A reinforced concrete separator

A reinforced concrete and separator technology, applied in solid separation, chemical instruments and methods, grain processing, etc., can solve problems such as inability to separate metals, and achieve the effect of convenient collection, recycling and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

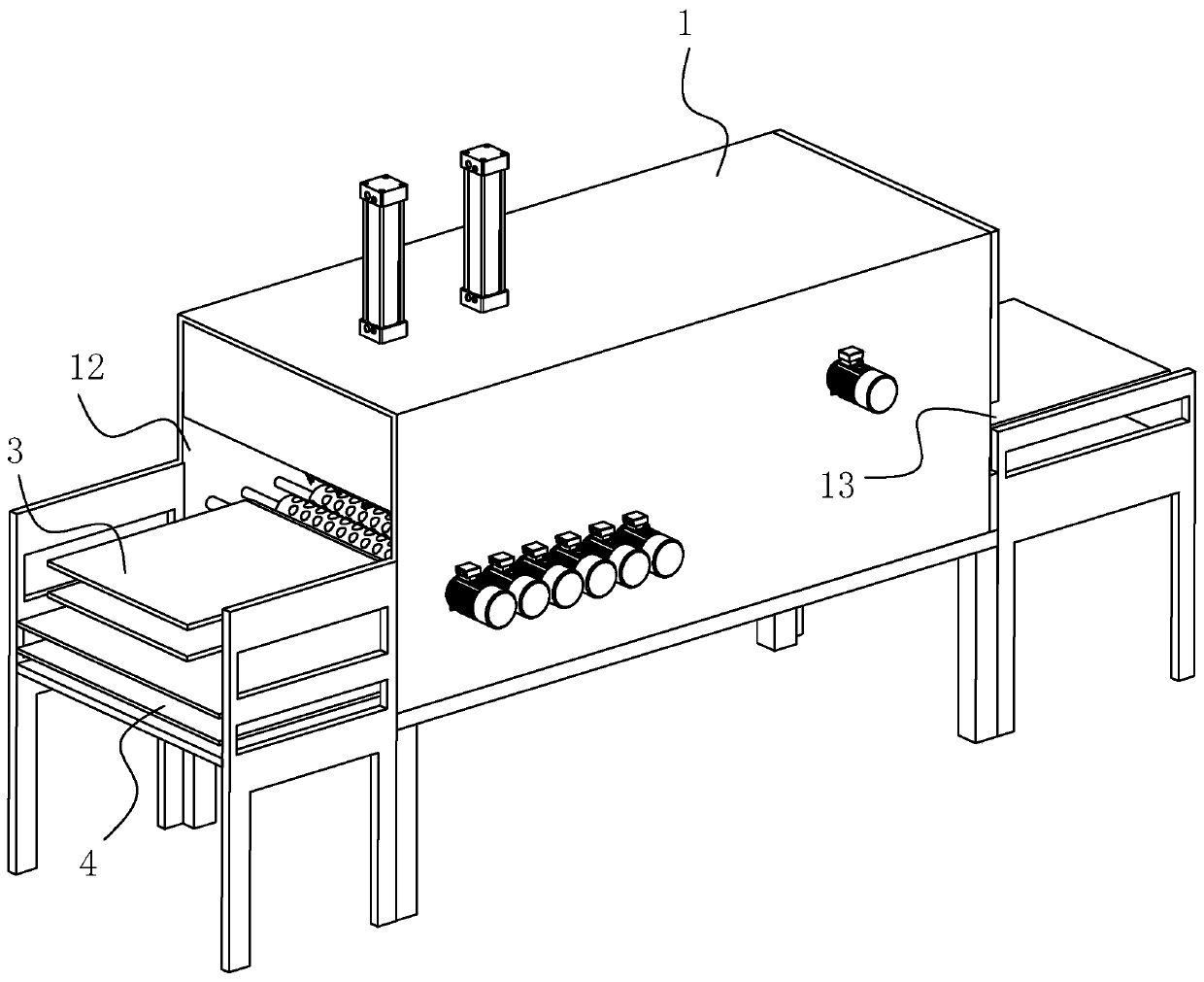

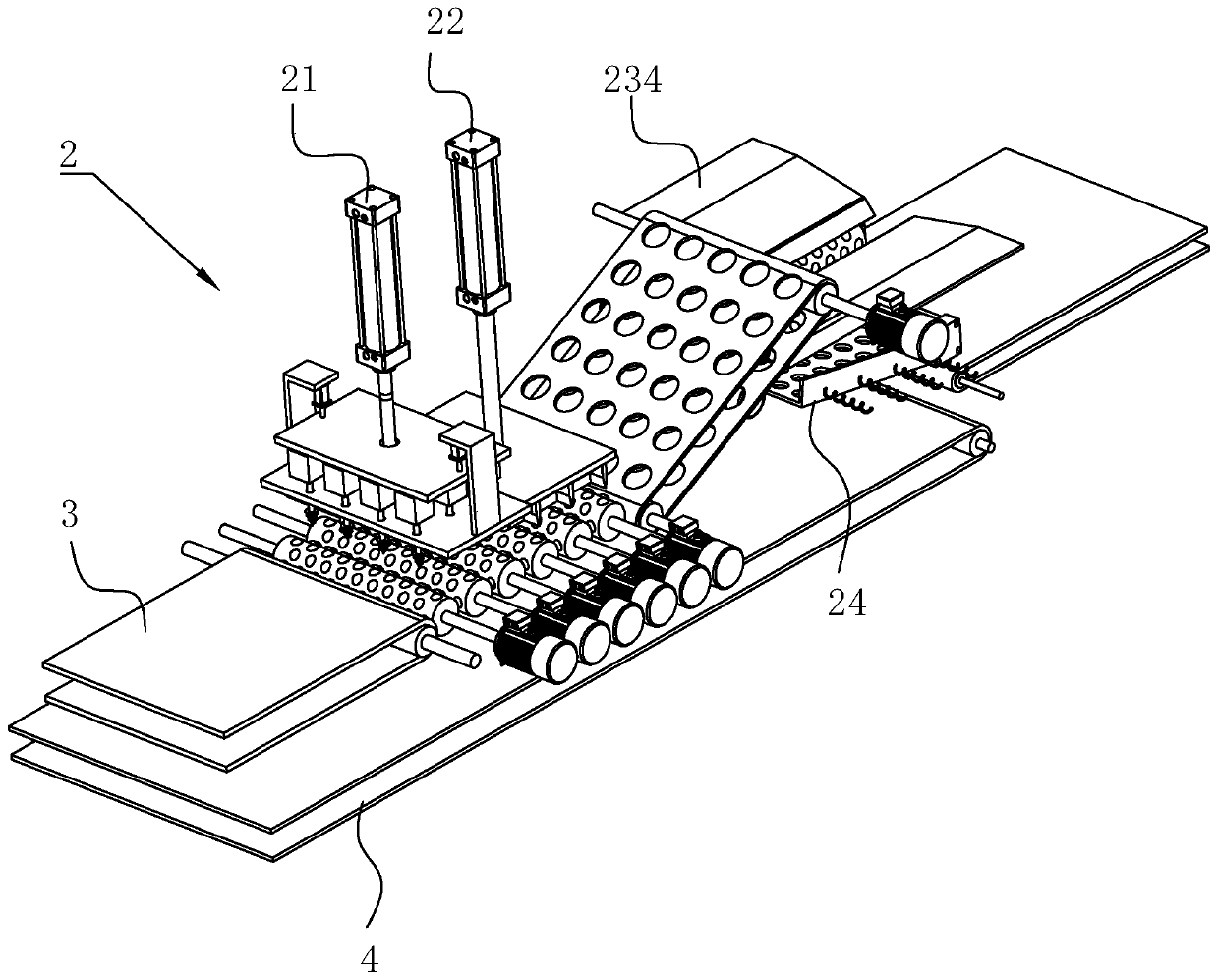

[0028] A reinforced concrete separator, such as figure 1 As shown, it includes a rectangular casing 1 supported on the ground, a rectangular feeding port 12 is provided on one side of the casing 1, and a rectangular discharging port 13 is provided on a side of the casing 1 facing away from the feeding port 12. The shell 1 is provided with a separation and crushing device 2 for crushing and collecting reinforced concrete. The casing 1 is provided with a primary conveyor belt 3 that guides the concrete wrapped with steel bars to the feed port 12 .

