Environment-friendly processing device for machining waste chips

A technology of environmental protection treatment and mechanical processing, which is applied in the direction of wood processing equipment, manufacturing tools, bark area/debris/dust/waste removal, etc., which can solve the inconvenient recycling, inconvenient cleaning of waste, and waste debris with many impurities To achieve the effect of enriching the functions of the device, facilitating recycling, and improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

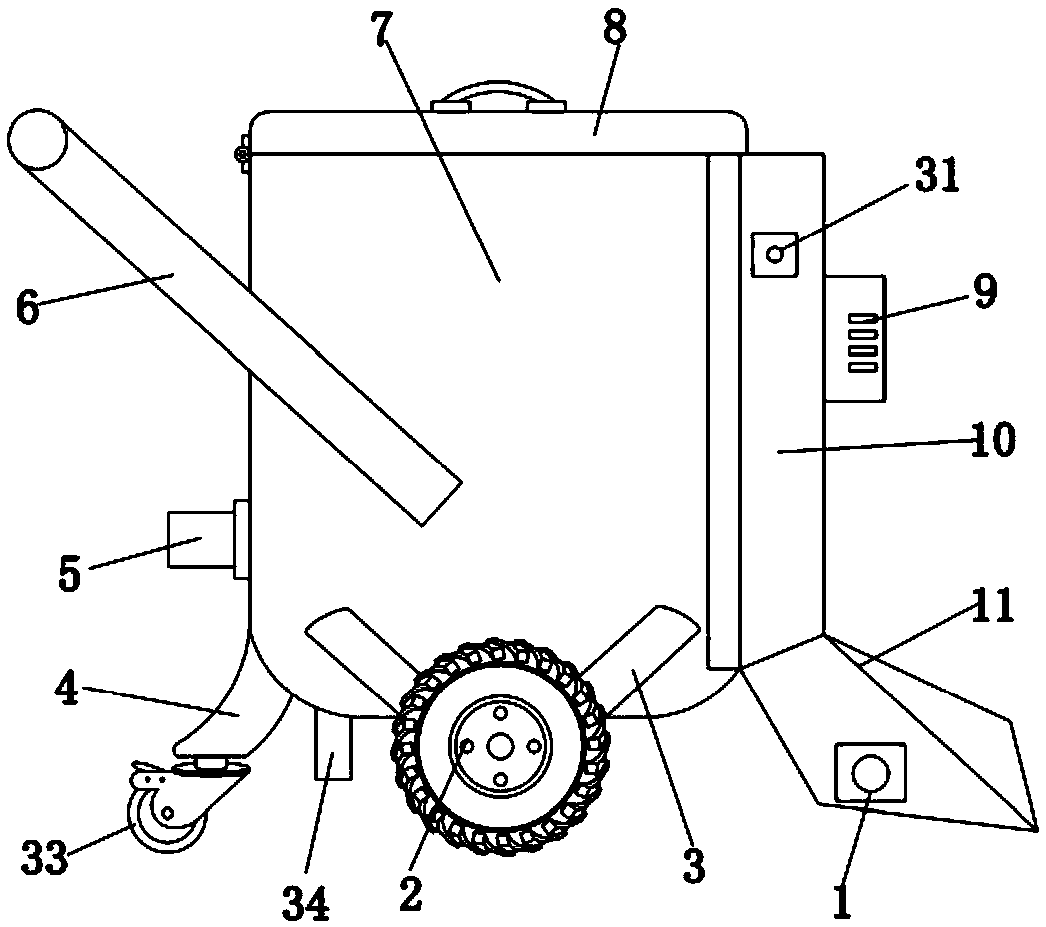

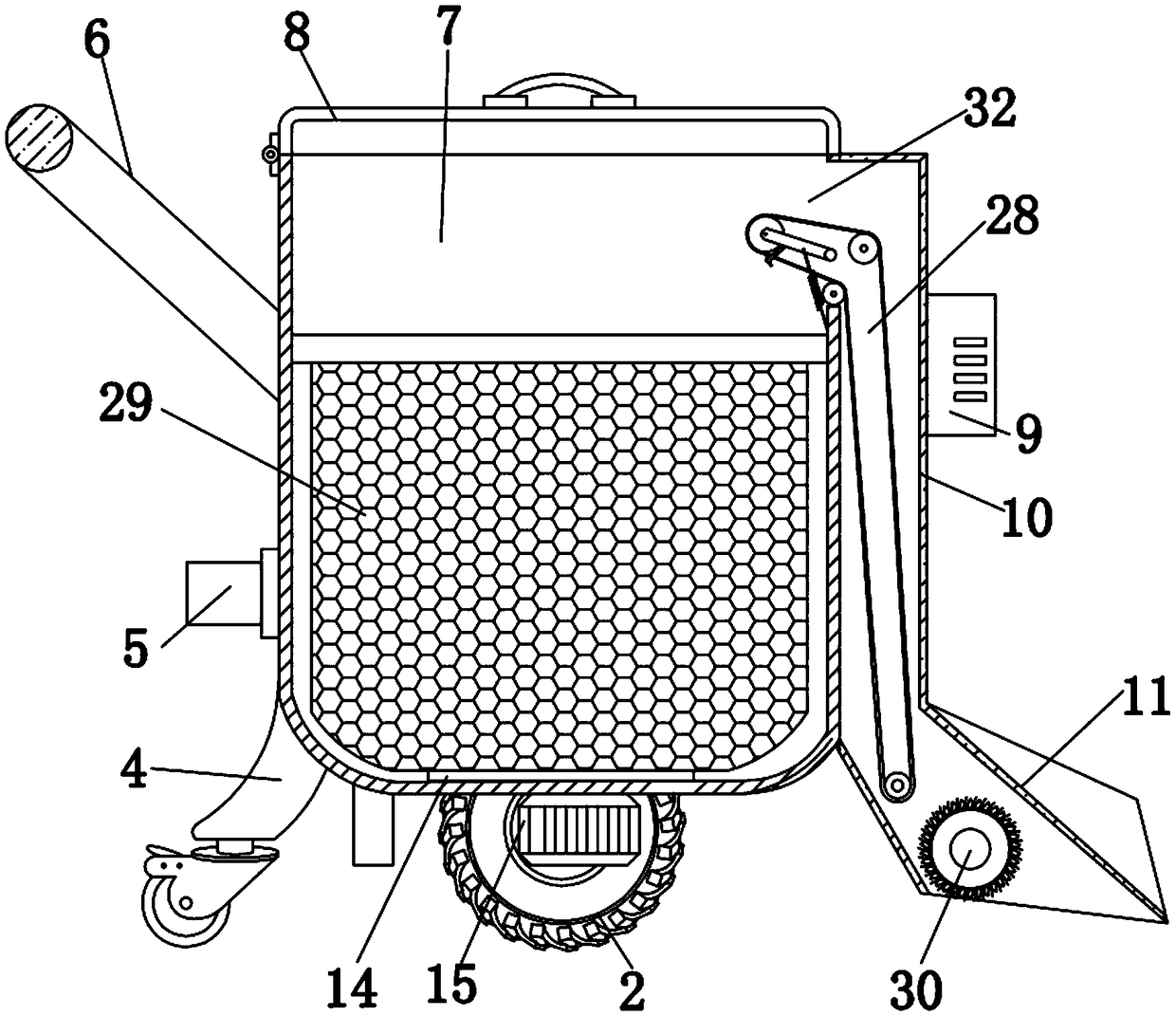

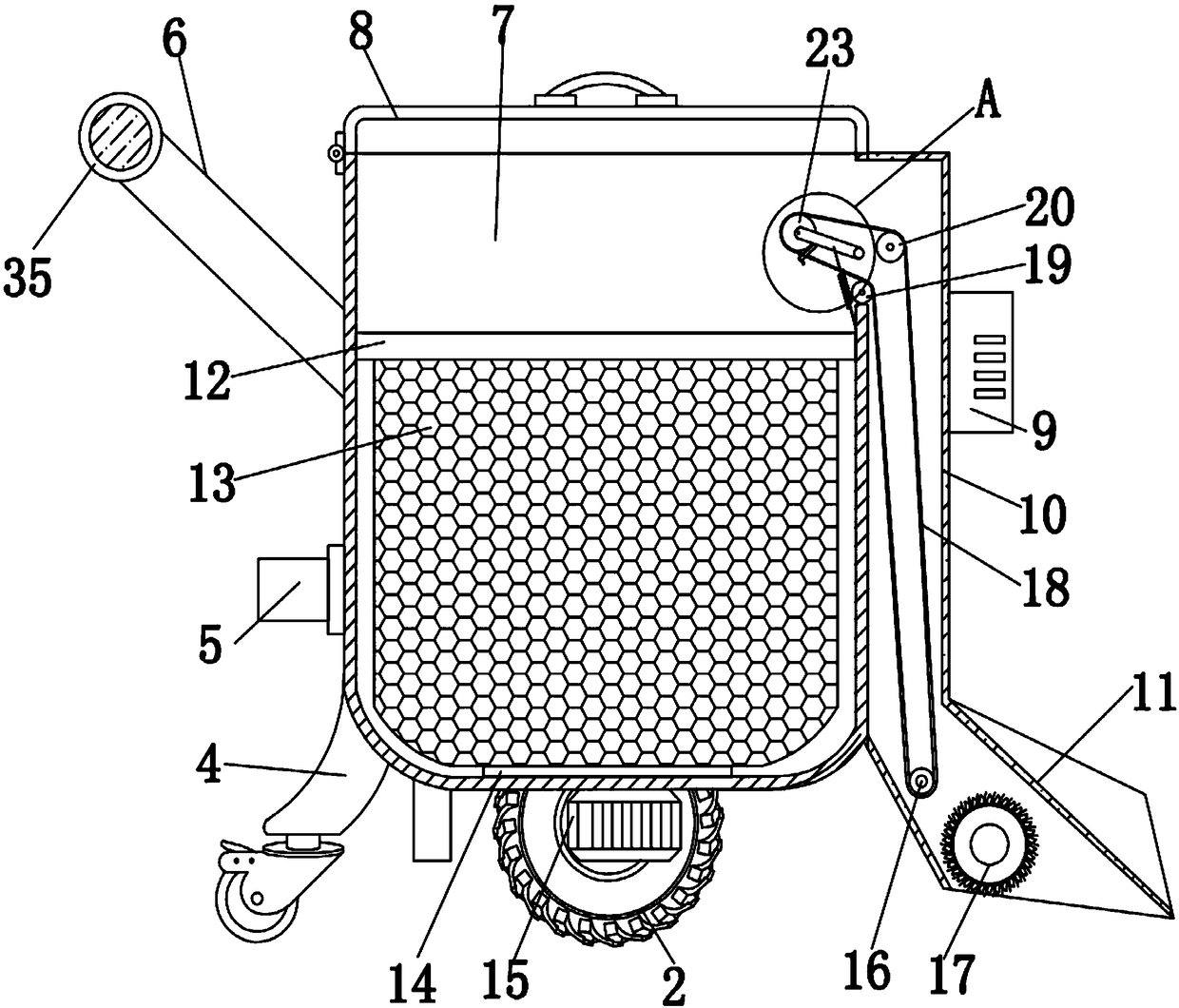

[0046] Example 1 reference Figure 1-5 , an environmental protection treatment device for machining waste, including a metal cylinder 7, a cylinder cover 8 is hinged on the outer wall of the top side of the metal cylinder 7, a handrail frame 6 is fixed on the outer wall of the metal cylinder 7 by bolts, and the outer walls of the metal cylinder 7 are on both sides. Brackets 3 are welded, and