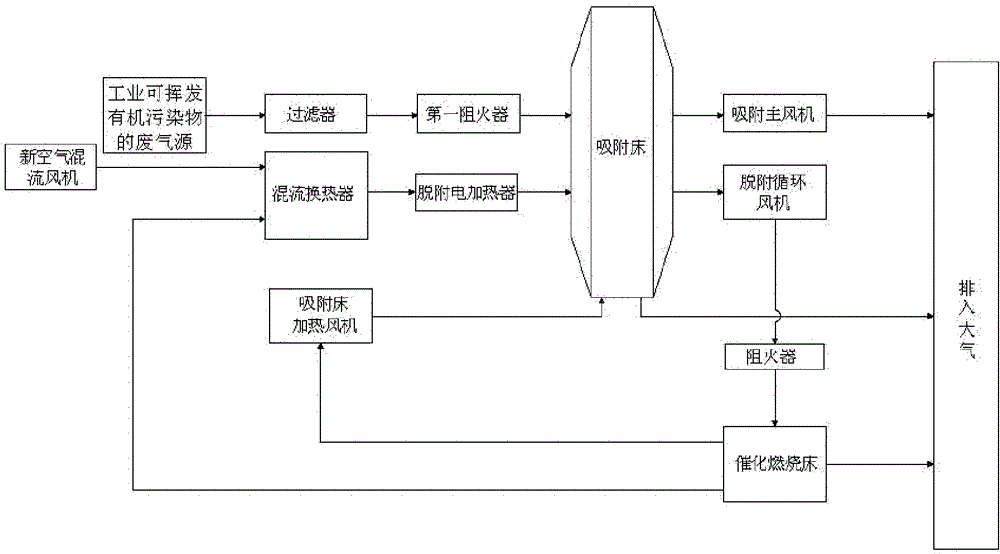

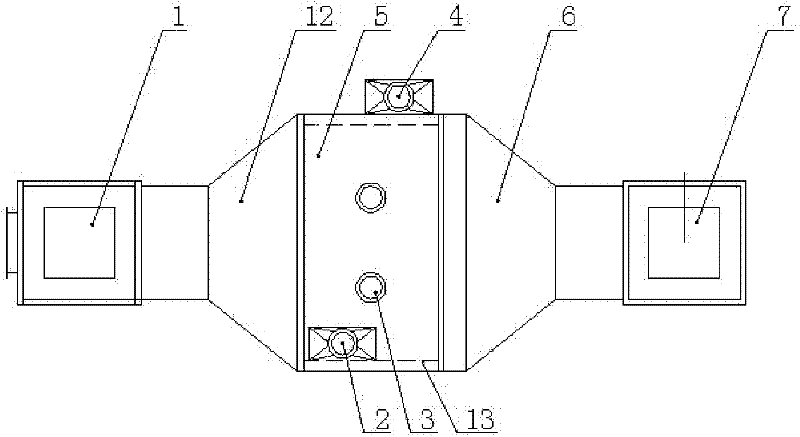

Automatic high-efficiency energy-saving purification system for industrial volatilizable organic pollutants

InactiveCN102172461AShorten desorption timeReduce power consumptionDispersed particle filtrationIncinerator apparatusActivated carbonActive carbon

The invention relates to an automatic high-efficiency energy-saving purification system for industrial volatilizable organic pollutants, which is characterized in that: (1) both opposite side walls of an active carbon bed body of an adsorption bed are set into side walls with hollow structures, an active carbon clapboard is set into an active carbon clapboard with a hollow structure, the active carbon clapboard with the hollow structure is communicated with the side walls with the hollow structures, and the two side walls with the hollow structures are respectively provided with a hot air inlet and a hot air outlet; and (2) a catalytic combustion bed is connected with a plate-type heat exchanger, and the plate-type heat exchanger is connected with the hot air inlets on the side walls withthe hollow structures of the adsorption bed through an adsorption bed heating fan. The automatic high-efficiency energy-saving purification system for the for industrial volatilizable organic pollutants has a simple and reasonable structure, can effectively reduce energy consumption, improve the purifying rate, prolong the service life of a catalyst, shorten the desorption process time, improve the purifying efficiency and reduce the operating cost, and is safe and reliable.

Owner:赛智环保科技(天津)有限公司

Series targeted adsorption and parallel desorption organic waste gas treatment device

ActiveCN111389175AAvoid reunionReduce heating frequencyDispersed particle separationIncinerator apparatusCombustion systemPtru catalyst

The invention discloses a series targeted adsorption and parallel desorption organic waste gas treatment device. The device comprises a series adsorption system, a parallel desorption system and a catalytic combustion system. The series adsorption system comprises a waste gas inlet pipeline, an adsorption box body, an exhaust pipeline, a circulating pipeline and a main fan. The parallel desorptionsystem comprises a desorption fan, a second-stage heat exchanger, a desorption air inlet pipe, an automatic valve and a desorption exhaust pipe. The catalytic combustion system comprises a first-stage heat exchanger A, a first-stage heat exchanger B, a heater and a catalytic reactor. According to the invention, corresponding targeted adsorbents are selected according to molecular diameters and adsorption characteristics of different pollutants, a thin adsorption bed layer and a multi-stage parallel desorption mode are adopted, the desorption time is shortened, and the desorption peak concentration can be effectively controlled, so that the safety problem caused by desorption due to an overlong adsorption band is avoided, the heating frequency of the catalytic combustion system is reduceddue to the relative stability of the VOCs concentration during desorption, the agglomeration of a catalyst is avoided, the VOCs combustion reaction heat is fully utilized, and the energy consumption is reduced.

Owner:南大恩洁优环境技术江苏股份公司

Novel capacitive deionization treatment device

PendingCN112499732AEfficient removalLong recycling lifeDispersed particle separationWater/sewage treatmentCapacitive deionizationEngineering

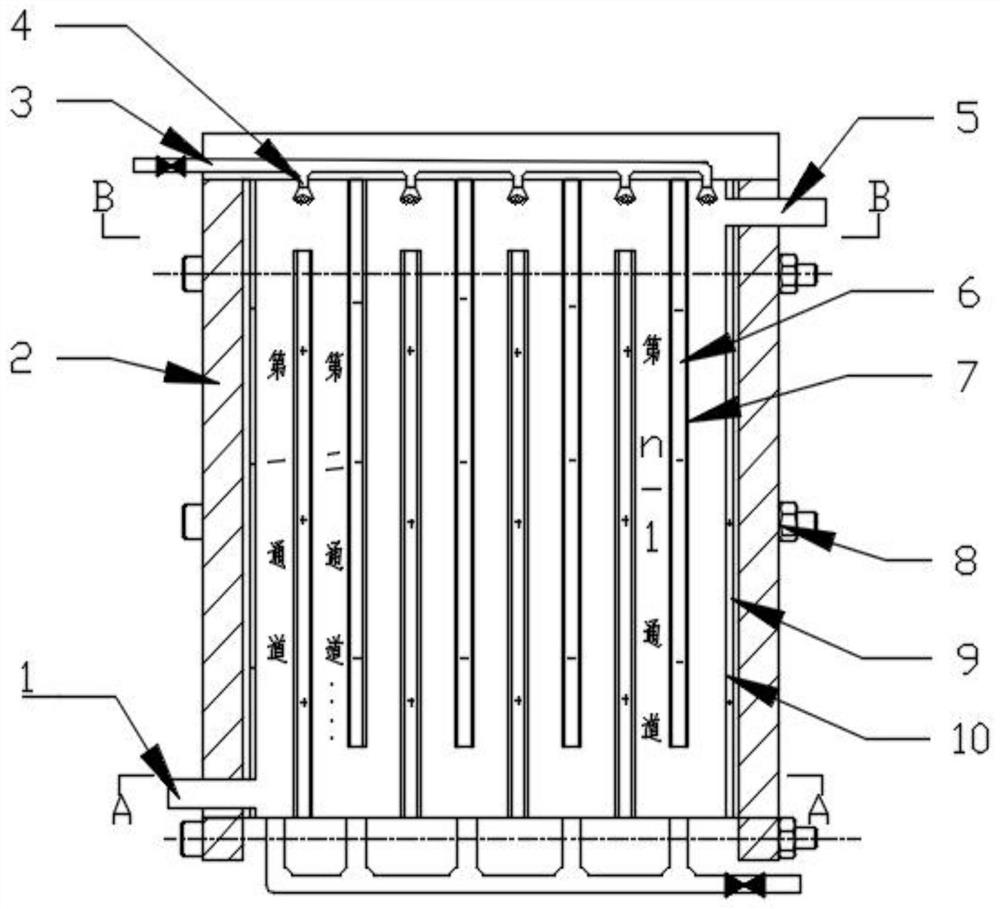

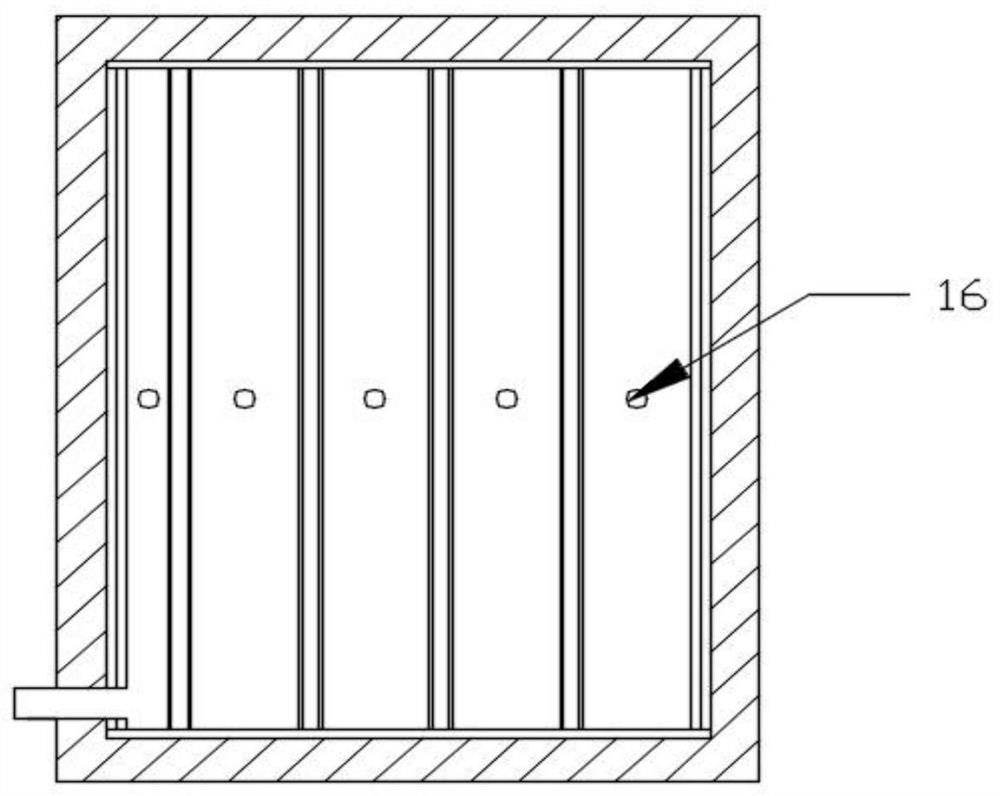

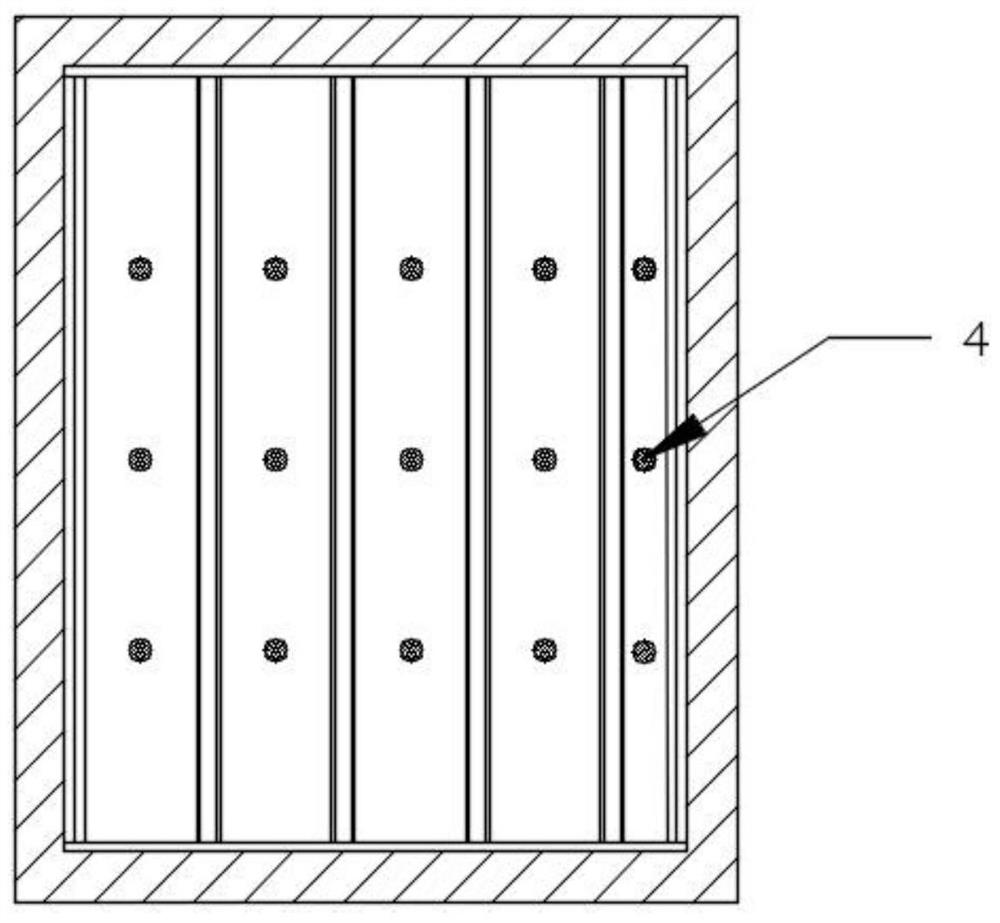

The invention relates to a novel capacitive deionization treatment device. A spraying device is arranged at the top of a device body, and four pieces of organic glass are arranged at the side edge part. A water inlet is formed in the lower left side of the side edge part, and a fresh water outlet is formed in the upper right side of the side edge part. The left organic glass, a sealing washer anda negative plate are fixed through studs. The right organic glass, a sealing washer and a positive plate are fixed through studs. A first channel, a second channel... an nth channel are formed in thedevice body at intervals through stainless steel base plates, and a Z-shaped circulation channel is formed among the first channel, the second channel... the nth channel. The stainless steel base plates and the organic glass on the side edges are fixed through studs, two same-stage electrode plates are arranged on the two sides of the same stainless steel base plate, the two same-stage electrode plates are negative plates or positive plates, the number of the negative plates and the number of the positive plates are both n, and the negative plates and the positive plates are arranged in the device body in parallel in a staggered mode.

Owner:JIANGSU JINGYUAN ENVIRONMENTAL PROTECTION

Effective organic waste gas recovery device and process

PendingCN112755719APlay a protective effectImprove efficiencyGas treatmentDispersed particle separationThermodynamicsExhaust fumes

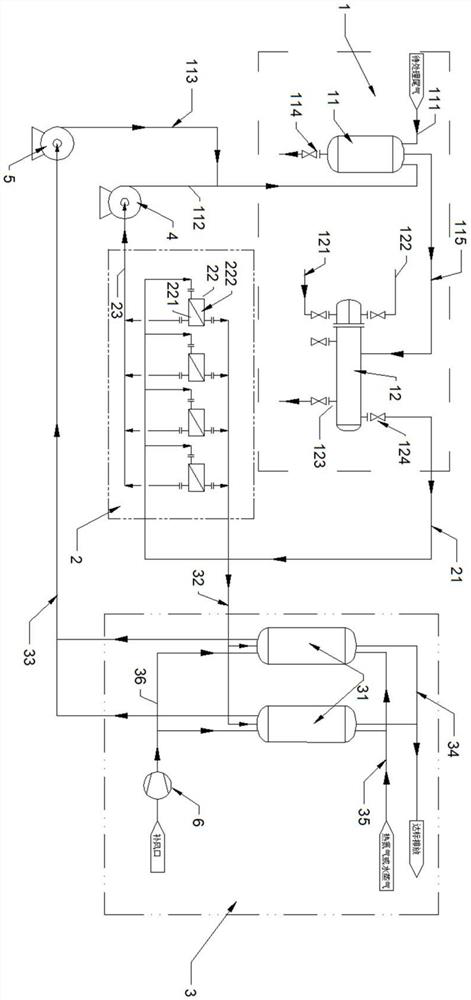

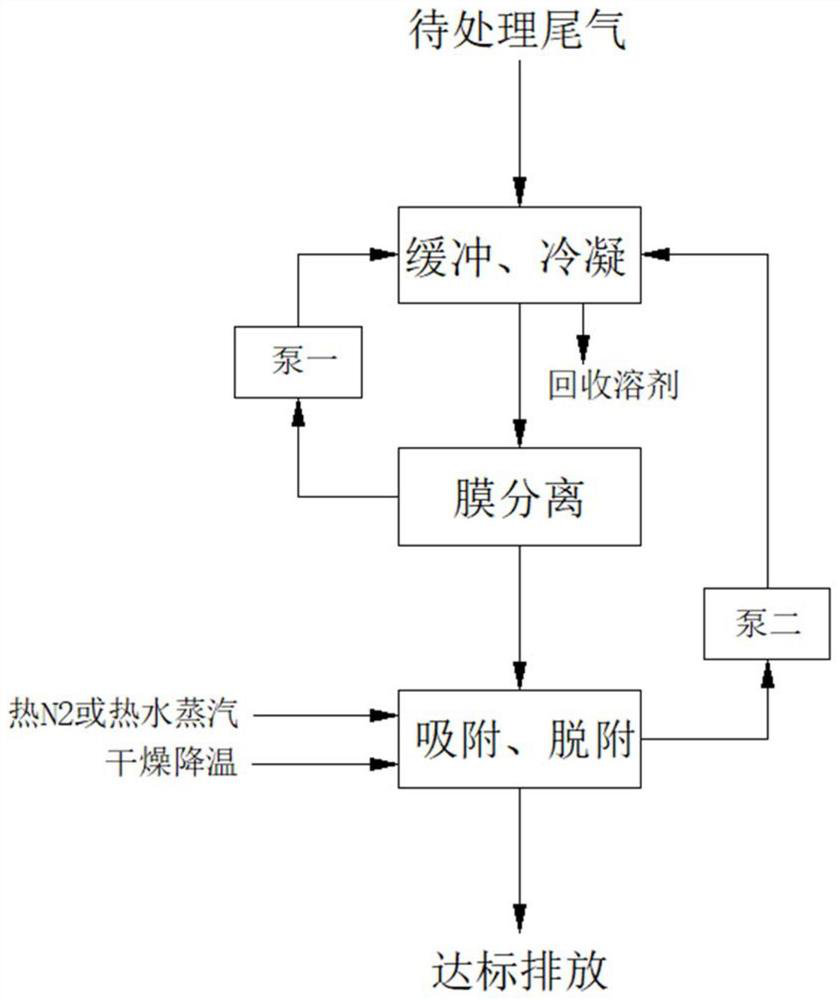

The invention provides an organic waste gas recovery device and process, and belongs to the technical field of organic waste gas treatment. The device comprises a condensation system, a membrane separation system, an adsorption system and a vacuum system, the vacuum system comprises a first vacuum pump and a second vacuum pump which operate independently, an inlet and an outlet of the first vacuum pump are connected with the membrane separation system and the condensation system respectively, and organic gas separated from the membrane separation system is circulated back to the condensation system through the first vacuum pump; an inlet and an outlet of the second vacuum pump are respectively connected with the adsorption system and the condensation system; and desorbed organic gas in the adsorption system is circulated back to the condensation system through the second vacuum pump. According to the invention, the membrane separation system and the adsorption system respectively carry out organic gas and air separation and organic matter desorption through independent vacuum pumps, so that the two systems do not interfere with each other, the intermittent vacuum operation of the adsorption system does not influence the continuous vacuum operation of the membrane separation system, and the working stability of the membrane separation system is effectively guaranteed.

