Patents

Literature

64results about How to "Easy to collect and recycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

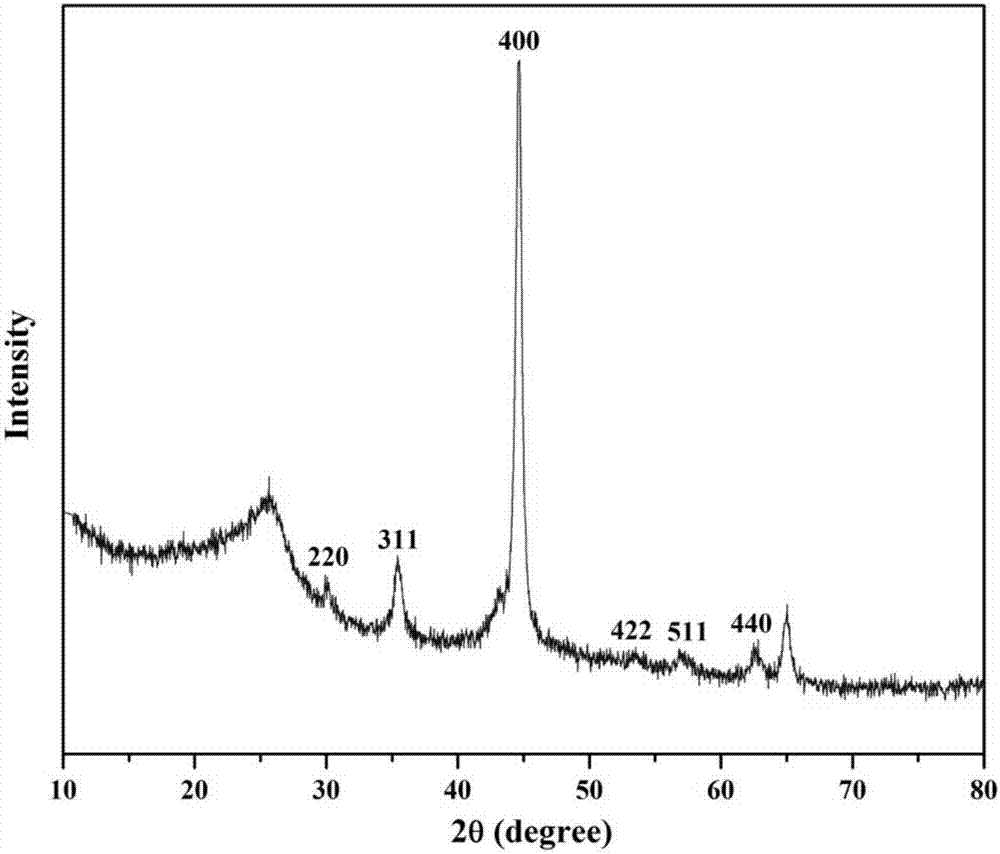

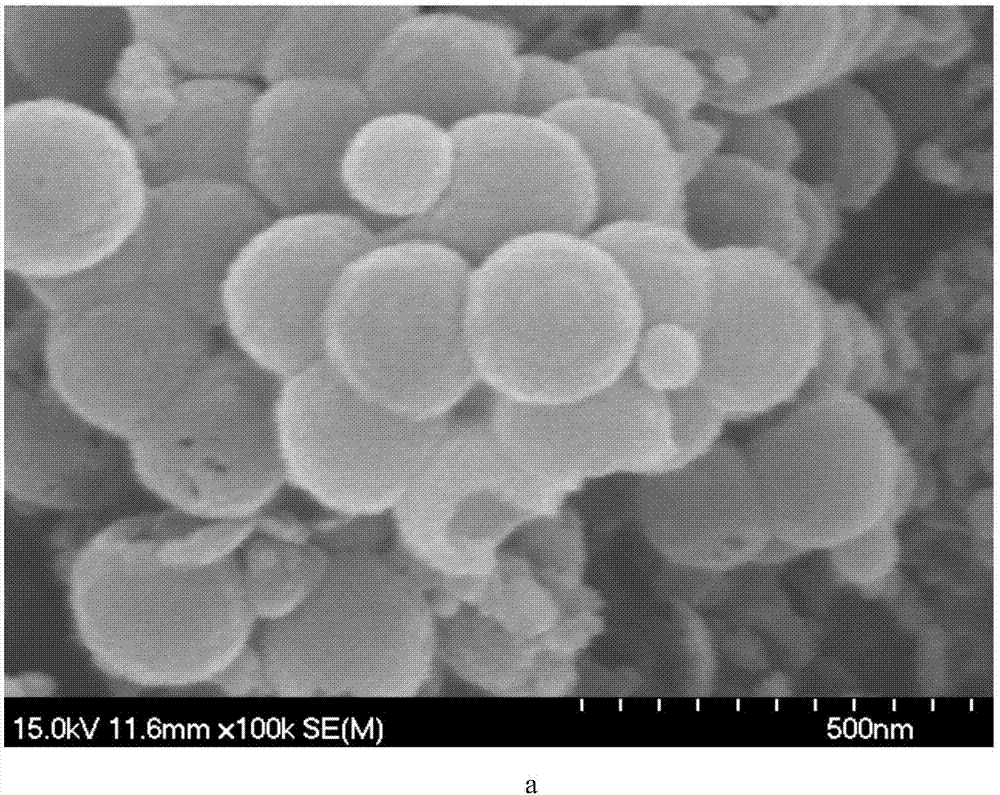

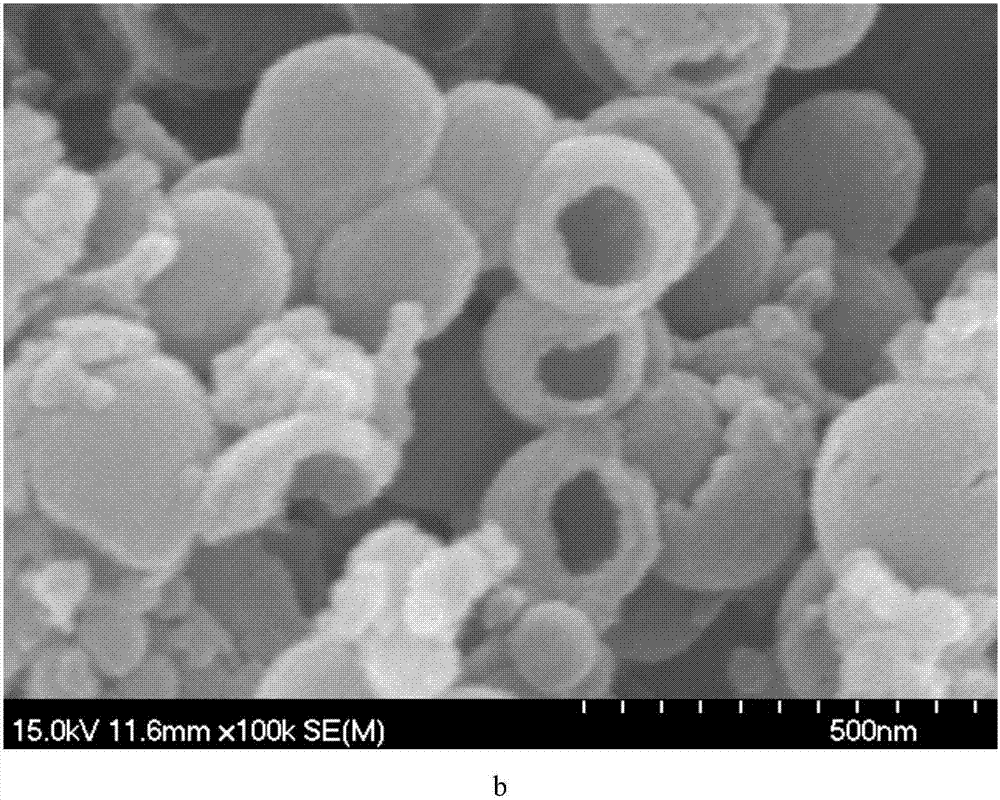

CoFe2O4/N/C hollow nanosphere and preparation and application thereof

InactiveCN106984261AImprove distributionImprove adsorption capacityPhysical/chemical process catalystsOther chemical processesMicrosphereCarbonization

The invention discloses a CoFe2O4 / N / C hollow nanosphere and preparation and application thereof. The preparation comprises: complexing dopamine with cobalt and iron metal ions under the condition of pH8-9 on a template as a SiO2 nanometer sphere to form a polymer shell layer, carbonization annealing to form N-doped carbon material loaded with CoFe2O4 metal nanoparticles, and finally, removing the SiO2 template with strong alkali to obtain CoFe2O4 / N / C hollow nanosphere. In the invention, the N / C matrix hollow structure is prepared by using the SiO2 nanosphere as the sacrificial template, theCoFe2O4 / N / C hollow nanosphere has a relatively large specific surface area and porosity, and can improve the distribution of CoFe2O4 nano metal particles loaded on the shell layer, enhance adsorption and catalytic activity on organic pollutants in waste water, and broaden the pH application range; the CoFe2O4 / N / C hollow nanosphere can be recycled due to magnetic performance, thus saving resources.