the side walls of the two brackets 3 are movably connected with wheels 2. The side of the metal cylinder 7 away from the armrest frame 6 is provided with a suction mechanism 28. The suction mechanism includes a metal cover 10, and the bottom end of the metal cover 10 is welded with a The suction hopper 11 is inclined. The inner wall of the suction hopper 11 is provided with a cleaning mechanism 30. The suction mechanism cooperates with the cleaning roller 17 to facilitate the collection and recycling of waste on the machined ground, which is conducive to the preliminary screening of iron wa...

Embodiment 2

[0047] Example two reference Figure 1-5 , the filter mechanism includes a first metal mesh cylinder 13, and the top position of the side wall of the first metal mesh cylinder 13 is sleeved with a bearing ring 12, and the side wall of the bearing ring 12 is clamped with the inner wall of the metal cylinder 7 near the bottom end of the feed hole The inner wall of the first metal mesh cylinder 13 is sleeved with a second metal mesh cylinder 25, and the inner walls of both sides of the second metal mesh cylinder 25 are welded with handles 24, and the inner wall of the bottom end of the metal cylinder 7 is fixed with a bearing turntable 14 by bolts, And the top of the bearing turntable 14 is fixed to the outer wall of the bottom end of the first metal mesh cylinder 13 by bolts, the middle position of the outer wall of the bottom end of the metal cylinder 7 is fixed with a third motor 15 by bolts, and the output shaft of the third motor 15 passes through the bottom end of the metal ...

Embodiment 3

[0048] Example three reference Figure 1-5 , the cleaning mechanism includes a cleaning roller 17, the cleaning roller 17 is movably connected with the inner wall of the suction hopper 11, the side wall of the suction hopper 11 is fixed with a first motor 1 by bolts, and the output shaft of the first motor 1 passes through the outer wall of one side of the suction hopper 11 One end of the cleaning roller 17 is fixed by bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com