Owner:浙江同善环保科技有限公司

High-performance carbon nano-material adsorbent and preparation and application thereof

ActiveCN106824073ANot easy to mergeHigh specific surface areaOther chemical processesSolid sorbent liquid separationGas phaseAdhesive

The invention discloses a high-performance carbon nano-material adsorbent and preparation and application thereof. The high-performance carbon nano-material adsorbent is composed of a carbon nano-material and an adhesive. Mass fraction of the carbon nano-material is 80-97 wt%. Specific surface area of the adsorbent is 800-2200 m<2> / g. The pore volume ratio of micropore to mesopore to macropore is (1-3): (1-6): (1-10). The invention also discloses a method for directly preparing the adsorbent by the utilization of a compound of the carbon nano-material obtained during the chemical vapor deposition process and an inorganic compound carrier. The adsorbent has advantages of long service life, large handling capacity, low preparation cost, etc., and is especially suitable for adsorption of low-concentration nonpolar organic matter in a fluid.

Owner:TSINGHUA UNIV

Adsorbing agent based on carbon nanomaterial and preparation and application method thereof

ActiveCN106732378ARich in channelsShorten desorption timeOther chemical processesSolid sorbent liquid separationChemistryMacropore

The invention discloses an adsorbing agent based on a carbon nanomaterial. The adsorbing agent is prepared from the carbon nanomaterial and an adhesive, wherein the mass fraction of the carbon nanomaterial ranges from 30 to 95 percent. The specific surface area of the adsorbing agent is 100 to 2000m<2> / g, and the pore volume proportion of micropores, mesopores to macropores is (1 to 2) to (1 to 5) to (1 to 20). The invention also discloses a method for preparing the adsorbing agent by adding a pore-forming agent. The adsorbing agent has the advantages of long service life, big treatment capacity, low preparation cost and the like, and is suitable for adsorbing non-polar organic compounds in a fluid.

Owner:TSINGHUA UNIV

Adsorption and in-situ desorption and regeneration equipment and method for volatile organic compounds

PendingCN109985482AReduce usageShorten desorption timeGas treatmentDispersed particle separationVolatile organic compoundChemistry

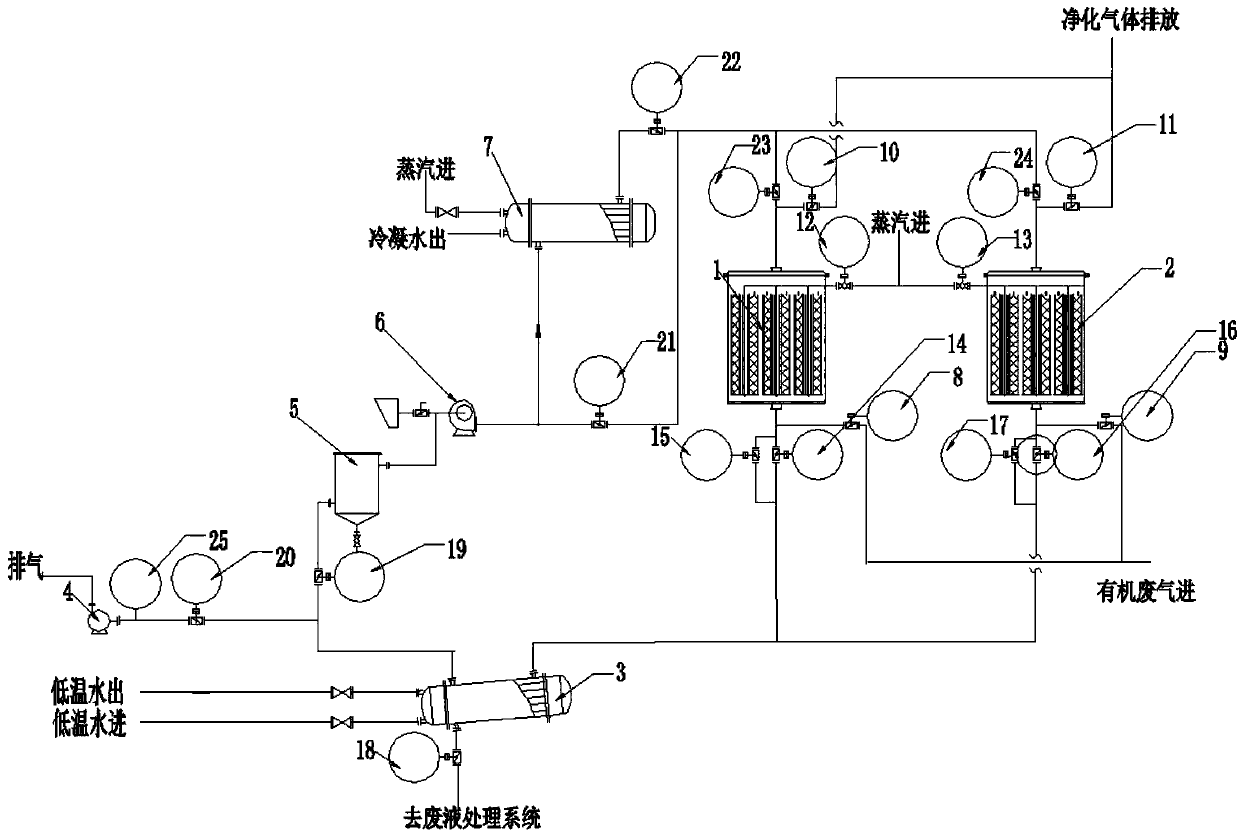

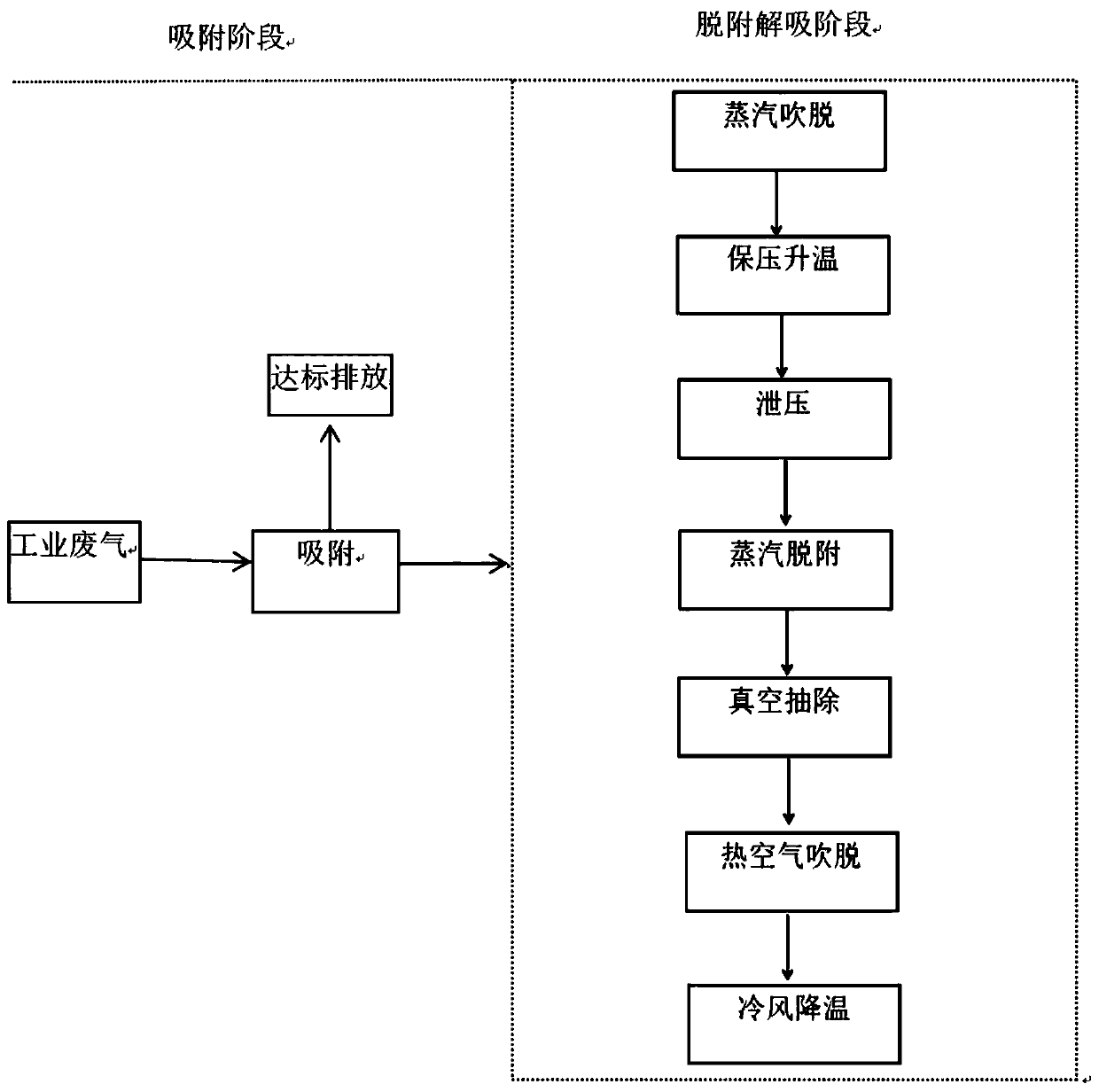

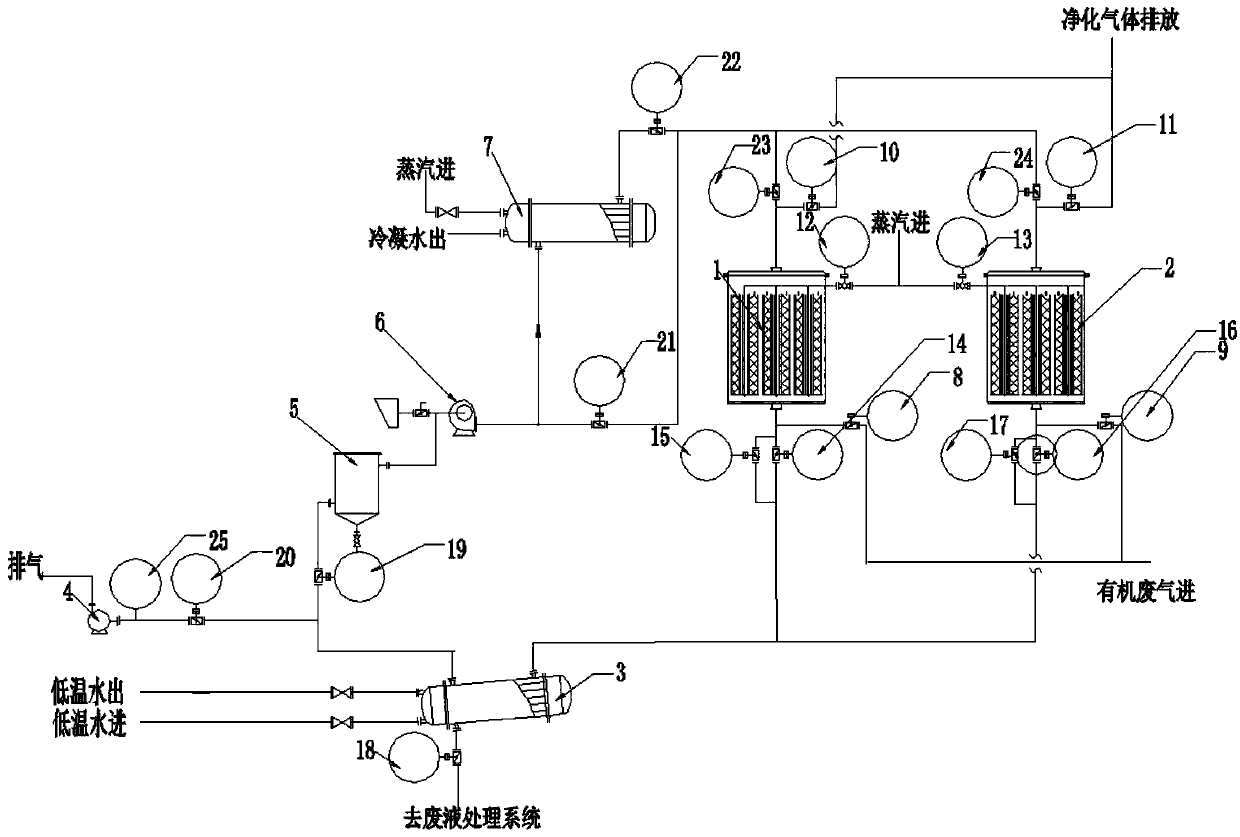

The invention discloses adsorption and in-situ desorption and regeneration equipment for volatile organic compounds. The adsorption and in-situ desorption and regeneration equipment comprises a left adsorption device, a right adsorption device, a condenser, a vacuum pump, a demister, a drying draught fan and a heater, wherein an organic waste gas pipeline inlet is connected with the left adsorption device and the right adsorption device through a first left valve and a first right valve respectively; the upper ends of the left adsorption device and the right adsorption device are connected with an exhausting barrel through a second left valve and a second right valve respectively; a steam pipeline inlet is connected with the left adsorption device and the right adsorption device through asixth left valve and a sixth right valve respectively. By adopting the adsorption and in-situ desorption and regeneration equipment, internal circulation of dry gas is realized; after being purified,the dry gas is discharged and secondary pollution is not caused; rapid desorption can be carried out in a desorption process, the utilization amount of high-temperature steam is reduced and the desorption time is shortened; an adsorbent is completely regenerated and the adsorption performance is completely recovered; and the drying time and the cooling time are shortened and energy saving and consumption reduction are realized.

