Series targeted adsorption and parallel desorption organic waste gas treatment device

A technology of organic waste gas and treatment device, which is applied in the field of series targeted adsorption and parallel desorption organic waste gas treatment device, can solve the problems of low adsorption and purification efficiency of primary activated carbon, unguaranteed purification efficiency and high one-time investment cost. To achieve the effect of saving land occupation and one-time investment, saving desorption time, saving investment and occupying land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

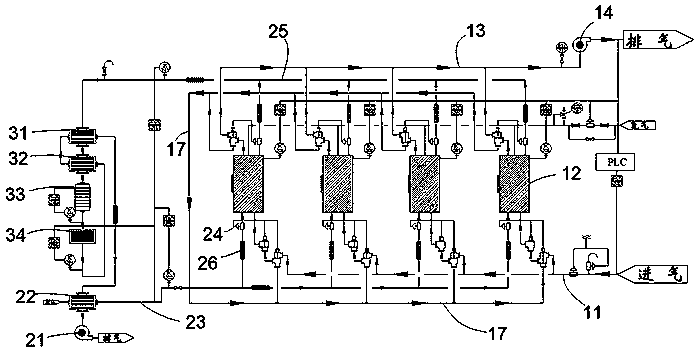

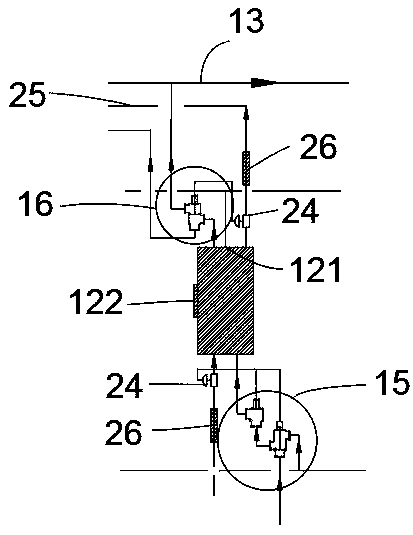

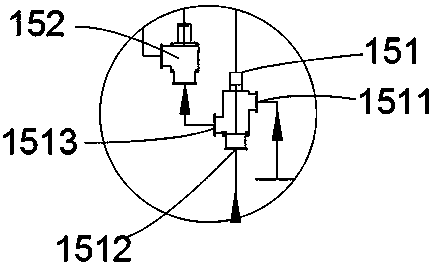

Embodiment 1

[0037] see figure 1 , the adsorption box 12 is provided with four groups, which are numbered 1#, 2#, 3# and 4# from left to right. The diameter and its adsorption characteristics are used to determine the adsorbent to be used. Molecular sieves are filled in the adsorption boxes of 1# and 4#, and activated carbon is filled in the adsorption boxes of 2# and 3#. Two-stage series adsorption is used to treat VOCs waste gas , the exhaust gas first passes through the 4# adsorption box, the three-way valve A of the 4# adsorption box is connected with the exhaust gas inlet pipe 11, and the two-way valve is opened. After treatment, the gas enters the 3-way valve B of the 4# adsorption box #The three-way valve A of the adsorption box. At this time, the two-way valve of the 3# adsorption box is opened, and the gas enters the 3# adsorption box for secondary adsorption. After the treatment, the gas enters from the three-way valve B of the 3# adsorption box. The exhaust pipe 13 is driven by...

Embodiment 2

[0039] When the production load of the enterprise increases or the temperature is high in summer, VOCs are not easy to adsorb, in order to ensure the purification efficiency, a three-stage series adsorption method is used to treat VOCs waste gas, see figure 1 , the adsorption box 12 is provided with four groups, which are numbered as 1#, 2#, 3# and 4# from left to right, and the two-way valves of 4#, 3# and 2# are opened at the same time for adsorption Treatment, after adsorption for a period of time, close the intake two-way valve of the 4# adsorption box, open the intake two-way valve of the 1# adsorption box, the adsorption mode becomes 3#, 2#, 1# for adsorption, and at the same time The 4# adsorption box is desorbed. After the desorption is complete, close the inlet two-way valve of the 3# adsorption box. The adsorption mode is changed to 2#, 1#, and 4# for adsorption. The box can be put into use immediately as a terminal adsorber. After two-stage adsorption, the exhaust g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com