Patents

Literature

71results about How to "Separation reached" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

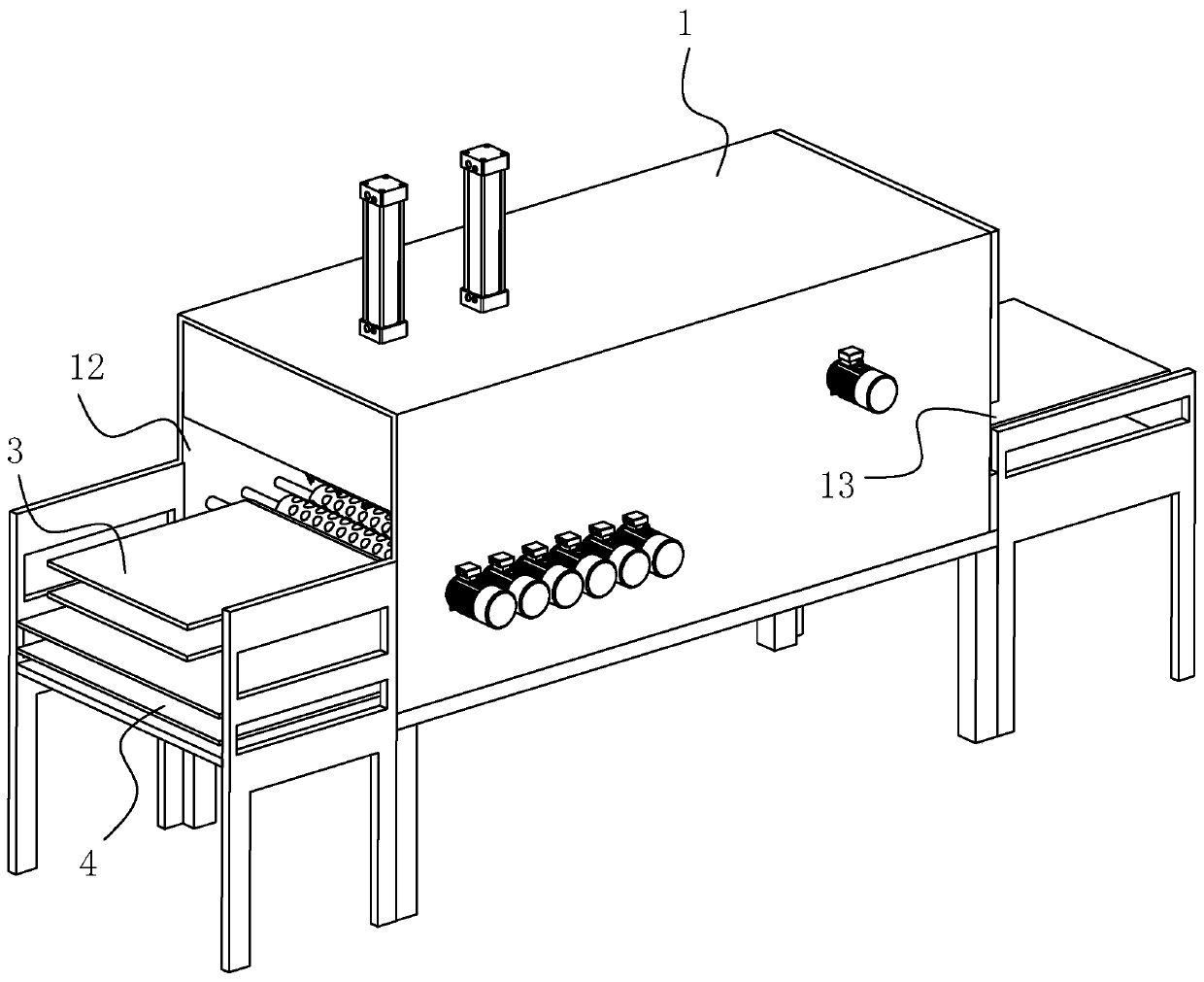

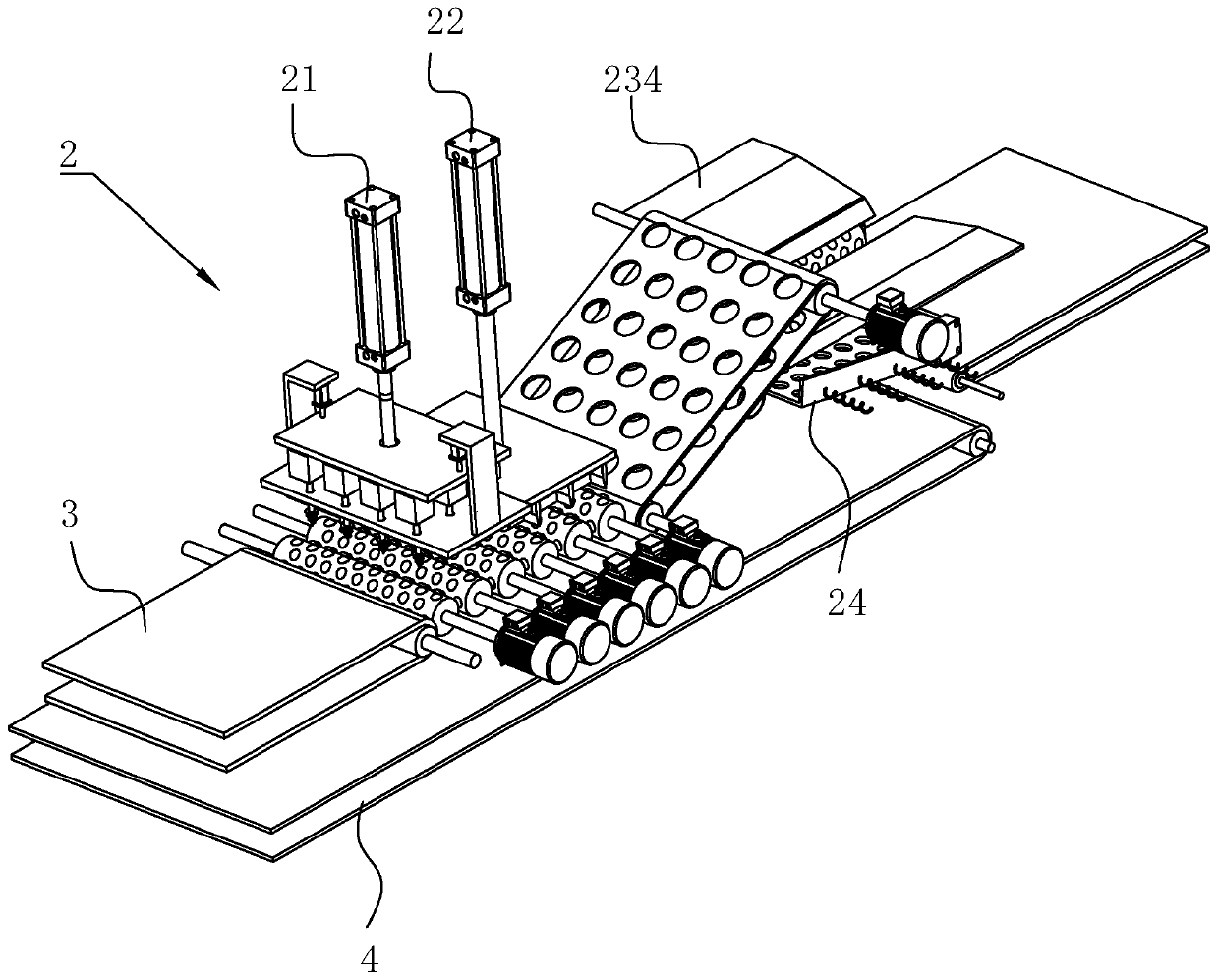

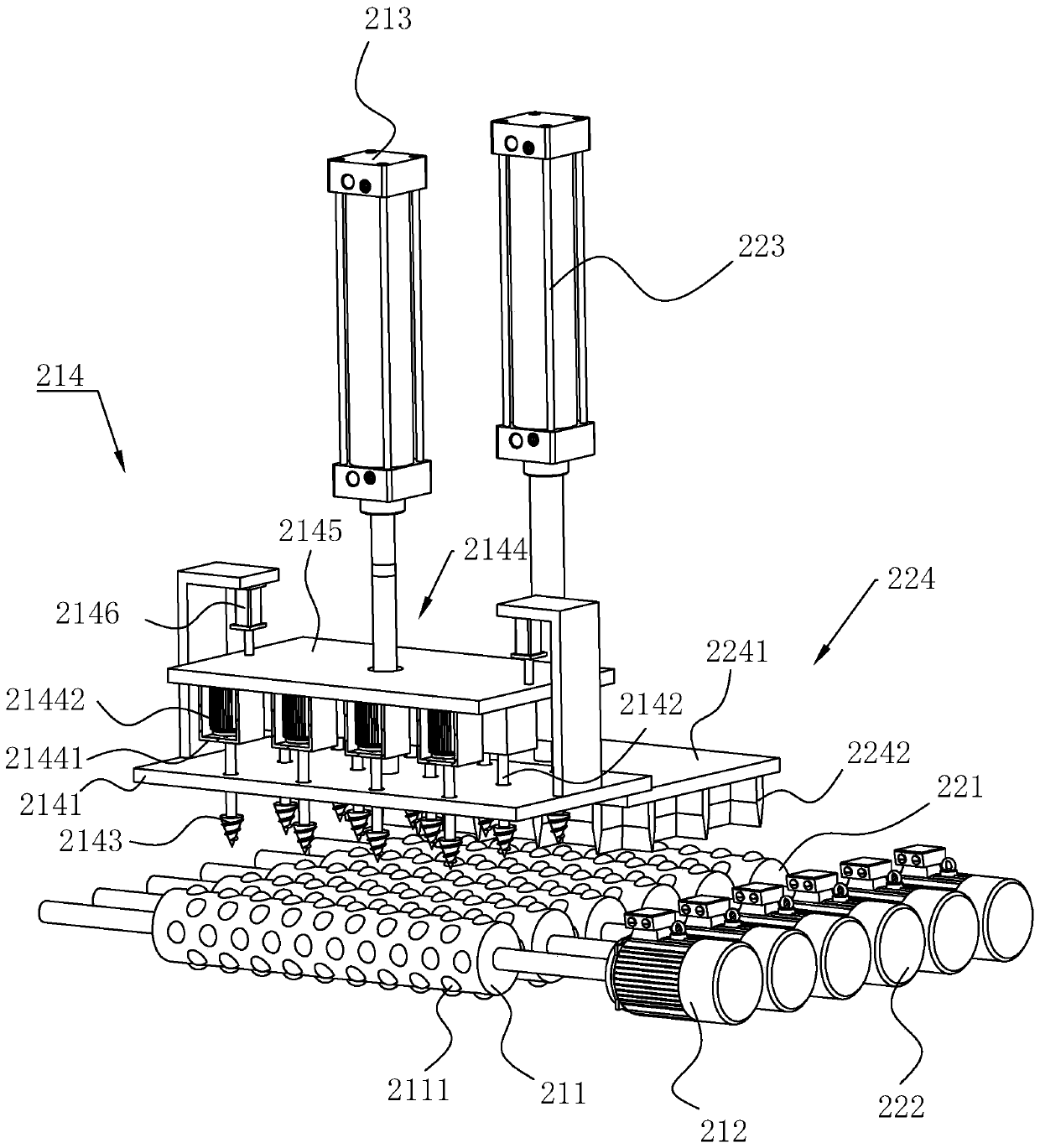

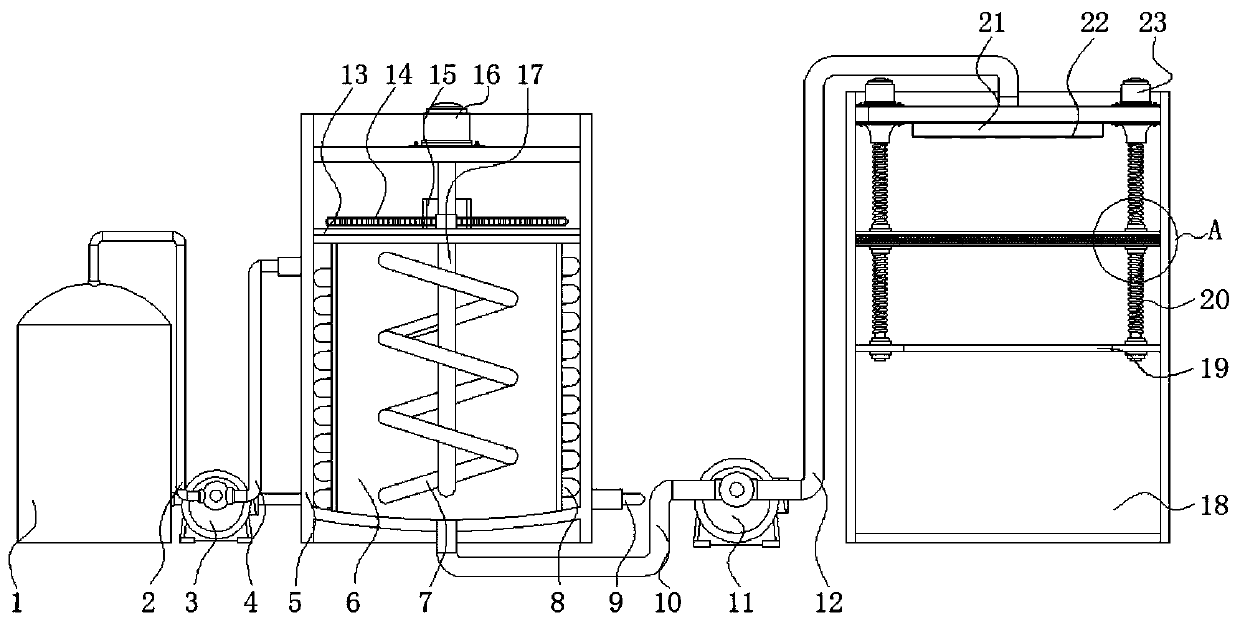

Steel bar and concrete separator

ActiveCN108283984ASeparation reachedEasy to collect and recycleSievingScreeningReinforced concreteArchitectural engineering

