Patents

Literature

124results about How to "Large porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

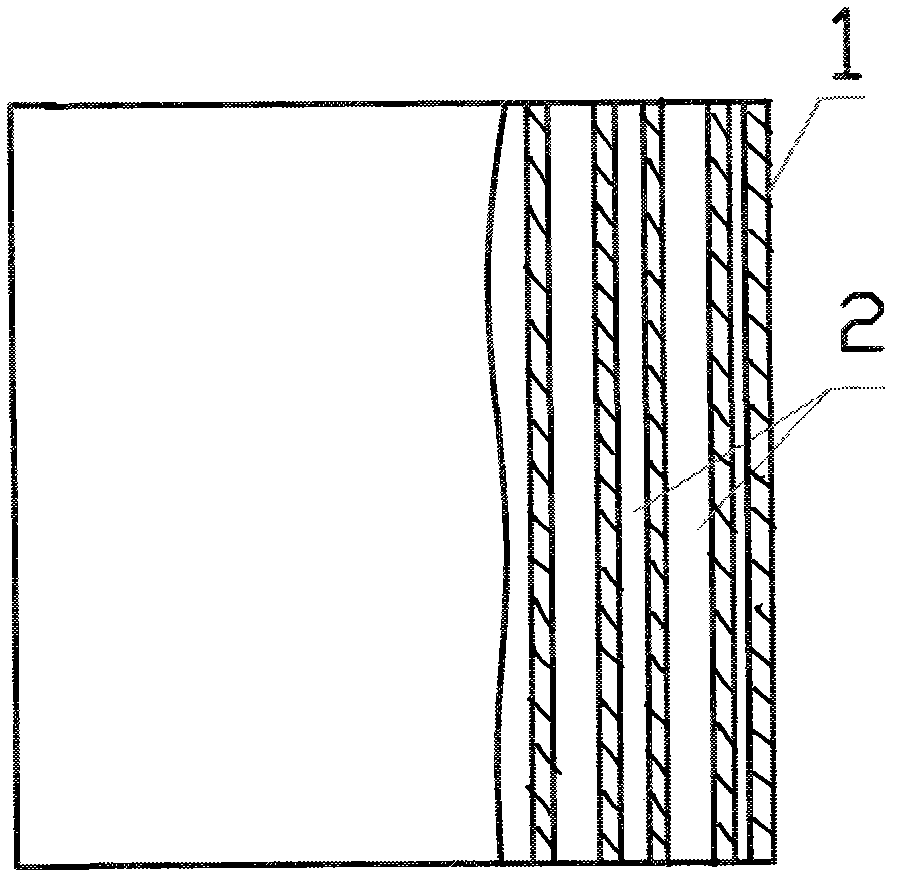

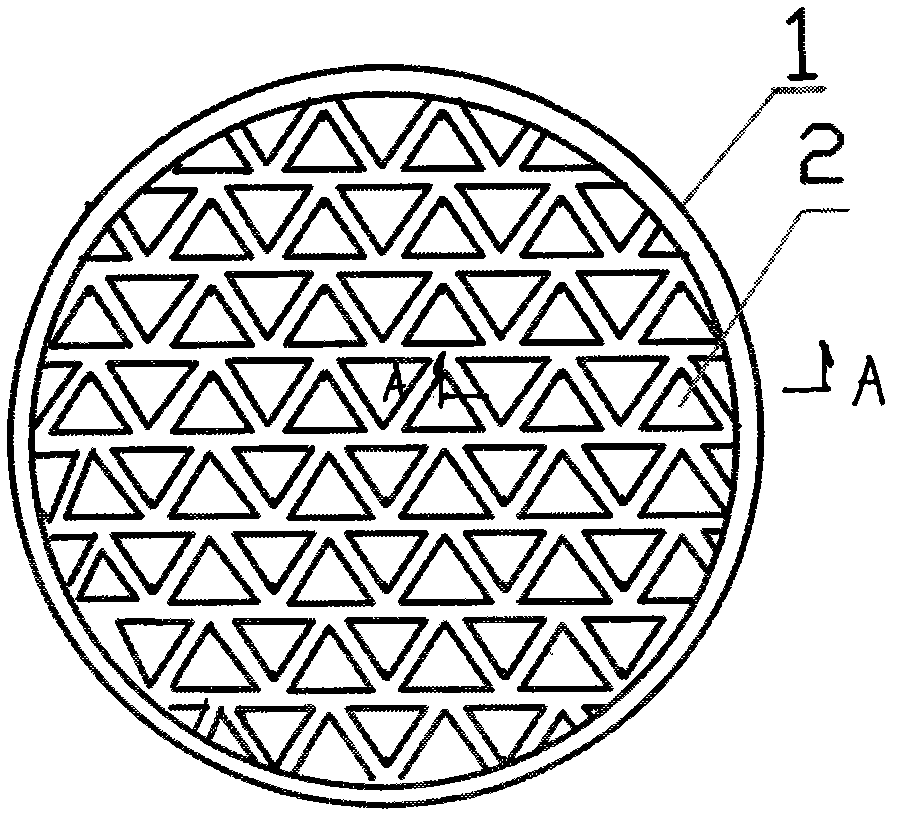

Method for preparing complexly shaped biomedical porous titanium molybdenum alloy implant body

InactiveCN102335742ADesign personalizationHigh dimensional accuracyIncreasing energy efficiencyProsthesisNatural boneMetallic materials

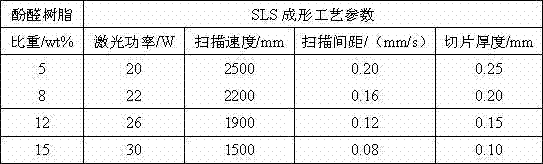

The invention provides a method for preparing a complexly shaped biomedical porous titanium molybdenum alloy implant body and belongs to the technical field of biomedical porous metallic material preparation. The method comprises the following steps of: taking a mixture of titanium and molybdenum metallic element powder and organic polymer powder as raw materials, and then preparing the biomedical porous titanium molybdenum alloy implant body by adopting the processes, such as three-dimensional modeling, selective laser-firing rapid forming, thermal de-greasing, vacuum sintering, and the like. The processing steps are simple, the period is short, the use ratio of materials is high, the cost is low, any complexly shaped porous titanium alloy implant body can be conveniently manufactured, and the method has efficiency and economic advantages in individual design and rapid manufacturing of the implant body. A titanium molybdenum alloy material prepared by using the method has the advantages that pore space is uniform, adjustment scopes of porosity, aperture ratio and aperture are wide, elasticity modulus and compression strength are in close proximity to natural bone, and the demand on biomechanical compatibility required by a biomedical material is met.

Owner:UNIV OF SCI & TECH BEIJING

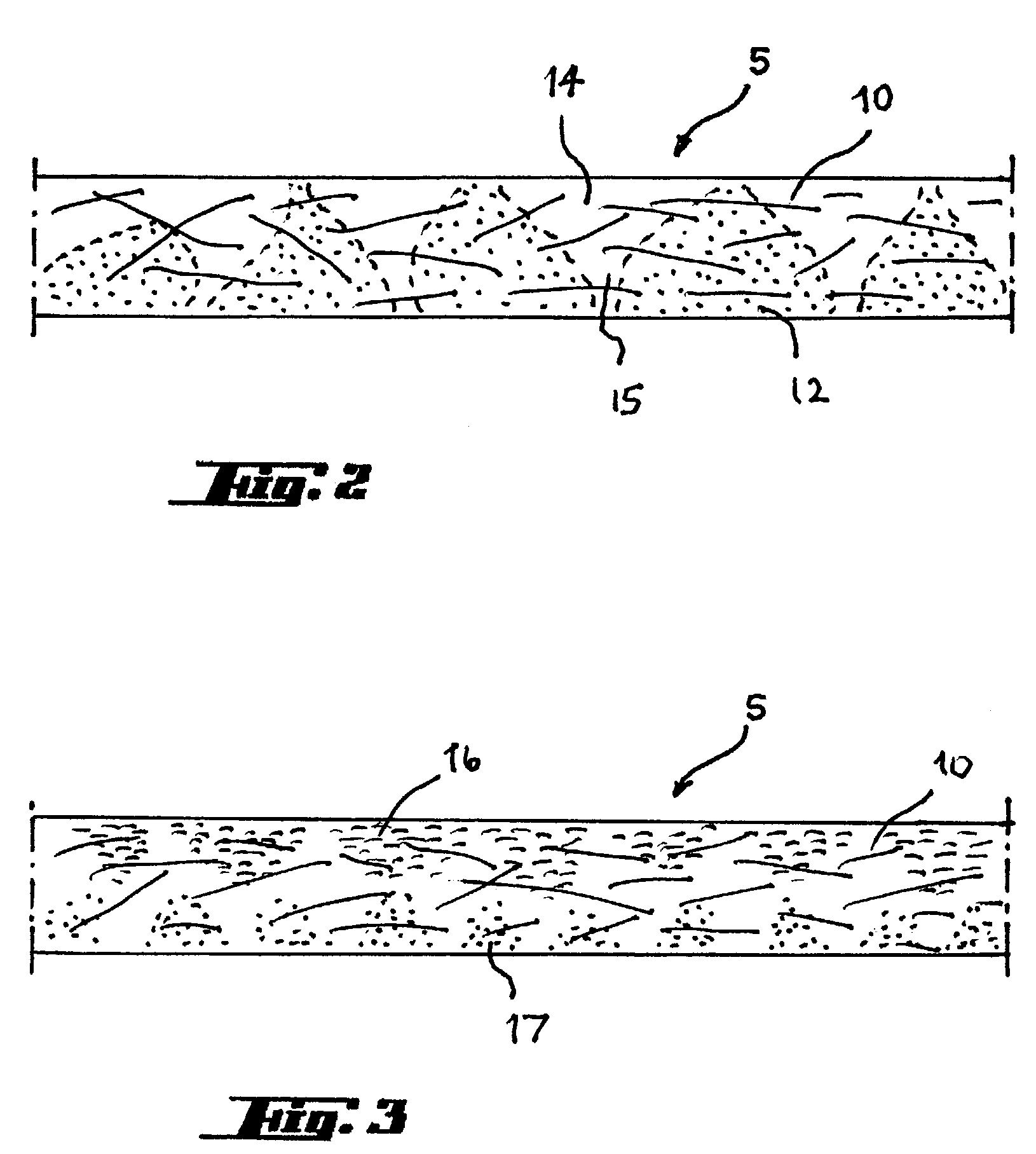

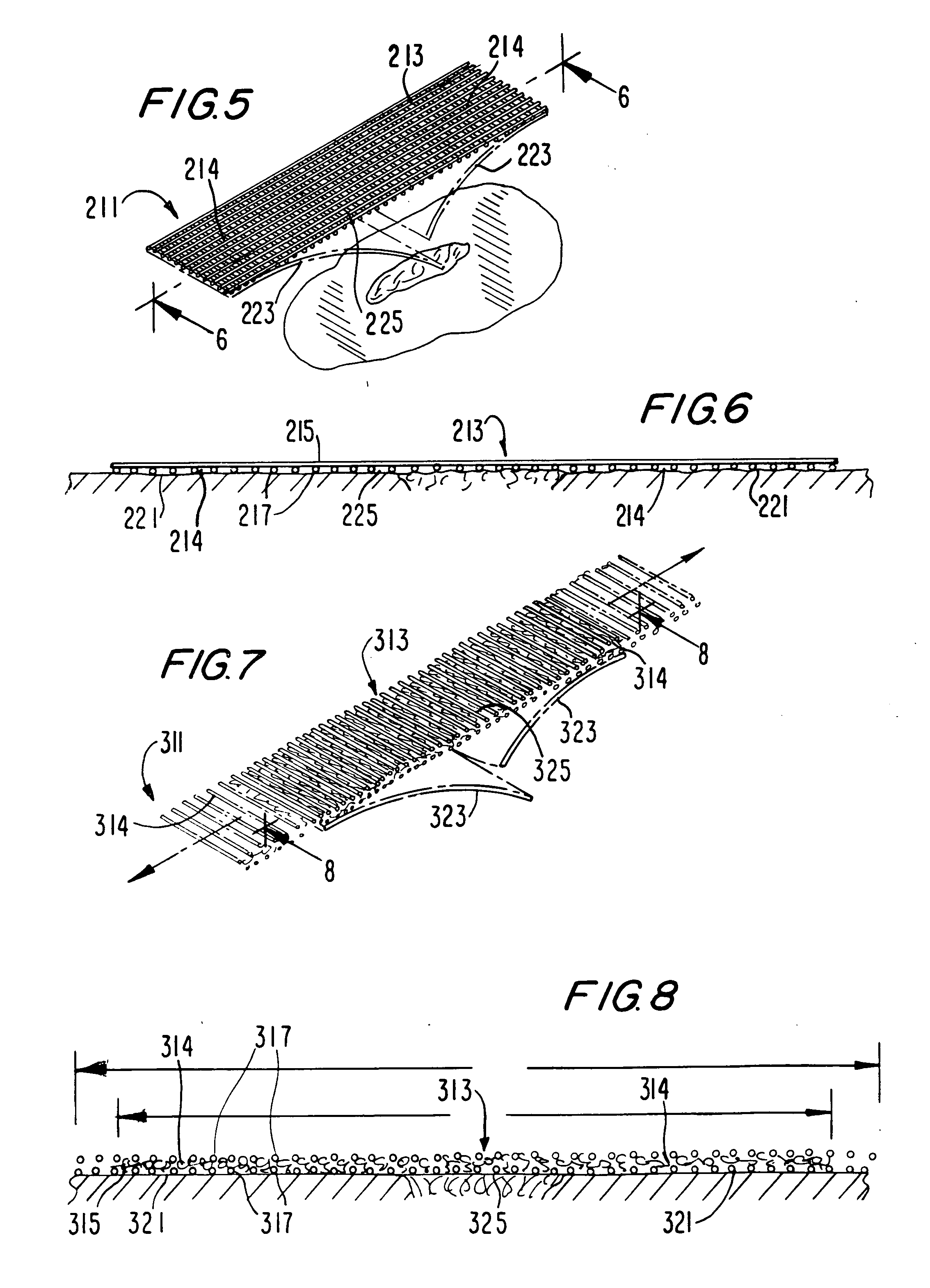

Bioactive, resorbable scaffolds for tissue engineering

InactiveUS20050118236A1High porosityImprove manufacturabilityBiocideSynthetic resin layered productsPorosityFiber

Flexible, bioactive glass meshes and scaffolds made therefrom are provided. The meshes comprise interwoven bioactive glass fibers that can be coated with resorbable polymers. Meshes can also be woven from glass fibers and resorbable polymers. Scaffolds can be constructed by a plurality of meshes, which can have varying porosities to create porosity gradients in the scaffold. Methods of making scaffolds are provided which can comprise pulling bioactive glass fibers, winding the fibers, forming the fibers into bundles, coating the fibers with a resorbable polymer, and creating a biaxial weave with the bundles. Soft tissue engineering methods are also provided for creating scaffolds for incubating cells such as fibroblasts and chondroblasts. Meshes and scaffolds are suitable for tissue engineering, such as bone tissue engineering and cartilage tissue engineering.

Owner:GENTIS

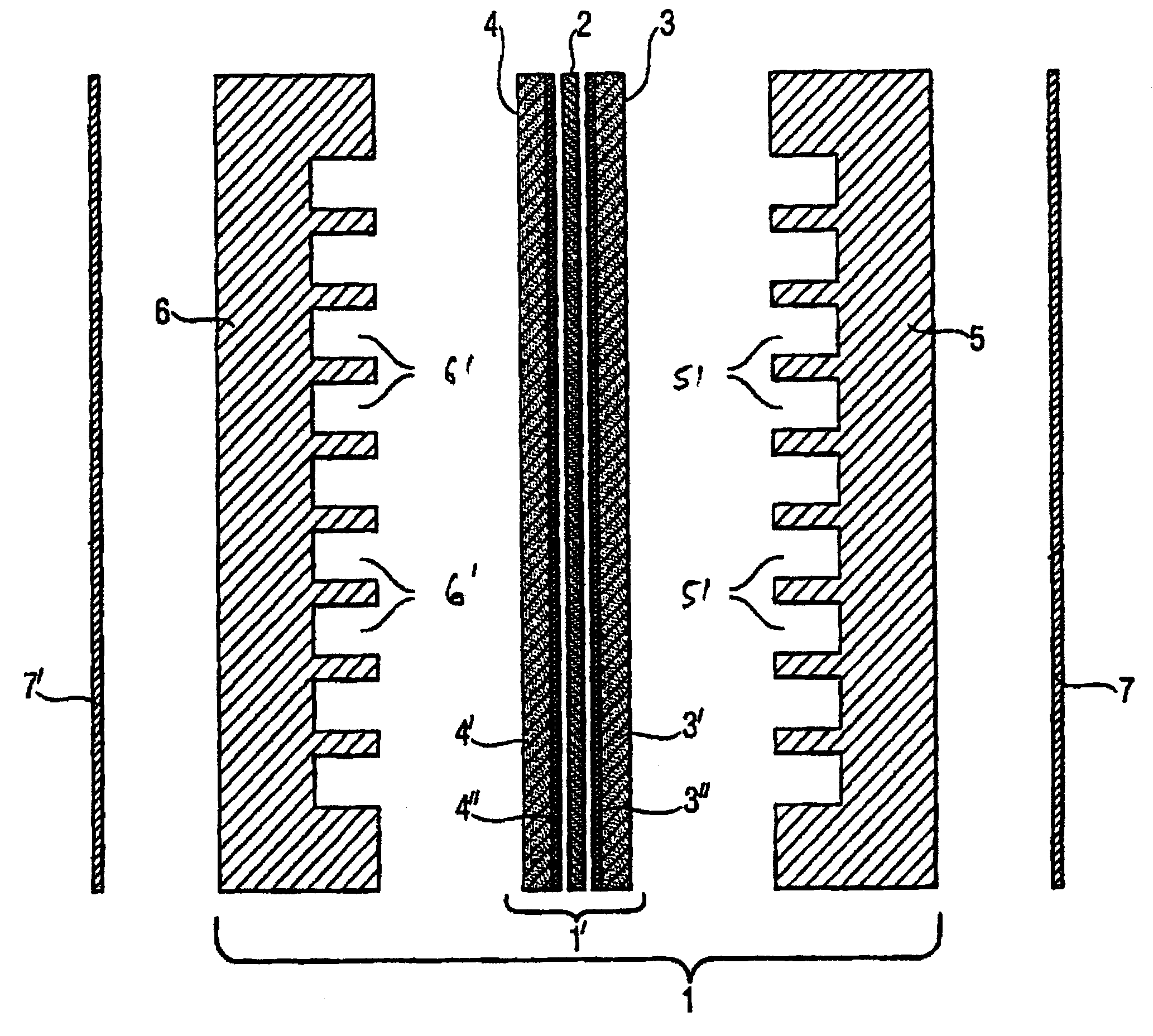

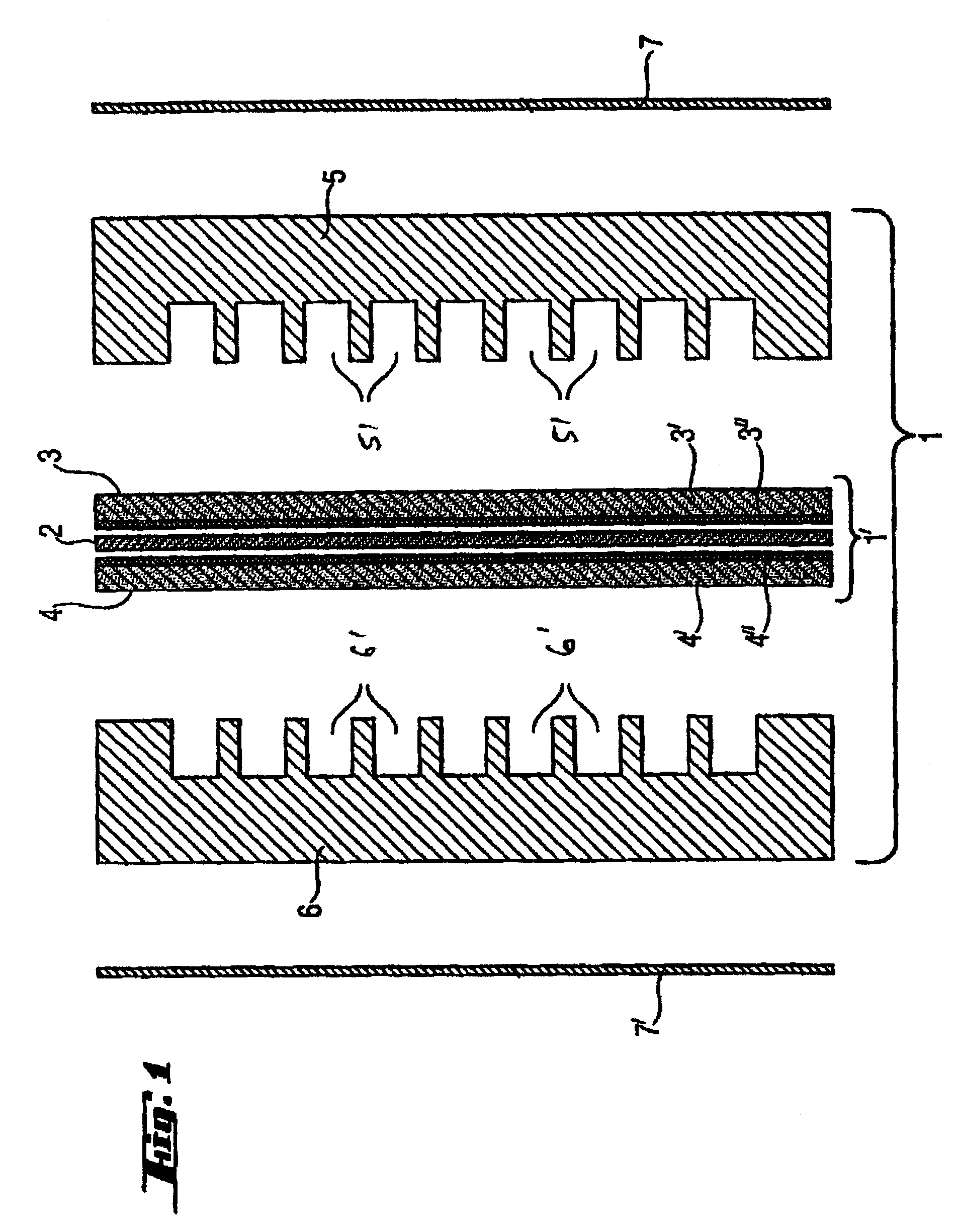

Carbon fiber electrode substrate for electrochemical cells

ActiveUS7144476B2High carbon contentImprove conductivityNon-fibrous pulp additionNatural cellulose pulp/paperFiberCarbon fibers

This invention relates to electrode substrates for electrochemical cells, particularly low-temperature fuel cells, and processes for their production. Low-cost carbon fiber paper structures are used as precursor for preparation of an all-carbon product that has a high electric conductivity and porosity and can be processed in a continuous reel-to-reel mode. These paper materials are further impregnated and processed to adjust the final product properties. This all-carbon electrode substrate is not brittle thereby avoiding the main disadvantage of the prior art.

