A method for extracting lithium by a split adsorption device

An adsorption device and a technology for extracting lithium, which are applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of improving desorption efficiency and ineffectiveness, and achieve shortening elution time, accelerating migration rate, and improving desorption rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

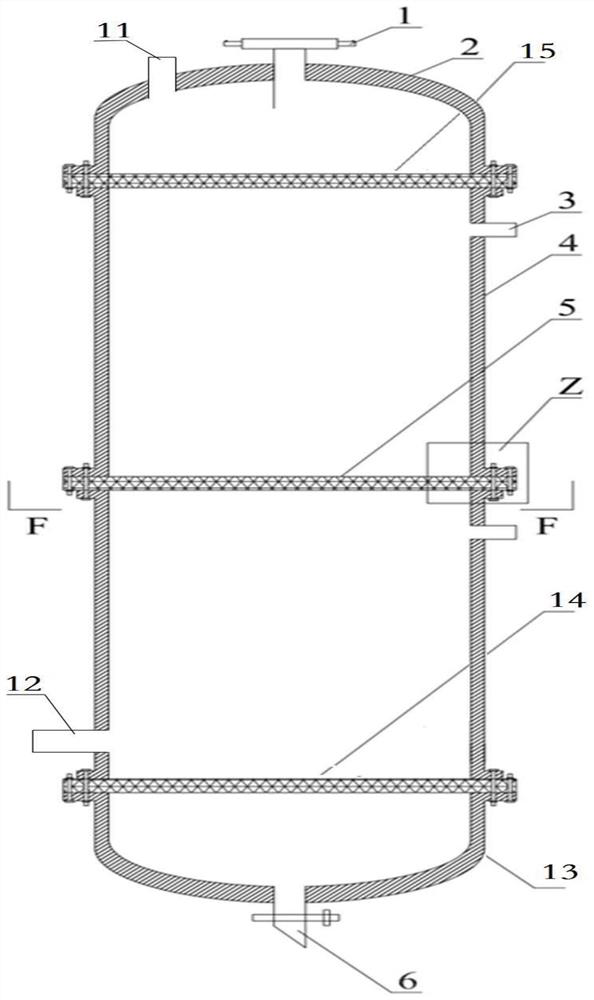

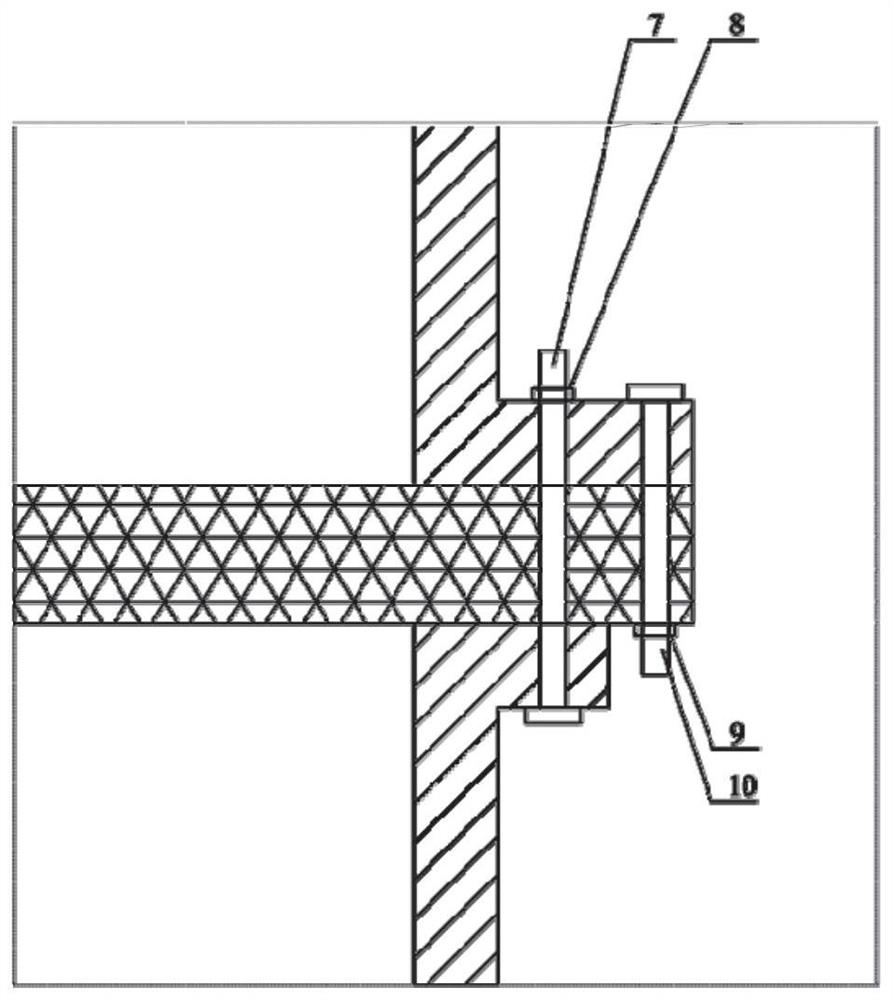

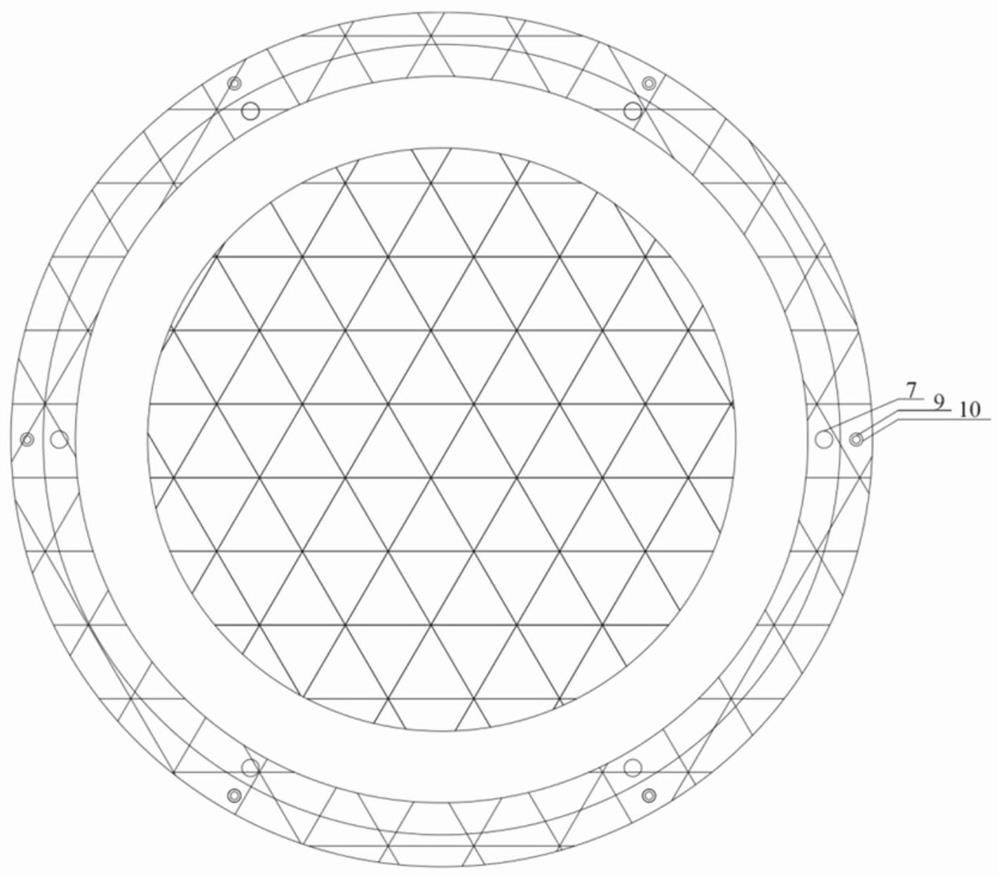

[0046] A lithium adsorbent with a particle size of 40 mesh is added to the adsorption column through the adsorbent addition port 3. The adsorption solution is the original brine of a lithium-containing magnesium sulfate subtype salt lake. The solution flows through the adsorption column at a flow rate of 200mL / h through the fluid inlet 1. , after 2 hours of adsorption, the liquid inlet is stopped, and water is added to the fluid inlet 1 to quickly wash the adsorbent, and then desorption is performed. Water enters from the fluid inlet 1, flows through the cylinder at a flow rate of 200mL / h, connects an external DC power supply through conductive screws between the conductive support net 5 and the conductive support net 14, and fixes the sealing ring coaxially to ensure that the fluid does not leak . The power supply voltage is 5V, wherein the conductive support net 5 is connected to the negative pole of the power supply, and the conductive support net 14 is connected to the pos...

Embodiment 2