Owner:ZHEJIANG UNIV OF TECH

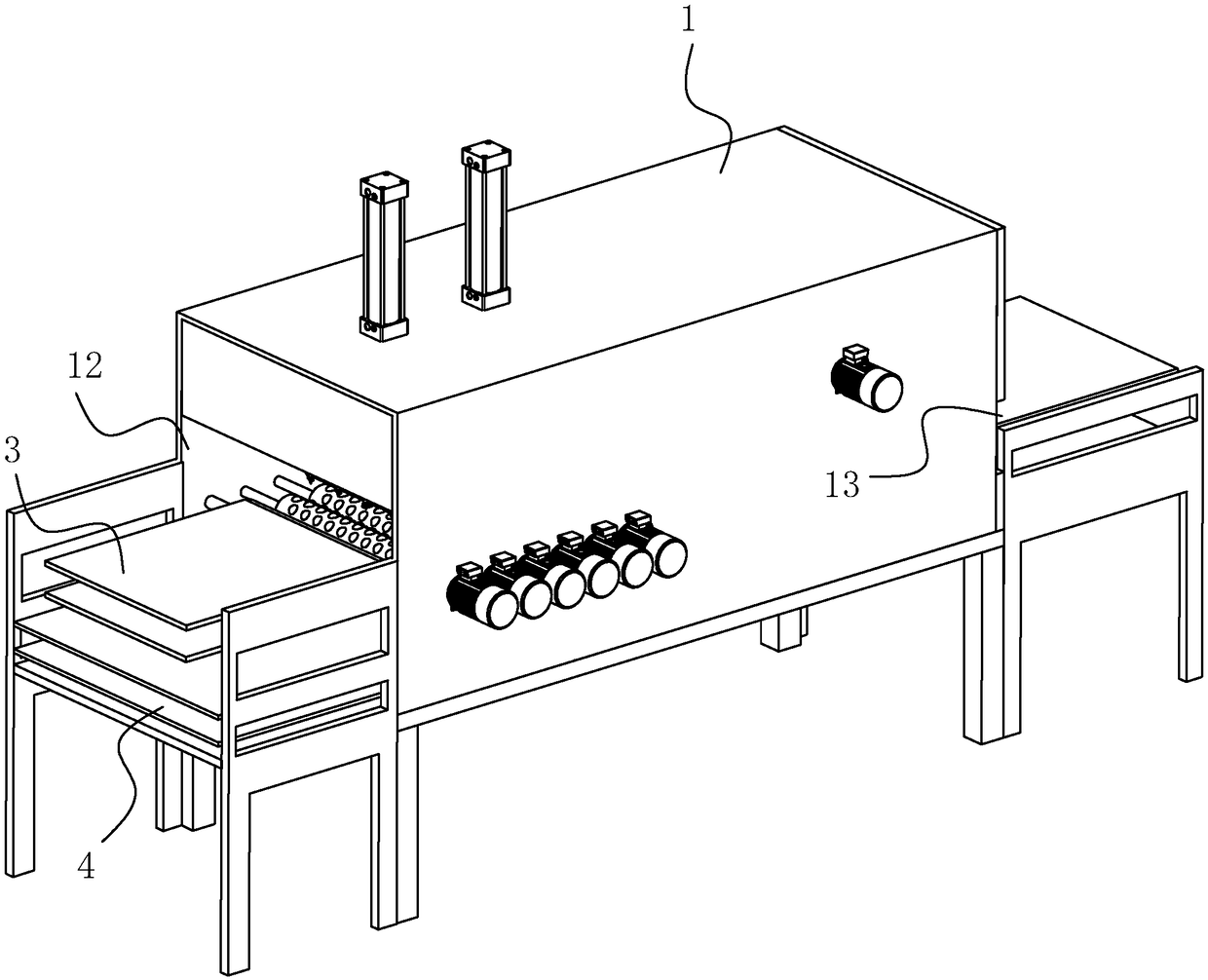

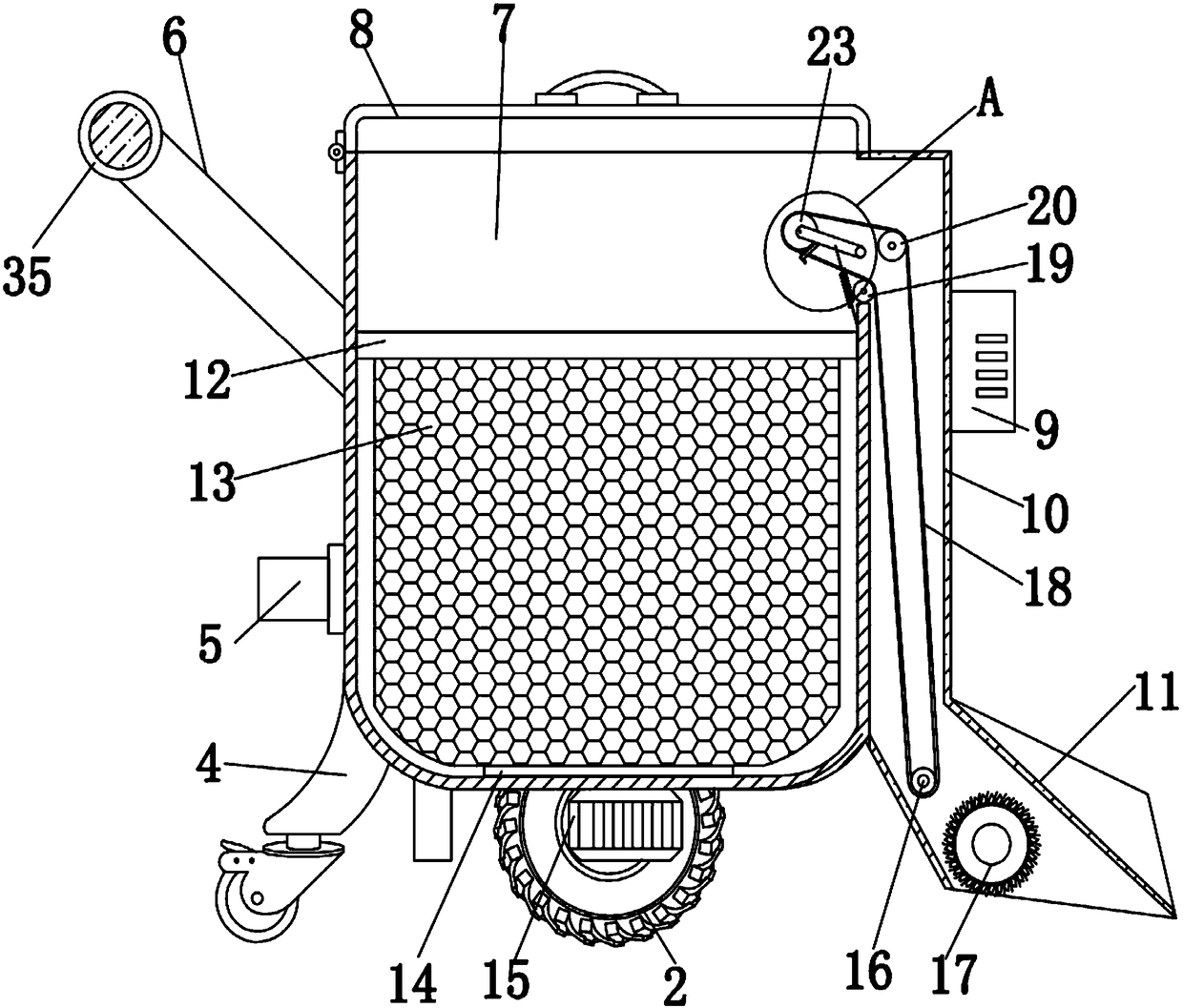

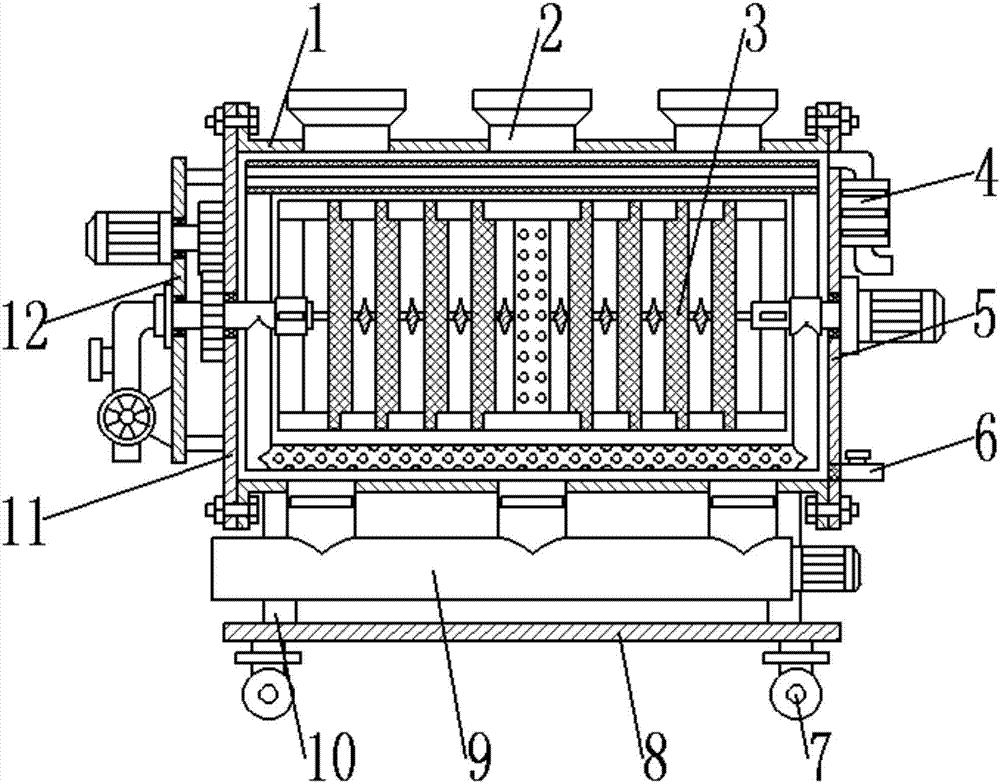

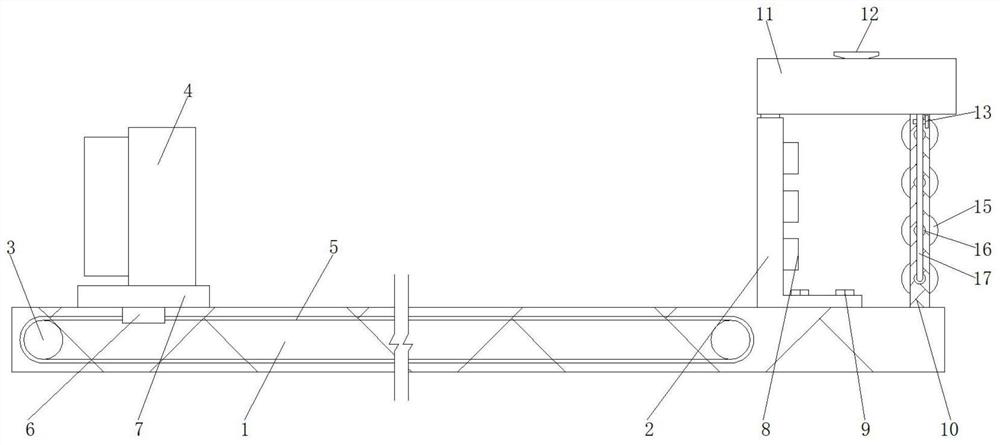

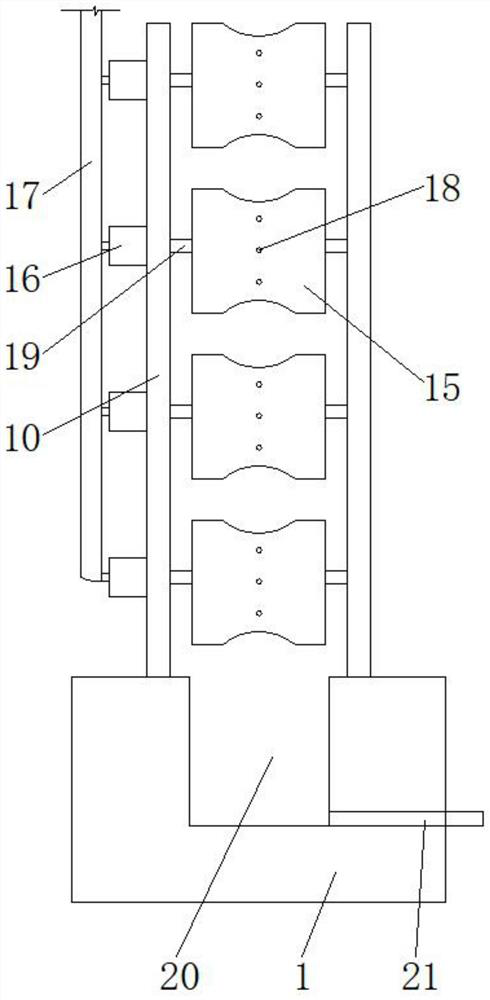

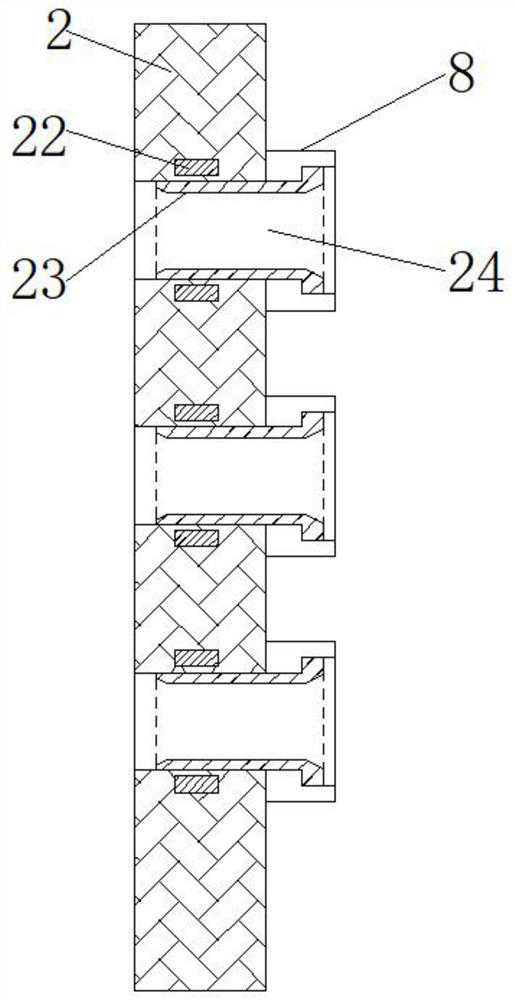

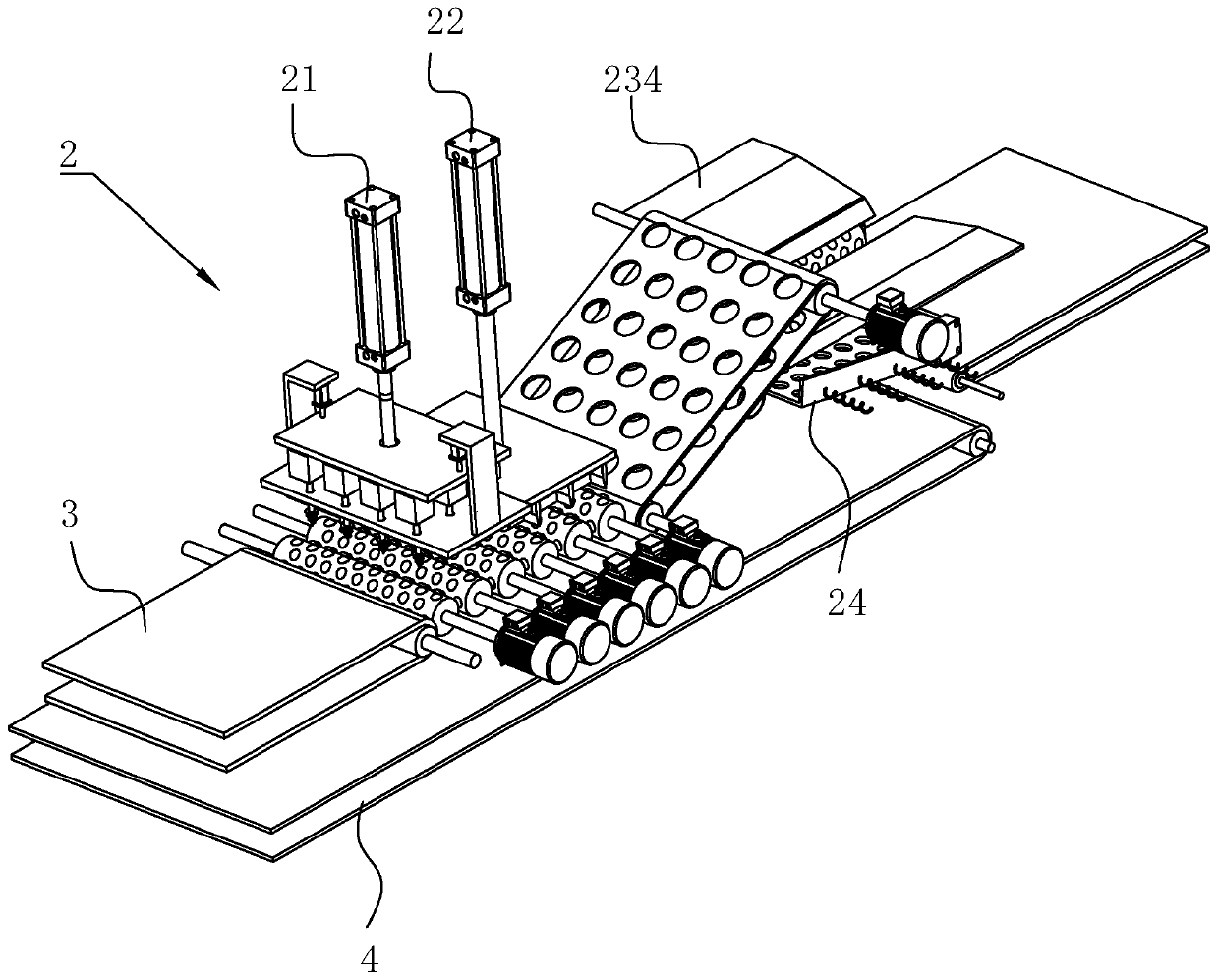

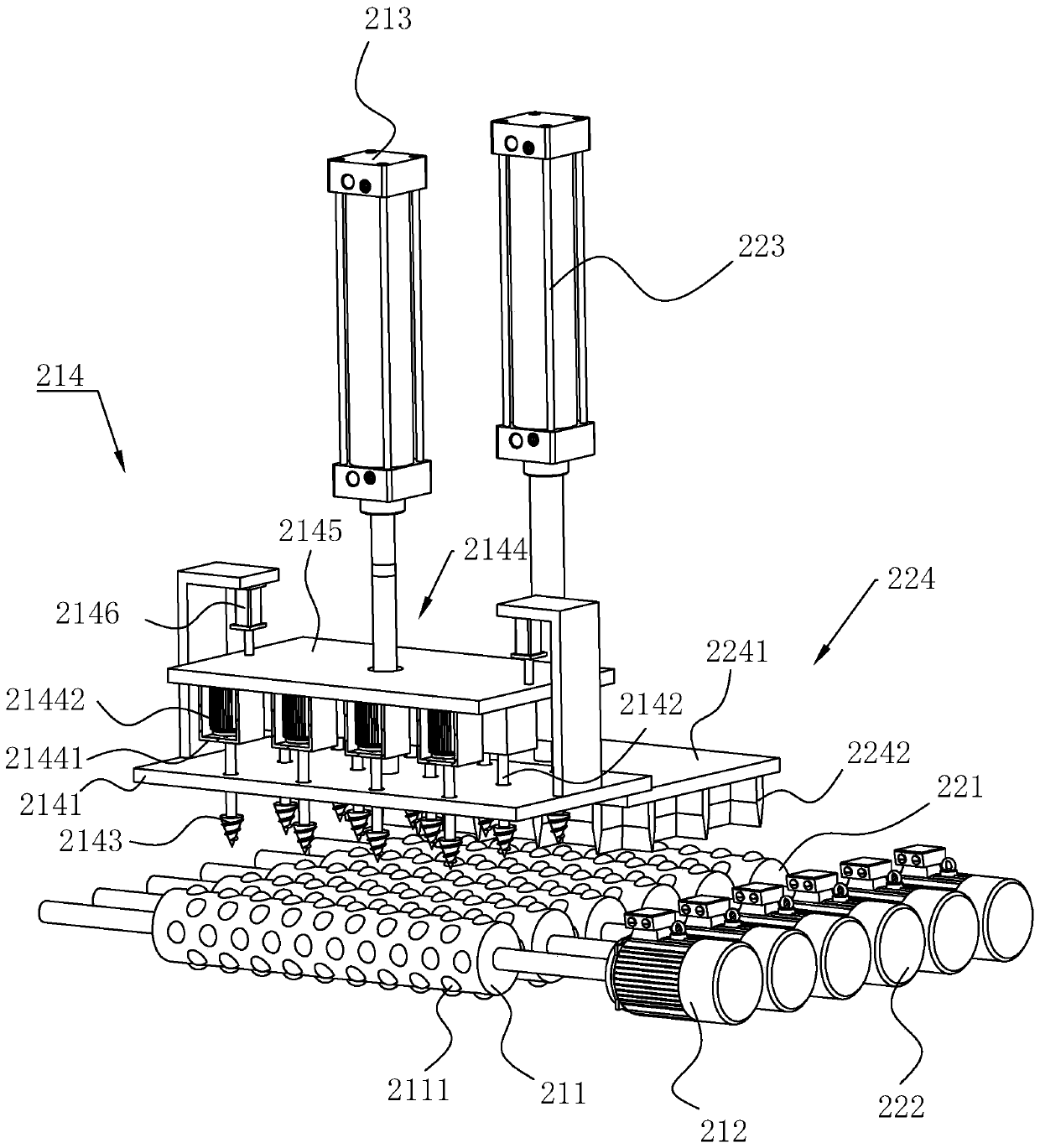

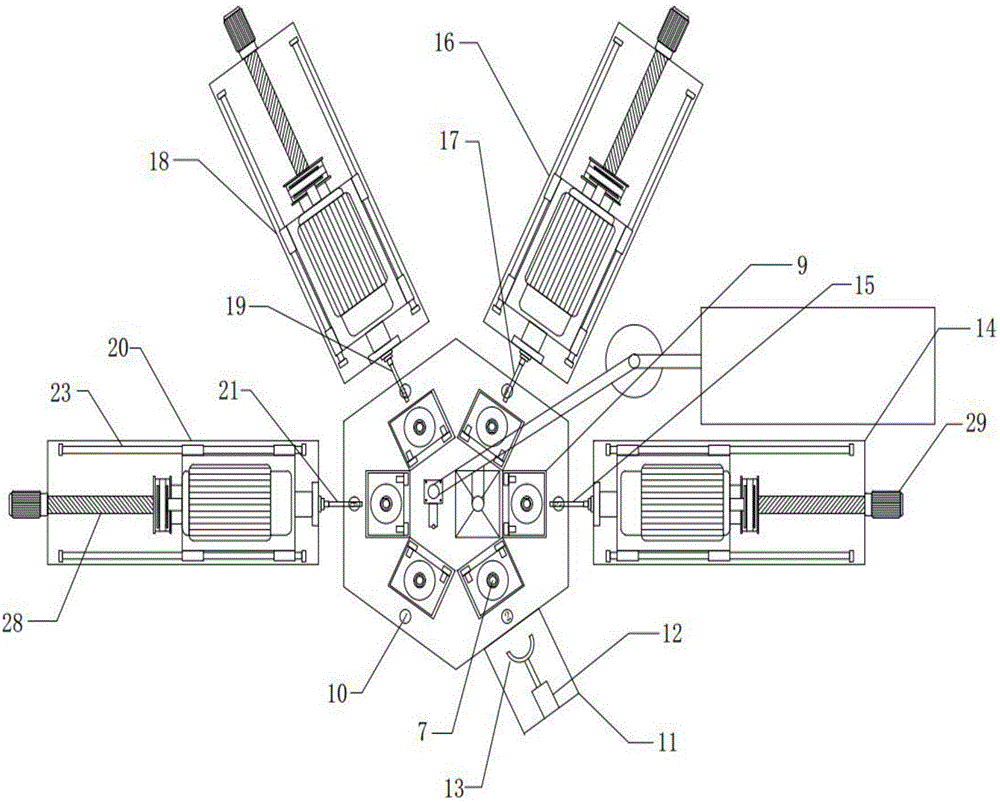

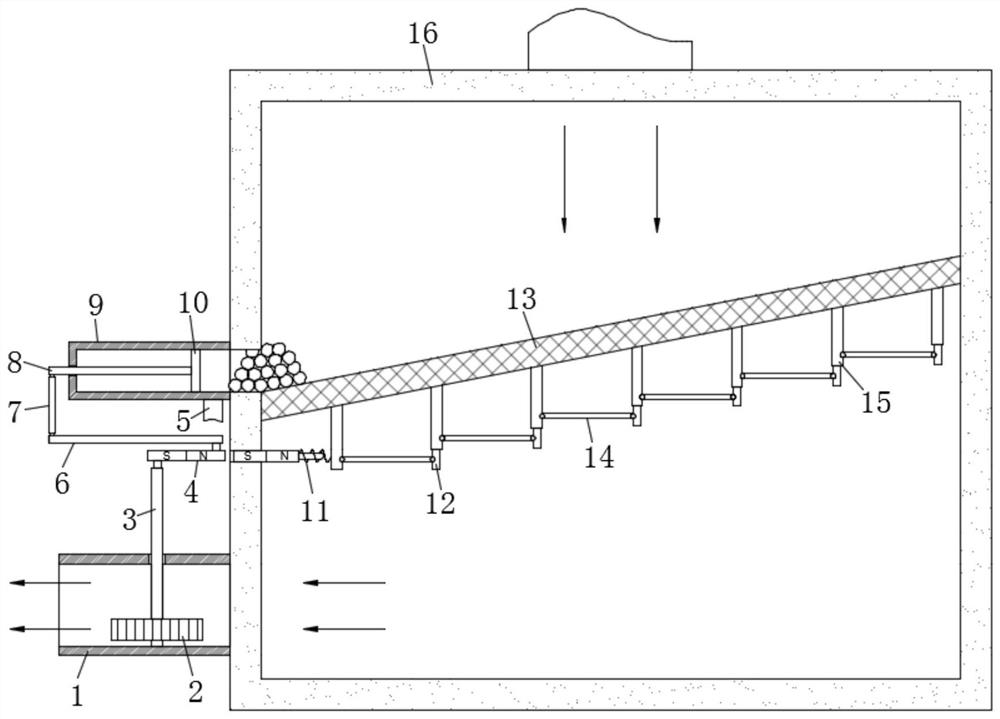

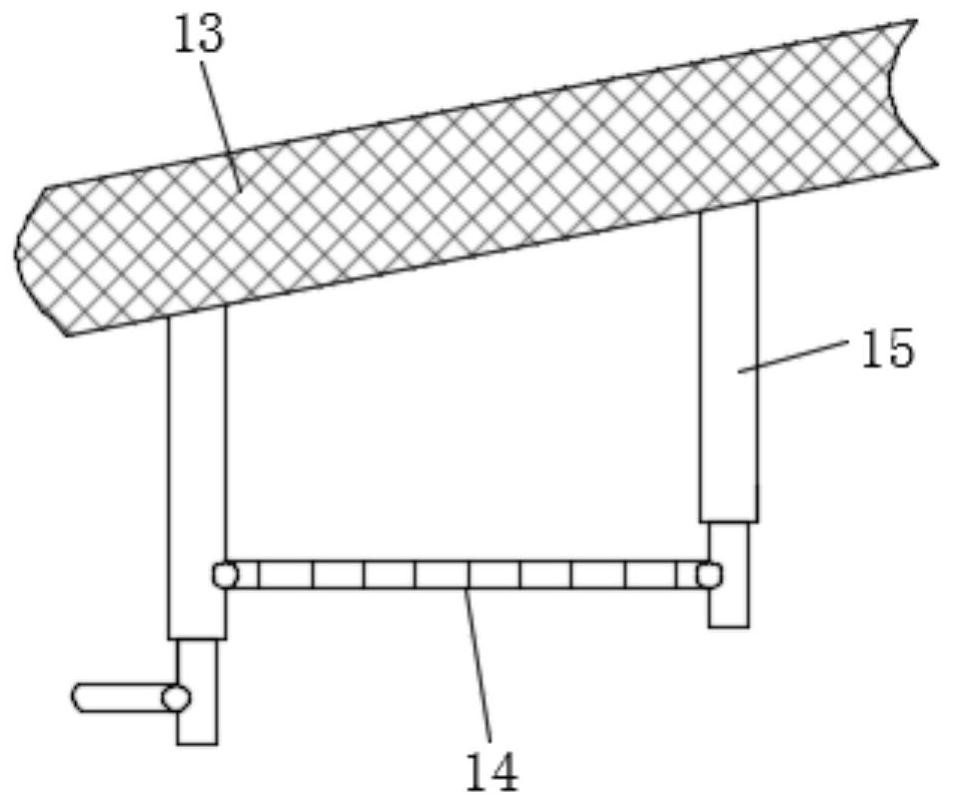

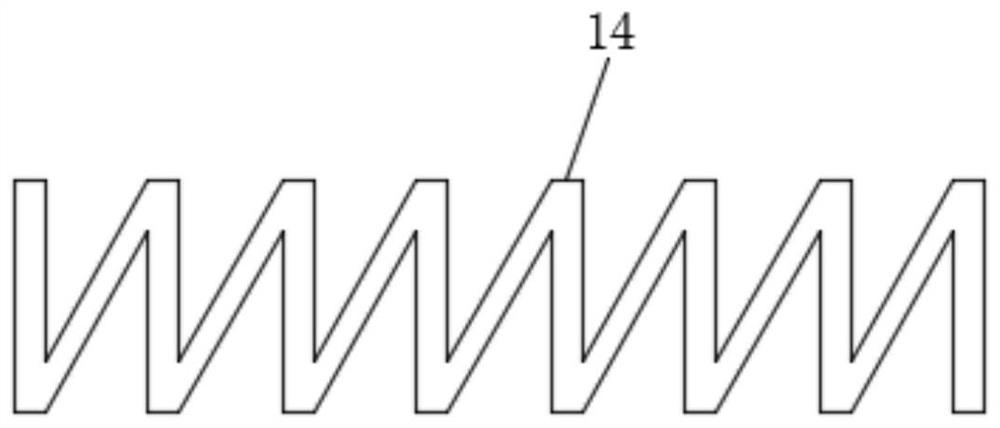

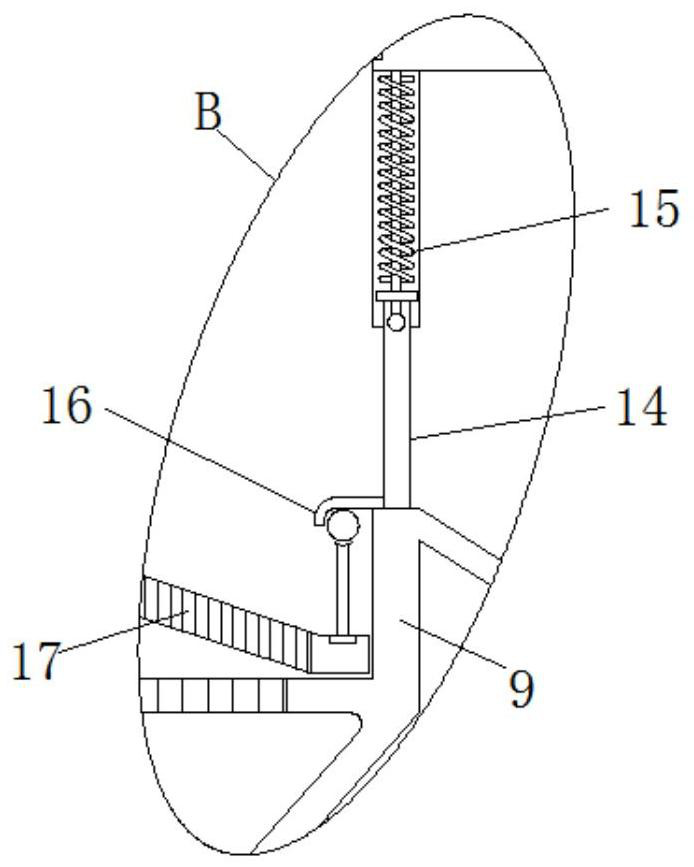

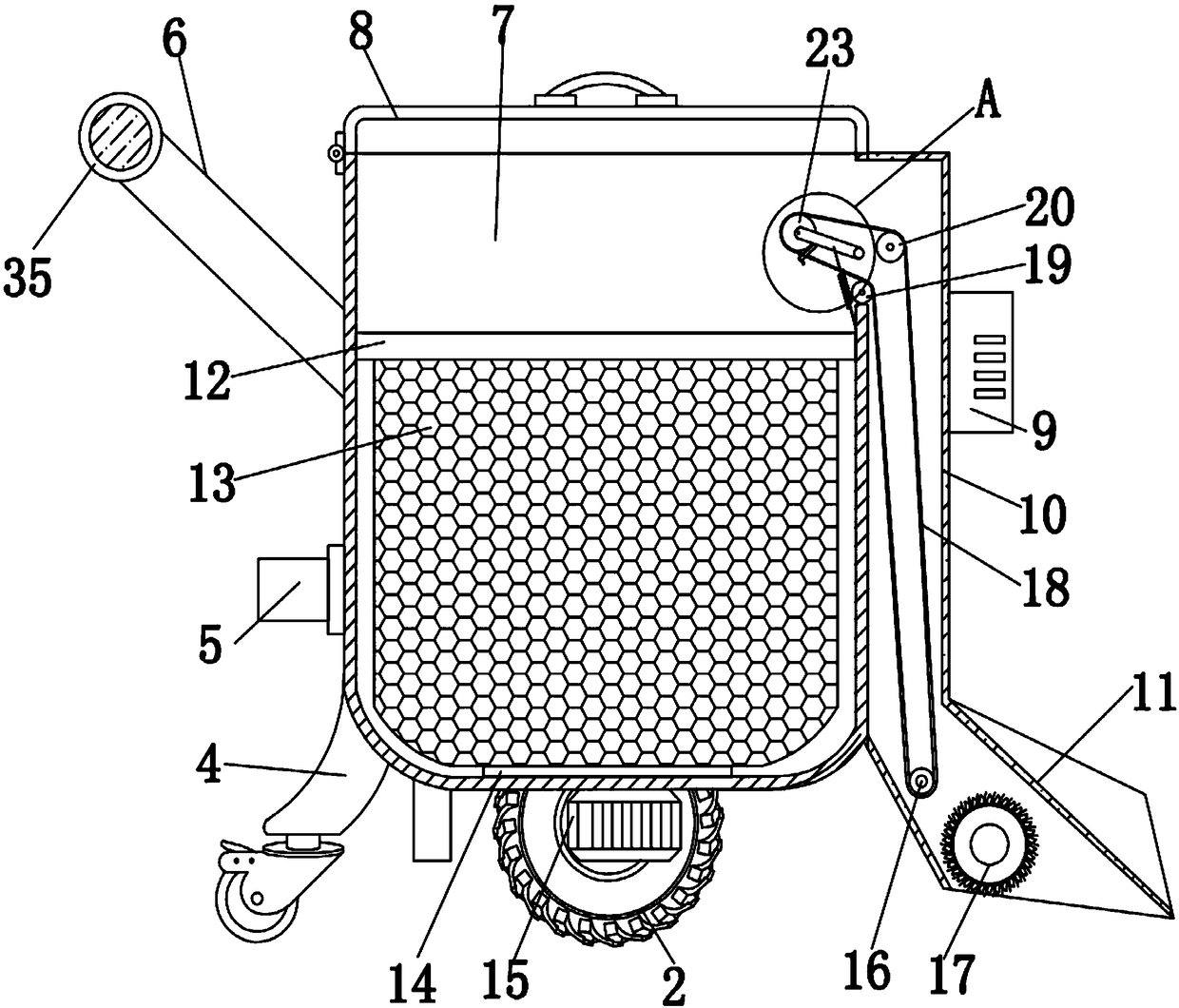

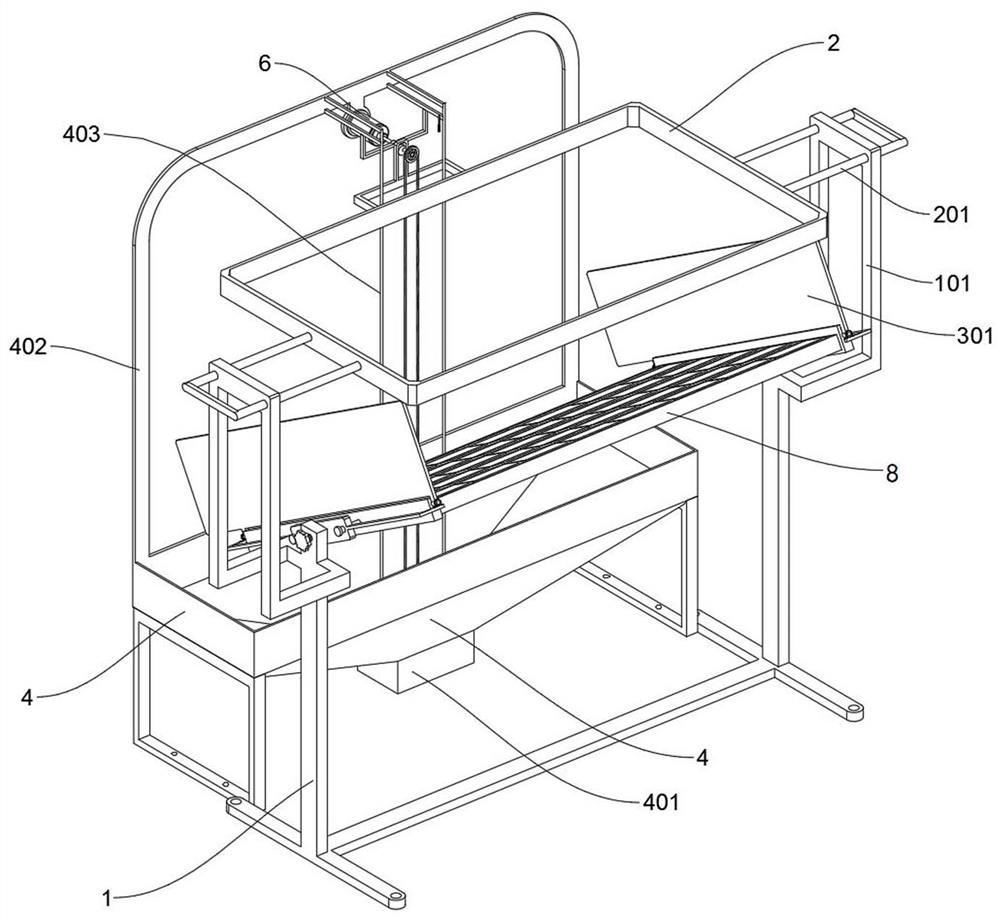

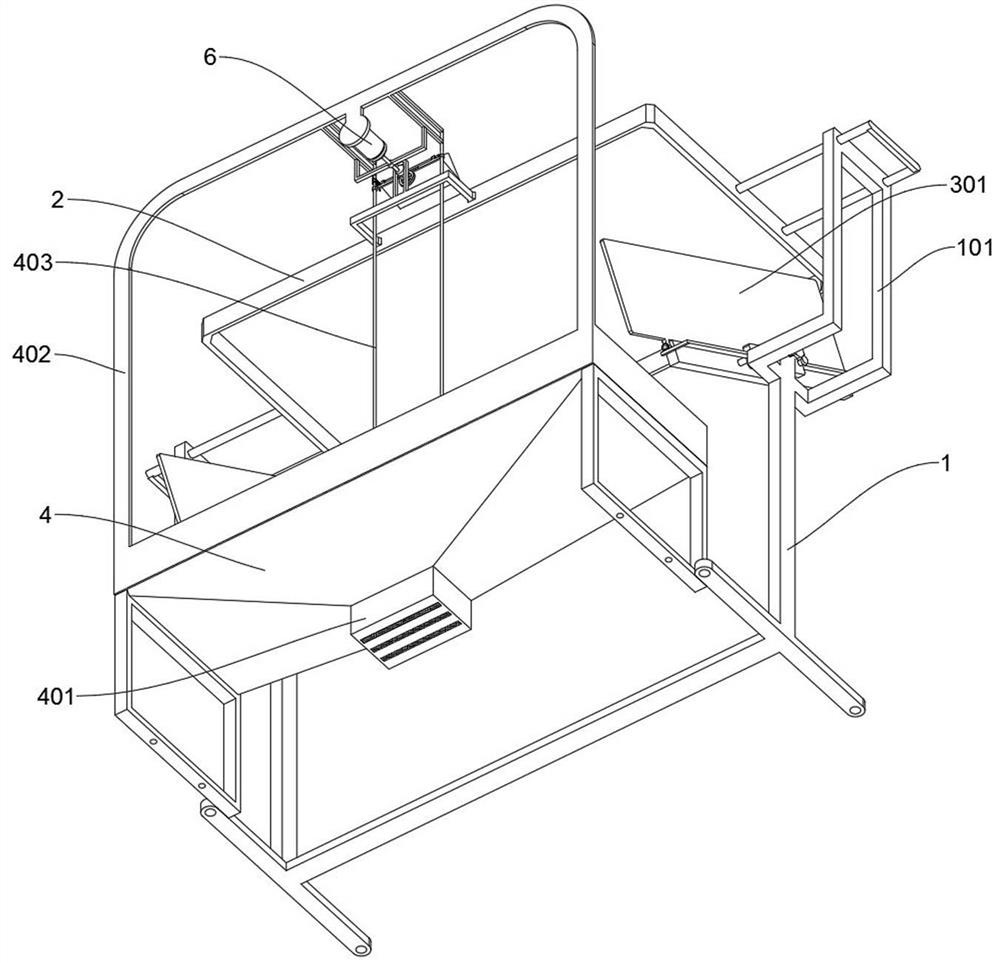

Steel bar and concrete separator

ActiveCN108283984ASeparation reachedEasy to collect and recycleSievingScreeningReinforced concreteArchitectural engineering