Owner:SGL CARBON SE

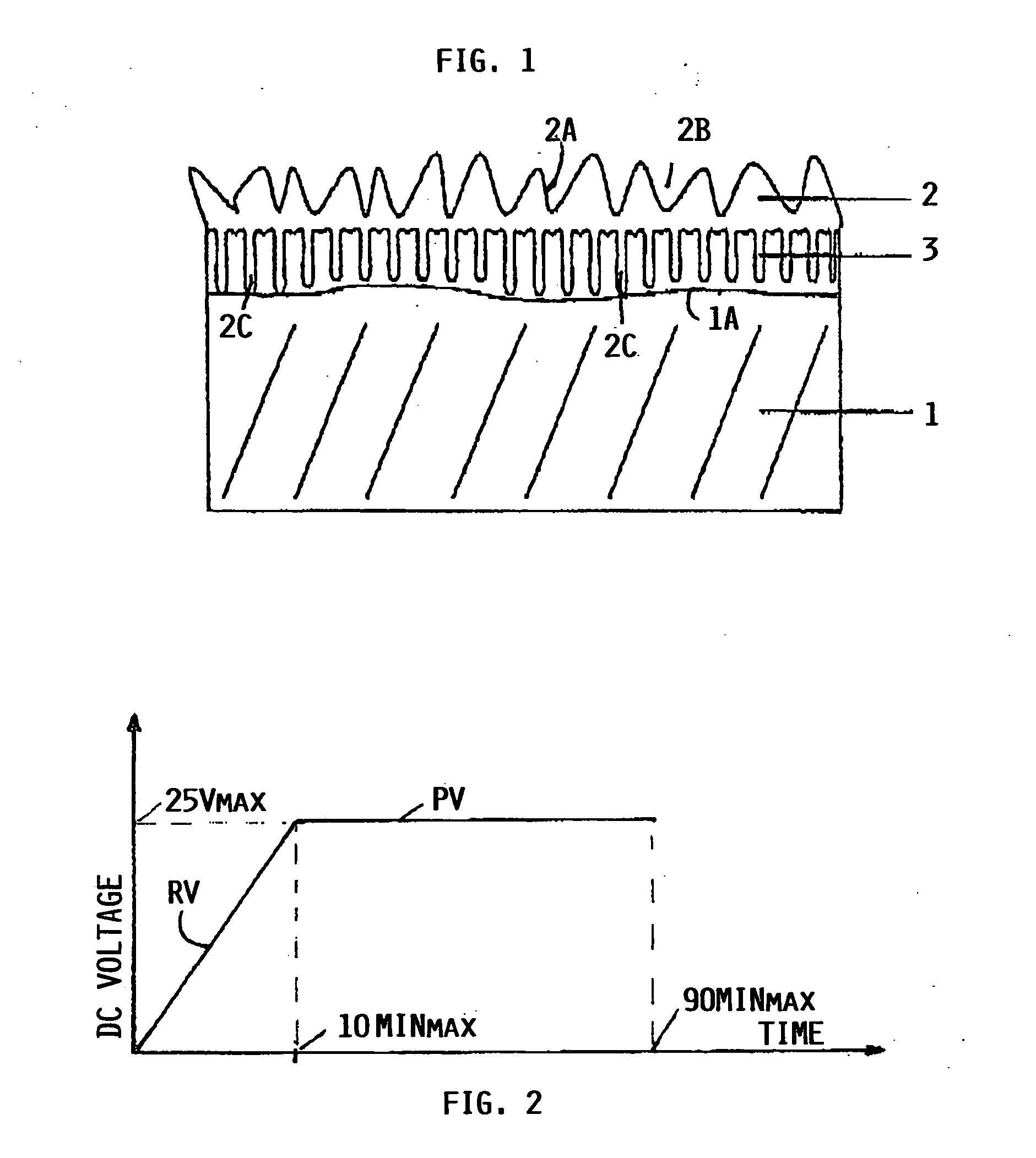

Method for anodizing aluminum materials

Structural components made of aluminum and aluminum alloys are anodized in two sequential steps in two different electrolytes. The first electrolyte is a mixed acid of two inorganic acids such as a phosphoric-sulfuric acid mixture. The second electrolyte is a further acid mixture of an organic acid and an inorganic acid to form a tartaric sulfuric acid mixture. The two sequential anodizing steps result in a surface texture that has three excellent surface characteristics simultaneously, namely: a corrosion resistance, a coating acceptance for lacquer coatings and an adhesive bonding with other aluminum material components.

Owner:KOCK ERICH +2

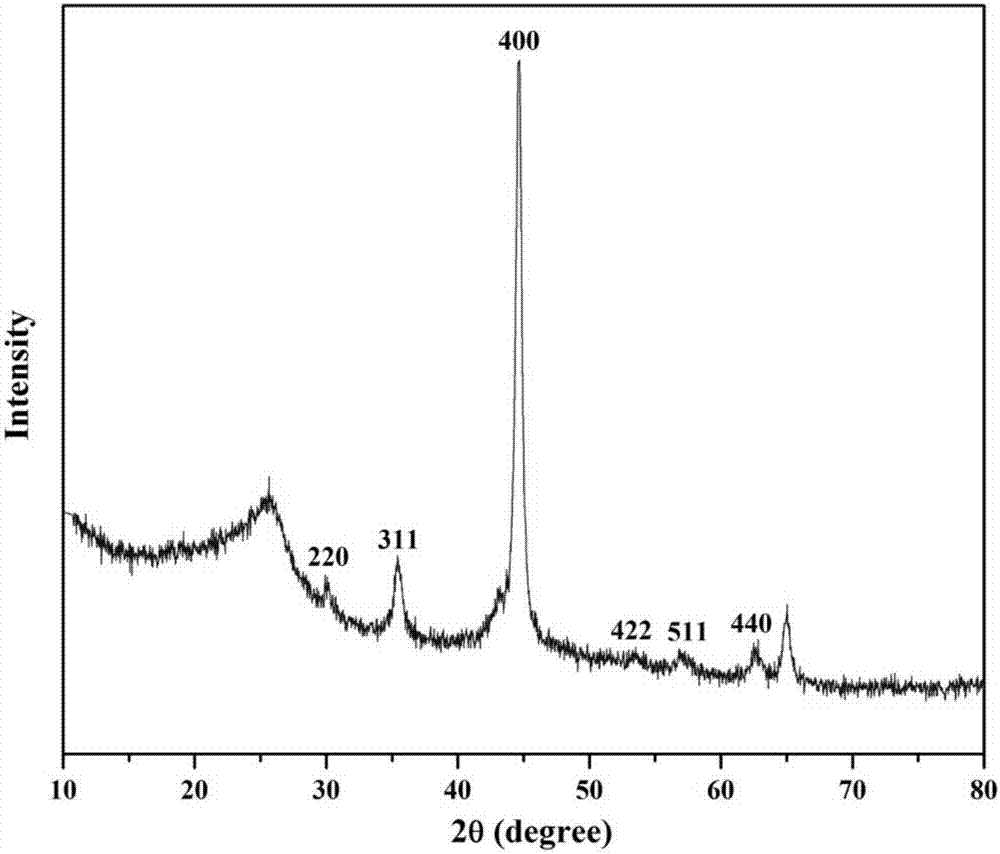

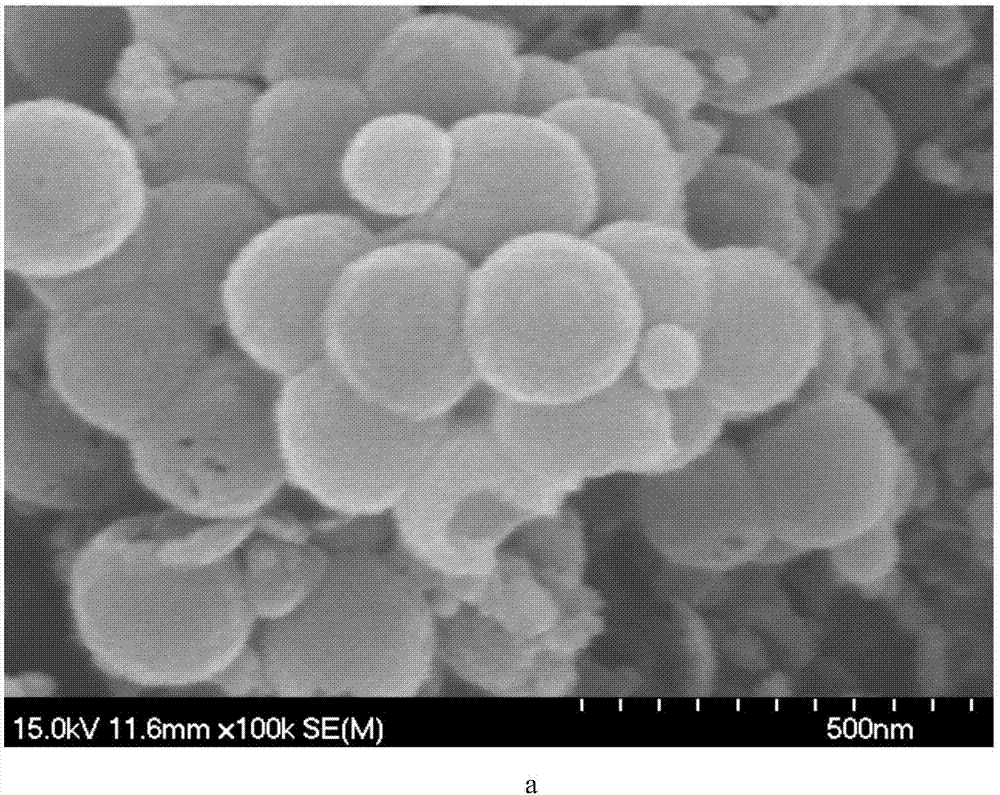

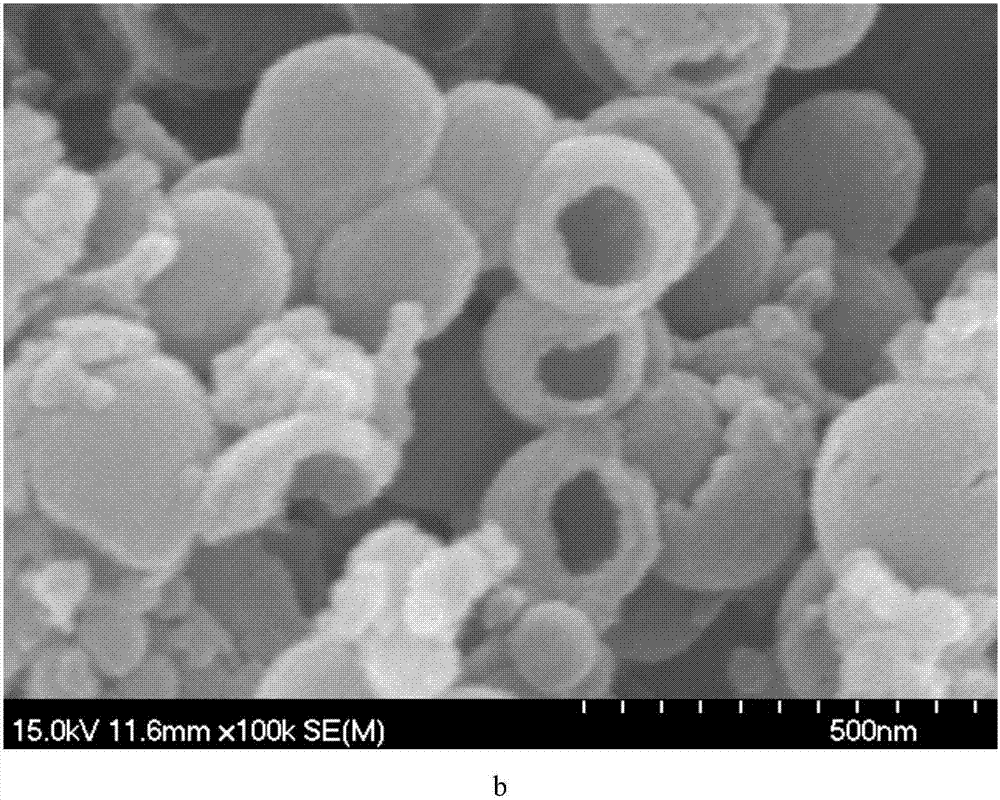

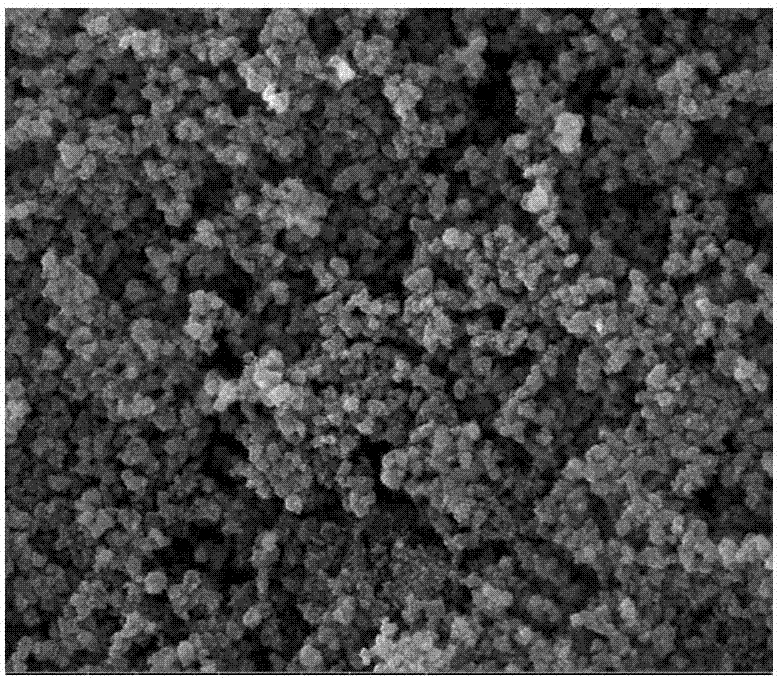

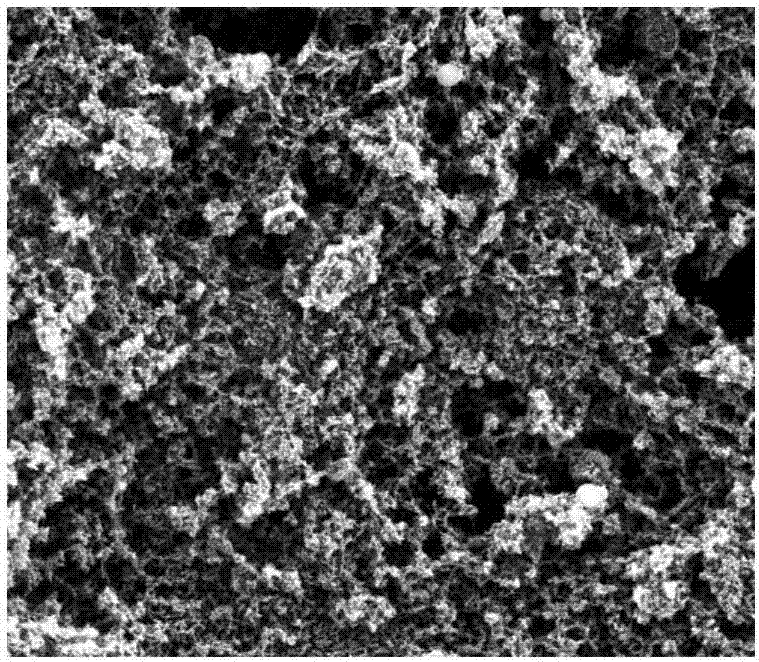

CoFe2O4/N/C hollow nanosphere and preparation and application thereof

InactiveCN106984261AImprove distributionImprove adsorption capacityPhysical/chemical process catalystsOther chemical processesMicrosphereCarbonization

The invention discloses a CoFe2O4 / N / C hollow nanosphere and preparation and application thereof. The preparation comprises: complexing dopamine with cobalt and iron metal ions under the condition of pH8-9 on a template as a SiO2 nanometer sphere to form a polymer shell layer, carbonization annealing to form N-doped carbon material loaded with CoFe2O4 metal nanoparticles, and finally, removing the SiO2 template with strong alkali to obtain CoFe2O4 / N / C hollow nanosphere. In the invention, the N / C matrix hollow structure is prepared by using the SiO2 nanosphere as the sacrificial template, theCoFe2O4 / N / C hollow nanosphere has a relatively large specific surface area and porosity, and can improve the distribution of CoFe2O4 nano metal particles loaded on the shell layer, enhance adsorption and catalytic activity on organic pollutants in waste water, and broaden the pH application range; the CoFe2O4 / N / C hollow nanosphere can be recycled due to magnetic performance, thus saving resources.

Owner:ZHEJIANG UNIV OF TECH

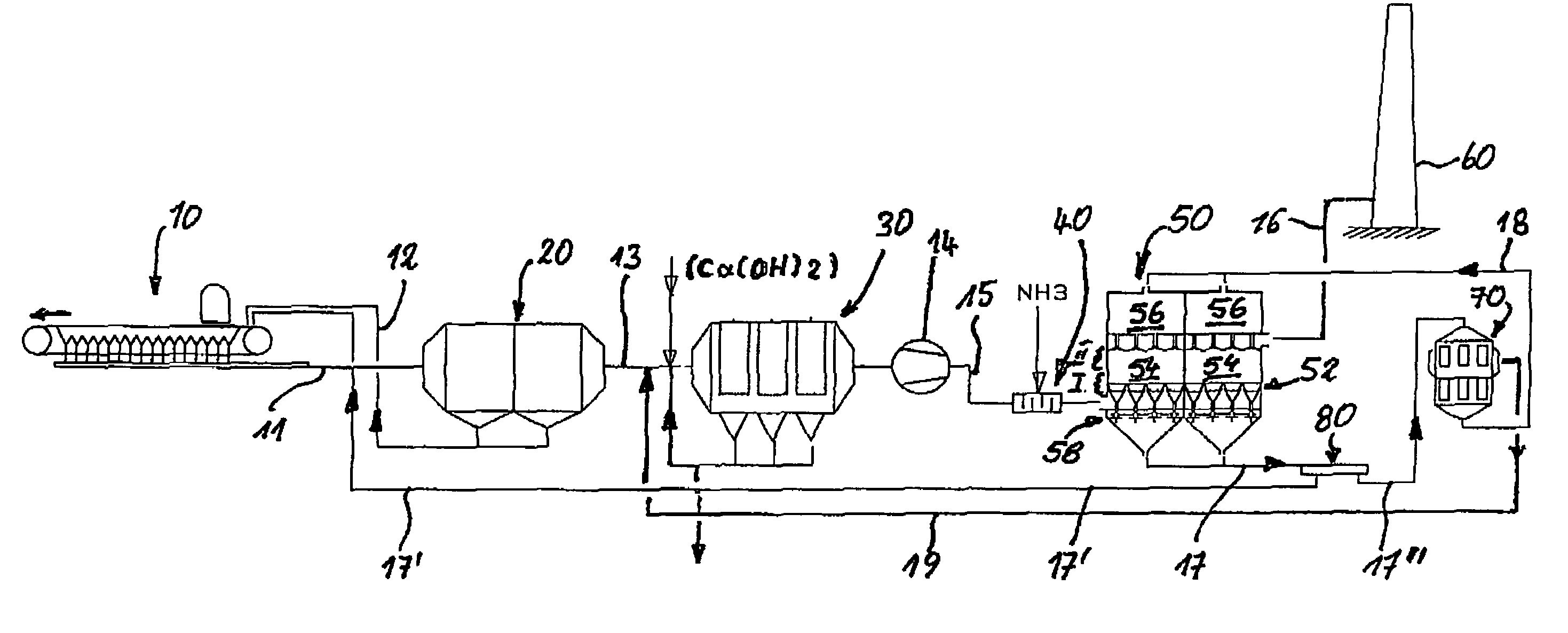

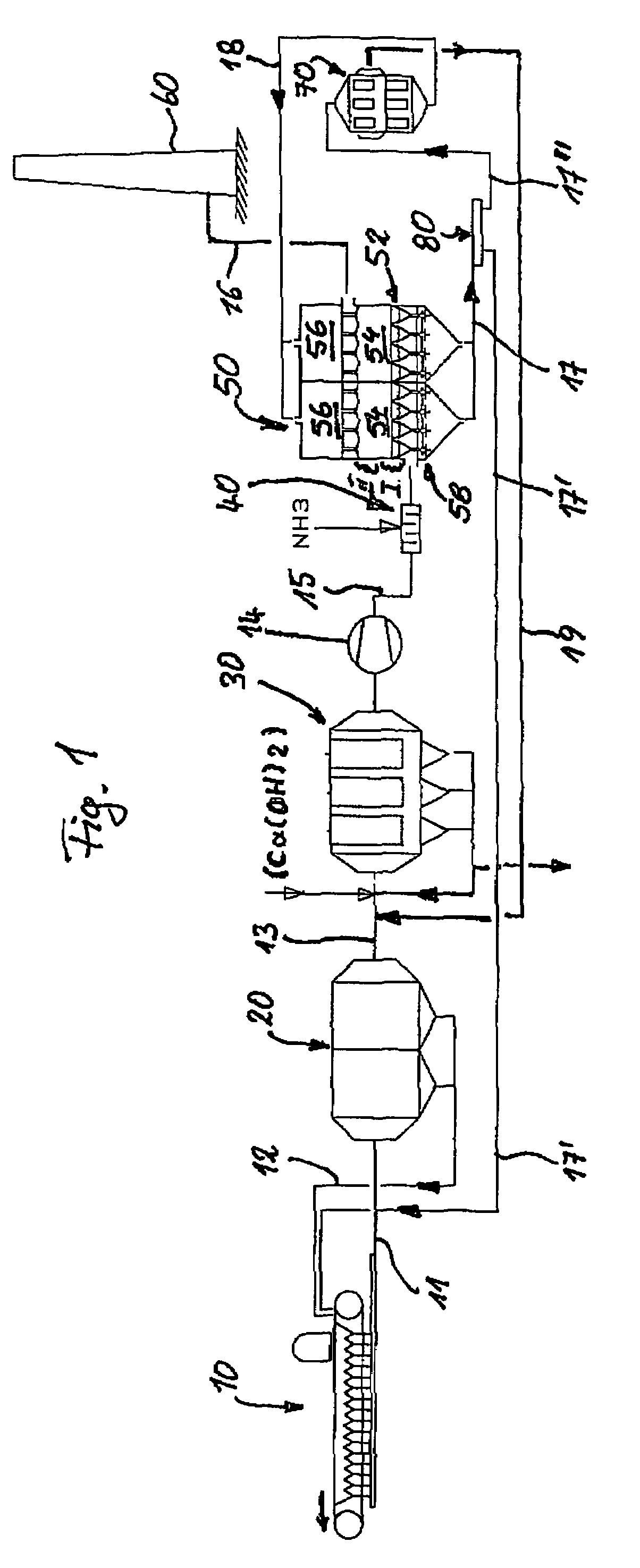

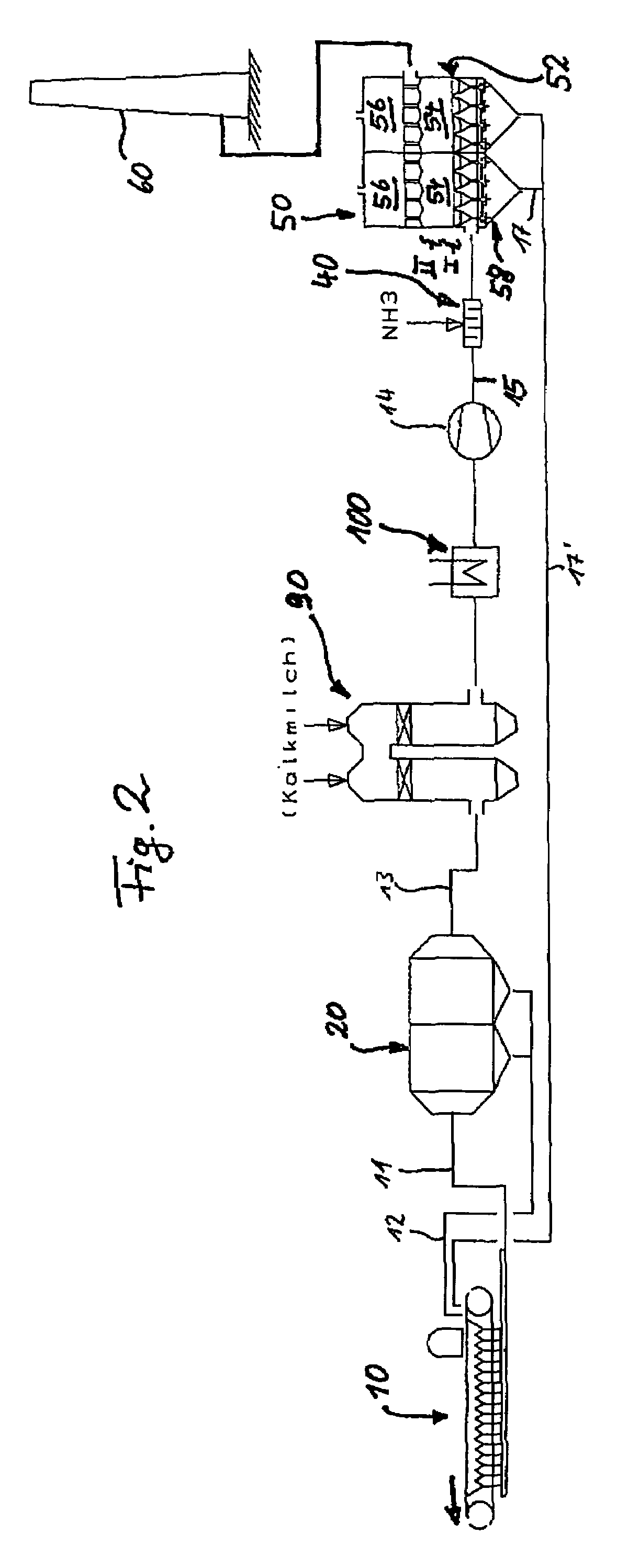

Method for cleaning exhaust gases produced by a sintering process for ores and/or other metal-containing materials in metal production

ActiveUS7666374B2Reduce and largely eliminate catalyst-degenerating effectSimple processOxygen/ozone/oxide/hydroxideGas treatmentFuranReactor system

The invention relates to a process for cleaning exhaust gases produced by a sintering process of metal-containing waste. The sintering exhaust gas includes one or more harmful substances which are eliminated in at least two steps by at least one adsorption and / or absorption agent in a single moving bed in a moving bed reactor system. The moving bed includes a particle layer (stage I) disposed above a flow input area and below an adsorption layer (stage II) of the moving bed. One or more harmful substances in the sintering exhaust gas are absorptively or adsorptively bound to potassium and / or sodium compounds and the harmful substances are trapped by adhesion in the flow input area or the Particle layer (stage I) of the moving bed. The substantial removal of NOx and the adsorptive or absorptive removal of dioxins and furans takes place in the adsorption layer (stage II) in the moving bed.