Owner:上海一飒环保工程科技有限公司

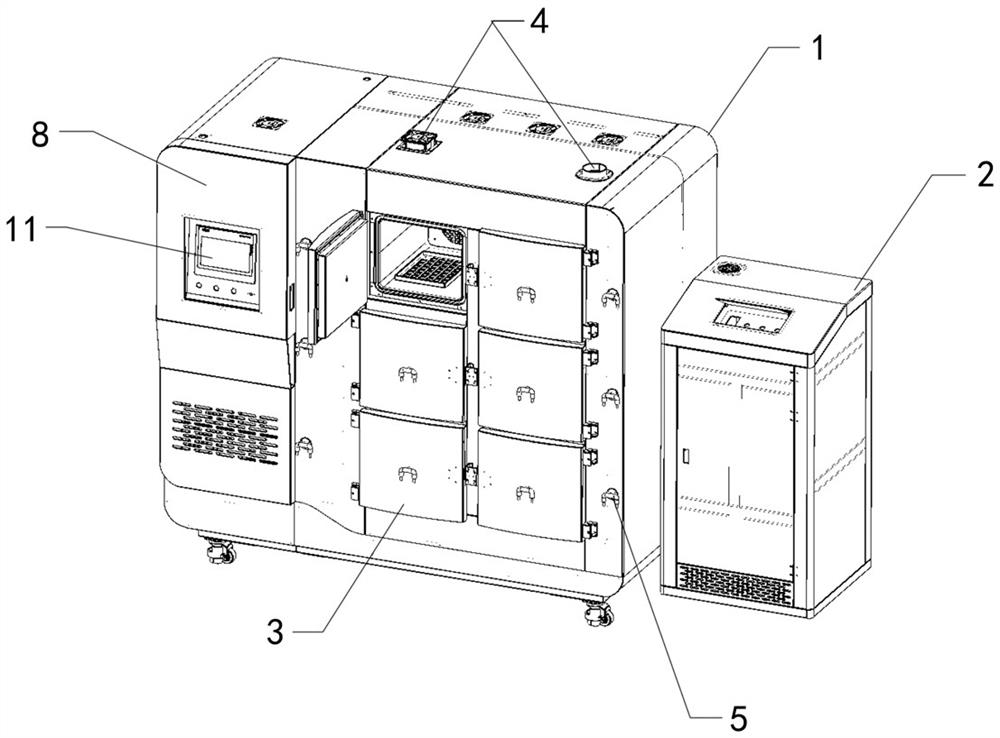

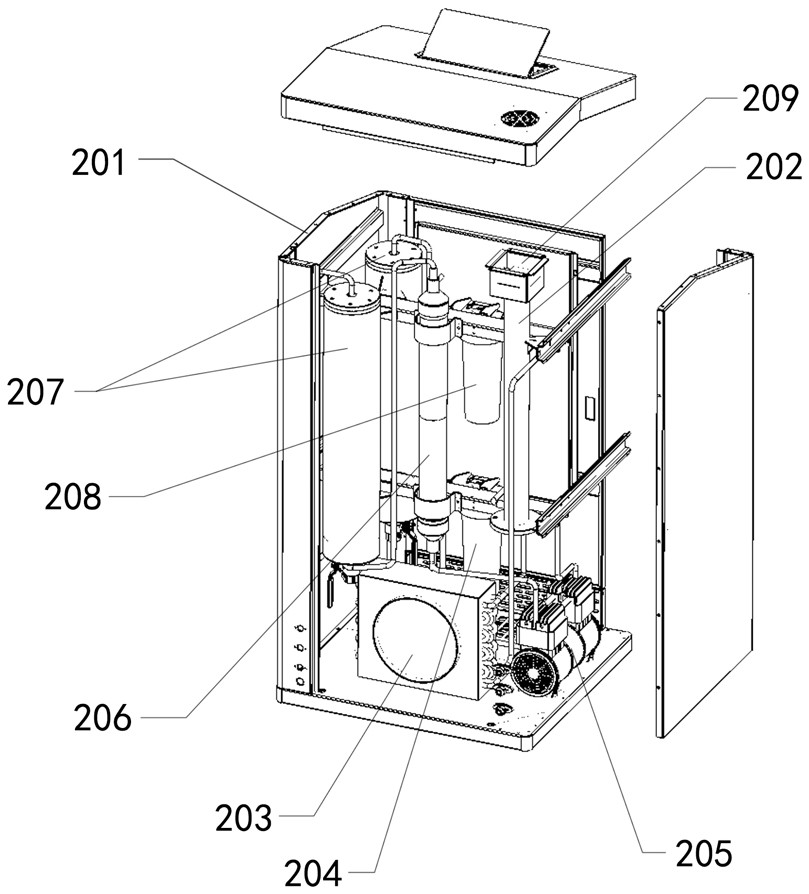

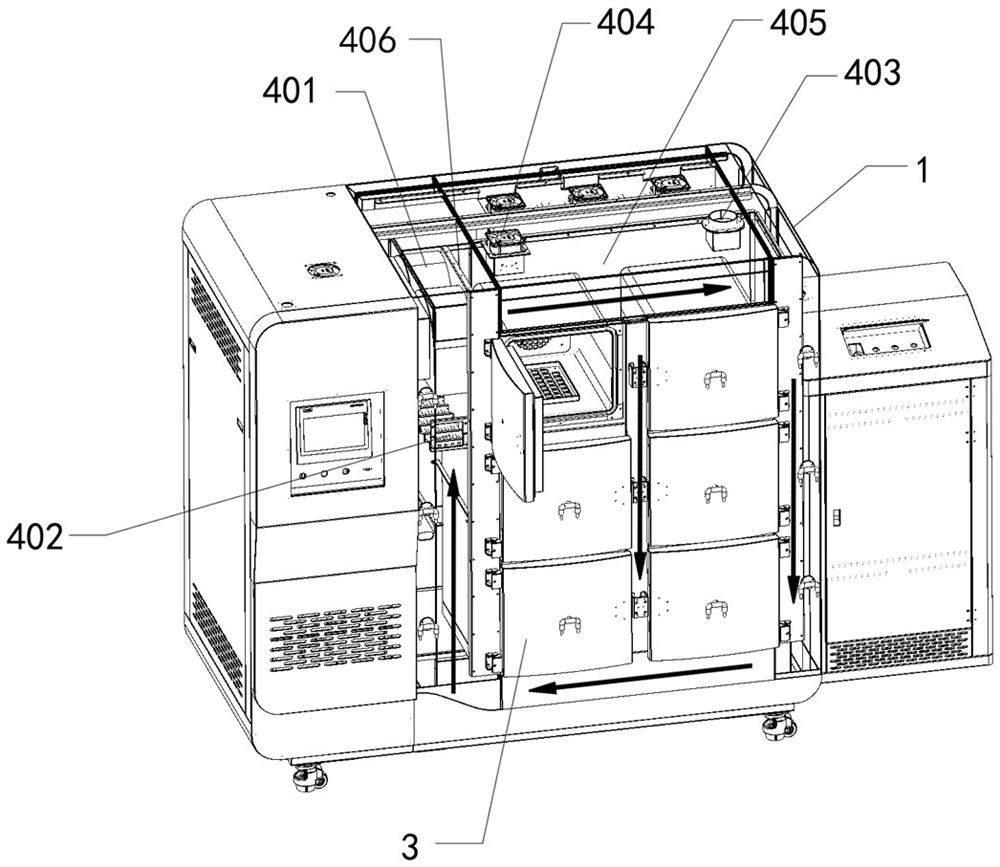

Climate chamber for measuring VOC release amount through multi-chamber method

PendingCN111896682AReduce energy consumptionReduce operating powerMaterial analysisNumerical controlTemperature control

The invention discloses a climate chamber for measuring the VOC release amount through a multi-chamber method. The climate chamber comprises a case and a clean gas generation device, the case is provided with a front case body and a rear case body, six experiment cabins and a jacket temperature control system are arranged in the front case body, a pressure regulating valve is arranged on the frontsurface of the front case body, a sampling pipe is arranged on a cabin door of each experiment cabin, and a dry and wet gas mixing humidity regulating system and a numerical control acquisition system are arranged in the rear case body on the rear side of each experiment cabin; an electric control mechanical chamber is arranged on one side of the case, and a logic control system, a refrigeratingsystem and a man-machine interaction system are arranged in the electric control mechanical chamber; the clean gas generating device is connected with the dry-wet gas mixing humidity adjusting systemand the electromagnetic valve flow adjusting control system, the dry-wet gas mixing humidity adjusting system is connected with the experiment cabin, and the experiment cabin is connected with the numerical control collecting system. Compared with the prior art, the climate chamber has the advantages that the background concentration requirement specified in the national standard is completely met; the energy consumption is low; the desorption time is reduced; and the use efficiency of equipment is improved.

Owner:上海怡骋工贸有限公司 +1

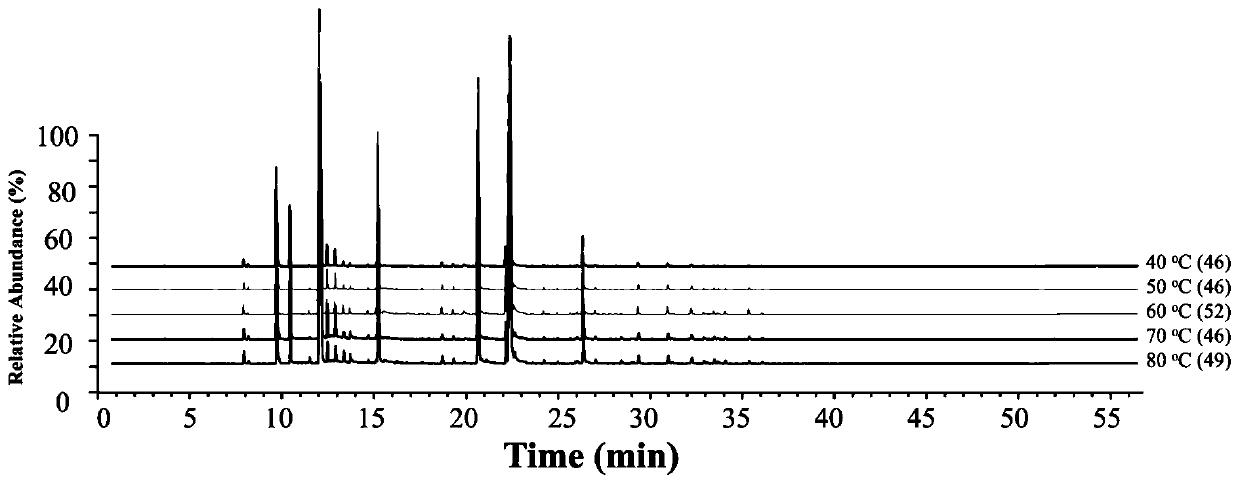

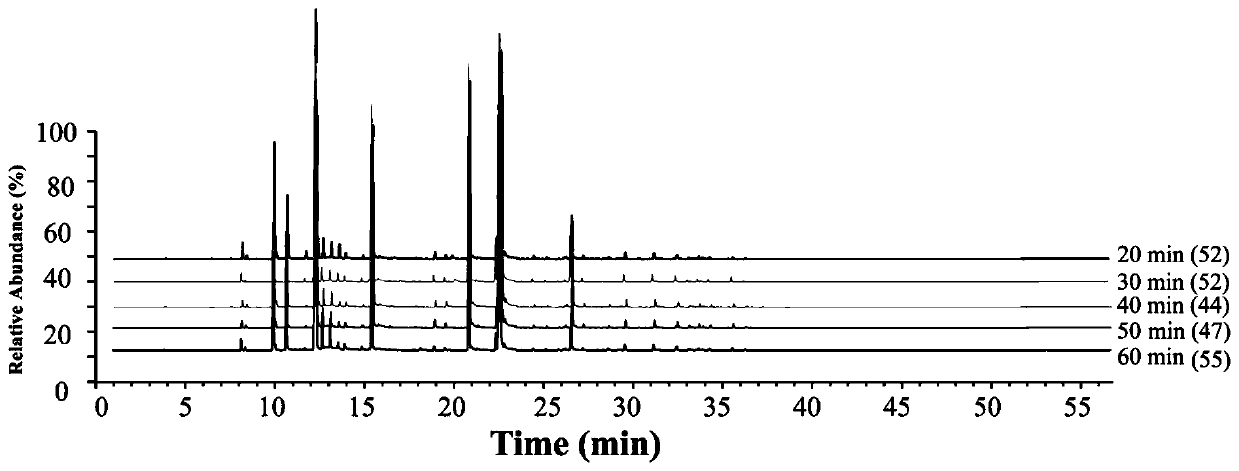

Chinese prickly ash peel aroma component detection method

InactiveCN110082457AEasy to detect and identifyGood aroma characteristicsComponent separationSolid-phase microextractionMedicine

The invention relates to a Chinese prickly ash peel aroma component detection method. The method is characterized by, to begin with, grinding a Chinese prickly ash peel sample to be detected into powders; after sieving, weighing a certain amount of Chinese prickly ash peel powders and placing the powders into a headspace bottle, wherein the headspace bottle is sealed by a silica gel isolation pad;and then, carrying out GC-MS detection directly on the fully-shaken sample. Through combination of headspace solid-phase microextraction and gas chromatography-mass spectrometry (GC-MS) technology, prickly ash aroma components are extracted and analyzed, and solvent extraction is not required for sample pretreatment, so that the method is green and safe, is easy and fast, prevents tedious pretreatment process, uses small amount of samples and can visually reflect Chinese prickly ash peel aroma component characteristics.

Owner:NORTHWEST A & F UNIV

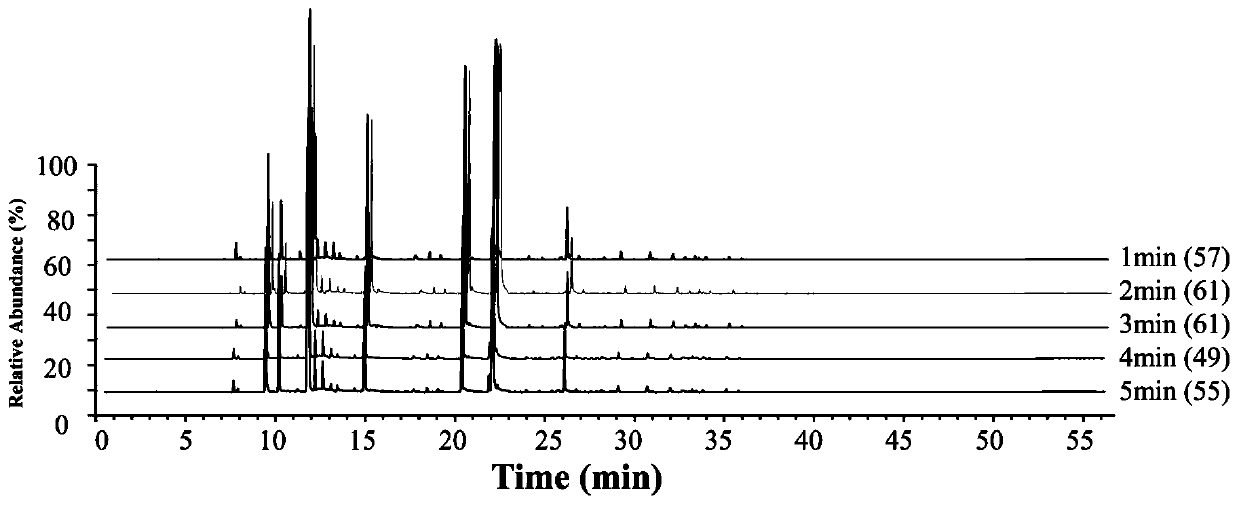

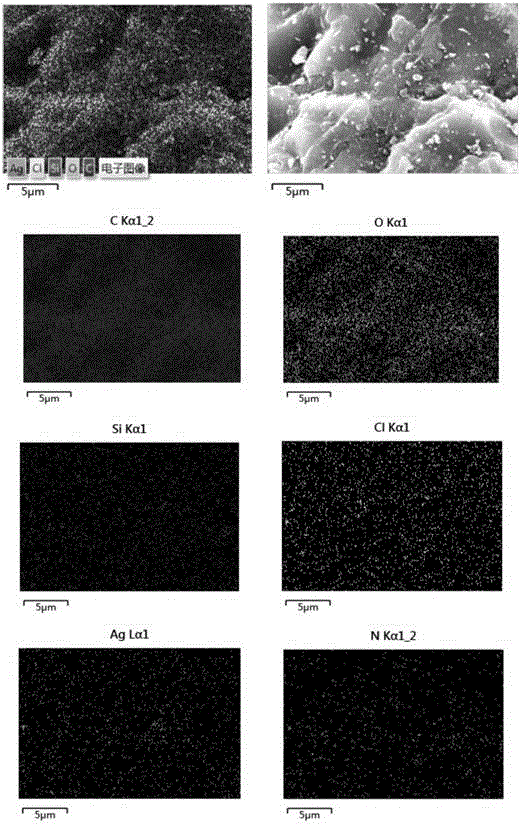

Chlorobenzene catalytic degradation method by absorption-low temperature plasma and preparation method of adsorptive catalyst thereof

InactiveCN107174948AReduce energy consumptionFacilitate chemical reactionsGas treatmentDispersed particle separationDielectric barrier dischargeCatalytic degradation

The invention discloses a chlorobenzene catalytic degradation method by absorption-low temperature plasma. The method includes steps of placing Ag / AC catalyst in a discharge zone of a dielectric barrier discharge low-temperature plasma reactor; carrying chlorobenzene in the air and charging to the dielectric barrier discharge low-temperature plasma reactor in a gas form; absorbing chlorobenzene by Ag / AC catalyst; at the moment, the plasma power of the reactor is under a closing state; after being absorbed fully, charging oxygen-containing gas while stopping blowing the air carried with chlorobenzene; opening the plasma power of the reactor, discharging and oxidizing the absorbed chlorobenzene by the plasma, and realizing the degradation of chlorobenzene. The method combines adsorptive catalyst with low-temperature plasma, displays advantages of the low-temperature plasma of low energy consumption of low-temperature plasma, rapid chemical reaction, complete purification, wide adaptation, and effectively realizes the chlorobenzene degradation.

Owner:ZHEJIANG UNIV OF TECH

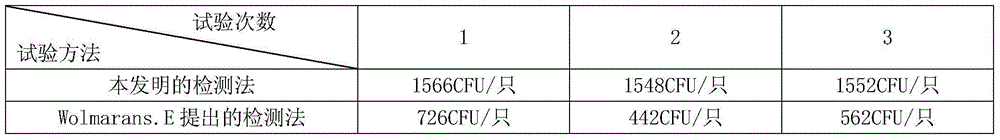

Detection method for bacteria attached to body surfaces of cyclops zooplankton

InactiveCN103451263BImprove desorption efficiencyHigh speedMicrobiological testing/measurementZooplanktonDaphnia

The invention provides a detection method for bacteria attached to the body surface of cyclops zooplankton. The method comprises the following steps: 1. taking cyclops in a water sample, and washing the cyclops till no bacterium is detected; 2. placing the cyclops obtained in the step 1 into a centrifuge tube, and adding a desorption reagent; 3. placing the centrifuge tube in the step 2 into a centrifugal machine for centrifugal treatment; 4. taking supernate after centrifugation, carrying out bacterial culture on the supernate by a testing method of total number of bacteria in household drinking water standard test method, and counting cultivated bacterial colonies. According to the method, the operating steps are simple, the detection period is short, and the remarkable detection effect to bacteria attached to the body surface of cyclops zooplankton is remarkable.

