A kind of temperature and humidity sensor for refrigerated transport vehicle and preparation method thereof

A temperature and humidity sensor and carrier technology, applied in thermometers, thermometers and instruments with direct heat-sensitive electric/magnetic elements, can solve the problems affecting the temperature measurement accuracy, sensor response speed, etc., to shorten the desorption time , reduce the impact, increase the effect of the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail through specific examples below. It should be noted that this example is illustrative rather than restrictive, and the protection scope of the present invention cannot be limited thereby.

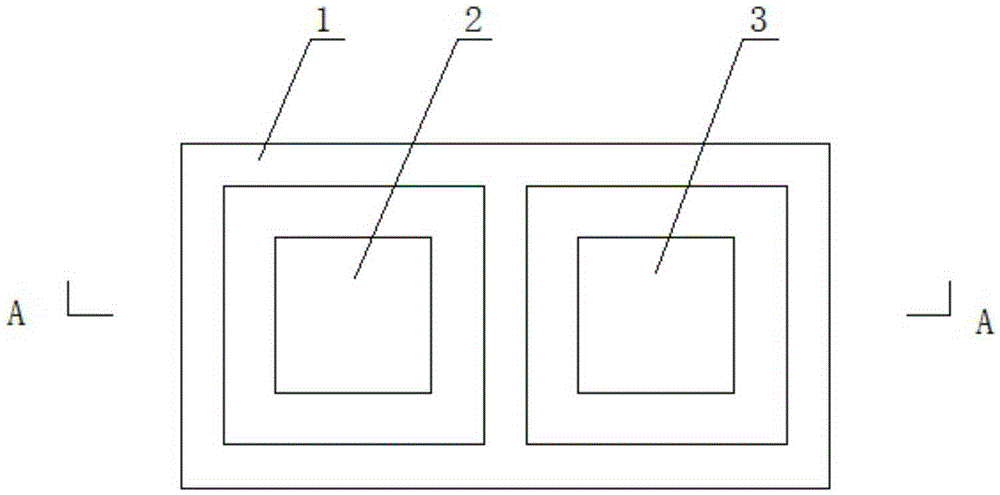

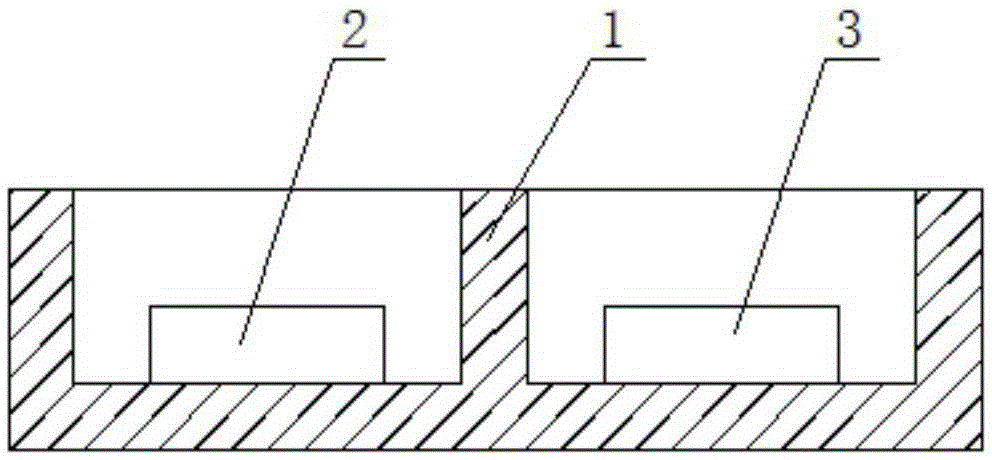

[0036] A temperature and humidity sensor for a refrigerated transport vehicle, its main structure can be found in figure 1 , 2 , which adopts NTC temperature sensing technology and comb-shaped capacitive humidity sensing technology. It is composed of temperature sensing unit 2, humidity sensing unit 3 and silicon nitride passivation layer 1. The temperature sensing unit and humidity sensing unit are fixed in their respective In the square groove made of silicon nitride passivation layer, the two are separated in space by the silicon nitride passivation layer, which can avoid the influence of the heating layer of the humidity sensing unit on the temperature sensing unit, and ensure the The accuracy of temperature measurement; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com