Owner:GROCHOWSKI HORST

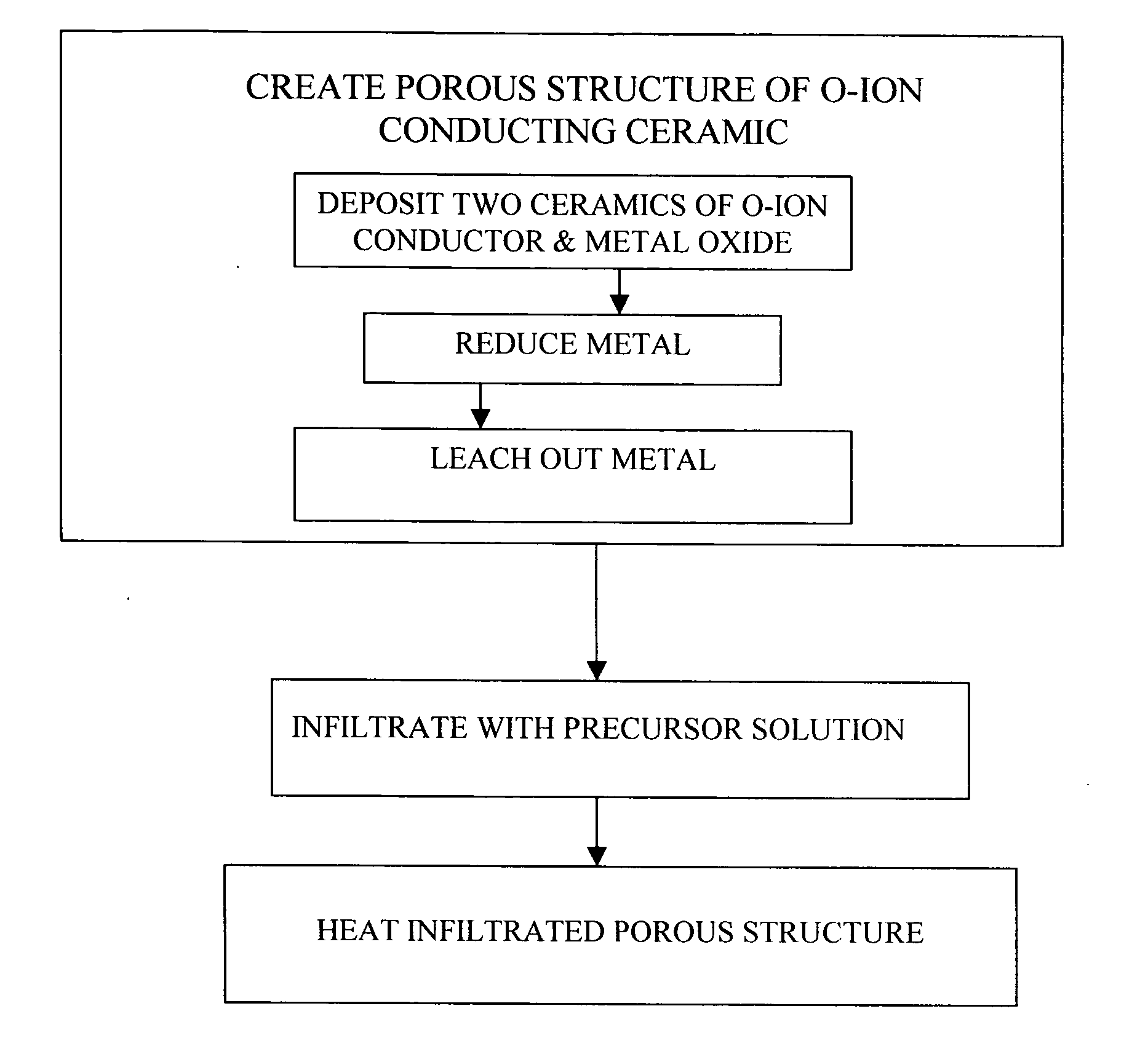

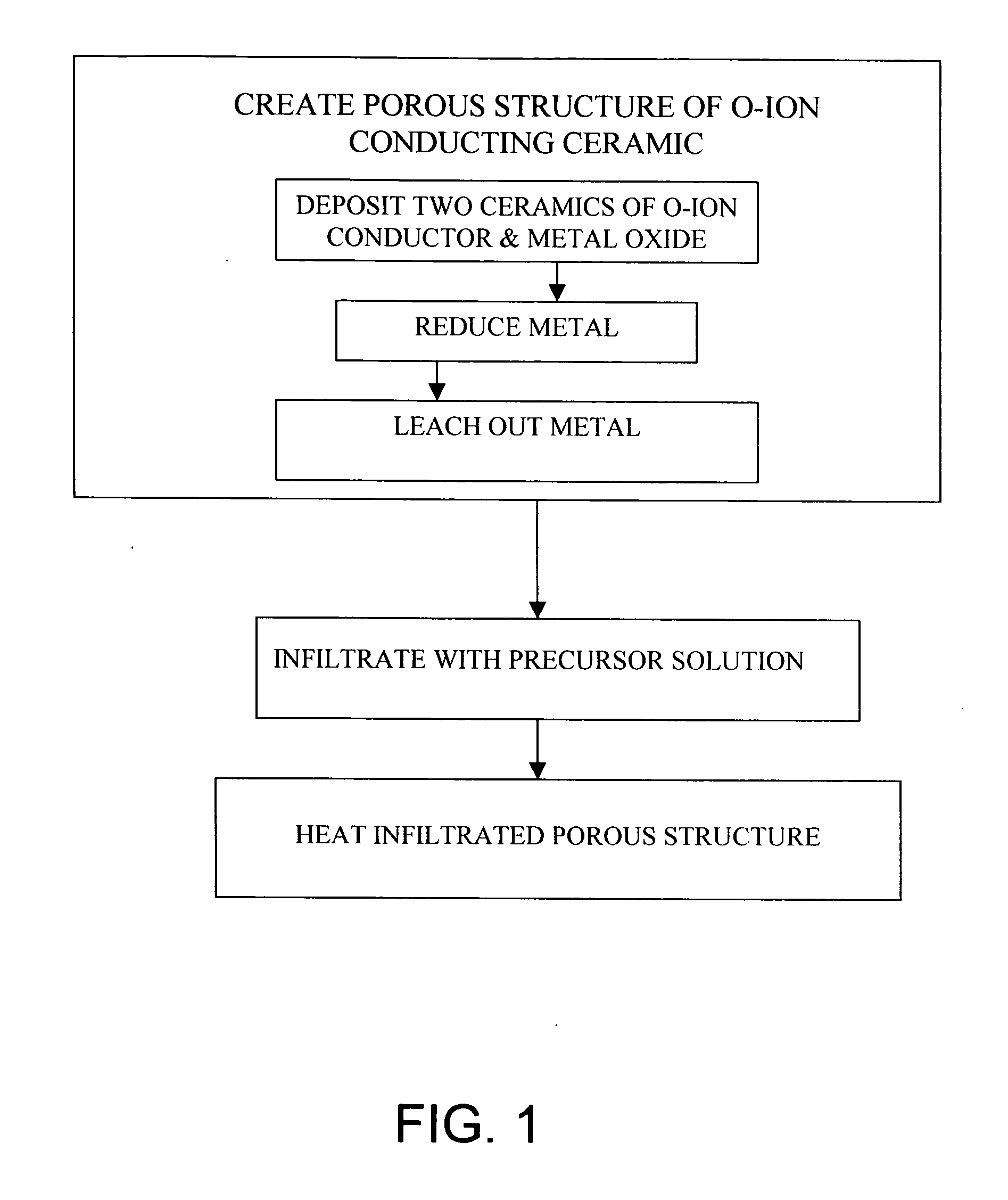

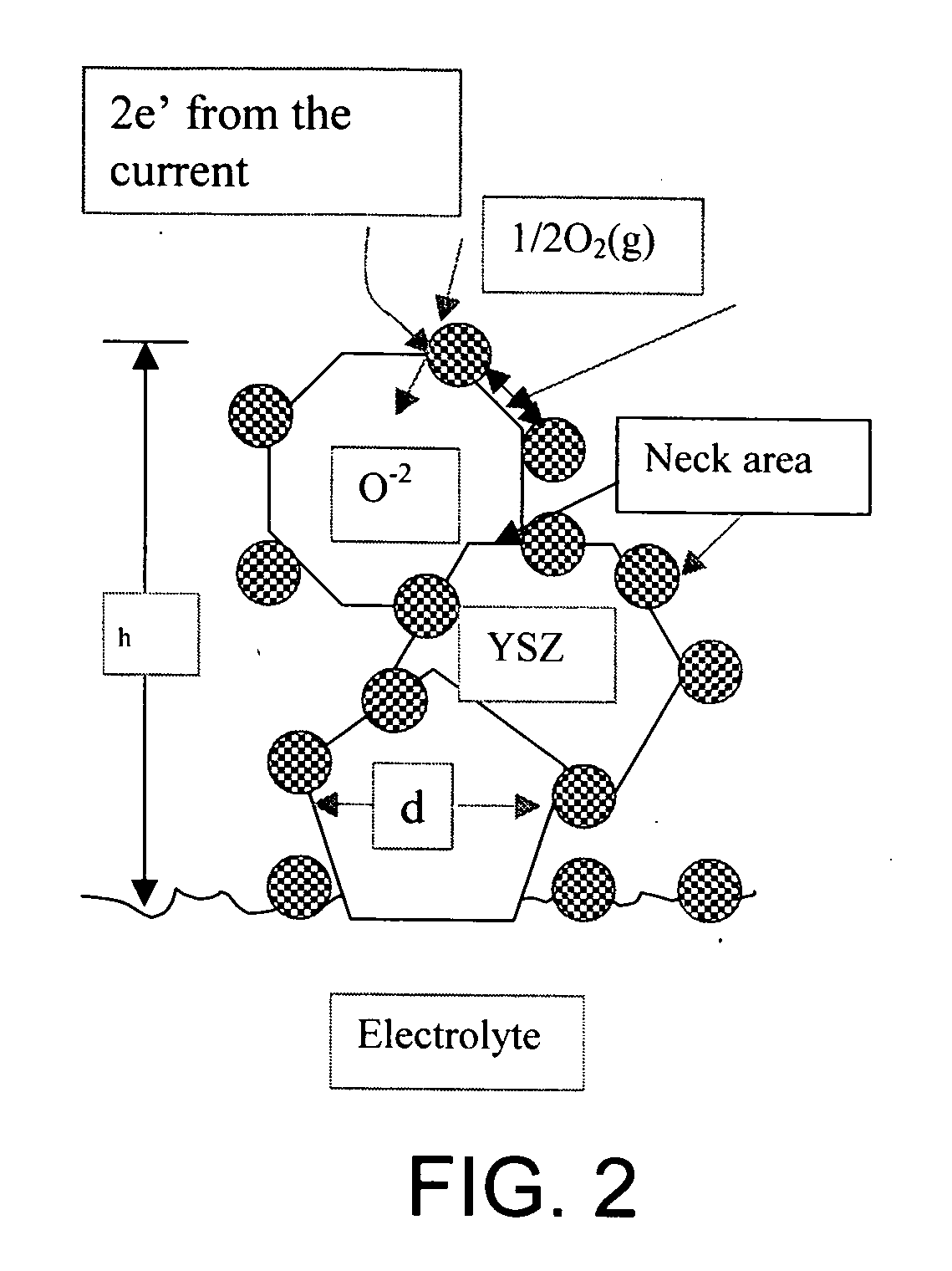

Method of fabricating composite cathodes for solid oxide fuel cells by infiltration

InactiveUS20050238796A1Improve performanceHighly desirable microstructureCell electrodesFinal product manufacturePorosityFuel cells

In the manufacture of a composite cathode, a porous structure is made of the electrolyte material by sintering a mixed material of primary material of the electrolyte and a secondary material. The mixture is treated to sinter the primary material. The secondary material is removed. The secondary material during sintering inhibits porosity loss and grain growth in the primary material while enabling formation of good necks for interparticle contact. The porous structure is then infiltrated with a liquid that contains precursors of an electrocatalytically active material. The infiltrated structure is then heated to convert the precursors to an electrocatalytically active material.

Owner:VERSA POWER SYST

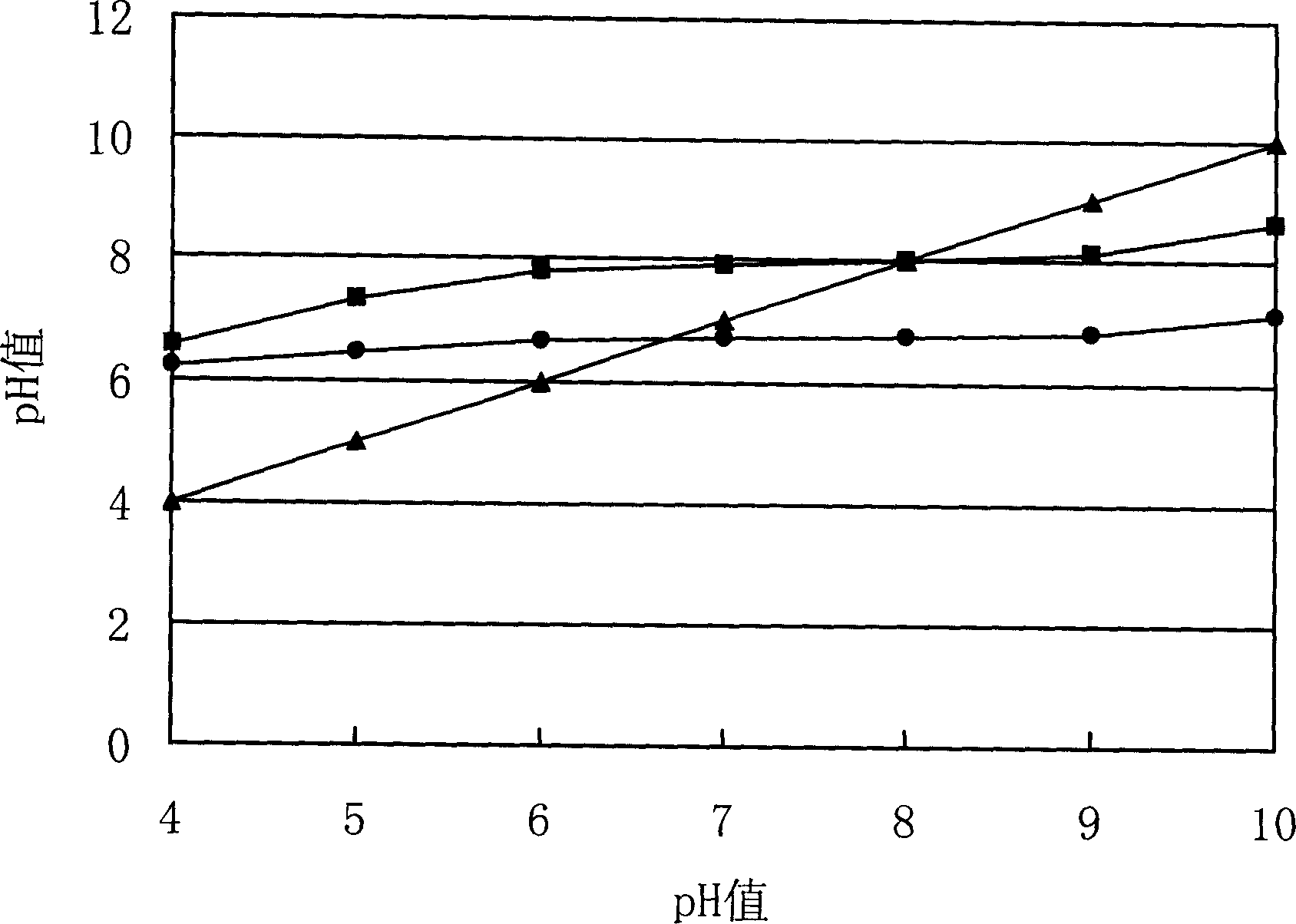

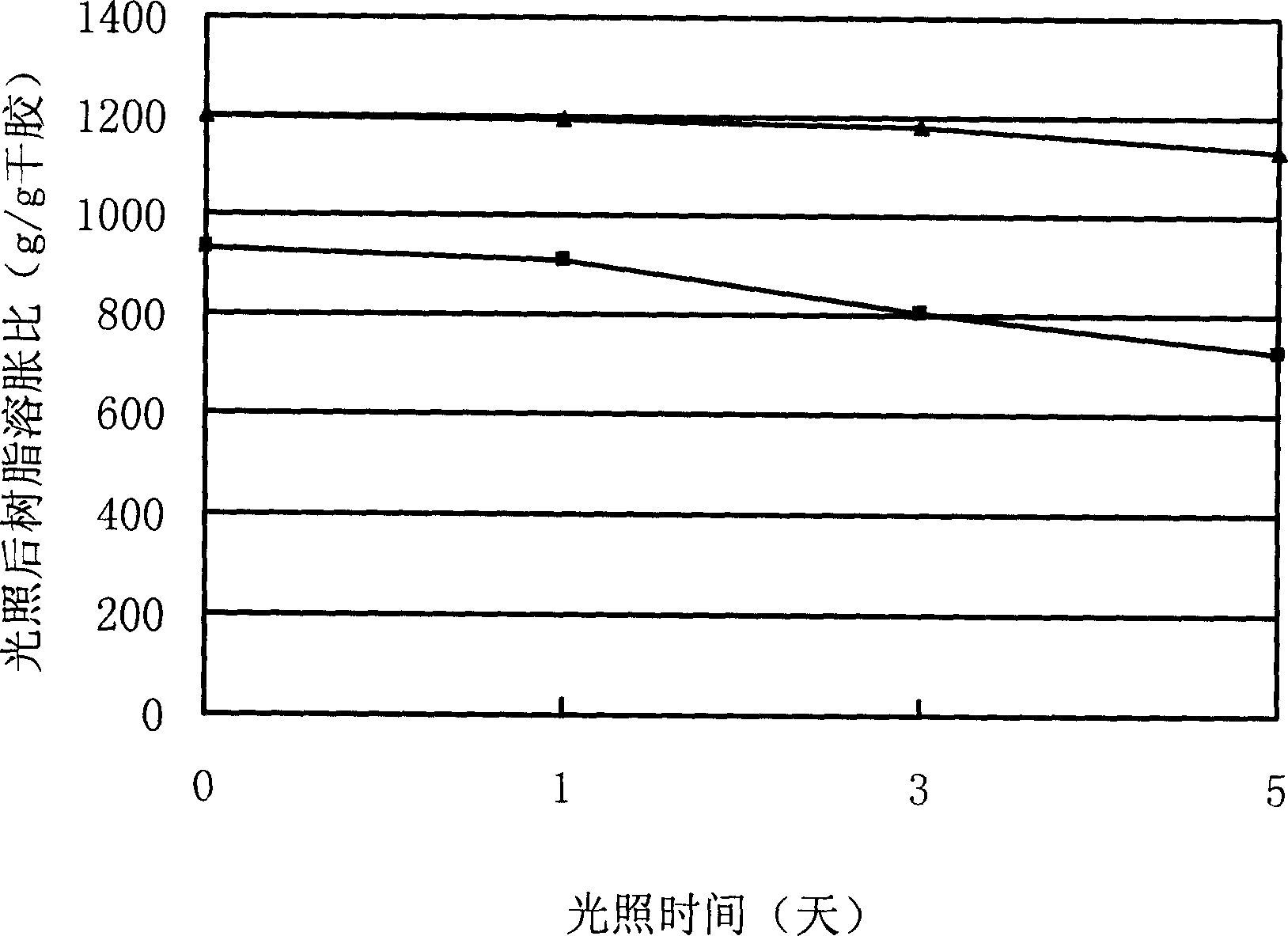

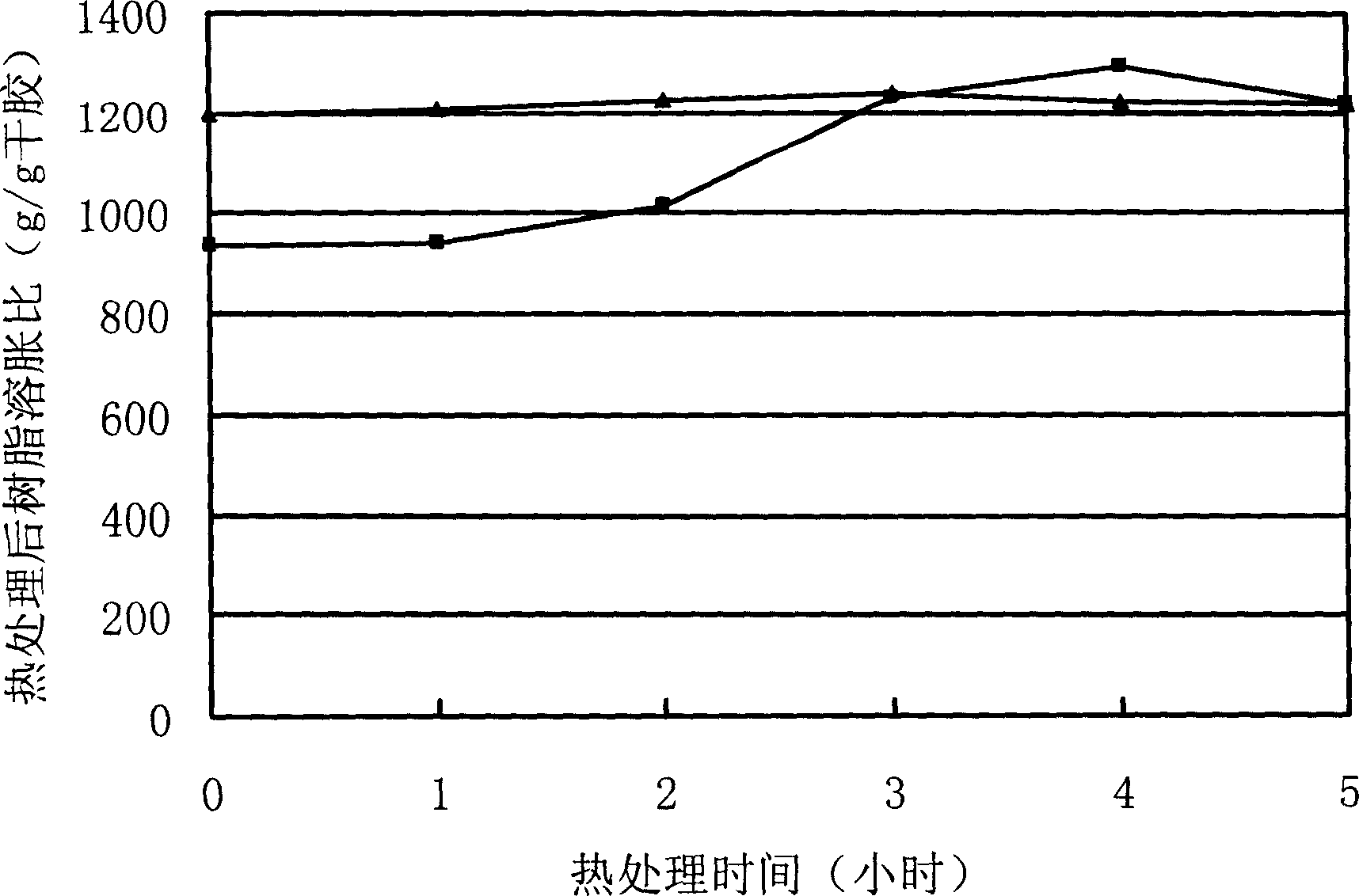

Method for preparing poly-aspartic-acid resin

This invention relates to a preparation method for poly-asparagic acid resin, which takes poly-pyrrolidine dione as the raw material to make crosslink poly-pyrrolidine dione with method of non-even phase suspended emulsion crosslink or non-even phase suspension crosslink and processes poly-asparagic acid resin by hydrolyzation characterizing that the crosslink poly-pyrrolidine dione is prepared by multi-section crosslink reaction, in which, the crosslinker is fed in for 2-4 times in equal volume and equal time interval, the crosslink poly-pyrrolidine dione and the resin are aged and crystallized and quickly dried, A ageing and crystallization process for 1-10 days under room temperature, B, quick drying process is carried out under -54-40deg.C.