Owner:HOHAI UNIV

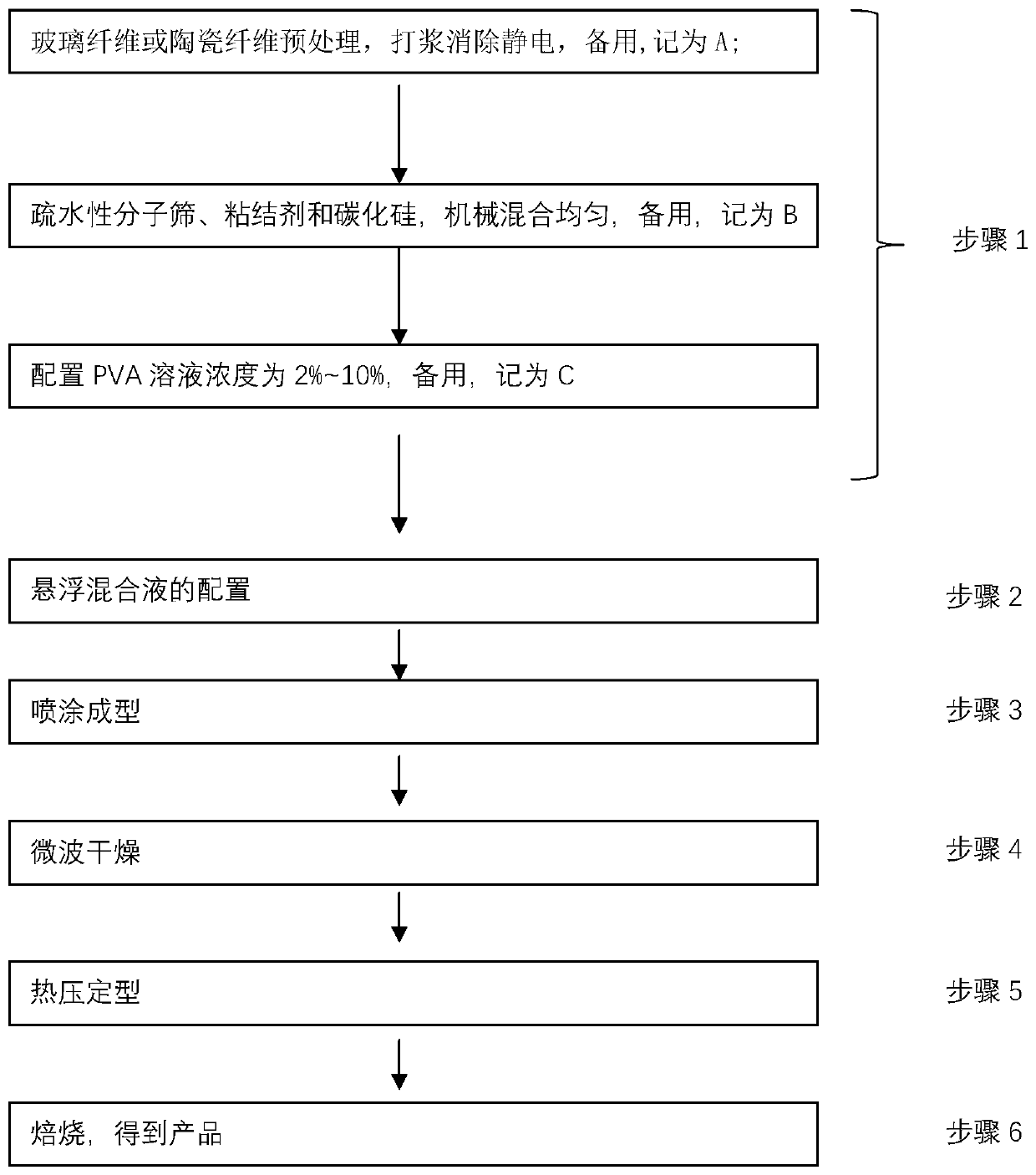

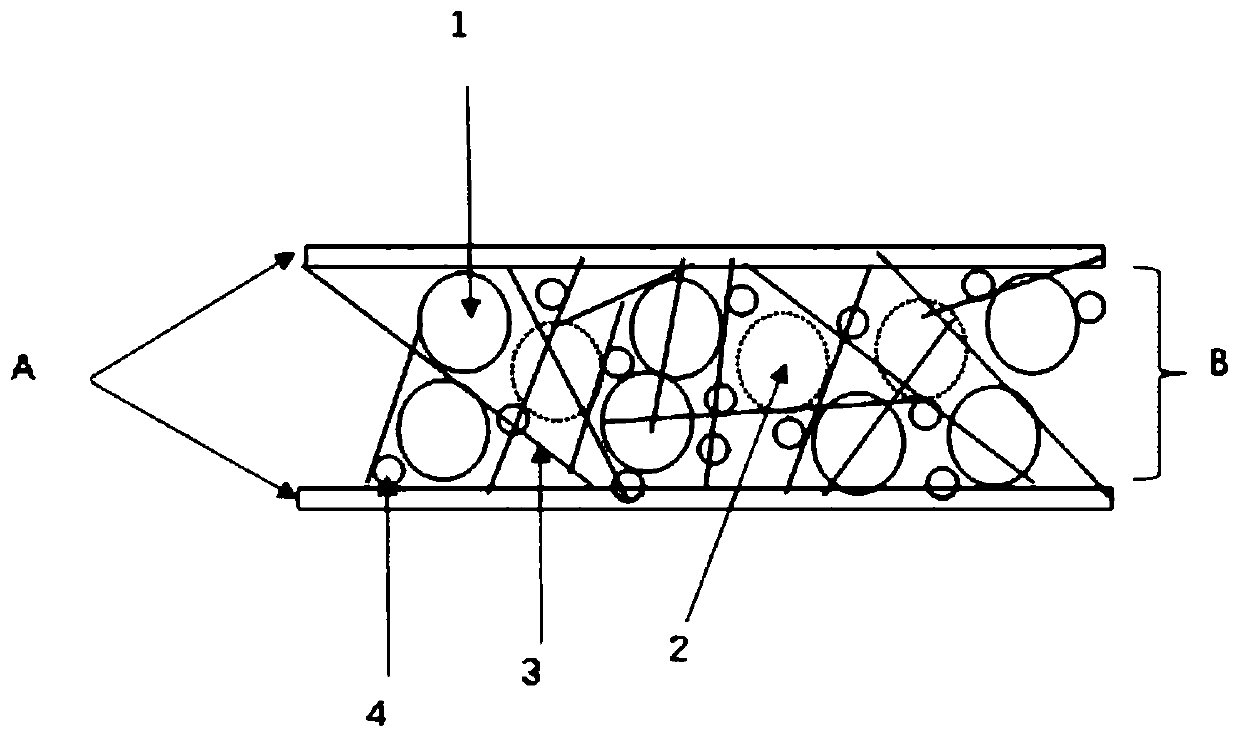

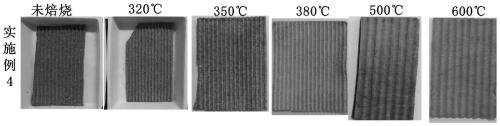

Filtering material for purifying volatile organic compounds and preparation method thereof

ActiveCN111545164AWide temperature rangeHigh molecular sieve contentGas treatmentOther chemical processesMolecular sieveGlass fiber

The invention belongs to the field of environmental protection, and particularly relates to a filtering material for purifying volatile organic compounds and a preparation method thereof. The filtering material comprises a filling layer and high-temperature-resistant fabric layers arranged on the two sides of the filling layer, wherein the filling layer comprises a three-dimensional porous fiber net and micron particles distributed in pores of the fiber net; the fiber net is made of glass fibers and / or ceramic fibers; the materials of the micron particles comprise a hydrophobic molecular sieve, an inorganic binder and silicon carbide in a weight ratio of (5-7): (1.5-2): (1-2); the weight ratio of the fiber net to the micron particles is (5-10): (70-80). The filtering material disclosed bythe invention has the characteristics of high temperature resistance, high molecular sieve content, light weight and the like, is similar to paper in shape, belongs to a flexible material and is convenient to process into various shapes. And meanwhile, the structure is stable, the service life is long, and application in actual production is facilitated.