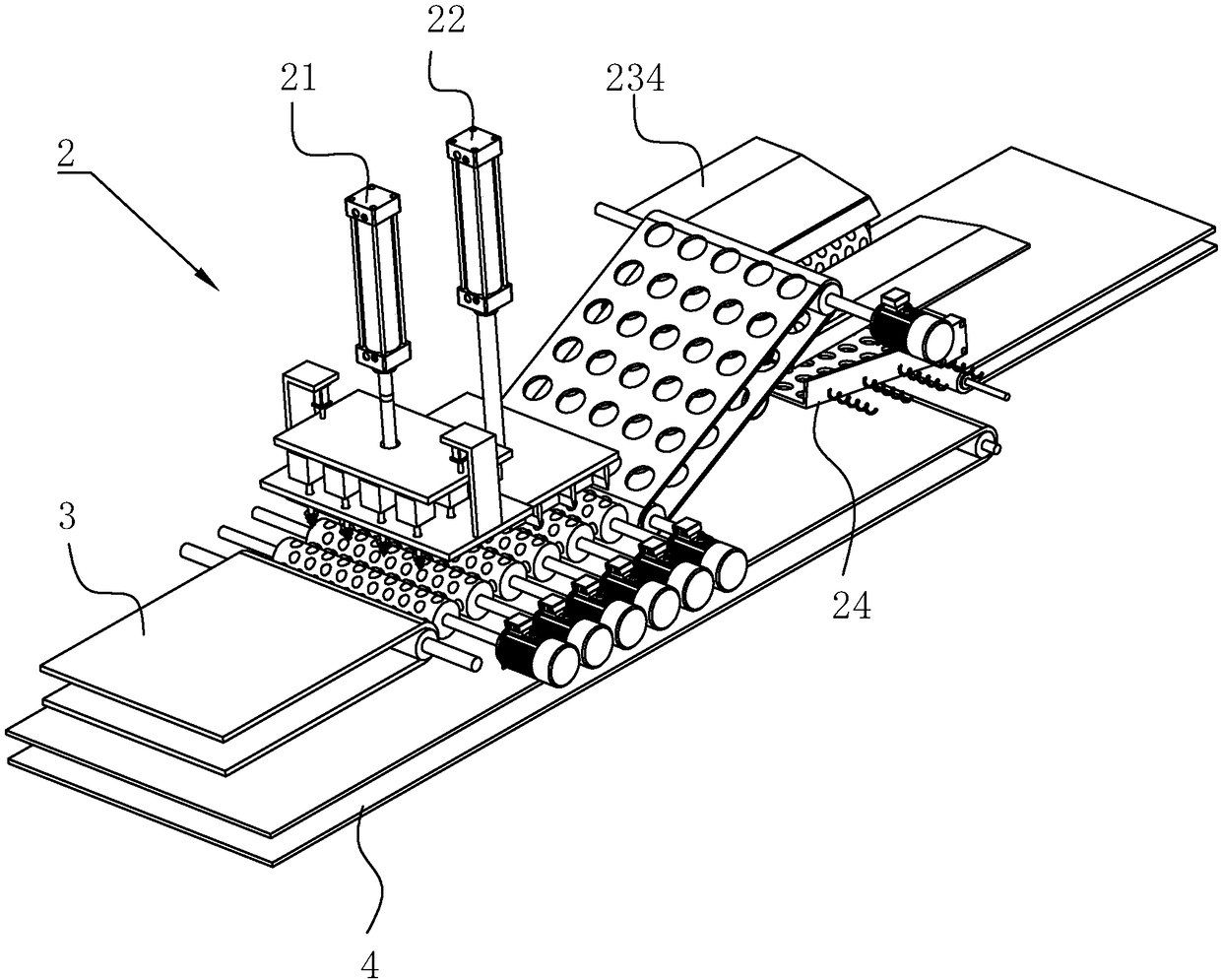

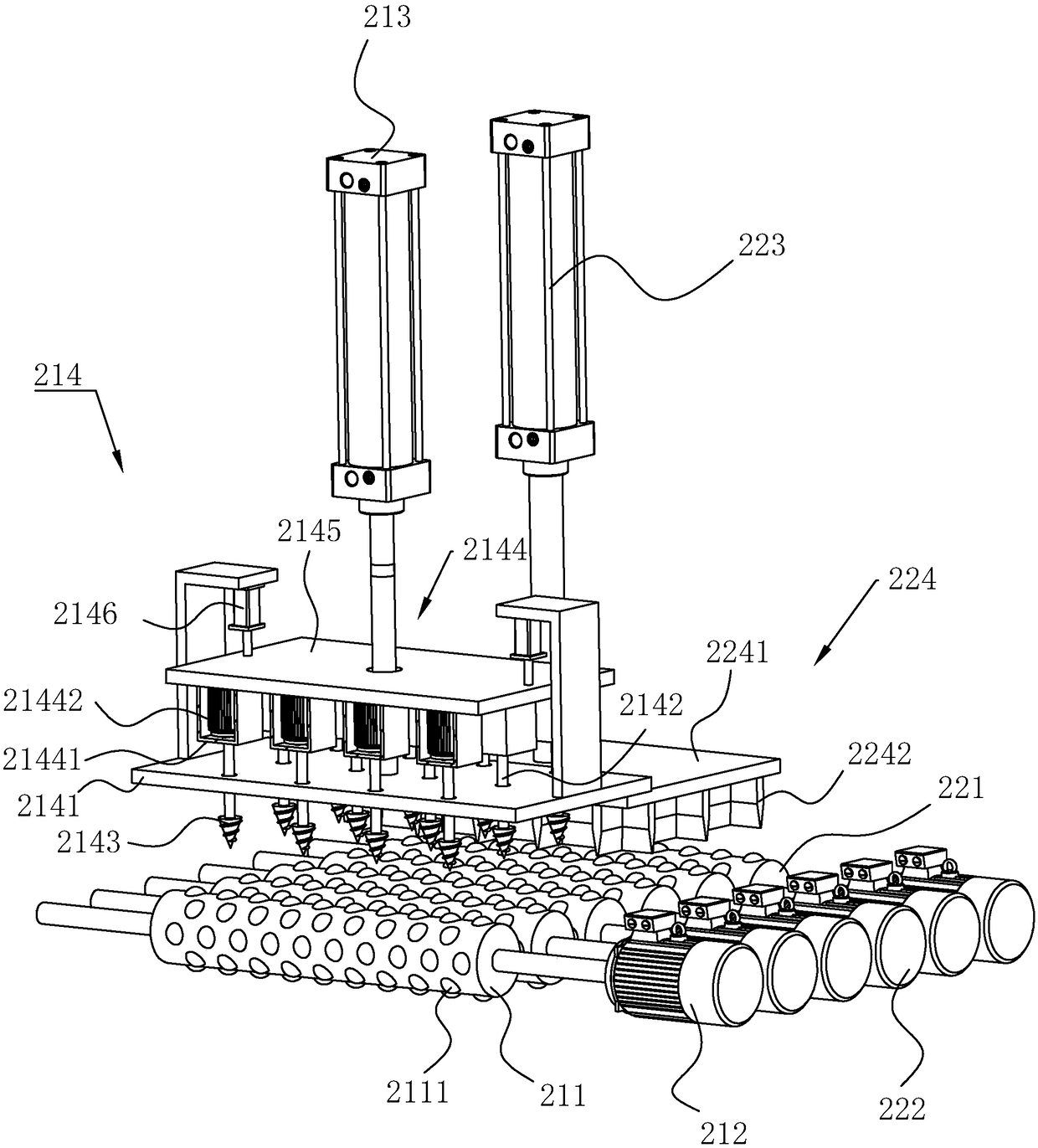

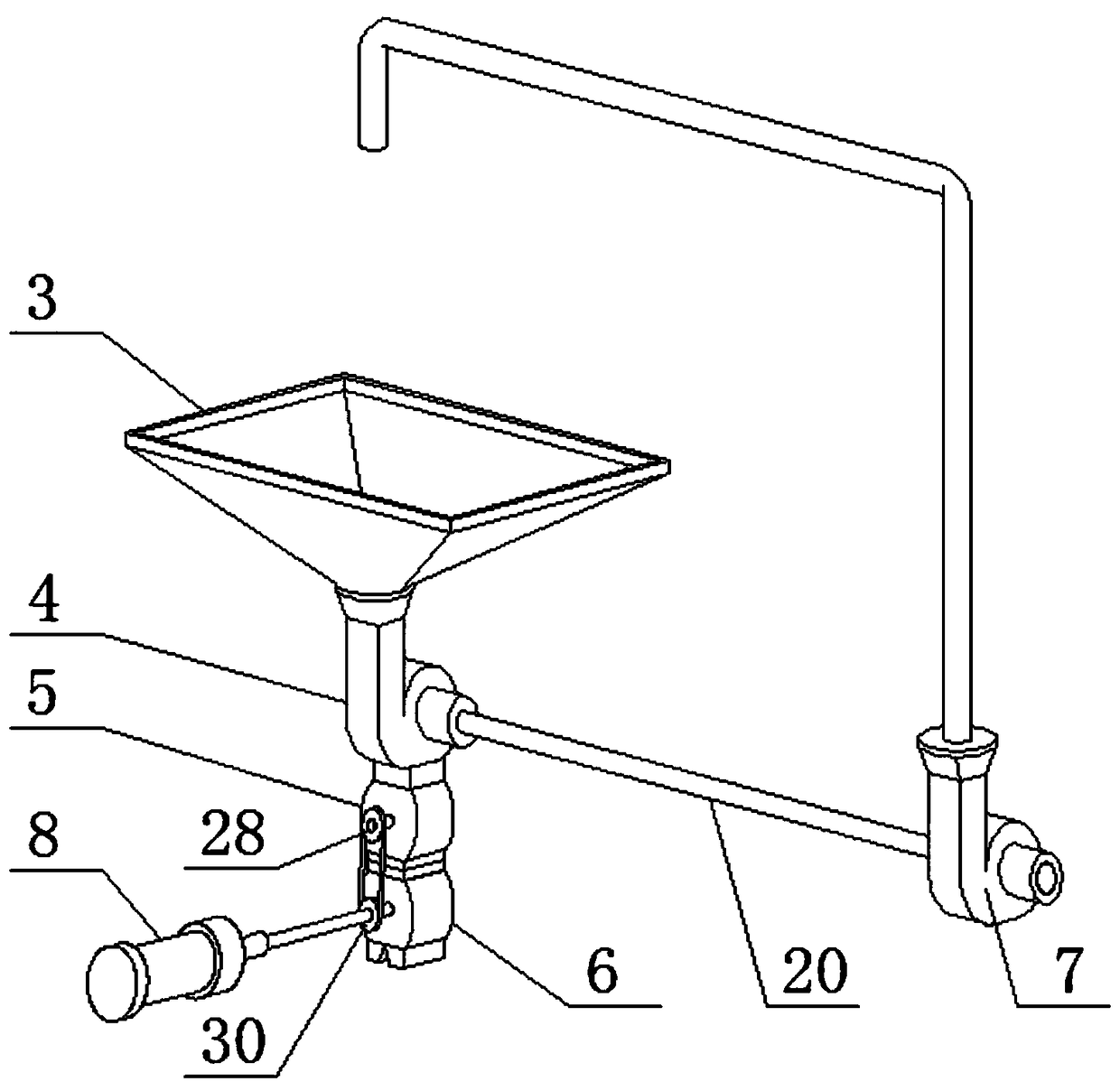

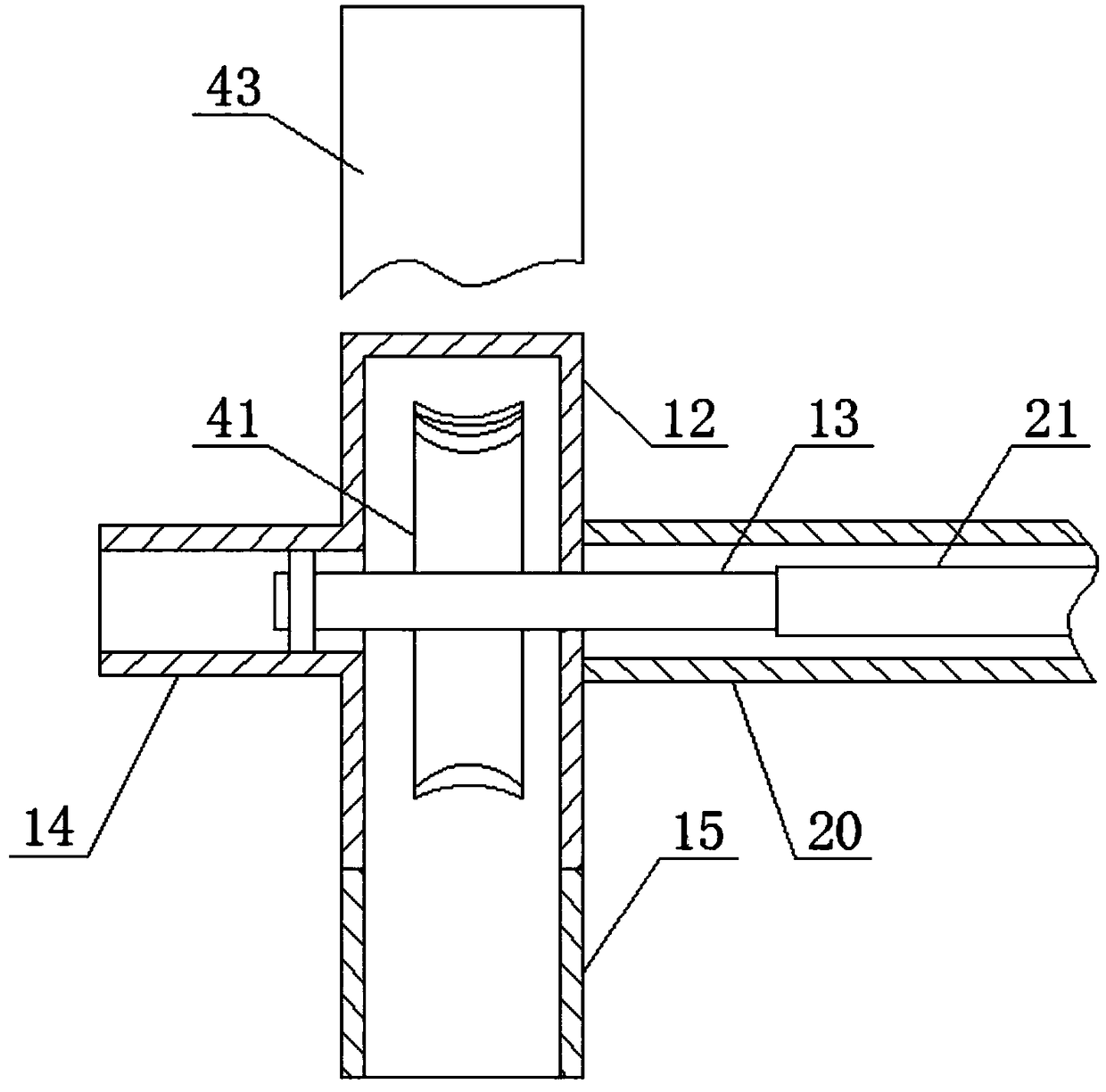

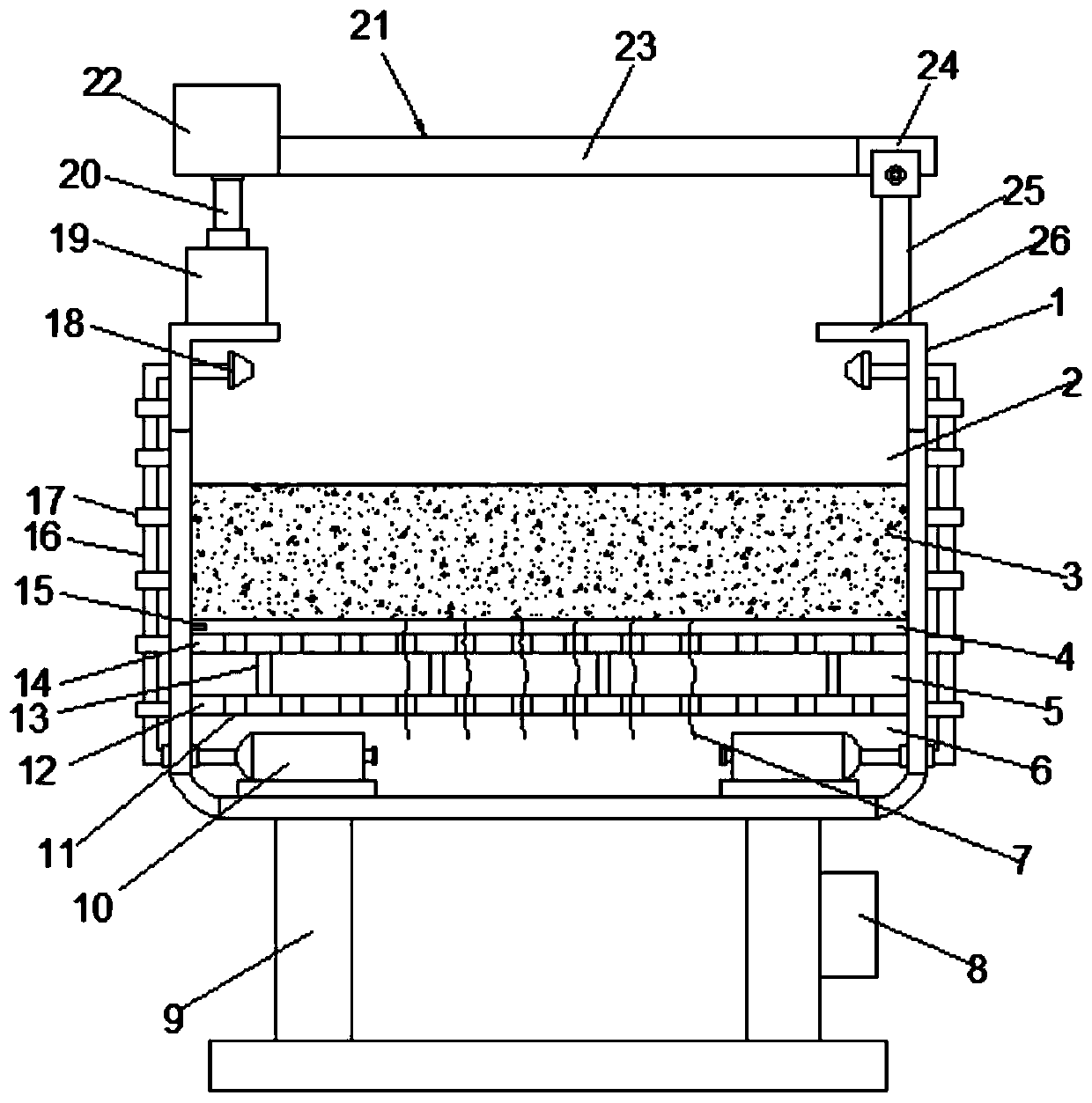

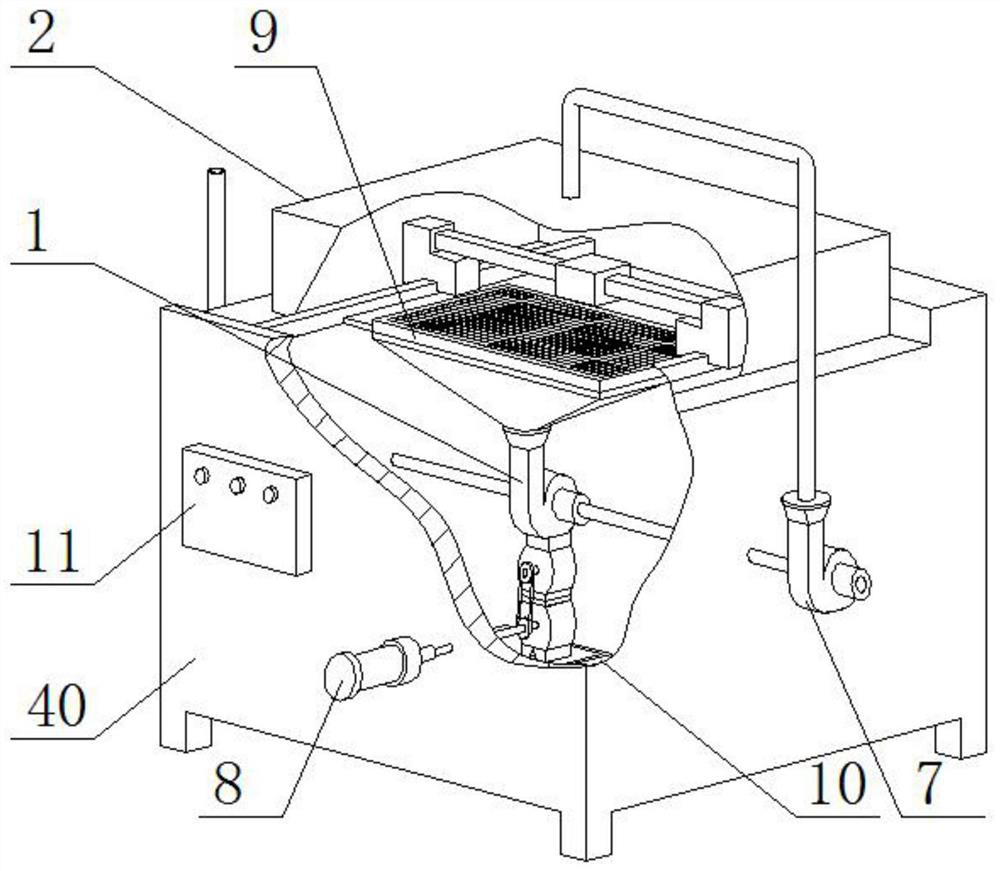

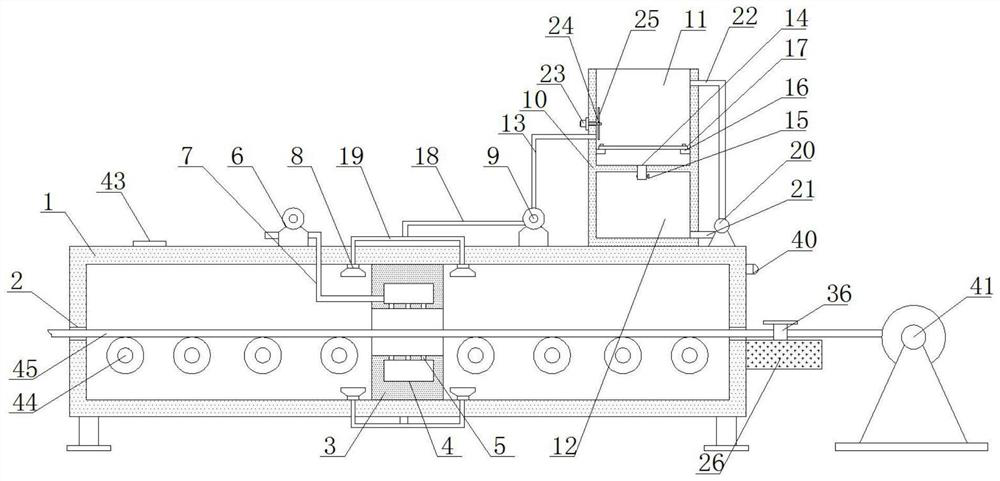

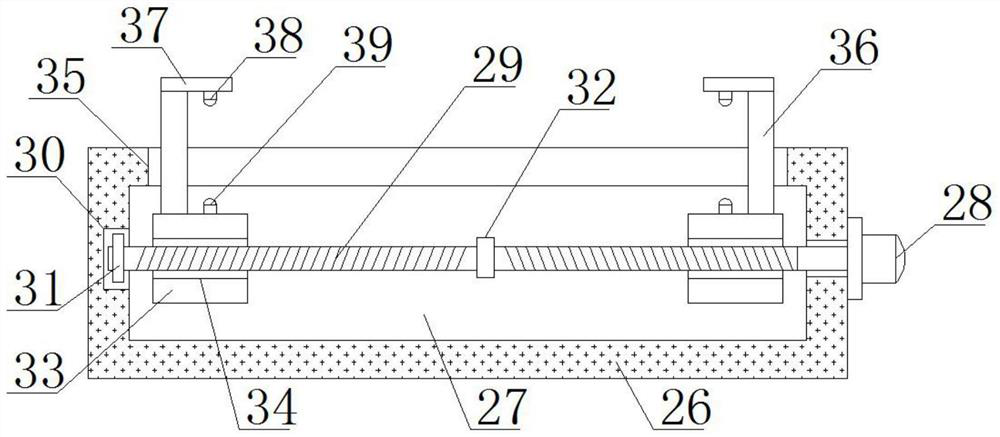

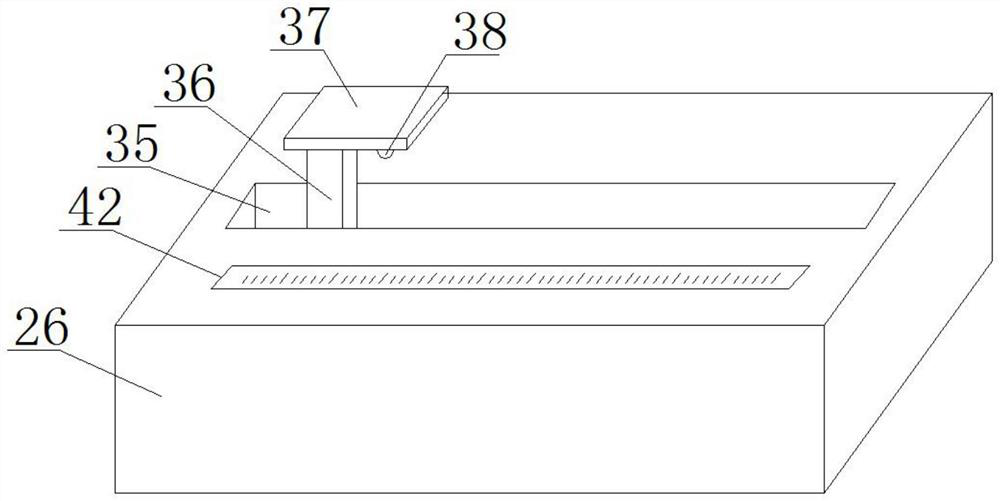

The invention discloses a steel bar and concrete separator. According to the key points of the technical scheme, the steel bar and concrete separator comprises a machine shell, a feeding opening is formed in one side of the machine shell, and a discharging opening is formed in the side, deviating from the feeding opening, of the machine shell; and a separating and crushing device used for separating concrete and steel bars is arranged in the machine shell, the separating and crushing device comprises a stamping mechanism used for crushing the concrete wrapped around the steel bars, a pressingand cutting mechanism used for finely crushing and cutting the concrete wrapped around the steel bars, a roller pressing mechanism used for rolling and crushing the concrete outside the steel bars, and a vibrating and screening mechanism used for separating the concrete and the steel bars, wherein the stamping mechanism, the pressing and cutting mechanism, the roller pressing mechanism and the vibrating and screening mechanism are sequentially arranged in the machine shell from the feeding opening to the discharging opening. The separator has the advantages that the steel bars can be separated from the concrete, and the concrete and the steel bars can be conveniently recycled and utilized.

