Adsorption and in-situ desorption and regeneration equipment and method for volatile organic compounds

A volatile organic compound and desorption technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of secondary pollution of dry waste gas and condensed waste water, long cooling time, large water vapor consumption, etc. The effect of complete recovery of adsorption performance, complete regeneration of adsorbent, and shortening of desorption time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

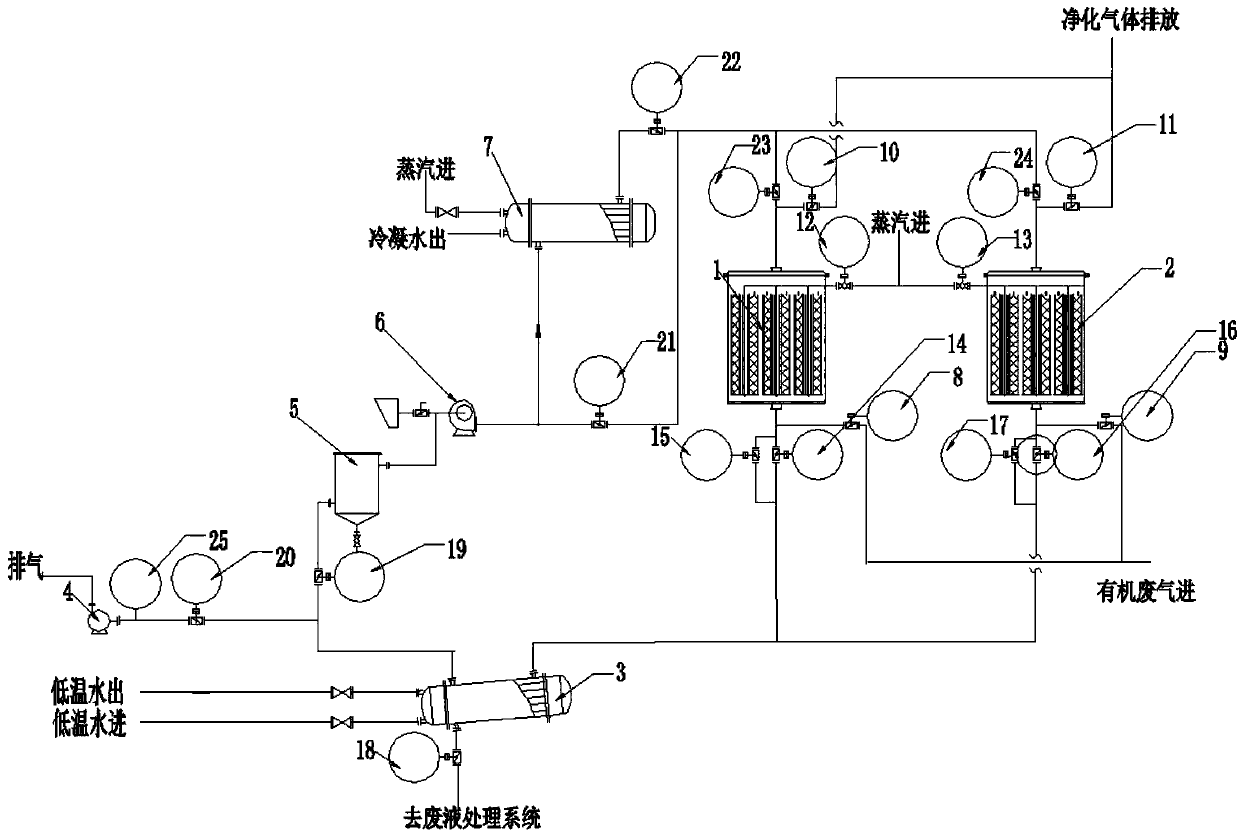

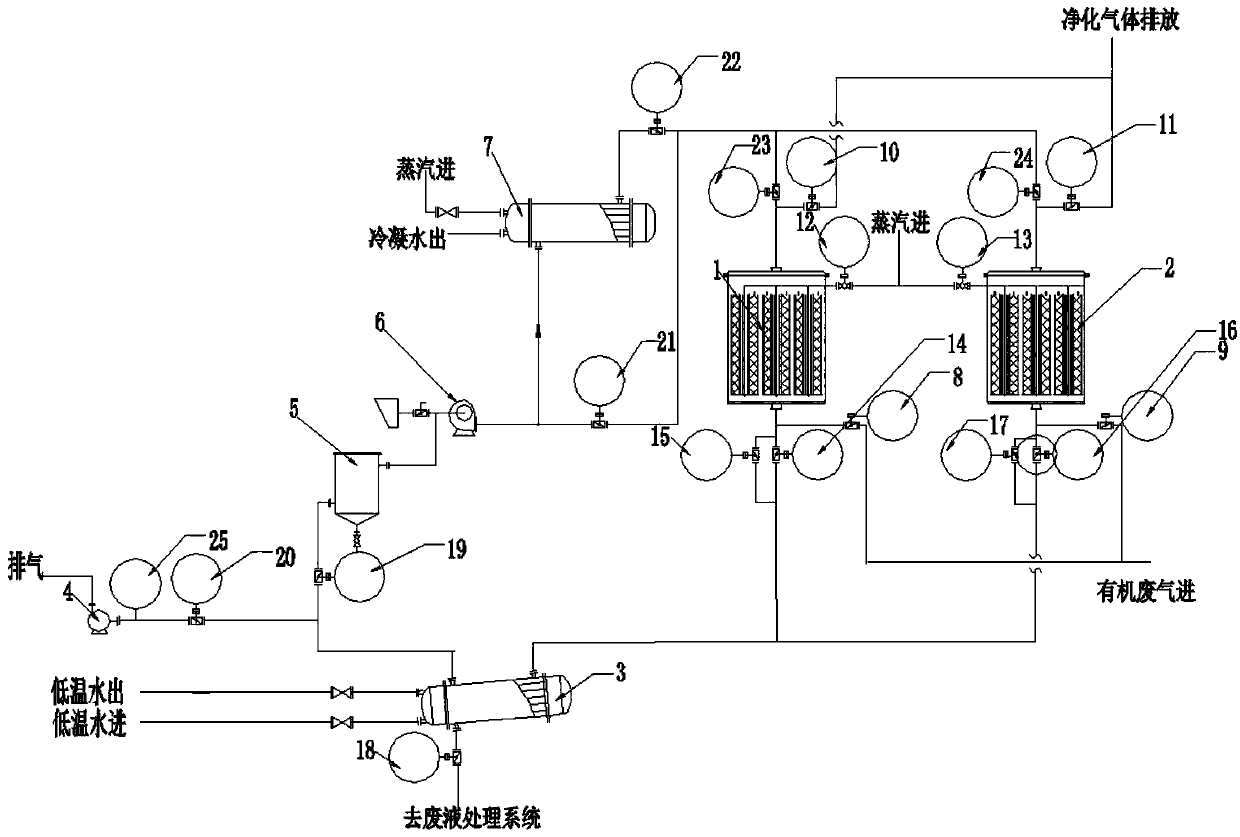

[0032] see figure 2 , a method for adsorption and in-situ desorption regeneration of volatile organic compounds. At this time, the left adsorber 1 is in the adsorption stage, and the right adsorber 2 is in the desorption and desorption stage. The specific steps are as follows:

[0033] 1) Adsorption stage: open the first left valve 8, pass the organic waste gas to be treated into the left adsorber 1, in the left adsorber 1, the organic waste gas is adsorbed by the adsorbent, and open the second left valve 10 to treat the waste gas The gas is discharged to the exhaust cylinder through the exhaust pipe of the left adsorber 1. After the adsorbent in the left adsorber 1 is saturated or according to the process setting requirements, it is switched to the right adsorber 2 for continuous adsorption;