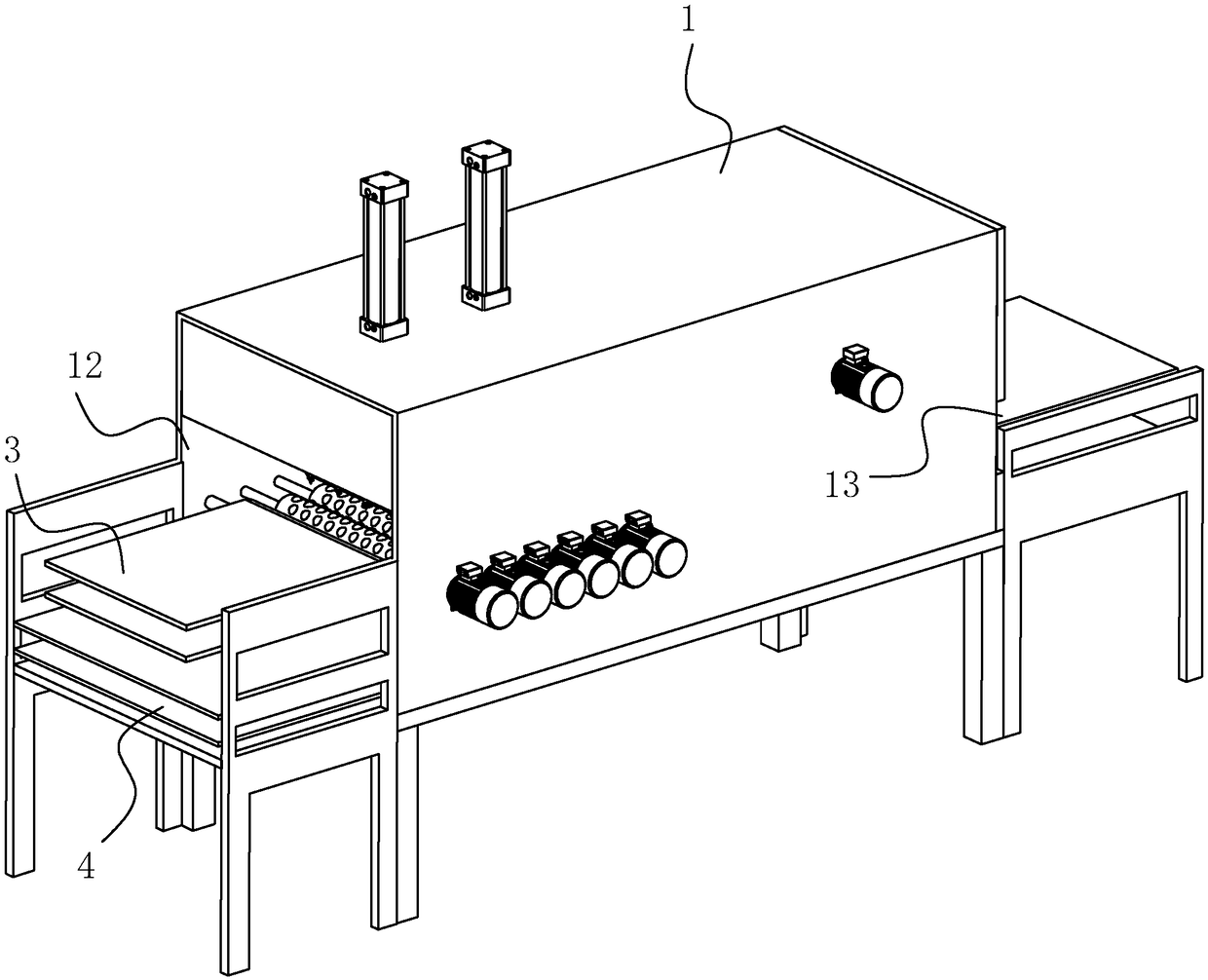

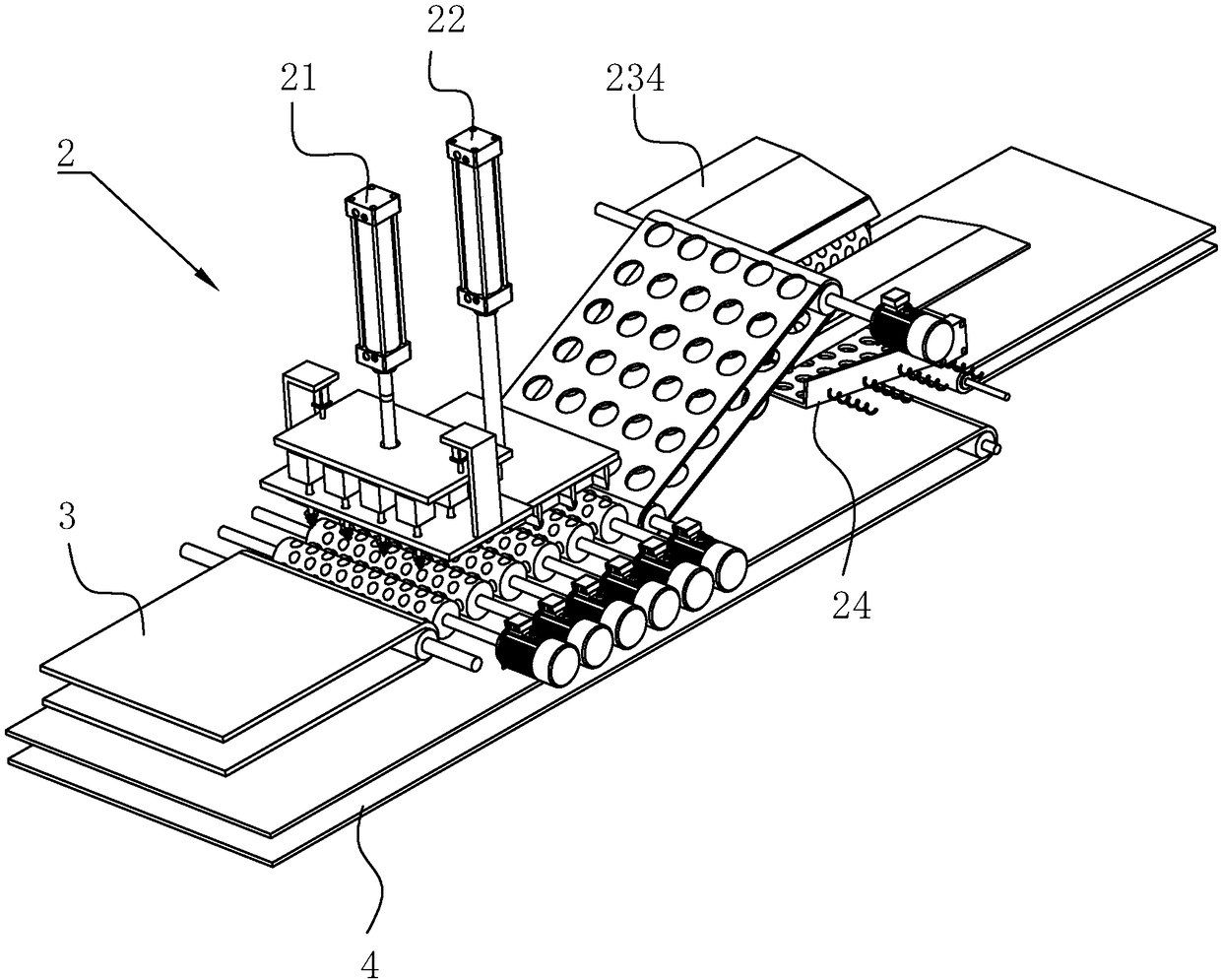

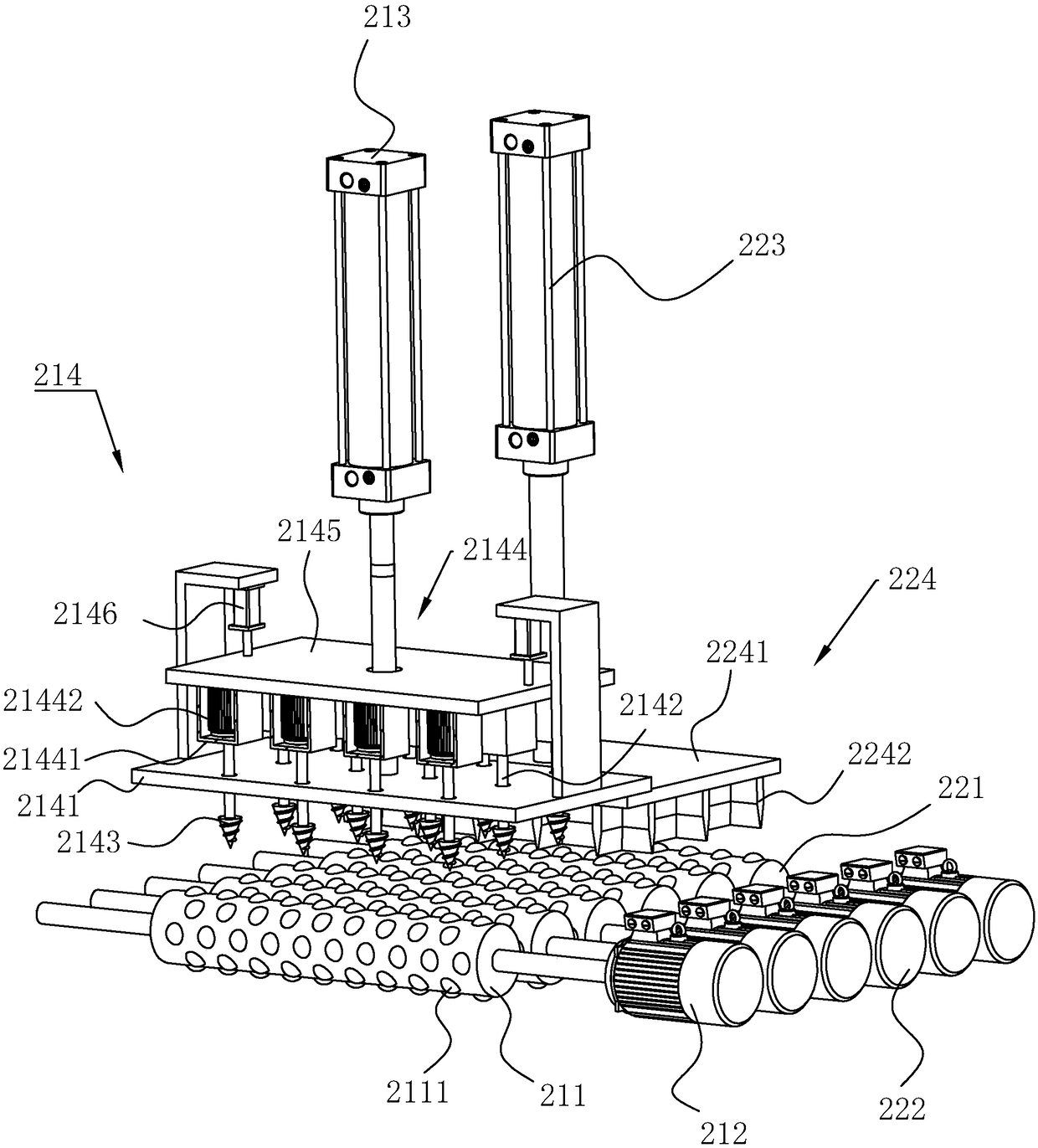

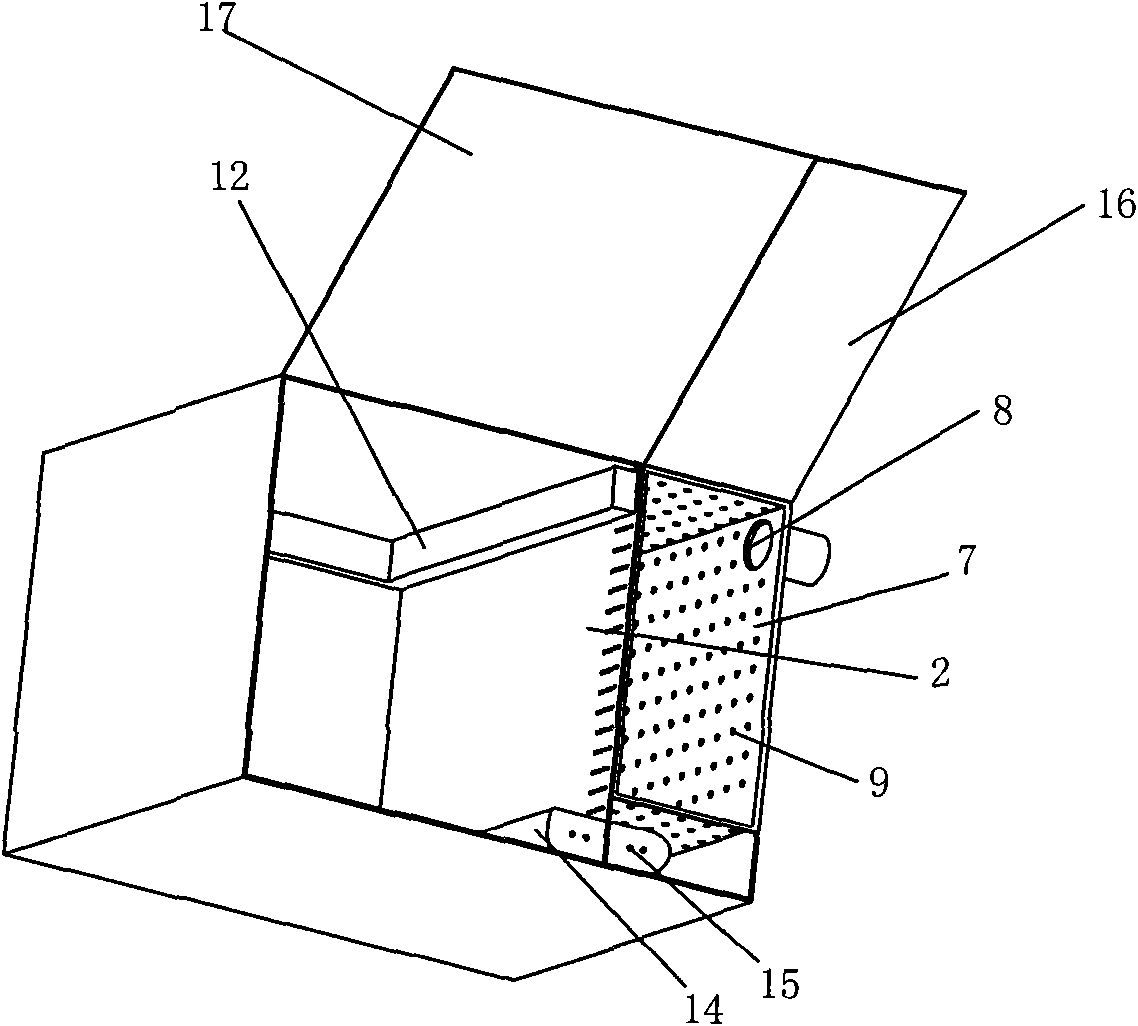

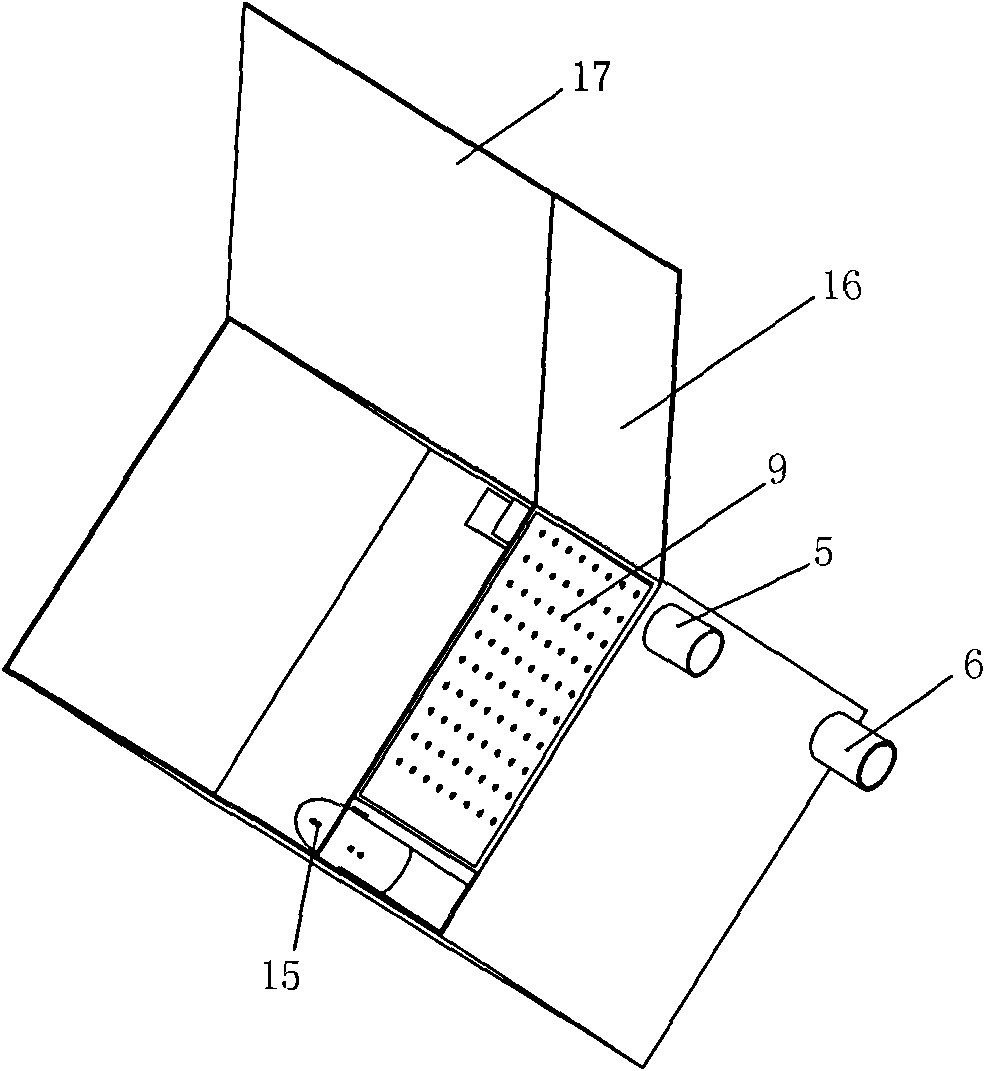

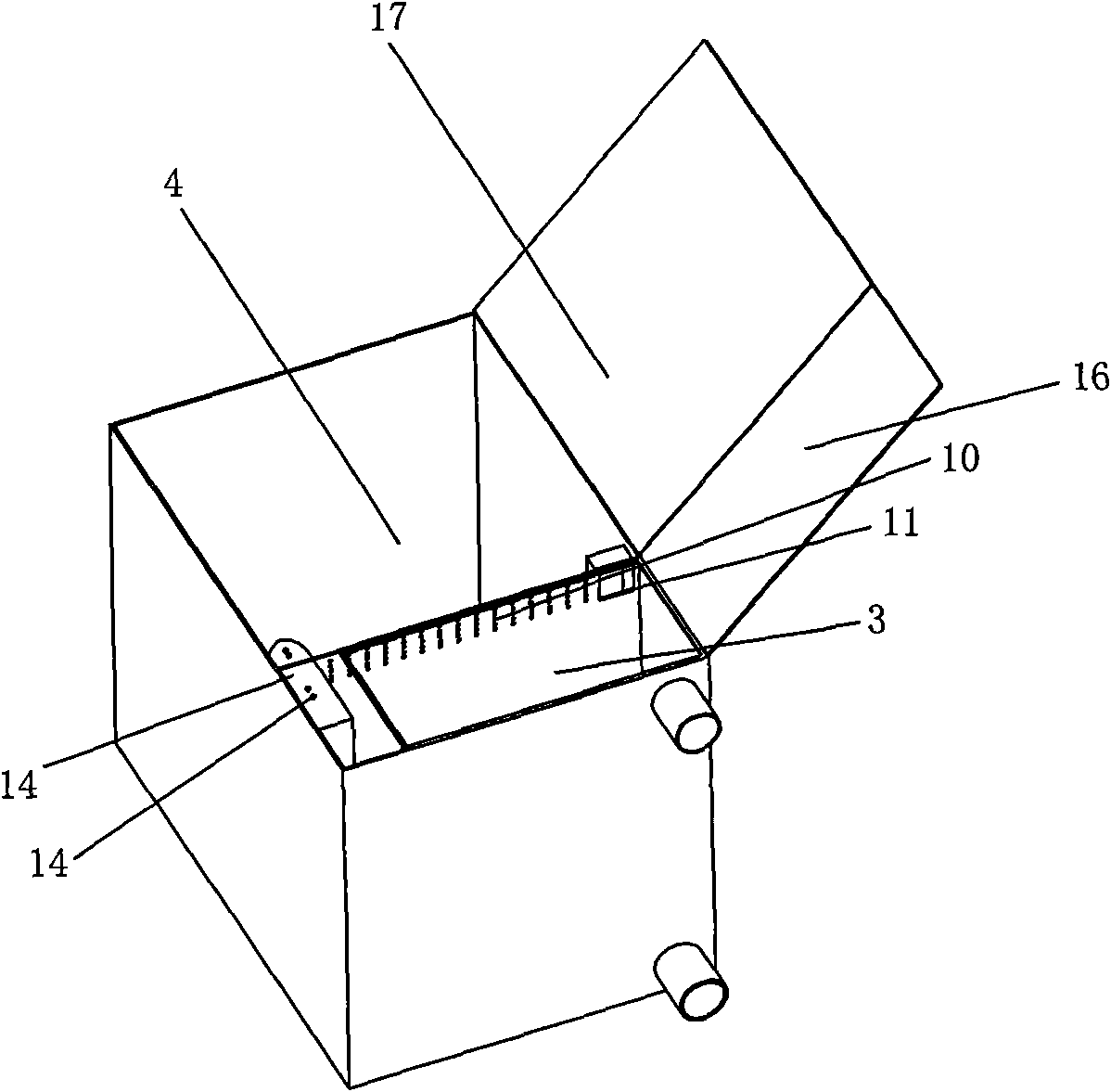

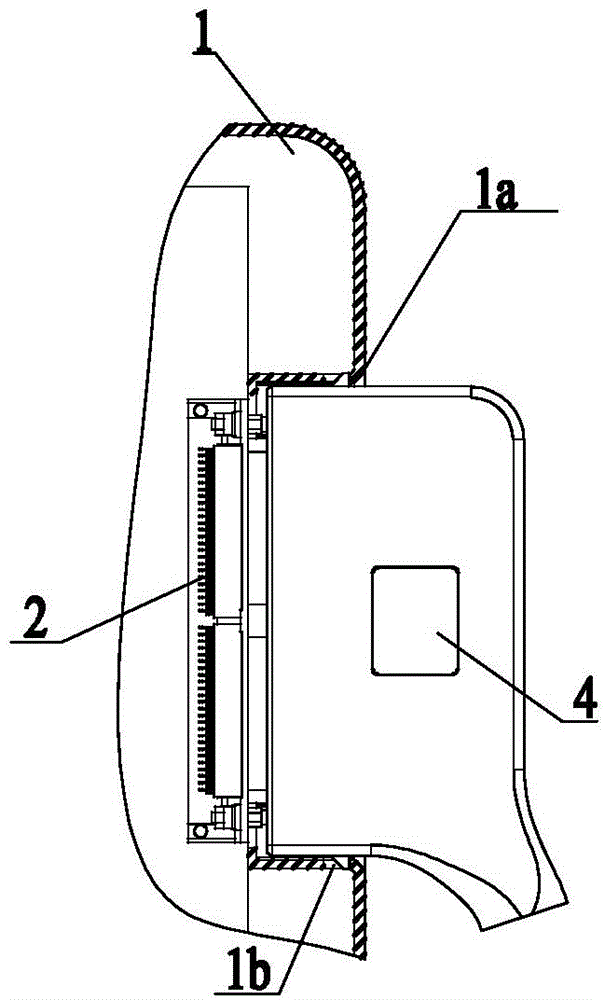

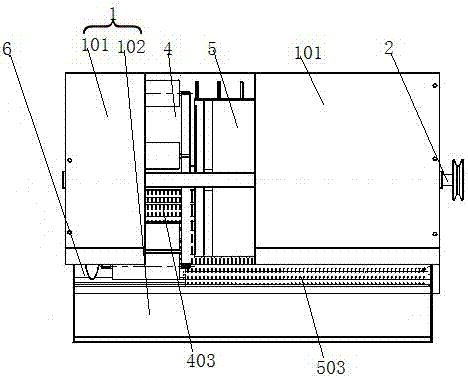

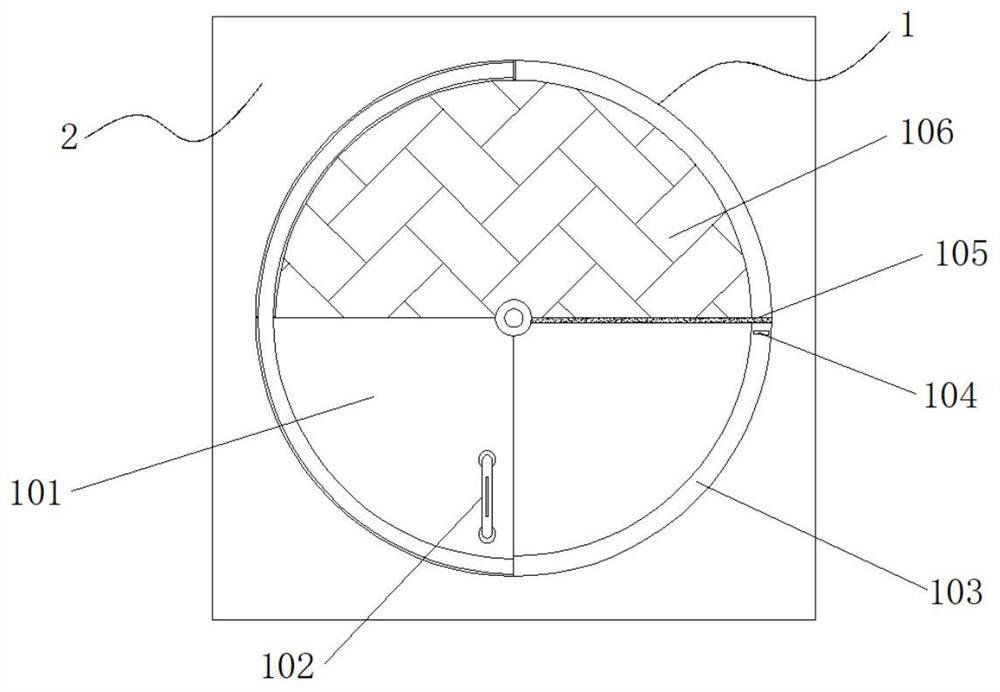

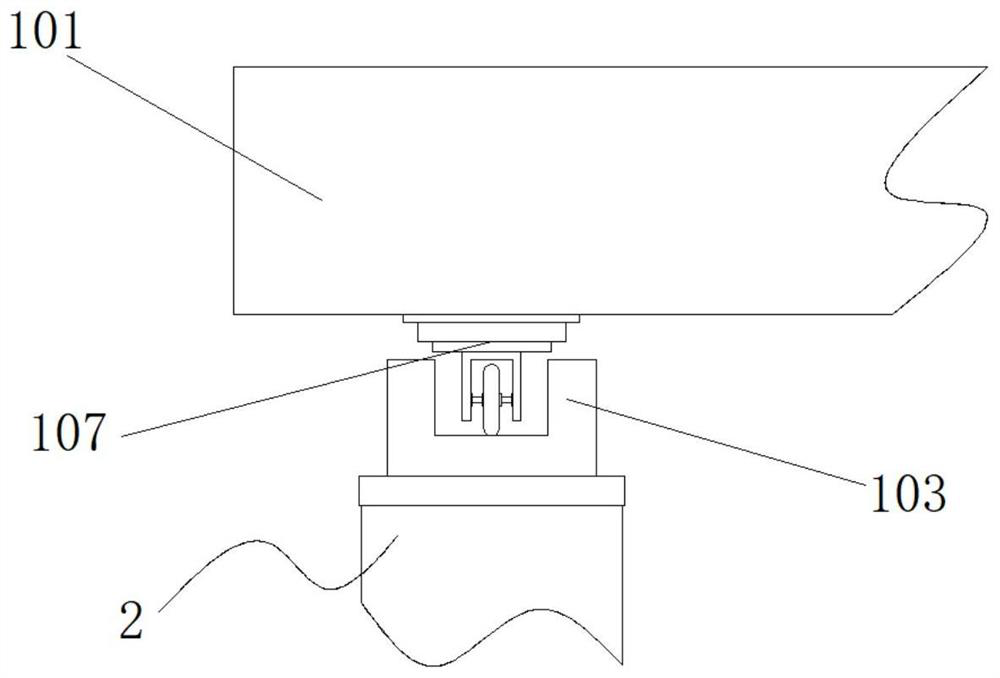

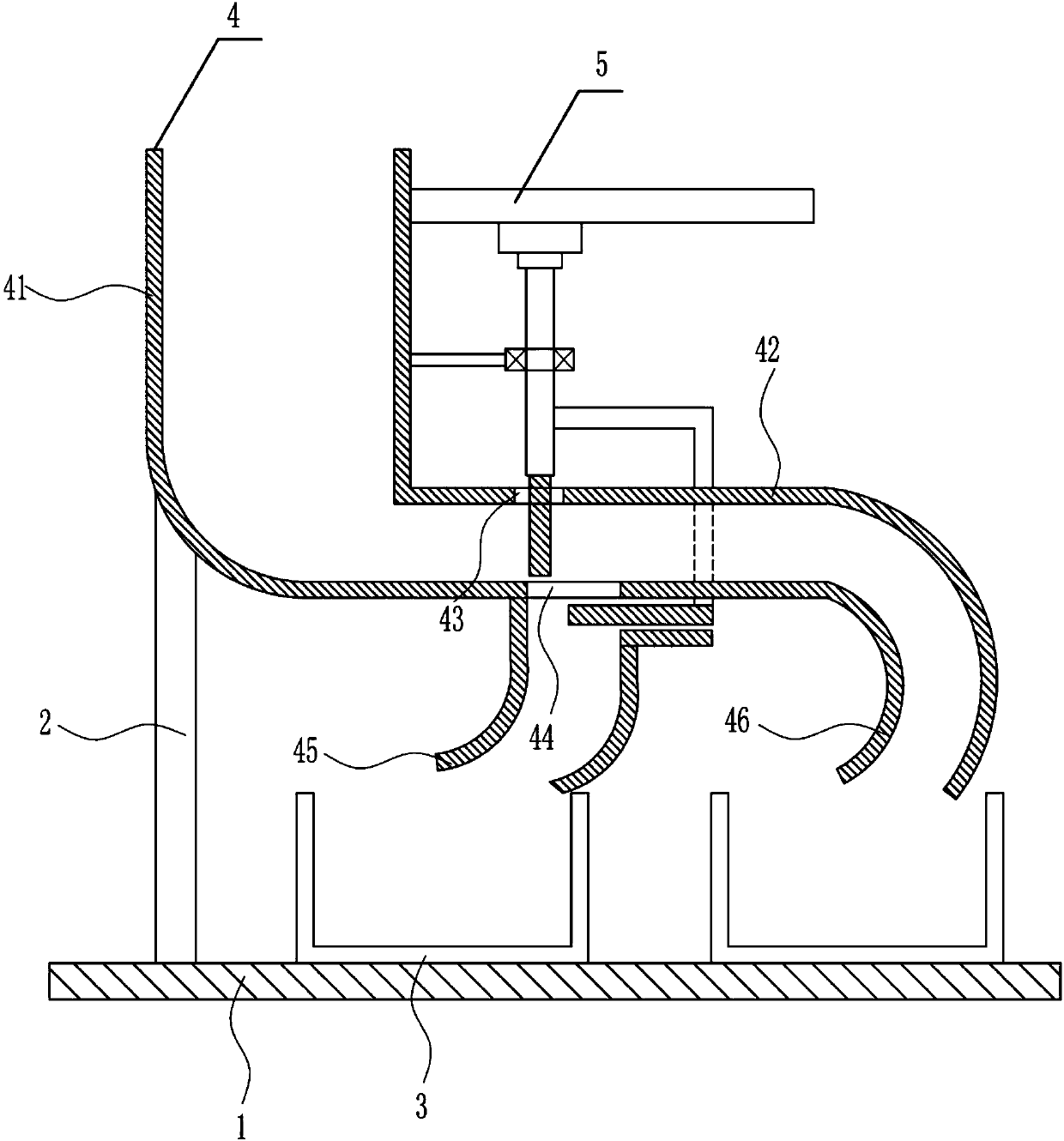

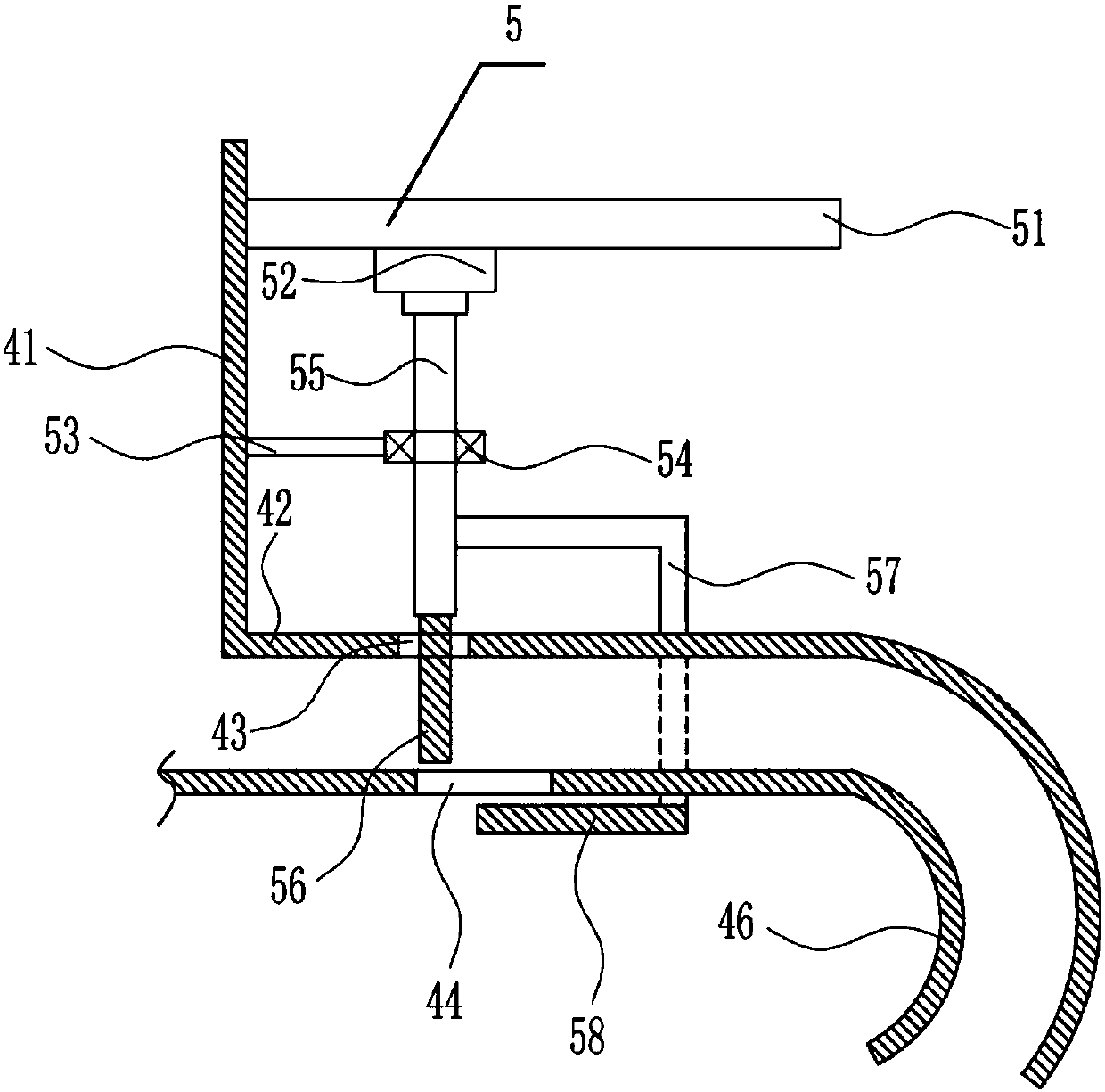

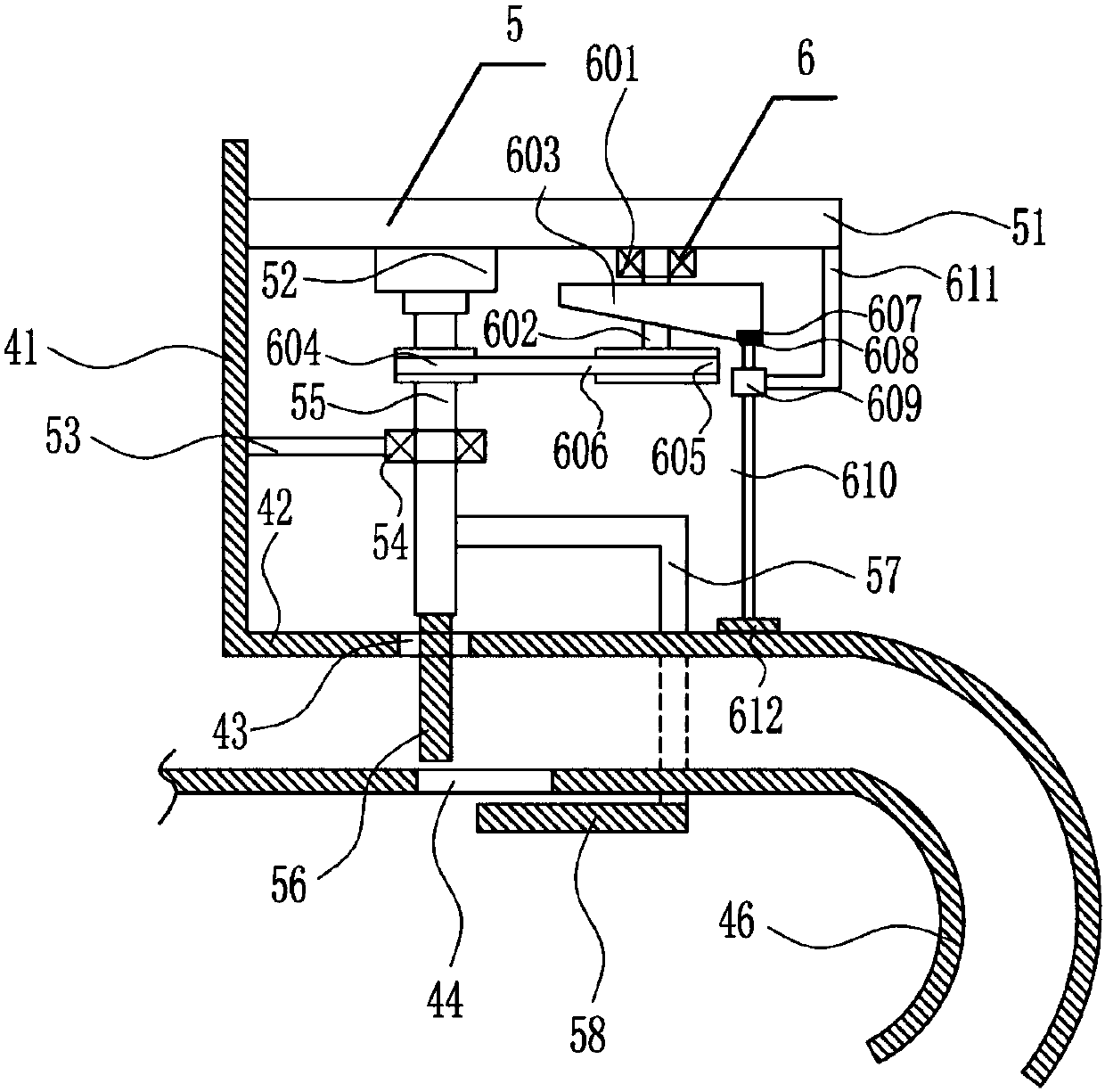

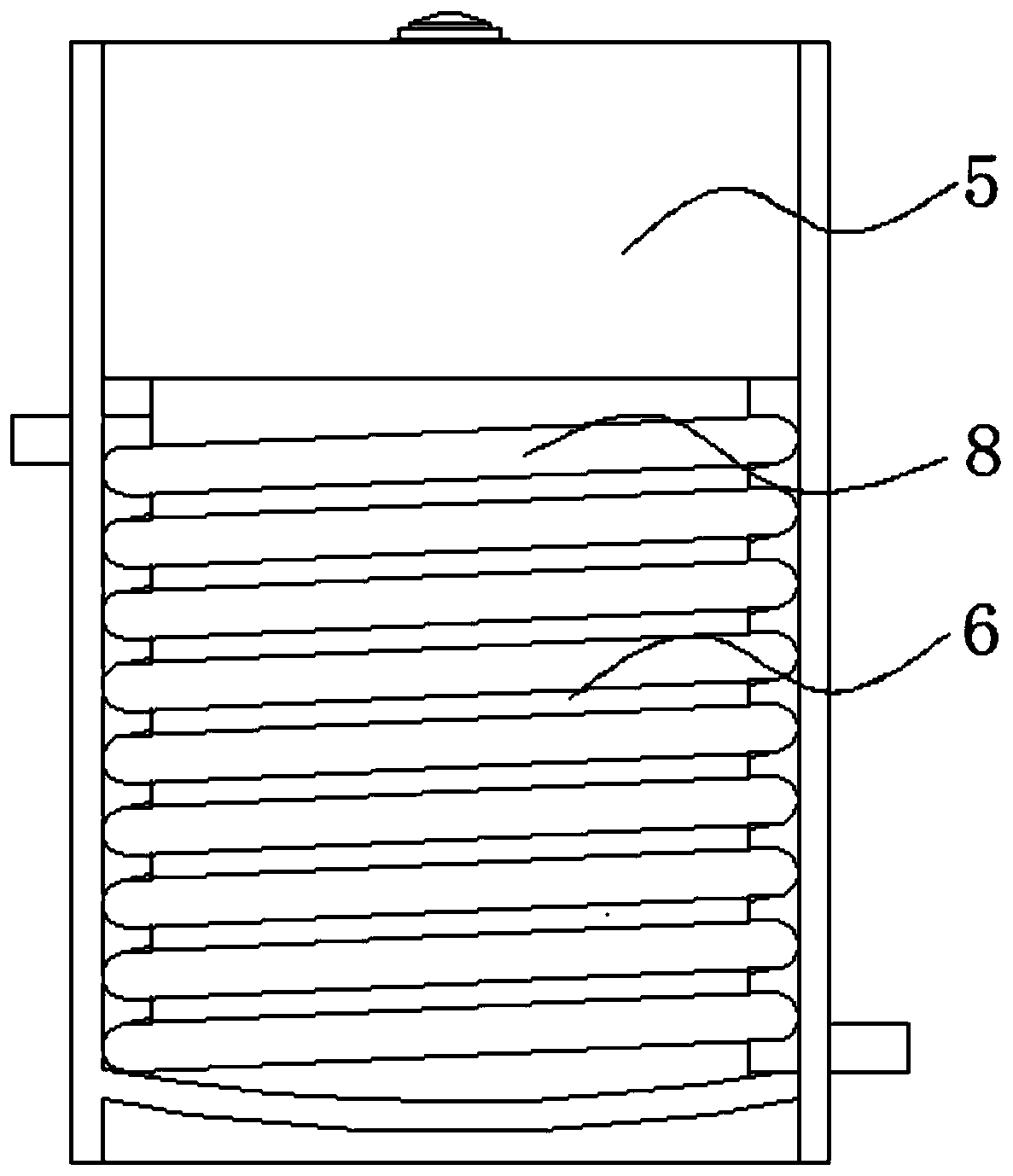

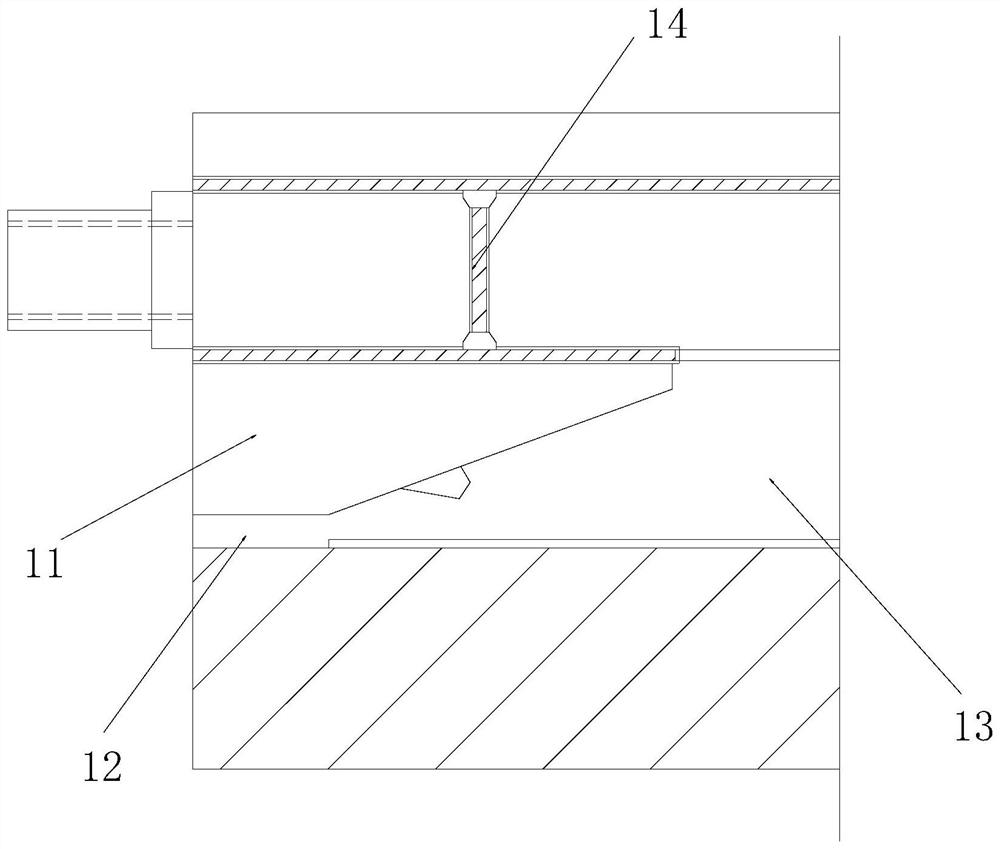

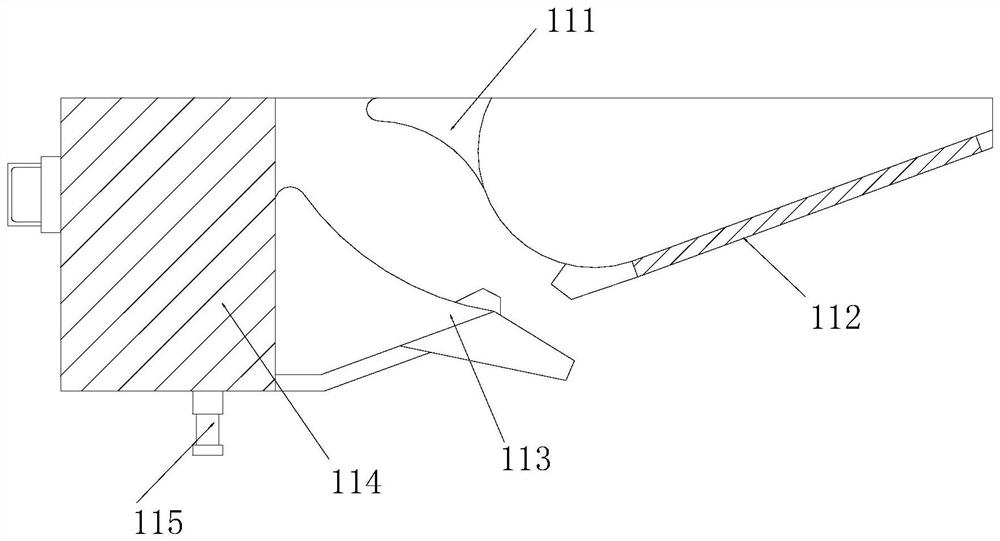

The invention discloses a steel bar and concrete separator. According to the key points of the technical scheme, the steel bar and concrete separator comprises a machine shell, a feeding opening is formed in one side of the machine shell, and a discharging opening is formed in the side, deviating from the feeding opening, of the machine shell; and a separating and crushing device used for separating concrete and steel bars is arranged in the machine shell, the separating and crushing device comprises a stamping mechanism used for crushing the concrete wrapped around the steel bars, a pressingand cutting mechanism used for finely crushing and cutting the concrete wrapped around the steel bars, a roller pressing mechanism used for rolling and crushing the concrete outside the steel bars, and a vibrating and screening mechanism used for separating the concrete and the steel bars, wherein the stamping mechanism, the pressing and cutting mechanism, the roller pressing mechanism and the vibrating and screening mechanism are sequentially arranged in the machine shell from the feeding opening to the discharging opening. The separator has the advantages that the steel bars can be separated from the concrete, and the concrete and the steel bars can be conveniently recycled and utilized.