Owner:北京博信晟益环保科技有限公司

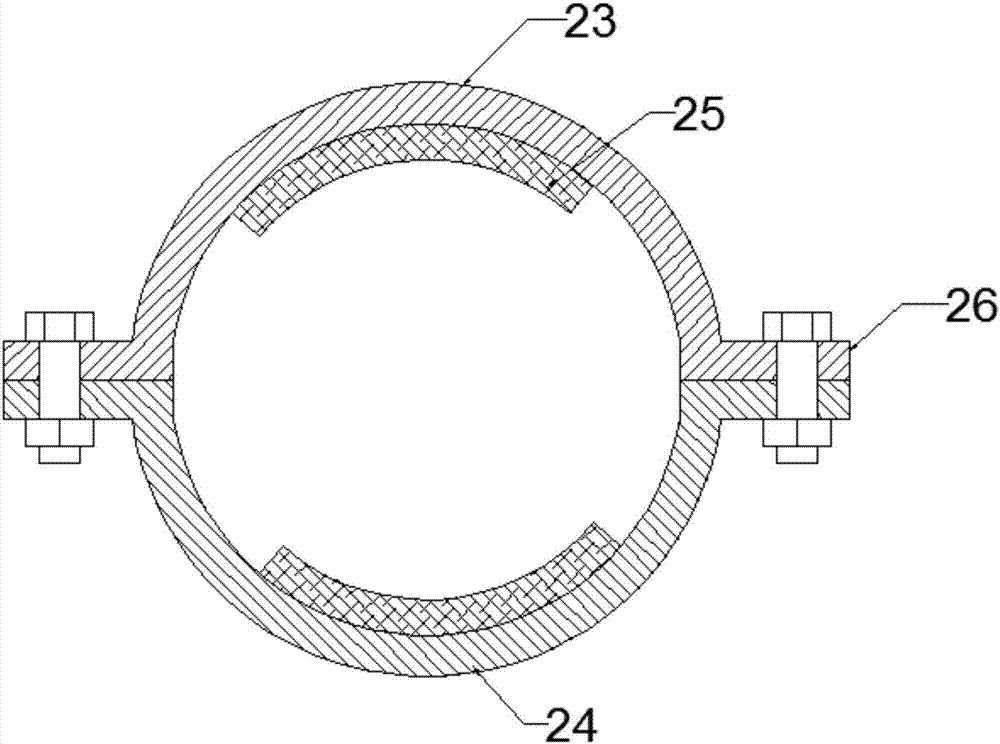

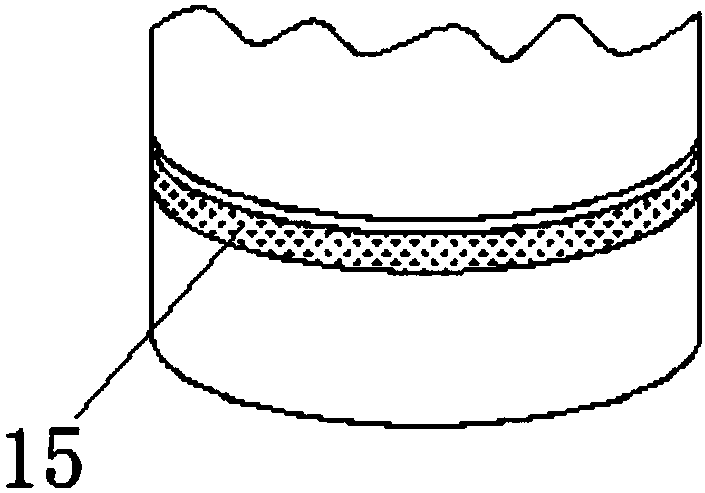

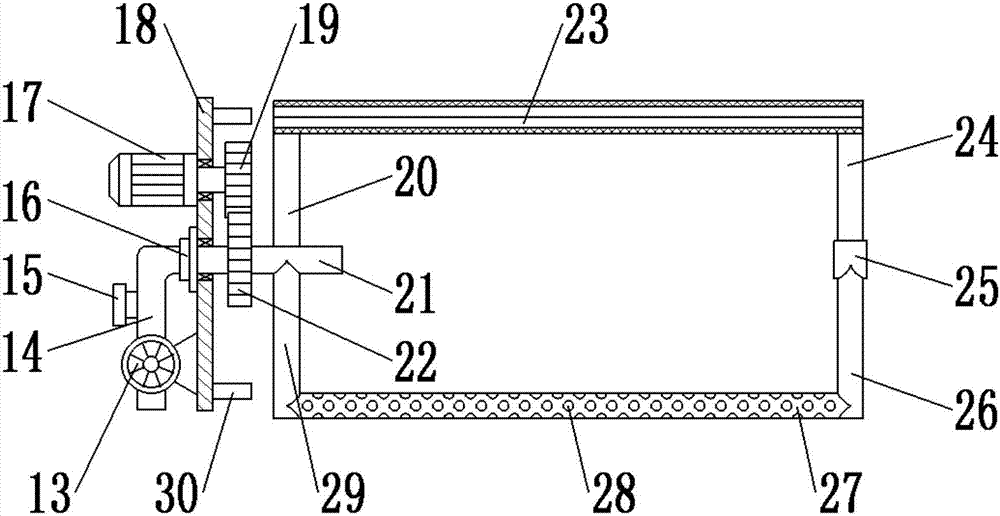

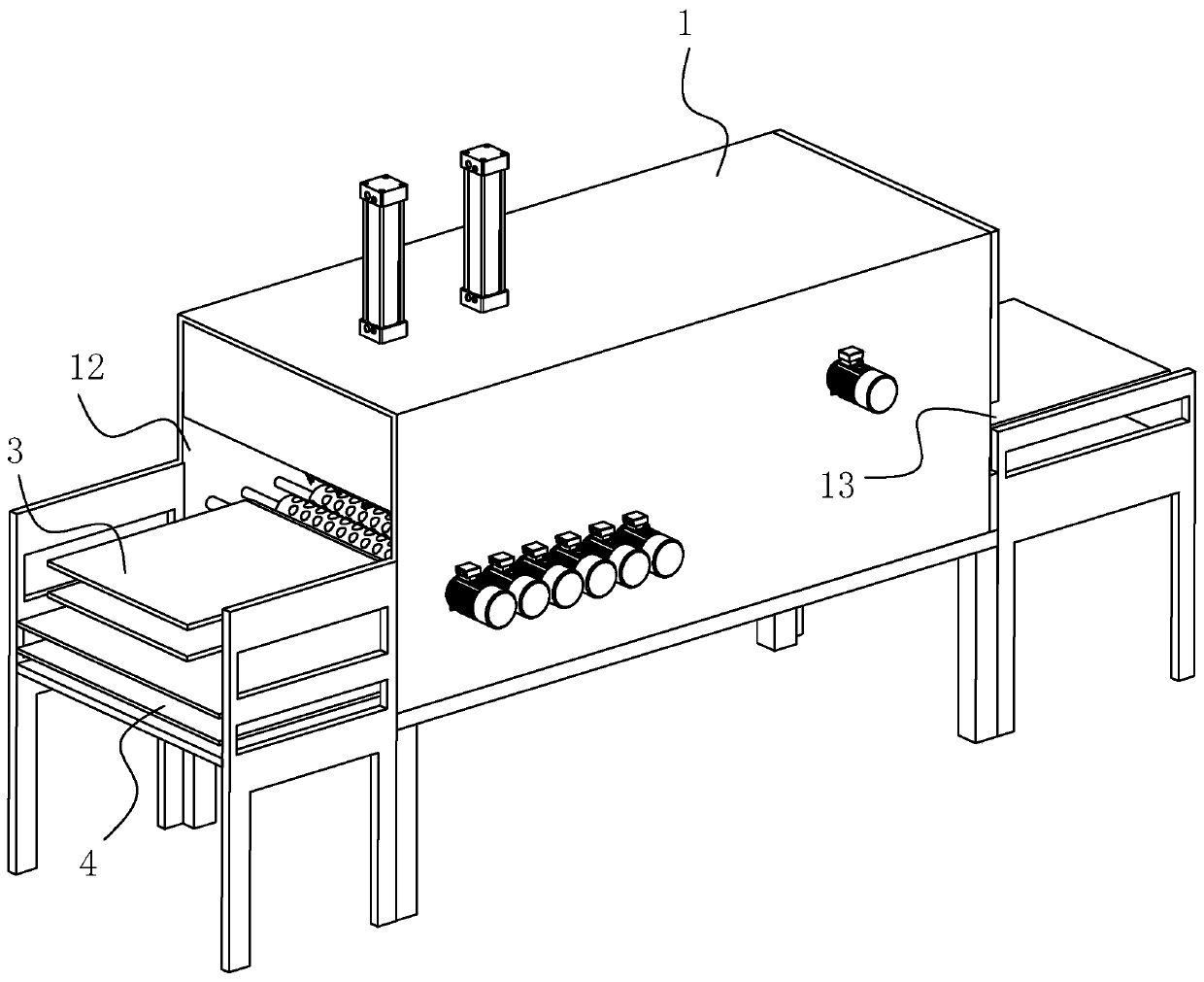

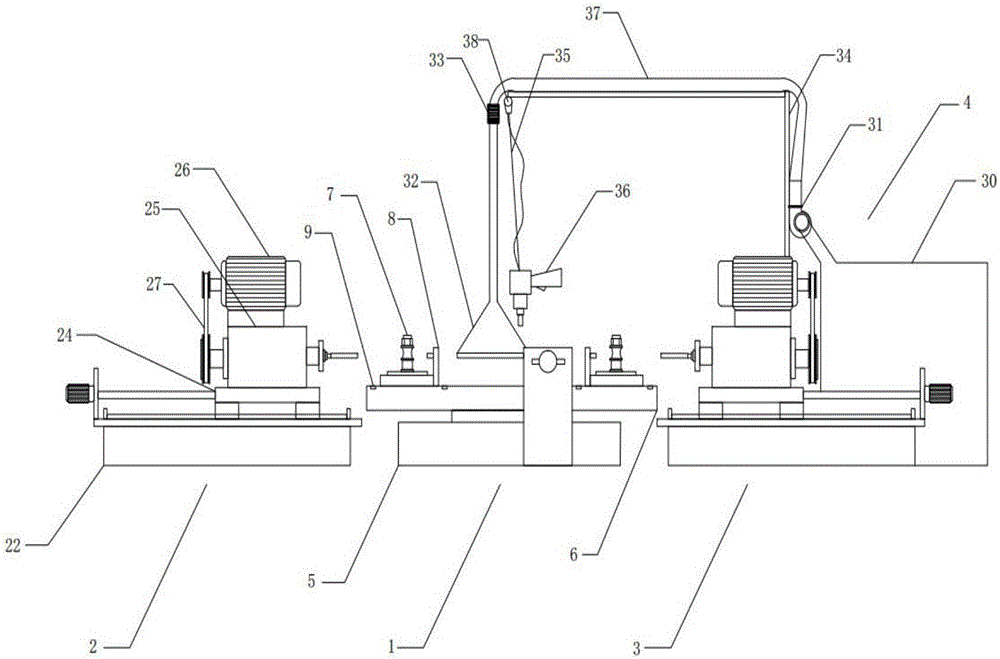

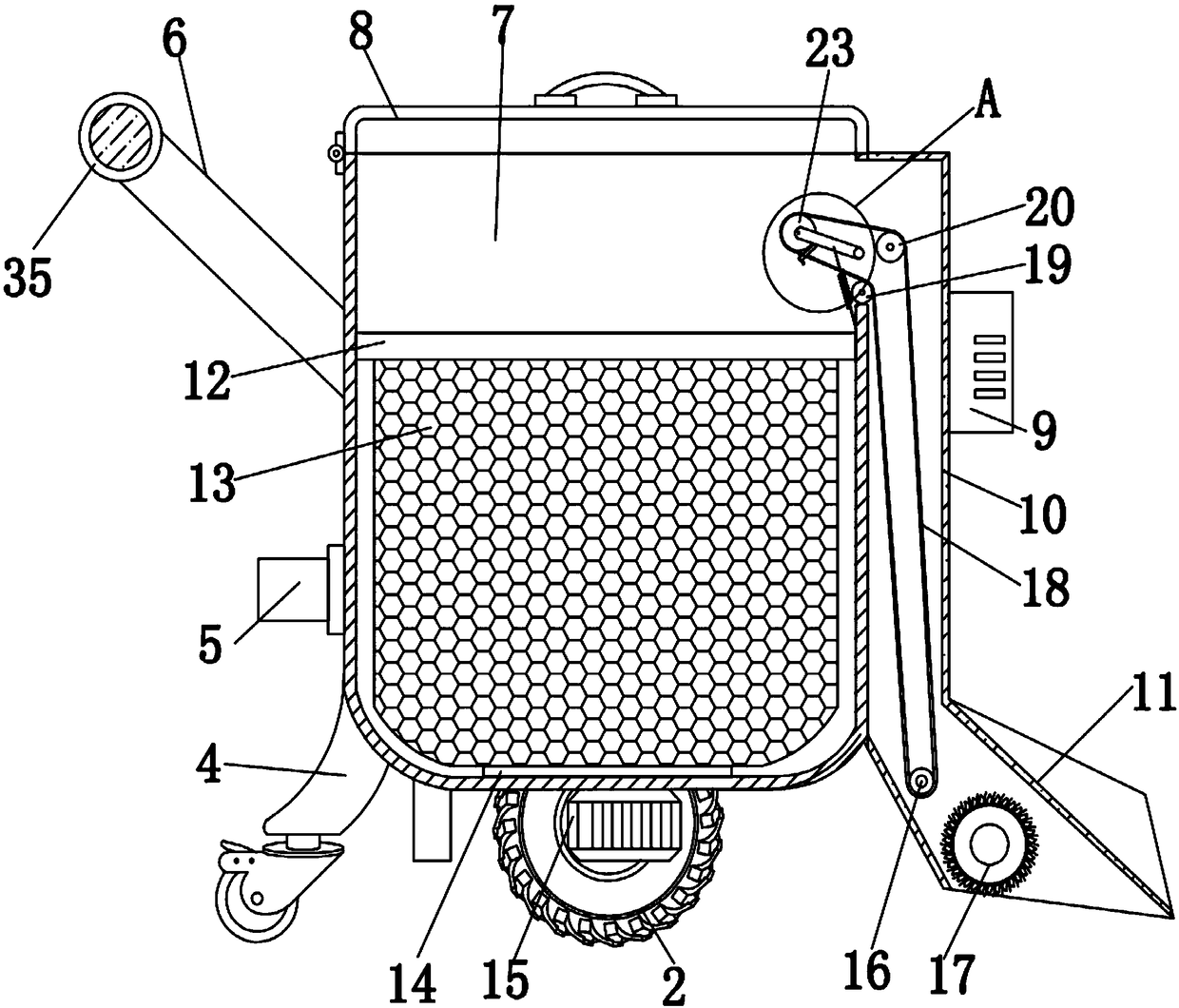

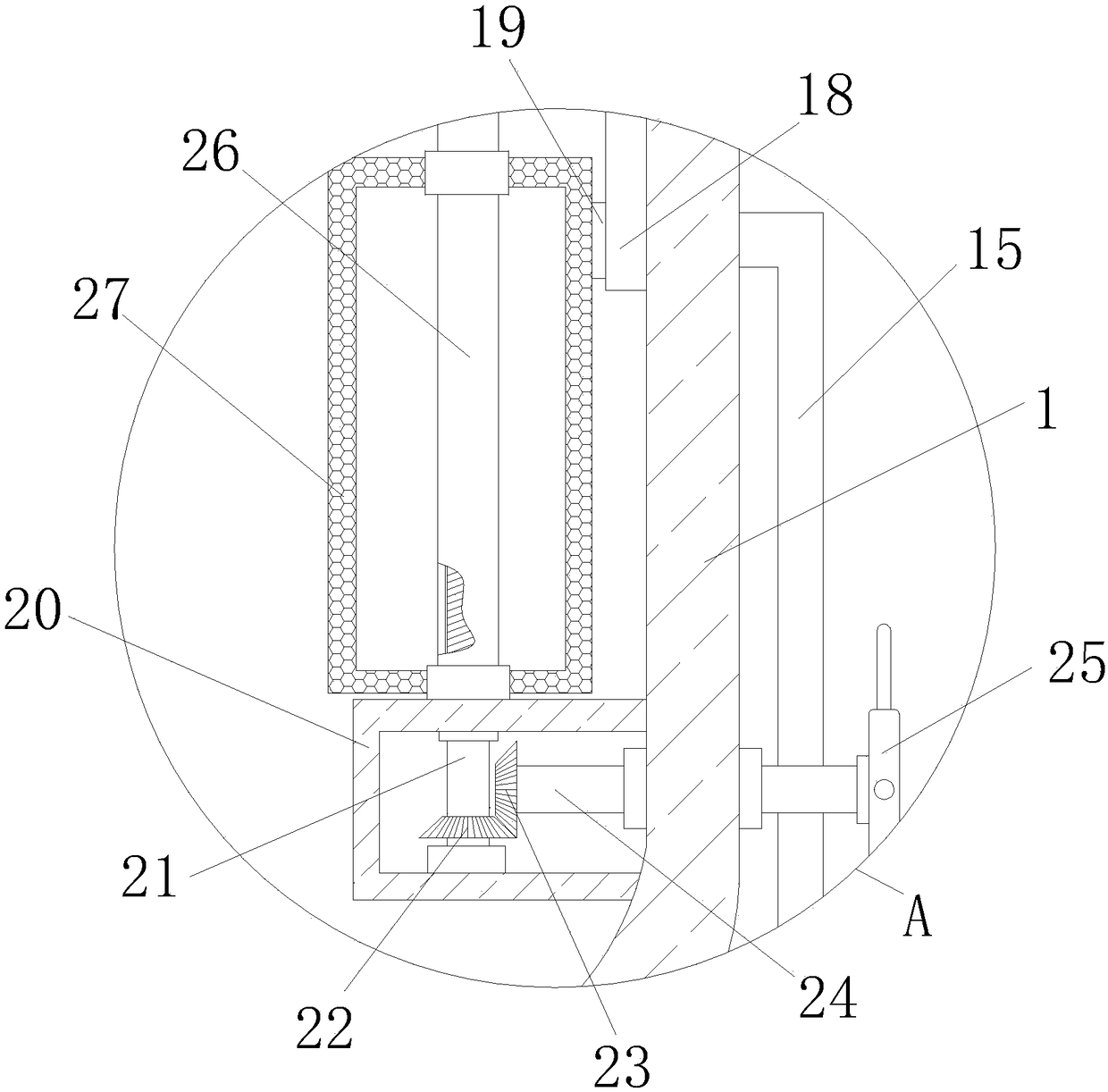

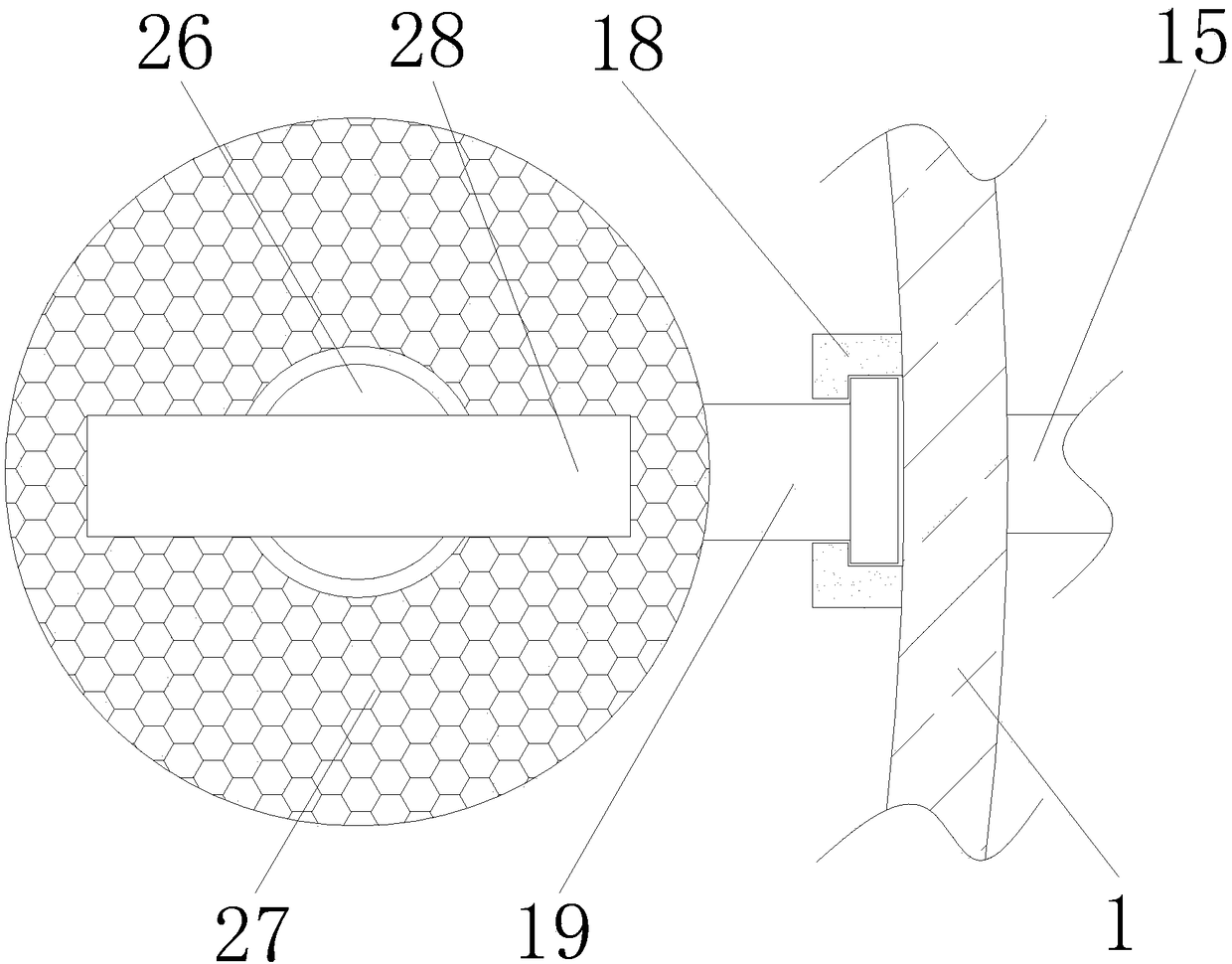

Building bar derusting device with good derusting effect

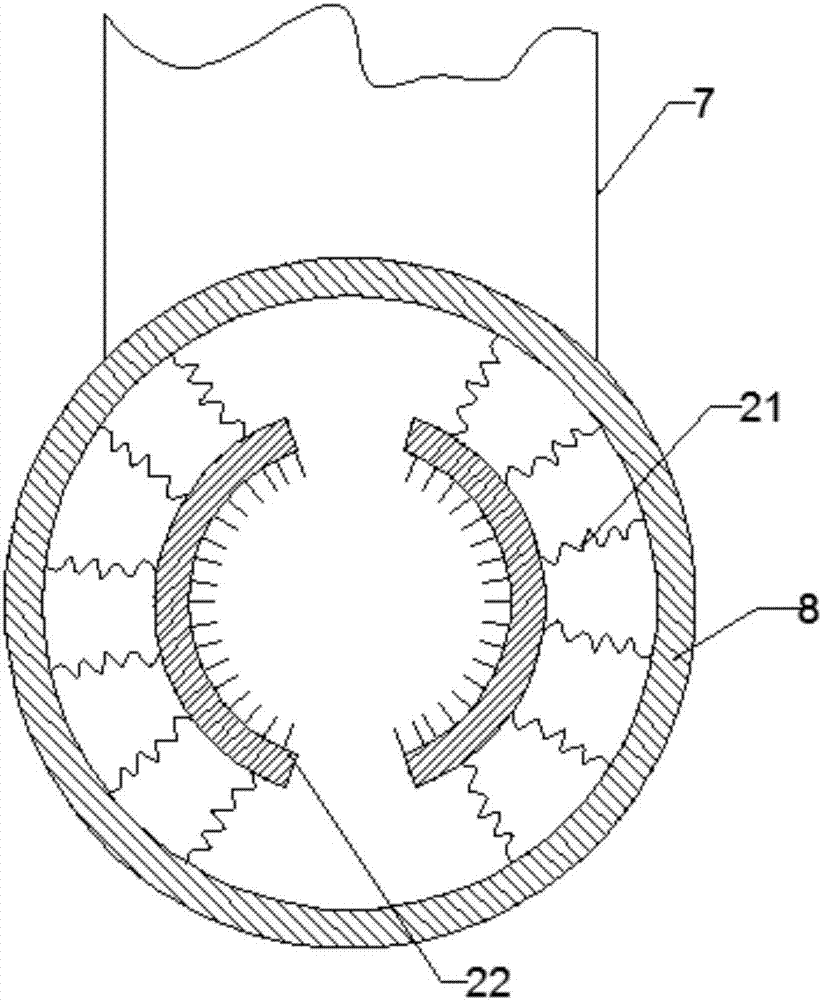

InactiveCN107962486AFast rust removalImprove rust removal effectGrinding machinesGrinding work supportsRebarDrive motor

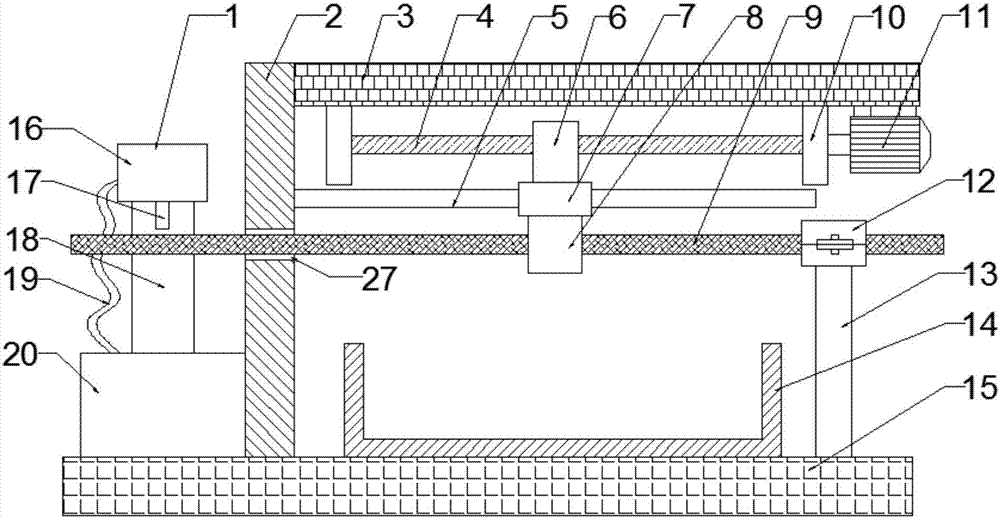

The invention discloses a building bar derusting device with a good derusting effect, and belongs to the field of building equipment. The building bar derusting device comprises a bottom plate, wherein a liquid containing box is arranged just below a nozzle, the liquid containing box is fixed to the upper surface of the bottom plate, and the liquid containing box is connected with an input port ofa liquid pump through a liquid draining pipe; a left side plate is vertically arranged on the left side of a spray device, and the left side plate is fixedly connected with the bottom plate; two mounting plates are respectively arranged on the left and right sides of the lower end surface of a top plate; a driving motor is fixedly arranged on the right side of the lower end surface of the top plate by virtue of a bracket, and an output shaft of the driving motor is connected with a screw rod; and a screw rod sleeve is arranged on the screw rod and is movably connected with the screw rod. Thebuilding bar derusting device has the advantage of reasonable structural design; two steel wire brushes are symmetrically arranged in an annular block, so that bars can be derusted all round; and auxiliary derusting liquid is sprayed to the bars by the spray device before the bars enter the derusting device, so that the bar derusting speed is increased, and additionally, the bar derusting effect is increased.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

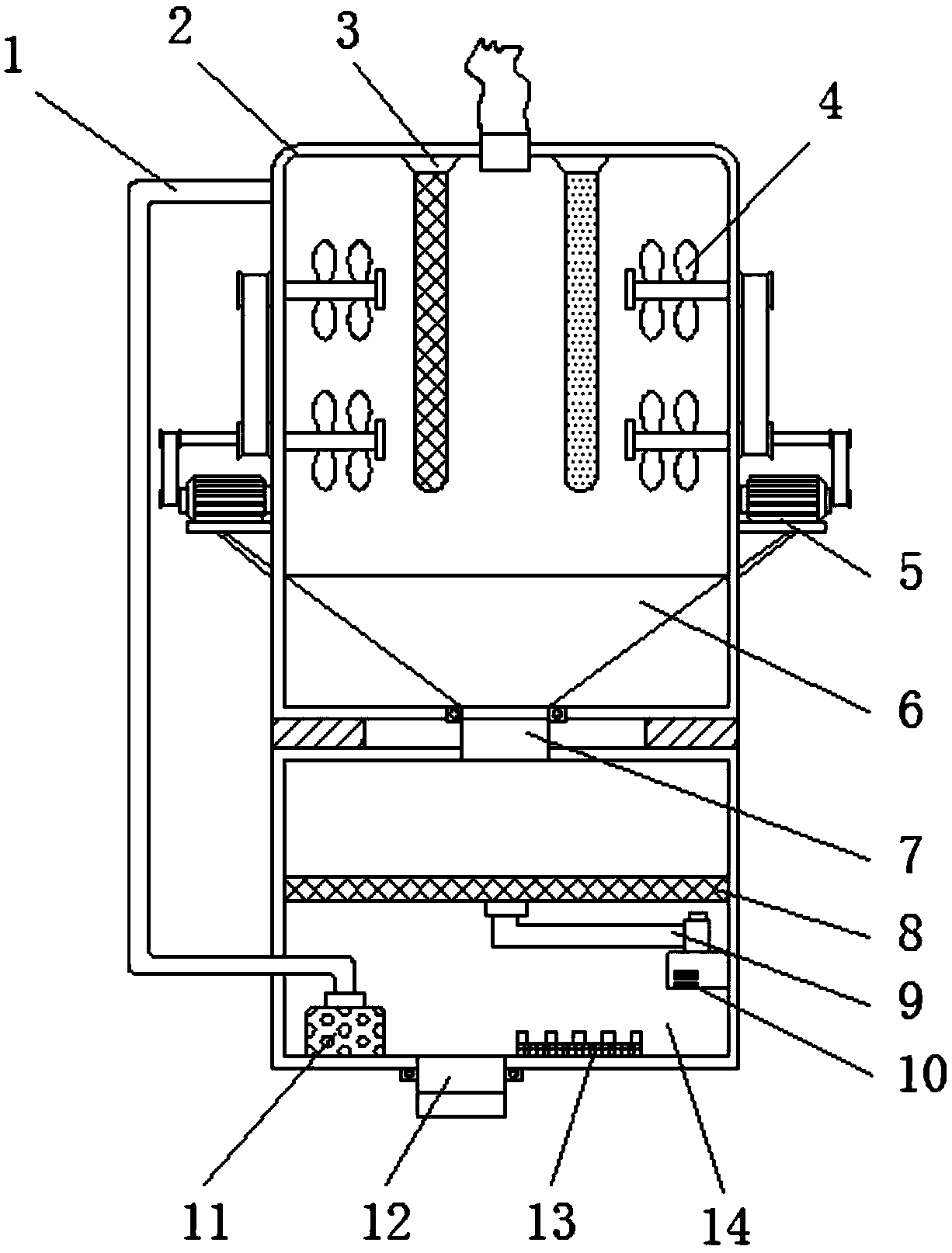

High-utilization-rate electroplating wastewater recycling device

InactiveCN107555674AIncrease reaction rateImprove work efficiencyWaste water treatment from metallurgical processMultistage water/sewage treatmentIonSewage

The invention discloses an electroplating waste water recycling device with high utilization rate, which comprises a waste water treatment device body, an electrolytic cell and a filter pool. An electrolytic cell is arranged above the waste water treatment device body. A sewage inlet is provided, a first solenoid valve is provided at the middle of the bottom of the electrolytic cell, a filter screen is provided inside the filter pool, and a suction pump is provided on one side of the bottom of the filter pool, and the suction pump passes through The return pipe communicates with the electrolytic cell. In the present invention, four stirring wheels are arranged on the side wall of the electrolytic cell, and the sewage can all be contacted with the electrodes under the stirring action of the four stirring wheels, thereby improving the reaction rate of the electrolytic reaction and making the metal ions in the sewage The reaction is sufficient and the work efficiency is improved. At the same time, the bottom of the electrolytic cell is a conical structure, which can effectively avoid the accumulation of metal deposits and facilitate the recovery of metals.

