Preparation method of low-arsenic kelp nutritional flavor ingredients

A technology of flavor components and kelp, which is applied in the field of preparation or processing of food or food materials, can solve problems such as the lack of arsenic removal process, the inability to ensure that the inorganic arsenic content of kelp nutrients meets the national food safety and hygiene standards, and the food safety of products needs to be studied. , to achieve the effects of good food safety, convenient collection and recycling, and full protection of nutrition and flavor components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Preparation of nutritional and flavor components of low-arsenic kelp

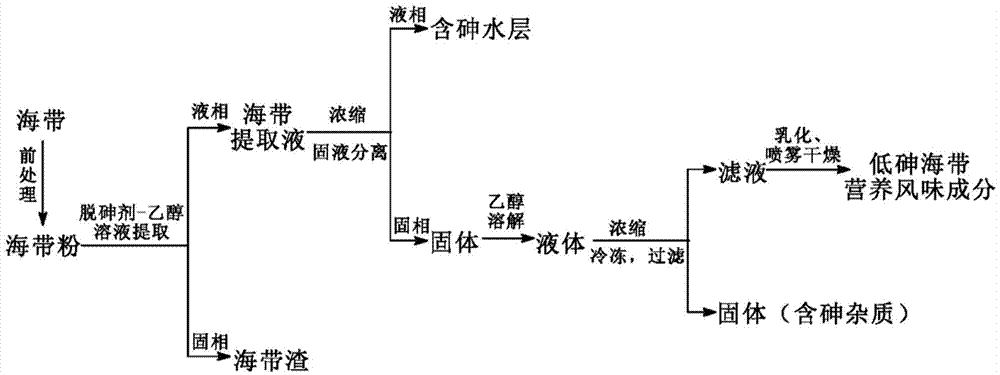

[0025] see figure 1 , the preparation method of low-arsenic kelp nutritional flavor components in this example is as follows:

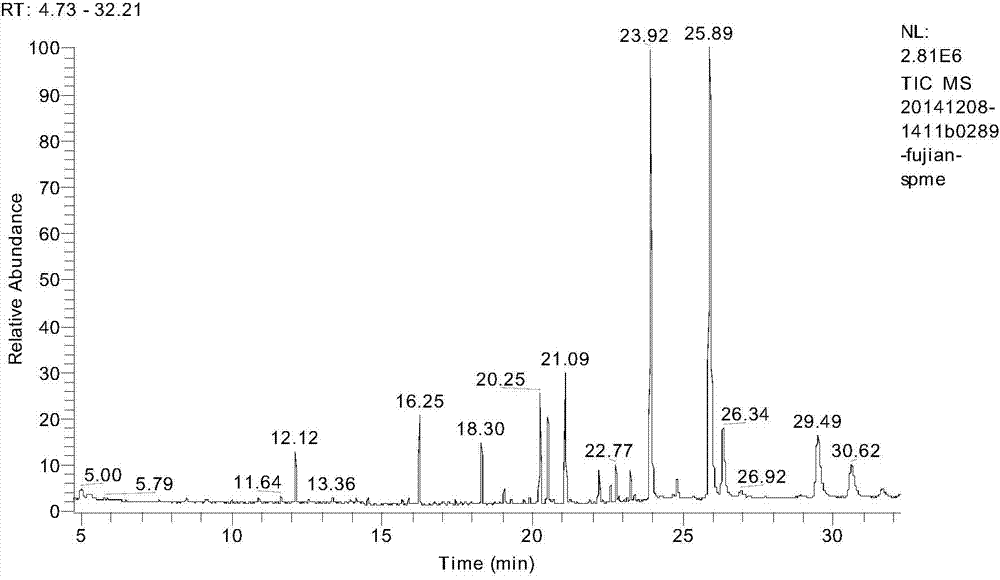

[0026] (1) Drying the kelp produced in Fujian at 100°C and pulverizing it to 50 meshes to obtain kelp powder;

[0027] (2) Put 100 g of the above-mentioned kelp powder into a microwave extraction device, add 600 mL of arsenic removal agent-ethanol mixed solution, conduct microwave extraction for 20 min, filter under reduced pressure, and collect the filtrate. Add 400mL of arsenic-removing agent-ethanol mixed solution to the filter residue, extract with microwave for 10min under the same conditions, filter under reduced pressure, collect and combine the filtrates, and obtain 808.01g of extract. Wherein, the arsenic-removing agent is water, and the mixing ratio of water and ethanol is water:ethanol=1:4 volume ratio; the microwave extraction conditions are that the tempera...