Owner:北京博信晟益环保科技有限公司

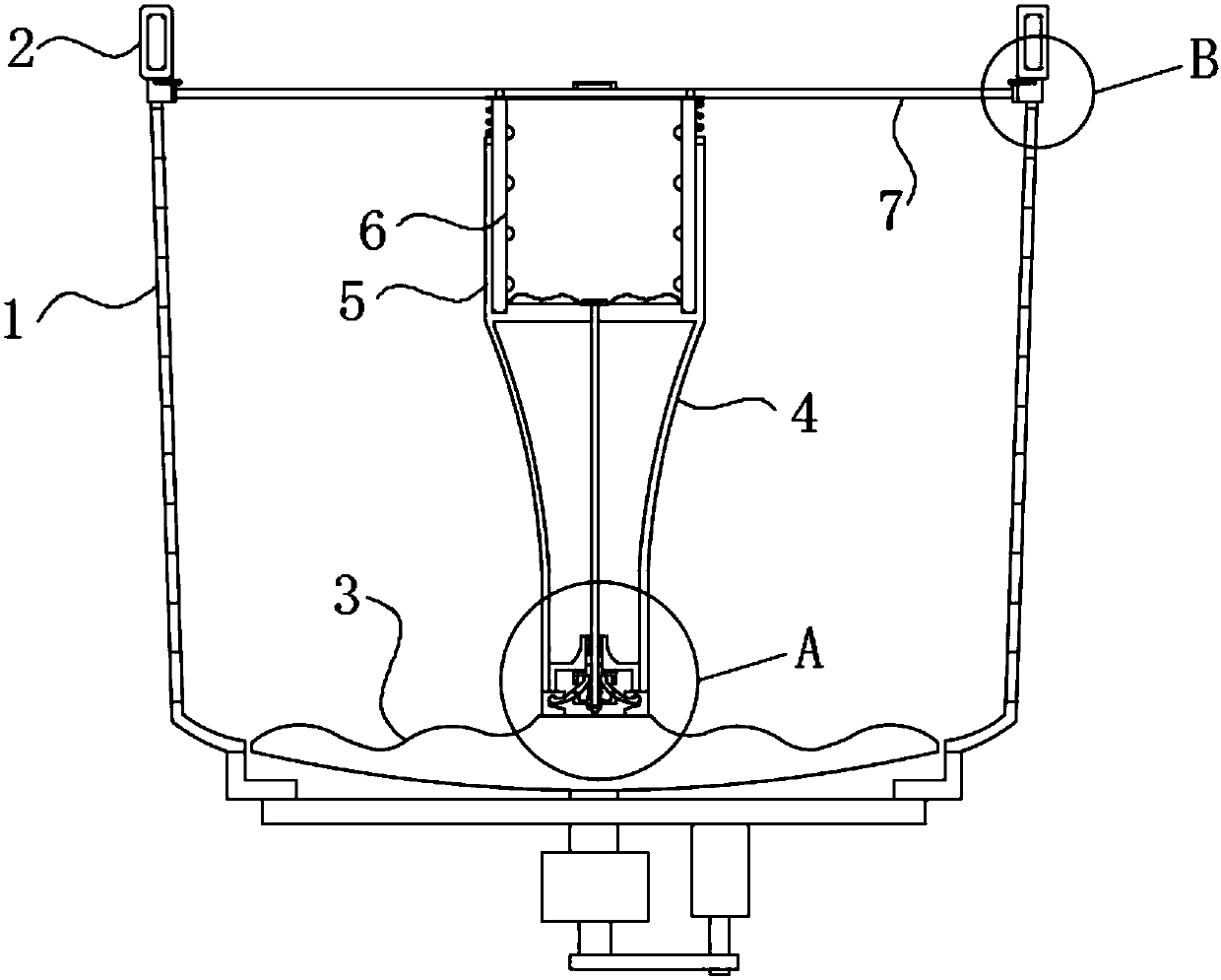

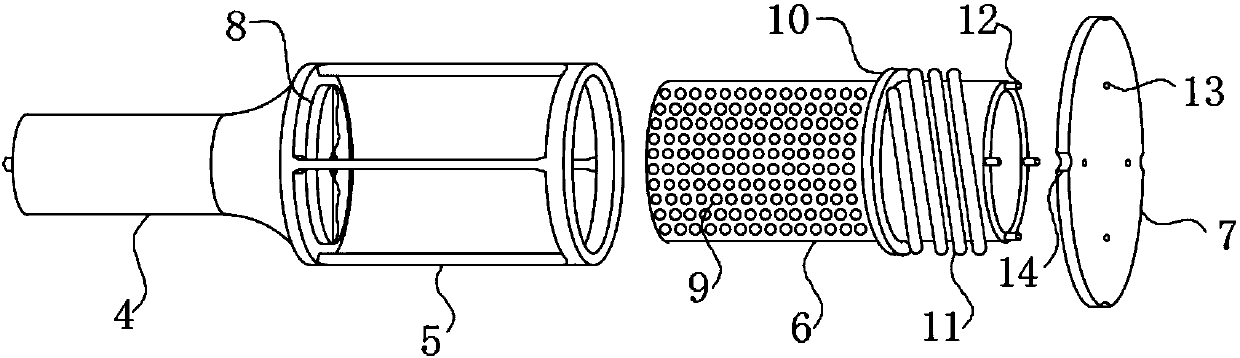

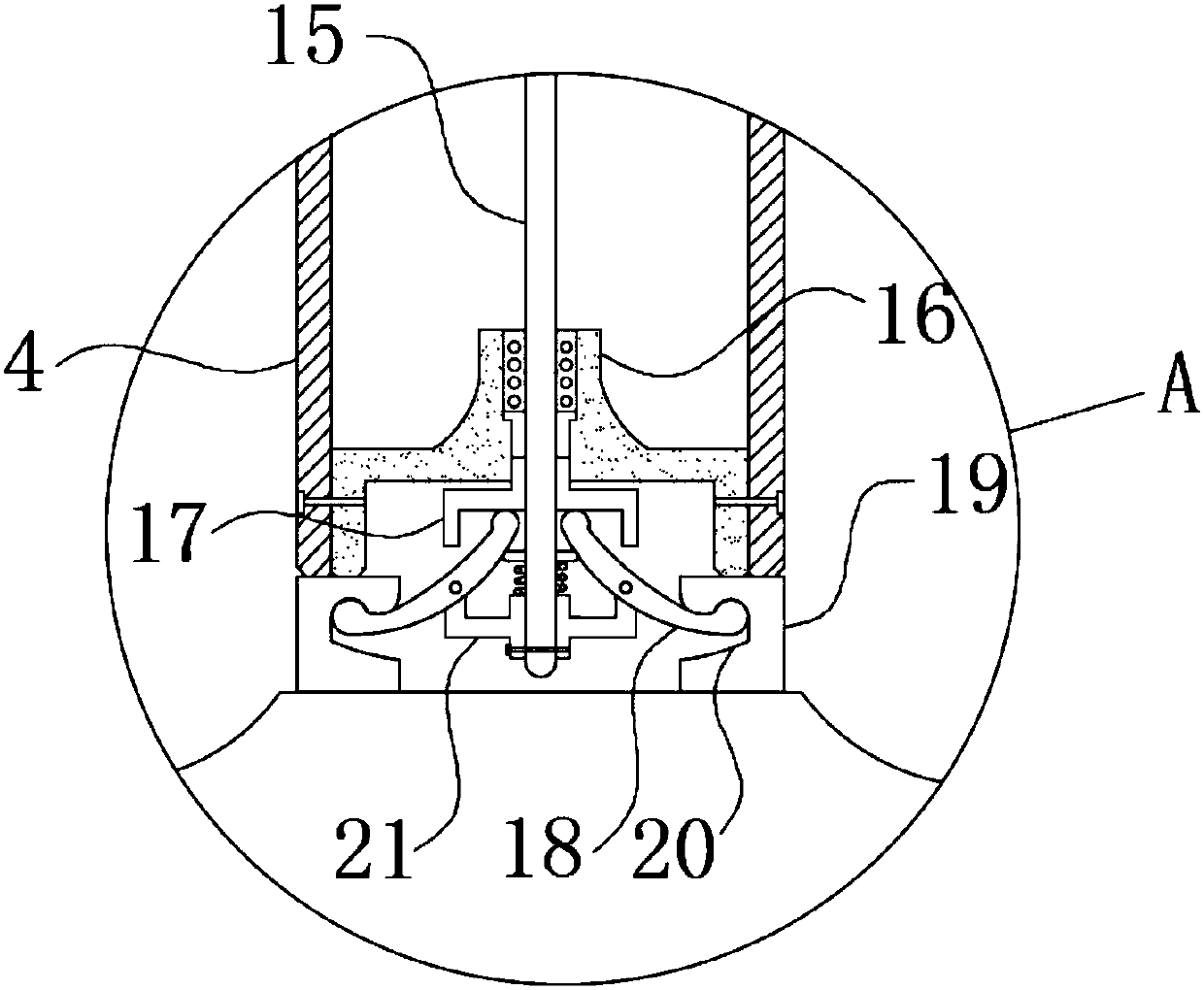

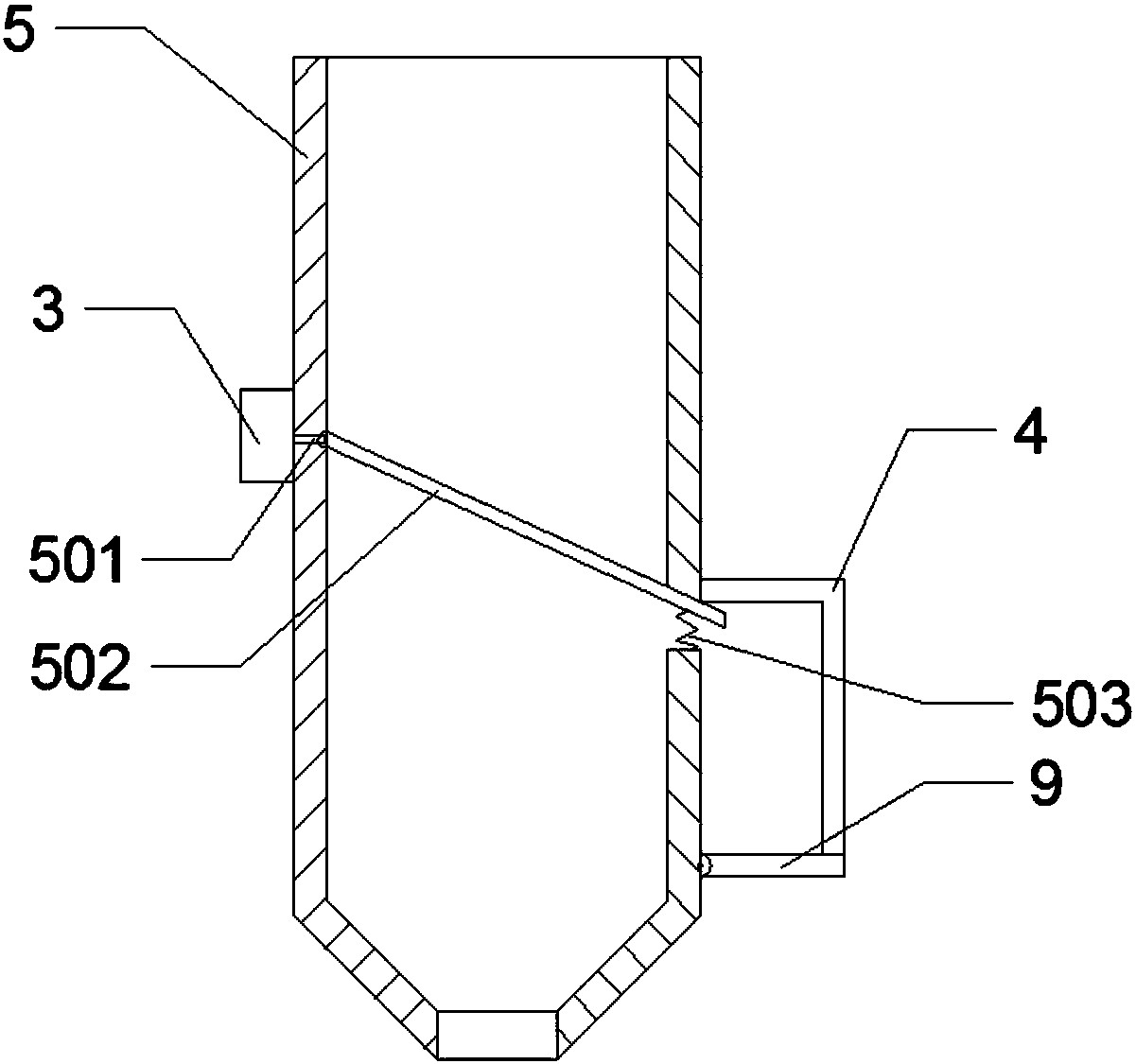

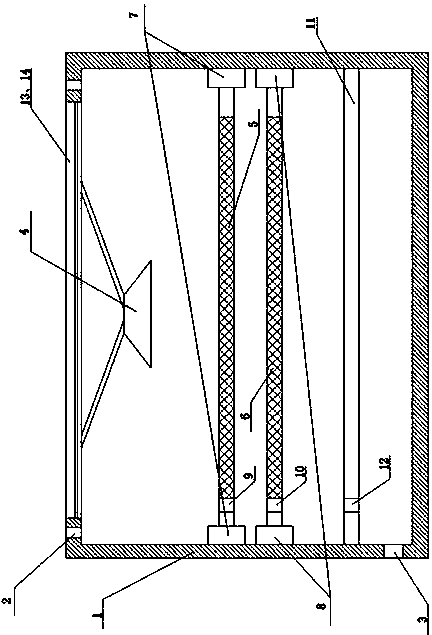

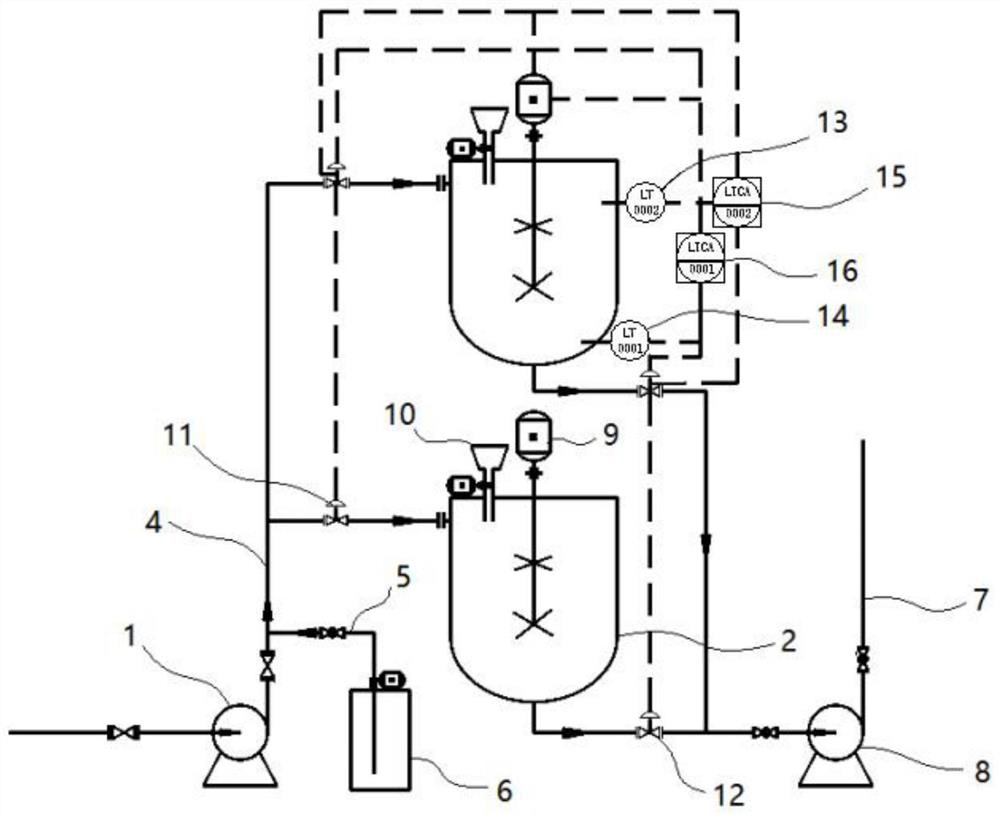

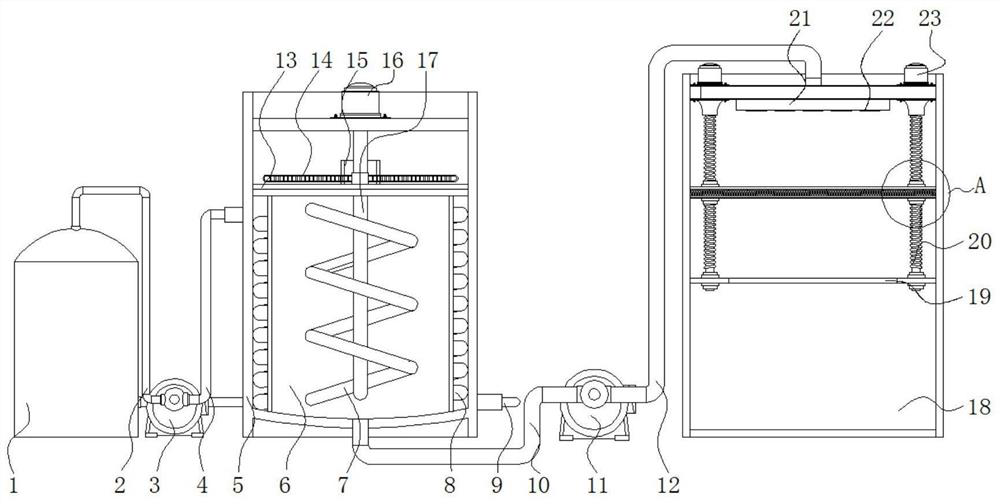

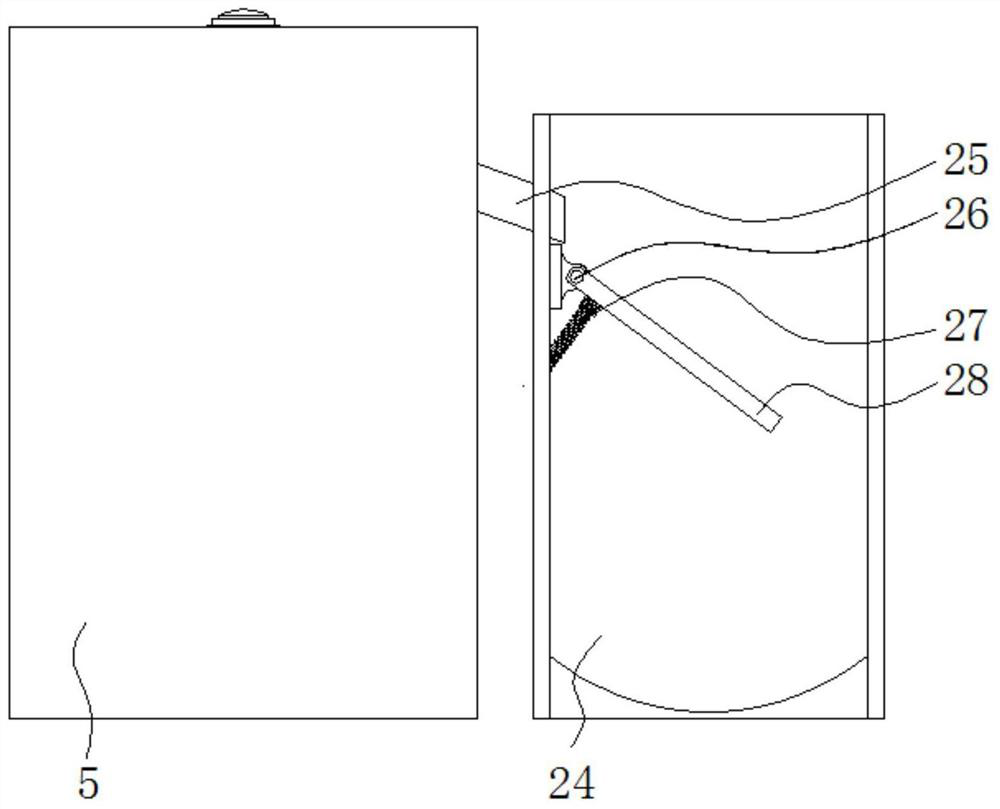

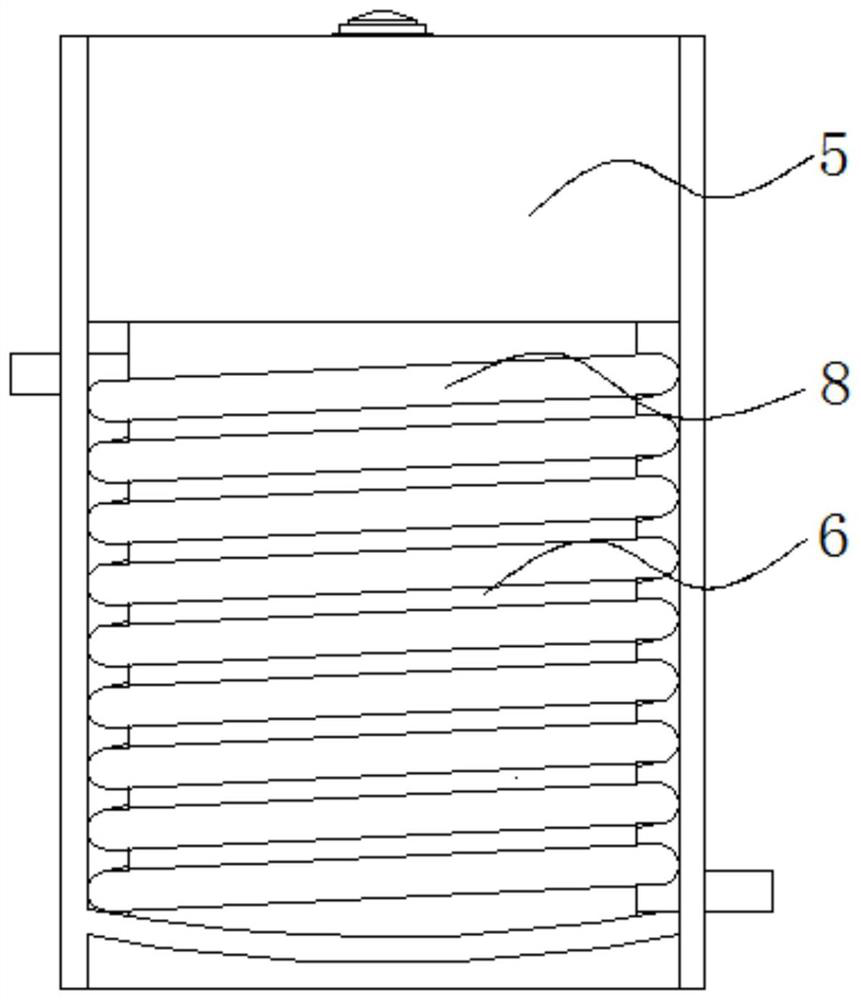

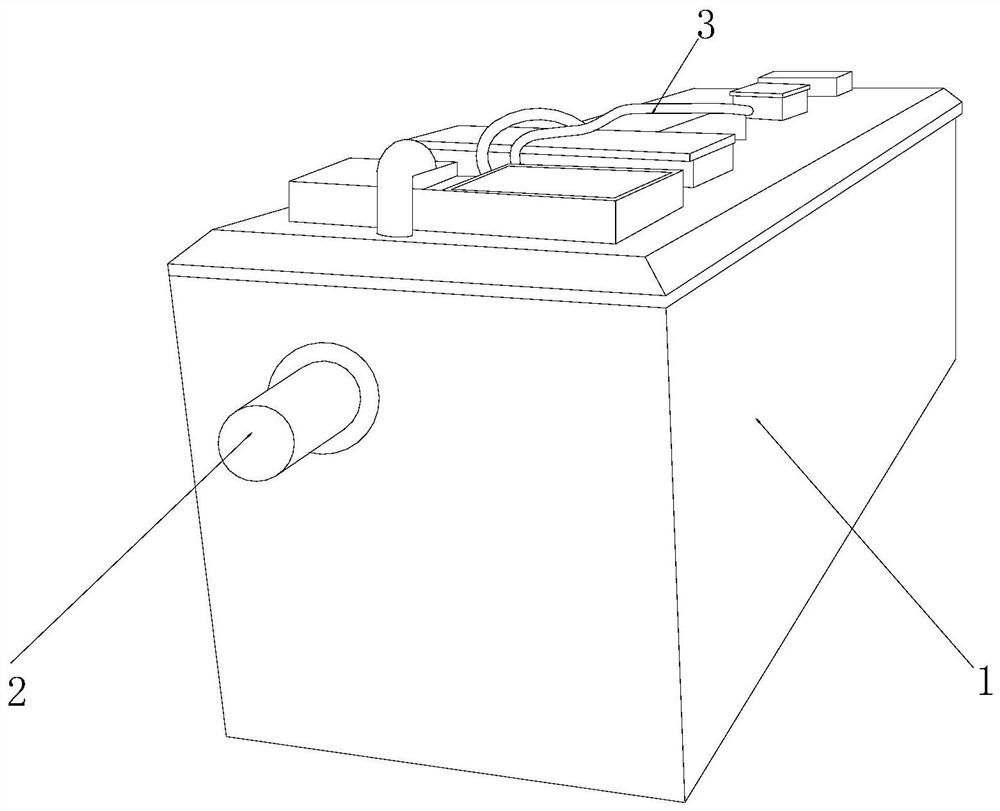

Vertical Anaerobic Reactor

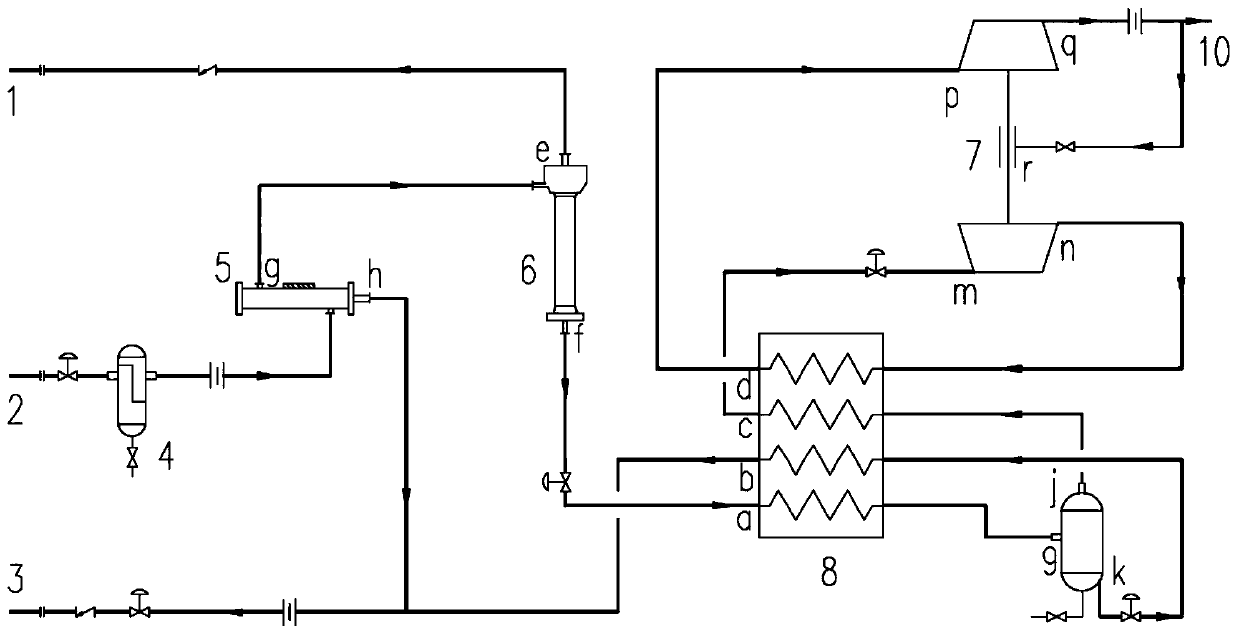

ActiveCN112010426BReduce the dilemma of mechanical failure requiring tank cleaning to maintainReduce the dilemma of cleaning to maintainWater treatment parameter controlTransportation and packagingSlurryProcess engineering

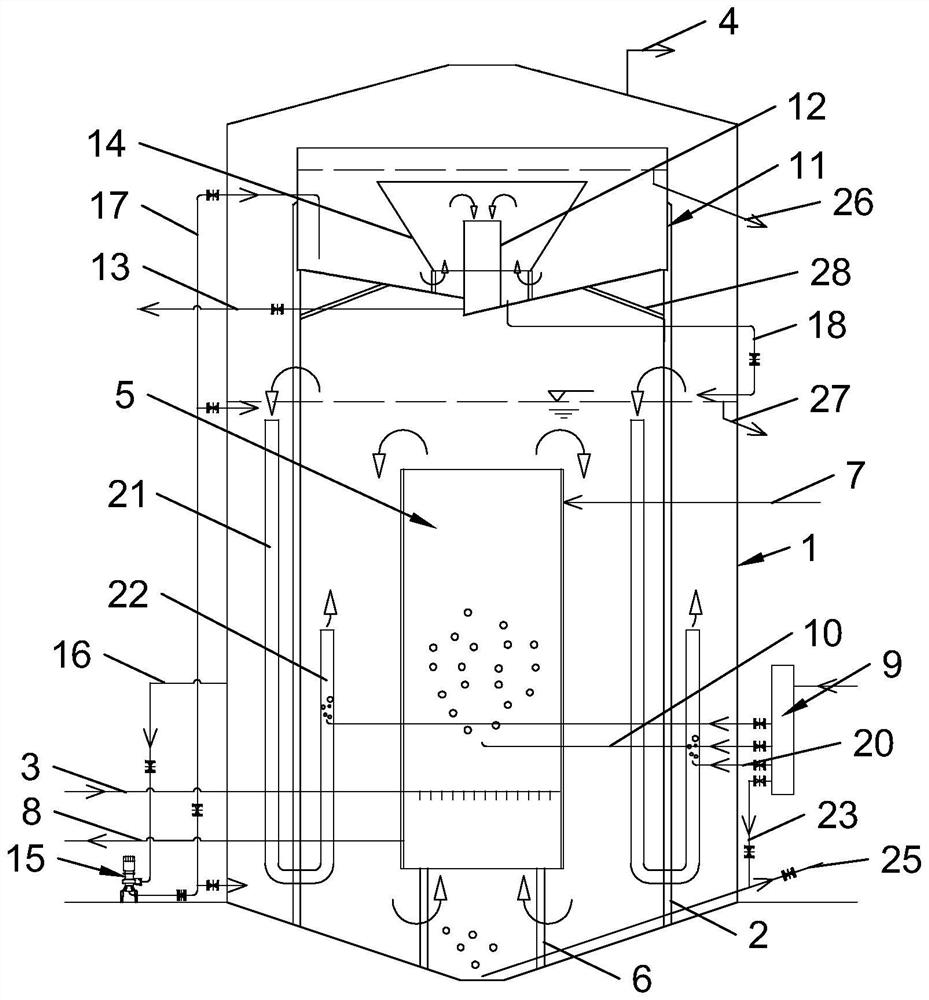

The invention discloses a novel vertical anaerobic reactor, which comprises a tank body, a material circulation stirring assembly arranged in the tank body, and a biogas slurry separator; the material circulation stirring assembly includes a heating reaction tube, and the heating reaction tube controls the material reaction zone in the tank body Separated into the first circulation reaction chamber and the second circulation reaction chamber, the high-pressure biogas buffer tank on one side of the tank sprays biogas above the heating reaction tube through the first biogas discharge pipe, so that the material forms a vertical circulation in the tank; The biogas slurry separator includes a separator shell, and a drainage casing is fixed inside the separator casing; at the same time, a drainage pipe is provided at the bottom of the drainage casing; a circulation pump is also provided on one side of the tank, and the circulation pump discharges the material in the reaction zone. The material is transported into the separator shell; the bottom of the separator shell is also provided with a sludge discharge pipe for transporting the sludge into the tank. The vertical anaerobic reactor can fully stir and mix the materials in the tank, and realize the discharge of biogas residue and the return of sludge.

Owner:SUZHOU CLEAR IND CO LTD

Method for extracting uranium and thorium from southern ionic rare-earth lixivium

The invention relates to a method for extracting uranium and thorium from a southern ionic rare-earth lixivium, which is characterized by comprising the following steps: (1) carrying out uranium and thorium extraction separation by using a 15-25 vol% naphthenate-15-25 vol% octanol or isooctanol-50-70 vol% kerosene extractant and a southern ionic rare-earth lixivium in a volume ratio of (0.5-5):1; and (2) carrying out back extraction on the loaded organic phase obtained in the step (1) and a 2-5 mol / L sulfuric acid, hydrochloric acid or nitric acid solution in a volume ratio of (0.1-10):1, wherein the organic phase after the back extraction returns to the step (1) for repeated use, and the water phase, which is the solution with enriched uranium and thorium, is used for recycling uranium and thorium. The method provided by the invention can selectively separate uranium and thorium from the rare-earth lixivium, has the advantages of fewer extraction stages, simple technique, favorable separating effect, no influence on subsequent rare-earth separation technique, and high extraction ratio of uranium and thorium.

Owner:GUANGDONG INST OF RARE METALS

Environment-friendly waste oil recoverer

The invention discloses an environment-friendly waste oil recoverer, which comprises a box body. The box body is internally divided into at least two chambers by clapboards; one chamber in the box body is a primary oil collection chamber, and the other one is a secondary oil collection chamber; an upper opening and a lower opening are formed on the primary oil collection chamber; a waste residue recovery basket is placed on the primary oil collection chamber; a through hole is formed on the waste residue recovery basket corresponding to the upper opening of the primary oil collection chamber; a plurality of filtering holes communicated with the primary oil collection chamber are formed on the wall of the waste residue recovery basket; a plurality of overflow pores and at least one overflow port are formed on the upper part of the clapboard between the primary oil collection chamber and the secondary oil collection chamber; the overflow port is connected with an overflow pipe the outlet of which extends to the bottom of the secondary oil collection chamber; and a delivery pipe is also arranged between the secondary oil collection chamber and the primary oil collection chamber and further communicated with the lower opening of the primary oil collection chamber through the upper part of the clapboard from the bottom of the secondary oil collection chamber. The invention has the beneficial effects of simple and reasonable structure and high oil-water separation rate.

Owner:刘廷 +1

Connector connection locking structure convenient to plug and pull

ActiveCN105990751AQuick changeAchieve separationIncorrect coupling preventionEngineeringMechanical engineering

Owner:CHISON MEDICAL TECH CO LTD

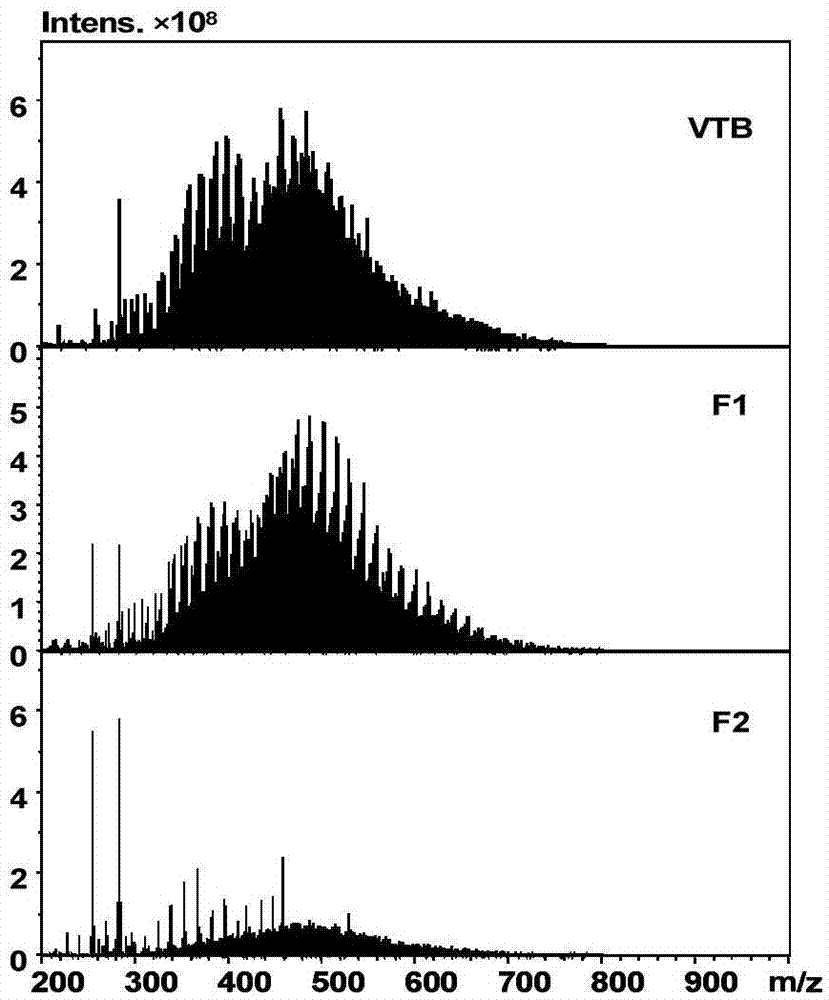

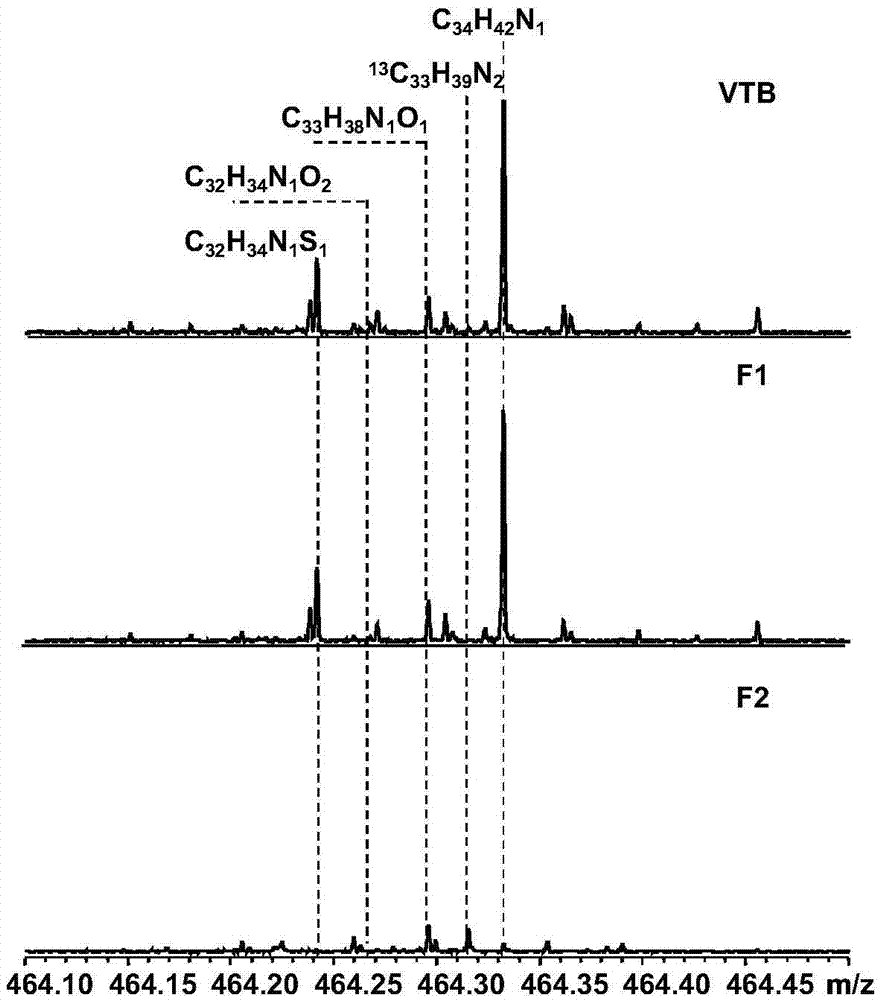

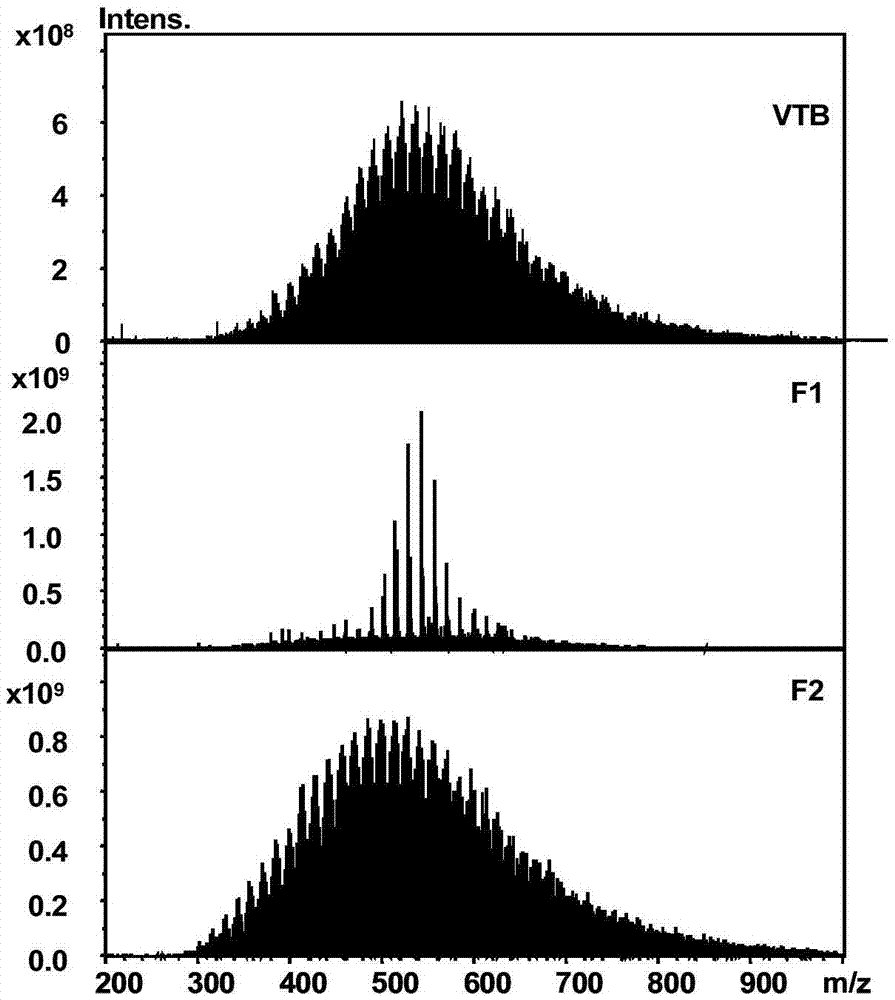

Separation analyzing method for nitrogen-containing compounds in heavy oil

InactiveCN106932521ADosage reachedReduce dosageComponent separationFourier transform on finite groupsComposition analysis

The invention discloses a separation analyzing method for nitrogen-containing compounds in heavy oil. The separation analyzing method includes: preparing a solid phase of a solid-phase extraction chromatographic column; separating alkaline components from non-alkaline components with a solid-phase extraction chromatography; analyzing the separated components by the aid of Fourier transform ion cyclotron resonance high-resolution mass spectra. Low solid phase to oil weight ratio, less flushing solvent dosage, shorter time and less manpower are needed in the method; compared with an existing method, the separation analyzing method has the advantages of higher separation efficiency, better separation effect and higher sample throughout, the method can be used for separation to meet the requirements of sample purity for subsequent analysis and preparing the nitrogen-containing compounds in the heavy oil rapidly to provide necessary sample quantity for subsequent reaction and evaluation experiment, and meanwhile, separation effect evaluation and product composition analysis can be achieved from the molecular level by the aid of the Fourier transform ion cyclotron resonance high-resolution mass spectra.