Owner:BEIJING LONGTAO ENVIRONMENTAL TECH CO LTD

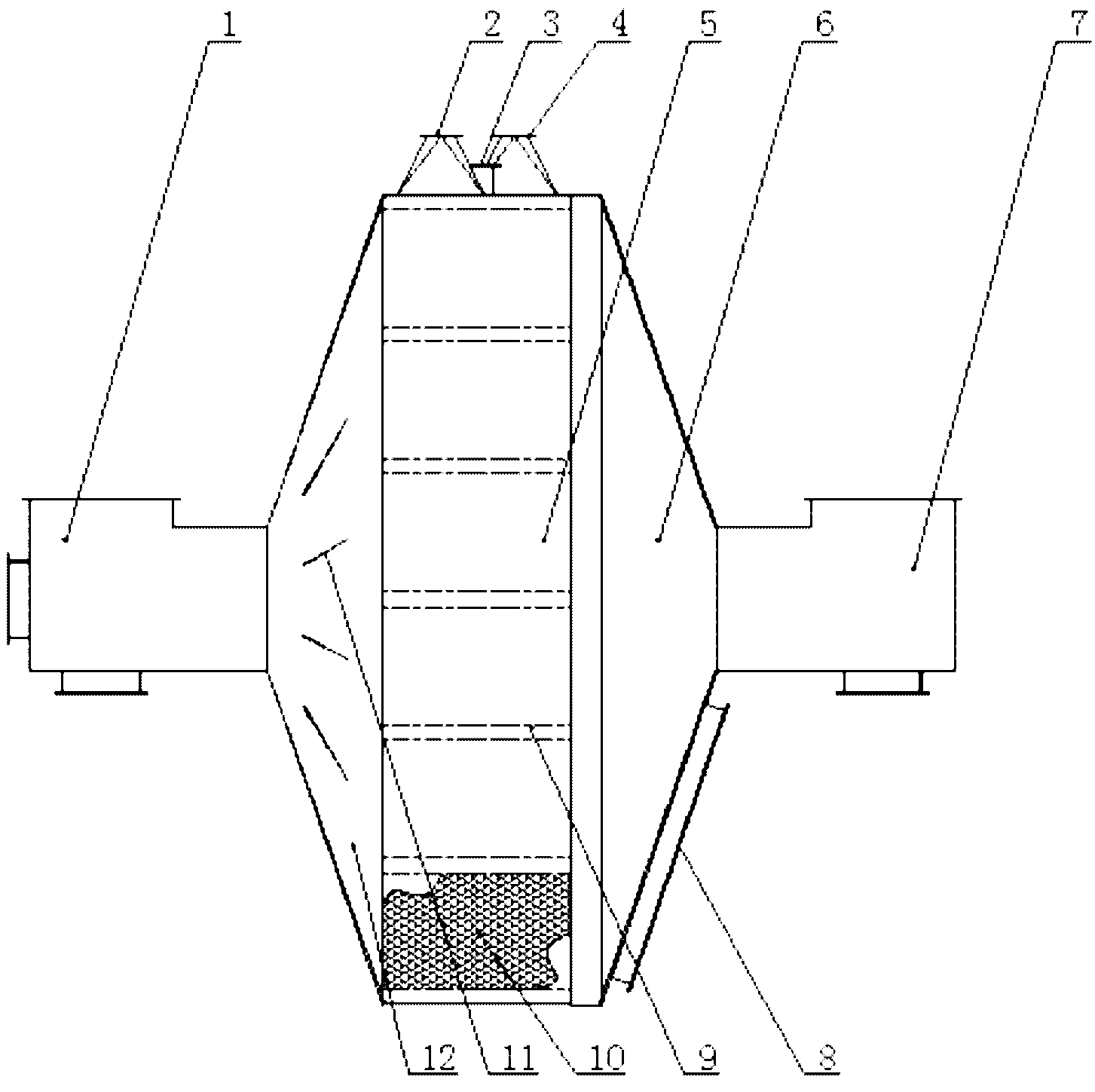

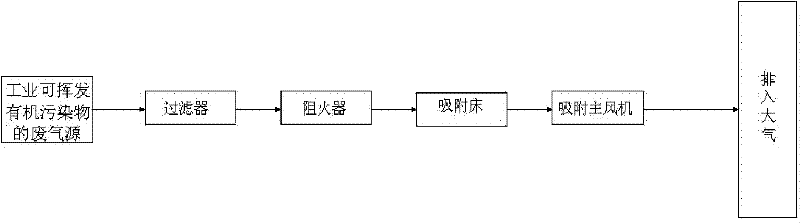

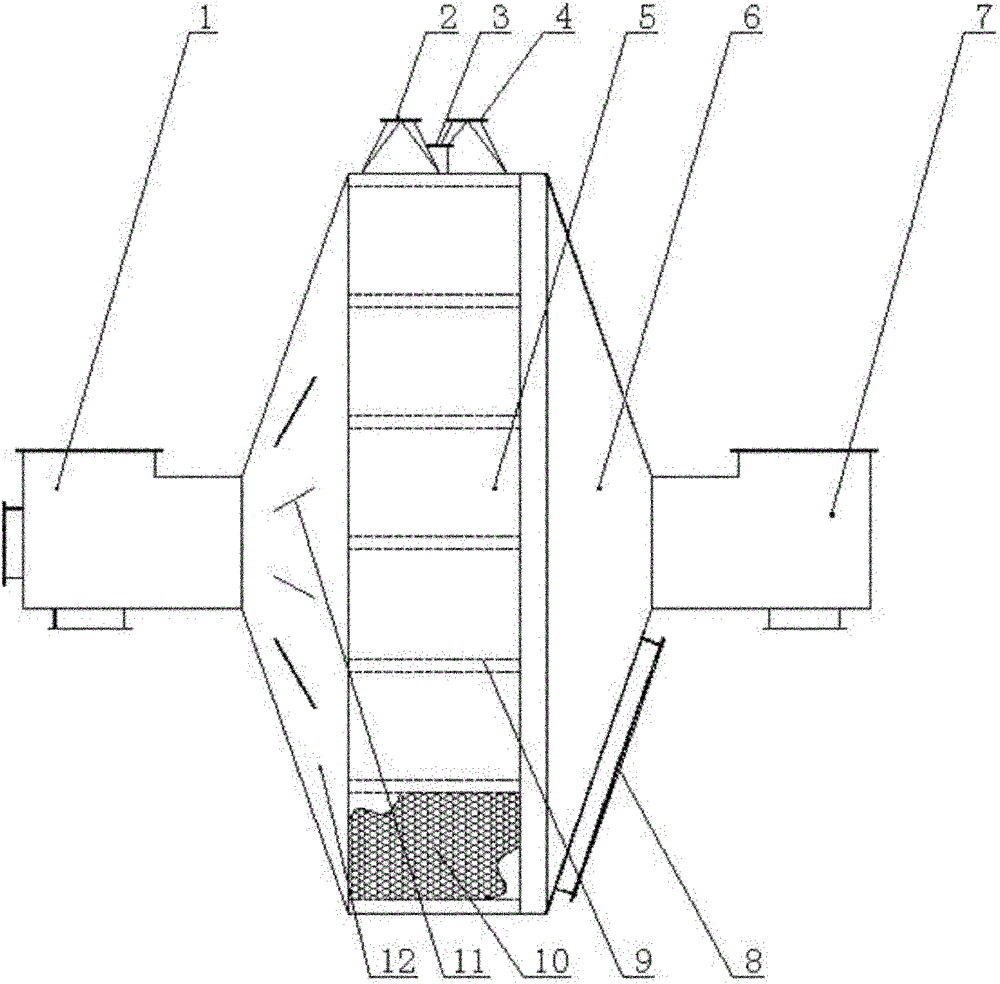

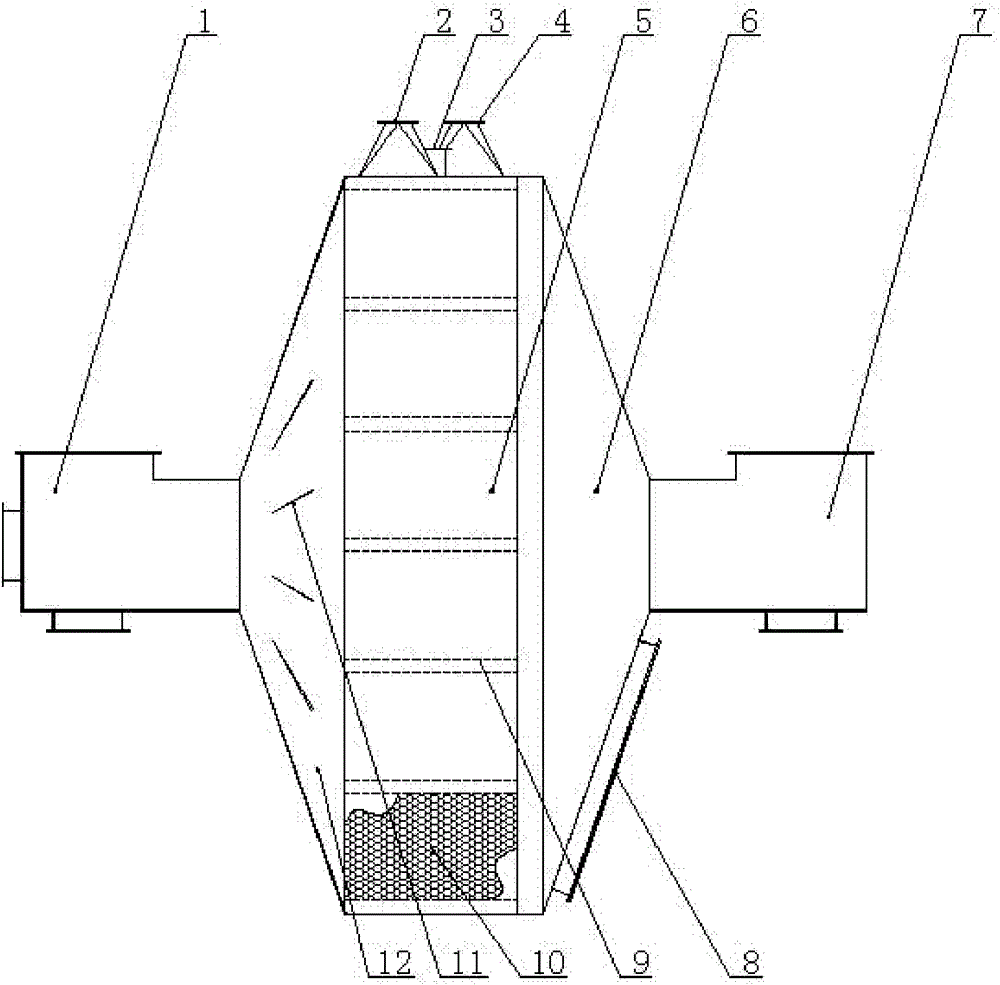

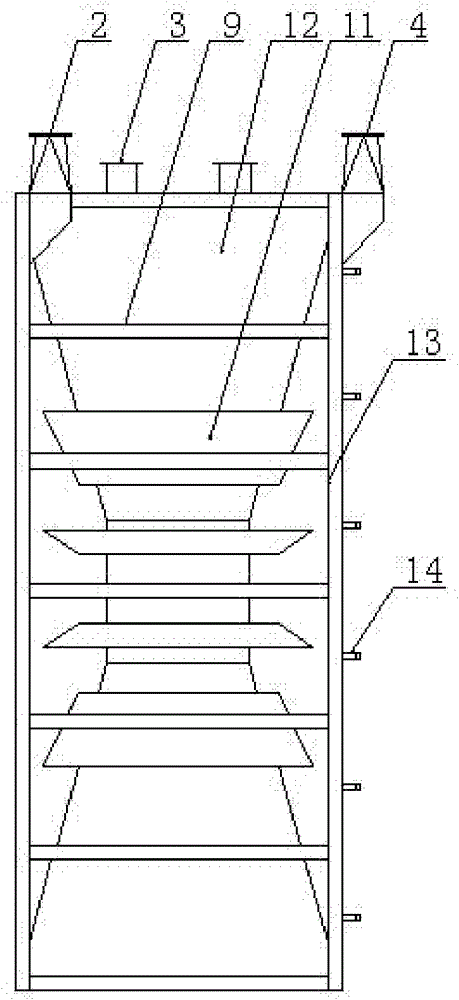

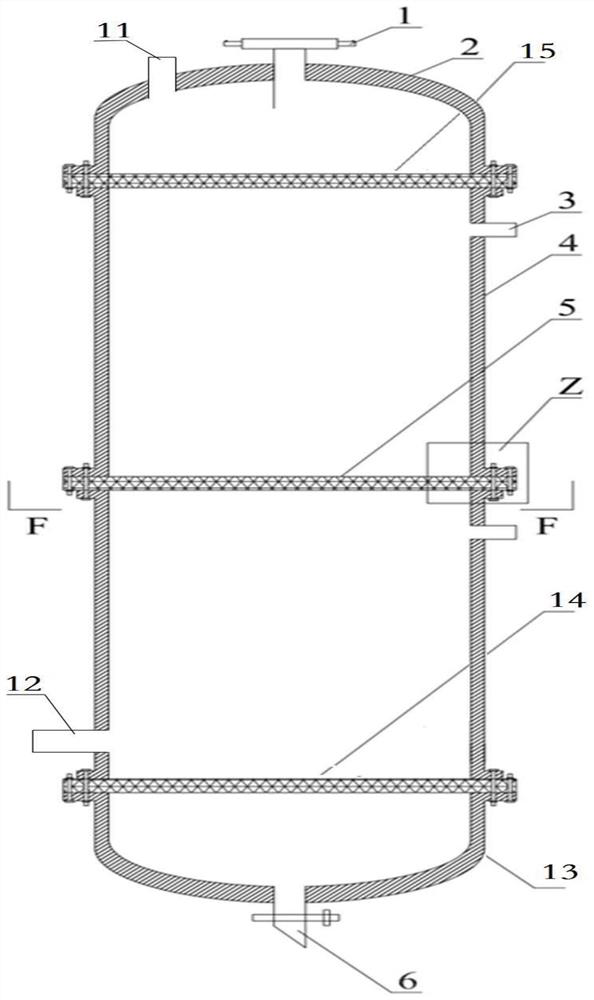

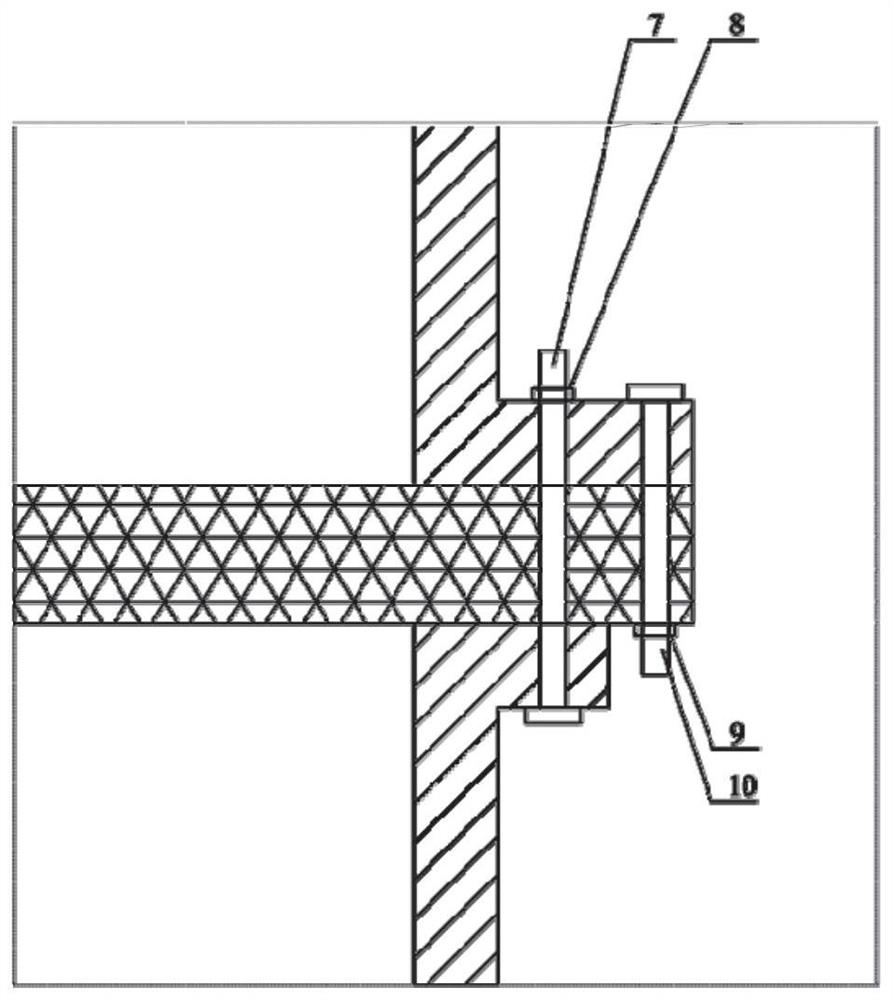

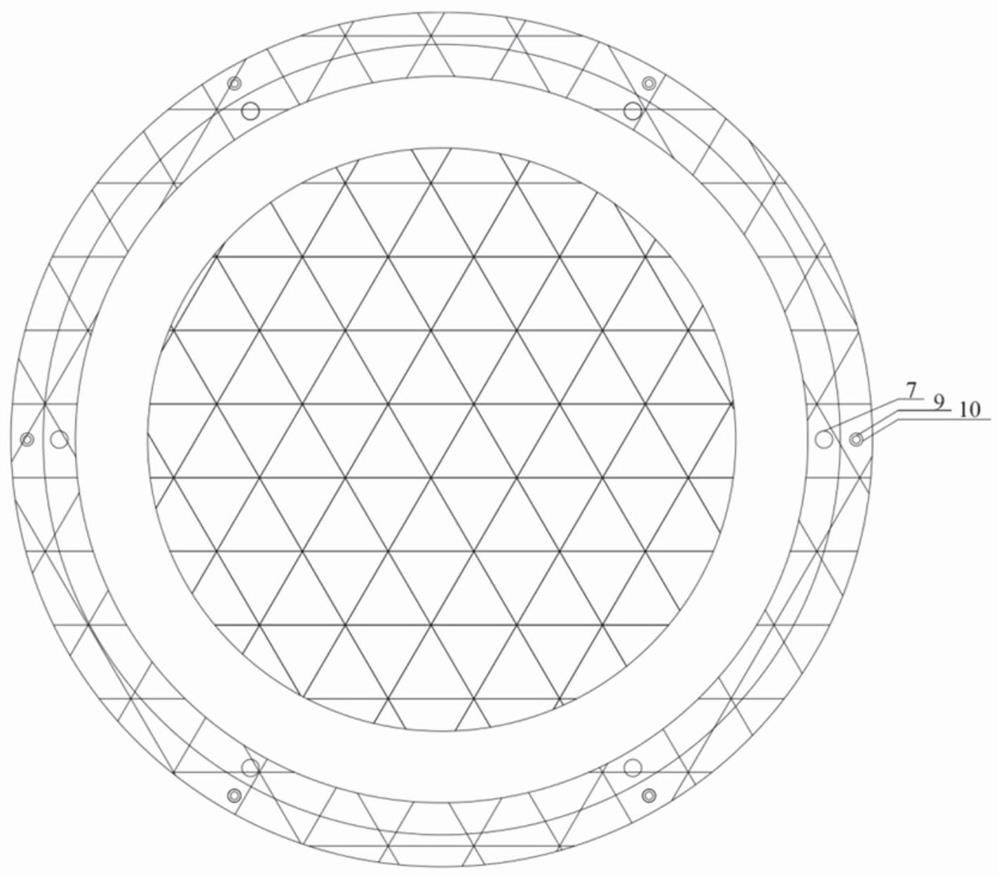

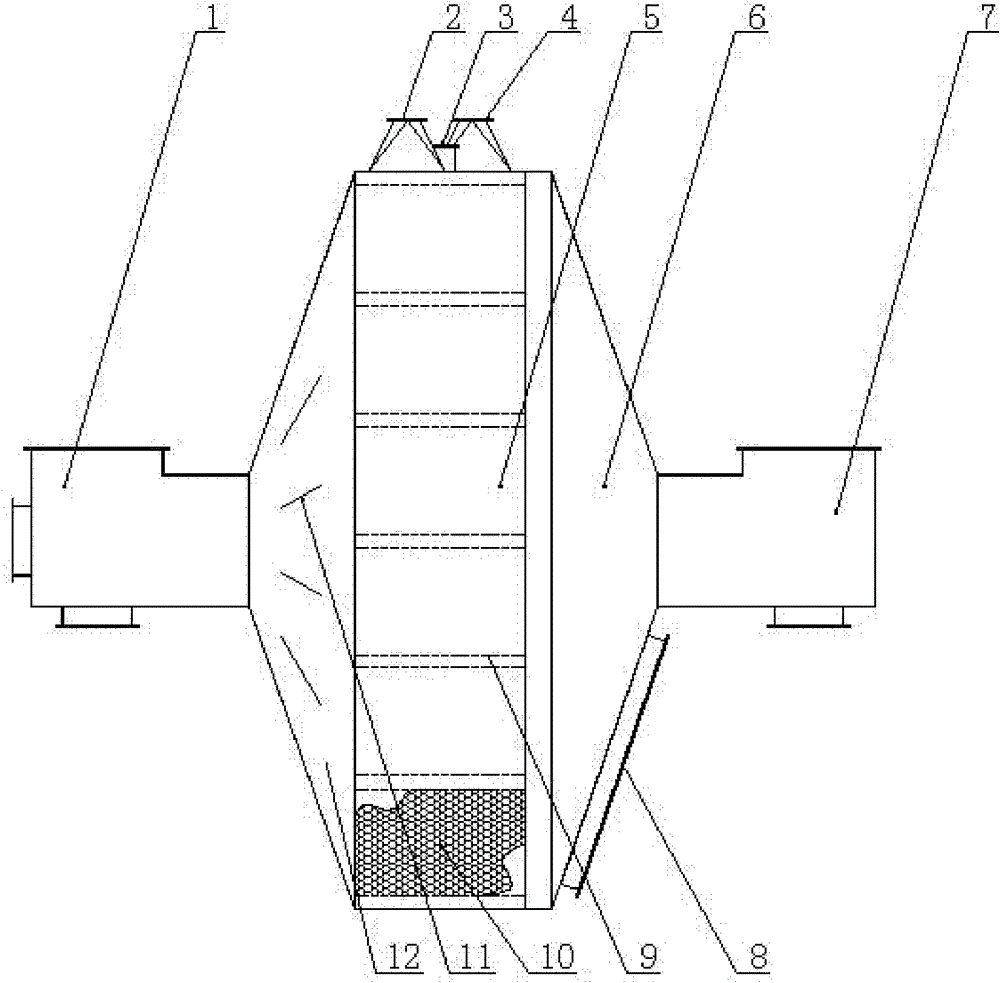

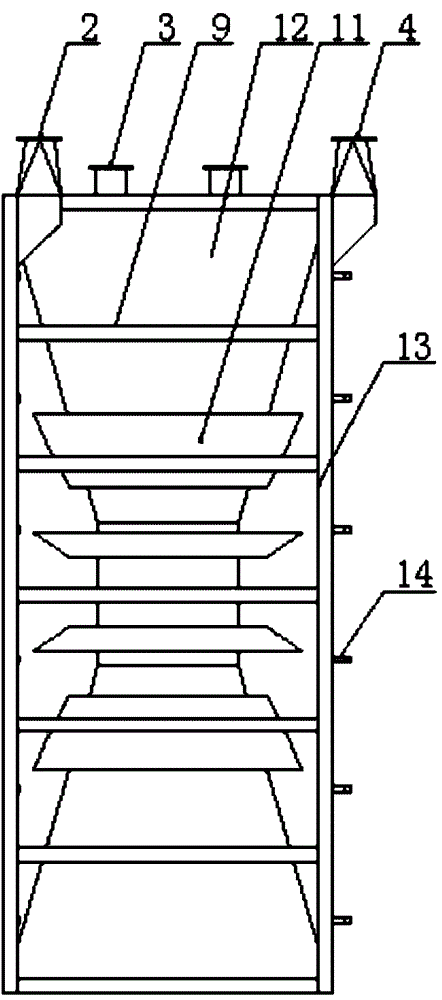

High-efficiency energy-saving adsorption system for industrial volatile organic pollutants

InactiveCN102188876AReduce consumptionImprove processing efficiencyDispersed particle filtrationFlame arresterActivated carbon