Owner:CHENGDU KECHUANGCHENG TECH

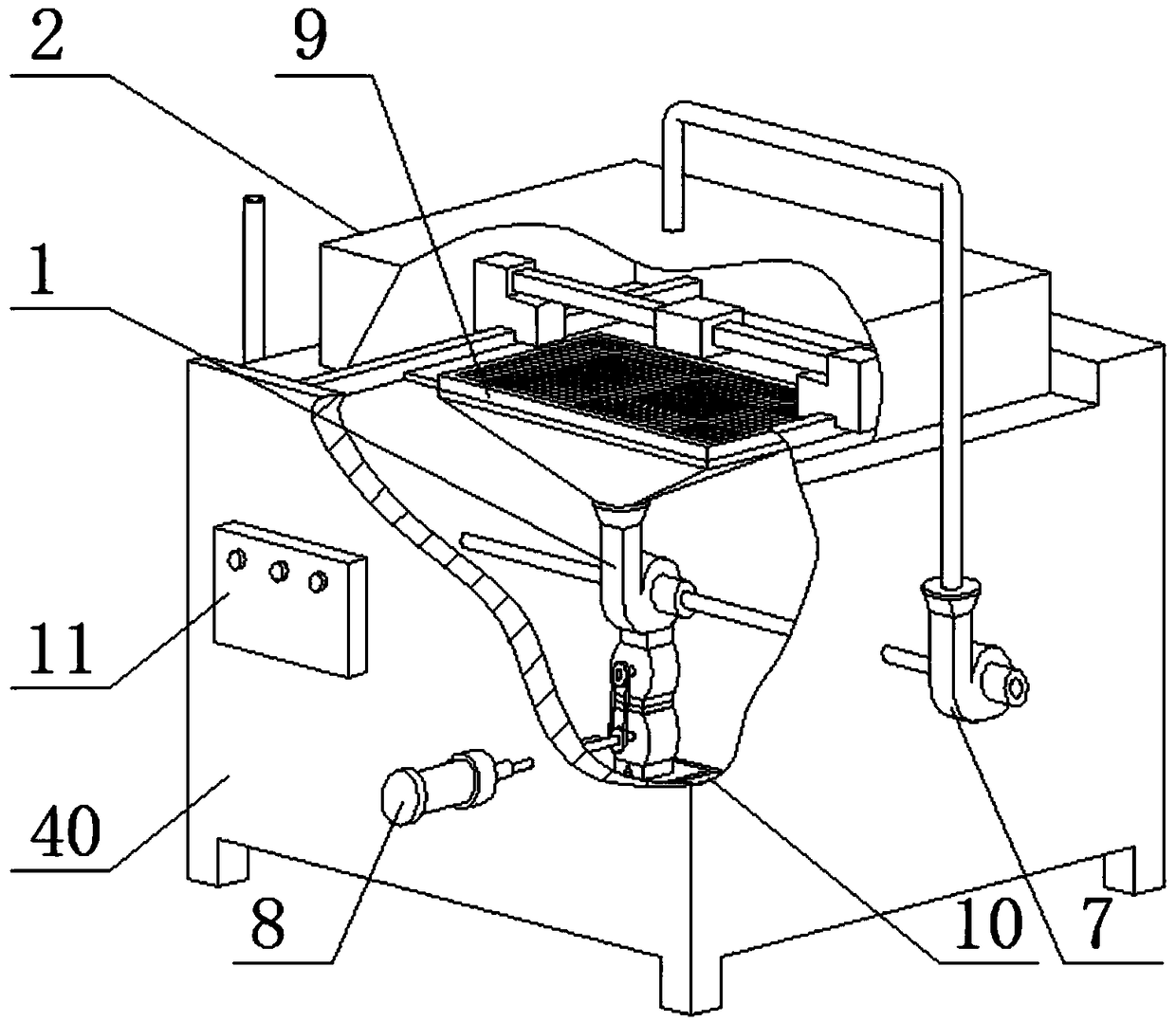

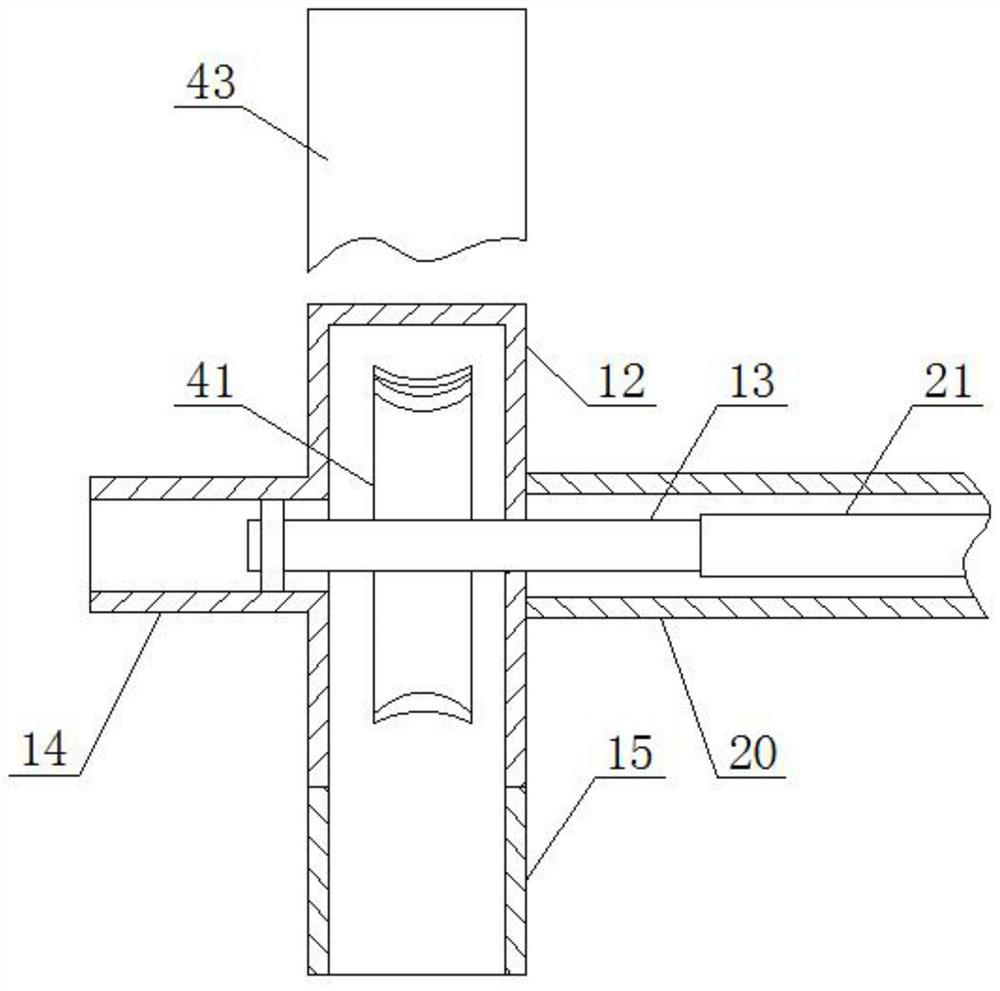

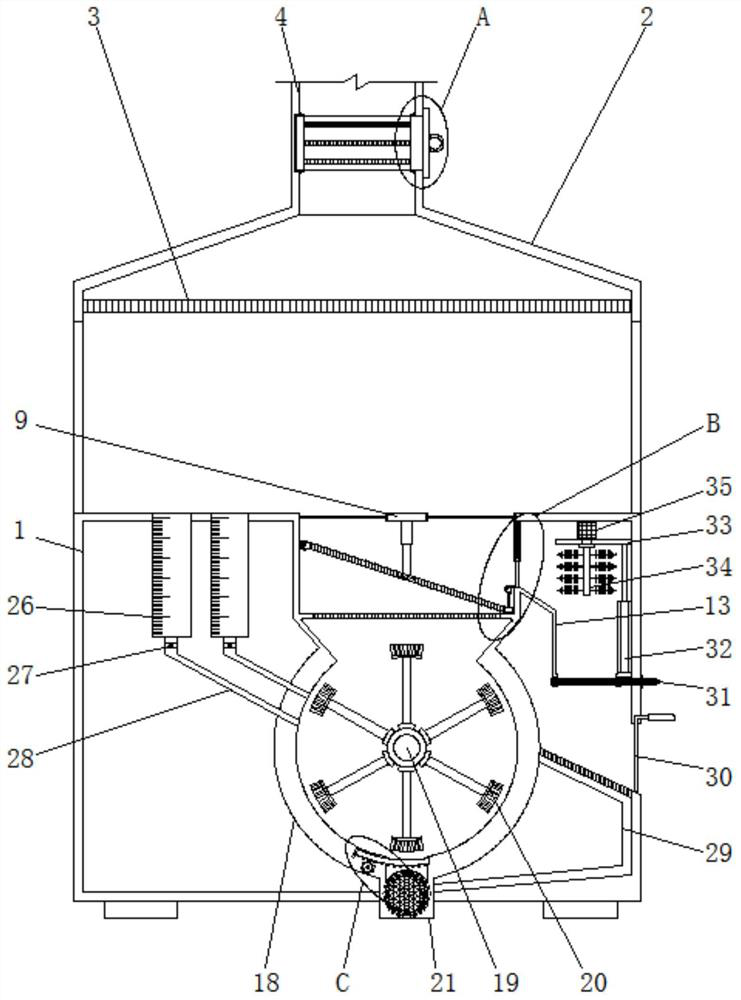

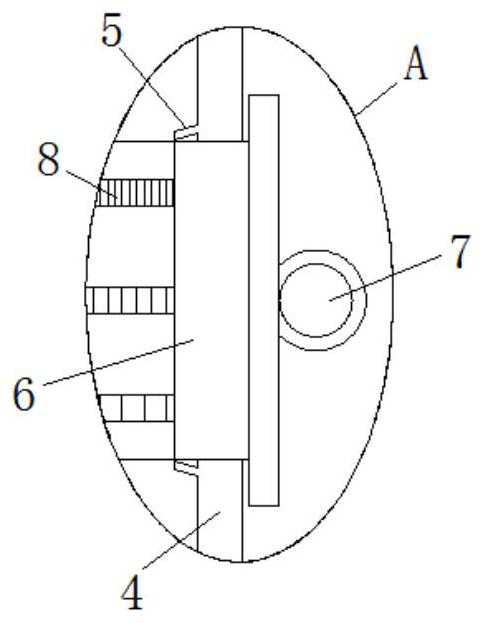

Laser cutting machine turbocharging dust removal and noise reduction device

ActiveCN109202280AGood for healthReduce noiseMachines/enginesWelding/soldering/cutting articlesEngineeringLaser cutting

The invention relates to the technical field of laser cutting environment-friendly machinery. A dust removal and noise reduction system, a laser cutting machine body and a seal cover are included, andthe laser cutting machine body is sleeved with the seal cover. The dust removal and noise reduction system is connected to the seal cover through a pipeline and comprises a fairing, a main turbine set, a special choke, an electromagnetic discharge device, an auxiliary turbine set, a motor, a waste box and a control box. The top of the fairing is fixed to the bottom of a support grid plate of thelaser cutting machine body. The main turbine set, the special choke and the electromagnetic discharge device are arranged in the laser cutting machine body sequentially from top to bottom. The fairing, the main turbine set, the special choke and the electromagnetic discharge device are fixedly connected through bolts. The waste box is fixed to the bottom of the inner side of the laser cutting machine body and corresponds to the electromagnetic discharge device. The auxiliary turbine set is fixed to the side wall of the laser cutting machine body. The equipment is low in energy consumption, simple to operate, small in noise and free of pollution, and generalization is facilitated.

Owner:赣州市畅达电梯销售有限公司

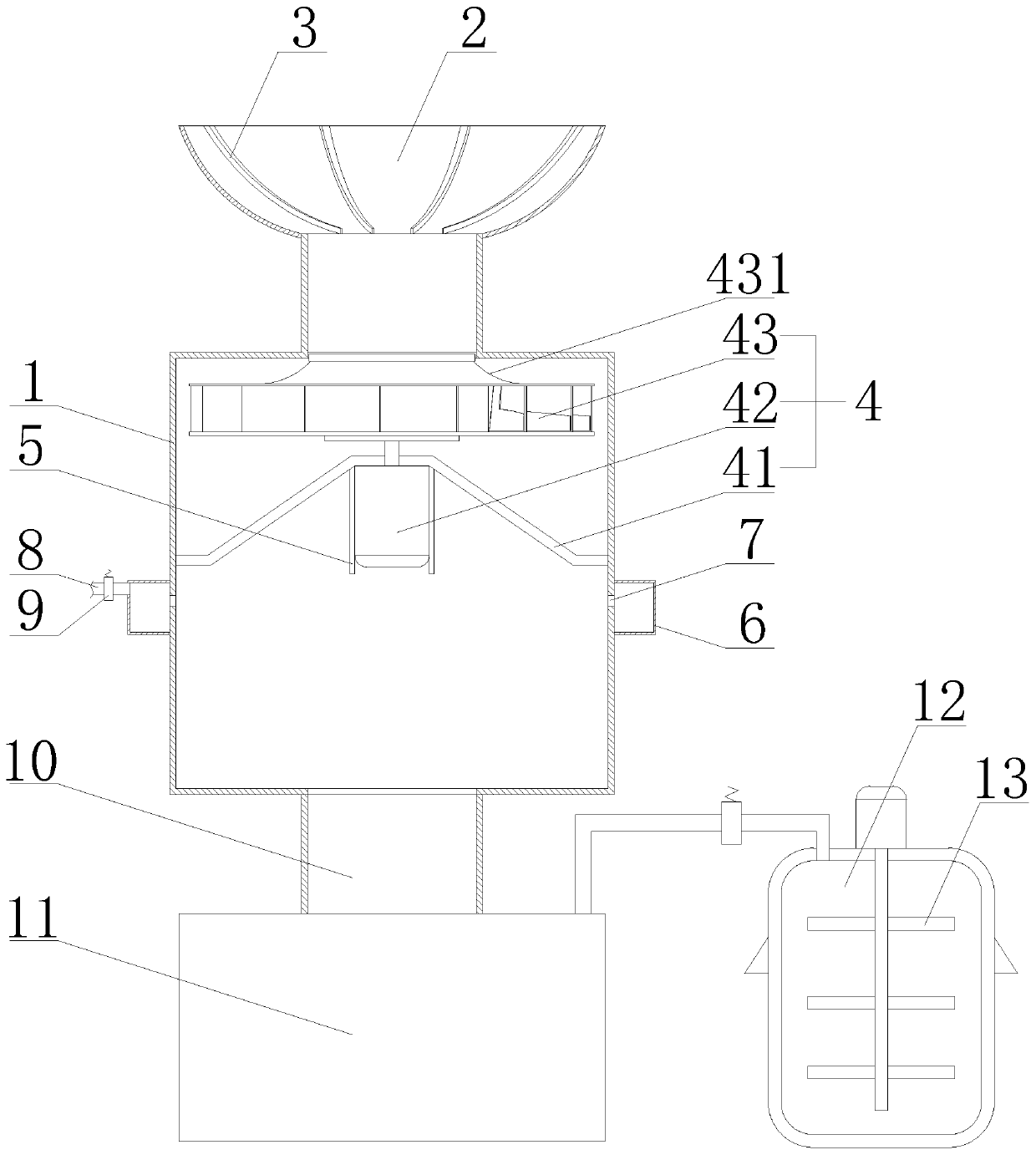

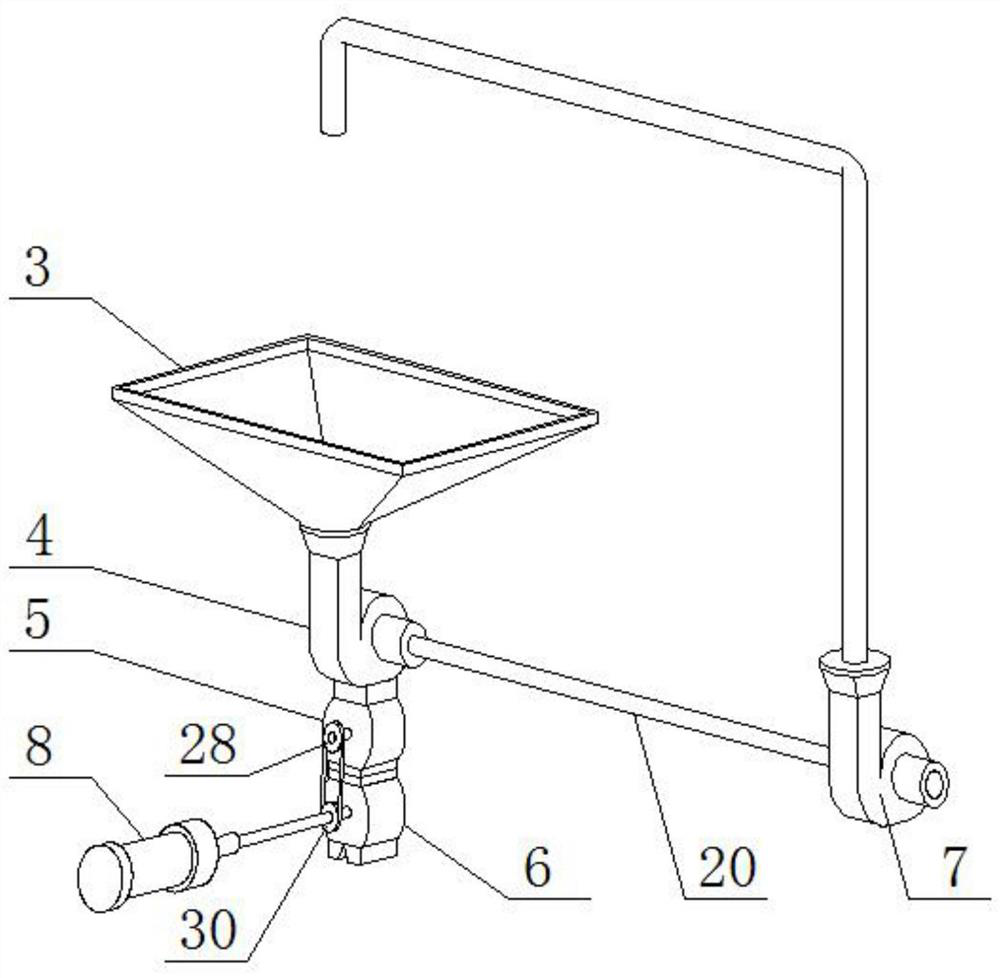

Oil paint recycling device for spraying and working method thereof

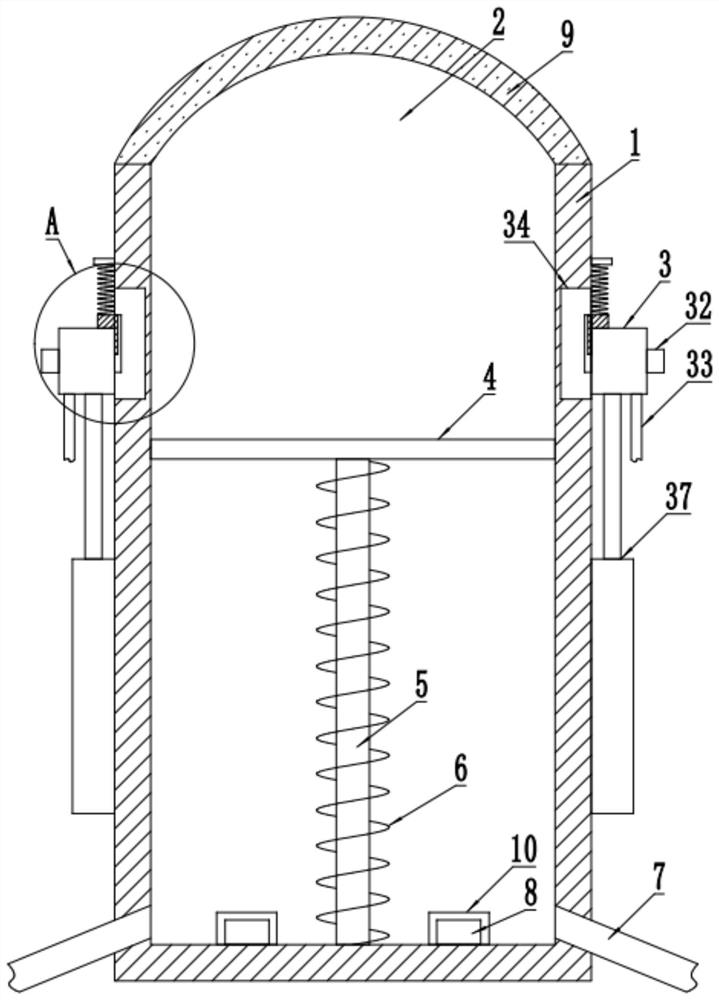

The invention discloses an oil paint recycling device for spraying and a working method thereof, relates to the field of coating, and aims at solving the problem that oil paint has viscosity and is liable to get attached to the wall in the collecting process. The oil paint recycling device is characterized by comprising a paint mist collecting mechanism, wherein the paint mist collecting mechanismcomprises a flow guide pipe, the flow guide pipe is provided with a paint mist entry channel which is used for collecting paint mist, an air guide mechanism which is used for guiding the paint mist,an alkaline liquor overflow mechanism which is used for lowering the viscosity of the paint mist and a paint mist escape channel which is used for discharging the paint mist from top to bottom in sequence, a paint mist collecting box is fixedly connected to the paint mist escape channel, and a reaction kettle used for regenerating the oil paint is connected to the paint mist collecting box. According to the oil paint spraying device, the paint mist is guided into the flow guide pipe through the air guide mechanism, the alkaline liquor overflow mechanism is utilized for lowering the viscosity of the paint mist, the situation that the oil paint is attached to the wall is reduced, the oil paint is conveniently collected into the paint mist collecting box, the discharge volume of VOC is reduced, then the reaction kettle is utilized for treating the collected oil paint so that the oil paint can become recyclable oil paint, and thus energy conservation and emission reduction are achieved.

Owner:绍兴市上虞嘉盛涂装有限公司

Sunshade flower box for garden landscape

PendingCN109769513AEasy to collect and recycleSave waterSelf-acting watering devicesReceptacle cultivationBad weatherWater pipe

The invention discloses a sunshade flower box for a garden landscape. The box comprises a flower box body, the interior of the flower box body is provided with a planting area, a filtering area and awater storage area from top to bottom, the bottom end of the flower box body is connected with a support base, and a controller is arranged on one side of the support base; the bottom of the plantingarea is provided with a soil layer, and the filtering area includes a first filtering plate and a second filtering plate. The box has the advantages that through the set filtering area, excess water can be filtered for collection and recycling, and a water source is saved; through the set water storage area, the excess water can be extracted through a set water pump and a water pipe, and convenience is provided for watering green plants in dry weather, which is conducive to the growth of the green plants; in addition, by setting a sunshade device, it is possible to open a sunshade curtain to achieve sun shade for the plants when encountering the bad weather or strong light illumination, the green plants are well protected, the structure is simple, the effect is obvious, and the practicality is strong.

Owner:安徽绿荣亭园林景观建设有限公司

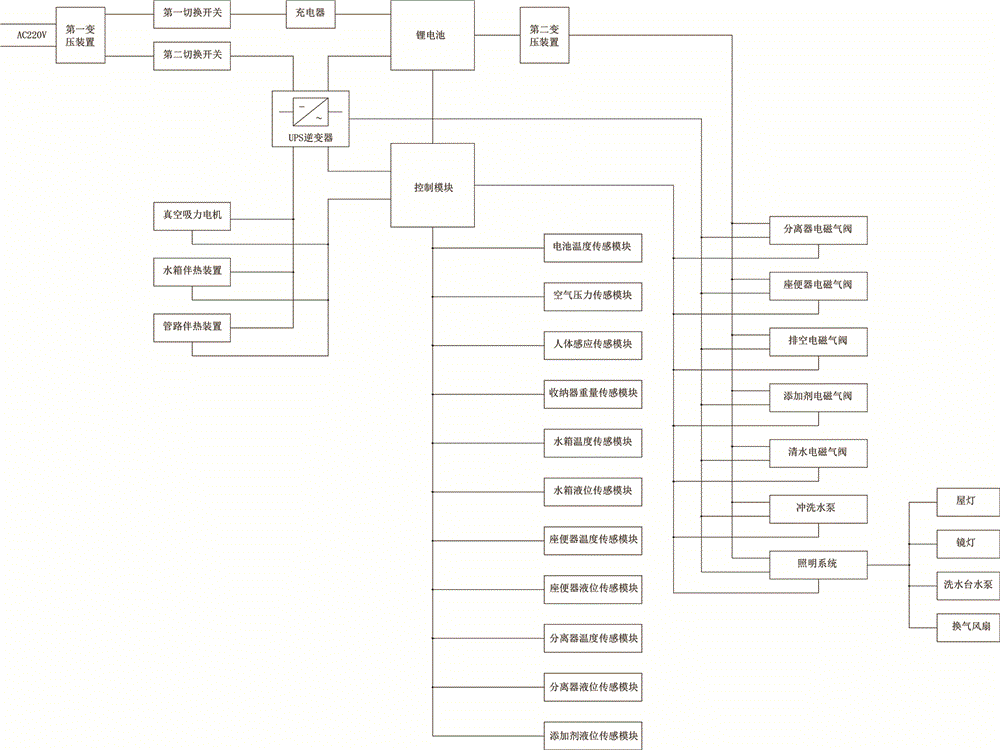

Integrated dry toilet system

InactiveCN106193226AEasy to collect and recycleSuppresses odorFlushing devicesLavatory sanitoryEmbedded systemLatrine

The invention discloses an integrated dry toilet system. Various sensing modules are detected through a control system, and work of various toilet devices is controlled through information fed back by the sensing modules. The toilet environment meets humanization conditions of modern homes, peculiar smells are restrained, dirt is collected and recycled more easily and conveniently, the environment temperature is automatically judged through sensors, and all toilet devices are subjected to antifreezing protection. A built-in lithium battery is used, a rail car power source can be used, and the rail car power source can be used for charging the built-in lithium battery to solve the problem that a toilet cannot be used under various conditions especially after hoop-drop regulation.

Owner:中铁伟业(宁波)轨道交通装备有限公司

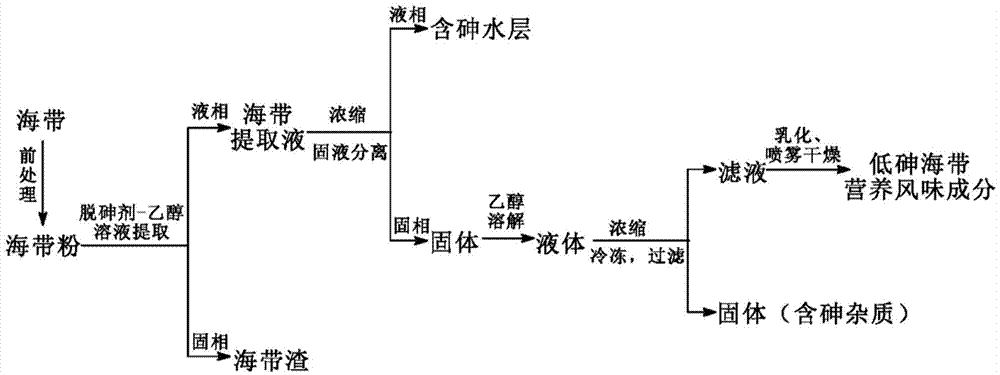

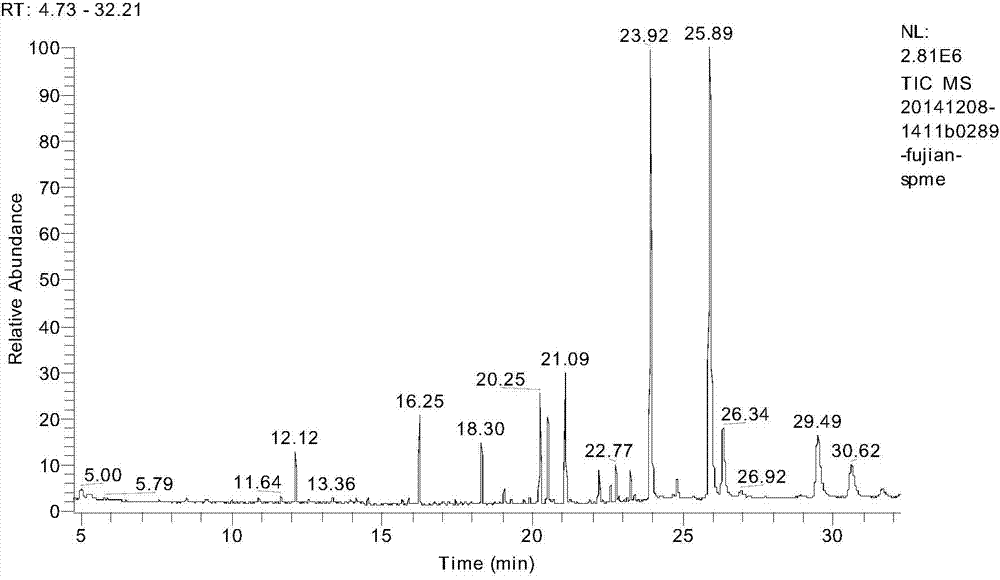

Preparation method of low-arsenic kelp nutritional flavor ingredients

The invention relates to a preparation method of low-arsenic kelp nutritional flavor ingredients. The method is composed of the following steps: drying kelp and crushing; adding 4-6 times of an ethanol-water solution into kelp powder and extracting for two times by microwaves; filtering under reduced pressure; combining filtrates to obtain a kelp extracting solution; concentrating the kelp extracting solution at a low temperature until the mass is 60%-75% of the mass of the raw materials; separating solid and a water layer to finish primary arsenic removal; dissolving the solids with ethanol and concentrating at a low temperature until the mass is 8%-23% of the mass of the raw materials; freezing and filtering; separating the filtrates and filtering dreg to finish secondary arsenic removal; and emulsifying, and spray-drying the filtrates to obtain a powdery product of the low-arsenic kelp nutritional flavor ingredients (the yield is about 6%-14% and the content of inorganic arsenic is less than or equal to 3mg / Kg). The preparation method takes the water as an arsenic removing agent and is safe and efficient; the removing rate of the inorganic arsenic is up to be more than 95%; the process is simple and convenient and the conditions are moderate; the nutritional and flavor ingredients in the product are sufficiently protected; and an inorganic arsenic layer has small weight and is free of emission.