Owner:PETROCHINA CO LTD

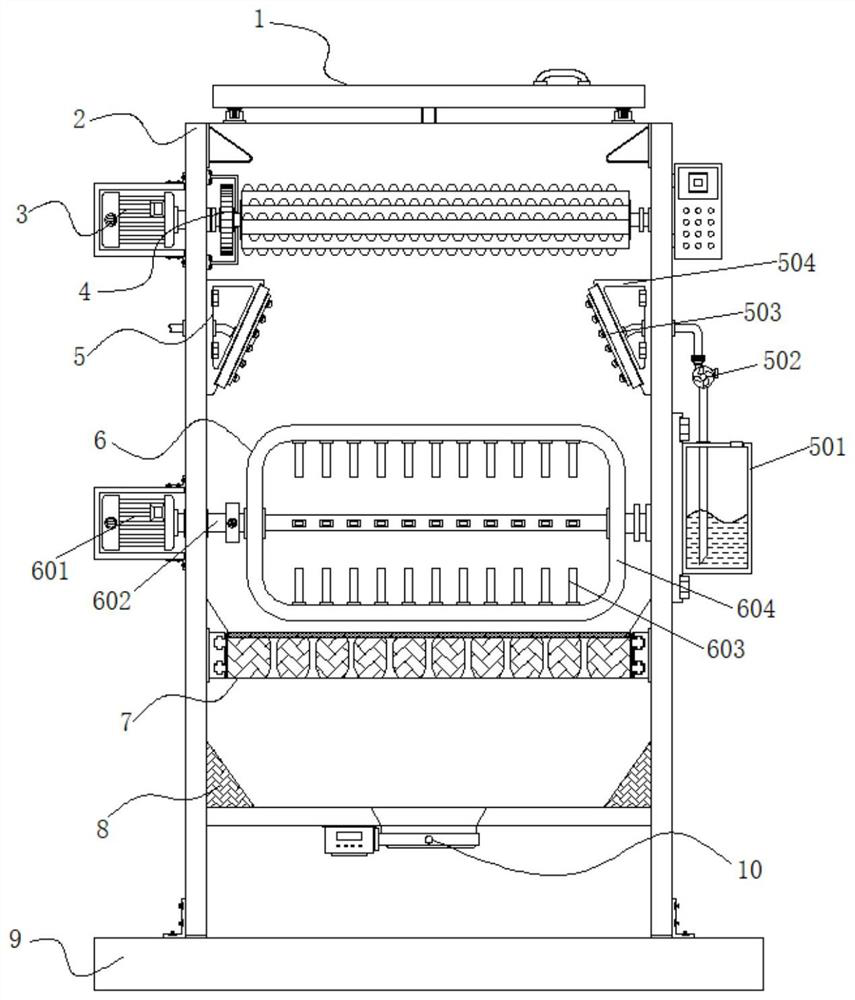

Full-automatic washing machine with internal compartments

PendingCN107761304ASeparation reachedAchieve separationOther washing machinesWashing machine with receptaclesImpellerRetaining ring

The invention relates to the technical field of washing machines, in particular to a full-automatic washing machine with internal compartments. The full-automatic washing machine comprises a washing drum, balance rings, an impeller, a speed reducer and a motor. The impeller is positioned in the middle of the inner bottom end of the washing drum, the upper end of the washing drum is fixedly connected with a fixing ring, a clamping block is arranged at the lower end of the inner sidewall of the fixing ring, the bottom end of an inner cavity of a pin groove is connected with one end of a second reset spring, a spring pin is fixedly connected with the other end of the second reset spring, and a positioning seat is fixed in the middle of the upper end of the impeller. The full-automatic washingmachine has the advantages that the interior of the washing drum is divided to achieve separate washing spaces; clothes can be washed separately and well protected from being torn and damaged by twisting due to materials; different clothes can be washed simultaneously, and accordingly both water resources and time are saved; the full-automatic washing machine is quite convenient and beneficial topopularization.

Owner:彭诚

Audio signal encoding device, audio signal decoding device, method thereof and program

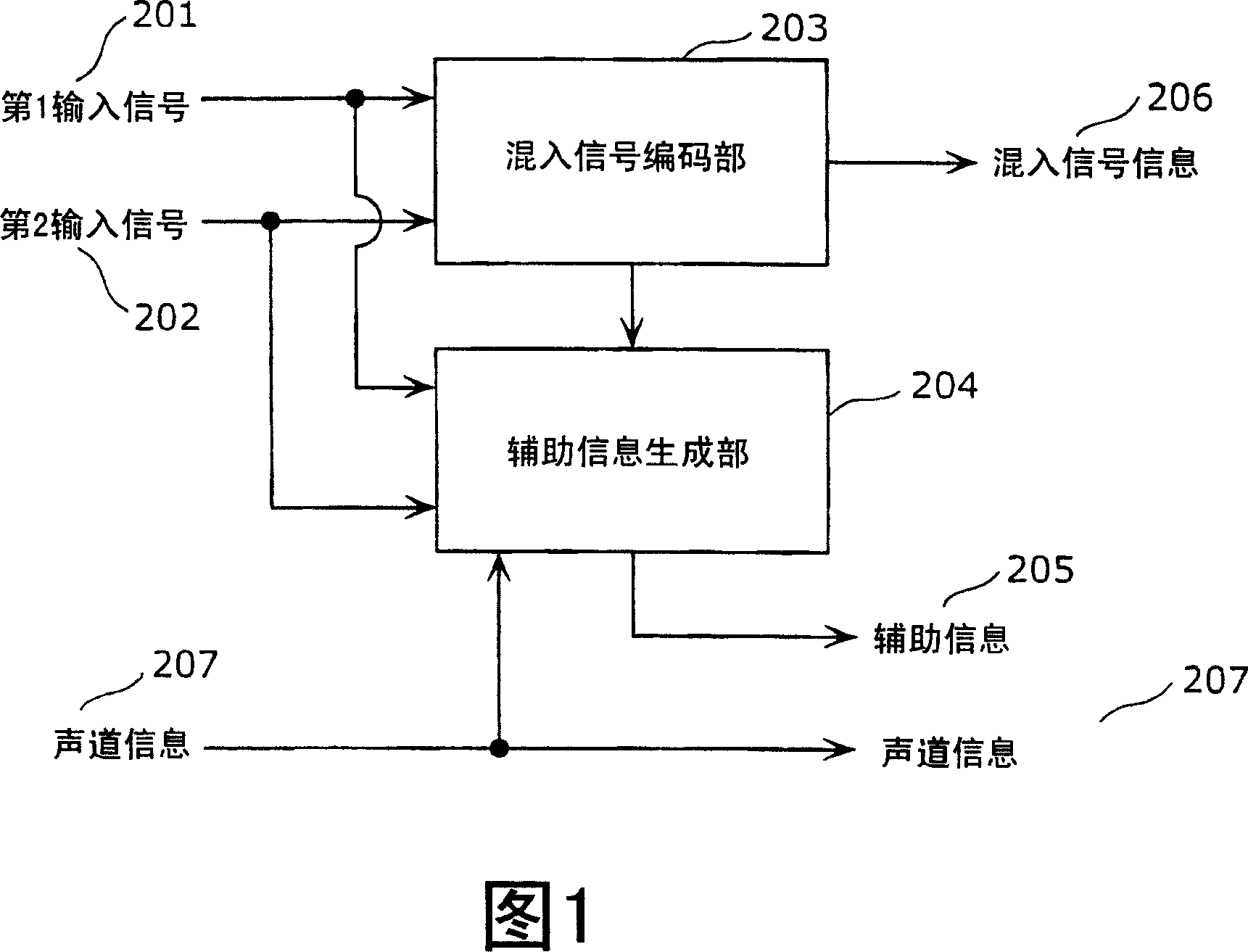

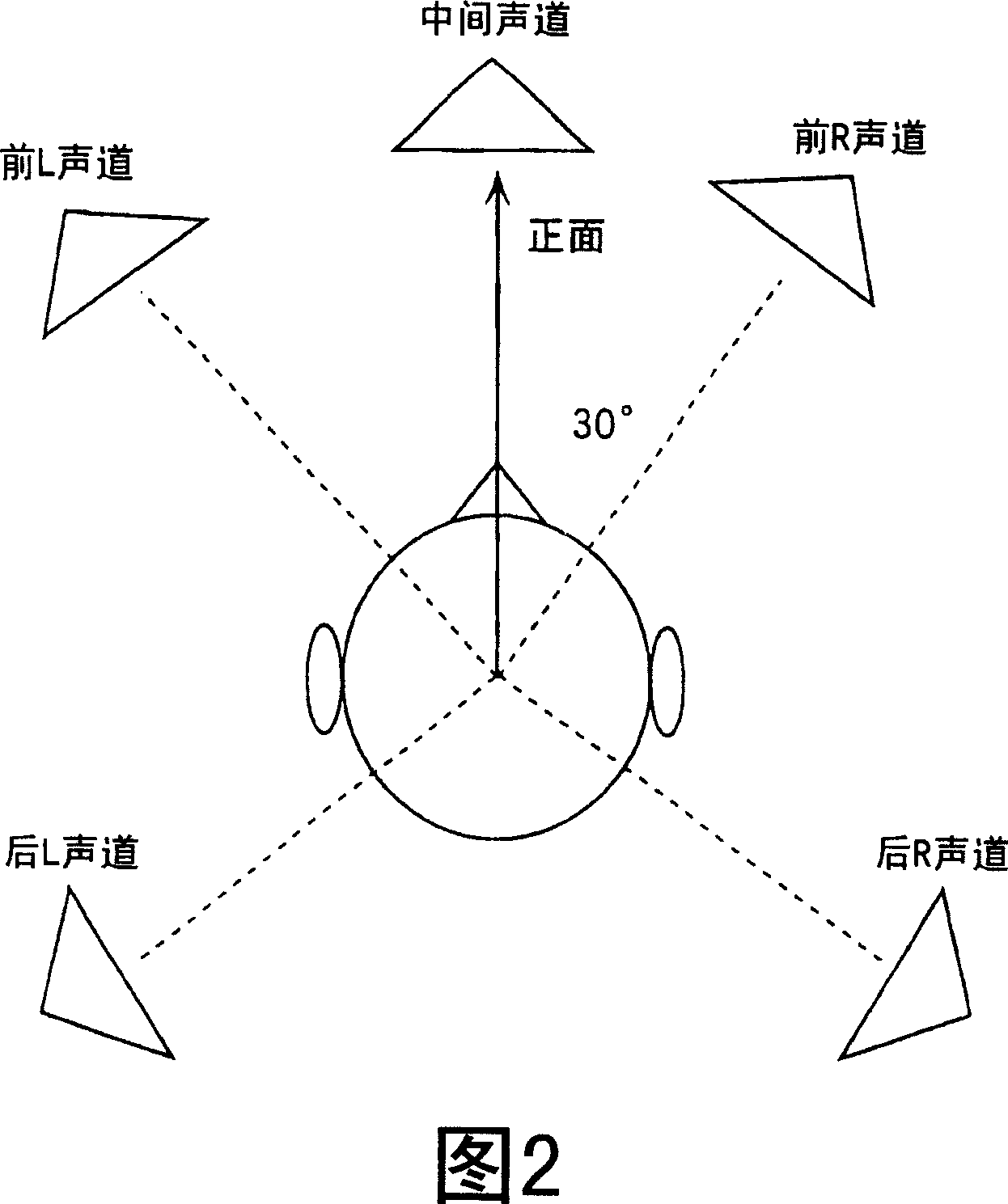

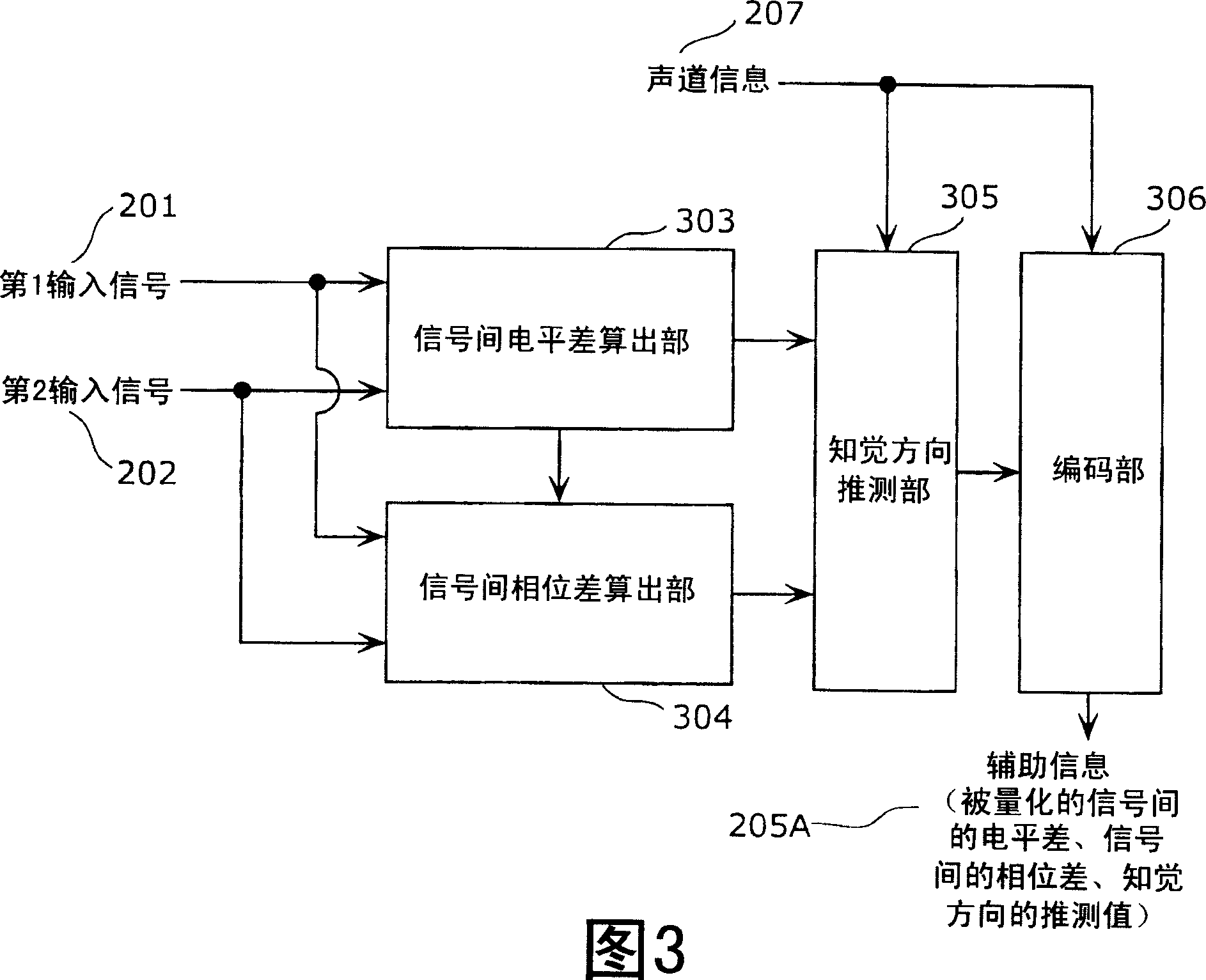

InactiveCN1922655ASeparation reachedImprove qualitySpeech analysisStereophonic systemsSound sourcesSignal encoding

An audio signal encoding device includes a downmix signal encoding unit 203 and an auxiliary information generation unit 204 . The downmix signal encoding unit 203 generates a downmix signal acquired by adding input signals each other using a predetermined method, encodes the downmix signal, and outputs downmix signal information 206 . The auxiliary information generation unit 204 generates auxiliary information 205 using the downmix signal and the downmix signal information 206 generated by the downmix signal encoding unit 203 . The auxiliary information generation unit 204 efficiently quantizes the auxiliary information 205 using human's characteristics of a perceptual direction of a sound source, a perceptual broadening, and a perceptual distance.

Owner:PANASONIC CORP

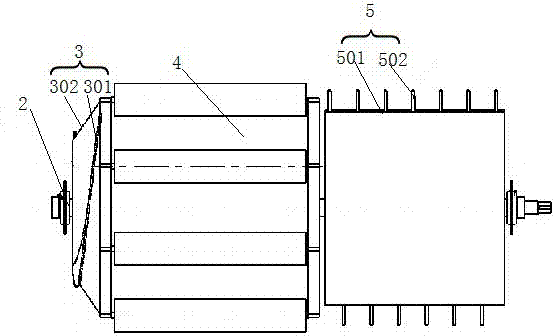

Millet threshing device

The invention provides a millet threshing device aiming at the problem that in the prior art, a grain threshing device is short in threshing distance, and consequently threshing is not thorough. The millet threshing device comprises a shell, a driving shaft rotationally arranged on the opposite side faces of the shell, a conical front end assembly arranged on the driving shaft and used for pushing grain ears, a rotary threshing assembly connected with the large diameter end of the conical front end assembly, driven by the driving shaft and used for threshing, and a shake separating assembly driven by the driving shaft and used for separating millet grains from impurities. The rotary threshing assembly and a grid concave plate I cooperate for threshing, the rotary threshing assembly is composed of a plurality of threshing rolls which are evenly distributed on the outer side of the driving shaft and are parallel to the axis of the driving shaft, and the threshing rolls all can rotate around the axes of themselves. The millet threshing device is simple in structure, the threshing rolls rotate around own axes, the rubbing distance can be increased, and the threshing efficiency can be improved.

Owner:HENAN UNIV OF SCI & TECH

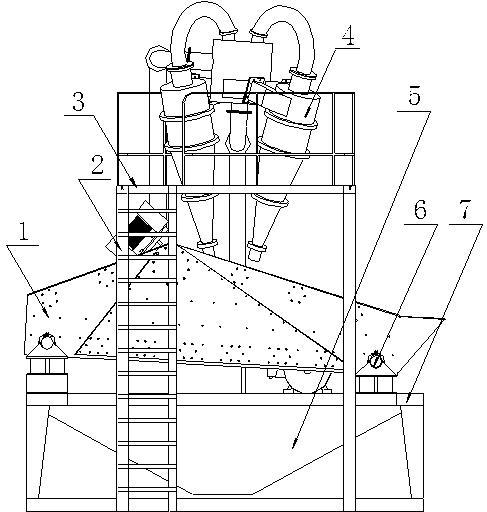

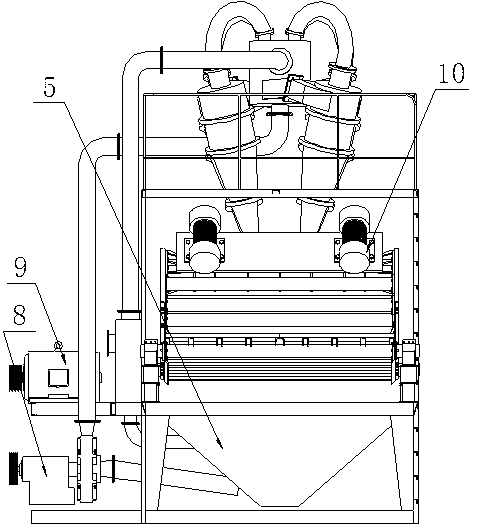

Special dehydration rotational flow assembly for sand and water separation system as well as sand and water separation method

The invention relates to a special dehydration rotational flow assembly for a sand and water separation system as well as a sand and water separation method, can effectively separate mud, water and sand in a mud, sand and water mixture, and also can dehydrate the sand and the water efficiently. The special dehydration rotational flow assembly for the sand and water separation system comprises a dehydration screen assembly, and a rotational flow device or a rotational flow device group; the rotational flow device or the rotational flow device group is integrated above the dehydration screen assembly through a support frame; a wide-amplitude water-storage-type dehydration screen in the dehydration screen assembly is positioned on a rack through a shock absorber, and is driven through a shock excitation motor or a cam wheel driving mechanism; a wide-amplitude water storage groove is positioned below the wide-amplitude water-storage-type dehydration screen; a material inlet of the rotational flow device or the rotational flow device group is communicated with an outlet of a slurry pump positioned at the side part of the rack through a conveying pipeline; and the motor drives the slurry pump through a belt driving mechanism. The special dehydration rotational flow assembly for the sand and water separation system and the sand and water separation method have the advantages that firstly, the integration of the dehydrating screen assembly and the rotational flow device or the rotational flow device group in the sand and water separation system is created for the first time; secondly, the investment is reduced greatly, the occupied area is small, and the energy consumption is reduced; and thirdly, the sand and water separation efficiency is high.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