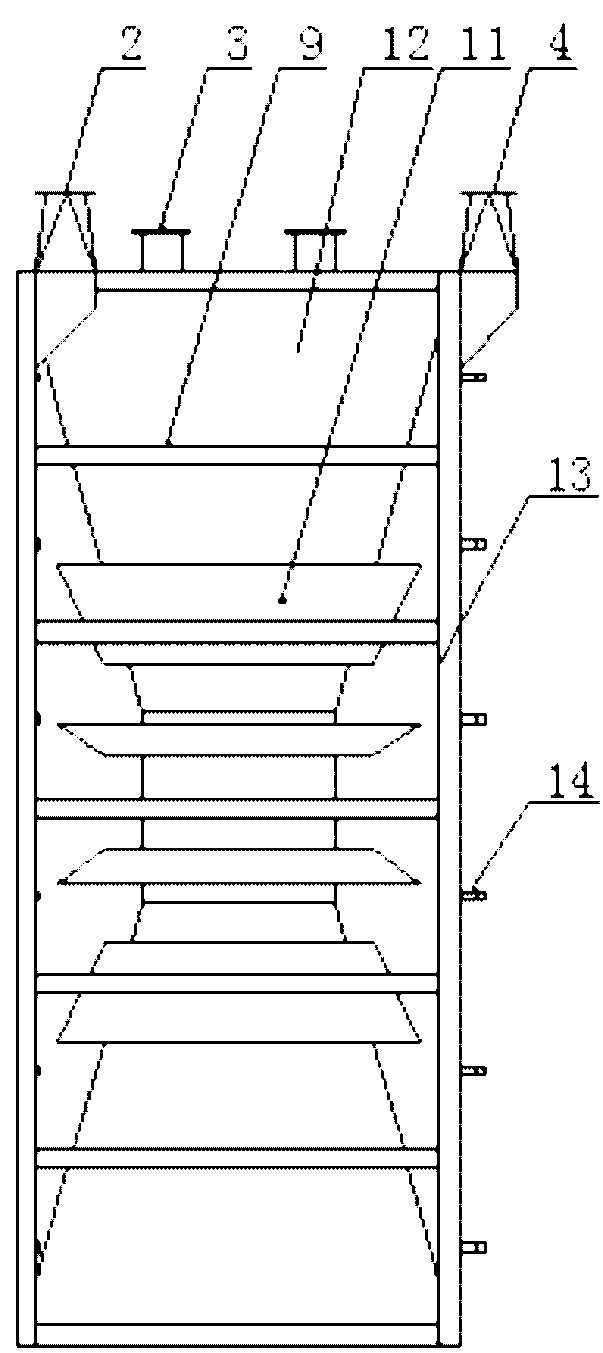

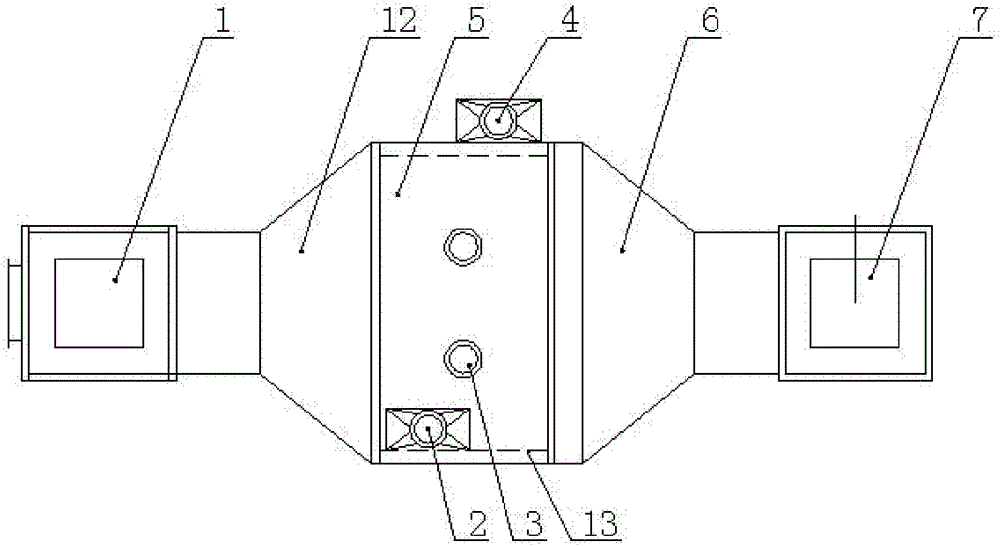

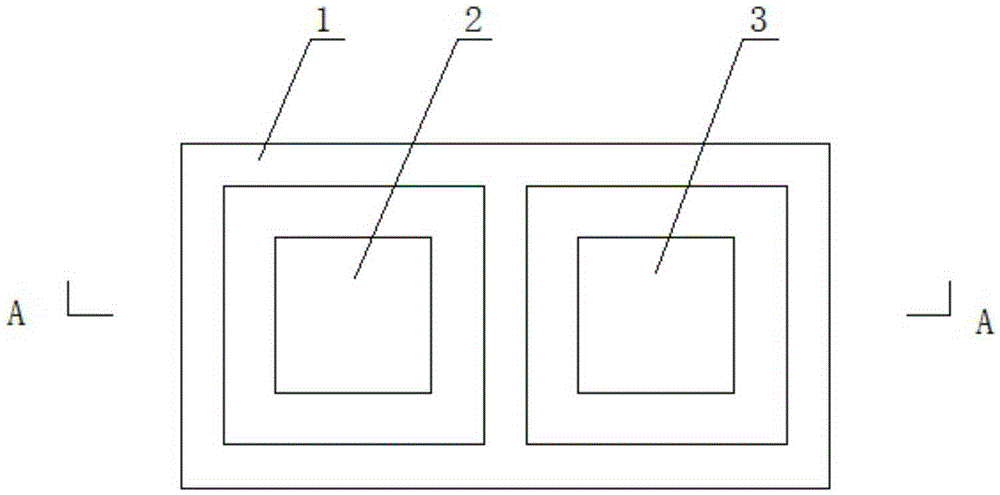

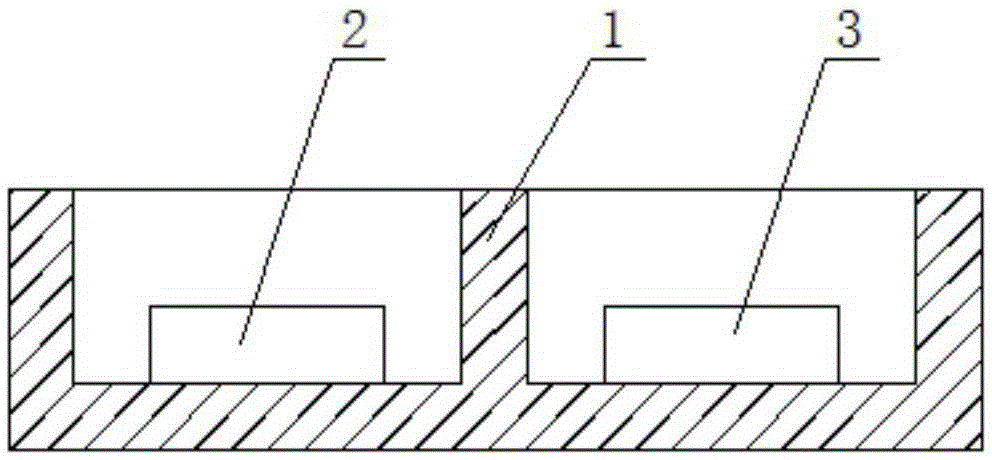

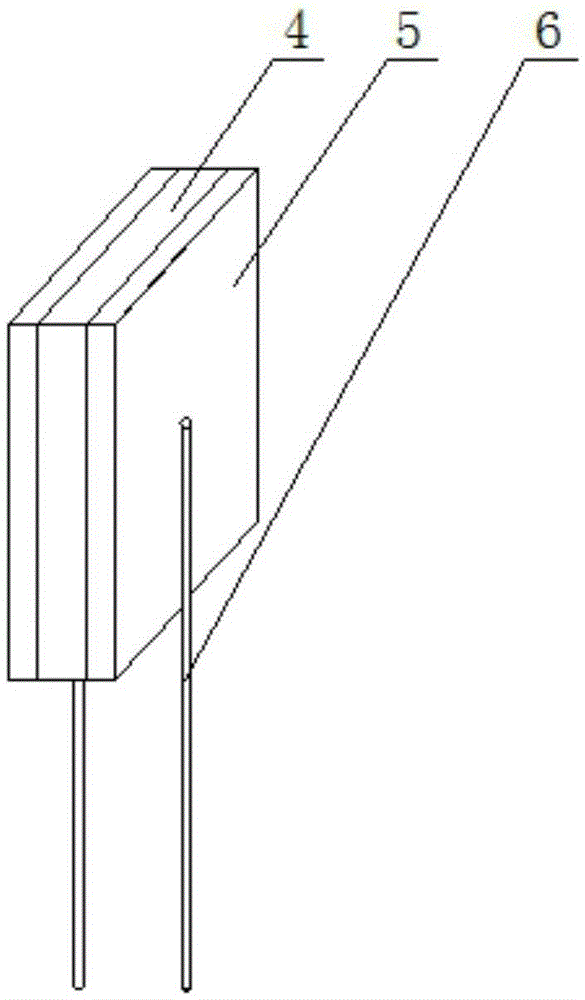

The invention relates to a high-efficiency energy-saving adsorption system for industrial volatile organic pollutants. The system comprises a filter, a flame arrester, an adsorption bed and an adsorption main fan which are connected through pipelines in turn, wherein the two opposite sides of an activated carbon bed body of the adsorption bed are connected with an air inlet expanding part and an air outlet necking part respectively; the air inlet expanding part is fixedly provided with an air distribution plate; a plurality of layers of activated carbon clapboards are arranged in the activated carbon bed body; the two opposite side walls of the activated carbon bed body have a hollow structure; the activated carbon clapboards have a hollow structure; the activated carbon clapboards with the hollow structure are communicated with the side walls with the hollow structure; and the two side walls with the hollow structure are provided with a hot air inlet and a hot air outlet respectively. The high-efficiency energy-saving adsorption system for the industrial volatile organic pollutants has a simple structure and a scientific and reasonable design, is safe and reliable, reduces the consumption of electric energy, shortens the desorption operation period, reduces operation cost, and accords with the national policy of energy conservation and emission reduction.