Owner:BEIJING UNIV OF CHEM TECH

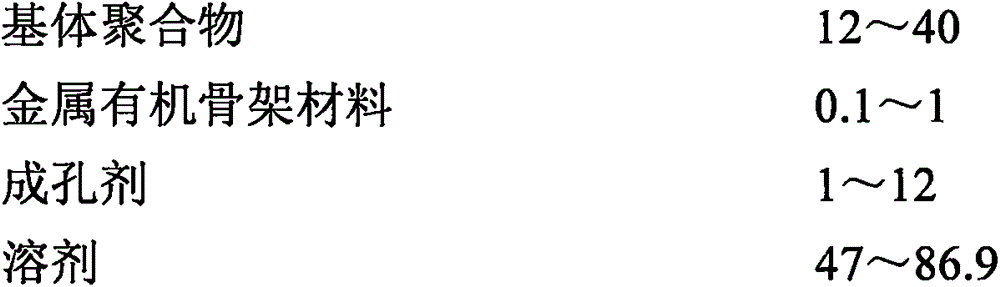

Inner support hollow fibrous membrane and preparation method and application thereof

InactiveCN106076127AHigh porosityIncrease the areaSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiberYarn

The invention relates to an inner support hollow fibrous membrane which adopts a hollow braided rope as an inner supporting material. A base body polymer, a metal organic framework material and a pore forming agent are mixed together to be dissolved with a solvent, a membrane casting solution is obtained, the membrane casting solution coats the hollow braided rope, and solidification forming is performed to obtain the inner support hollow fibrous membrane. The metal organic framework material is adopted for improving the porosity and water flux of the inner support membrane; the proper proportion of the metal organic framework material to the pore forming agent in the membrane casting solution, organic coordination and synergism of the components are utilized, the interface wettability of the membrane casting solution and a coagulating bath can be effectively controlled, a coagulator and solvents in the membrane casting solution are easily dispersed and penetrate into the interface, effective combination of the membrane casting solution formula and the pore forming conditions is utilized, and the inner support hollow fibrous membrane of different pore diameters and different rejection performances can be spun; the obtained inner support hollow fibrous membrane can be used for an MBR and an immersed ultrafiltration assembly, the probability of broken yarn and sewage plugging is lowered, and the service life of the membrane is prolonged.

Owner:盐城海普润科技股份有限公司

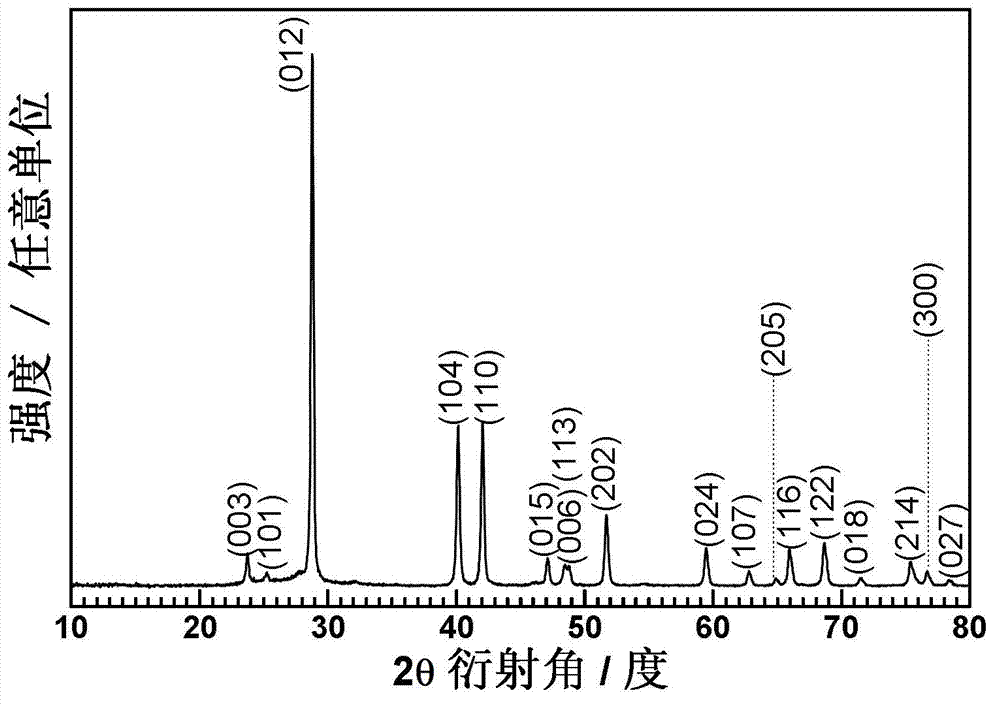

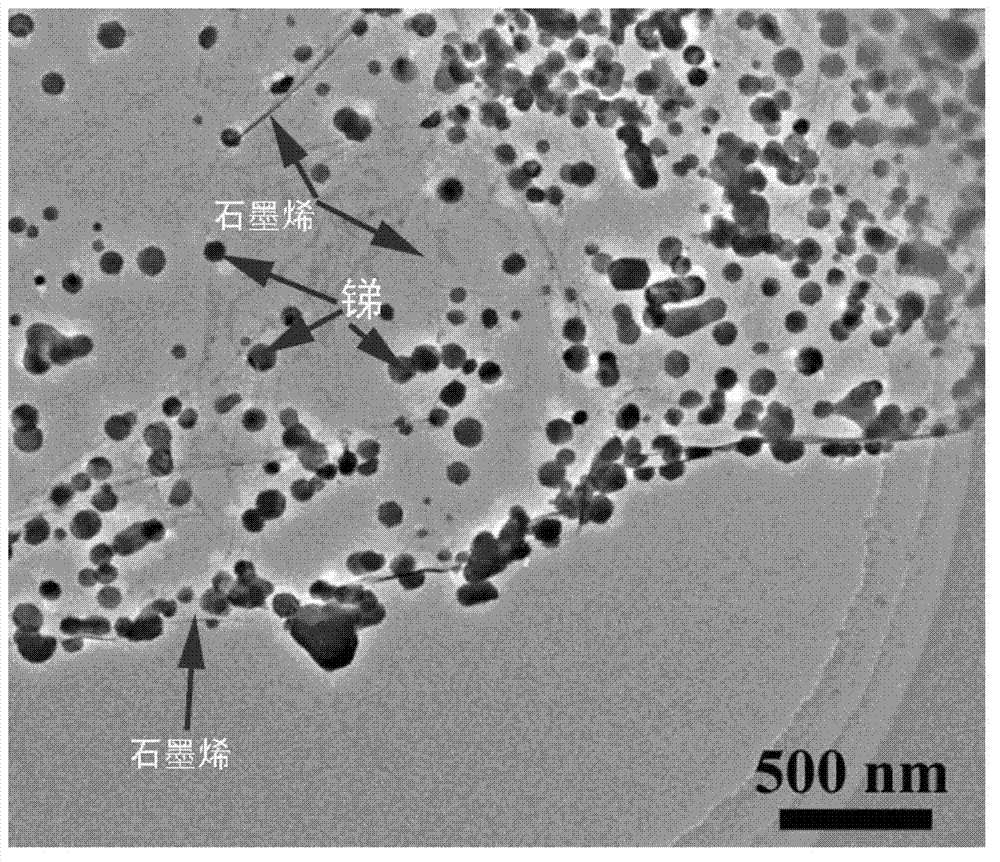

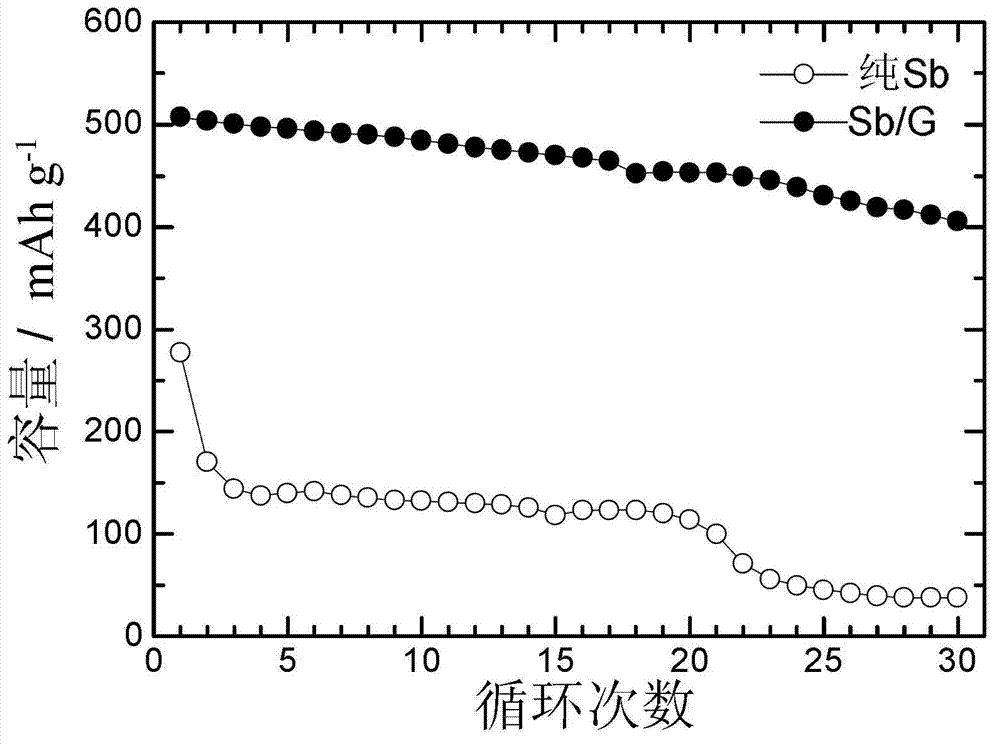

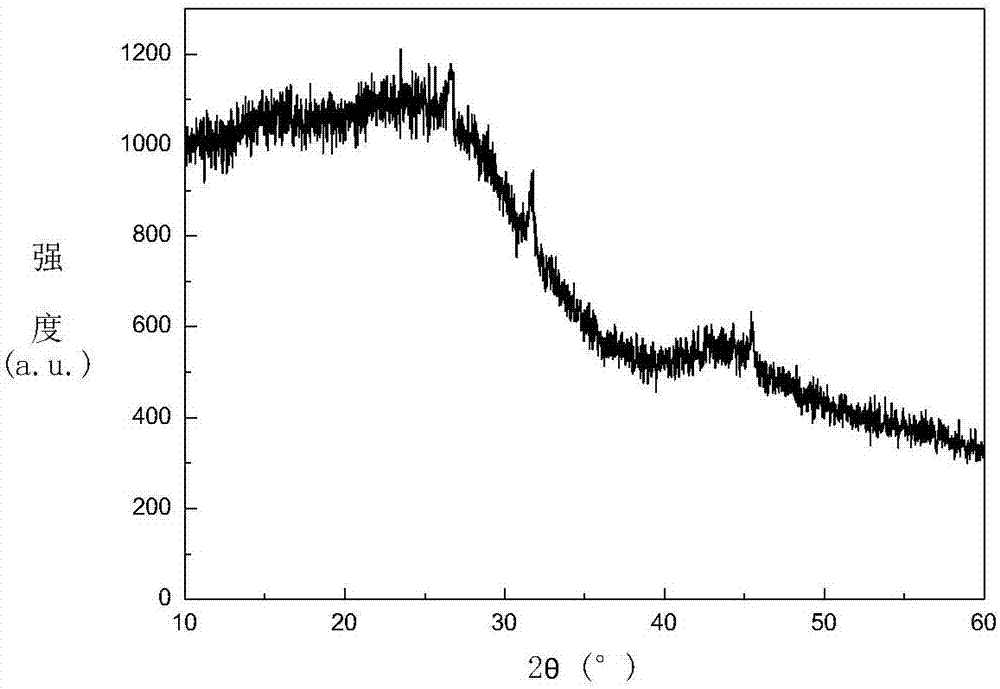

Metallic antimony/graphene composite material, and preparation method and application thereof

InactiveCN102760871AImprove electrochemical stabilityImprove stabilityCell electrodesCvd grapheneAntimony

The invention discloses a metallic antimony / graphene composite material which is composed of nano metallic antimony and graphene. Under the dispersion and loading action of the graphene, the metallic antimony can be distributed uniformly, the stability of the metallic antimony in the charging / discharging process can be effectively enhanced, and the composite material can be used as a lithium ion battery negative pole material. The invention also discloses a preparation method of the composite material by a one-step hydrothermal process or one-step solvothermal process, which has the advantages of simple technique, low cost, short cycle, low energy consumption and the like.

Owner:ZHEJIANG UNIV

Method for making particulate slurries and particulate slurry compositions

ActiveUS7723274B2Improve conductivityEasy to dehydrateSolid sorbent liquid separationWater/sewage treatment by ion-exchangeParticulatesChemical compound

An aqueous slurry composition for use in industries such as the petroleum and pipeline industries includes a particulate, an aqueous liquid and a chemical compound that renders the particulate surface extremely hydrophobic. The slurry is produced by rendering the surface of the particulate extremely hydrophobic during or before making the slurry.