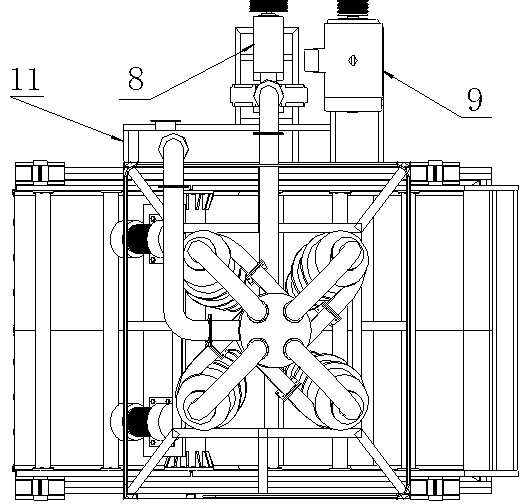

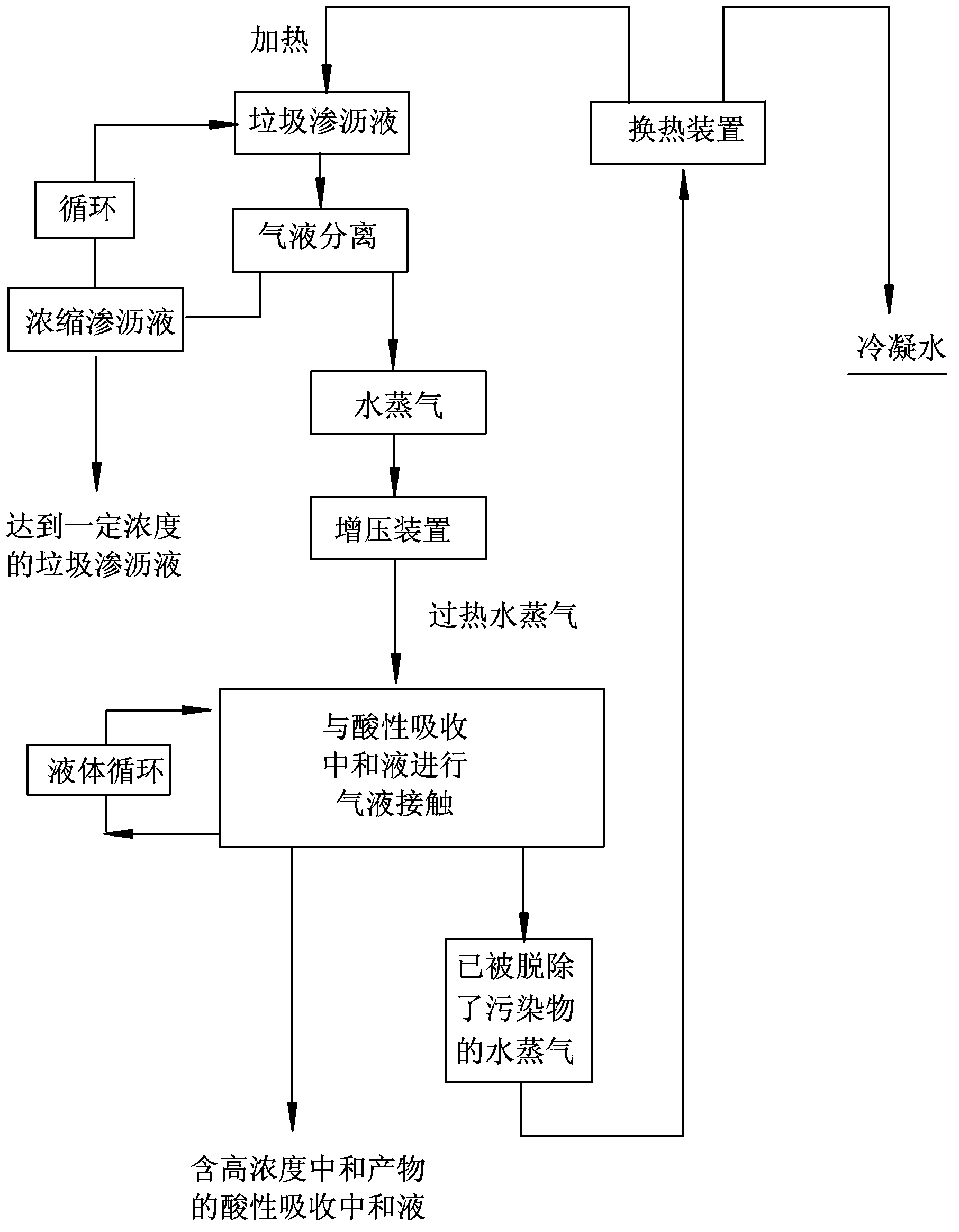

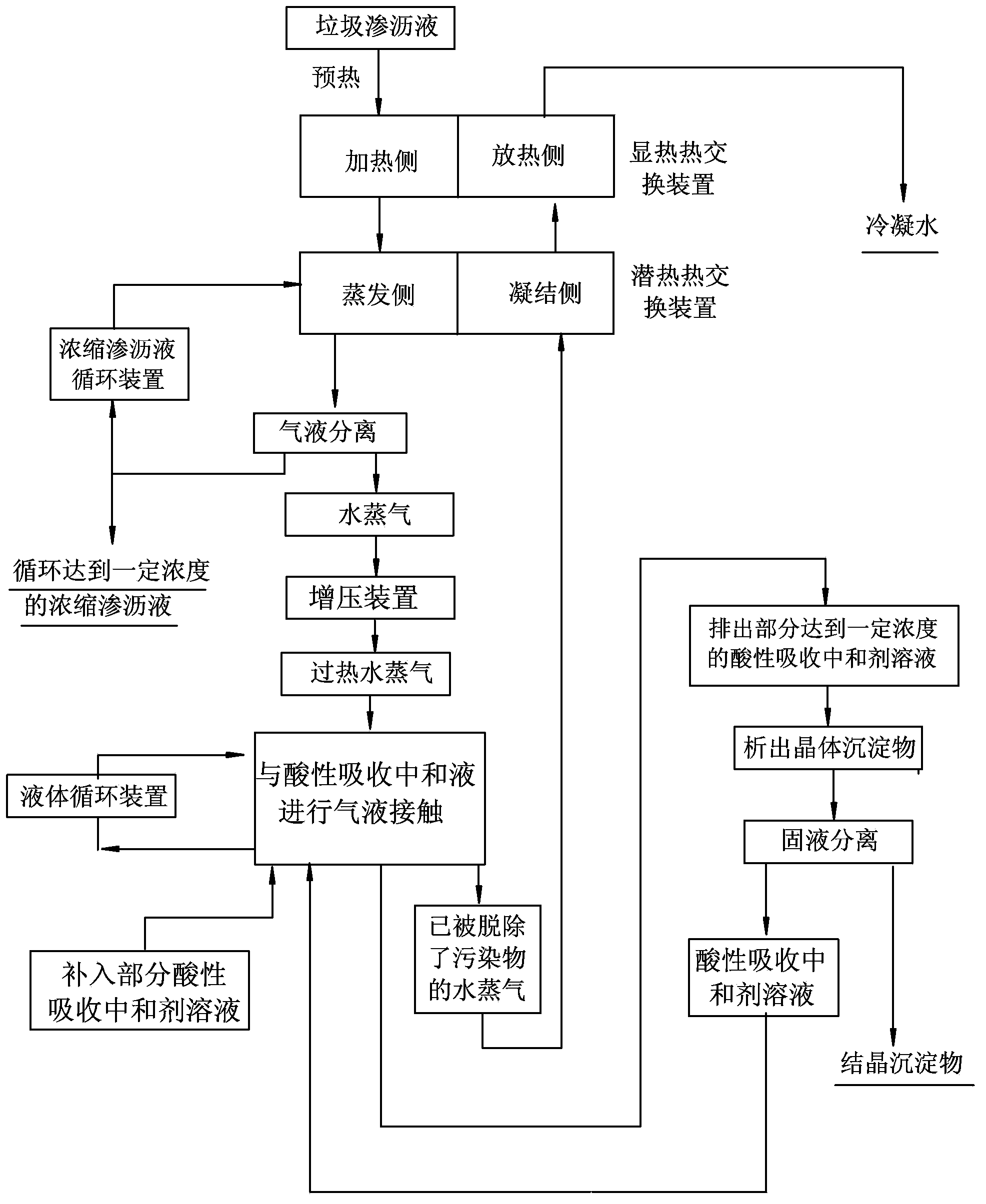

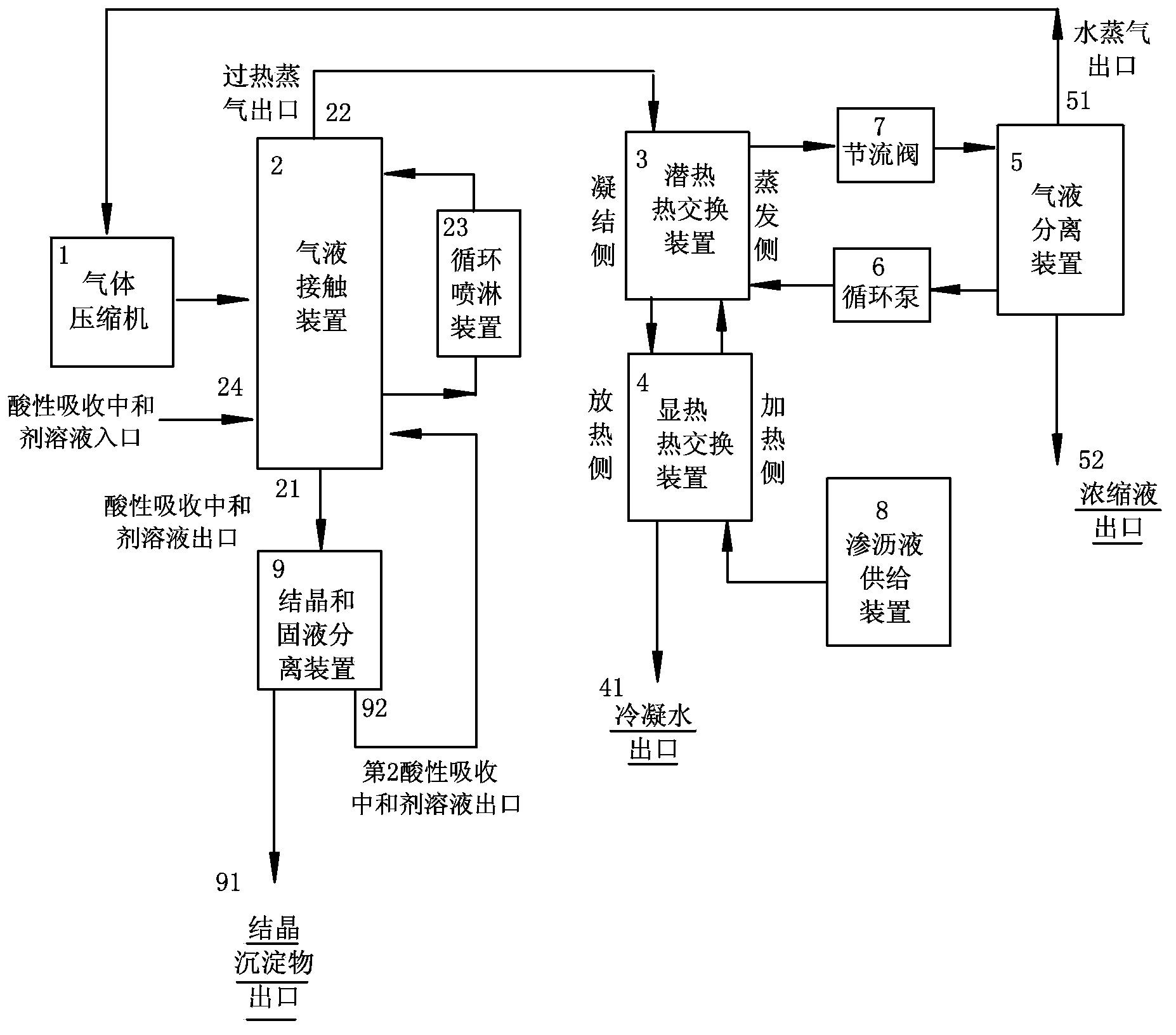

Treatment method for realizing leachate pollutant zero-discharge and recycling

ActiveCN103420439ASeparation reachedAchieving zero emissionsDispersed particle separationWater/sewage treatment by heatingWater vaporThermal water

The invention discloses a treatment method for realizing leachate pollutant zero-discharge and recycling. The treatment method comprises the following steps of heating a garbage leachate, carrying out gas-liquid separation, heating the steam to obtain superheated steam, carrying out gas-liquid contact between the superheated steam and an acidic absorption and neutralization agent solution so that gaseous alkaline pollutants in the steam are absorbed and neutralized and the pollutants are transformed into difficultly-volatilizable salts, carrying out repeated circulation absorption of the gaseous pollutants in the steam by the acidic absorption and neutralization agent solution, evaporating water in the acidic absorption and neutralization agent solution so that a salt concentration of the solution is improved, discharging the acidic absorption and neutralization agent solution, and carrying out recycling. The pollutants in the superheated steam are absorbed by the acidic absorption and neutralization agent solution and then can be used for heating the garbage leachate, and after repeating circulation heating and separation, the garbage leachate having a certain concentration is discharged and recycled. The treatment method has simple processes, a low device cost and a low treatment cost, realizes efficient and deep treatment on the garbage leachate, and realizes zero-discharge and recycling of pollutes.

Owner:李虹

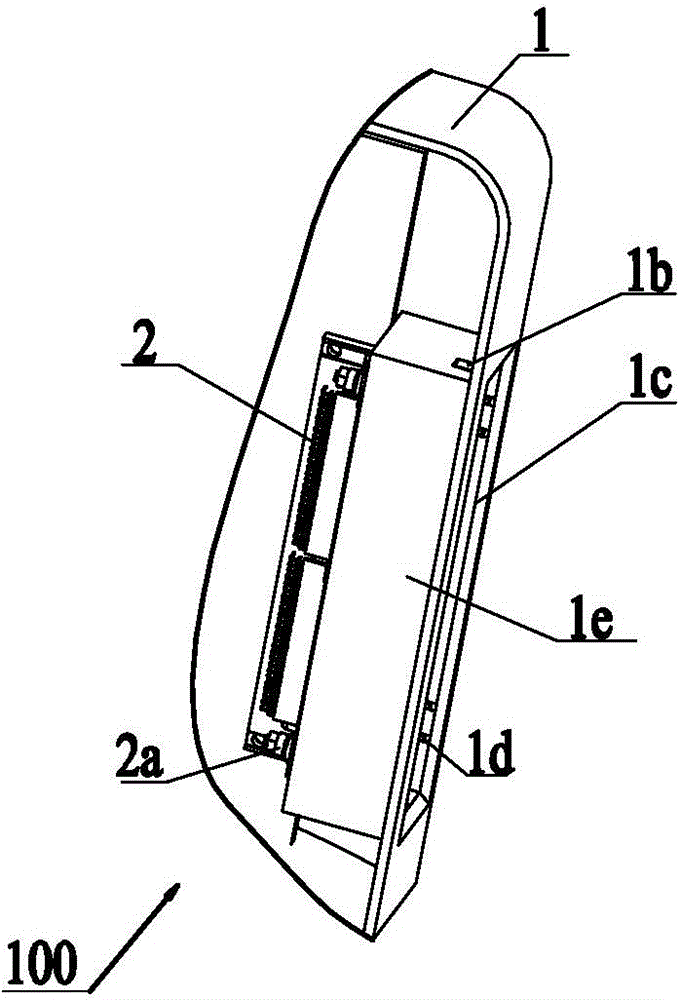

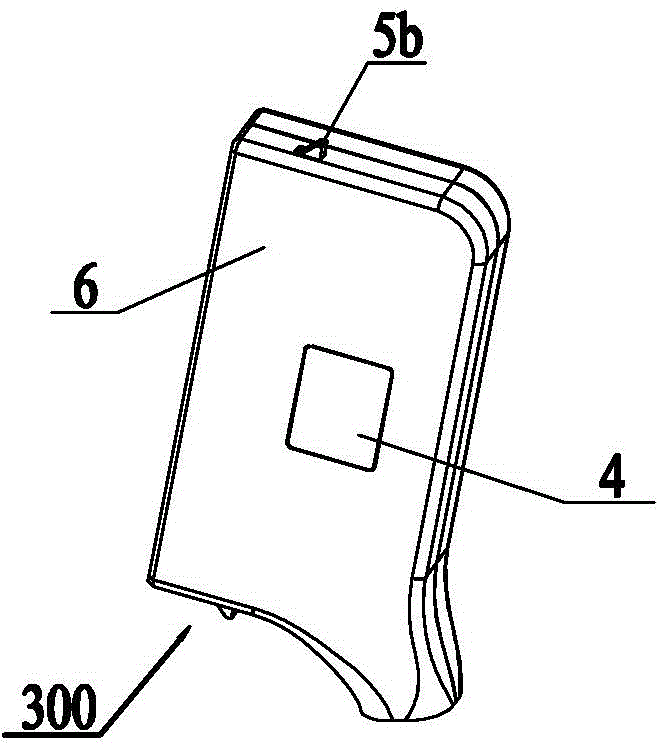

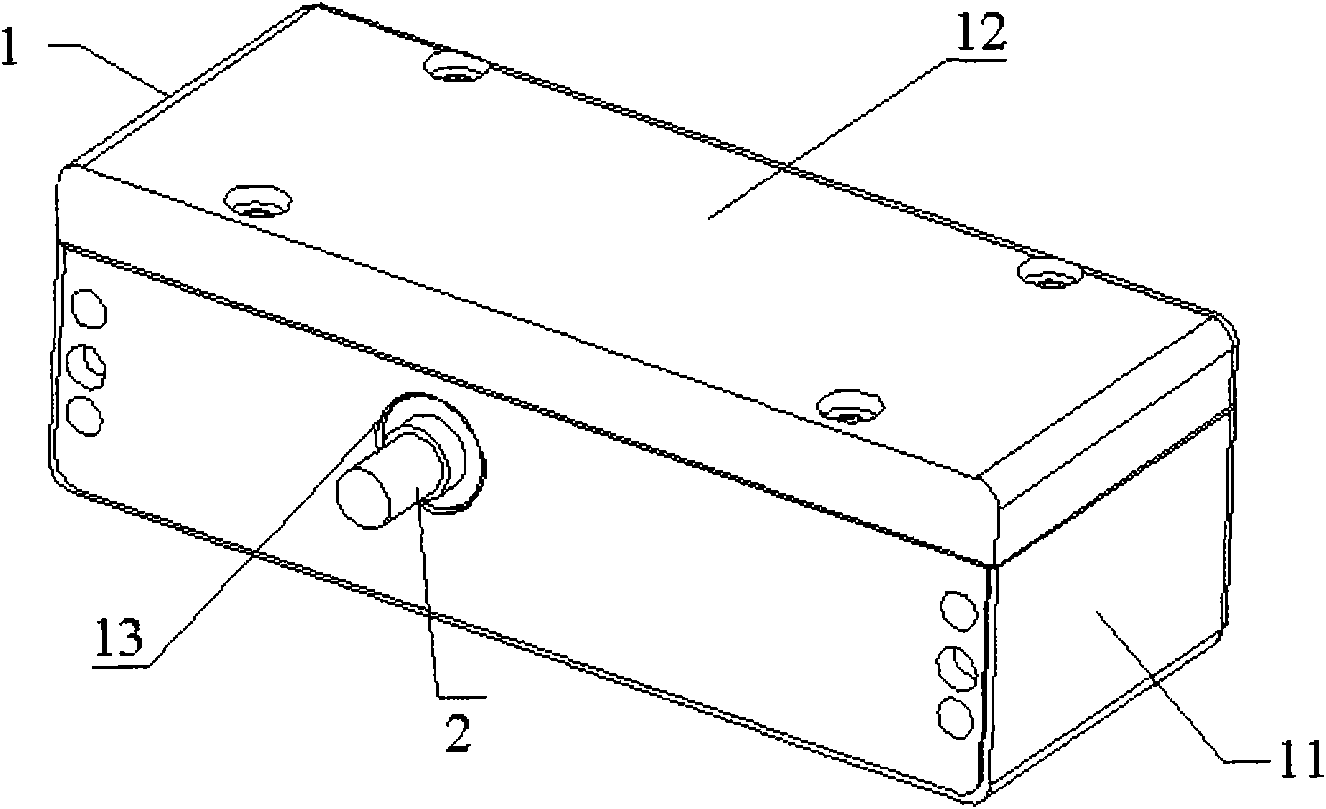

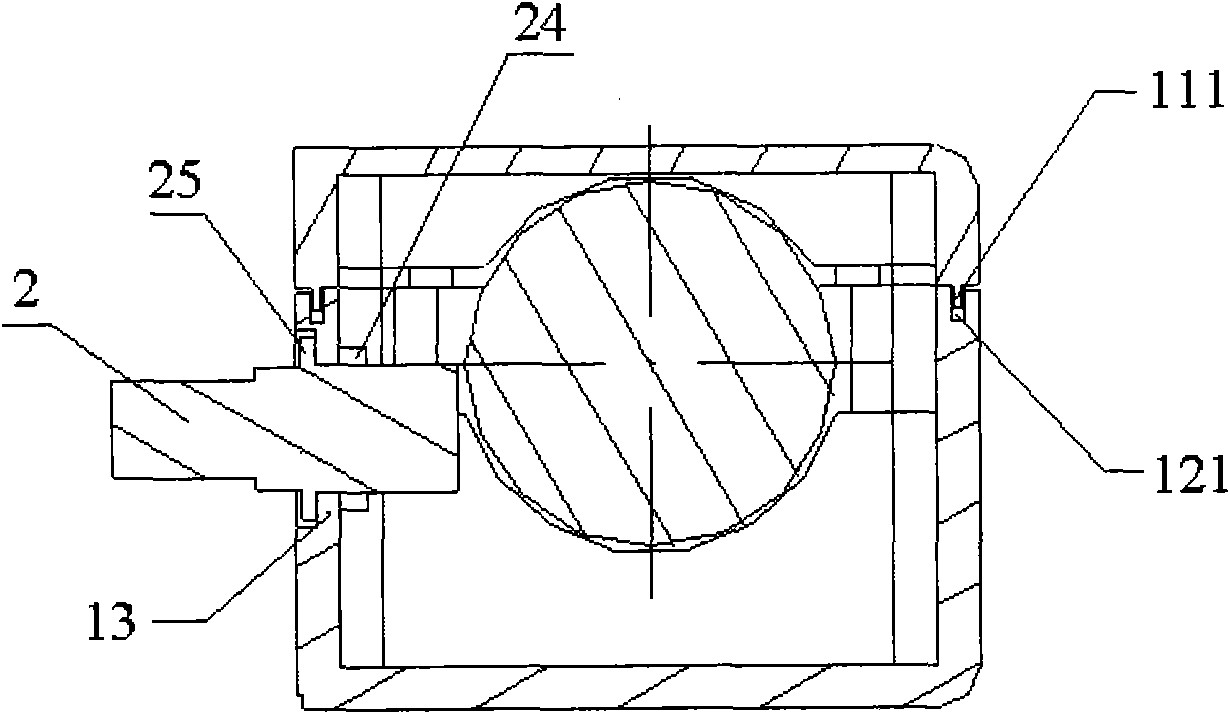

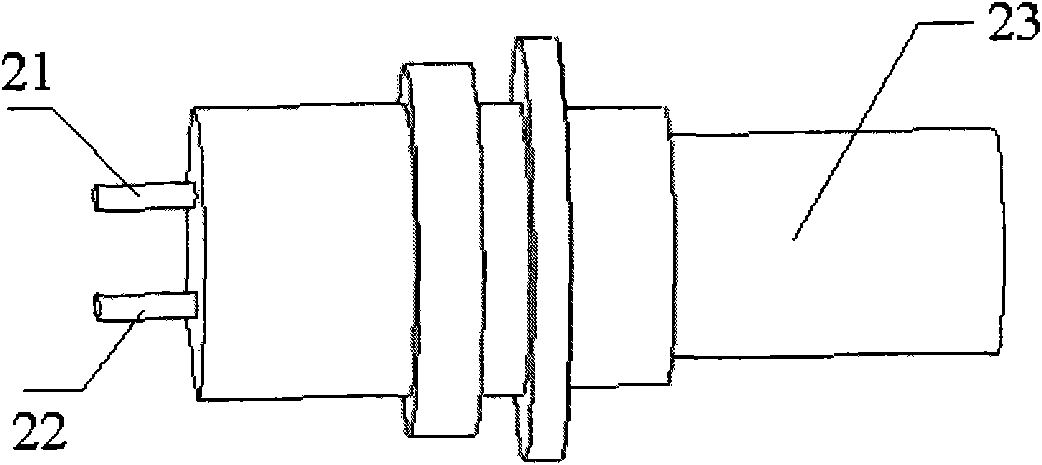

Independent battery compartment and electric product

InactiveCN101937978ASolve the problem that the battery is not easy to replaceSeparation reachedCoupling device connectionsCell lids/coversBiochemical engineeringElectrical battery

The invention discloses an independent battery compartment and an electric product. The independent battery compartment comprises a compartment body and a connector, wherein the compartment body comprises a comportment chamber and a compartment chamber cover covered on the upper part of the compartment chamber; the connector is arranged on the compartment body, the first end of the connector is connected with a battery arranged in the compartment chamber, and the second end is used for connecting an electric product body arranged outside the compartment chamber. The invention can make the battery equipment and the electric product body separate. The electric equipment is convenient to dismount, and has higher usability.

Owner:BEIJING JINGWEI HIRAIN TECH CO INC

Urban and rural household garbage treatment and decomposition device

InactiveCN112191649AAchieve separationEmission reductionSolid waste disposalGrain treatmentsGear wheelAgricultural engineering

The invention discloses an urban and rural household garbage treatment and decomposition device, and particularly relates to the technical field of garbage treatment and decomposition devices. The urban and rural household garbage treatment and decomposition device comprises a base, wherein a tank body is fixedly connected to the top of the base; a discharging valve is fixedly connected to the middle of the bottom end of the exterior of the tank body; spraying mechanisms are fixedly connected to one side of the exterior of the tank body; a rotating structure is arranged at the top end of the exterior of the tank body; guide blocks are fixedly connected to the two sides of the bottom end of the interior of the tank body; and separation structures are fixedly connected to the bottoms of thetwo sides of the interior of the tank body. According to the urban and rural household garbage treatment and decomposition device provided by the invention, crushing mechanisms are fixedly connected to the two sides of the top end of the interior of the tank body, a controller controls a first driving motor to work, the first driving motor drives a second crushing roller to rotate through a coupler, and a first gear on one side of the second crushing roller drives a first crushing roller to rotate reversely through a second gear, so that the household garbage put into the opening is crushed, and the purpose of convenience in decomposition is achieved.

Owner:叶广丽

Concentration method of pseudo-ginseng total saponin extracting solution

ActiveCN102441016AReduce hydrolysis rateHigh concentration ratePlant ingredientsReverse osmosisGinseng

The invention relates to a concentration method of a pseudo-ginseng total saponin extracting solution. A reverse osmosis process is mainly utilized to concentrate the pseudo-ginseng total saponin extracting solution. The concentration method provided by the invention has the advantages of favorable concentration effect and small loss.

Owner:GUANGXI WUZHOU PHARMA GRP

Large and small cargo separating device for truck unloading

ActiveCN107626596ASeparation reachedAchieve the effect of separating large and small goodsGradingEngineeringTruck

The invention relates to a separating device, in particular to a large and small cargo separating device for truck unloading. According to the technical aims, the large and small cargo separating device for truck unloading saves time, reduces manpower and improves the working efficiency. In order to achieve the above technical aims, the large and small cargo separating device for truck unloading is provided and comprises a base plate and the like; a first strut is arranged on the left side of the top of the base plate, containing frames are installed on the left and right sides of the top of the base plate, a discharging device is connected to the top of the first strut, and a separating device is arranged on the right side of the outer side of the discharging device. According to the large and small cargo separating device for truck unloading, the discharging device is matched with the separating device for separating cargoes; the separating device is hit through a hitting device, andthe better separating effect is achieved; and the working convenience is improved through a lifting device.