Owner:GUANGZHOU UNIVERSITY

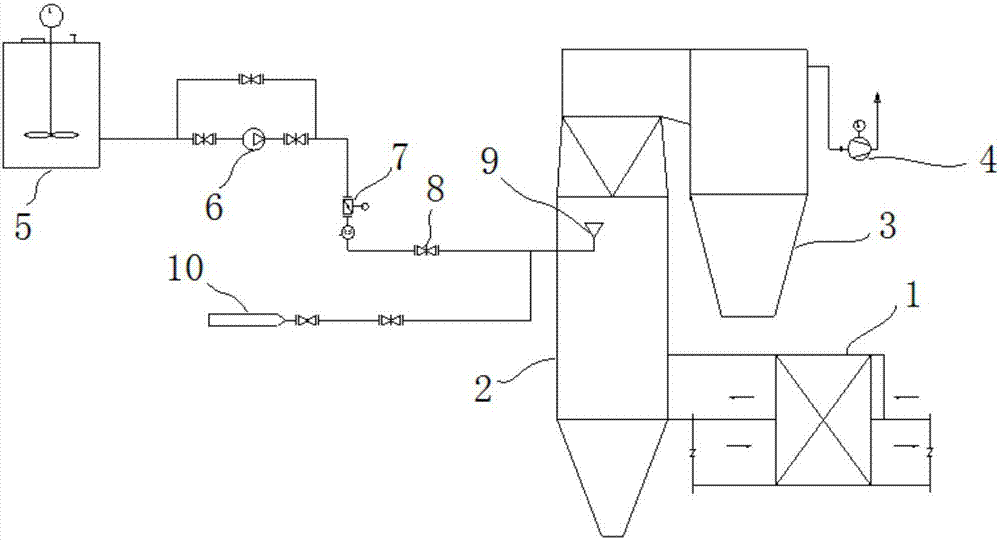

Desulfurization wastewater treatment method

InactiveCN106986401AAchieve pollutionNo corrosion problemsGeneral water supply conservationWaste water treatment from gaseous effluentsGas phasePhase change

The invention discloses a desulfurization wastewater treatment method, and belongs to the field of desulfurization wastewater treatment. A hot air unit introduces hot air into a phase change generator; meanwhile, a wastewater system conveys desulfurization wastewater to an atomizer in the phase change generator for atomization, hot wind formed by the desulfurization wastewater and the hot air is changed into a gas phase from a liquid phase through mass and heat exchange and the gas phase is discharged from an outlet of the phase change generator along with the hot wind; a solid formed by impurity crystal in the desulfurization wastewater enters the hot air unit at a solid outlet of the phase change generator under the action of gravity. According to the desulfurization wastewater treatment method, hot air in the phase change generator and atomized desulfurization wastewater drops are subjected to mass and heat exchange, and the desulfurization wastewater drops are evaporated and crystallized and then subjected to gas-solid separation. The problems that an original desulfurization balance is broken and equipment corrosion is caused in the desulfurization wastewater treatment process in a flue are solved, so that zero pollution and zero emission of the desulfurization wastewater are achieved.

Owner:张玉君

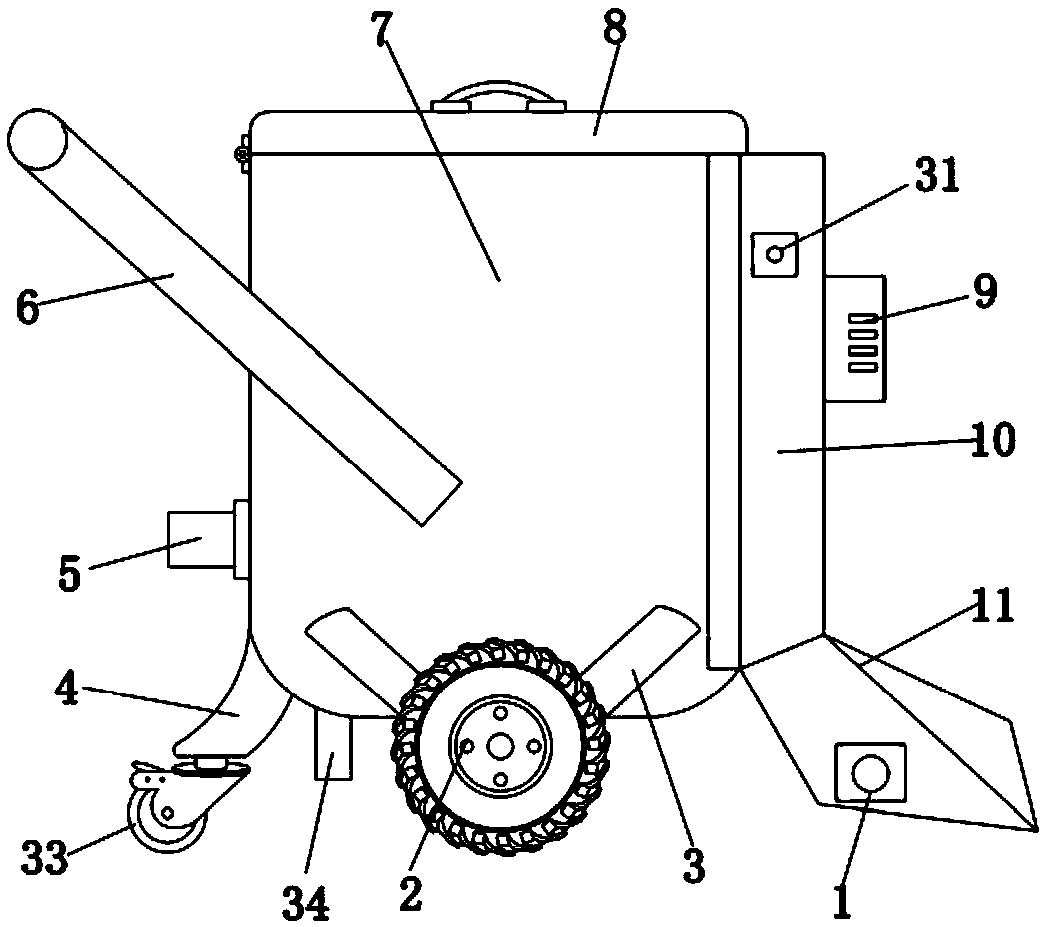

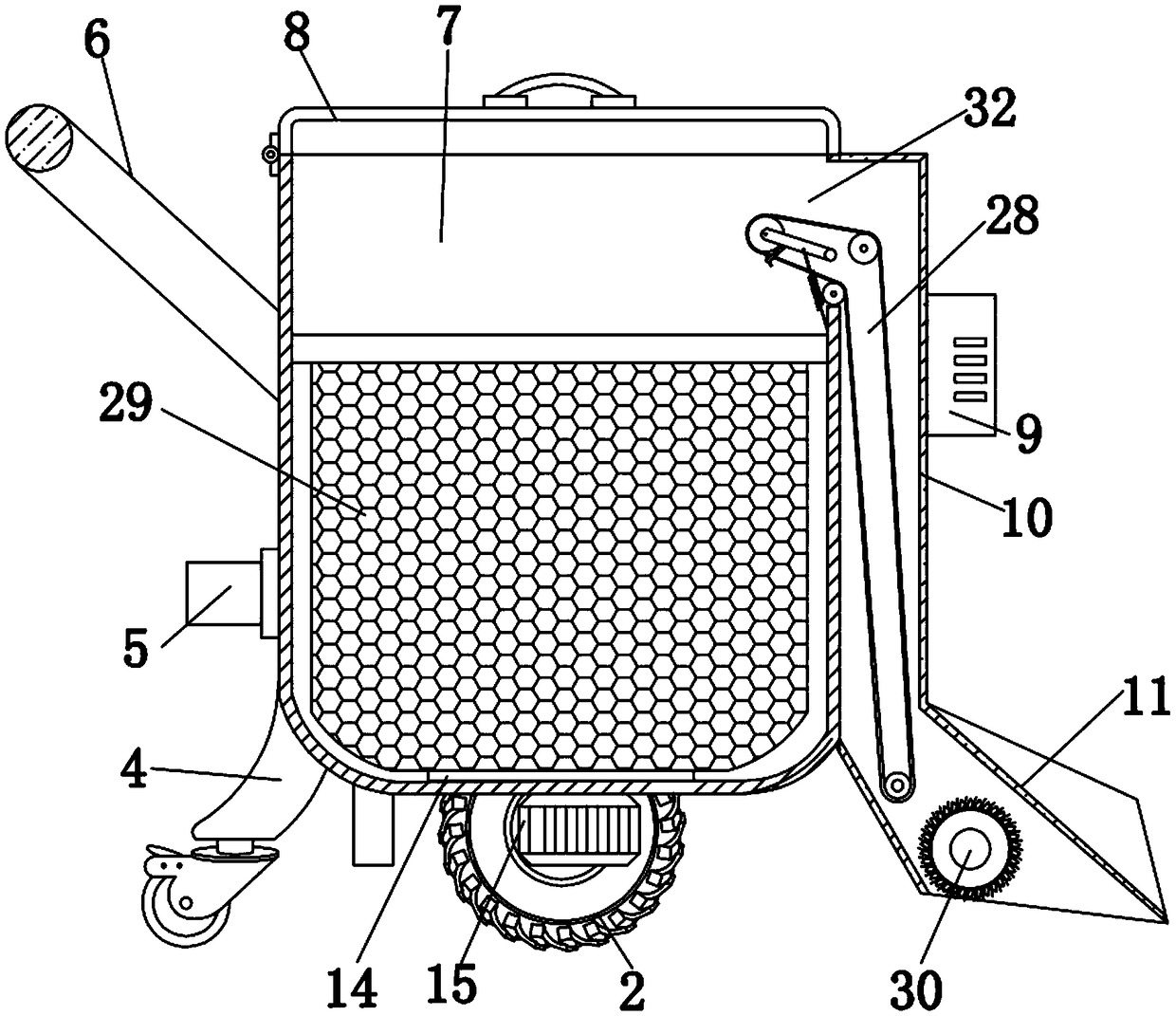

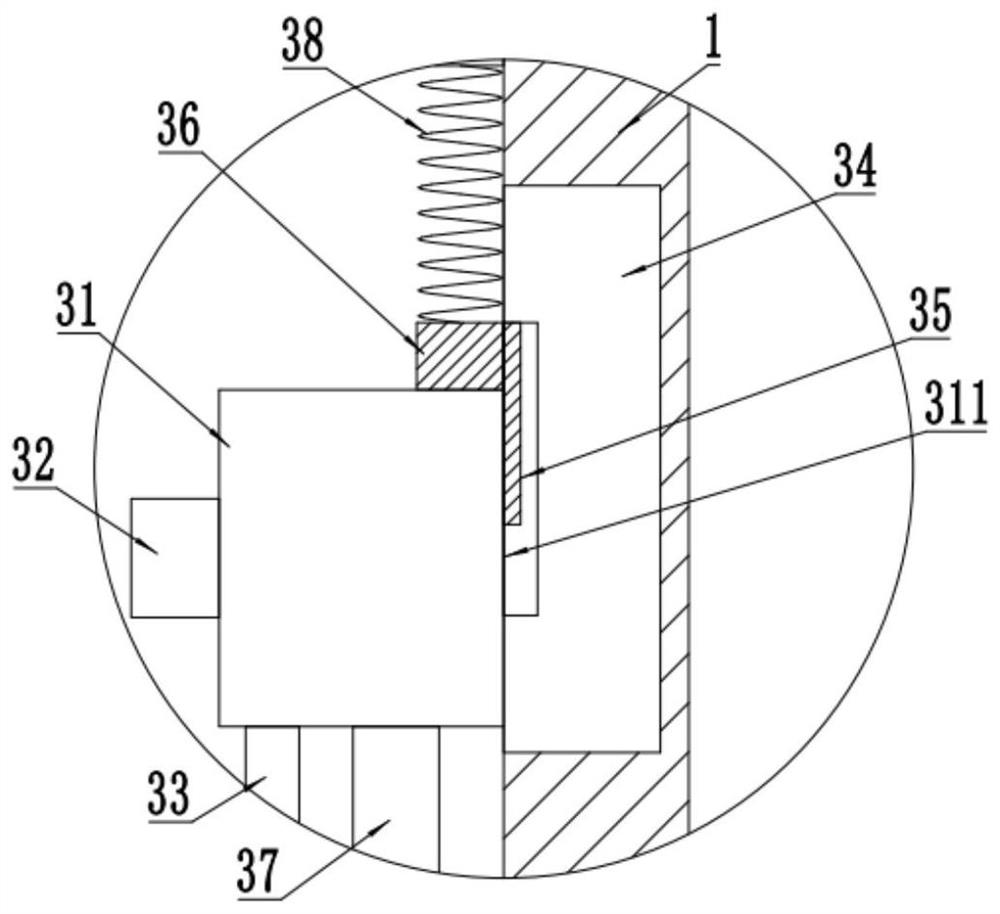

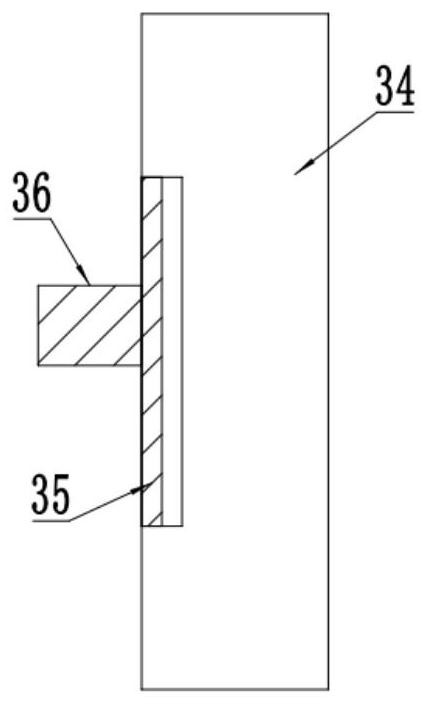

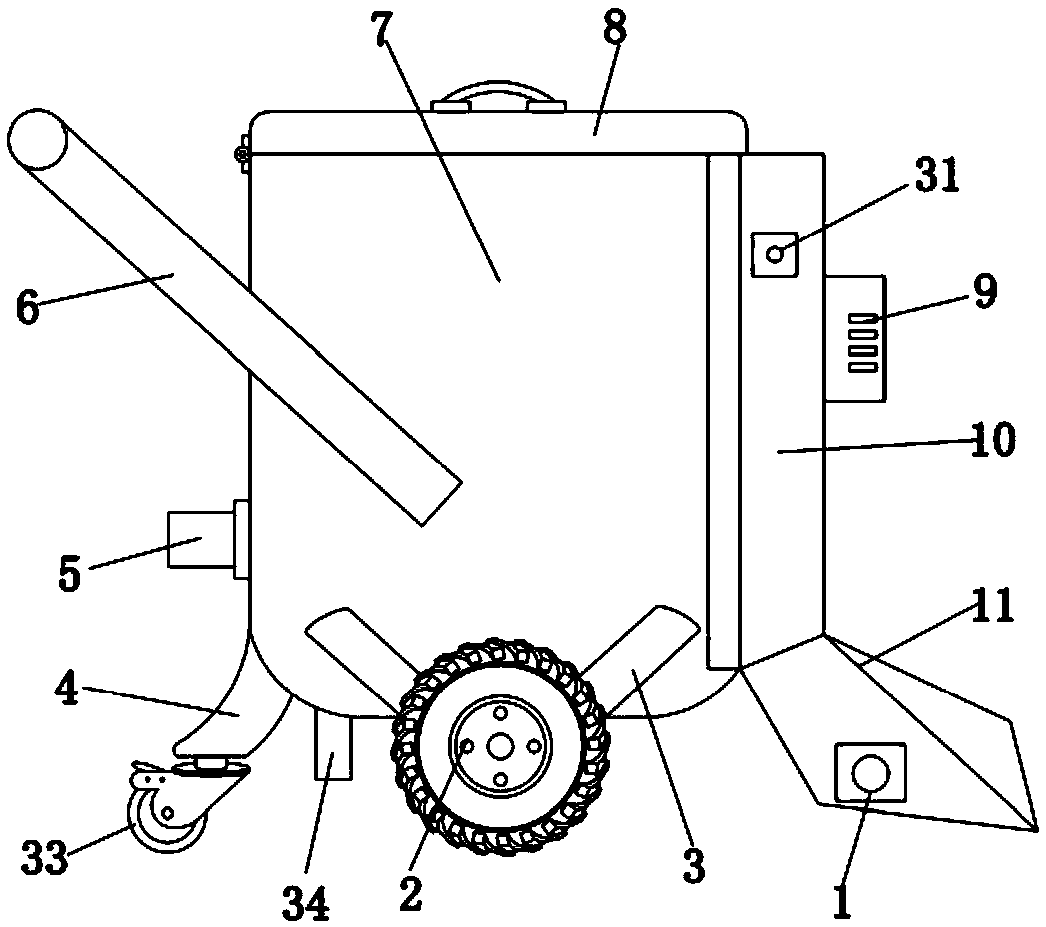

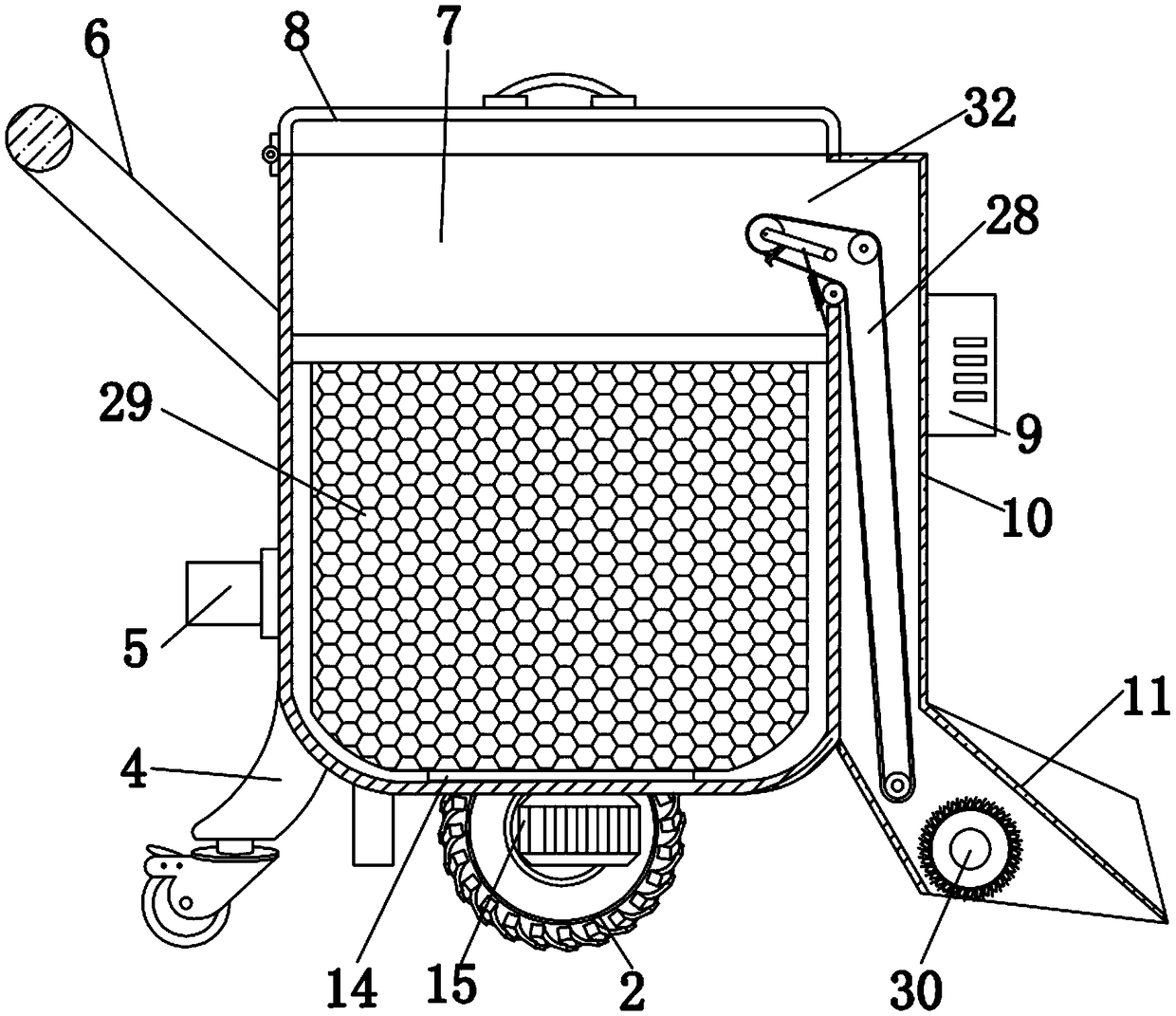

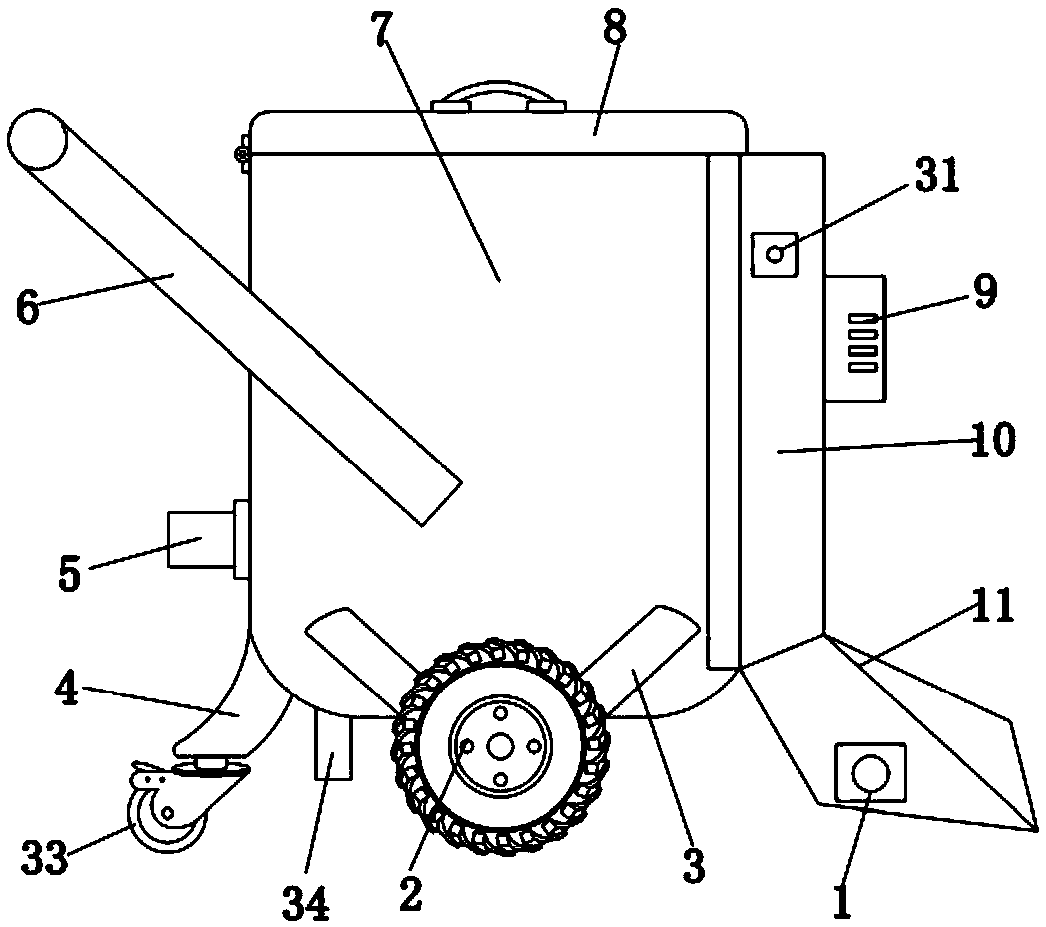

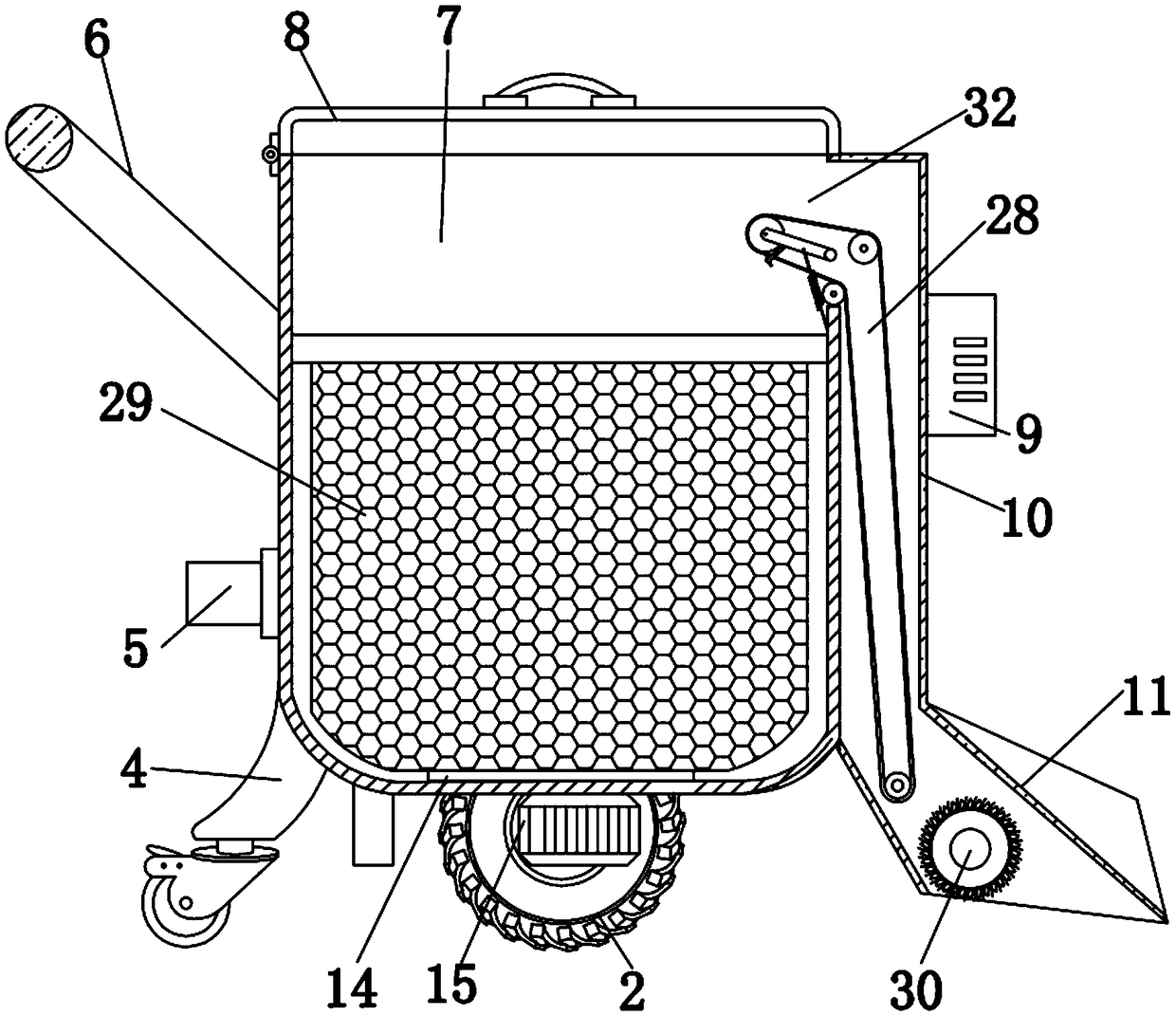

Waste scrap collection device for machining

The invention discloses a waste scrap collection device for machining. The device comprises a metal cylinder, a cylinder cover is hinged to the outer wall of one side of the top of the metal cylinder,an armrest frame is fixed to the outer wall of one side of the metal cylinder through bolts, brackets are welded to the outer walls of the two sides of the metal cylinder, and wheels are movably connected to the side walls of the two brackets; the side, away from the armrest frame, of the metal cylinder is provided with a waste scrap suction mechanism, the waste scrap suction mechanism comprisesa metal cover, an inclined waste scrap suction hopper is welded to the bottom of the metal cover, and the inner wall of the waste scrap suction hopper is provided with a cleaning mechanism; the side wall of the metal cover is fixedly provided with a negative pressure fan through bolts, the negative pressure fan is communicated with the inner wall of the metal cover, and a first roller is movably connected to the top of the inner wall of the waste scrap suction hopper. The device can clean collected waste scraps, the functions of the device are enriched, recycling is facilitated, the waste scraps are conveniently separated from other impurities, the purity of the waste scraps is improved, the waste scraps are conveniently driven to turn over, the effect of cleaning the waste scraps is improved, and the waste scraps are conveniently taken out.