Owner:TRICAN WELL SERVICE

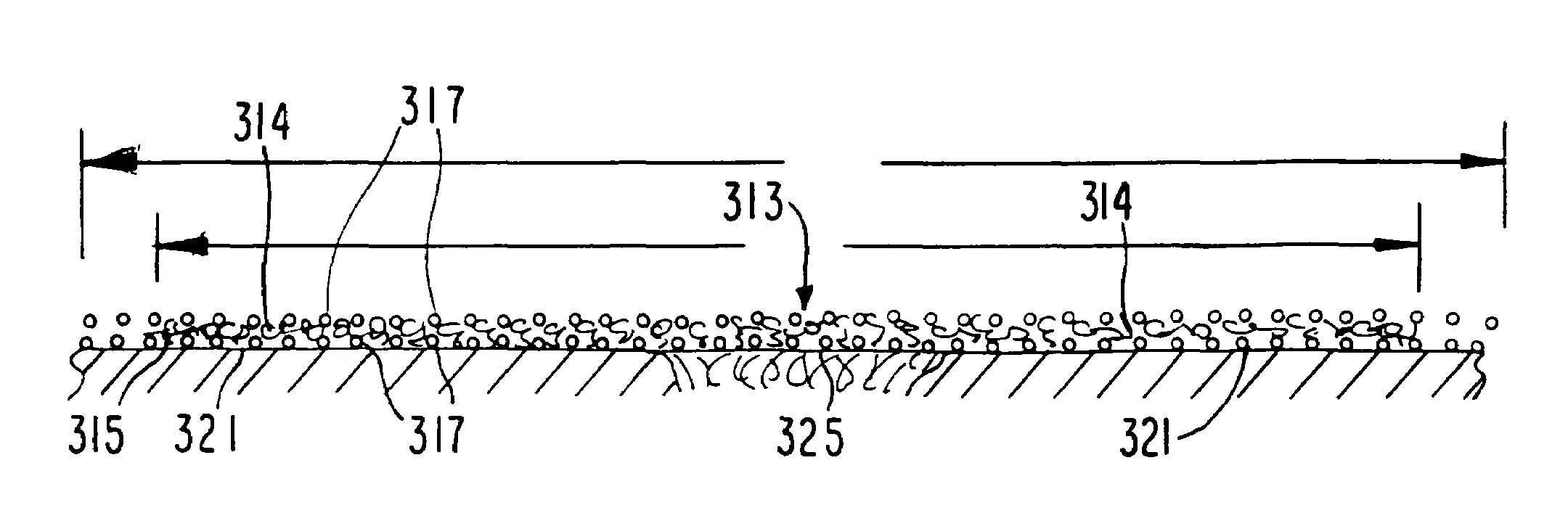

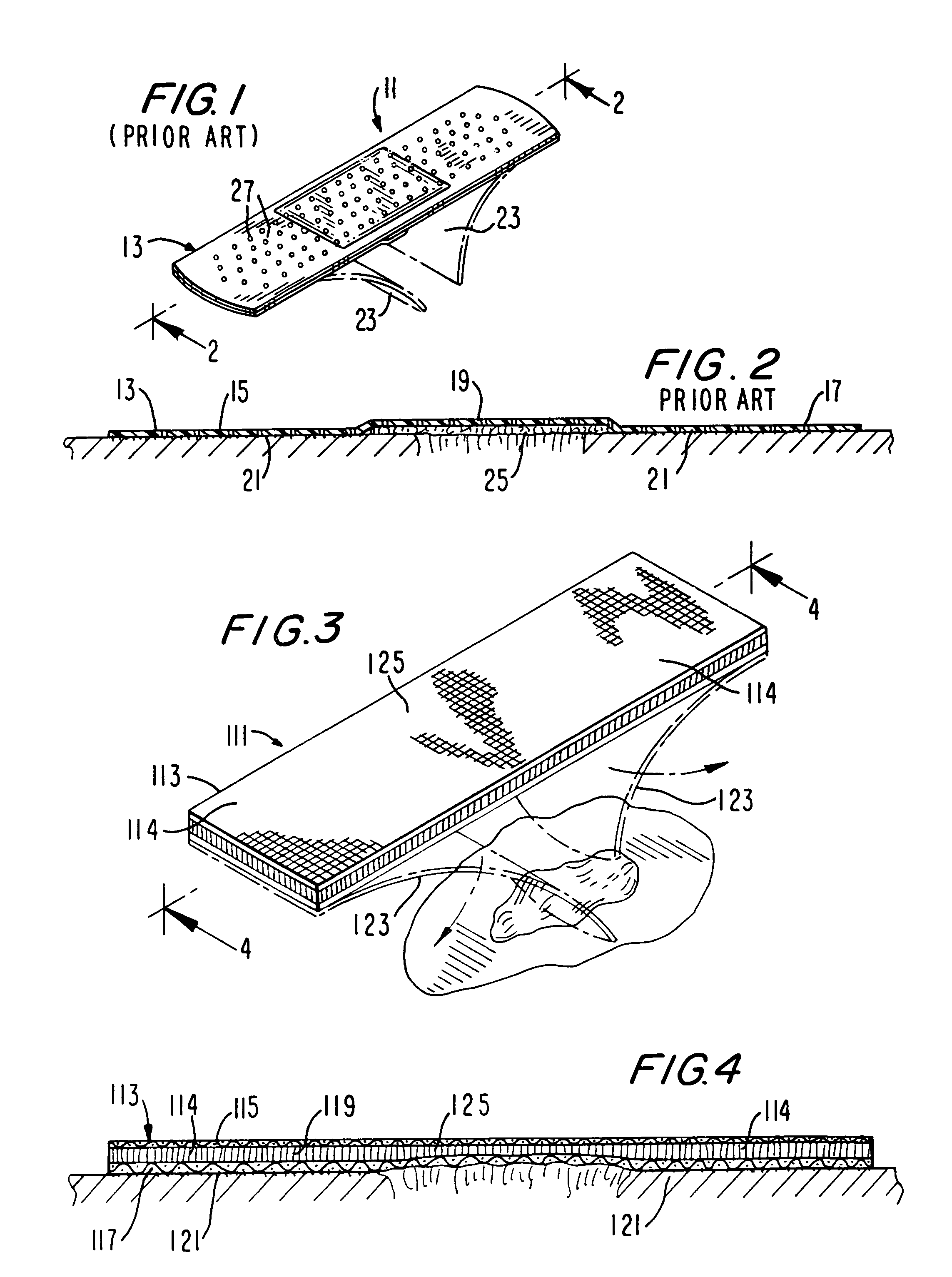

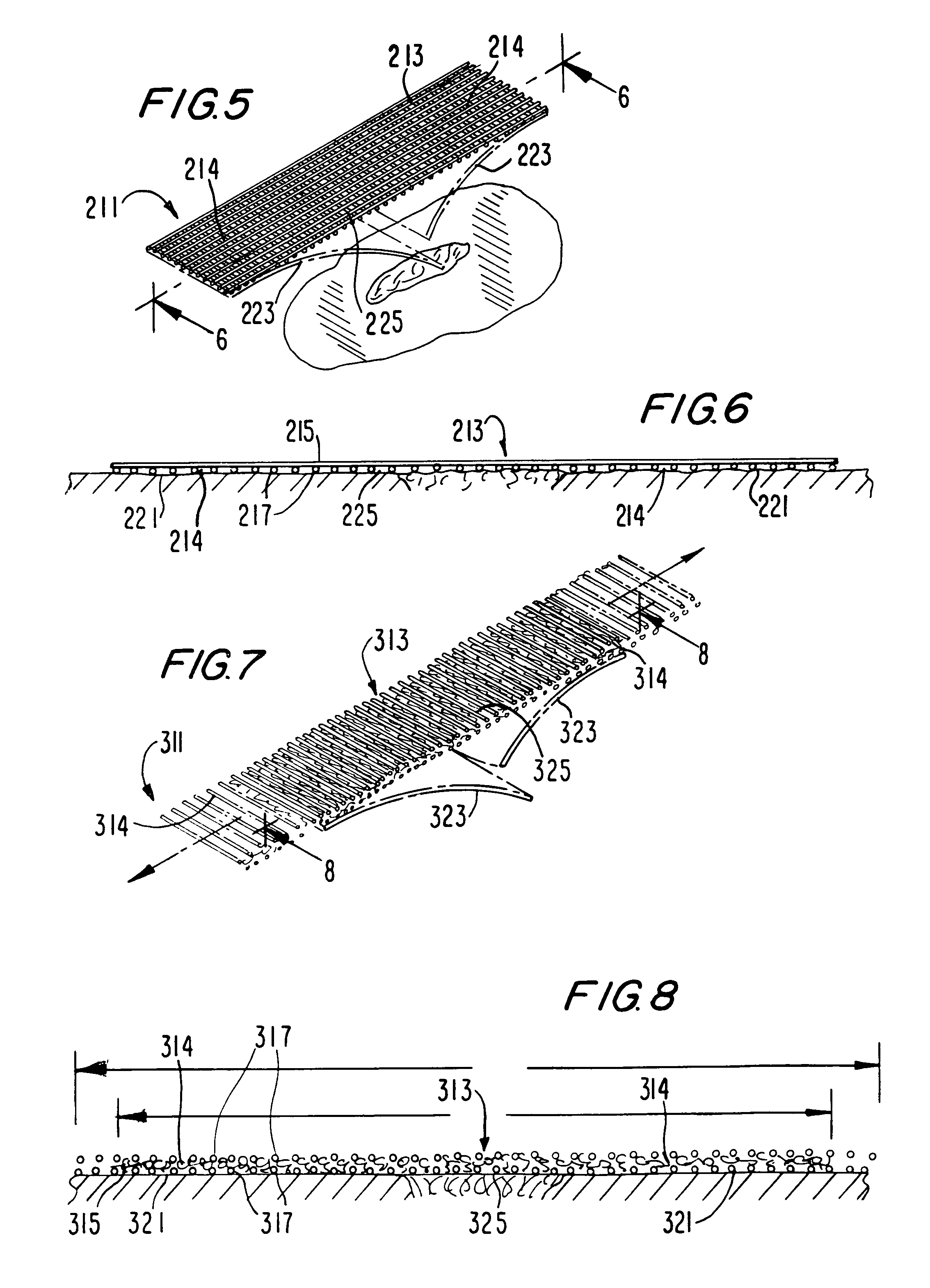

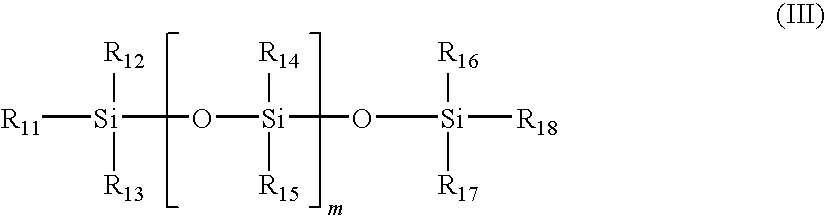

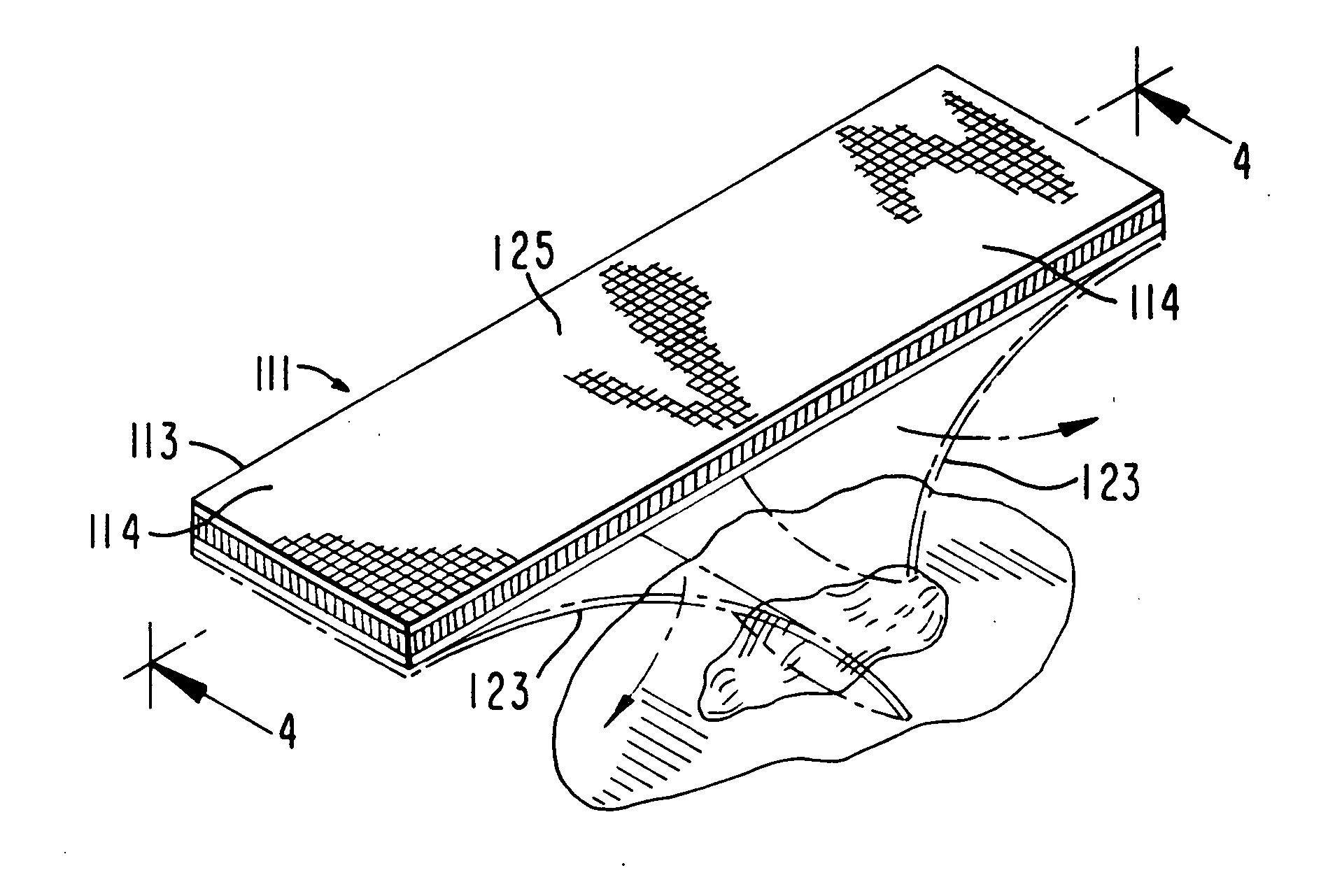

Scab protecting bandage

An improved bandage for application to a wound scab is provided. The bandage comprises a bandage strip defined by a material having an air porosity of at least 50 cubic ft. / min. / sq. ft. The strip includes three sections, two end sections and a middle section, all of which are preferably made from one continuous integrally formed porous material. The end sections have an adhesive which is applied to the underlying portion thereof to enable the bandage strip to be fixedly positioned over a wound scab. The central section, which is applied over the wound scab itself, solely comprises the porous strip material.

Owner:SCHLUSSEL ED

Method for making particulate slurries and particulate slurry compositions

ActiveUS20100197526A1Improve conductivityEasy to dehydrateChemical liquid solidificationFluid removalParticulatesChemical compound

An aqueous slurry composition for use in industries such as the petroleum and pipeline industries includes a particulate, an aqueous liquid and a chemical compound that renders the particulate surface extremely hydrophobic. The slurry is produced by rendering the surface of the particulate extremely hydrophobic during or before making the slurry.

Owner:TRICAN WELL SERVICE

Scab protecting bandage

InactiveUS20050154340A1Improved bandage structureFacilitating wound scab healingPlastersAdhesive dressingsPorosityAdhesive

An improved bandage for application to a wound scab is provided. The bandage comprises a bandage strip defined by a material having an air porosity of at least 50 cubic ft. / min. / sq. ft. The strip includes three sections, two end sections and a middle section, all of which are preferably made from one continuous integrally formed porous material. The end sections have an adhesive which is applied to the underlying portion thereof to enable the bandage strip to be fixedly positioned over a wound scab. The central section, which is applied over the wound scab itself, solely comprises the porous strip material.

Owner:SCHLUSSEL ED

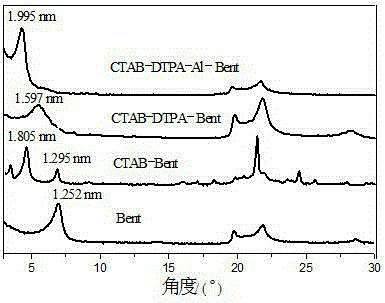

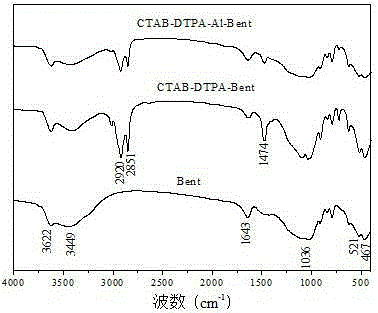

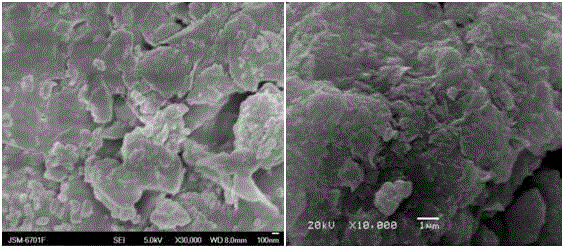

Multielement modified bentonite adsorption material and preparation method thereof

InactiveCN105289506AHigh selectivity of adsorptionLarge porosityOther chemical processesSodium BentoniteActive agent

The invention discloses a multielement modified bentonite adsorption material and belongs to the technical field of composite materials and water treatment. Sodium bentonite as a main material is modified by a multielement composite modifier containing an organic long carbon chain cationic surfactant, inorganic polyhydroxyl-based metal cations and a functional short carbon chain organic complexing agent by a copolymerization method to form the organic-inorganic multielement composite bentonite adsorption material. The organic-inorganic multielement composite bentonite adsorption material has porous and large specific surface area characteristics of inorganic pillared bentonite and high carbon content and strong hydrophobicity characteristics of organic bentonite and has strong metal ion complexation and adsorption functions of bentonite and thus organic matters can be adsorbed by surface adsorption and distribution and heavy metal ions in water can be removed by complexation. The organic-inorganic multielement composite bentonite adsorption material can be popularized and used in the waste water treatment field.

Owner:LANZHOU JIAOTONG UNIV

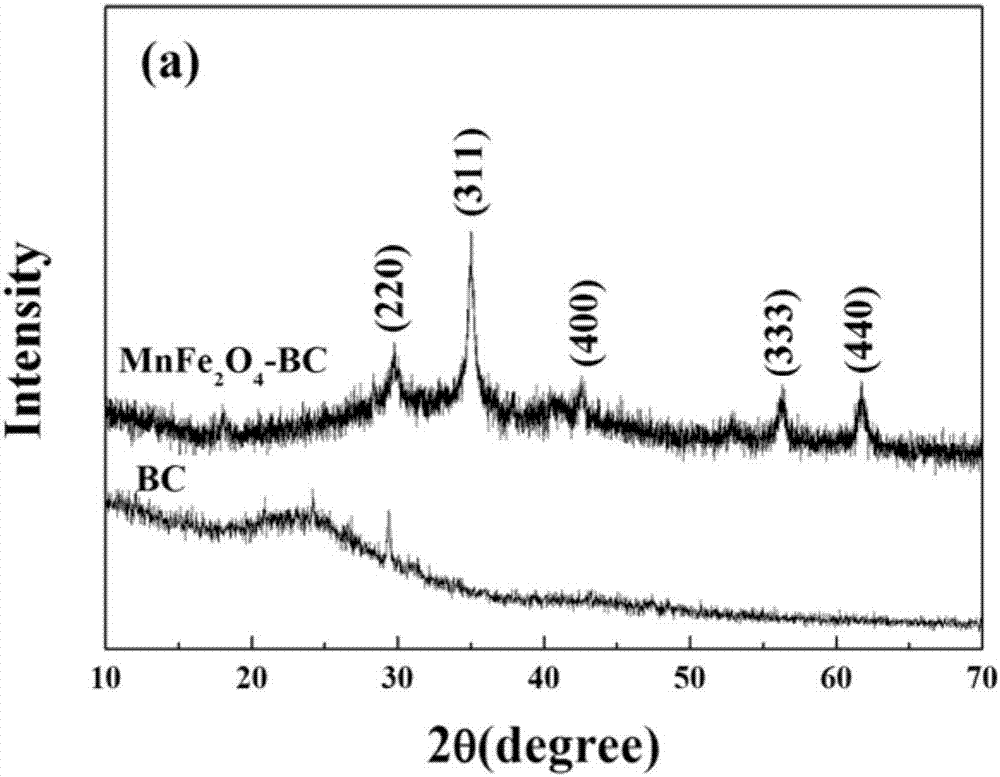

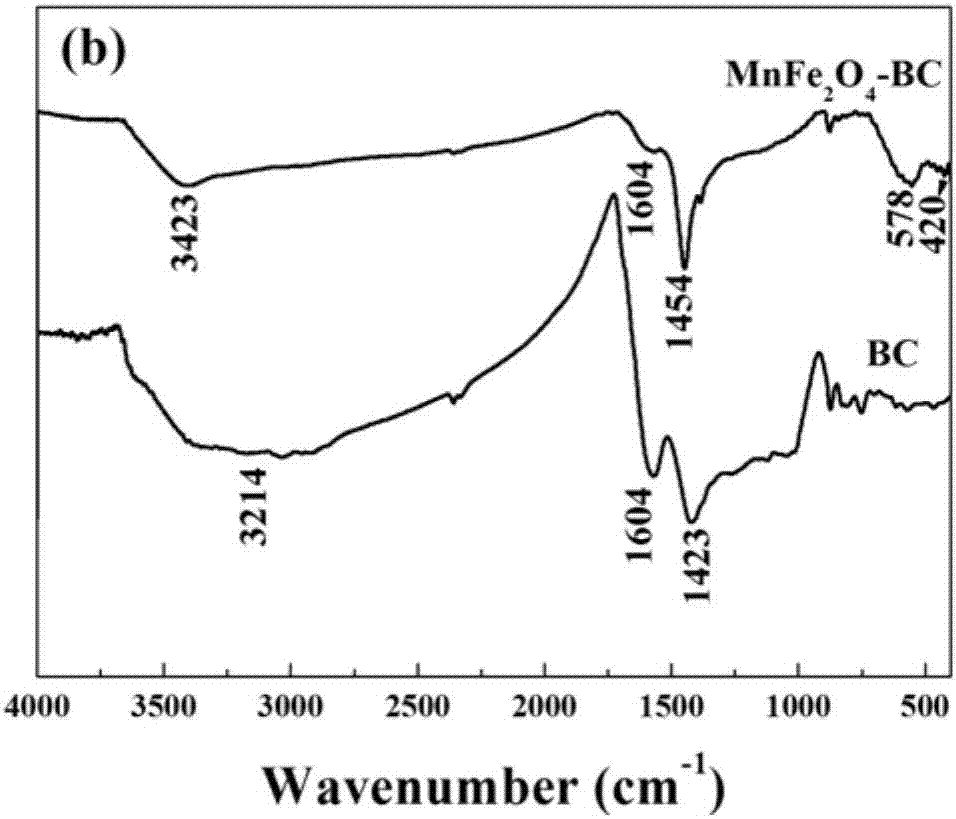

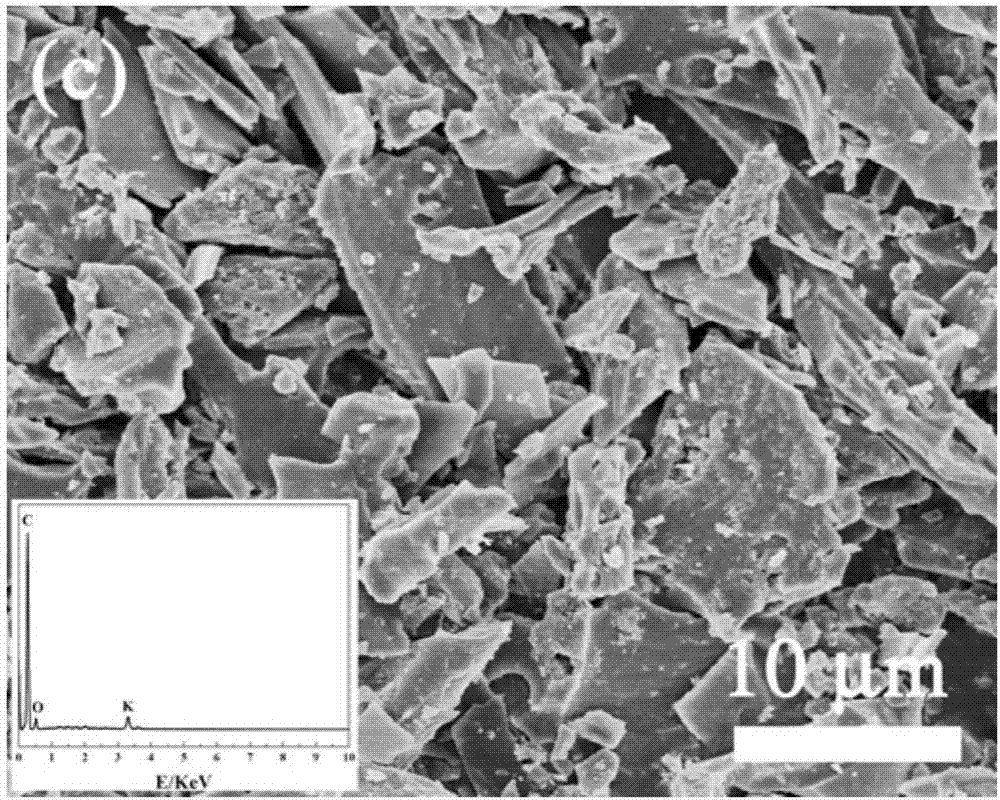

Biochar, iron and manganese spinel composite material for adsorbing heavy metal antimony and cadmium

ActiveCN107413296AIncrease the areaLarge porosityOther chemical processesWater contaminantsPorosityCadmium Cation

The invention belongs to the technical field of adsorption materials, and discloses a biochar, iron and manganese spinel composite material for adsorbing heavy metal antimony and cadmium. Solution B is dripped into suspension A at the constant speed, the solution B and the suspension A are stirred for 2.5-3.5 hours and are centrifuged, washed and dried to obtain the biochar, iron and manganese spinel composite material. The solution B is potassium permanganate solution with the concentration of 0.1 mol / L, and the suspension A comprises water, ferrous sulfate heptahydrate and from tea leaf and branch biochar according to a weight ratio of 100:(8.0-8.5):(0.8-1.2). The biochar, iron and manganese spinel composite material has the advantages that the biochar, iron and manganese spinel composite material has a large specific surface area and is large in porosity and favorable for adsorbing the heavy metal; adsorption environments are mild, and the heavy metal can be efficiently adsorbed in neutral and slightly weakly acidic environments; excellent adsorbing and removing effects can be realized by the biochar, iron and manganese spinel composite material for single heavy metal environments, and excellent heavy metal adsorbing and removing effects also can be realized by the biochar, iron and manganese spinel composite material for heavy metal antimony and cadmium co-existence environments.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

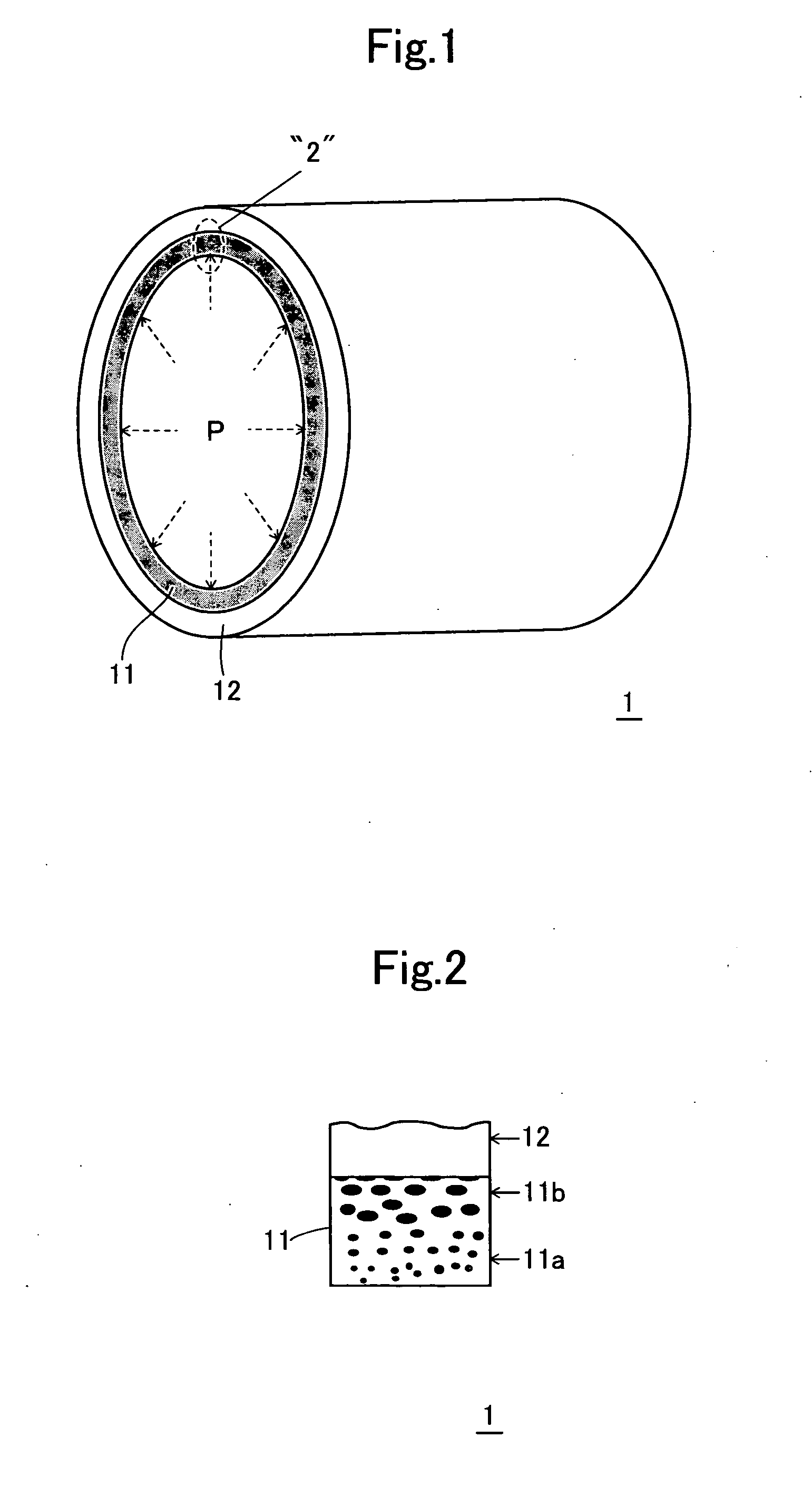

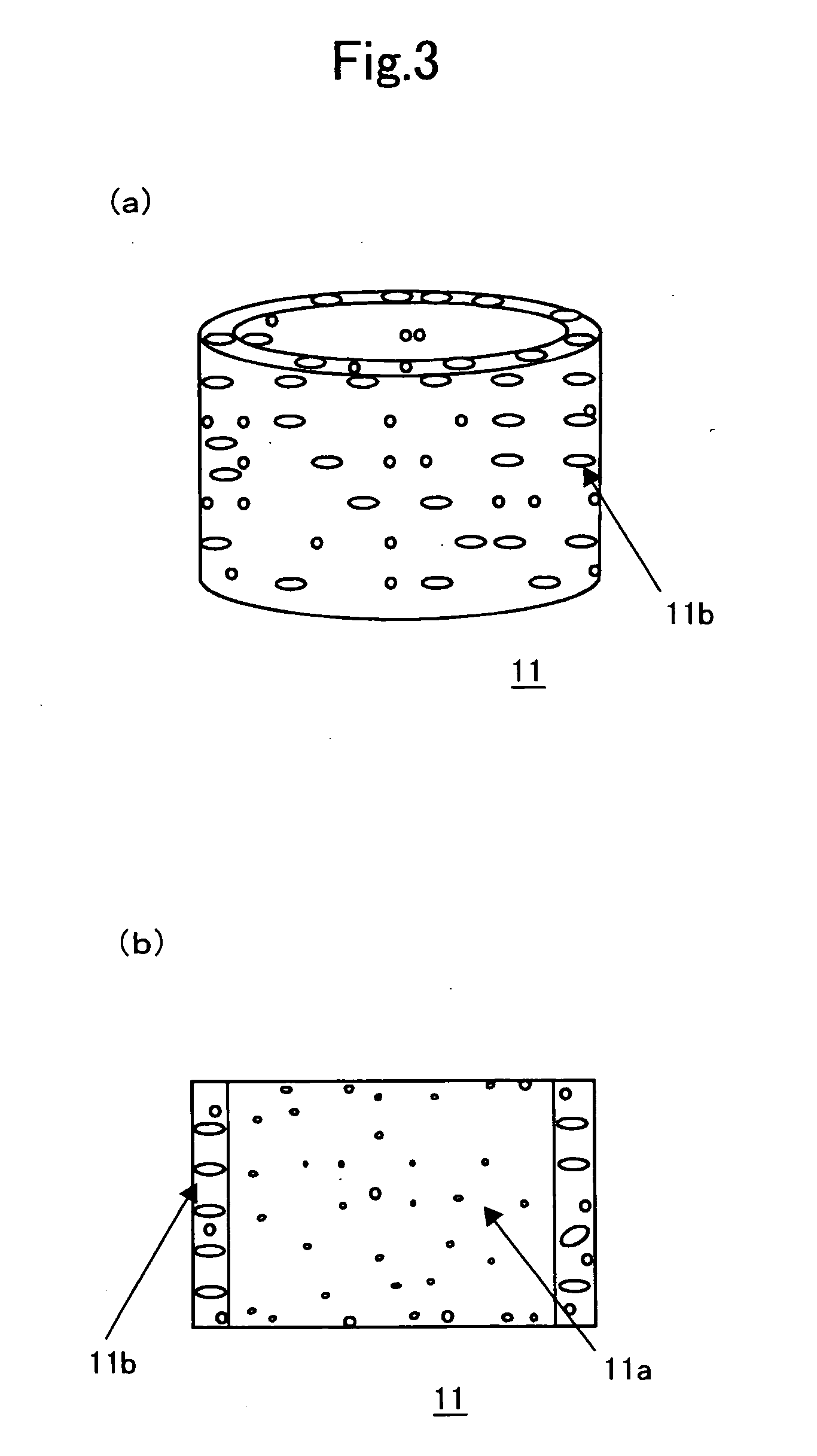

Composited cast member, iron-based porous substance for composited cast members, and pressure casing processes for producing the same, constituent member of compressors provided with composited cast members and the compressors

InactiveUS20050153156A1High strengthSmall porosityPositive displacement pump componentsLayered productsPorosityHigh intensity

A pressure casing includes a composited cast member. The composited cast member includes an iron-based porous substance whose major component is Fe and which has a large number of pores, and a cast-wrapping member whose major component is a light metal and which cast-wraps a part of the iron-based porous substance at least. The iron-based porous substance includes a connector disposed adjacent to a boundary between the iron-based porous substance and the cast-wrapping member and exhibiting a larger porosity, and a high-strength reinforcer disposed in the iron-based porous substance free from the connector and exhibiting a smaller porosity. The connector is impregnated with the cast-wrapping member, and solidifies therewith, thereby firmly bonding the iron-based porous substance and the cast-wrapping member in the composited cast member. The pressure casing secures strength with the reinforcer, and secures adhesiveness with the connector.