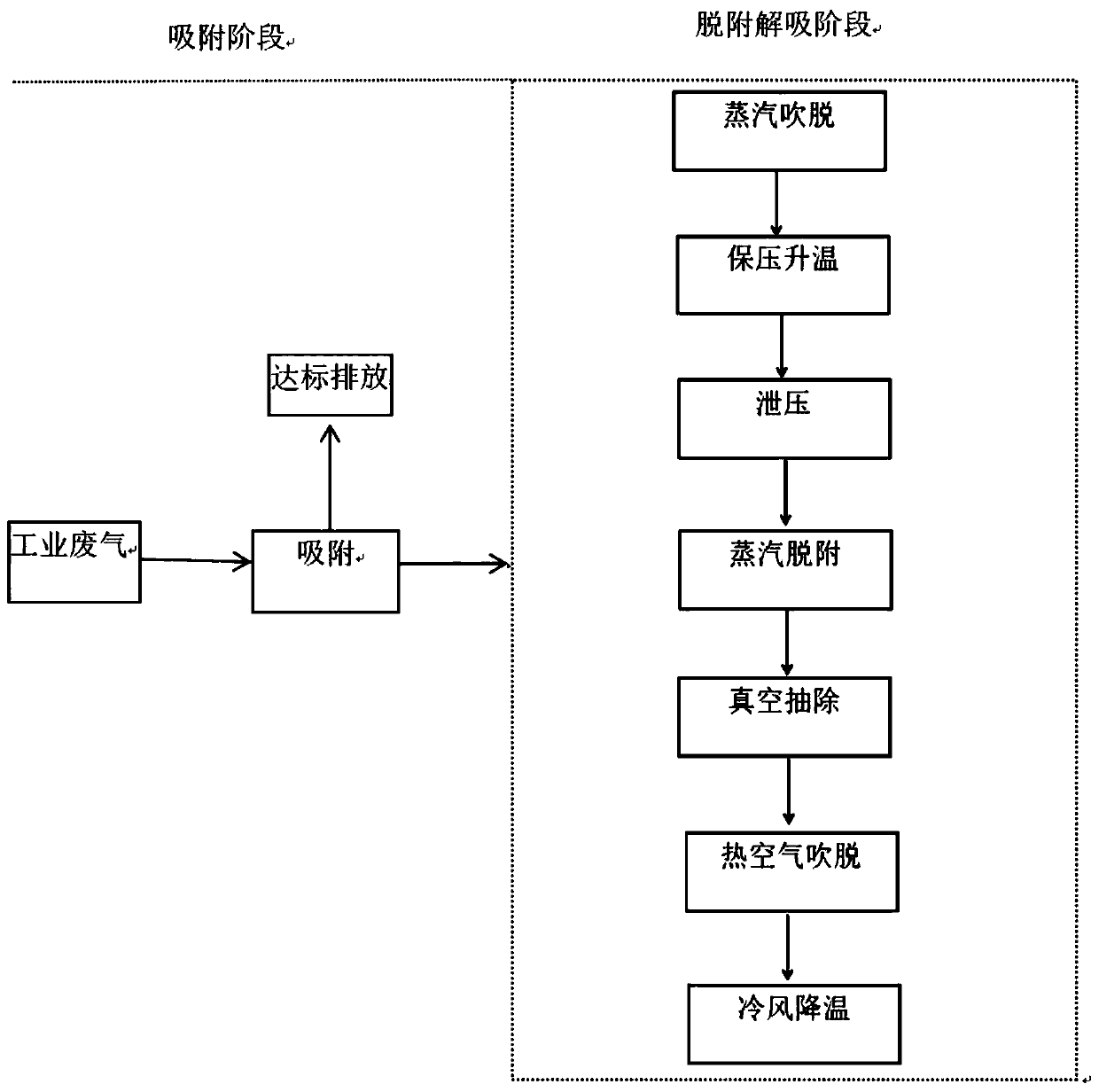

[0034] 2) Desorption and desorption stage: Desorption and desorption adopts a seven-step method, including steam blowing off, pressure maintaining and heating, pressure relief, steam d...

Embodiment 2

[0043] see figure 2 , a method for adsorption and in-situ desorption regeneration of volatile organic compounds. At this time, the left adsorber 1 is in the adsorption stage, and the right adsorber 2 is in the desorption and desorption stage. The specific steps are as follows:

[0044] 1) Adsorption stage: open the first right valve 9, and pass the organic waste gas to be treated into the right adsorber 2, where the organic waste gas is adsorbed by the adsorbent in the right adsorber 2, and the treated gas passes through the right adsorber 2 Open the second left valve 10 to discharge to the exhaust pipe, after the adsorbent in the right adsorber 2 is saturated or according to the process setting requirements, switch to the left adsorber 1 for continuous adsorption;

[0045] 2) Desorption and desorption stage: Desorption and desorption adopts a seven-step method, including steam blowing off, pressure maintaining and heating, pressure relief, steam desorption, vacuum pumping, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com