Embodiment 2

[0053] One, the preparation method of low-arsenic kelp nutritional flavor components

[0054] see figure 1 , the preparation method of low-arsenic kelp nutritional flavor components in this example is as follows:

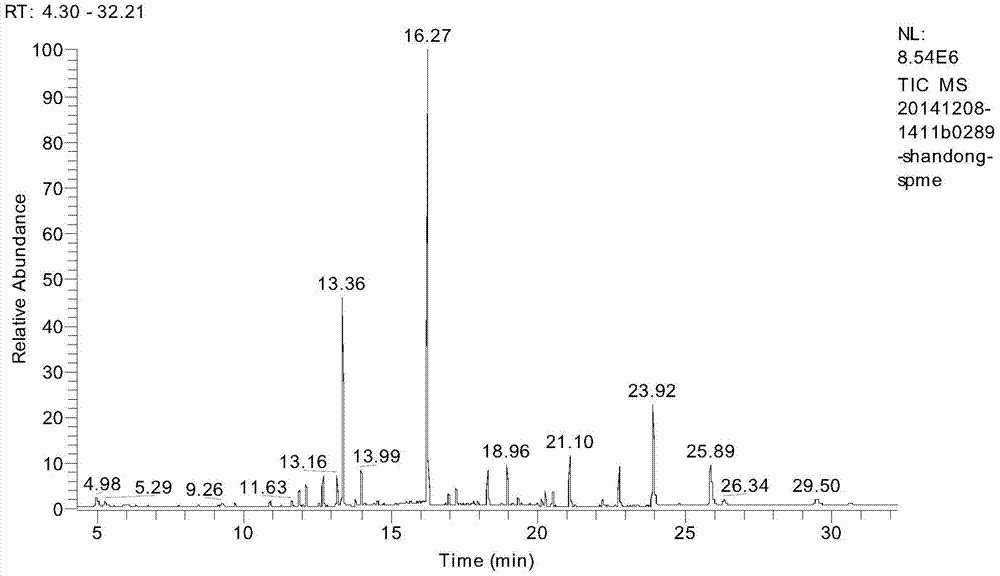

[0055] (1) After drying the kelp produced in Shandong at 55°C, it was pulverized to 50 mesh to obtain kelp powder;

[0056] (2) Put 103.27 g of the above kelp powder into a microwave extraction device, add 619.62 mL of arsenic removal agent-ethanol mixed solution, extract by microwave for 20 min, filter under reduced pressure, and collect the filtrate. Add 413.08mL of arsenic-removing agent-ethanol mixed solution to the filter residue, extract with microwave for 10min under the same conditions, filter under reduced pressure, collect and combine the filtrates, and obtain 777g of extract. Wherein, the arsenic removal agent is water, and the mixing ratio of water and ethanol is water:ethanol=1:7.33 by volume; the microwave extraction conditions are as follows: the te...

Embodiment 3

[0068] see figure 1 , the preparation method of low-arsenic kelp nutritional flavor components in this example is as follows:

[0069] (1) drying the kelp at 95°C and pulverizing it to 30 meshes to obtain kelp powder;

[0070] (2) Put 124.49 g of the above-mentioned kelp powder into a microwave extraction device, add 746.94 mL of arsenic removal agent-ethanol mixed solution, extract by microwave for 20 min, filter under reduced pressure, and collect the filtrate. Add 497.96 mL of arsenic-removing agent-ethanol mixed solution to the filter residue, extract with microwave for 10 min under the same conditions, filter under reduced pressure, collect and combine the filtrates, and obtain 1022 g of extract. Wherein, the arsenic-removing agent is water, and the mixing ratio of water and ethanol is water:ethanol=1:2.8 volume ratio; the microwave extraction conditions are, the temperature is 75°C, and the microwave power is 500W;

[0071] (3) The kelp extract obtained in step (2) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com