Owner:TOYOTA IND CORP

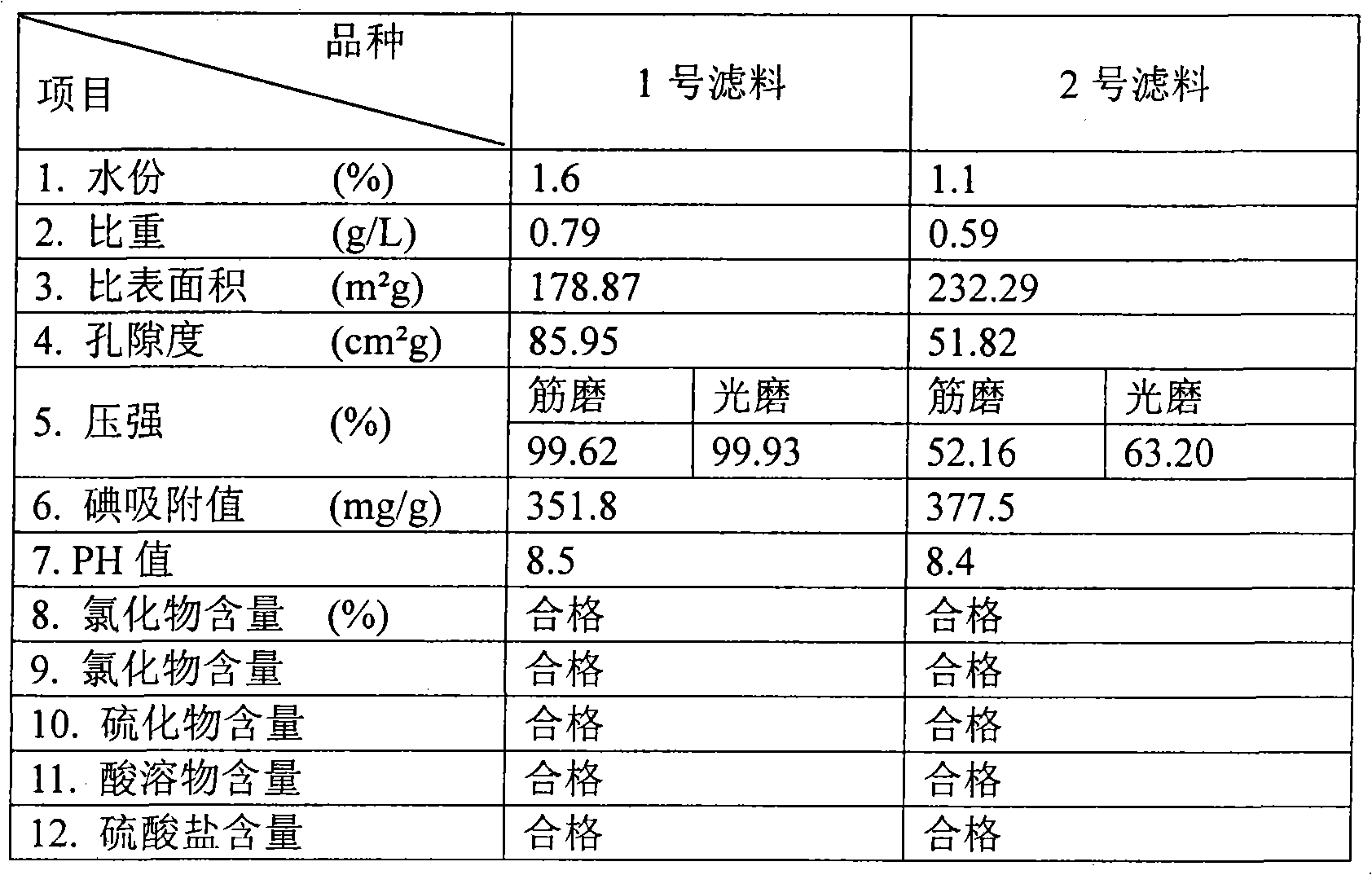

Composite filtering material for activating and regenerating coal ash and production method thereof

InactiveCN101274172ALow costReduce processingOther chemical processesFiltration separationFiltrationGranularity

The invention discloses a fly ash activation regeneration composite filtration material and a manufacture method of the filtration material, belonging to the field of water treatment technique. The fly ash activation regeneration composite filtration material consists of 80 to 90 portions of fly ashes or furnace ashes (by weight) with the grain diameter not less than 80 meshes and 10 to 20 portions of porous aluminosilicate mixed powders (by weight); the fly ash or the furnace ash are bonded as grain shape with the granularity less than 8mm; the porous aluminosilicate mixed powders are enwrapped on the surface of the fly ashes or the furnace ashes and burned so as to form a ceramic layer which is provided with an adsorption micro-hole which is communicated with an internal core. The fly ash activation regeneration composite filtration material is fabricated and formed by the steps of raw material mixing, primary granulation, secondary granulation, drying, roasting, etc., and has the advantages of low cost and good purification effect.

Owner:江苏正本净化节水科技实业有限公司

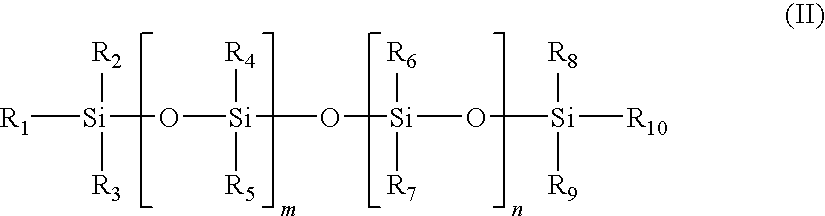

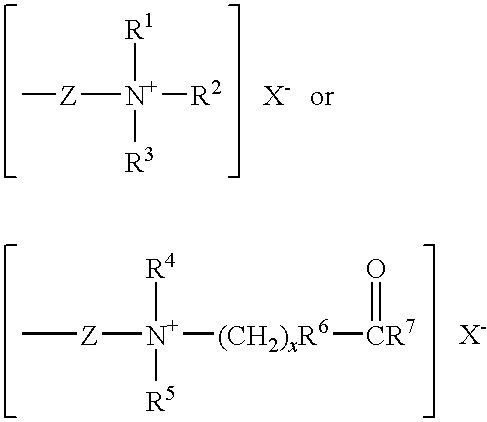

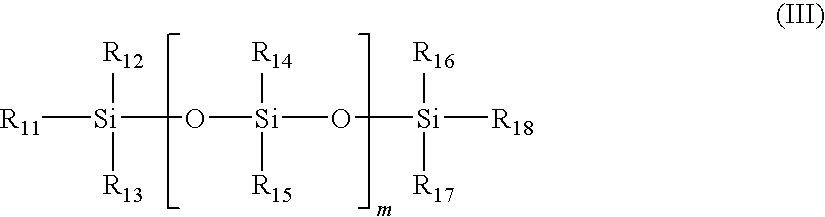

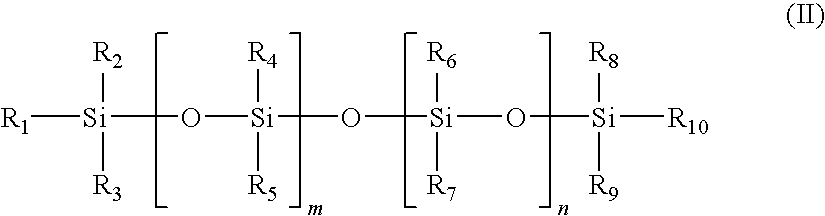

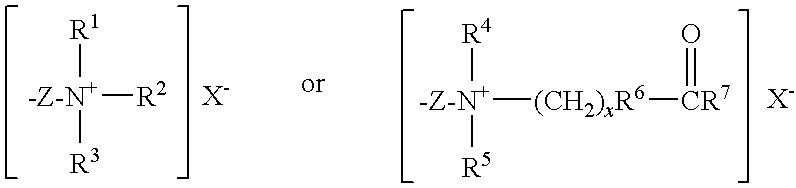

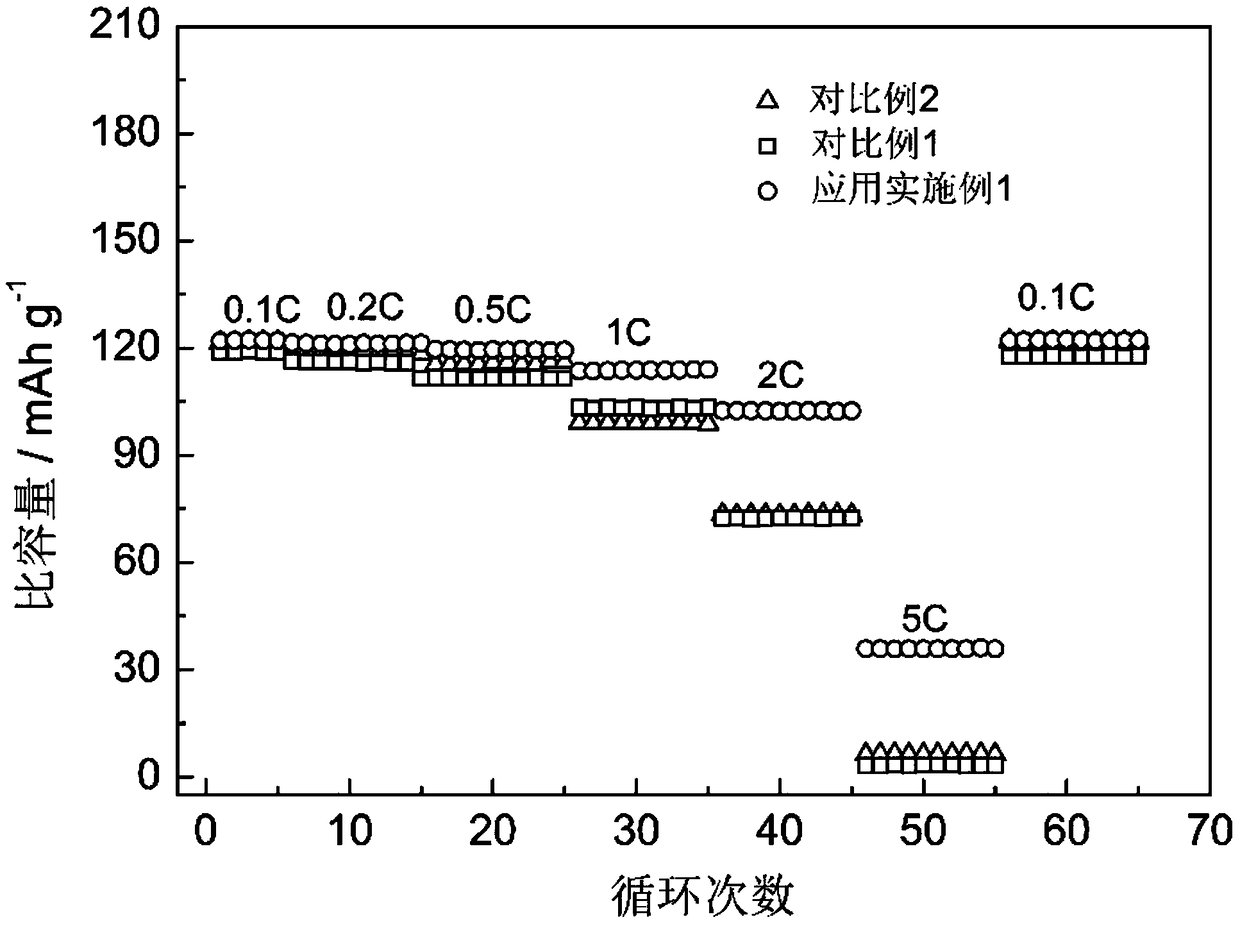

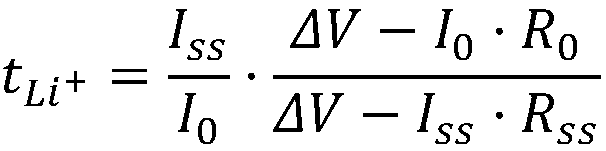

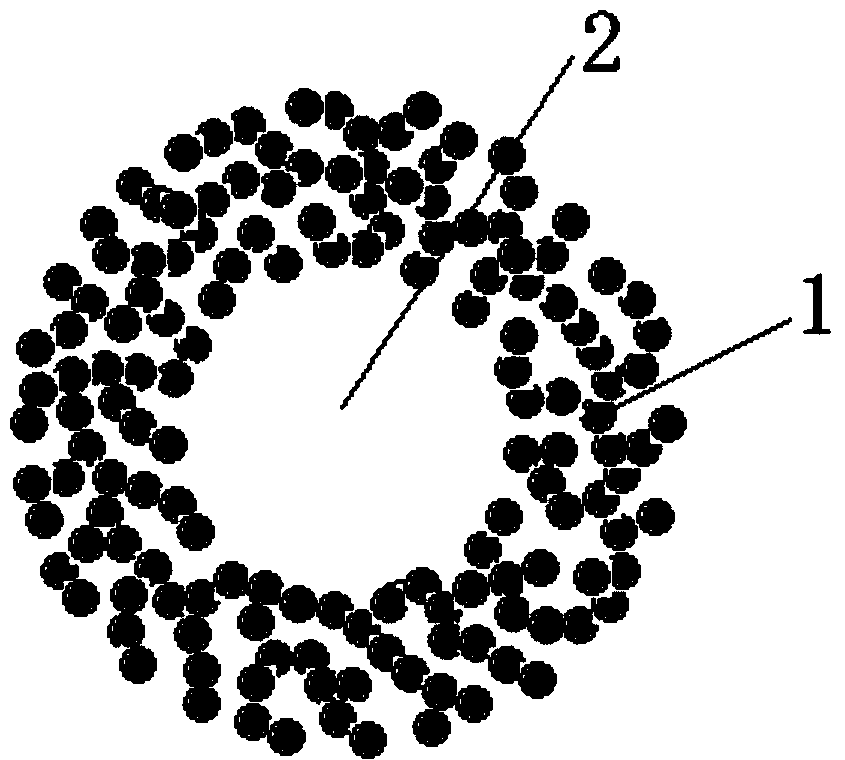

Modified SiO2 nanoparticle, preparation method thereof, nanofiber membrane containing same, gel electrolyte and lithium metal battery

ActiveCN108281705AIncrease the number of transfersIncrease migration resistanceLi-accumulatorsFiberHigh rate

The invention provides a modified SiO2 nanoparticle, a preparation method thereof, a nanofiber membrane containing the modified SiO2 nanoparticle, a gel electrolyte and a lithium metal battery. The modified SiO2 nanoparticle comprises an SiO2 nanoparticle and a specific ionic liquid grafted on the SiO2 nanoparticle. The nanofiber membrane is composed of a vinylidene fluoride-hexafluoropropylene copolymer and fiber consisting of the modified SiO2 nanoparticle. The gel electrolyte comprises the nanofiber membrane and a plasticizer adsorbed inside the nanofiber membrane. An electrolyte of the lithium metal battery is the gel electrolyte. According to the modified SiO2 nanoparticle provided by the invention, the mutual effect of the nanofiber membrane and the plasticizer can be strengthened, the transference number of Li+ is increased, the modified SiO2 nanoparticle is matched with the structure of the nanofiber membrane, and the ionic conductivity and specific capacity of the gel electrolyte and the cycling stability under high rate can be further improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method for aerogel particle in cavity structure

ActiveCN103432968ATargetedStable structureMicroballoon preparationMicrocapsule preparationControlled releaseMetallurgy

The invention discloses a preparation method for an aerogel particulate in a cavity structure. The preparation method for a SiO2 aerogel particulate in the cavity structure comprises the following steps of wrapping metal particles by SiO2 aerogel, grinding and separating the SiO2 aerogel which wraps the metal particles, and drying to obtain the aerogel particulate which wraps the metal particles and is of a required size; soaking the aerogel particulate which wraps the metal particles in dilute acid, and slowly dissolving the metal particles; after the metal particles are completely dissolved, forming a cavity in the SiO2 aerogel particulate which originally wraps the metal particles due to dissolution of the metal particles, and performing washing, drying and heat treatment to obtain the SiO2 aerogel particulate in the cavity structure. The preparation method is simple. The prepared aerogel particulate in the cavity structure is stable in structure and can be used for medicine carrying and controlled release, and the particle size of the particulate is 1 to 10 microns.

Owner:常州循天节能科技有限公司

Preparation method of modified carbon fiber thermal insulation composite material

ActiveCN108017362AImprove thermal insulation performanceImprove adsorption capacityPhysical treatmentCarbon fibresFiberCarbon fibers

The invention discloses a preparation method of a modified carbon fiber thermal insulation composite material. The modified carbon fiber thermal insulation composite material is prepared from raw materials of silicon powder, coconut shell, phenol, polyvinyl alcohol, etc. The preparation method is characterized in that the coconut shell is used to prepare porous carbon fiber and undergoes a plurality of modification processes to obtain porous carbon fiber with high mechanical strength and high adsorption; and then the porous carbon fiber is impregnated with alkaline silica sol, so that the well-developed mesoporous structure of the silica sol makes the carbon fiber have high temperature resistance and extremely low thermal conductivity, and further strengthens the thermal insulation capacity of the carbon fiber. The obtained composite material is not only light in weight, but also has high thermal insulation ability and low thermal conductivity, so that use cost of the thermal insulation material is greatly reduced, and the modified carbon fiber thermal insulation composite material is suitable for the needs of thermal insulation materials in various fields.

Owner:嘉兴德毅新材料有限公司

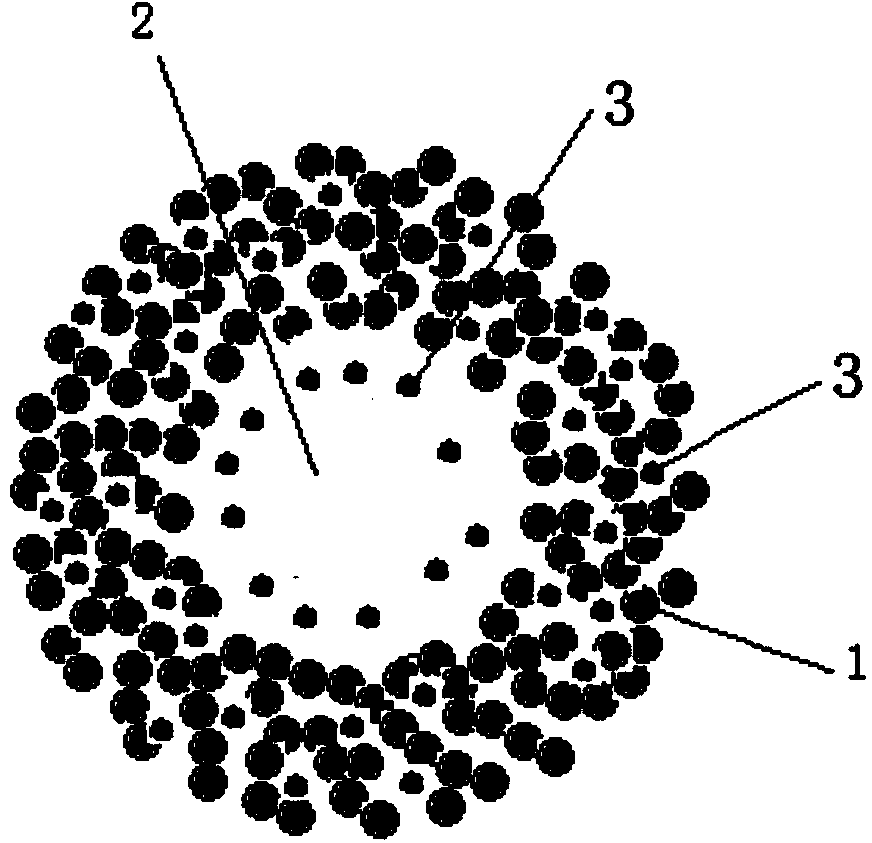

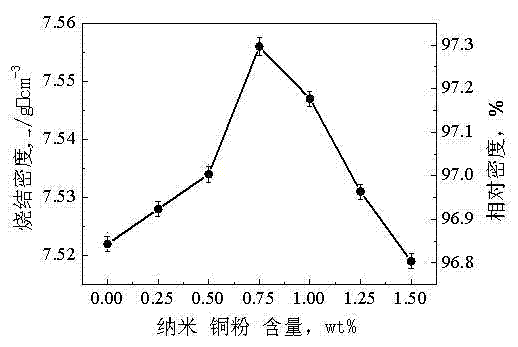

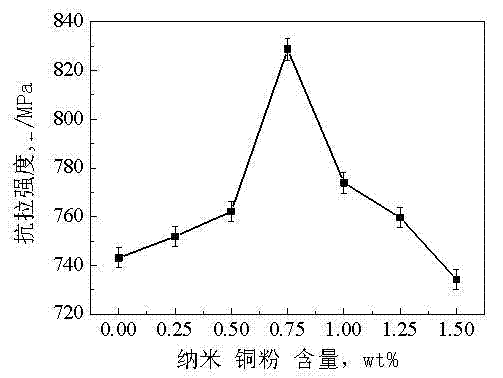

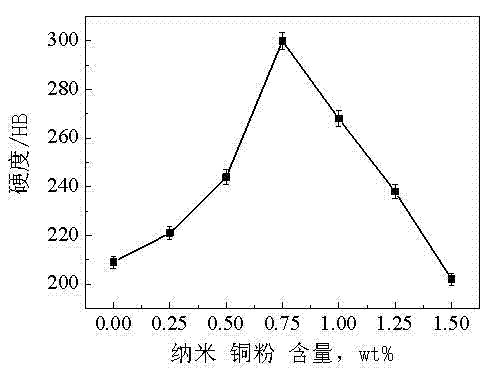

Method of improving performance of iron-based powder metallurgy parts prepared by high velocity compaction

InactiveCN102773481AExacerbate cold weldingImprove mechanical propertiesPowder mixtureMechanical property

A method of improving performance of iron-based powder metallurgy parts prepared by high velocity compaction belongs to the technical field of powder metallurgy. An optimization method that nanometer copper powder is used for replacing partial copper powder in iron-based mixed powder is adopted. The nanometer copper powder, the copper powder and iron powder are prepared in a glove box filled with high-purity argon according to a certain mass fraction, and fed into a charging barrel. The charging barrel is sealed, and put into a centrifugal drum machine to carry out mixing for a certain period of time, so that a uniform iron-based powder mixture is obtained. Zinc stearate acetone suspension is used as a die wall lubricant, and the iron-based parts are prepared by the high velocity compaction. The parts are sintered for a certain period of time under the protective atmosphere of hydrogen at the temperature of 1150-1280DEG C, so as to obtain iron-based products with high mechanical properties. According to the invention, the nanometer metal powder is combined with an advanced high velocity compaction technology, the iron-based powder metallurgy parts with high mechanical properties are successfully prepared, and the method has the advantages that the preparation process is simple, the cost is low, the production efficiency is high, the part density and the mechanical property are stable, the part sintering size precision is high, and the like.

Owner:UNIV OF SCI & TECH BEIJING

Nonaqueous electrolyte secondary battery

ActiveUS20160133934A1Optimize timingSpeed up the flowFinal product manufactureSmall-sized cells cases/jacketsLithium carbonateEngineering

A non-aqueous electrolyte secondary battery includes a pressure-sensitive current shut-off mechanism, wherein a positive electrode core body exposed portion is disposed at one end portion of a flat rolled electrode assembly, a negative electrode core body exposed portion is disposed at the other end portion, lithium carbonate is contained in a positive electrode mix layer, and a protective layer is disposed along the border with the positive electrode mix layer at the position opposite to a separator on the positive electrode core body exposed portion.