Owner:NANTONG ZHI HANG MECHANICAL & ELECTRICAL TECH CO LTD

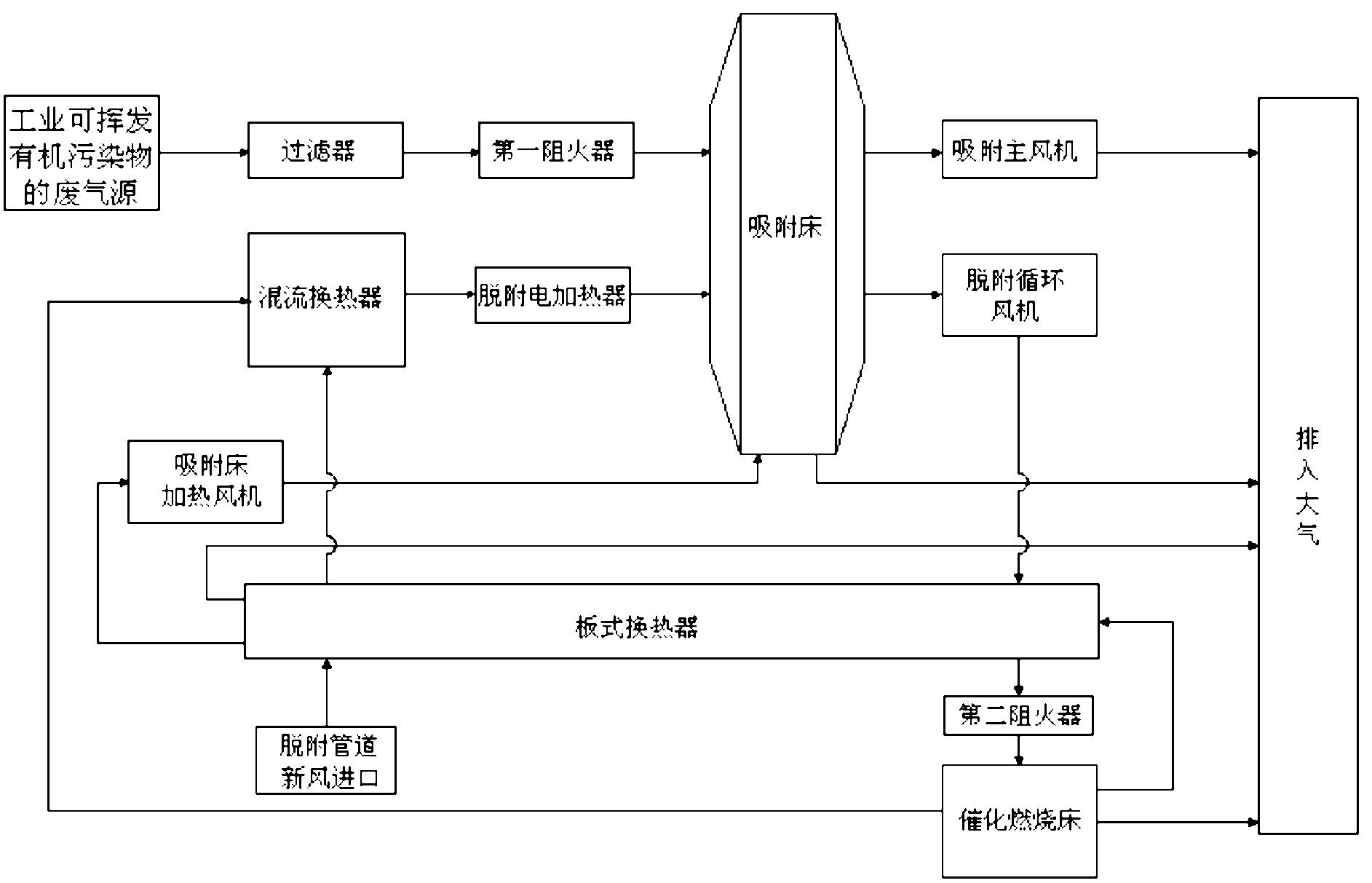

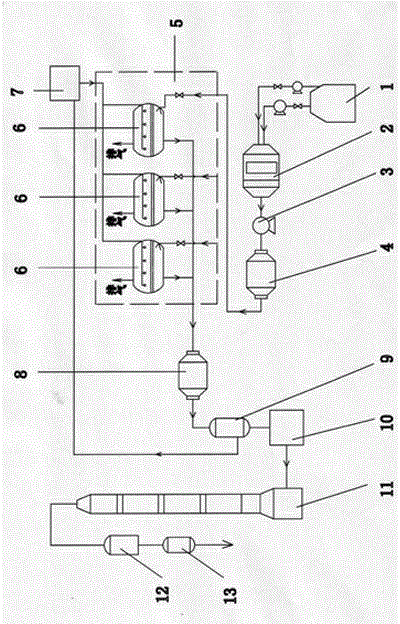

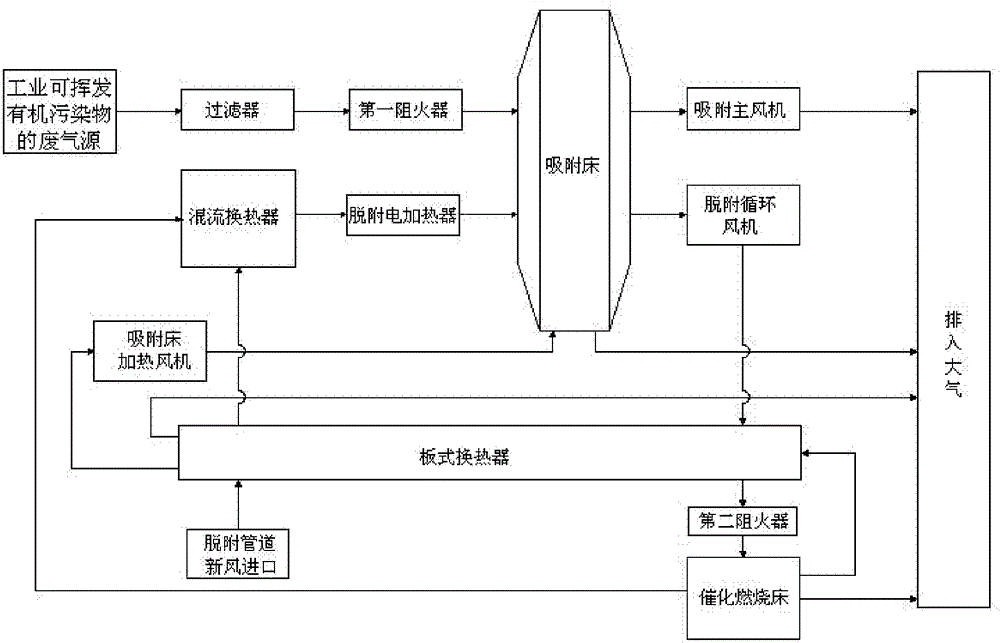

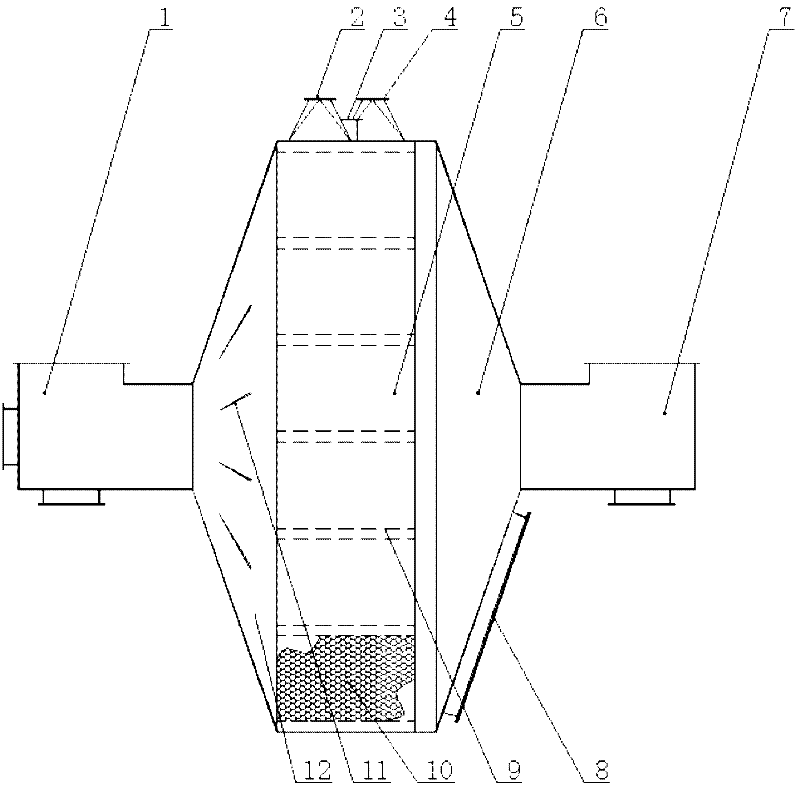

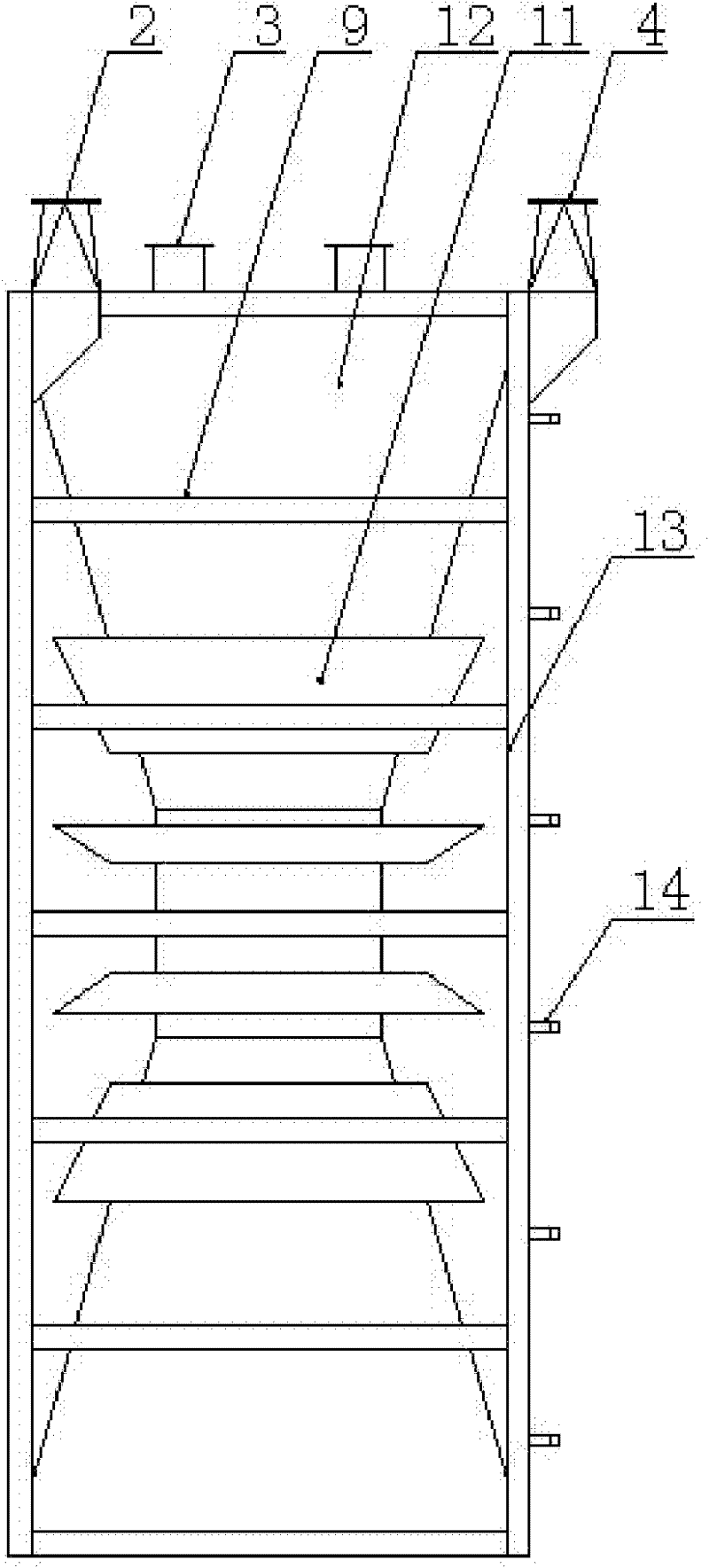

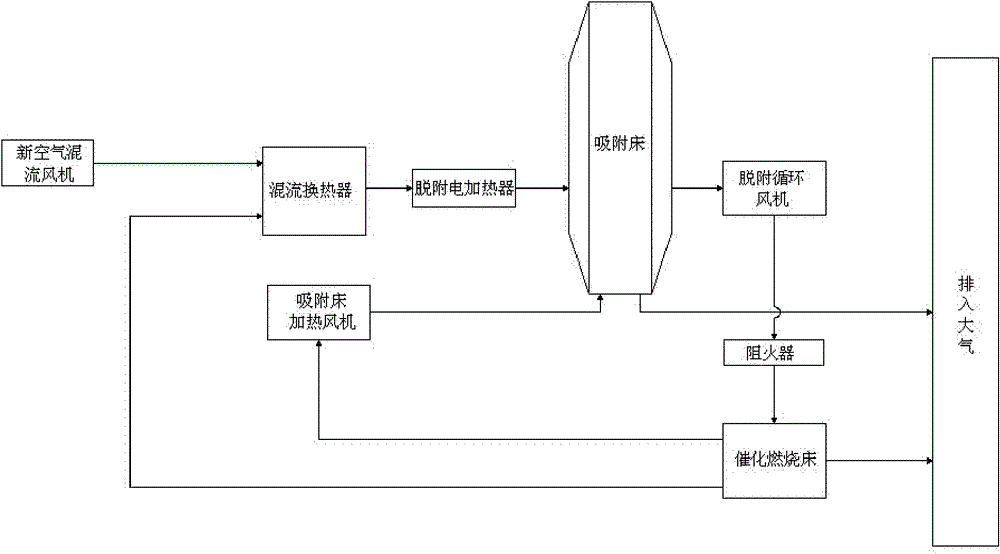

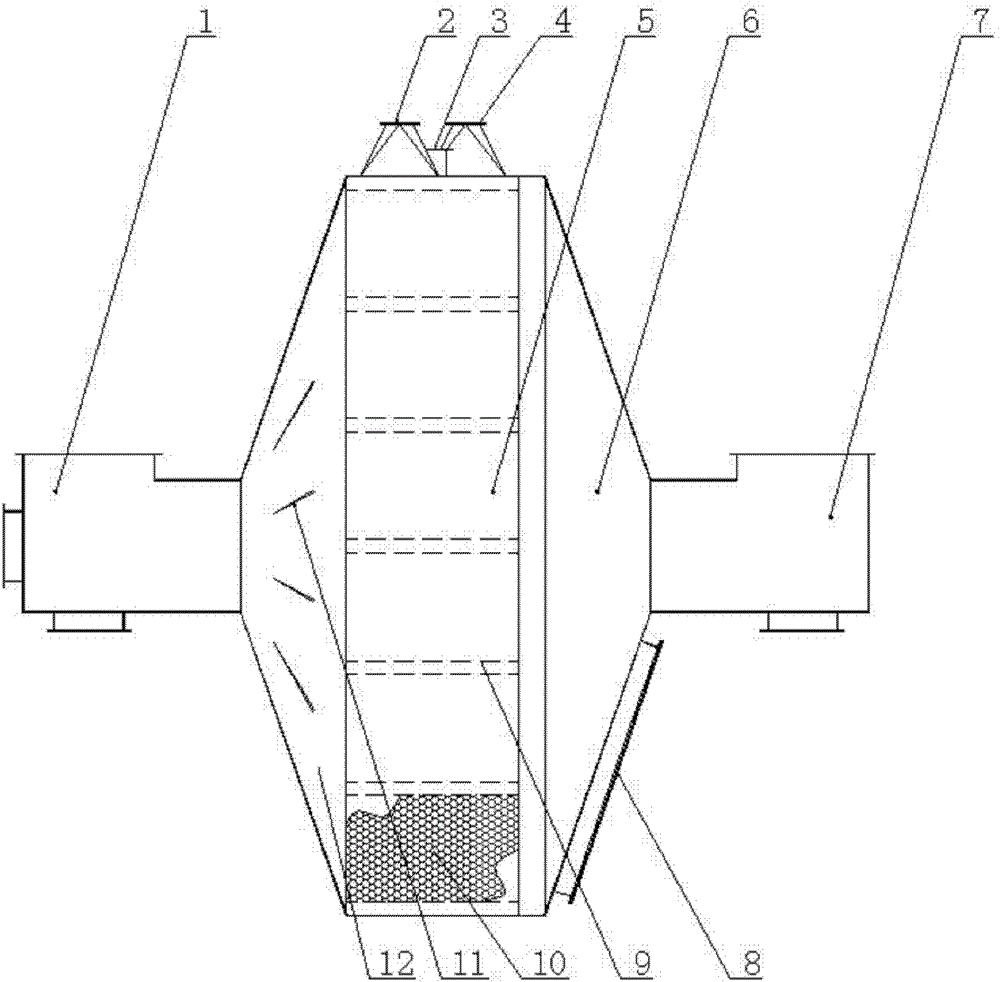

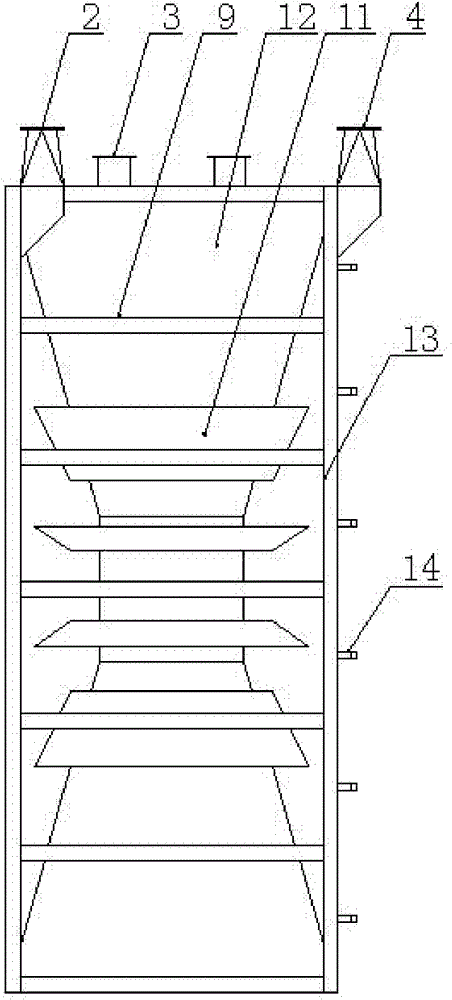

Energy-saving efficient adsorption and desorption combined system

InactiveCN102188873BReduce consumptionImprove processing efficiencyDispersed particle separationMixed flowDesorption

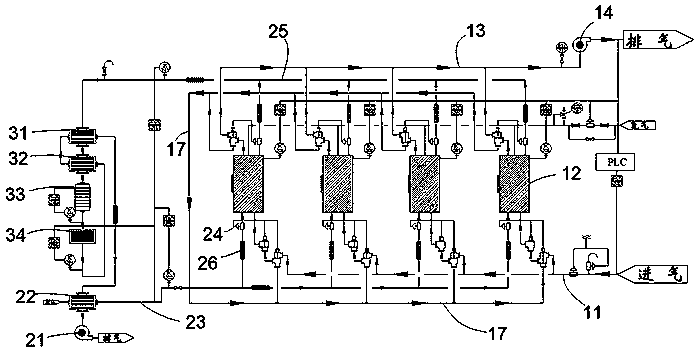

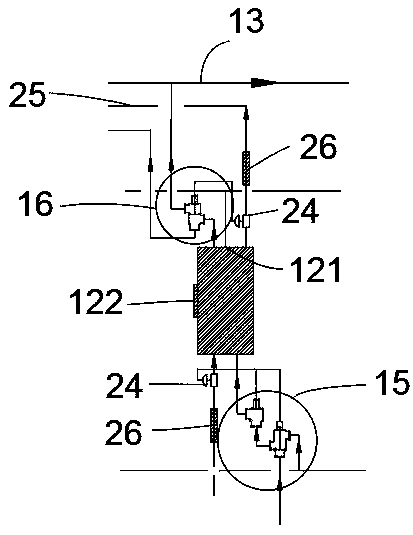

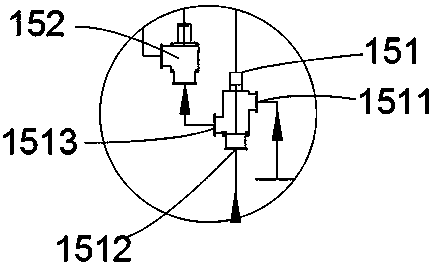

The invention relates to an energy-saving efficient adsorption and desorption combined system which is characterized in that (1) an adsorption bed is provided with a hollow active carbon clapboard which is communicated with hollow side walls; and the two hollow side walls are respectively provided with a hot air inlet and a hot air outlet; and (2) a catalyst bed body of a catalytic combustion bed is sequentially provided with a catalyst electric heater, an air distributing plate and a catalytic bed layer from top to bottom; a first air outlet of the catalytic combustion bed is connected with a first air inlet of a mixed flow heat exchanger through a pipeline; a second air outlet of the catalytic combustion bed is connected with the hot air inlet of the hollow side wall of the adsorption bed through an adsorption bed heating fan; the air outlet of a fresh air mixed flow fan is connected with a second air inlet of the mixed flow heat exchanger; and the air outlet of a desorption circulating fan is connected with the air inlet of the catalytic combustion bed through a second flame damper. The system is simple and reasonable in structure, and safe and reliable; and moreover, the system has the advantages that the energy consumption is effectively reduce, the purifying rate is improved, the time of a desorption process is shortened, the purifying efficiency is improved, and the operation cost is lowered.

Owner:NANTONG ZHI HANG MECHANICAL & ELECTRICAL TECH CO LTD

Apparatus for recovering ethanol in organic exhaust gas from tipping paper printing

ActiveCN102512908BEfficient recyclingImprove pollutionDispersed particle filtrationVapor condensationOrganic solventVapor–liquid separator

The invention discloses an apparatus for recovering ethanol in organic exhaust gas from tipping paper printing. In production technology of printing industry, usage of a great amount of organic solvent causes indoor air pollution. The apparatus of the invention comprises a filter (2), a blower fan (3), a secondary surface cooler (4), an absorber assembly (5), a desorption device condenser (8), a gas-liquid separation device (10), a liquid storage tank (11) and a rectifying tower (12). An 80-mesh primary sieve (17) is arranged on one side of an air intake of the filter (2) casing; a 120-mesh secondary sieve (18) is arranged on one side of an air outlet; and the absorber assembly (5) comprises three horizontal absorbers (6) in parallel connection. If employed, the apparatus for treating printing exhaust gas of the invention not only improves pollution caused by direct discharge but also effectively recovers ethanol in the printing exhaust gas, at low cost and low energy consumption.

Owner:YUNNAN YUXI TIPPING PAPER FACTORY

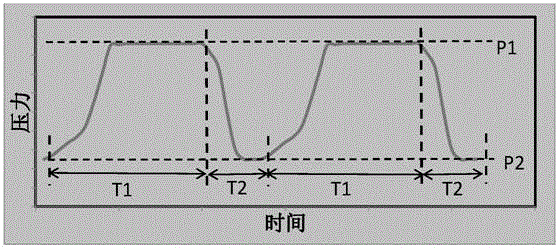

Catalytic adsorption-desorption isomerization method

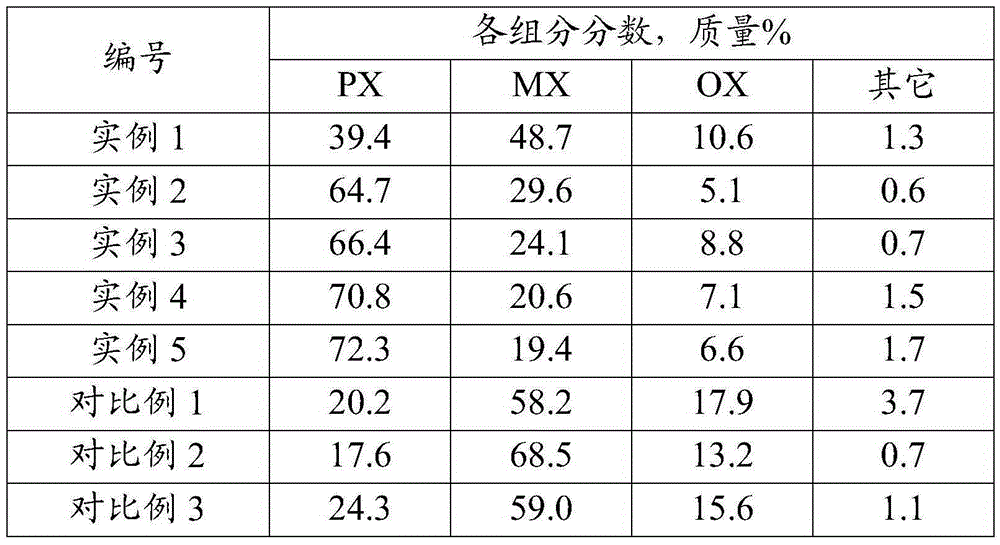

ActiveCN106495979AHigh yieldExtended reaction timeHydrocarbon by isomerisationBulk chemical productionIsomerizationGas phase

The invention discloses a catalytic adsorption-desorption isomerization method. According to the catalytic adsorption-desorption isomerization method, reaction raw materials are delivered into a catalyst bed, and isomerization reaction conditions are achieved; reaction is carried out without discharging materials; pressure is reduced for desorption; and a reaction product is discharged from the catalyst bed; wherein the ratio of the reaction time to the desorption time is controlled to be larger than 10. Gas phase reaction process and pressure swing adsorption process are combined so as to increase reaction conversion rate, and obtain the target product with a concentration higher than a chemical equilibrium value.

Owner:CHINA PETROLEUM & CHEM CORP +1

Series targeted adsorption and parallel desorption organic waste gas treatment device

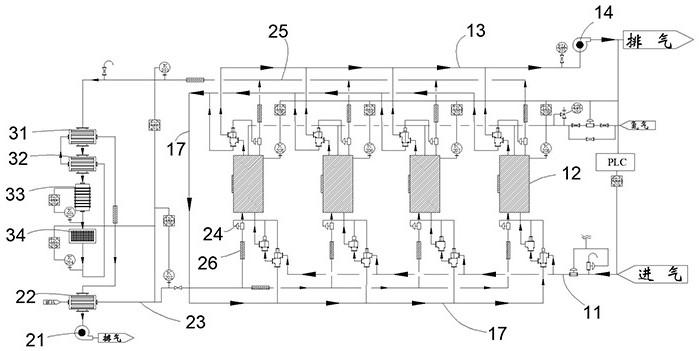

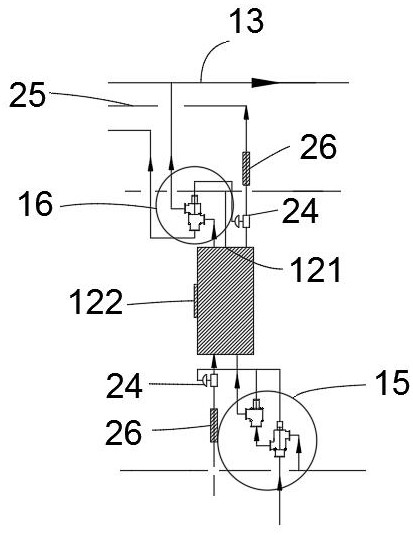

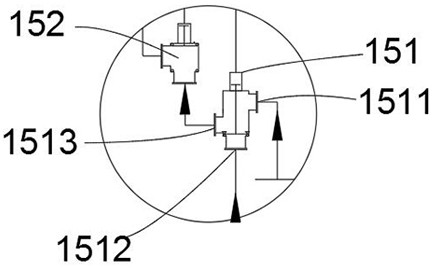

ActiveCN111389175BAvoid reunionReduce heating frequencyDispersed particle separationIncinerator apparatusCombustion systemPtru catalyst

The invention discloses a series targeted adsorption and parallel desorption organic waste gas treatment device, which comprises a series adsorption system, a parallel desorption system and a catalytic combustion system; Circulation pipeline and main fan; parallel desorption system includes desorption fan, secondary heat exchanger, desorption intake pipe, automatic valve and desorption exhaust pipe; catalytic combustion system includes primary heat exchanger A, primary heat exchange B, heater and catalytic reactor. The invention selects corresponding targeted adsorbents according to the molecular diameter and adsorption characteristics of different pollutants, the thin layer design of the adsorption bed and the multi-stage parallel desorption mode, shortens the desorption time and can effectively control the desorption peak concentration. In order to avoid the safety problems caused by desorption due to the excessively long adsorption zone, the relative stability of the VOCs concentration during desorption reduces the heating frequency of the catalytic combustion system, avoids the agglomeration of the catalyst, and makes full use of the energy saved by the combustion reaction heat of VOCs.

Owner:南大恩洁优环境技术江苏股份公司

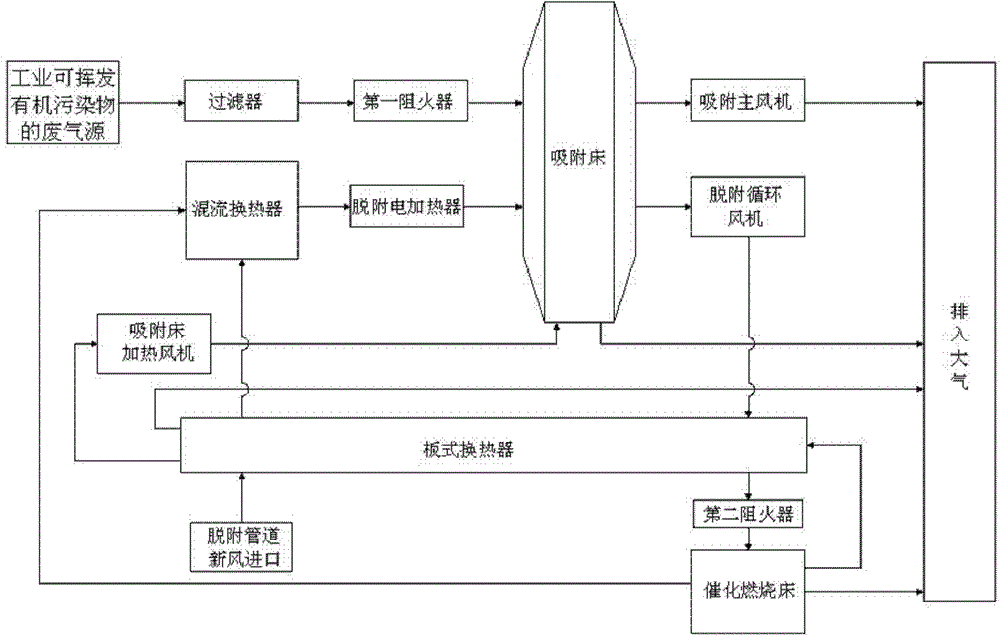

Automatic high-efficiency energy-saving purification system for industrial volatilizable organic pollutants

InactiveCN102172461BReduce consumptionImprove processing efficiencyDispersed particle filtrationIncinerator apparatusActivated carbonDesorption

The invention relates to an automatic high-efficiency energy-saving purification system for industrial volatilizable organic pollutants, which is characterized in that: (1) both opposite side walls of an active carbon bed body of an adsorption bed are set into side walls with hollow structures, an active carbon clapboard is set into an active carbon clapboard with a hollow structure, the active carbon clapboard with the hollow structure is communicated with the side walls with the hollow structures, and the two side walls with the hollow structures are respectively provided with a hot air inlet and a hot air outlet; and (2) a catalytic combustion bed is connected with a plate-type heat exchanger, and the plate-type heat exchanger is connected with the hot air inlets on the side walls with the hollow structures of the adsorption bed through an adsorption bed heating fan. The automatic high-efficiency energy-saving purification system for the for industrial volatilizable organic pollutants has a simple and reasonable structure, can effectively reduce energy consumption, improve the purifying rate, prolong the service life of a catalyst, shorten the desorption process time, improve the purifying efficiency and reduce the operating cost, and is safe and reliable.

Owner:赛智环保科技(天津)有限公司

Efficient energy-saving purifying system for industrial volatile organic pollutants

InactiveCN102172462BReduce consumptionImprove processing efficiencyDispersed particle filtrationIncinerator apparatusEngineeringSystem structure

The invention relates to an efficient energy-saving purifying system for industrial volatile organic pollutants. The system is characterized in that (1) an adsorbent bed is provided with an active carbon clapboard of a hollow structure, wherein the active carbon clapboard is communicated with side walls of a hollow structure, and the two side walls of a hollow structure are provided with a hot air inlet and a hot air outlet respectively; and (2) a catalytic combustion bed is connected with a plate type heat exchanger, wherein the plate type heat exchanger is connected with the hot air inlets of the side walls of a hollow structure of the adsorbent bed through an adsorbent bed heating fan. The system provided by the invention is of a simple and reasonable structure, and ensures that the energy consumption can be effectively reduced, the purifying rate is improved, the service life of a catalyst is prolonged, the desorption time is shortened, the purifying efficiency is improved, and the operation cost is lowered, thereby being a safe and reliable efficient energy-saving purifying system for industrial volatile organic pollutants.

