High-efficiency energy-saving adsorption system for industrial volatile organic pollutants

An organic pollutant, high-efficiency and energy-saving technology, applied in the field of adsorption systems, can solve problems such as high operating costs, waste of the environment, and thermal pollution, and achieve the effects of reducing equipment operating costs, reducing power consumption, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below through specific examples. The following examples are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

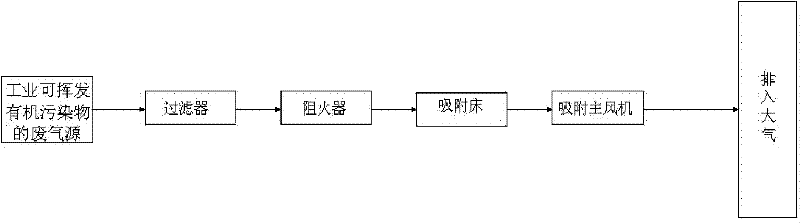

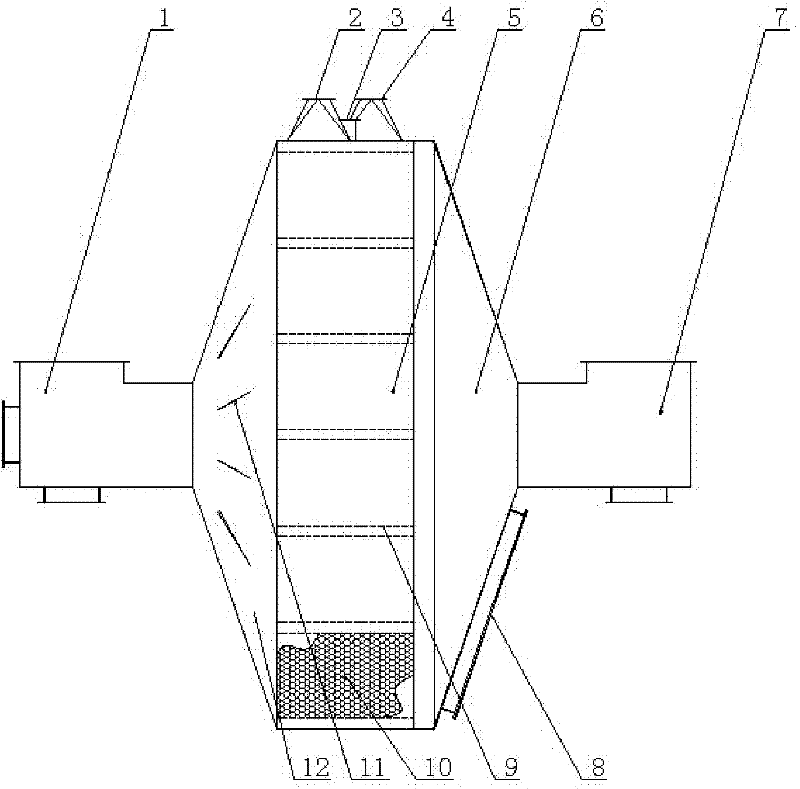

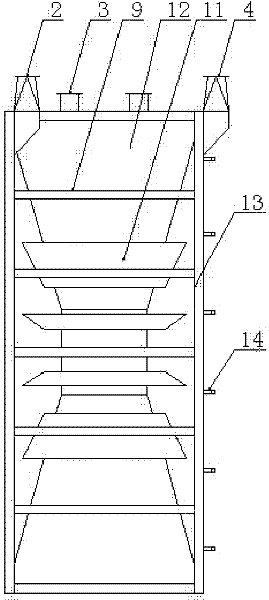

[0020] A high-efficiency and energy-saving adsorption system for industrial volatile organic pollutants, including a filter, a flame arrestor, an adsorption bed, and a main adsorption fan connected by pipelines. The adsorption bed includes an air inlet flaring portion 12, an activated carbon bed body 5, and an outlet The small-caliber end of the air inlet flaring part is connected to the air inlet pipe 1. The air inlet pipe can be connected to a flame arrester and a filter through a tee and an inlet of the valve to realize the docking of industrial exhaust gas that can volatilize organic pollutants. The other interface is connected to the standard hot gas source treated by the combustion catalytic bed. The small diameter end of the air outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com