Owner:SANYO ELECTRIC CO LTD

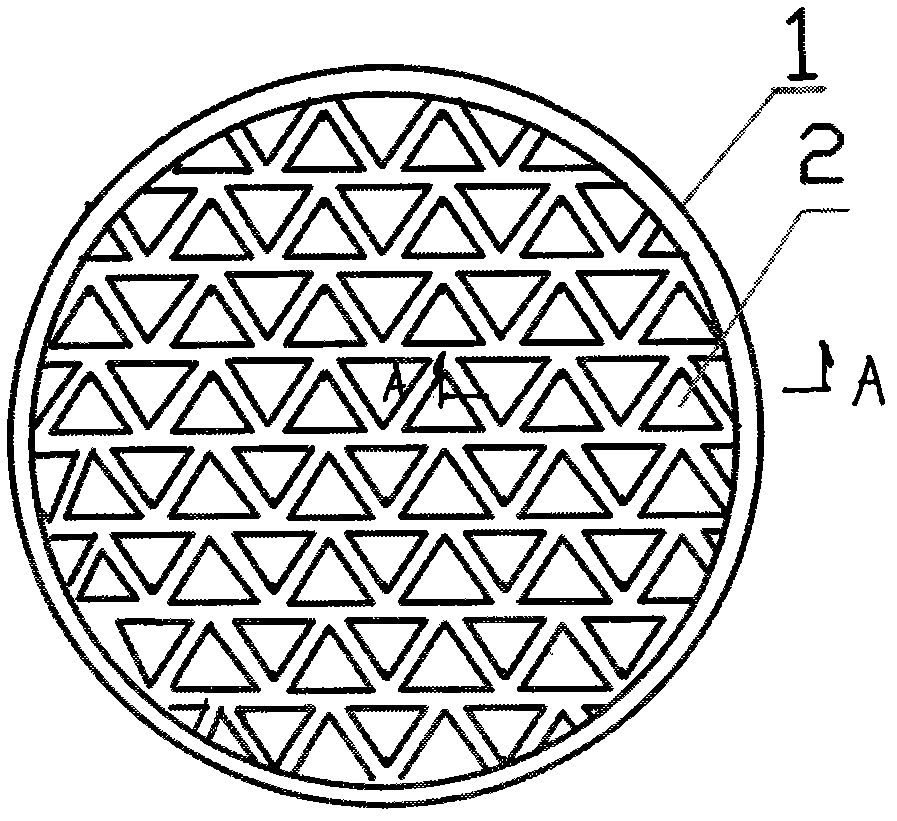

Bird-nest catalyst carrier

The invention discloses a bird-nest catalyst carrier, which comprises a body (1). The body is cylindrical or cuboid; and honeycomb holes (2) which are uniformly distributed, and parallel or staggered vertically and staggered or parallel horizontally are formed in an inner cavity of the body. One or a mixture of more of activated aluminium oxide, zirconium oxide, magnesium oxide, silicon carbide, titanium dioxide and natural clay is taken as a main raw material, is added with an adhesive, a fusing agent and a proper amount of water, and is subjected to ball milling, kneading, ageing, mixing, molding, drying, shaping, cutting and low-temperature sintering to form the bird-nest catalyst carrier. Due to large specific surface area and void ratio, large internal through pore diameter and large pore volume, the bird-nest catalyst carrier can improve the total effective contact quantity to the greatest extent and shorten the flowing path of raw oil in the catalyst, so that the catalyst in the carrier can fully achieve the effect, and the raw oil flowing through the catalyst is fully separated, adsorbed, purified and filtered.

Owner:姚光纯

Porous carbon material, preparation method and application thereof

InactiveCN107500262APrevent collapsePlay a supporting roleCarbon preparation/purificationOrganic acidInorganic salts

The invention provides a porous carbon material, a preparation method and application thereof. The preparation method comprises: preparation of a precursor: dissolving a metal salt and organic acid in an organic solvent, adding an additive, then conducting stirring and centrifugation to obtain a precursor, wherein the metal salt, organic acid and organic solvent are in a mole ratio of 1-10:1-10:0-100; and preparation of the porous carbon material: mixing the precursor with a support agent, performing carbonization under the protection of inert gas, and conducting washing and drying to obtain the porous carbon material, wherein the support agent includes an inorganic salt. The preparation method of the porous carbon material provided by the invention avoids the hole collapse phenomenon during carbonization, and increases the specific surface area and porosity of the porous carbon material.