Owner:江西佰嘉实业有限公司

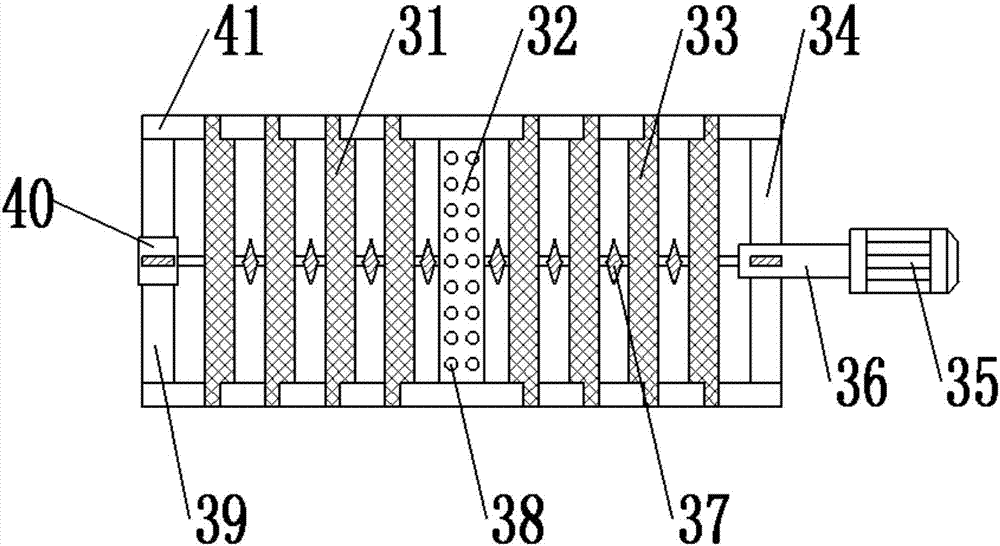

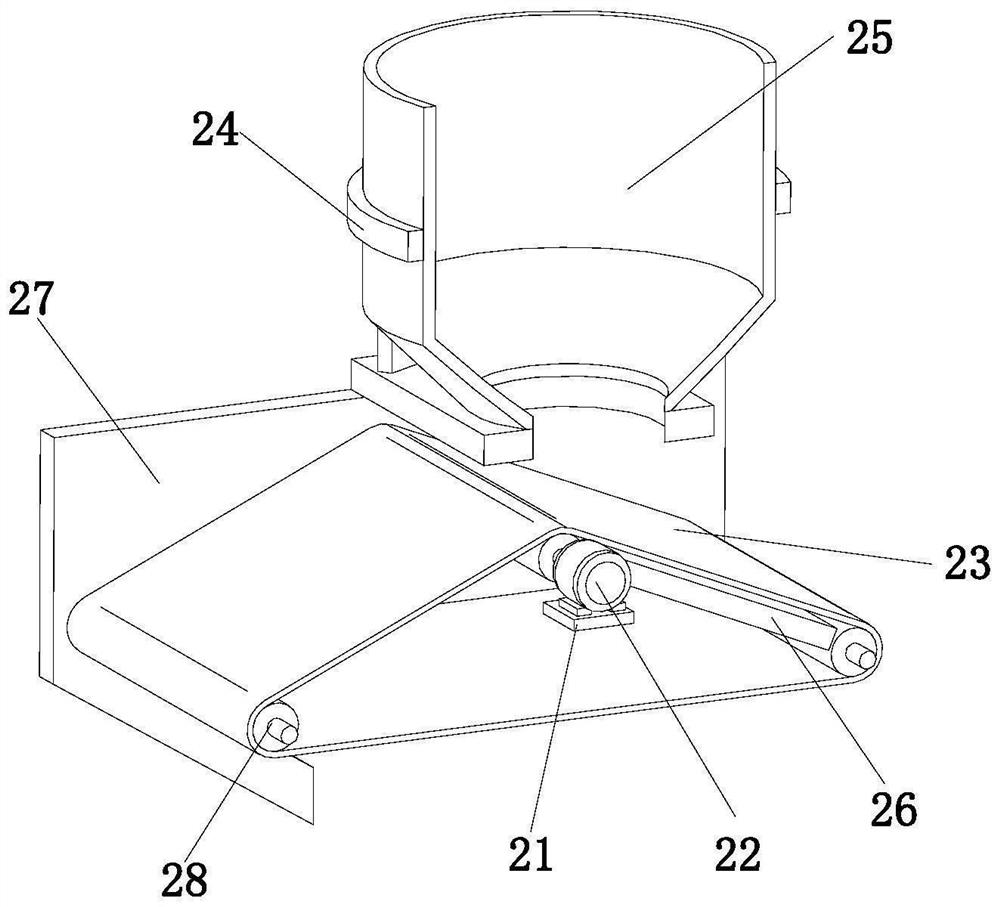

Fermenting equipment for agricultural organic fertilizer

InactiveCN107986832AFully fermentedAvoid accumulationBio-organic fraction processingOrganic fertiliser apparatusAgricultural engineeringOrganic fertilizer

The invention provides fermenting equipment for agricultural organic fertilizer. The fermenting equipment comprises a tank body, wherein a left end cover is arranged at a left-end opening of the tankbody; a right end cover is arranged at a right-end opening of the tank body; three sets of feeding pipes are equidistantly welded and fixed on the top surface of the tank body; the outer wall of the tank body is welded and fixed with a base plate by supporting plates; the base plate is arranged into a rectangular stainless steel plate; in addition, four sets of universal wheels with locks are fixed at four included angles of the bottom surface of the base plate by bolts; a material discharging device is welded and fixed on the bottom surface of the tank body; one set of first material turningdevice and one set of second material turning device are arranged inside the tank body; a waste gas filtering device is arranged at the top of the outer wall of the right end cover; a liquid drainingpipe is welded and fixed at the bottom of the right end cover. According to the fermenting equipment provided by the invention, the organic fertilizer in the tank body is stirred and turned over by the first material turning device and the second material turning device, so that sufficient turning of the organic fertilizer is facilitated, and the stacking phenomenon of the organic fertilizer is prevented; in addition, air is blown into the tank body, so that sufficient growth and reproduction of zymophyte are facilitated and full fermentation of the organic fertilizer is realized.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

Three-wire drawing steel pipe machine and using method thereof

The invention relates to the technical field of three-wire drawing machines, and discloses a three-wire drawing steel pipe machine and a using method thereof. The three-wire drawing steel pipe machinecomprises a frame and a drawing plate, the drawing plate is installed on the upper surface of the right side of the frame through bolts, and a drawing mechanism and an oiling mechanism are arranged above the frame; the drawing mechanism comprises a chain wheel, a clamping mechanism, a chain, a sliding block, a moving plate, a sleeve, a rotating shaft, a magnet, a stretching cylinder and an inserting groove; the number of the chain wheels is two, the chain wheels are rotatably installed on the two sides of the interior of the frame through rotating shafts, a chain is in transmission connectionbetween the chain wheels on the two sides, and a movable plate is slidably arranged on the surface of the frame above the chain. According to the steel pipe drawing device, the replaceable stretchingcylinder is inserted into the inserting groove, when steel pipes with different diameters are drawn, the stretching cylinder can be conveniently replaced, so that the different steel pipes are conveniently drawn, and in addition, structures such as a brush cylinder and an oil tank are arranged on the right side of the drawing plate, so that the drawn steel pipes can be conveniently oiled; therefore, the working efficiency is improved, and the waste of oil is reduced.

Owner:常州亿仁机械科技有限公司

A reinforced concrete separator

ActiveCN108283984BSeparation reachedEasy to collect and recycleSievingScreeningReinforced concreteRebar

Owner:北京博信晟益环保科技有限公司

Numerical control six-station drilling and reaming integrated machine

InactiveCN106799593AThe processing position is accurateImprove pass rateOther manufacturing equipments/toolsMaintainance and safety accessoriesNumerical controlElectrical and Electronics engineering

The invention relates to a numerical control six-station drilling and reaming integrated machine. The numerical control six-station drilling and reaming integrated machine is characterized in that six part fixtures are uniformly distributed on the circumference adopting the axis of a rotary disc as the circle center; each part fixture corresponds to one station label; limiting devices are arranged on the part fixtures; grooves are formed in the peripheries of the part fixtures; a locating device is arranged at a station of one station label; a cylinder is connected on the locating device; the end part of the cylinder is connected with a locating piece; a rough drilling mechanism, a fine drilling mechanism, a rough reaming mechanism and a fine reaming mechanism are anticlockwire arranged at a station of the station label on the right side of the locating device sequentially; a chip removal mechanism comprises a bracket; the tail end of the bracket is arranged right above the axis of the rotary disc; an air pipe is fixed to the bracket; one end of the air pipe is connected with a chip removal hood; the other end of the air pipe is connected with a chip collection tank through an induced draft fan; a collecting and releasing part is arranged at the tail end of the bracket; and the collecting and releasing part is connected with a clamping gun through a hanging rope. According to the numerical control six-station drilling and reaming integrated machine, the drilling and reaming processing positions are guaranteed accurate, the processing effect is good, and a chip removal protection function is achieved.

Owner:TIANJIN LONGZHI VALVE

A laser cutting machine turbocharged dust removal and noise reduction device

ActiveCN109202280BGood for healthReduce noiseMachines/enginesWelding/soldering/cutting articlesElectric machineDust control

The invention relates to the technical field of laser cutting environment-friendly machinery. A dust removal and noise reduction system, a laser cutting machine body and a seal cover are included, andthe laser cutting machine body is sleeved with the seal cover. The dust removal and noise reduction system is connected to the seal cover through a pipeline and comprises a fairing, a main turbine set, a special choke, an electromagnetic discharge device, an auxiliary turbine set, a motor, a waste box and a control box. The top of the fairing is fixed to the bottom of a support grid plate of thelaser cutting machine body. The main turbine set, the special choke and the electromagnetic discharge device are arranged in the laser cutting machine body sequentially from top to bottom. The fairing, the main turbine set, the special choke and the electromagnetic discharge device are fixedly connected through bolts. The waste box is fixed to the bottom of the inner side of the laser cutting machine body and corresponds to the electromagnetic discharge device. The auxiliary turbine set is fixed to the side wall of the laser cutting machine body. The equipment is low in energy consumption, simple to operate, small in noise and free of pollution, and generalization is facilitated.

Owner:赣州市畅达电梯销售有限公司

Ultra-fine powder classifying device

InactiveCN105013707AEasy to collect and recycleReduce health hazardsGas current separationDevice formUltra fine

The invention discloses an ultra-fine powder classifying device. The ultra-fine powder classifying device is formed by connecting two or more scattering chambers in series through pipelines. Discharge valves are arranged at the bottoms of the scattering chambers. An outlet of the scattering chamber in the former stage is connected with an inlet of the scattering chamber in the later stage. A material / gas feeding port of the first scattering chamber is externally connected with a material / gas feeding pipe. The last scattering chamber is connected with a dust collector through a pipeline. A feeding hopper is arranged on the material / gas feeding pipe. An air inlet of the material / gas feeding pipe is connected with an air compressor. The ultra-fine powder classifying device is simple in structure, convenient to overhaul and maintain and high in classification accuracy and efficiency, and powder is fully scattered in the scattering chambers under the effect of compressed air; the device forms a closed space, the risks to human health are small, and the environmental pollution is low; collecting openings are formed in the lower ends of the scattering chambers, and the powder is conveniently collected and recycled; the scattering chambers and the pipelines are plastic parts, and no pollution is generated to the powder; and the collected powder can be directly used without being treated, and the production efficiency is effectively improved.

Owner:BENGBU SILICON BASED MATERIALS IND TECH RES INST

Nanoparticle-embedded nitrogen-doped carbon nanotube and method for degrading tetracycline by using nanoparticle-embedded nitrogen-doped carbon nanotube

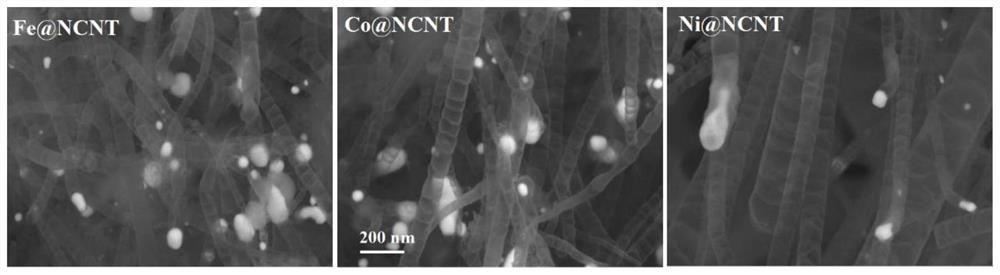

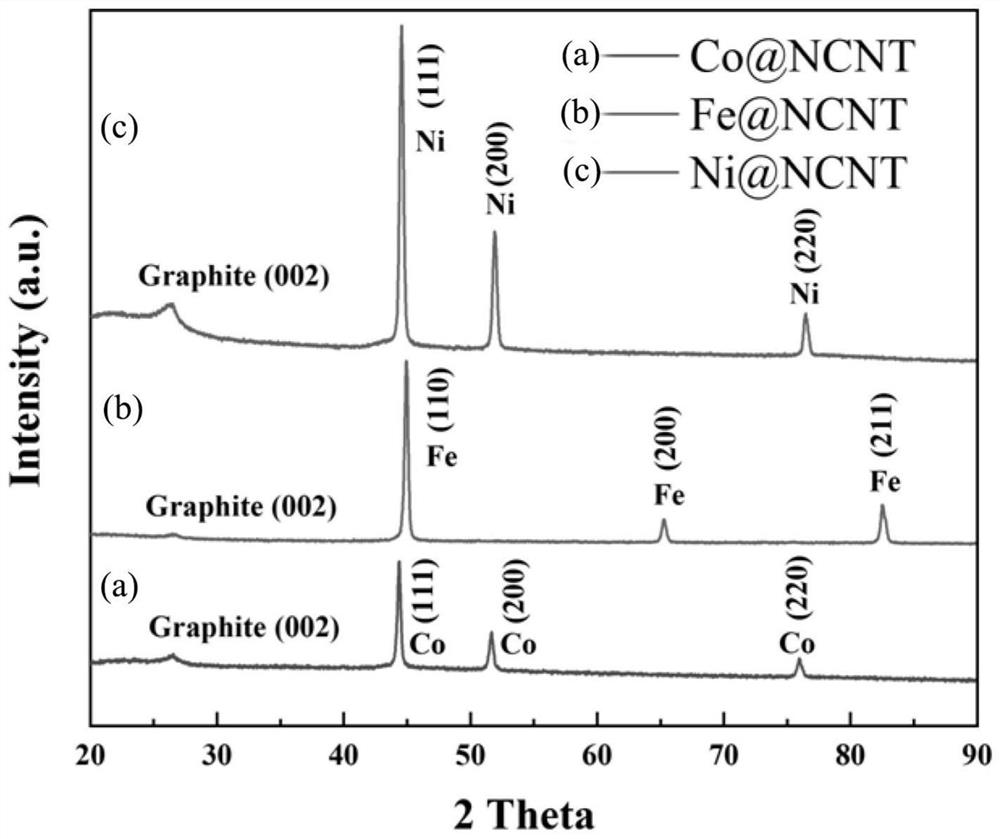

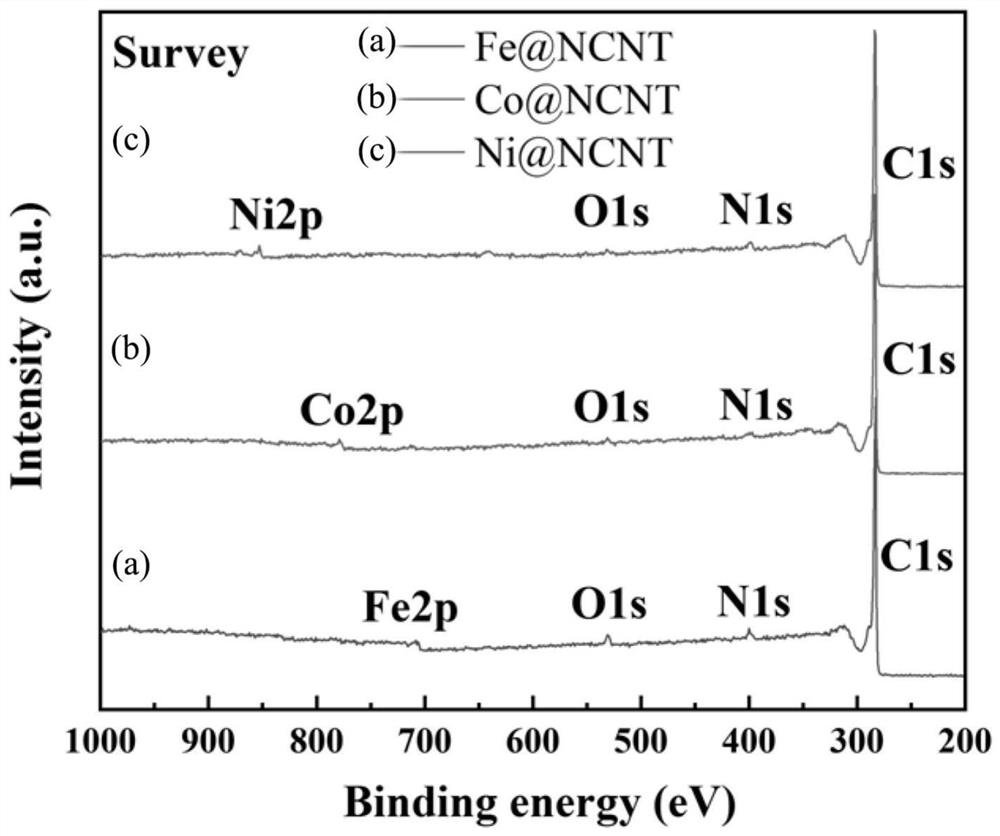

ActiveCN114849684ARich sourcesSimple preparation processWater/sewage treatment by irradiationWater contaminantsPtru catalystMicrowave - action

The invention provides a nanoparticle-embedded nitrogen-doped carbon nanotube and a method for degrading tetracycline by using the nanoparticle-embedded nitrogen-doped carbon nanotube. The preparation method of the nanoparticle-embedded nitrogen-doped carbon nanotube comprises the following steps: dissolving a metal salt and melamine in a solvent, uniformly mixing, and drying to obtain a precursor, the metal salt being one or more of a Fe-containing metal salt, a Co-containing metal salt and a Ni-containing metal salt; and in an inert atmosphere, pyrolyzing the precursor at 700-1200 DEG C until the reaction is finished, so as to obtain the nano particle embedded nitrogen-doped carbon nano tube. The method for degrading the tetracycline comprises the following steps: mixing the nano particle embedded nitrogen-doped carbon nano tube with a solution containing the tetracycline, and carrying out microwave irradiation to degrade the tetracycline. The Fe, Co and / or Ni nanoparticle embedded nitrogen-doped carbon nanotube catalyst prepared by the method has good microwave absorption performance, tetracycline can be rapidly and efficiently degraded under the action of microwaves, and the degradation rate can reach 99.5% or above.

Owner:重庆优钛实业有限公司 +1

Intelligent water-saving landscaping irrigation system

InactiveCN113229112AWon't wasteAvoid problems that interfere with normal irrigationWatering devicesLiquid fertiliser regulation systemsAgricultural engineeringLandscaping

One or more embodiments of the invention provide an intelligent water-saving landscaping irrigation system. The intelligent water-saving landscaping irrigation system comprises an irrigation pile, wherein a water receiving port is formed in the top end of the irrigation pile, a spraying unit is arranged at the side end of the irrigation pile in the circumferential direction, a water receiving plate is transversely arranged in the irrigation pile, a plurality of water seepage holes are uniformly formed in the water receiving plate at intervals, and meanwhile, a sensing unit is arranged at the inner bottom end of the irrigation pile; the spraying range of the spraying unit covers the adjacent irrigation pile, so that water is received through the water receiving port to press the water receiving plate to move downwards and compress an elastic piece in the last spraying irrigation process or when rainfall occurs, the received water slowly seeps and leaks downwards along the water seepage holes until the water completely seeps downwards, when the elastic piece pushes the water receiving plate to move upwards and reset, the sensing unit is triggered again to trigger the spraying unit to spray again, the adaptive self-adjustment of the irrigation amount is intelligently completed, and in addition, the received water is discharged through a drainage pipe so as to be conveniently collected and recycled.

Owner:WUHU INST OF TECH

A machine waste scrap cleaning apparatus

The invention discloses a machine waste cleaning apparatus including a metal barrel, At that top side of the metal barrel, an outer wall is hinged with a barrel cover, An out wall of one side of thatmetal barrel is fixed with an armrest by bolts, A support is weld on that outer wall of both sides of the metal barrel, side wall of the two brackets are movably connected with the wheels, A materialsuction mechanism is arranged on that side of the metal barrelr far away from the armrest frame, The suction mechanism comprises a metal cover, the bottom end of the metal cover is welded with an inclined suction hopper, the inner wall of the suction hopper is provided with a cleaning mechanism, the side wall of the metal cover is fixed with a negative pressure fan by bolts, and the negative pressure fan is communicated with the inner wall of the metal cover, and the top end of the inner wall of the suction hopper is movably connected with a first roller. The invention can clean the collectedwaste chips, enriches the function of the device, facilitate recovery, facilitates separation of the waste chips from other impurities, improves the purity of the waste chips, facilitates driving thewaste chips to turn over, improves the cleaning effect of the waste chips, and facilitates taking out the waste chips.

Owner:江西佰嘉实业有限公司

Filter screen cleaning structure

The invention discloses a filter screen cleaning structure. The filter screen cleaning structure comprises a shell, wherein a filter screen plate is obliquely arranged in the shell, a discharging opening is formed in the left side wall of the shell, a sealing pipe is fixedly mounted on the left side wall of the shell, an opening in the right end of the sealing pipe corresponds to the discharging opening, a liquid discharging pipe is fixedly mounted on the side wall of the lower end of the shell, the right end of the liquid discharging pipe penetrates through the side wall of the shell and communicates with the interior of the shell, an impeller is arranged in the liquid discharging pipe, a connecting rod is vertically inserted in the center of the impeller in a penetrating mode, the lower end of the connecting rod is rotationally connected to the bottom end face in the liquid discharging pipe, the upper end of the connecting rod penetrates through the upper end face of the liquid discharging pipe and is rotationally connected to a magnetic rotary disc. According to the structure, sludge and impurities can conveniently enter the sealing pipe along the discharging opening at the lower end of the inclined surface of the filter screen plate to be collected and recycled, so that meshes in the filter screen plate are prevented from being blocked by the sludge impurities, and the filtering effect of a filter is ensured.

Owner:山东凤鸣桓宇环保有限公司

Non-woven fabric winding device for non-woven fabric machinery

PendingCN113860039AEasy to cleanAvoid Wrinkle OffsetMechanical cleaningPressure cleaningEngineeringNonwoven fabric

The invention relates to the technical field of non-woven fabric production, and discloses a non-woven fabric winding device for non-woven fabric machinery. The non-woven fabric winding device for the non-woven fabric machinery comprises a shell, wherein guide grooves are formed in the middles of the inner walls of the left side and the right side of the shell in a penetrating manner; a fixing frame is vertically and fixedly mounted in the middle of the inner wall of the shell; an air guide groove is formed in the fixing frame; and air blowing holes are uniformly formed in the inner side of the fixing frame. According to the non-woven fabric winding device for the non-woven fabric machinery provided by the invention, through combination of an air blowing pump, the fixing frame, an air suction nozzle, an air suction pump and a purification water tank, thread residues adhering to the two sides of a non-woven fabric body can be effectively cleaned, and meanwhile, the cleaned thread residues can be guided into the purification water tank so as to be collected and purified; a filter screen plate is arranged in the purification water tank, so that the thread residues in water can be filtered so as to be conveniently collected and recycled; and through combination of a servo motor, a lead screw, a limiting block, an infrared emitter and an infrared receiver, the non-woven fabric body can be limited, and meanwhile, the non-woven fabric body can be detected.

Owner:YANGZHOU ATLAN PERFORMANCE MATERIALS CO LTD

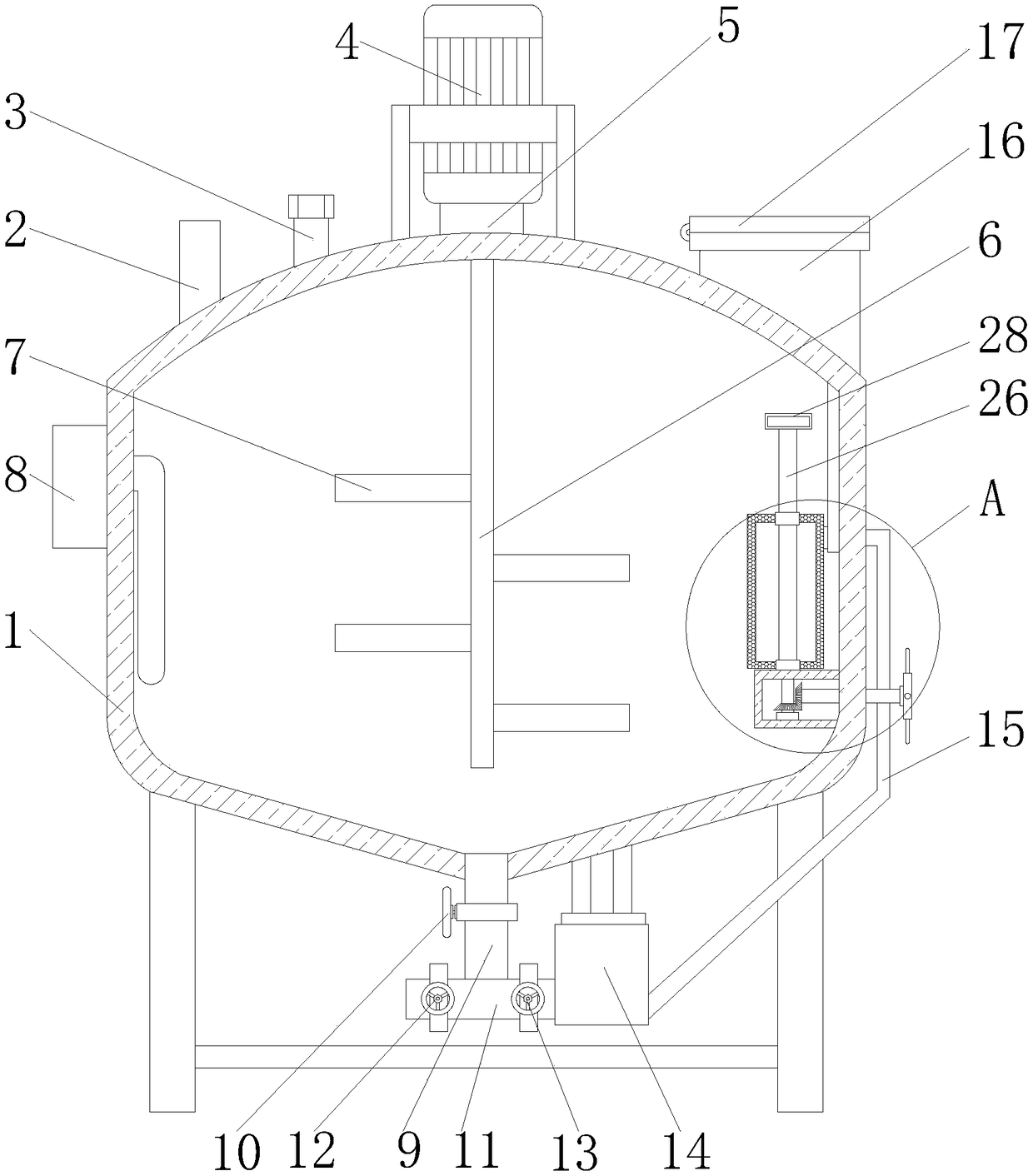

Environment-friendly utilization device for recycling zinc sulfate production waste residues

PendingCN109433118AUniform temperatureUniform concentrationChemical/physical/physico-chemical processesEnvironmental resistanceSulfate

The invention discloses an environment-friendly utilization device for recycling zinc sulfate production waste residues. The environment-friendly utilization device comprises a tank body, wherein a feeding tube and a supply tube are arranged on the left side of the top of the tank body; a cap is connected with the top of the side surface of the supply tube in a threaded sleeving manner; a drivingmotor is fixedly mounted at the top of the tank body; the output end of the driving motor is fixedly connected with a speed reducer; a shaft rod is fixedly connected with the bottom end of the speed reducer. Zinc powder in precipitate collected from a filtering cylinder can be effectively utilized, so that the utilization rate of the zinc powder is increased, waste of a zinc powder material is avoided, and the cost of materials is lowered; in addition, a threaded rod fixed with a first bevel gear is driven to rotate by a second bevel gear by rotating a rotating handle, and a threaded sleeve and a filtering cylinder are moved upwards, so that the precipitate is conveniently taken out from an overhaul hole and is collected and recycled, the consequence that production is affected as the precipitate is accumulated in a tank is avoided, manual cleaning in the tank is avoided, and consumption of labor can be reduced.