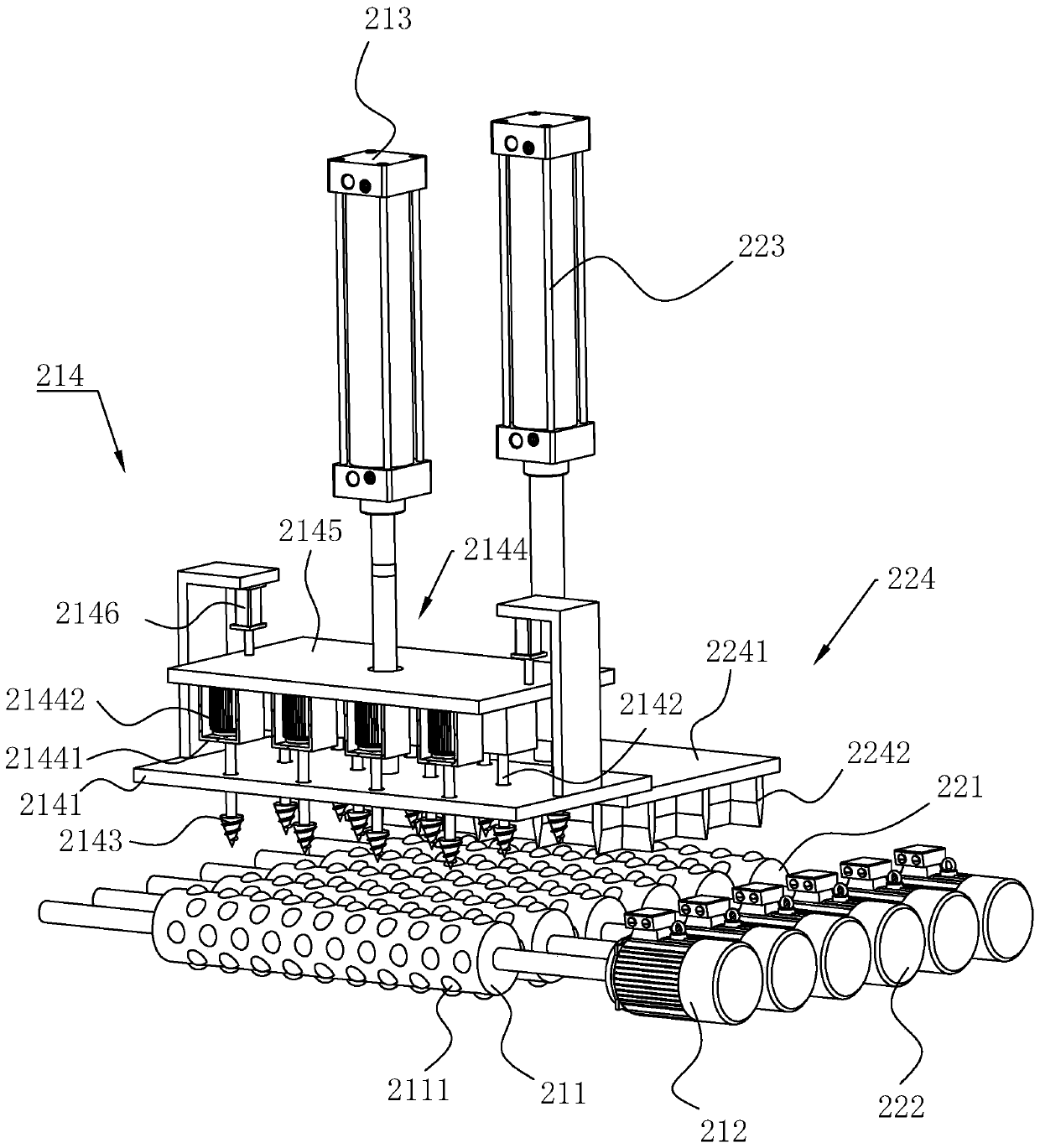

[0029] Such as figure 1 and figure 2 As shown, the crushing device includes a stamping mechanism 21, a press-cutting mechanism 22, and a rolling mechanism 23 arranged sequentially from the feed port 12 to the discharge port 13 in the casing 1 (here Figure 4 shown) and vibrating screen mechanism 24.

[0030] Such as figure 2 and image 3 As shown, the stamping mechanism 21 includes a feed port 12 (here as figure 1 shown) and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com