[0048] A lithium adsorbent with a particle size of 50 mesh is added to the adsorption column through the adsorbent addition port 3. The adsorption solution is a chloride-type lithium-containing brine of a certain potassium salt segment. The solution flows through the adsorption column at a flow rate of 200mL / h through the fluid inlet 1. , after 2 hours of adsorption, the liquid inlet is stopped, and water is added to the fluid inlet 1 to quickly wash the adsorbent, and then desorption is performed. Water enters from the fluid inlet 1, flows through the cylinder at a flow rate of 200mL / h, and connects an external DC power supply through conductive screws between the conductive support net 5 and the conductive support net 14, and fixes the sealing ring coaxially to ensure that the fluid does not leak . The power supply voltage is 8V, wherein the conductive support net 5 is connected to the negative pole of the power supply, and the conductive support net 14 is connected to the p...

Embodiment 3

[0050] Add a lithium adsorbent with a particle size of 5 mesh to the attached column through the adsorbent addition port 3. The adsorption solution is the chloride-type salt lake old brine diluted twice. The solution flows through the adsorption at a flow rate of 200mL / h through the fluid inlet 1 After 2 hours of adsorption, stop feeding the column, add water through fluid inlet 1 to quickly wash the adsorbent, and then perform desorption. Water enters from the fluid inlet 1, flows through the cylinder at a flow rate of 200mL / h, connects an external DC power supply through conductive screws between the conductive support net 5 and the conductive support net 14, and fixes the sealing ring coaxially to ensure that the fluid does not leak . The power supply voltage is 12V, wherein the conductive support net 5 is connected to the negative pole of the power supply, and the conductive support net 14 is connected to the positive pole of the power supply, wherein the lower surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com