Owner:赛智环保科技(天津)有限公司

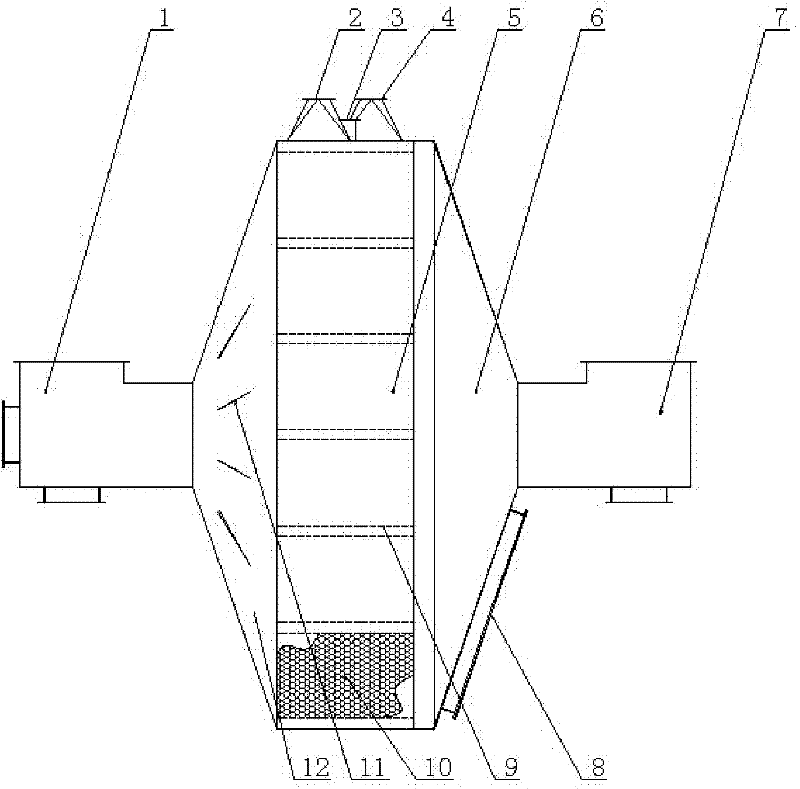

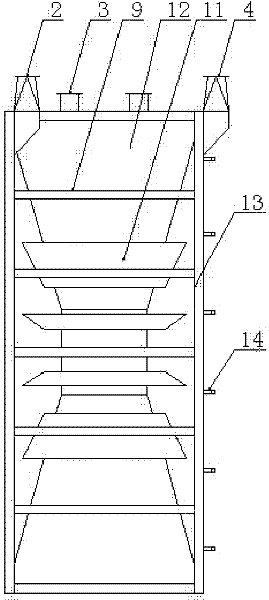

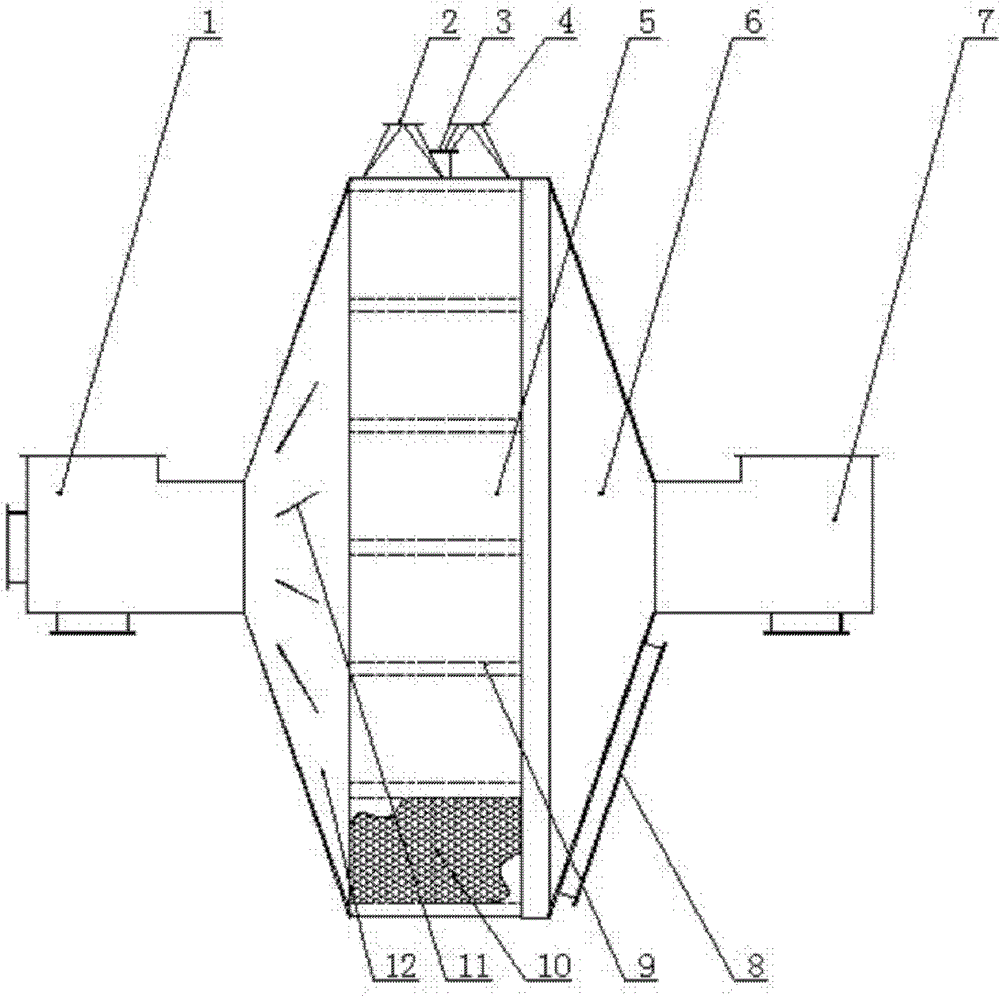

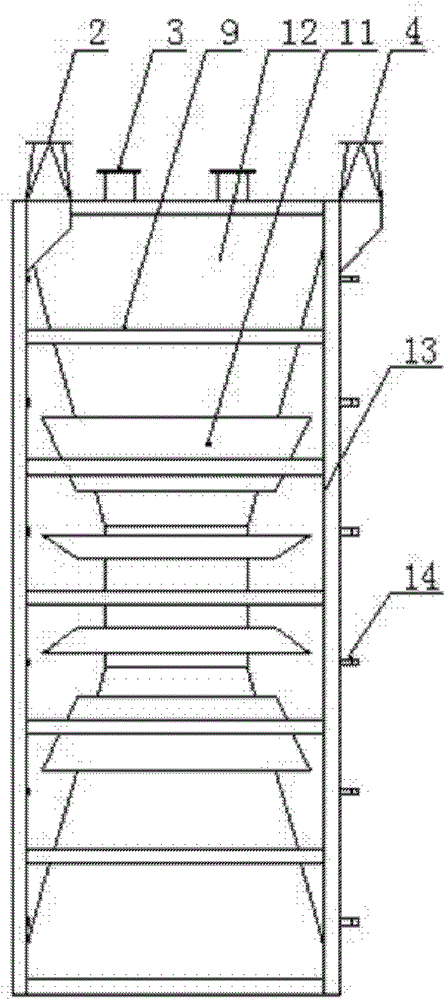

High-efficiency energy-saving absorption device of industrial volatilizable organic pollutant

InactiveCN102188874AReduce consumptionImprove processing efficiencyDispersed particle separationActivated carbonBiochemical engineering

The invention relates to a high-efficiency energy-saving absorption device of an industrial volatilizable organic pollutant. The device comprises an air inlet flaring part, an active carbon bed body and an air outlet reducing part, wherein two opposite faces of the active carbon bed body are connected with the air inlet flaring part and the air outlet reducing part respectively; an air distribution plate is fixedly arranged on the air inlet flaring part; a plurality of layers of active carbon partition plates are arranged in the active carbon bed body; two opposite side walls of the active carbon bed body are set as side walls having a hollow structure respectively; the active carbon partition plates have the hollow structure; the active carbon partition plates having the hollow structureare communicated with the side walls having the hollow structure; and a hot air inlet and a hot air outlet are respectively formed on the two side walls having the hollow structure. The high-efficiency energy-saving absorption device of the industrial volatilizable organic pollutant is simple in structure, scientific and reasonable in design, safe and reliable, effectively utilizes catalytic combustion waste heat, shortens desorption time, reduces the consumption of electric energy, reduces operating cost, and is accordant with the national policy of energy conservation and emission reduction.

Owner:NANTONG ZHI HANG MECHANICAL & ELECTRICAL TECH CO LTD

Method for activated carbon fiber variable voltage desorption gas

InactiveCN101444693BShorten desorption timeSave energyOther chemical processesDispersed particle separationFiberChemical physics

Owner:HARBIN INST OF TECH

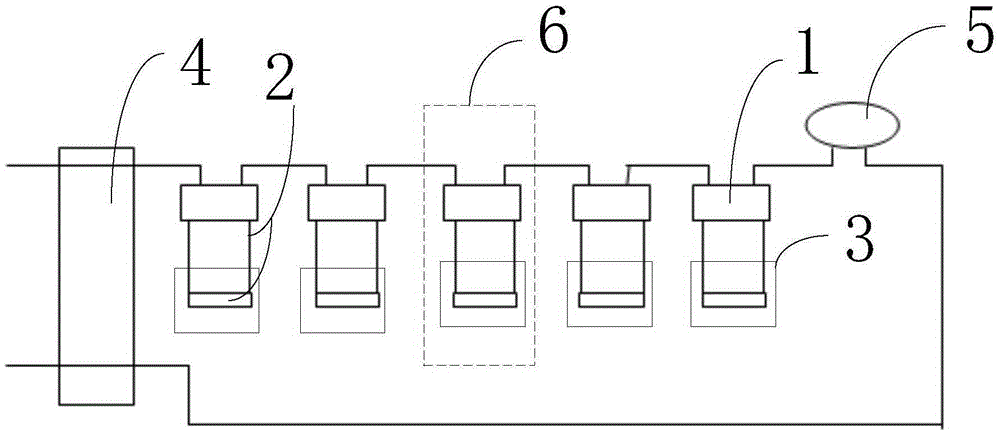

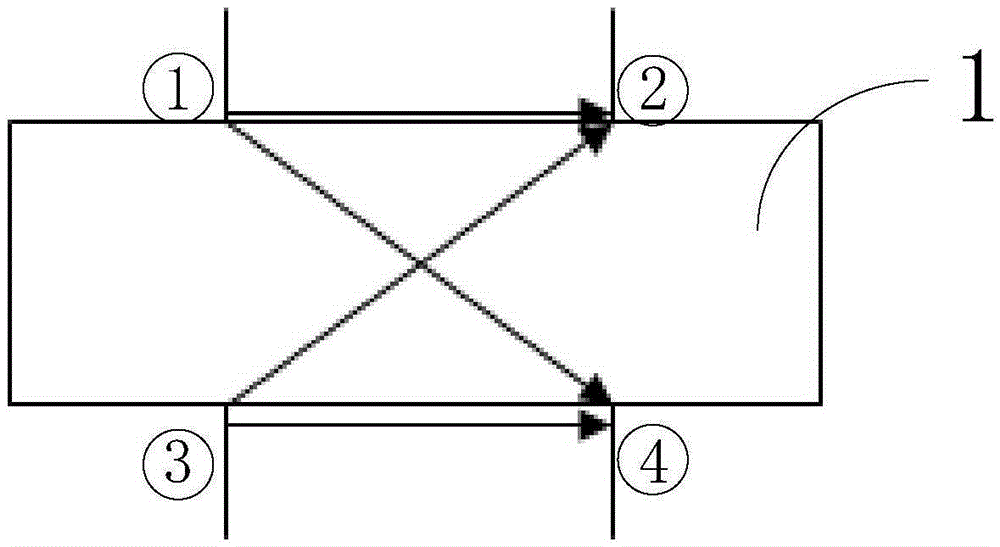

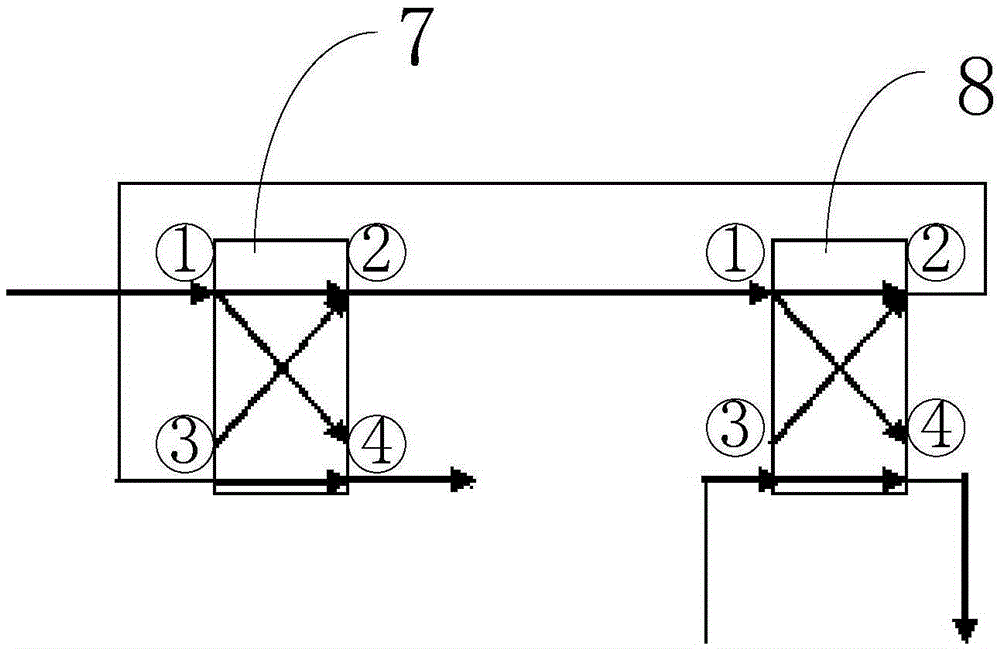

A multi-station series dynamic nitrogen adsorption specific surface meter and specific surface measurement method

The invention relates to a multistation in-series dynamic nitrogen adsorption specific surface instrument and a specific surface measuring method, the multistation in-series dynamic nitrogen adsorption specific surface instrument comprises a plurality of four-way electromagnetic valves, a plurality of U shape sample tubes, a plurality of liquid nitrogen cups, a thermal conductivity cell and a quantitative nitrogen pipeline; an adsorbing unit respectively comprises one four-way electromagnetic valve, one sample tube and one liquid nitrogen cup, the third communication port and the fourth communication port of the four-way electromagnetic valve are respectively connected with the two connecting ends of the sample tube; a plurality of adsorbing units are in in-series connection, the first communication port at the head end of the four-way electromagnetic valve in the adsorbing unit is communicated with a reference wall port of the thermal conductivity cell, the second communication port at the tail end of the four-way electromagnetic valve in the adsorbing unit is communicated with a measuring arm port of the thermal conductivity cell by the quantitative nitrogen pipeline, the second communication port close to the head end of the four-way electromagnetic valve and the first communication port close to the tail end of the four-way electromagnetic valve in two adjacent adsorbing units are communicated. The multistation in-series dynamic nitrogen adsorption specific surface instrument can greatly improve the shape of absorption and desorption peaks, improve the test precision, and shorten the test time during measuring of a small specific surface.

Owner:北京精微高博仪器有限公司

A method for extracting lithium by a split adsorption device

ActiveCN109110860BHigh elution rateImprove desorption efficiencyWater contaminantsCombustible gas purificationLithiumPhysical chemistry

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Energy-saving high-efficiency purification system for industrial volatilizable organic pollutant

InactiveCN102188875BUniform temperatureIncrease contact timeDispersed particle filtrationIncinerator apparatusActivated carbonDesorption

The invention relates to an energy-saving high-efficiency purification system for industrial volatilizable organic pollutant. A catalytic electric heater, a grid plate and a catalytic bed layer are arranged successively in the body of a catalytic combustion bed from top to bottom, wherein the first air outlet of the catalytic combustion bed is connected with the air inlet of a mixed-flow heat exchanger by a pipeline; an activated carbon plate of an adsorption bed, which is of a hollow structure, is communicated with a side wall of a hollow structure, and two side walls of a hollow structure are respectively provided with a hot air inlet and a hot air outlet; and the second air outlet of the catalytic combustion bed is connected with the hot air inlet of the side wall of a hollow structure of the adsorption bed by a heating fan of the adsorption bed. The system provided by the invention has a simple and reasonable structure, can effectively lower the energy consumption, improve the purification rate, prolong the service life of the catalyst, shorten the desorption flow time, improve the purification rate and reduce the operation cost, and is a safe and reliable energy-saving high-efficiency purification system for industrial volatilizable organic pollutants.

Owner:NANTONG ZHI HANG MECHANICAL & ELECTRICAL TECH CO LTD

High-efficiency energy-saving absorption device of industrial volatilizable organic pollutant

InactiveCN102188874BReduce consumptionImprove processing efficiencyDispersed particle separationActivated carbonBiochemical engineering

The invention relates to a high-efficiency energy-saving absorption device of an industrial volatilizable organic pollutant. The device comprises an air inlet flaring part, an active carbon bed body and an air outlet reducing part, wherein two opposite faces of the active carbon bed body are connected with the air inlet flaring part and the air outlet reducing part respectively; an air distribution plate is fixedly arranged on the air inlet flaring part; a plurality of layers of active carbon partition plates are arranged in the active carbon bed body; two opposite side walls of the active carbon bed body are set as side walls having a hollow structure respectively; the active carbon partition plates have the hollow structure; the active carbon partition plates having the hollow structure are communicated with the side walls having the hollow structure; and a hot air inlet and a hot air outlet are respectively formed on the two side walls having the hollow structure. The high-efficiency energy-saving absorption device of the industrial volatilizable organic pollutant is simple in structure, scientific and reasonable in design, safe and reliable, effectively utilizes catalytic combustion waste heat, shortens desorption time, reduces the consumption of electric energy, reduces operating cost, and is accordant with the national policy of energy conservation and emission reduction.

Owner:NANTONG ZHI HANG MECHANICAL & ELECTRICAL TECH CO LTD

A kind of temperature and humidity sensor for refrigerated transport vehicle and preparation method thereof

InactiveCN103616087BReduce thicknessShort response timeThermometers using electric/magnetic elementsUsing electrical meansCapacitanceCMOS

Owner:TIANJIN UNIV OF SCI & TECH

A kind of adsorbent based on carbon nanomaterial and its preparation and use method

ActiveCN106732378BReduce dosageRich in channelsOther chemical processesSolid sorbent liquid separationAdhesiveSorbent

The invention discloses an adsorbing agent based on a carbon nanomaterial. The adsorbing agent is prepared from the carbon nanomaterial and an adhesive, wherein the mass fraction of the carbon nanomaterial ranges from 30 to 95 percent. The specific surface area of the adsorbing agent is 100 to 2000m<2> / g, and the pore volume proportion of micropores, mesopores to macropores is (1 to 2) to (1 to 5) to (1 to 20). The invention also discloses a method for preparing the adsorbing agent by adding a pore-forming agent. The adsorbing agent has the advantages of long service life, big treatment capacity, low preparation cost and the like, and is suitable for adsorbing non-polar organic compounds in a fluid.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com