Owner:良求机械有限公司

Device and technical process for one-stop recovery and treatment of steel skeleton plastic composite pipes

InactiveCN104175420AFulfilling Recycling RequirementsSmooth and orderly separationPlastic recyclingMagnetic separatorEngineering

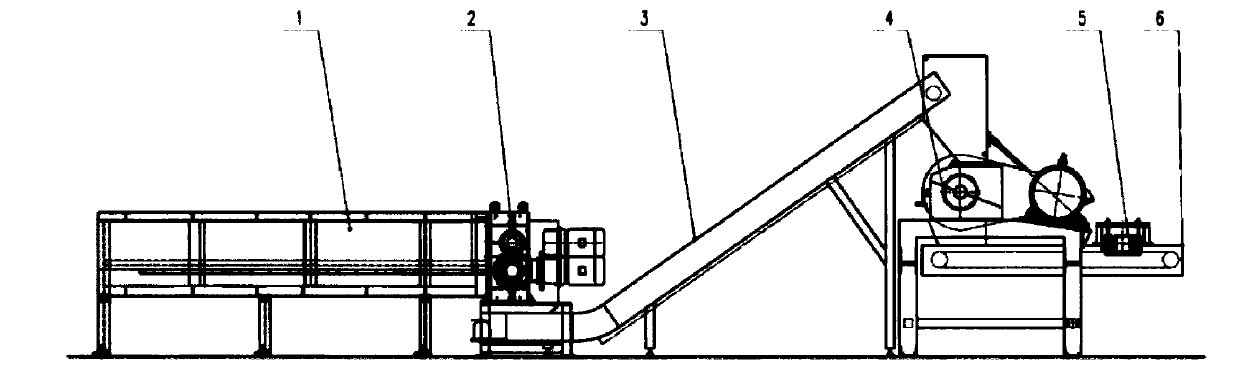

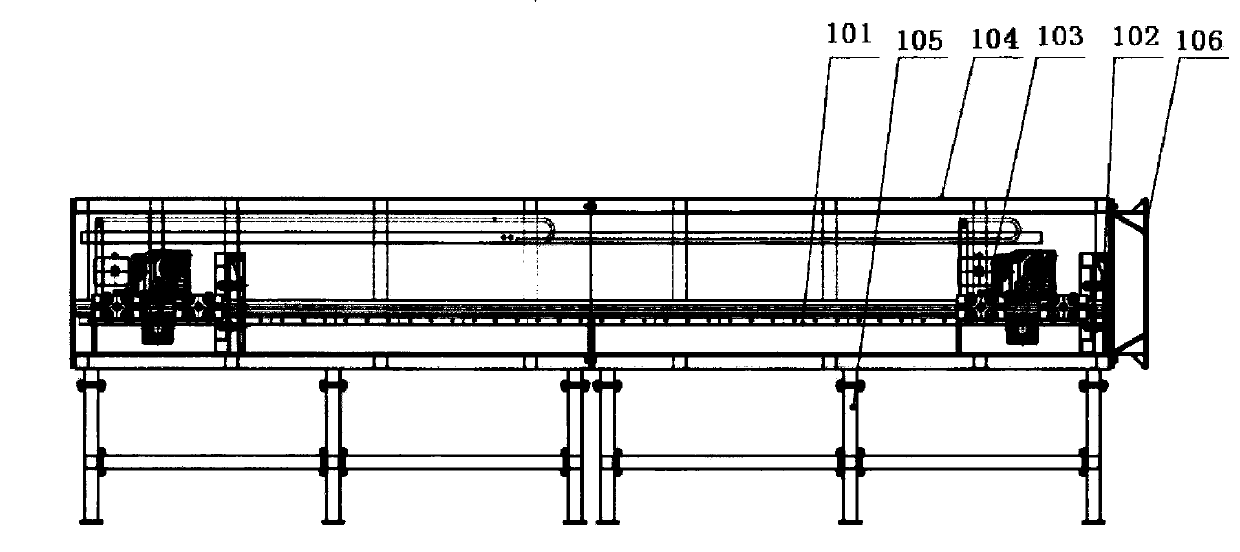

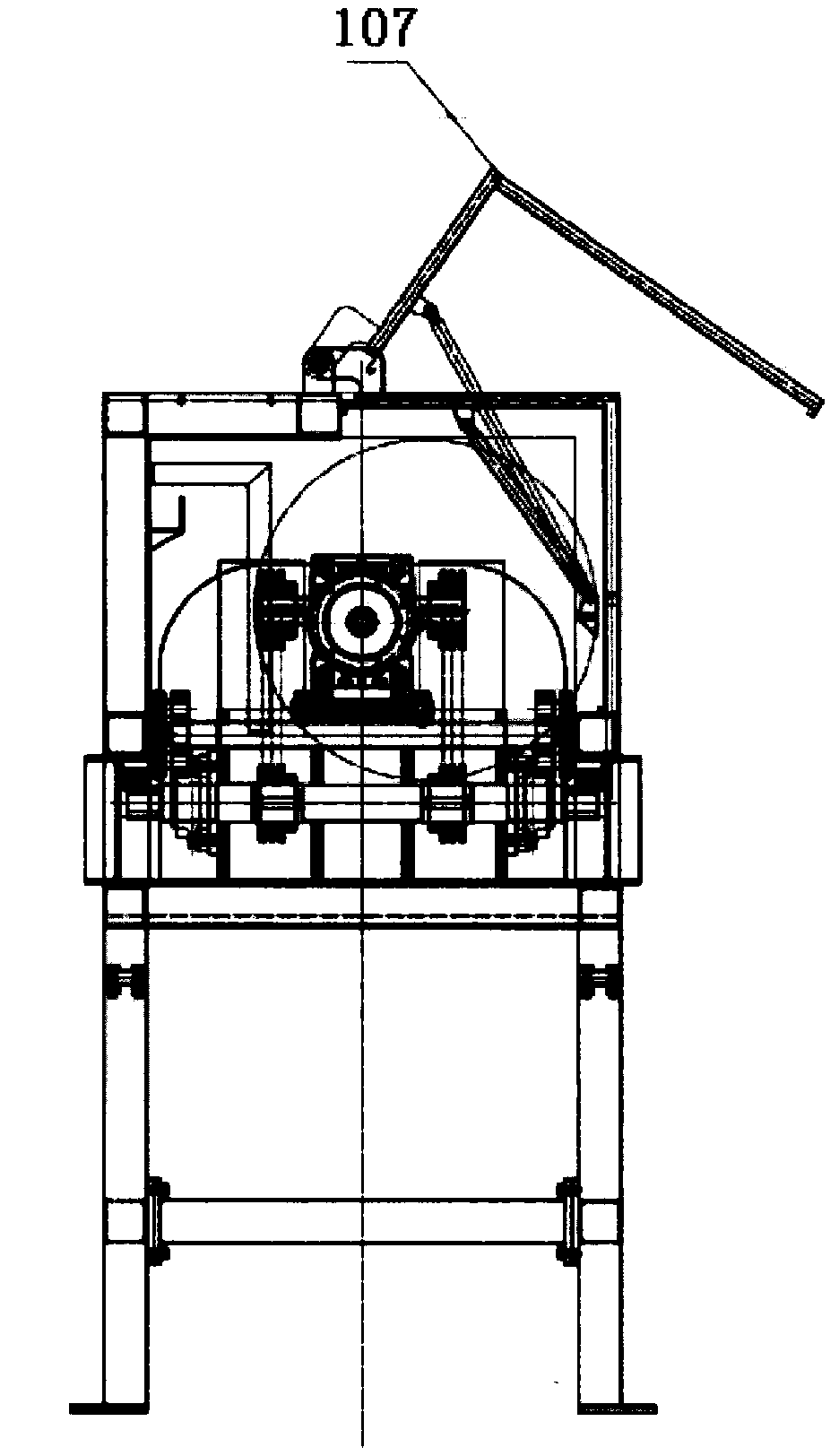

The invention relates to a device and a technical process for one-stop recovery and treatment of steel skeleton plastic composite pipes. The device comprises a pipe pushing machine, a double-shaft pipe shredding machine, a Z-shape belt conveyer, a steel wire separator, a horizontal belt conveyer and a magnet separator. The pipe pushing machine is connected to one end of the double-shaft pipe shredding machine. The Z-shape belt conveyer is disposed below the double-shaft pipe shredding machine. One end of the Z-shape belt conveyer is connected to the other end of the double-shaft pipe shredding machine, and the other end of the Z-shape belt conveyer is connected to the steel wire separator. The horizontal belt conveyer is disposed between the steel wire separator and the magnet separator. The steel wire separator is connected to the magnet separator through the horizontal belt conveyer. By the device and the technical process, success separation of plastic and steel wire in the steel skeleton plastic composite pipes can be performed smoothly and orderly.

Owner:GUANGZHOU 3E MACHINERY

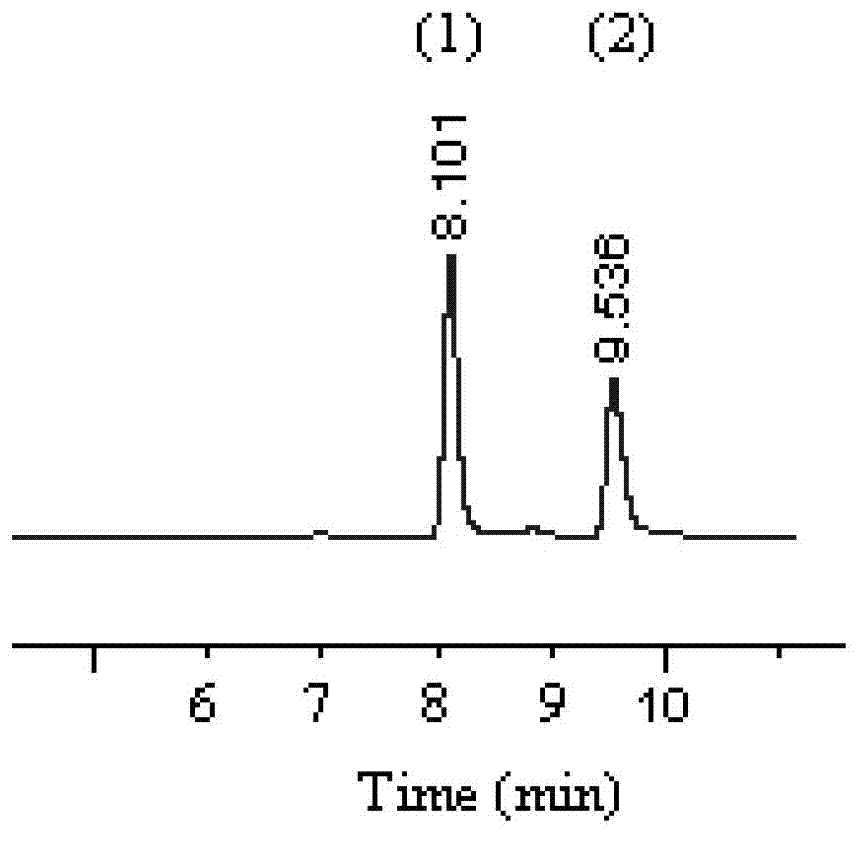

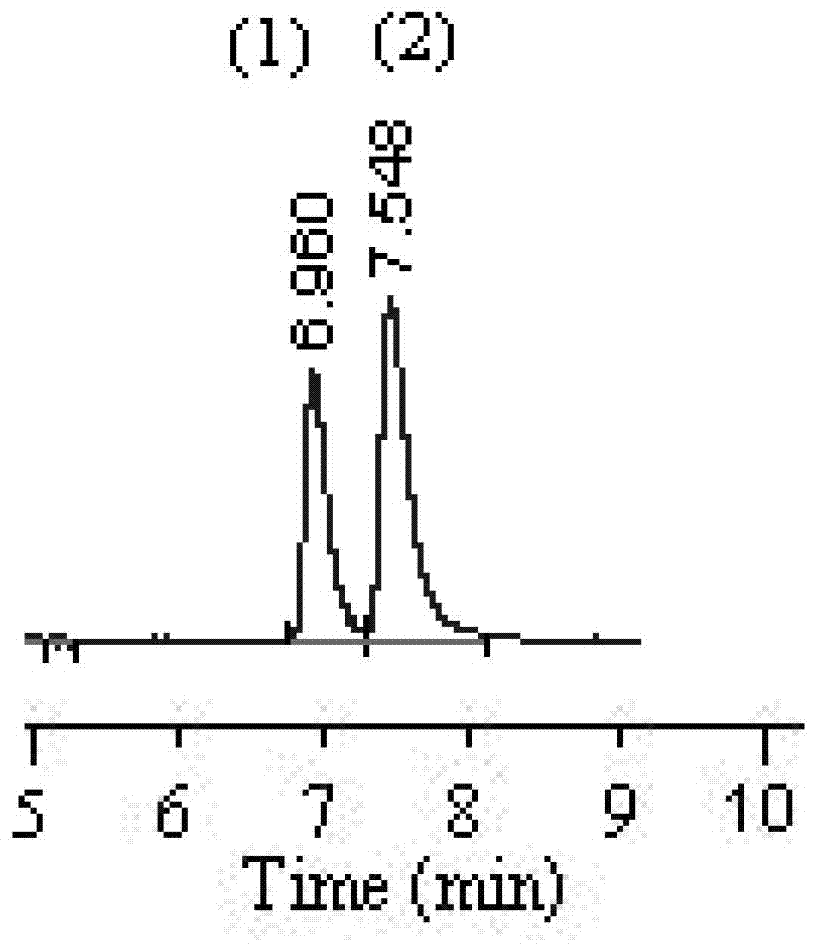

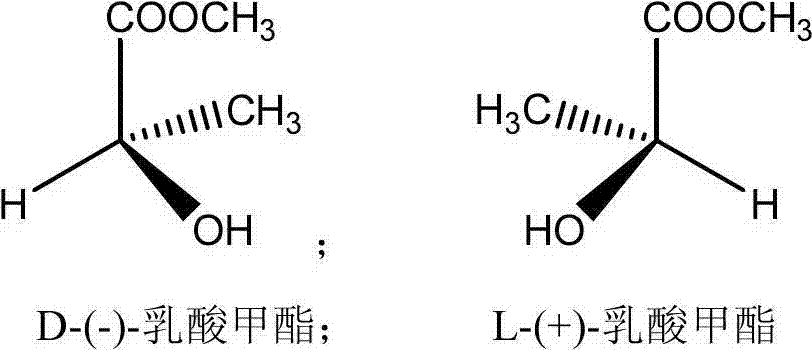

Method for determining methyl lactate optical isomer based on capillary gas phase chromatogram chiral separation

InactiveCN102759594ASeparation reachedComponent separationStationary phaseCapillary gas chromatography

The invention discloses a method for separating and detecting methyl lactate optical isomers. In the method for separating and detecting the methyl lactate optical isomers, the capillary gas phase chromatogram chiral separation method is adopted, and the preferable chromatogram conditions are as follows: a capillary chiral column taking wall coated 2,3,6-tri-O-valeryl-delta-cyclodextrin as a chiral stationary phase is adopted; a chromatogram column has the length of 20m-30m and the internal diameter of the chromatogram column is 250mum-320 mum, and a stationary phase film in the chromatogram has the thickness of 0.31mu m; a mobile phase adopts inert gases, and the flow velocity is 25-35cm / s; a detector is a hydrogen flame ionization detector; the temperature of a sample feeding port is 200-280 DEG C; the temperature of the detector is 250-280 DEG C; and the temperature of the chromatogram column is 50-80 DEG C. By using the determination method, the baseline separation of the chromatogram peaks of methyl lactate D, L enantiomers can be achieved with the separating degree reaching 6.08; and the method can simultaneously be used for the quantification of the methyl lactate D, L enantiomers.

Owner:CHINA AGRI UNIV

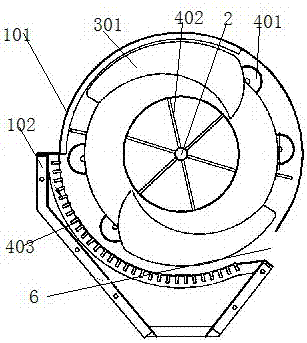

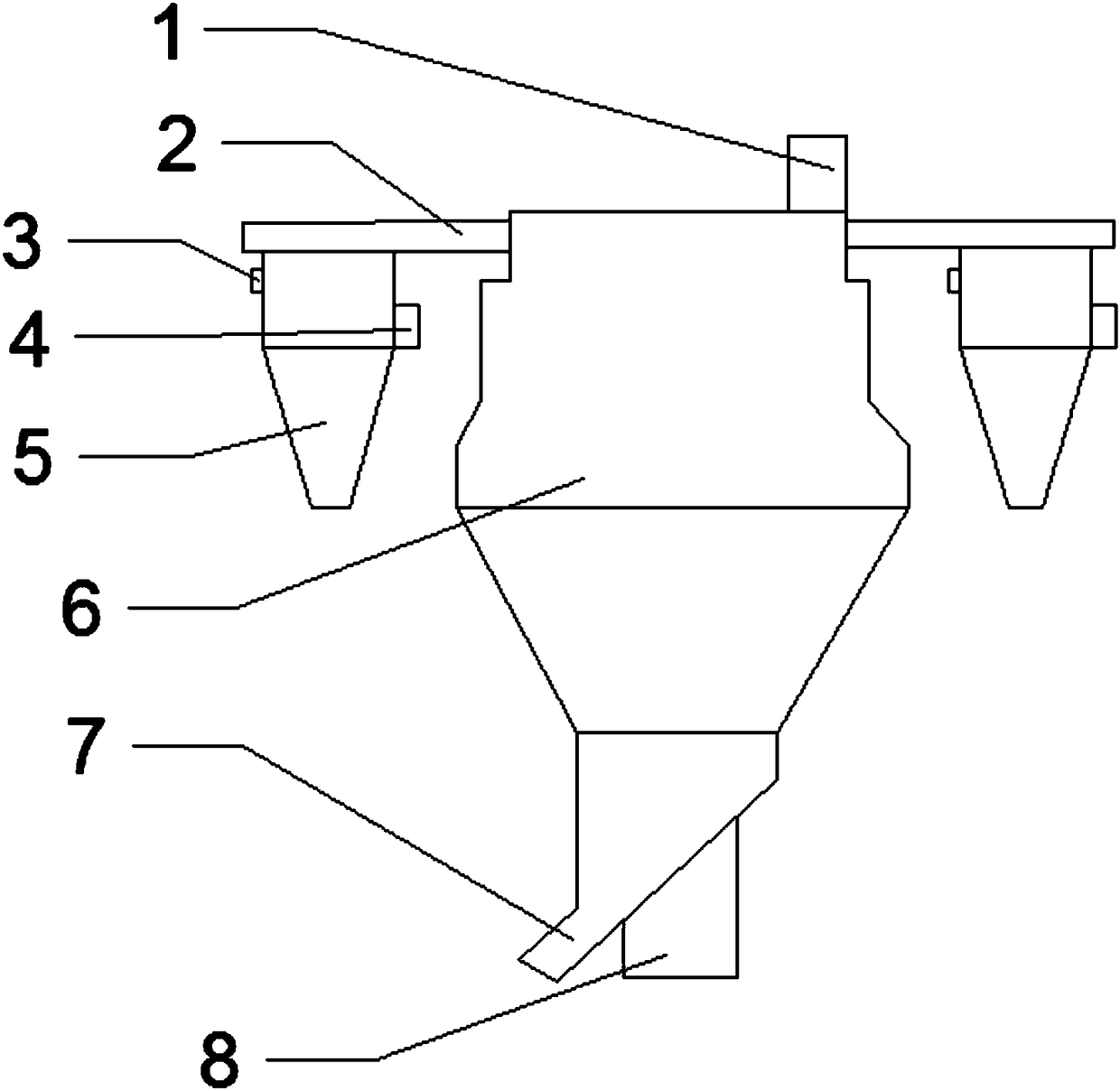

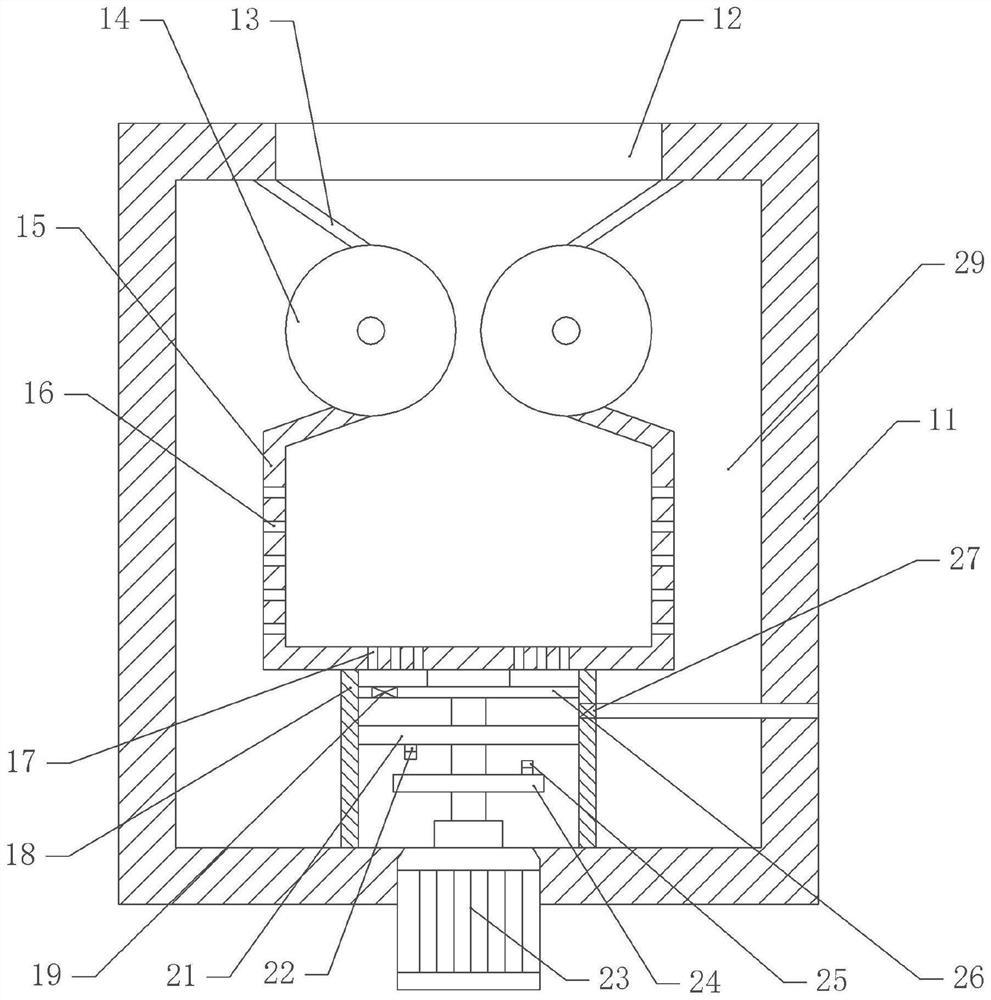

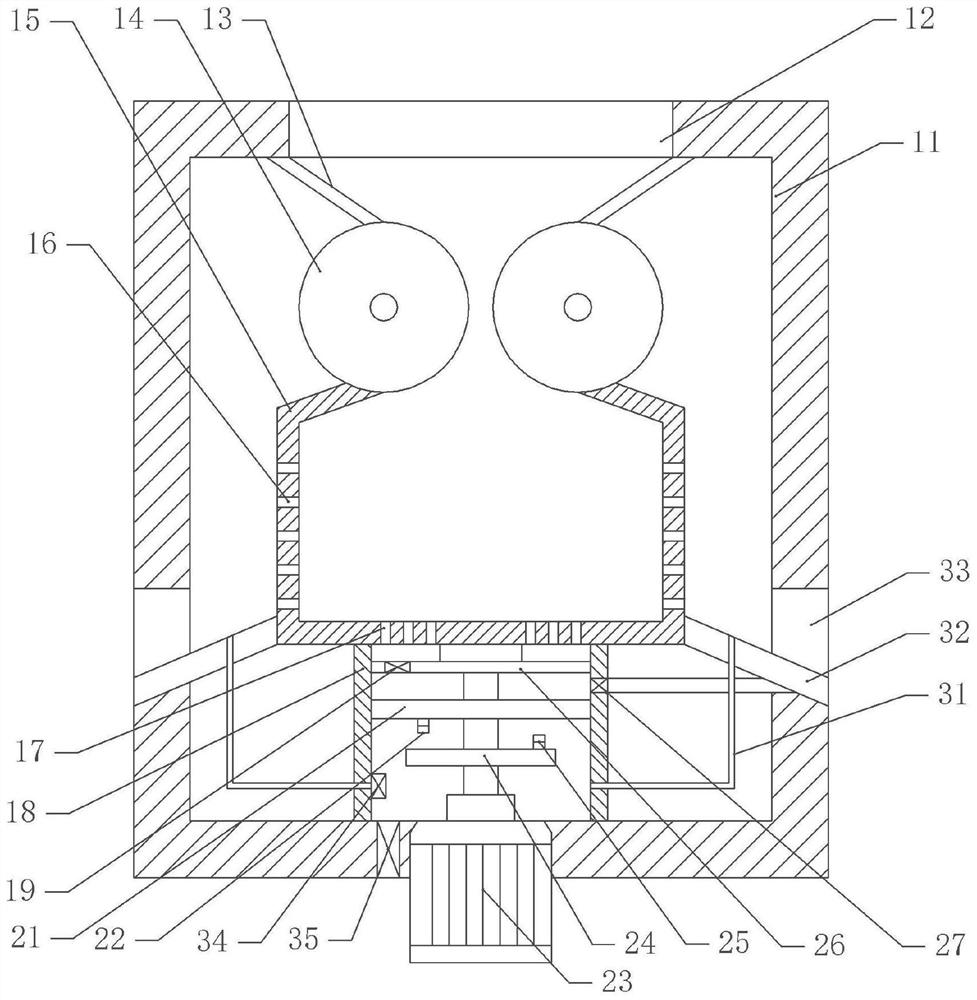

Powder concentrator being convenient for fine powder collection

PendingCN108311384ASeparation reachedAvoid causingGas current separationDispersed particle filtrationCycloneMaterials science

The invention discloses a powder concentrator being convenient for fine powder collection and relates to the technical field of mineral powder screening. The powder concentrator comprises a powder concentrator body, wherein the powder concentrator body comprises a transmission device, a feeding hopper, a shell body, a rotor and two cyclone barrels; an air inlet is arranged at the bottom end of theshell body; a fan is connected into the air inlet; the shell body communicates with the feeding hopper; ventilating pipes correspondingly communicate with two sides of the top end of the shell body;two ends of the ventilating pipes are both positioned outside the shell body; the transmission device is arranged at the inner top of the shell body; the cyclone barrels correspondingly communicate with the two ends of the ventilating pipes; openings are formed in the side walls of the cyclone barrels; collecting tanks are connected onto the openings; inclined filtering plates are rotationally connected into the cyclone barrels; the ends, far away from the rotational connecting positions, of the filtering parts are positioned in the openings, and springs are connected between the ends and thebottom ends of the openings; vibrating motors are arranged on the outer walls of the cyclone barrels; and output shafts of the vibrating motors penetrate through the side walls of the cyclone barrelsand are connected with the filtering plates. By adoption of the powder concentrator, the problem that when being collected, fine powder is blown by airflow to form flying dust, and then part of the fine powder is wasted can be solved.