Owner:江西神叶实业有限公司

Chemical laboratory garbage treatment device capable of avoiding pollution and using method thereof

InactiveCN112264114AAvoid polluting the soilConvenient filtration and purificationDispersed particle filtrationSpecific water treatment objectivesElectric machineryPolluted environment

Owner:李珂

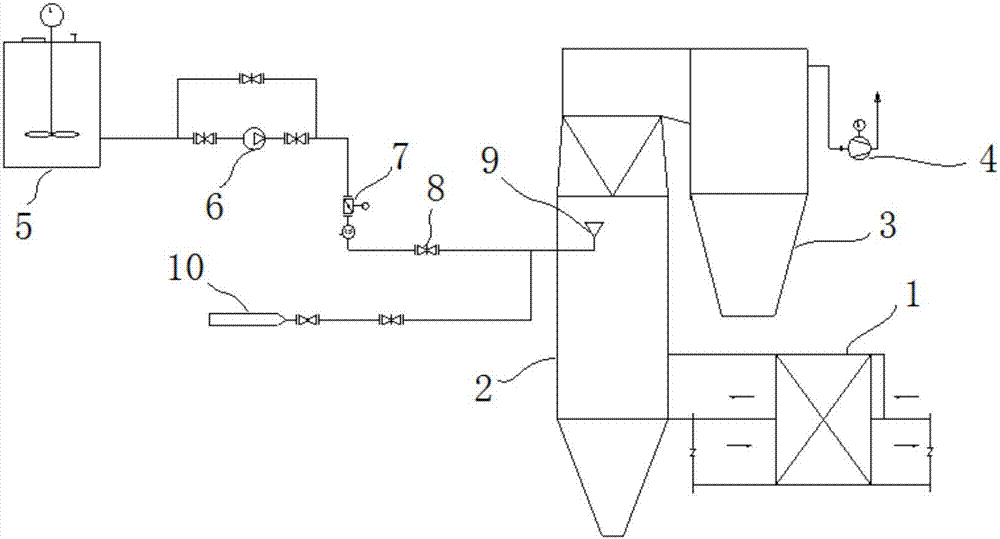

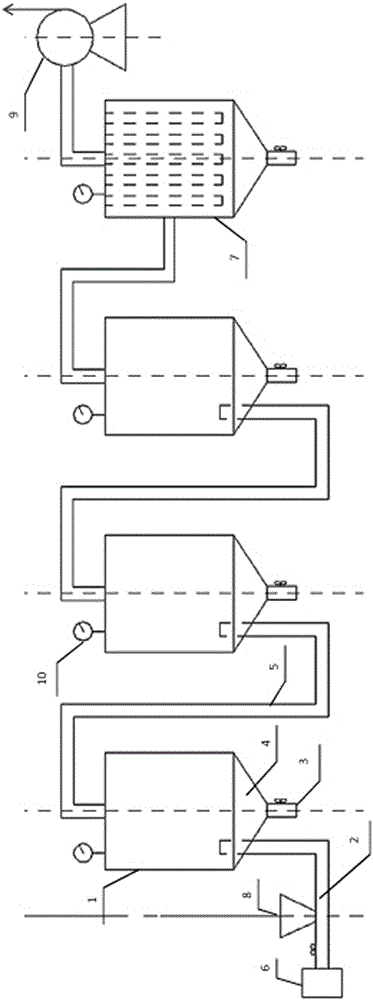

Desulfurization wastewater treatment apparatus and control system and control method thereof

PendingCN107010687AEasy to collect and recycleAvoid corrosionWater/sewage treatmentWaste water treatment from gaseous effluentsEngineeringPollution

The invention discloses a desulfurization wastewater treatment apparatus and a control system and control method thereof, and belongs to the field of desulfurization wastewater treatment. The desulfurization wastewater treatment apparatus comprises a wastewater system, a phase change generator, and a hot air unit; the top of the phase change generator is provided with an outlet, the bottom of the phase change generator is provided with a solid outlet, the phase change generator is communicated with the hot air unit, and the wastewater system is communicated with an atomizer in the phase change generator. A controller is electrically connected to a water pump, adjusting valve and flowmeter in the wastewater system, a compressed air unit, a temperature detector, a fan and a heater. The controller controls the temperature of an outlet of the phase change generator to be 10 DEG C and above higher than the dew point temperature, and hot air temperature is controlled to 80 DEG C and above. The problems are solved that original desulfurization balance is destroyed and equipment corrosion s caused during desulfurization wastewater treatment in a flue, and zero pollution and emission of the desulfurization wastewater are achieved.

Owner:张玉君

Environment-friendly processing device for machining waste chips

InactiveCN108943216AHigh purityEasy flipBark-zones/chip/dust/waste removalEnvironmental resistanceEngineering

The invention discloses an environment-friendly processing device for machining waste chips. The environment-friendly processing device for the machining waste chips comprises a mental barrel, a barrel cover is hinged to the outer wall of one side of the top end of the metal barrel, the outer wall of one side of the metal barrel is fixedly provided with an armrest frame through bolts, supports areconnected to the outer walls of the two sides of the metal barrel in a welded mode, a wheel is movably connected to the side walls of the two supports, a material sucking mechanism is arranged on oneside, far away from the armrest frame, of the metal barrel, the material sucking mechanism comprises a metal cover, a suction hopper which is obliquely arranged is connected with the bottom end of the metal cover in a welded mode, a cleaning mechanism is arranged on the inner wall of the suction hopper, a negative pressure fan is fixedly arranged on the side wall of the metal cover through bolts,the negative pressure fan communicates with the inner wall of the metal cover, and a first roller is movably connected to the top end of the inner wall of the suction hopper. According to the environment-friendly processing device for the machining waste chips, the collected waste chips can be cleaned, functions of the device are enriched, the waste chips can be recycled conveniently and separated conveniently from other impurities, so that purity of the waste chips can be improved; and the waste chips can be conveniently driven to overturn, the cleaning effect of the waste chips can be improved, and the waste chips can be conveniently taken out.

Owner:江西佰嘉实业有限公司

Inflatable packing bag convenient to recycle

InactiveCN110104329AEasy to collect and recycleQuick deflationPackage recyclingContainers to prevent mechanical damageEngineeringBreathing

The invention relates to the field of inflatable packing bag equipment, in particular to an inflatable packing bag convenient to recycle. The inflatable packing bag convenient to recycle comprises anair inlet chamber and a plurality of air columns, second heatsealing lines are arranged between the air columns and the air inlet chamber, ventilation holes communicating with the air inlet chamber and the air columns are reserved on the second heatsealing lines, one end of the air inlet chamber is closed, the other end of the air inlet chamber is open, and an air valve is arranged at an opening of the air inlet chamber. According to the inflatable packing bag convenient to recycle, the multiple air columns are inflated by the same air inlet chamber, the air valve is shared, after the air valve is used, the air inlet chamber is torn down through tearing lines, so that the air columns discharge air in the air columns through the ventilation holes communicating with the air columns, rapid air releasing is realized, and collection and recycling are facilitated.

Owner:天津东远立信科技有限公司

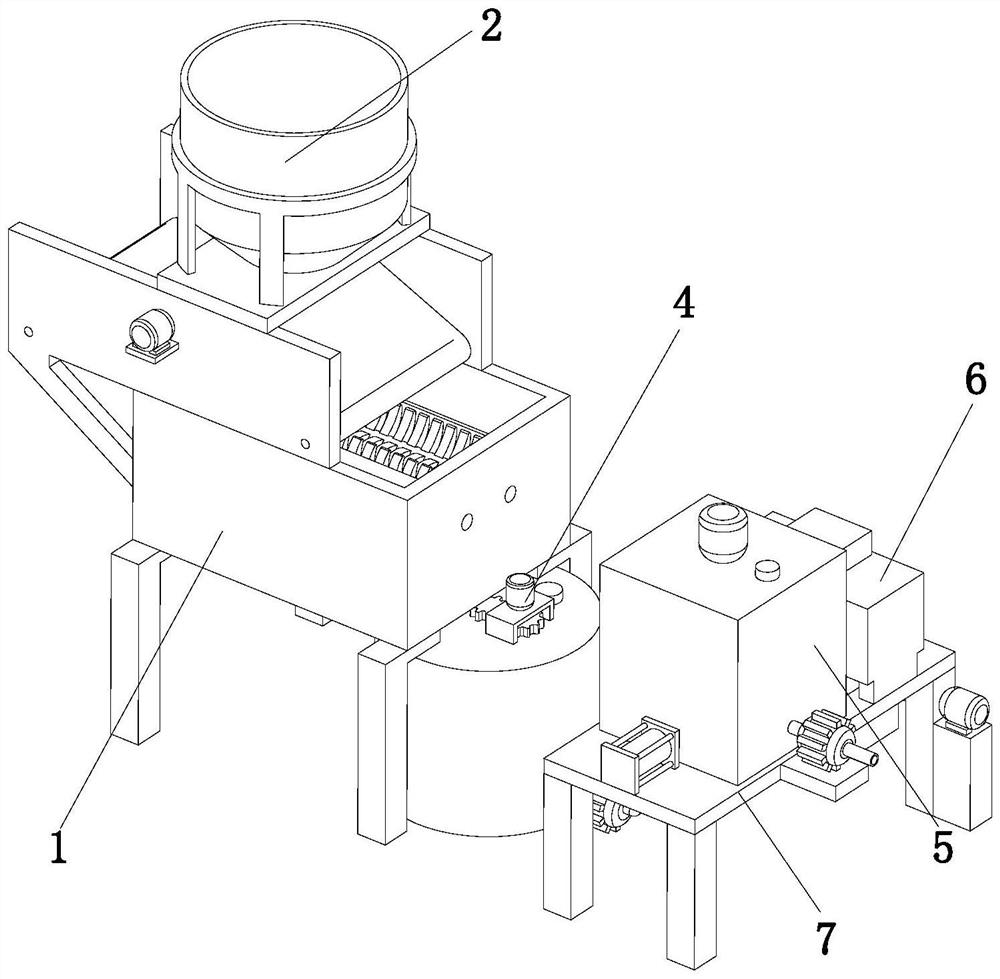

Equipment for preparing aluminum fluoride from electrolytic aluminum carbon residues

InactiveCN113264545AImprove crushing efficiencyPromote leachingAluminium fluoridesAluminum fluoridePhysical chemistry

The invention discloses equipment for preparing aluminum fluoride from electrolytic aluminum carbon residues, and belongs to the technical field of electrolytic aluminum carbon residue recycling, the equipment comprises a crushing device, a screening device, a leaching device and a filtering device, the crushing device is horizontally arranged on the ground, the screening device is arranged on the crushing device, the leaching device is arranged beside the crushing device and is in butt joint with the crushing device, and the filtering device is arranged beside the leaching device. Impurities in the electrolytic aluminum carbon residues are screened through the screening device firstly, then the electrolytic aluminum carbon residues are smashed through the smashing device, subsequent leaching and filtering are more thorough, the preparation purity of aluminum fluoride is improved, the screened and smashed electrolytic aluminum carbon residues are fully leached through the leaching device, And the filtering device is used for carrying out sufficient fluorine precipitation and filtrating on the leached liquid, so that the preparation efficiency is high.

Owner:深圳市红火火机械装备有限公司

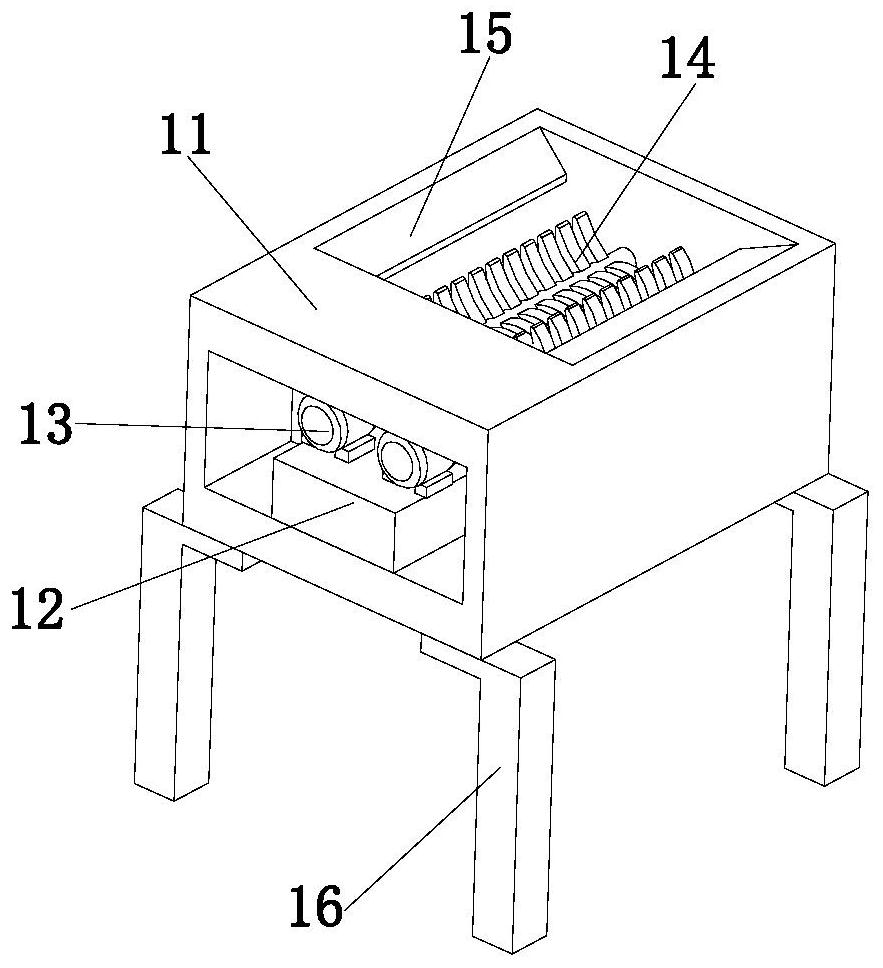

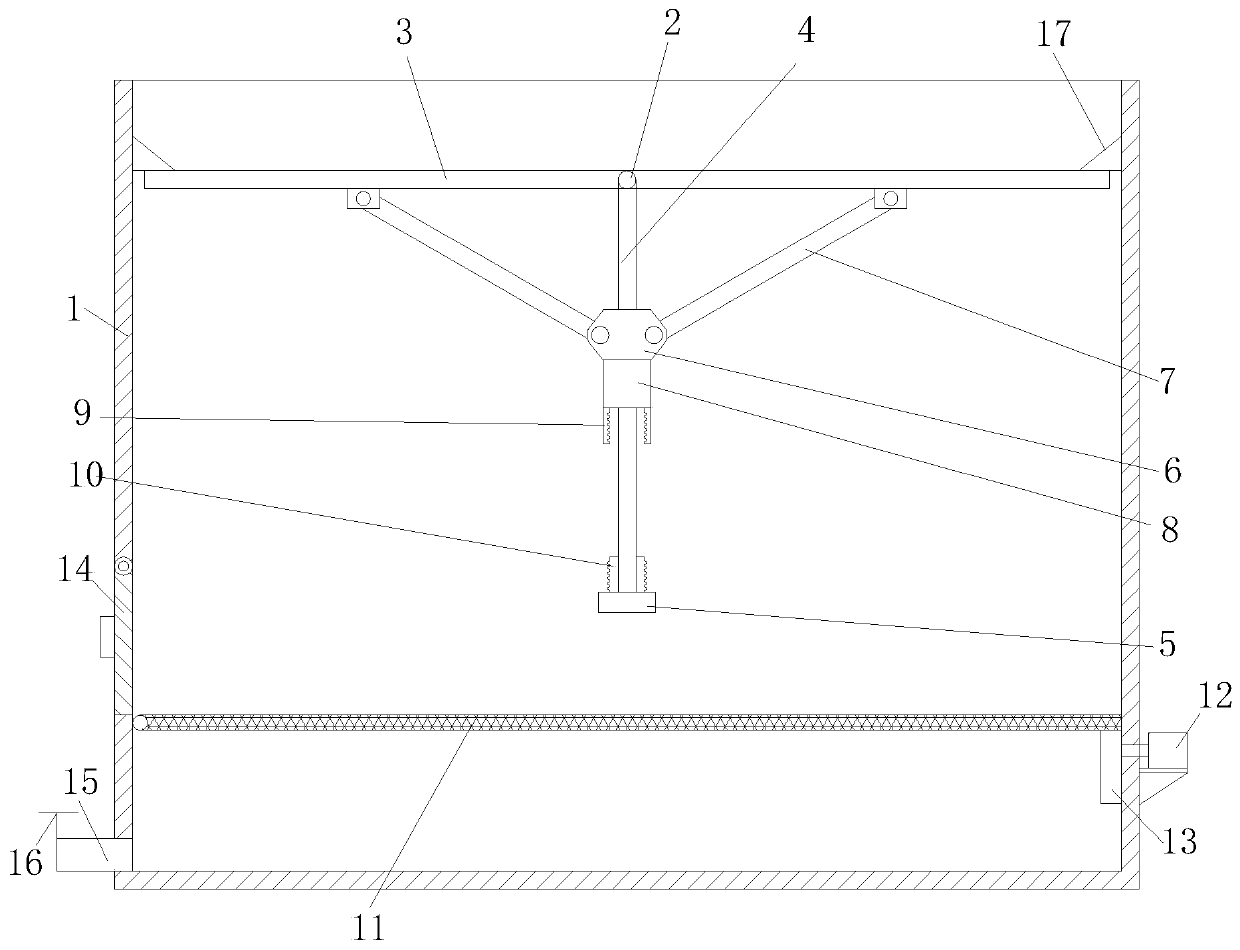

A chip collection device for CNC machine tools

ActiveCN108890379BRealize unified collectionEasy to collect and recycleMaintainance and safety accessoriesNumerical controlStructural engineering

The invention discloses a debris collection device for computer numerical control machine tools which is arranged below a machine tool and which comprises a box body; the box body is of open-top box structure; a rotary rod is arranged in the middle of the top of the box body along the length of the top of the box body; two bearing plates are mounted on the rotary rod in hinged manner and are arranged in symmetry about the midline of the rotary rod; when the two bearing plates are rotated to be horizontal, the top of the box body is closed; a bearing component that drives the bearing plates torotate is mounted below the bearing plates; a separation component is arranged below the box body; the separation component and the bottom of the box body are spaced. The debris collection device provides centralized collection of debris and prevents manual collection; the separation component helps implement solid-liquid separation and facilitates the collection and recycling of waste; a vibrating component helps automatically clean debris on the bearing plates so that labor intensity is reduced for operators.

Owner:安徽省临泉县智创精机有限公司

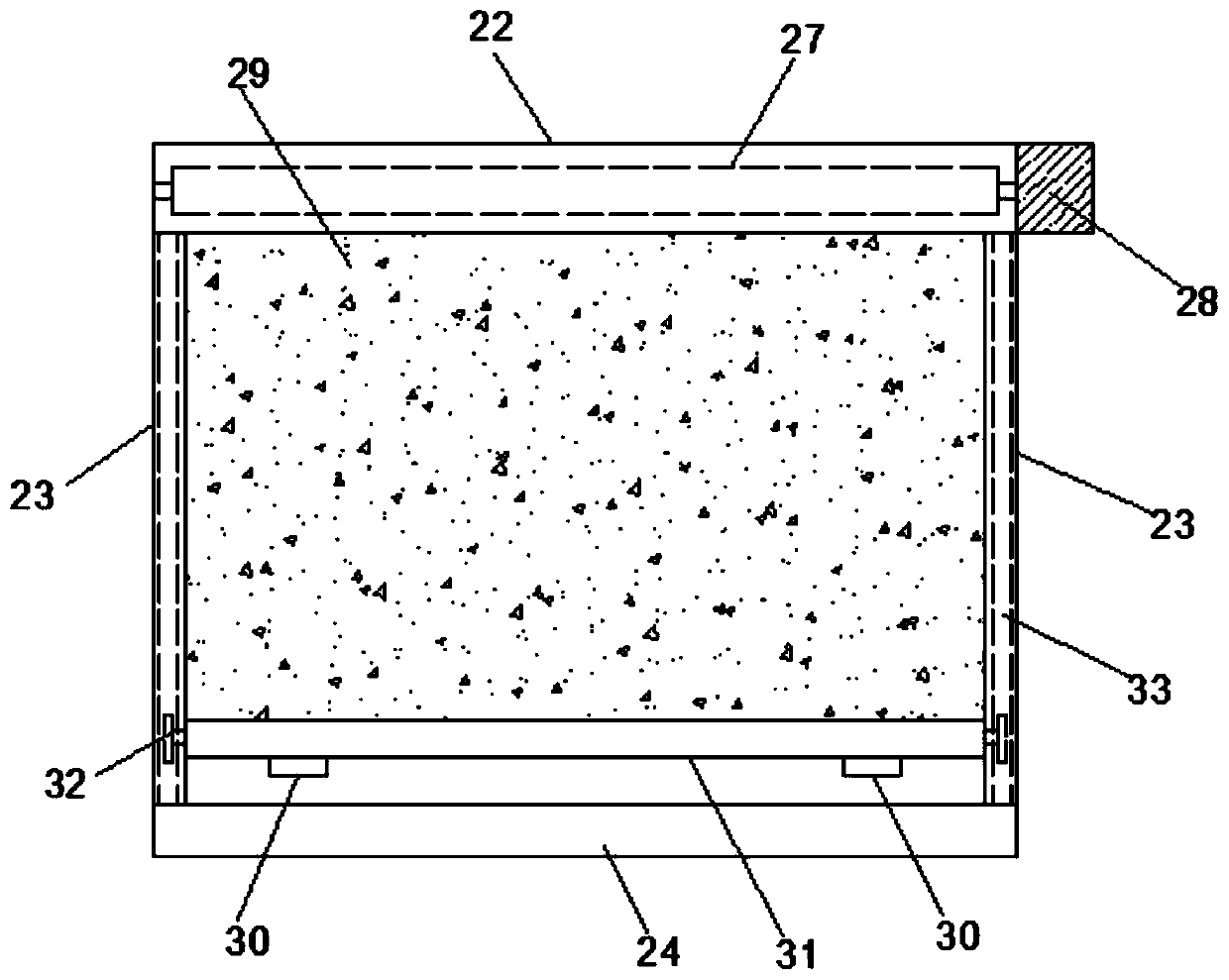

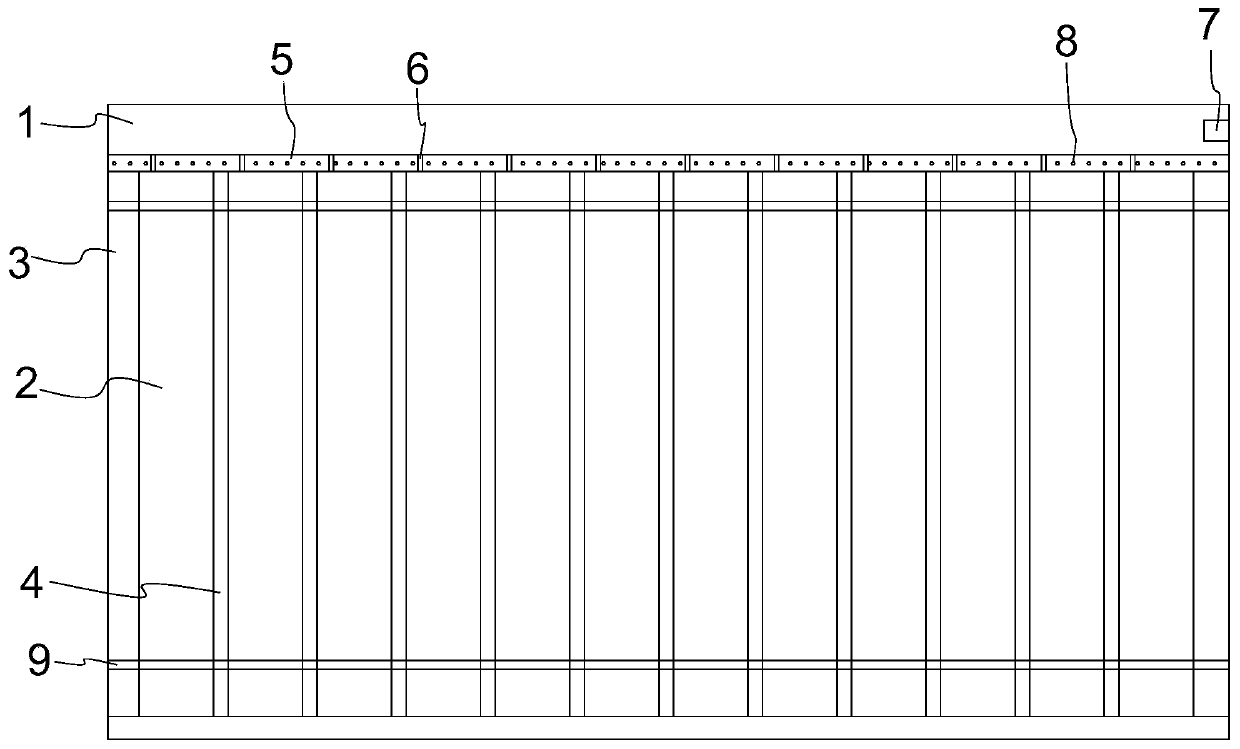

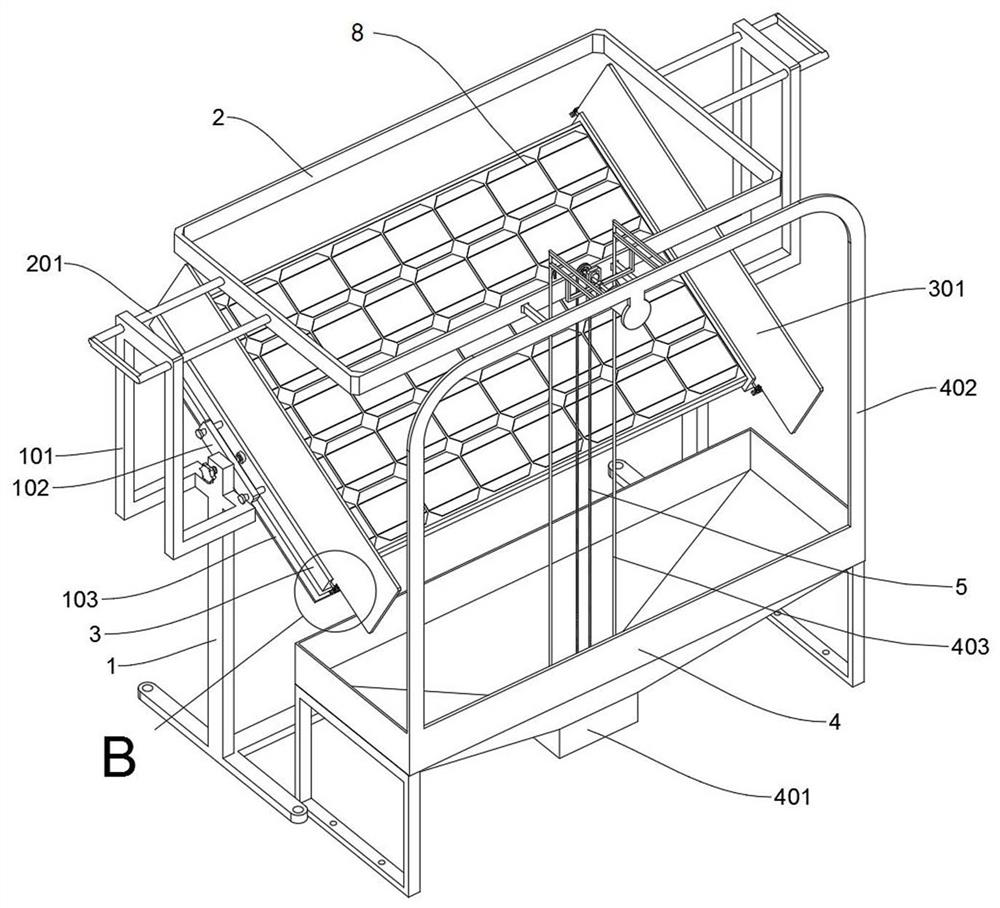

A Physical Load Photovoltaic Module Testing Equipment

The invention discloses a physical load photovoltaic component testing equipment, relates to the technical field of photovoltaic testing equipment, and solves the problem that in the existing testing equipment, in order to facilitate the disassembly and replacement of photovoltaic panels, it is necessary to switch and switch the ice particle blocking mechanism manually and frequently. The operation is troublesome and inconvenient. A physical load photovoltaic module testing equipment, including a bracket; the bracket includes a vertical support frame and an inclined installation plate, and the whole bracket is composed of left and right vertical support rods and bottom I-shaped ground contact seats welded together, wherein the left and right vertical support rods Two vertical bracing frames are welded symmetrically at the top, and a rectangular lowering tray is slidably installed between the top bracing plates of the two vertical bracing frames, and two inclined mounting plates are welded symmetrically on the inside of the top of the left and right vertical bracing bars. The blocking frame of the present invention can block the ice particles flying forward from the photovoltaic panel, which can further reduce the falling loss of the ice particles when used together with the shutter, and facilitate subsequent collection and recycling.

Owner:JIANGSU LINYANG PHOTOVOLTAIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com