Owner:ZUNYI JUYUAN BUILDING MATERIAL CO LTD

Waste separator

InactiveCN103372342AAvoid separationSeparation reachedStationary filtering element filtersWater pipeWaste management

The invention discloses a waste separator composed of a tank body, a melt water inlet, a filtered water outlet, a flushing spray head, a filter silkscreen, a filter silkscreen clamping slot, a filter silkscreen outlet, a filtered water tray and a filtered water tray outlet. The waste separator is characterized in that the melt water inlet is arranged at the uppermost end of the tank body; the flushing spray head is connected with a water pipe; the filter silkscreen clamping slot is arranged at two sides of the tank body and below the tank body; the filter silkscreen is arranged above the filter silkscreen clamping slot; the filter silkscreen outlet is arranged at the side of the filter silkscreen; the filtered water tray is arranged at the bottommost of the tank body; the filtered water tray outlet is arranged at the side of the filtered water tray; and a snow blocking silkscreen inlet and a snow blocking silkscreen outlet are arranged at the uppermost end of the tank body.

Owner:袁子淇

Rice huller

ActiveCN114308191AAchieve the purpose of separationSeparation reachedSievingGrain huskingAgricultural engineeringMechanical engineering

The invention belongs to the technical field of rice processing equipment, and provides a rice huller which comprises a machine body with an opening in the upper portion and a plurality of driving parts arranged on the machine body, rubber rollers located below the opening are coaxially fixed to output shafts of the driving parts, and a gap is reserved between every two adjacent rubber rollers; a separation barrel located below the gap is arranged in the machine body, the upper portion of the separation barrel abuts against the rubber roller, a plurality of first separation holes are formed in the side wall of the separation barrel, a power piece is fixed to the machine body, and an output shaft of the power piece is fixedly connected with the separation barrel; a supporting cylinder located outside the power part is arranged on the lower portion of the separation cylinder and is in running fit with the separation cylinder, and a plurality of second separation holes communicating with the supporting cylinder are formed in the bottom of the separation cylinder. The rice processing device is simple in structure, rice is processed and produced, rice hulls in the rice processing process are removed, and the rice processing efficiency is improved.

Owner:重庆灏真现代农业有限公司

A reinforced concrete separator

ActiveCN108283984BSeparation reachedEasy to collect and recycleSievingScreeningReinforced concreteRebar

Owner:北京博信晟益环保科技有限公司

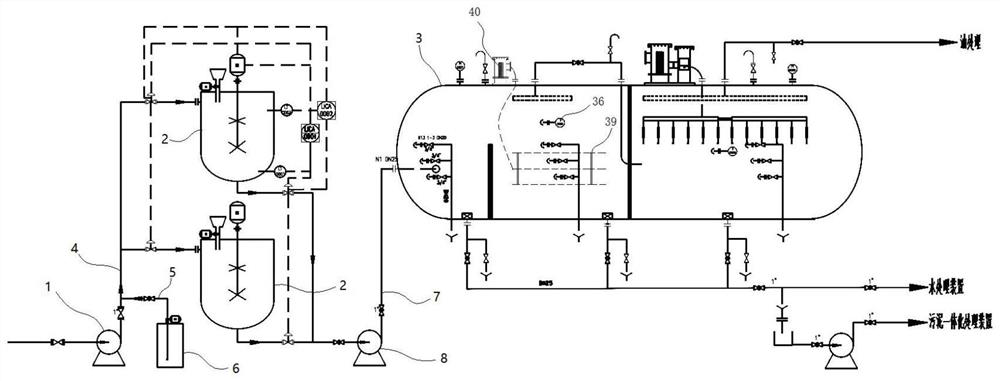

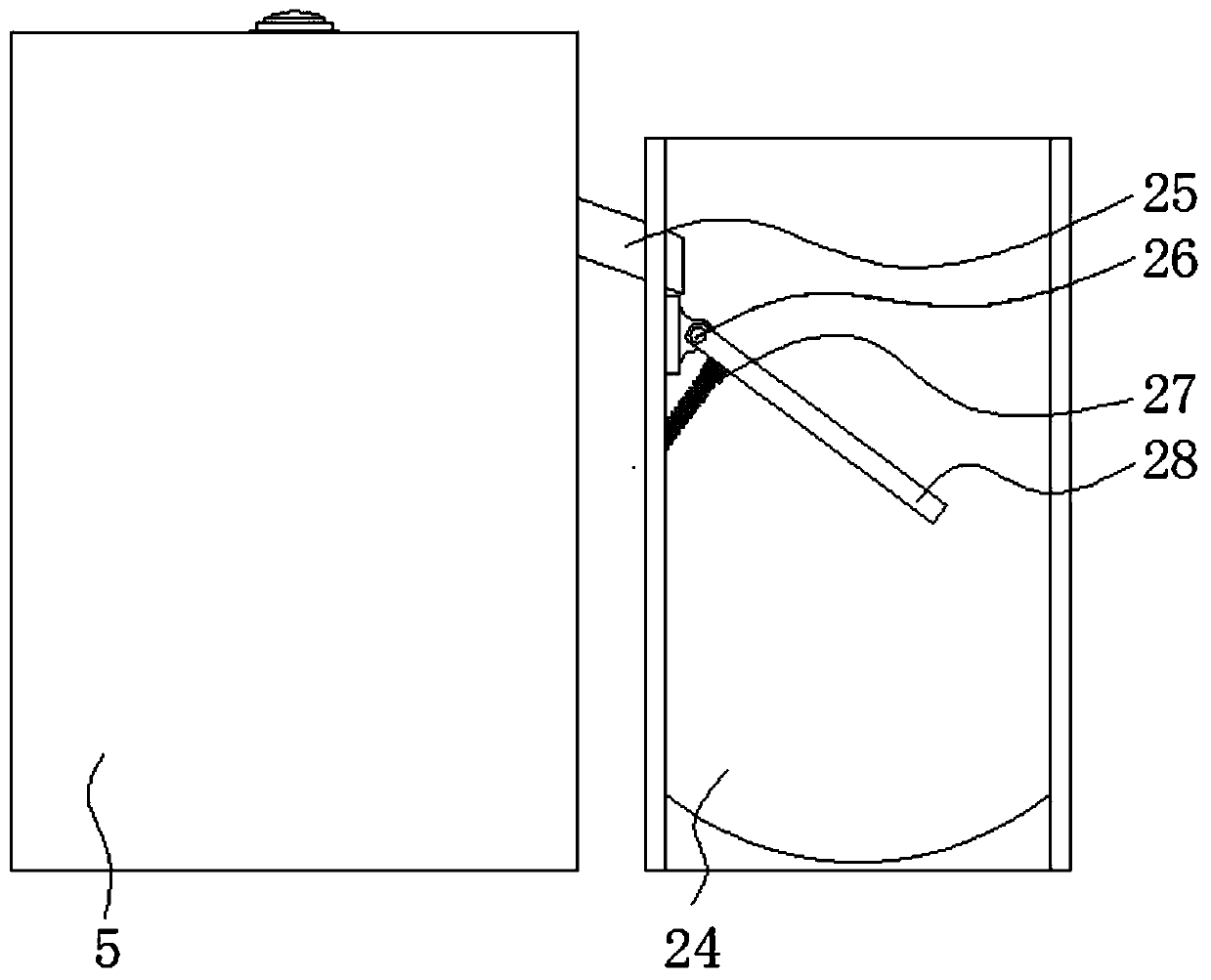

Reduction and resourceful treatment process and equipment for oily sludge and emulsified sump oil

PendingCN113213730AEasy to operateRealize the utilization of recycling resourcesSludge treatment by de-watering/drying/thickeningOil canSludge

The invention discloses a reduction and resourceful treatment process and equipment for oily sludge and emulsified sump oil. The equipment comprises a raw material pump, a material homogenizing tank, and a variable-frequency electric field modification and electric field separation refining tank, and is used for separating the oily sludge and the emulsified sump oil, and the homogeneous water-containing and oil-containing sludge is subjected to variable-frequency electric field modification and electric field separation, so that the sludge, water and oil can be quickly and efficiently separated, the recycling of crude oil, the reduction of hazardous wastewater and the harmlessness of the subsequent treatment of the sludge are realized, the environmental protection concept is met, and the requirements of recycling, harmlessness and resourceful treatment of the crude oil are met; anddifferent types of high-voltage electric fields are introduced into treatment of oily sludge and emulsified dirty oil, so the crude oil recovery rate reaches 98% or above, and the purposes of crude oil recovery and hazardous waste reduction are really achieved.

Owner:长江三星能源科技股份有限公司

Oil-water separation process for kitchen waste treatment

ActiveCN110606611APrevent splashAvoid secondary pollutionFatty/oily/floating substances removal devicesTreatment involving filtrationOil and greaseWater storage tank

The invention discloses an oil-water separation process for kitchen waste treatment and relates to the technical field of kitchen waste treatment. An oil-water separation device comprises a water storage tank and a telescopic motor, wherein a water outlet pipe is mounted on one side of the water storage tank; a first water pump is mounted on one side of the water outlet pipe; a water inlet pipe ismounted on one side of the first water pump; a water inlet pipe is arranged in the tank body, a tank body is arranged on one side of the water inlet pipe, an aluminum pipe is arranged in the tank body, an inner tank is arranged in the aluminum pipe, a stirring blade is arranged in the inner tank, a stirring shaft is fixed in the stirring blade, a filter plate is arranged above the stirring shaft,and a stirring arm is arranged above the filter plate. According to the oil-water separation process for kitchen waste treatment, a water-oleophobic microporous filter membrane is arranged, under theaction of gravity, due to the fact that the density of grease in water is smaller than that of water, the grease floats on the surface of sewage, water on the lower portion is separated through the water-oleophobic microporous filter membrane, and oil-water separation is achieved.

Owner:桐乡恒易环保科技有限公司

Multi-stage nitrogen recovery system and recovery method

InactiveCN110482500AAvoid wastingSolve real problems of waste and impact on the environmentNitrogen purification/separationSolidificationRecovery methodEnvironmental resistance

The invention discloses a multi-stage nitrogen recovery system and a recovery method. The system sequentially comprises a first-stage recovery system and a second-stage recovery system. The first-stage recovery system utilizes the dissolution-diffusion principle, namely molecules move towards the chemical potential reduction direction through a membrane, and because the speeds of gas with different components in mixed gas passing through the membrane are different, the purposes of gas separation and gas recovery are achieved. Molecules of nitrogen are different from olefin and hydrogen molecules, and the purity of nitrogen subjected to multistage separation can reach 99% or above. An unpowered expansion cryogenic technology is adopted in the second-stage recovery system, wherein gas with certain pressure is subjected to adiabatic expansion in an expansion machine to do work outwards to consume the internal energy of the gas, so that the gas is cooled intensively to achieve the purposeof refrigeration, nitrogen is liquefied and recycled, and the low temperature can be generated without any external energy consumption or power. The multi-stage nitrogen recovery system and the methodhave the advantages of a simple structure, a simple flow, a low cost, economy, environmental protection and the like.

Owner:JIANGSU XINJIUYANG ENVIRONMENTAL PROTECTION EQUIP TECH

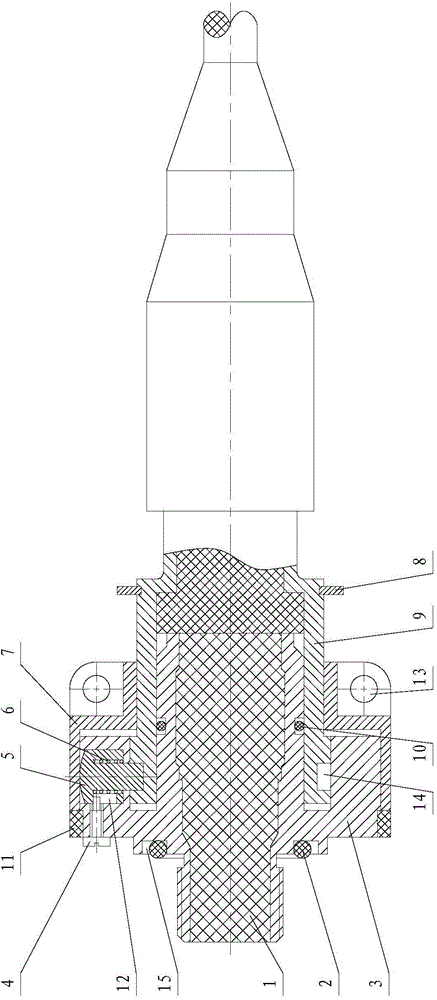

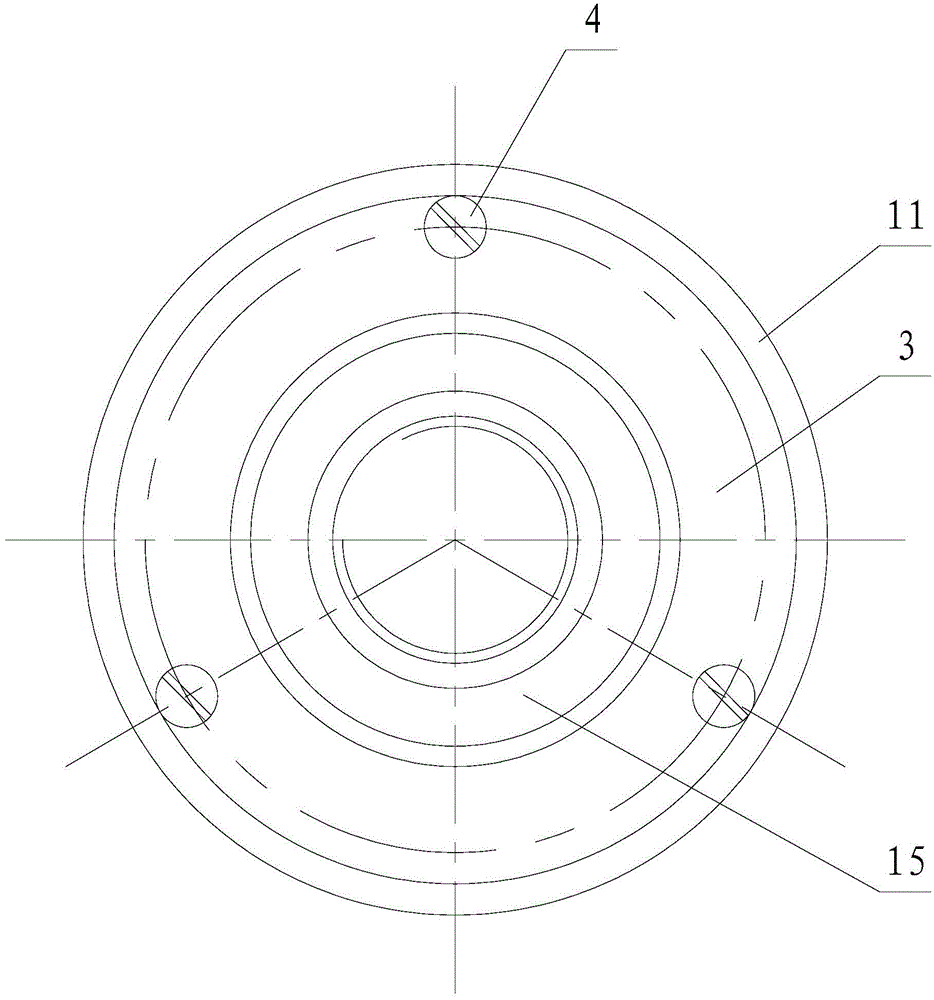

Automatic separating type waterproof connector

ActiveCN104682086ASimple structureEasy to installEngagement/disengagement of coupling partsTwo-part coupling devicesUnderwaterBiomedical engineering

The invention belongs to the field of underwater submersibles, and particularly relates to an automatic separating type waterproof connector, which comprises a waterproof insertion head and a waterproof insertion seat, wherein the waterproof insertion seat comprises an insertion seat shell and a magnet ring; one side of the waterproof insertion seat is arranged on a submersible body; the magnet ring is arranged on the external circumferential face of the insertion seat shell; the waterproof insertion head comprises an insertion head shell and an unlocking sleeve; one side of the insertion head shell is arranged on external equipment; the other side of the insertion head shell is in seal insertion with the insertion seat shell; the unlocking sleeve sleeves the insertion head shell; one end of the unlocking sleeve is connected with the magnet ring through magnetic force; the waterproof insertion head and the waterproof insertion seat are connected into a whole through the magnetic force between the magnet ring and the unlocking sleeve; the other end of the unlocking sleeve is connected with the external equipment through a rope; after the external equipment is separated from the submersible, the unlocking sleeve is separated from the magnet ring through the dead load of the external equipment, so that the separation of the waterproof insertion head and the waterproof insertion seat is realized. After the submersible is separated from the external equipment, the automatic separating type waterproof connector can be separated automatically, and is simple in structure, and convenient to install and separate.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Concentration method of pseudo-ginseng total saponin extracting solution

ActiveCN102441016BConcentration effect is goodReduce hydrolysis rateOrganic active ingredientsPlant ingredientsReverse osmosisGinseng

The invention relates to a concentration method of a pseudo-ginseng total saponin extracting solution. A reverse osmosis process is mainly utilized to concentrate the pseudo-ginseng total saponin extracting solution. The concentration method provided by the invention has the advantages of favorable concentration effect and small loss.

Owner:GUANGXI WUZHOU PHARMA GRP

Method for extracting and separating xanthohumol and flavone compounds

ActiveCN102040500BSeparation reachedMeet analysisSugar derivativesSugar derivatives preparationOrganic filmAlcohol

The invention relates to a method for extracting and separating xanthohumol and flavone compounds. The method comprises the following steps of: leaching hops and a supercritical CO2 extraction residue thereof with an alcohol solution to ensure that flavone compounds, particularly xanthohumol, are sufficiently dissolved out; filtering to obtain a filter liquor after leaching, and decompressing anddistilling the filter liquor to obtain a concentrated liquor; centrifuging the concentrated liquor, taking an obtained supernate, and filtering by using a 0.45muL of organic film; removing partial impurities, and eluting with an eluant to elute the flavone compounds from macroporous adsorption resin; collecting effluent liquid and concentrating; and freezing and drying to obtain yellow powder. In the invention, the hops, the supercritical CO2 extraction residue, and the like are used as raw materials, particularly, a waste material which is the supercritical CO2 hop extract extraction residuein a hop product processing process is used as the raw material, thus the xanthohumol which has the main efficacy and is difficult to separate is independently extracted, and other flavone compounds rich in the hop waste material are also extracted; and the invention also provides a development approach for hops which cannot be used for beer brewing, thereby improving the resource utilization ratio and the added value of the hops and having important significance to prolonging the hop industrial chain.

Owner:TIANJIN UNIV OF SCI & TECH

Oil-water separation process for kitchen waste treatment

ActiveCN110606611BPrevent splashAvoid secondary pollutionFatty/oily/floating substances removal devicesTreatment involving filtrationOil and greaseWater storage

The invention discloses an oil-water separation process for kitchen waste treatment, and relates to the technical field of kitchen waste treatment, in particular to an oil-water separation process for kitchen waste treatment, comprising a water storage tank and a telescopic motor. A water outlet pipe is installed on one side, and a first water pump is installed on one side of the water outlet pipe, a water inlet pipe is installed on one side of the first water pump, and a tank body is installed on one side of the water inlet pipe, and the inside of the tank body is arranged There is an aluminum tube, and an inner tank is arranged inside the aluminum tube, a stirring blade is arranged inside the inner tank, and a stirring shaft is fixed inside the stirring blade, a filter plate is installed above the stirring shaft, and the filter plate is A stirring arm is installed above. The oil-water separation process for kitchen waste treatment is provided with a water-oleophobic microporous filter membrane. Under the action of gravity, since the density of oil in water is lower than that of water, the oil floats on the surface of sewage, so the lower water passes through the water-oleophobic microporous membrane. Pore filter membrane separation, so as to achieve oil-water separation.

Owner:桐乡恒易环保科技有限公司

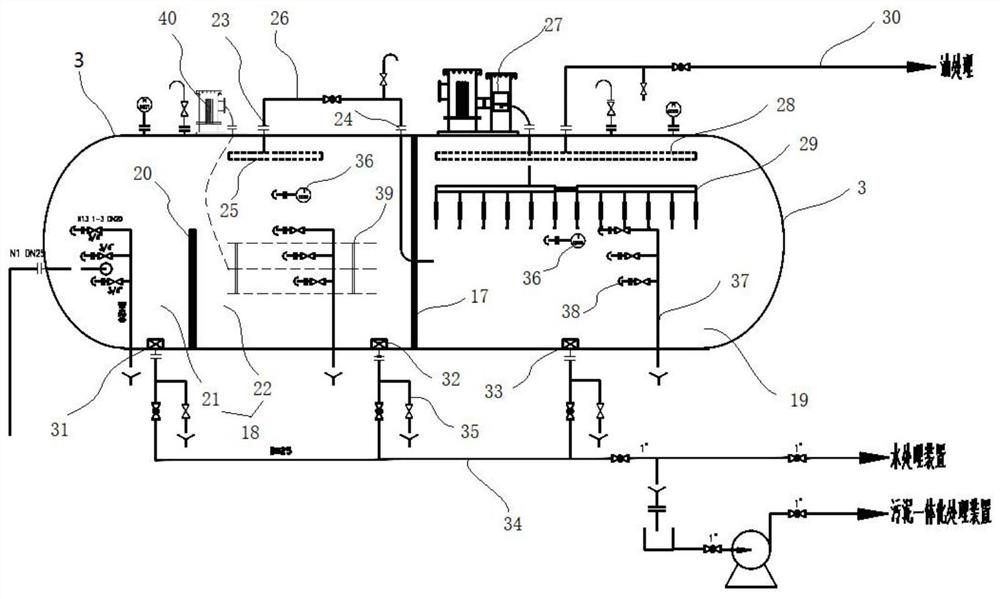

Suburb domestic sewage ecological interception equipment

InactiveCN112520873ASeparation reachedAvoid influenceFatty/oily/floating substances removal devicesSpecific water treatment objectivesOil and greaseSewage

The invention discloses suburb domestic sewage ecological interception equipment which structurally comprises a purification box, a sewage connector and a conduction pipe, the sewage connector is fixedly embedded in the end face of the left side of the purification box, the sewage connector is embedded in the lower portion of the left side of the conduction pipe, and the conduction pipe is embedded in the upper end face of the purification box; as the density and the mass of grease are smaller than those of sewage, the grease floats on the surface of the sewage, when the sewage flows along thesurface of the lower end of the filtering mechanism, the grease floating on the surface of the upper end of the sewage flows into the flowing groove along the guide of the collecting mechanism, and then enters the separating mechanism by utilizing the guide block and changing the flowing direction to be collected; due to the fact that the second leakage opening and the sealing plate are arrangedin the leakage opening, in the flowing process of sewage, heavy sewage can be discharged outwards along the collection opening and the flow guide hole along with leakage of the second leakage opening,separation of the sewage and the grease is achieved, and the grease is prevented from affecting filtering in equipment.

Owner:郑温斌

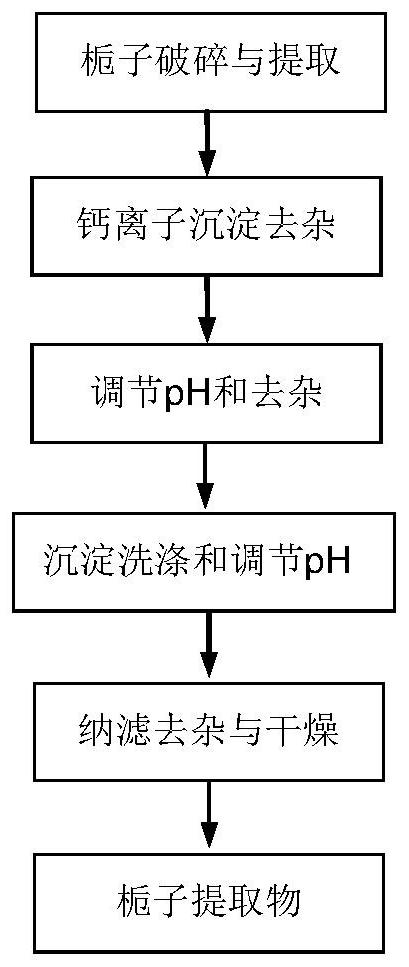

Preparation method of gardenia extract

ActiveCN112717009AHard to releaseSolve dissolutionSugar derivativesSugar derivatives preparationGARDENIA FRUIT EXTRACTTraditional medicine

The invention discloses a preparation method of a gardenia extract, which comprises the following steps: (1) carrying out crushing, primary enzymolysis extraction and secondary water extraction on fresh gardenia to obtain a gardenia water extracting solution; (2) precipitating the water extract of cape jasmine by calcium ions under an alkaline condition to remove impurities, so as to obtain an alkaline precipitate and an alkaline supernatant; (3) adjusting the pH of the alkaline supernatant, and removing impurities to obtain a subacid precipitate and a subacid supernatant; (4) mixing the alkaline precipitate and the subacid precipitate, adding water to wash the precipitate, and adjusting the pH value to obtain a subacid washing solution; and (5) performing nanofiltration impurity removal and drying: combining subacid supernatant and subacid washing, carrying out secondary nanofiltration impurity removal and concentration, and drying to obtain the gardenia extract product. The method is low in cost, sufficient in impurity removal, high in product purity, good in environmental friendliness, low in energy consumption and high in extraction utilization rate.

Owner:HUBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com