Owner:CHINA BUILDING MATERIALS ACAD

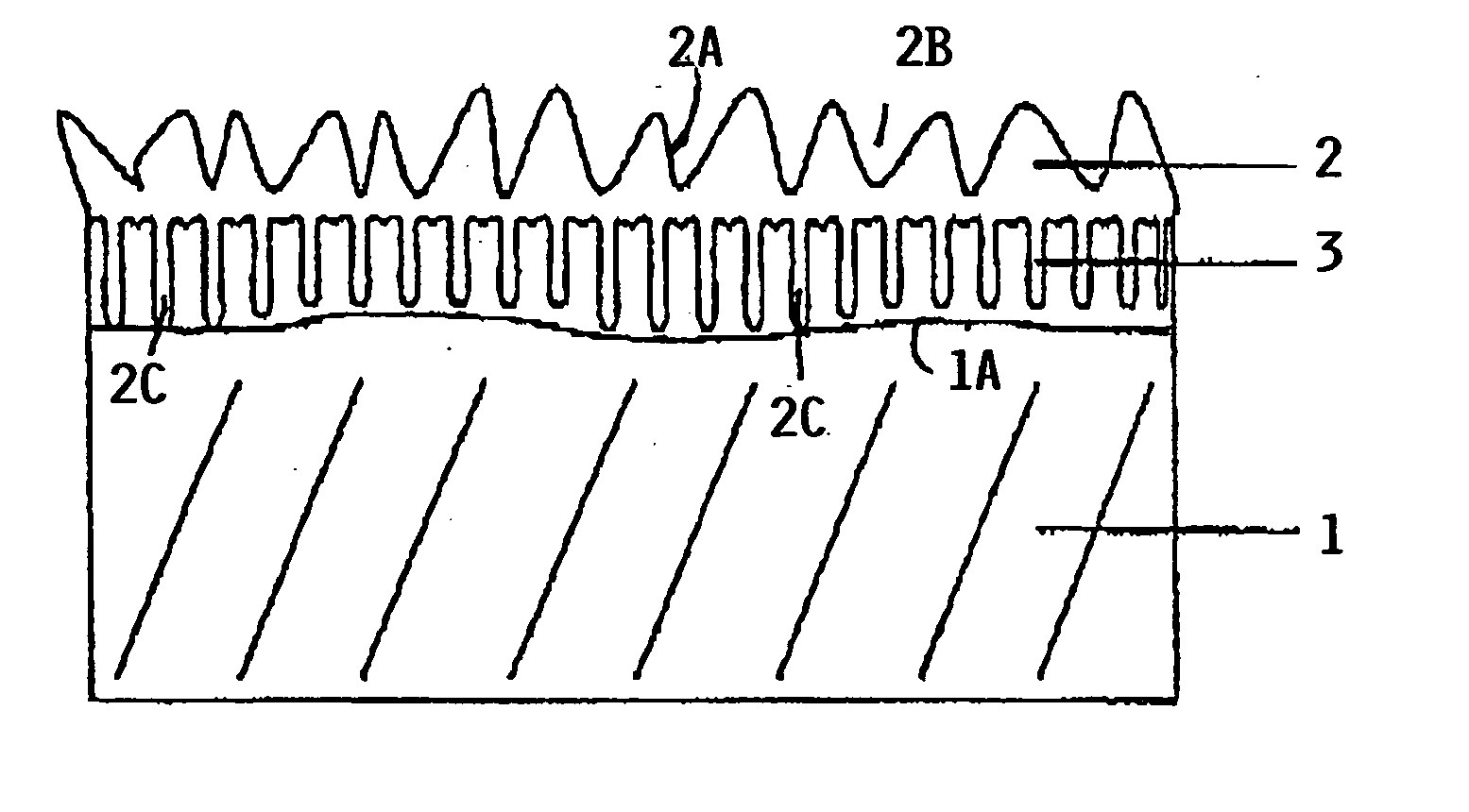

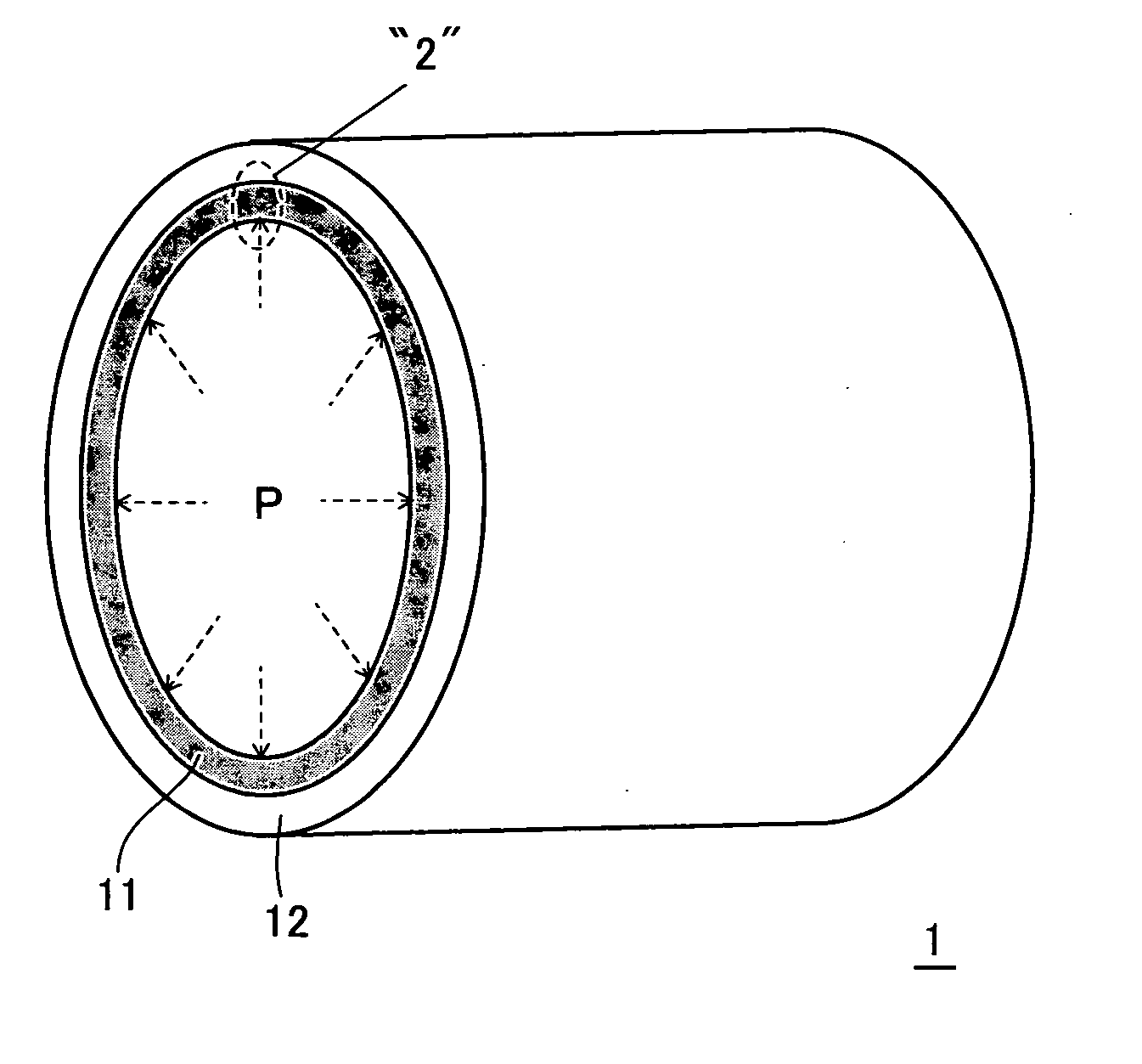

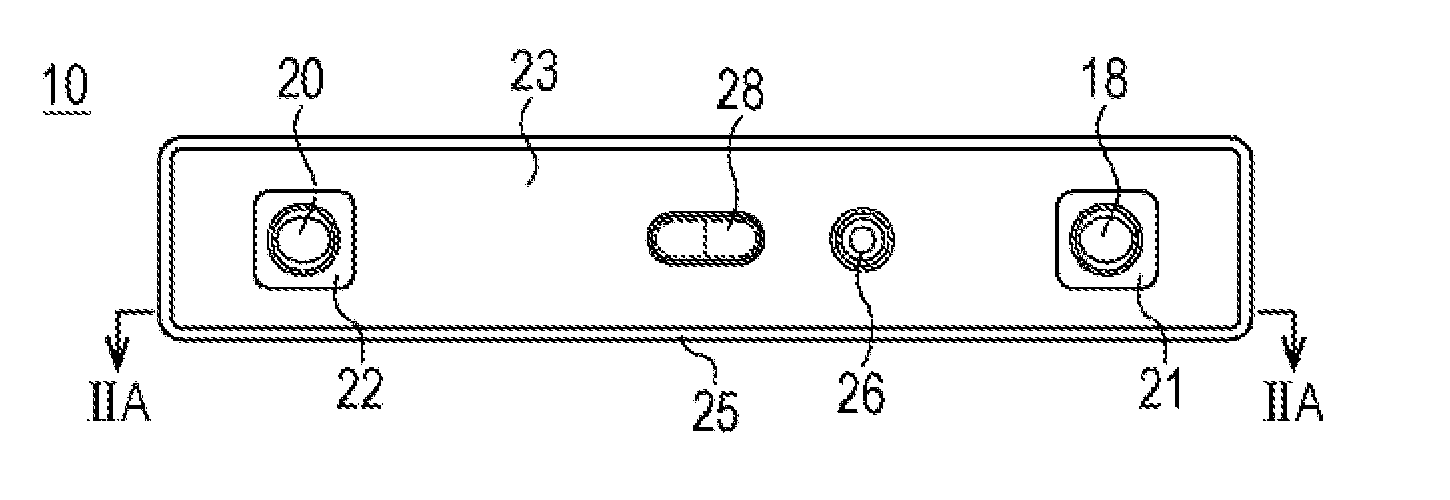

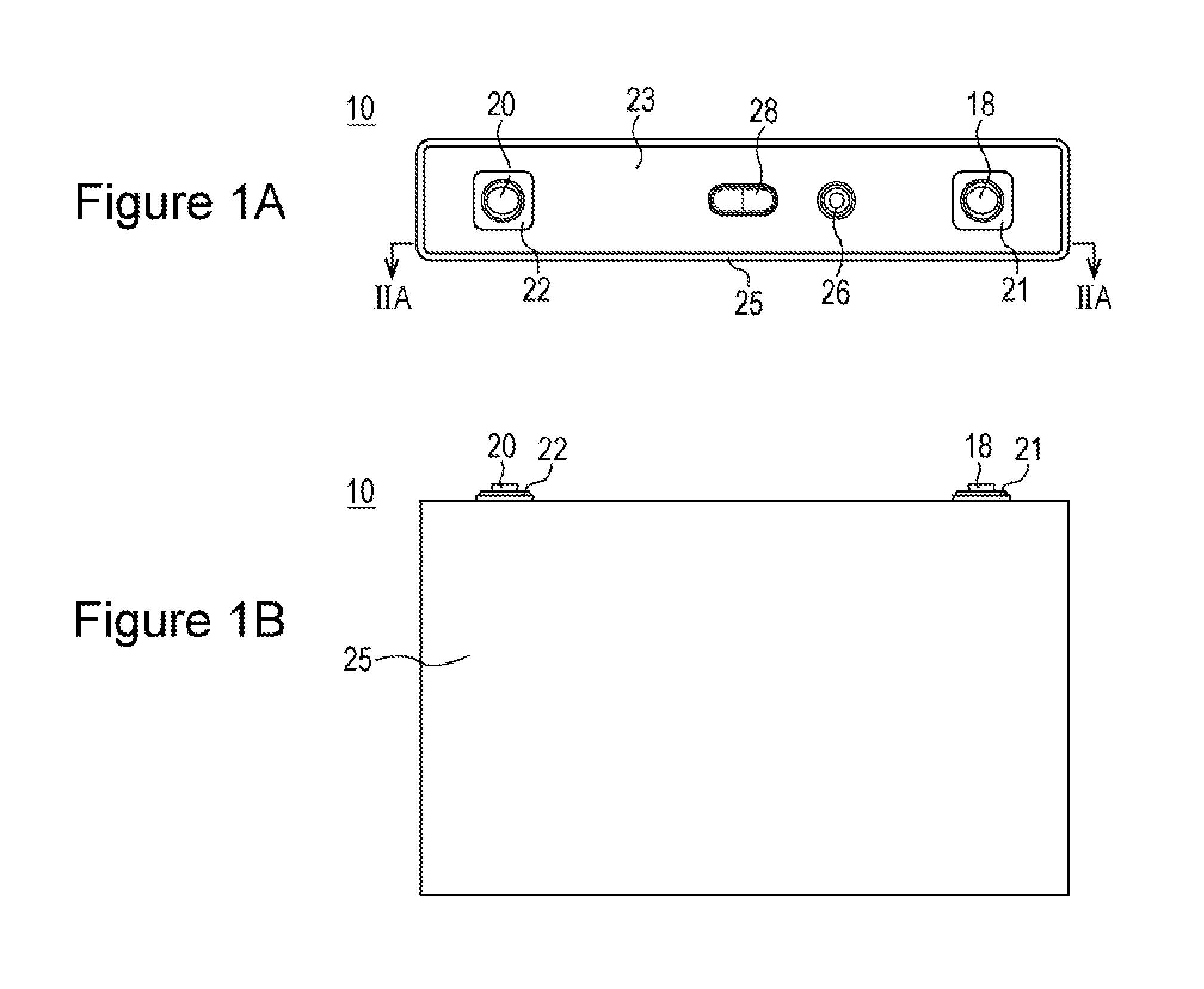

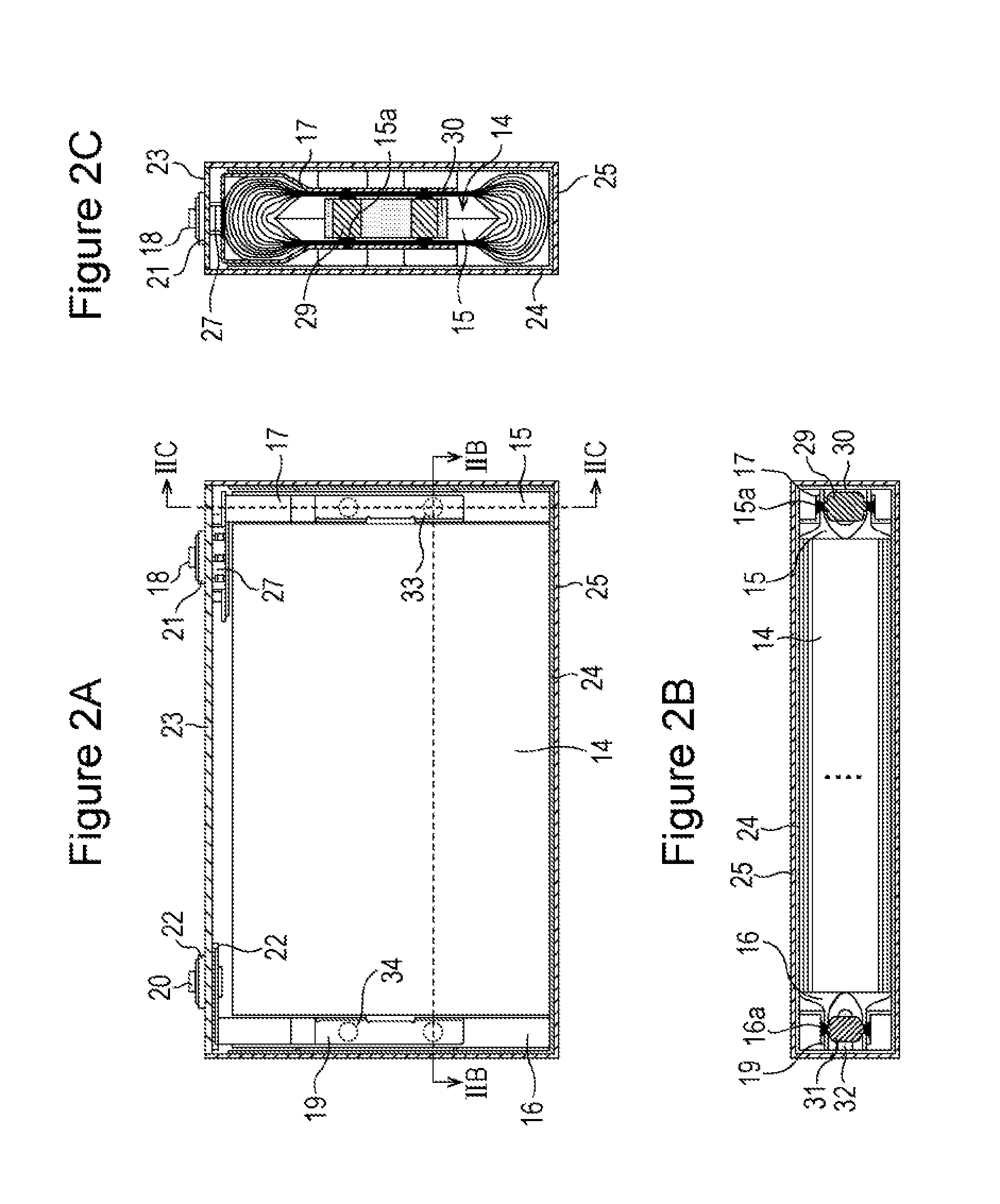

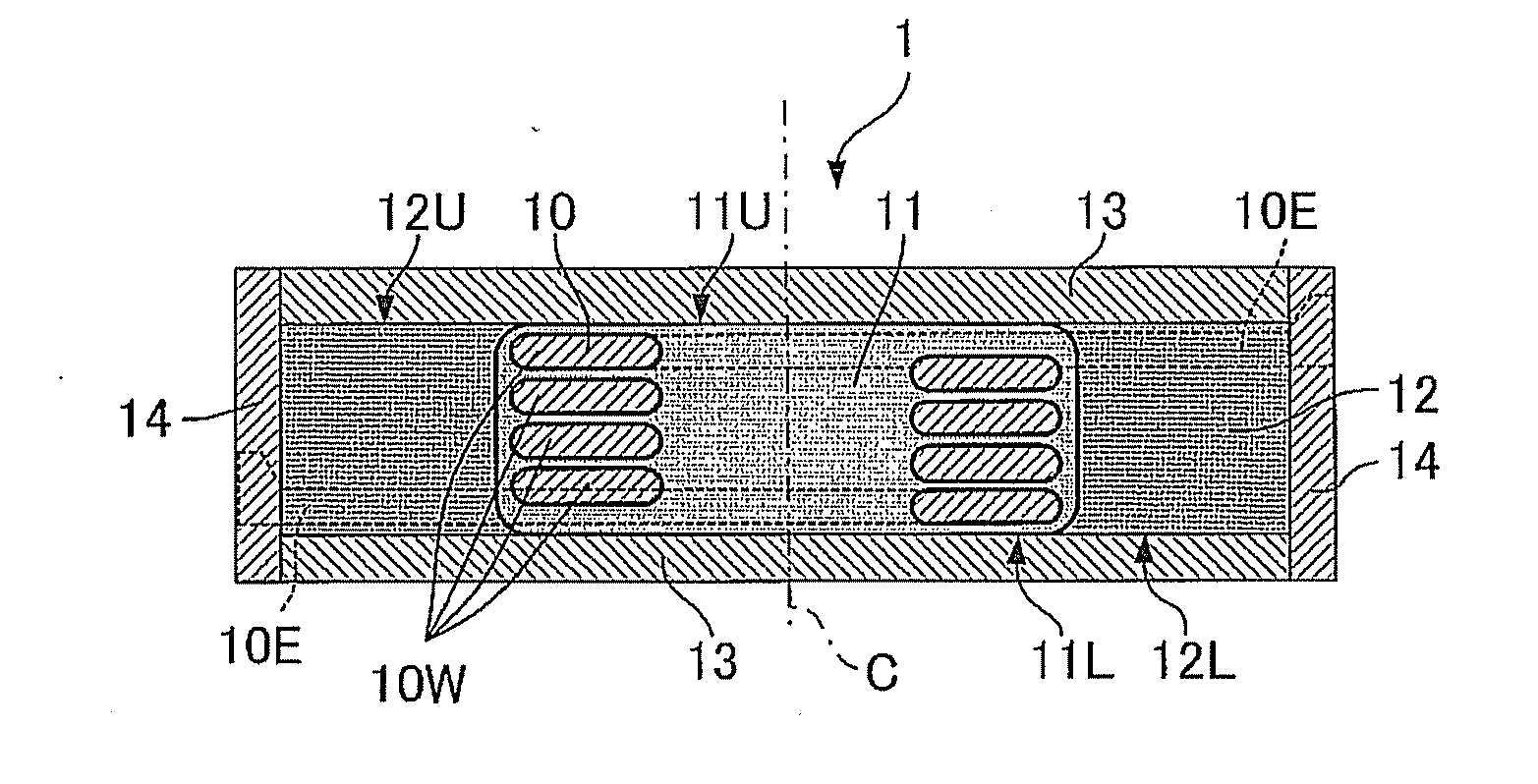

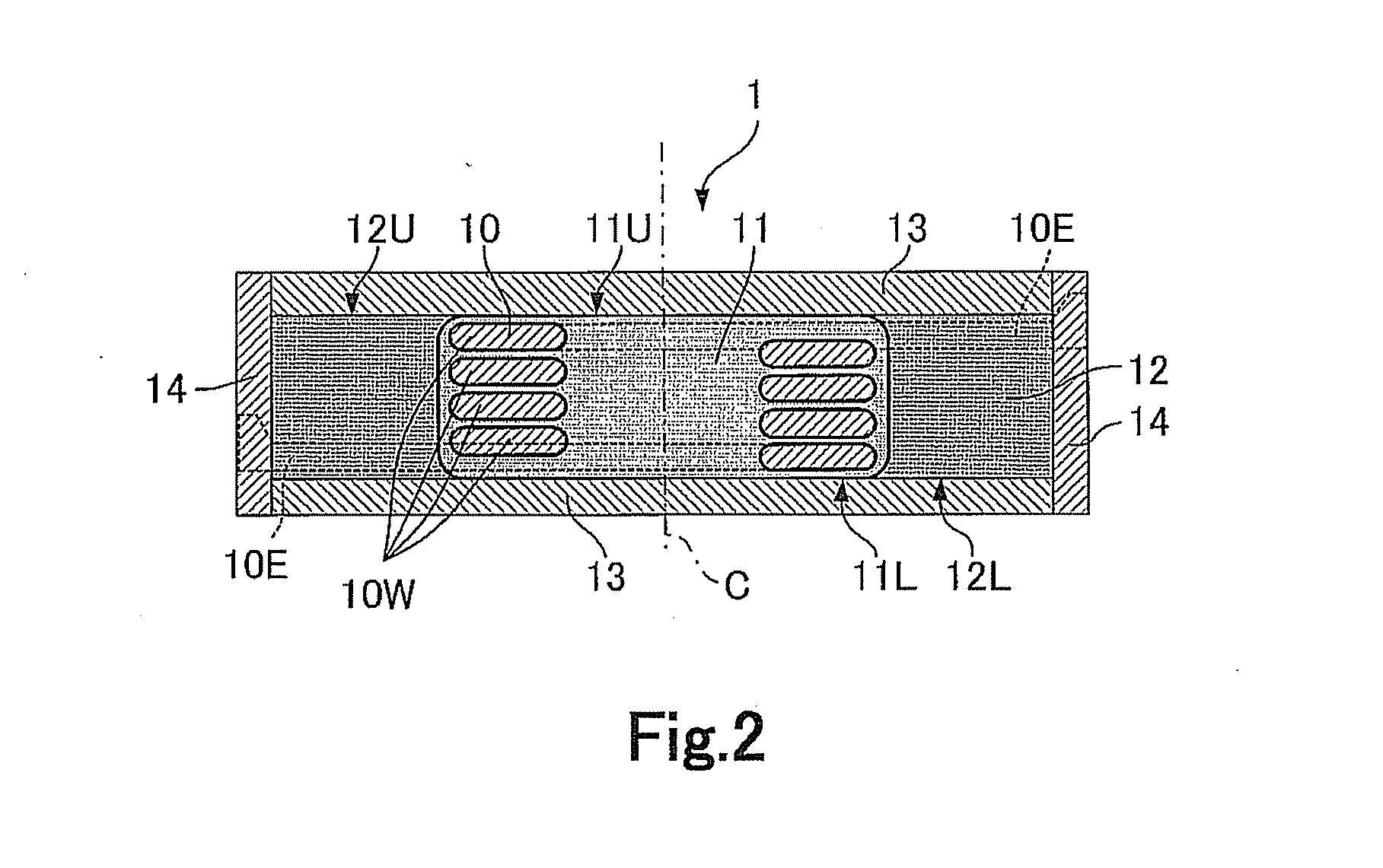

Coil-buried type inductor and a method for manufacturing the same

InactiveUS20110121930A1Simple manufacturing processLarge porosityTransformers/inductances casingsCoils manufacturePorosityInductor

The invention relates to a coil-buried type inductor. The inductor comprises a conductive coil, a first fired ceramics body arranged at least in an area along an inner periphery of the coil, and a second fired ceramics body arranged so as to surround the entire of the coil along with the first fired ceramics body. The first fired ceramics body has porosity equal to or larger than 40 percent and smaller than 70 percent.

Owner:NGK INSULATORS LTD

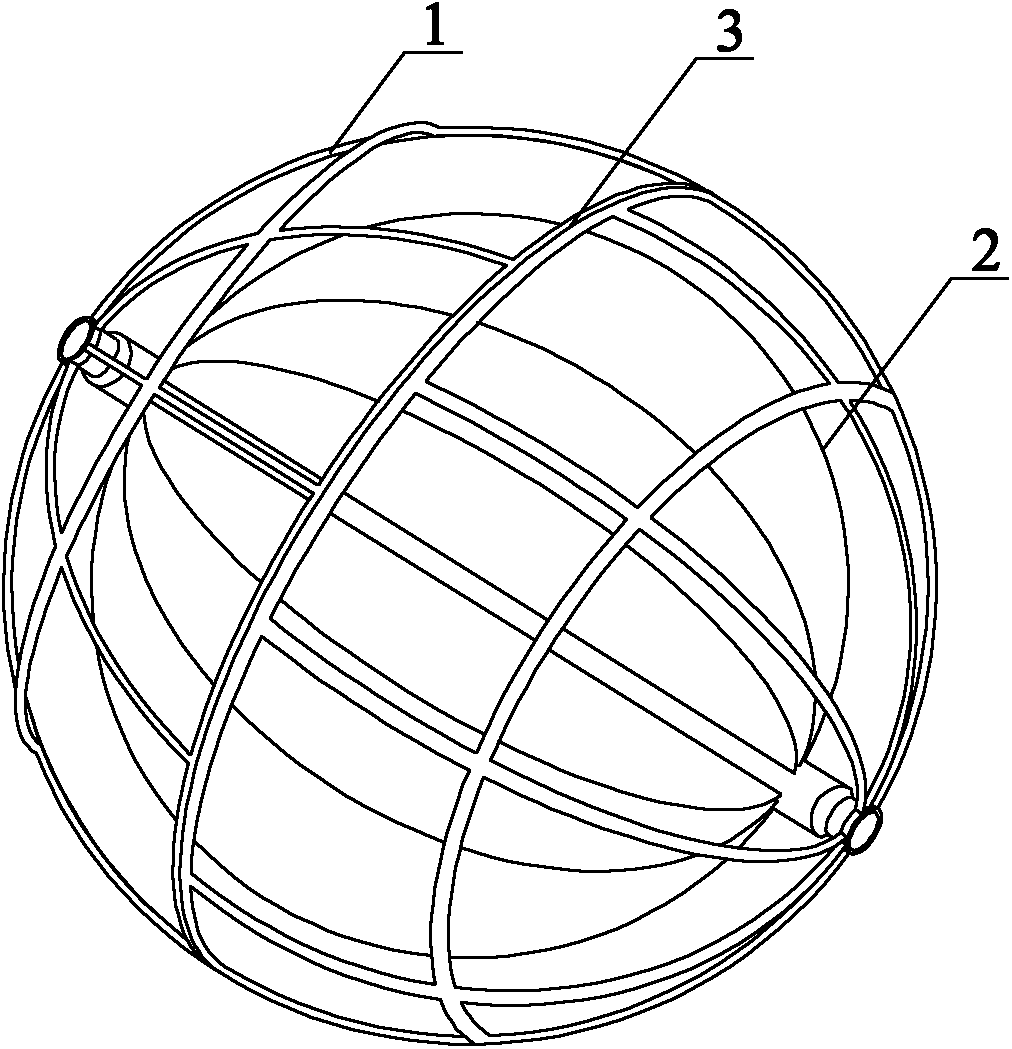

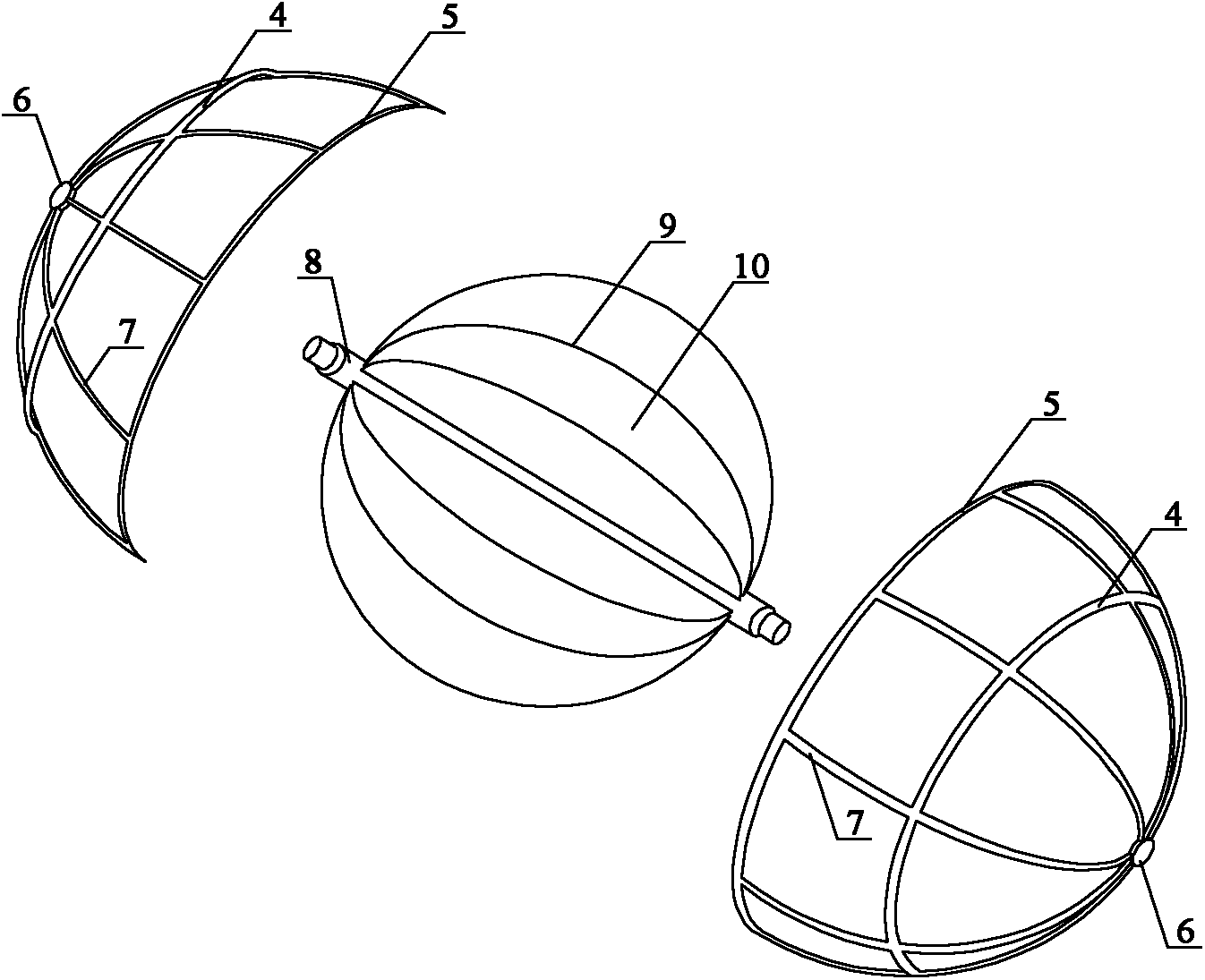

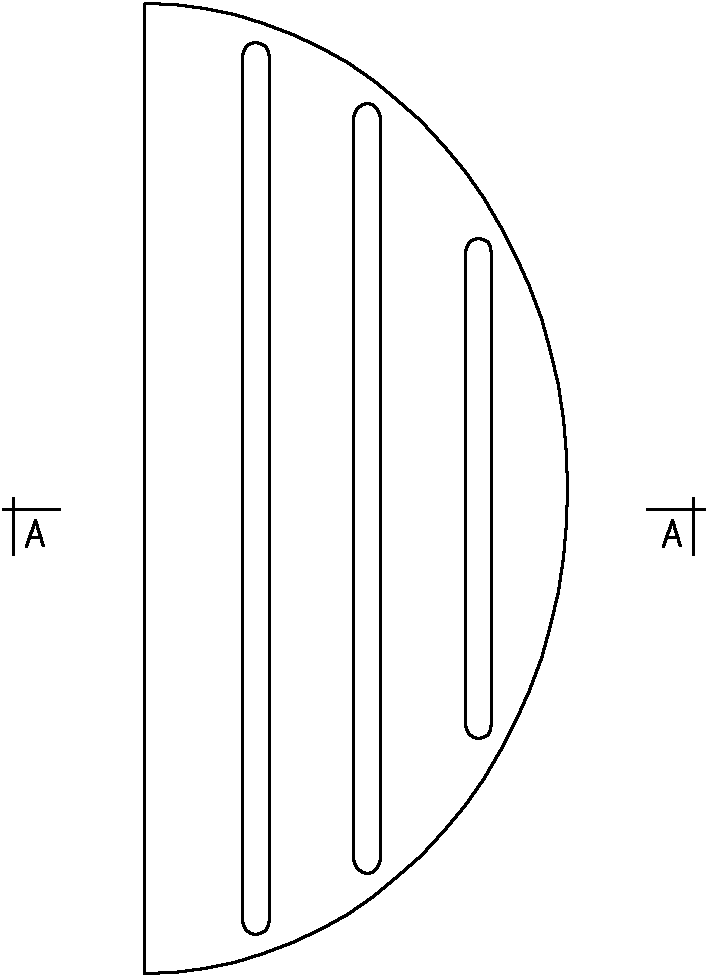

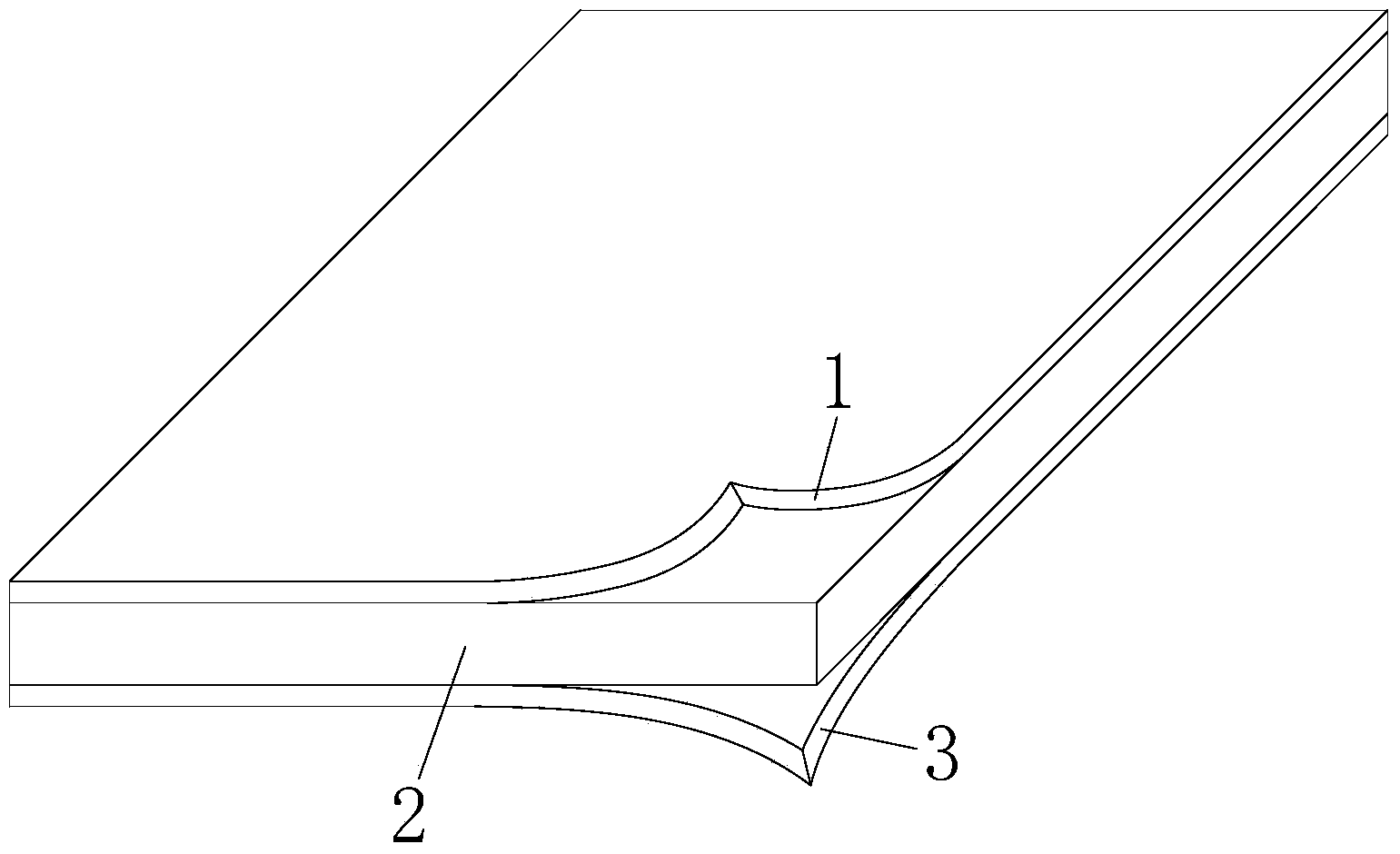

Biological filler with self-rotating function for waste gas treatment

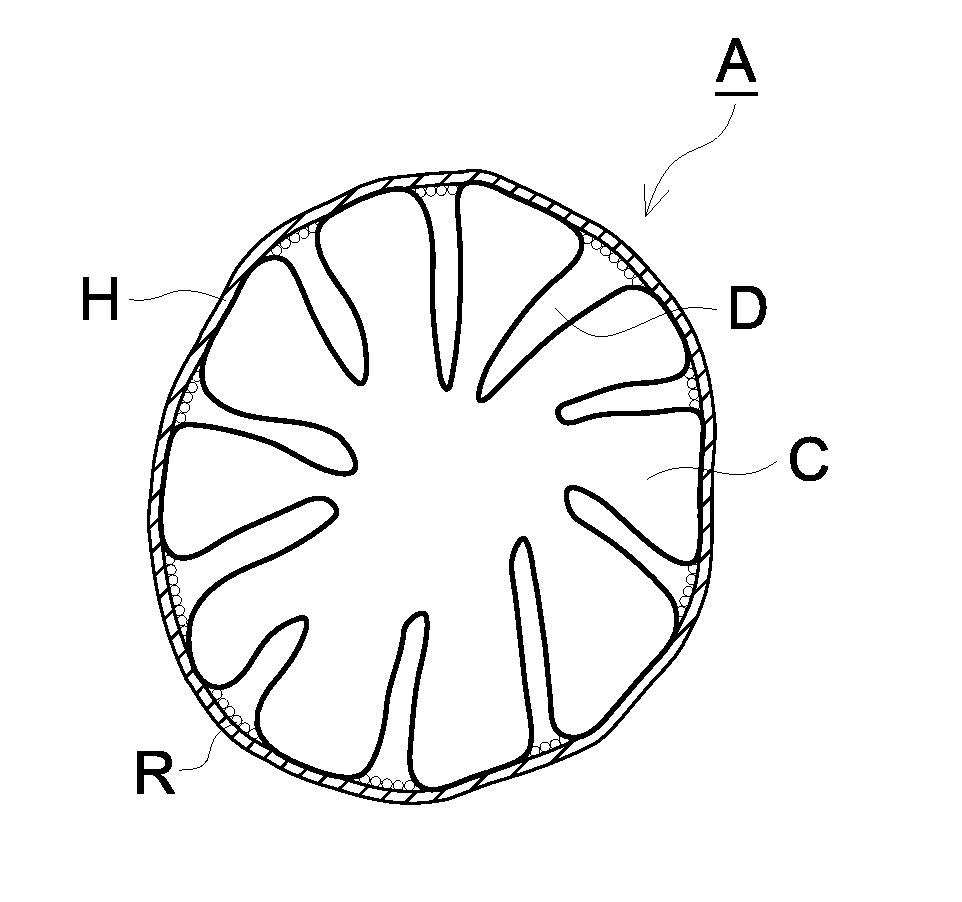

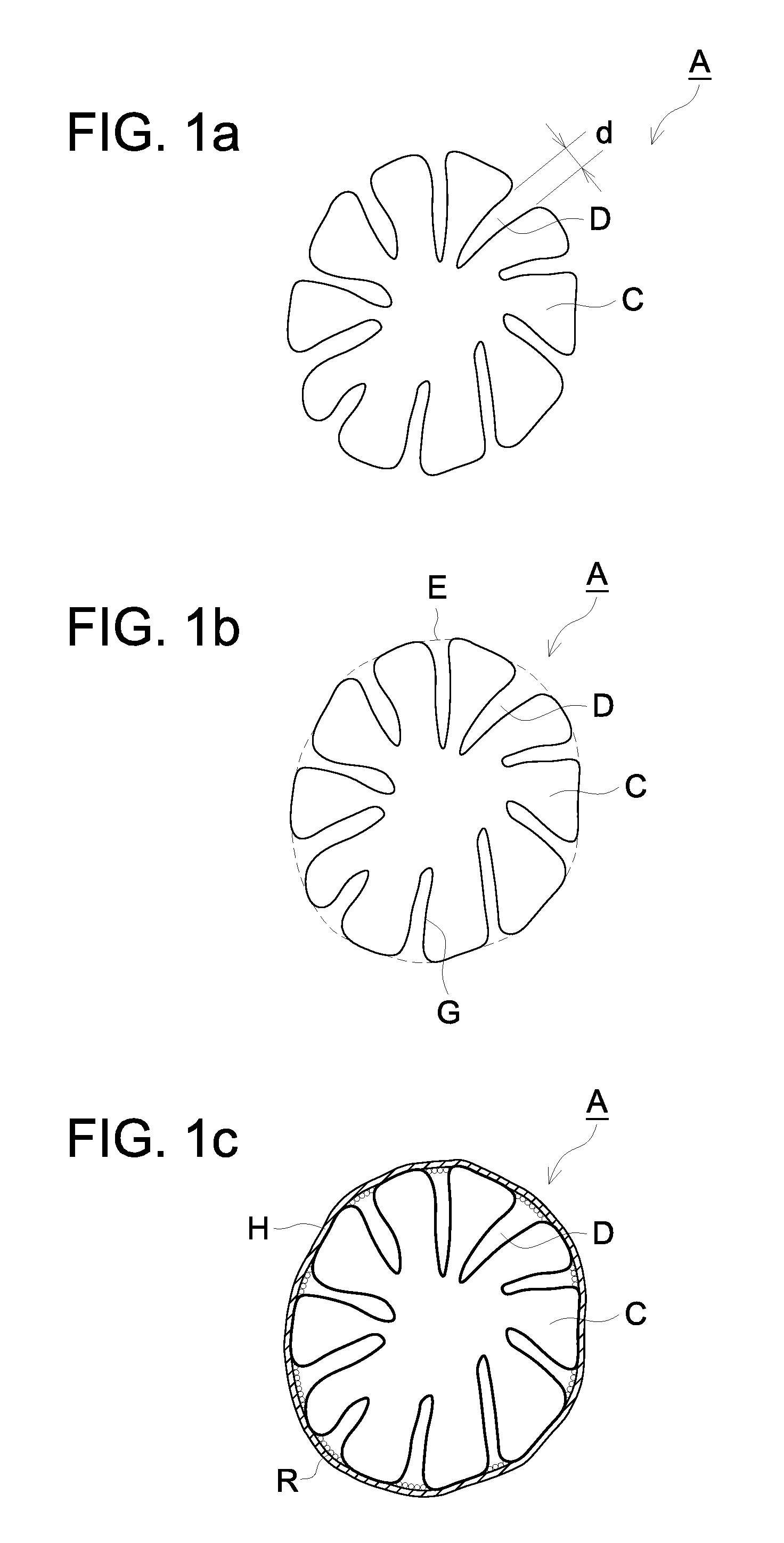

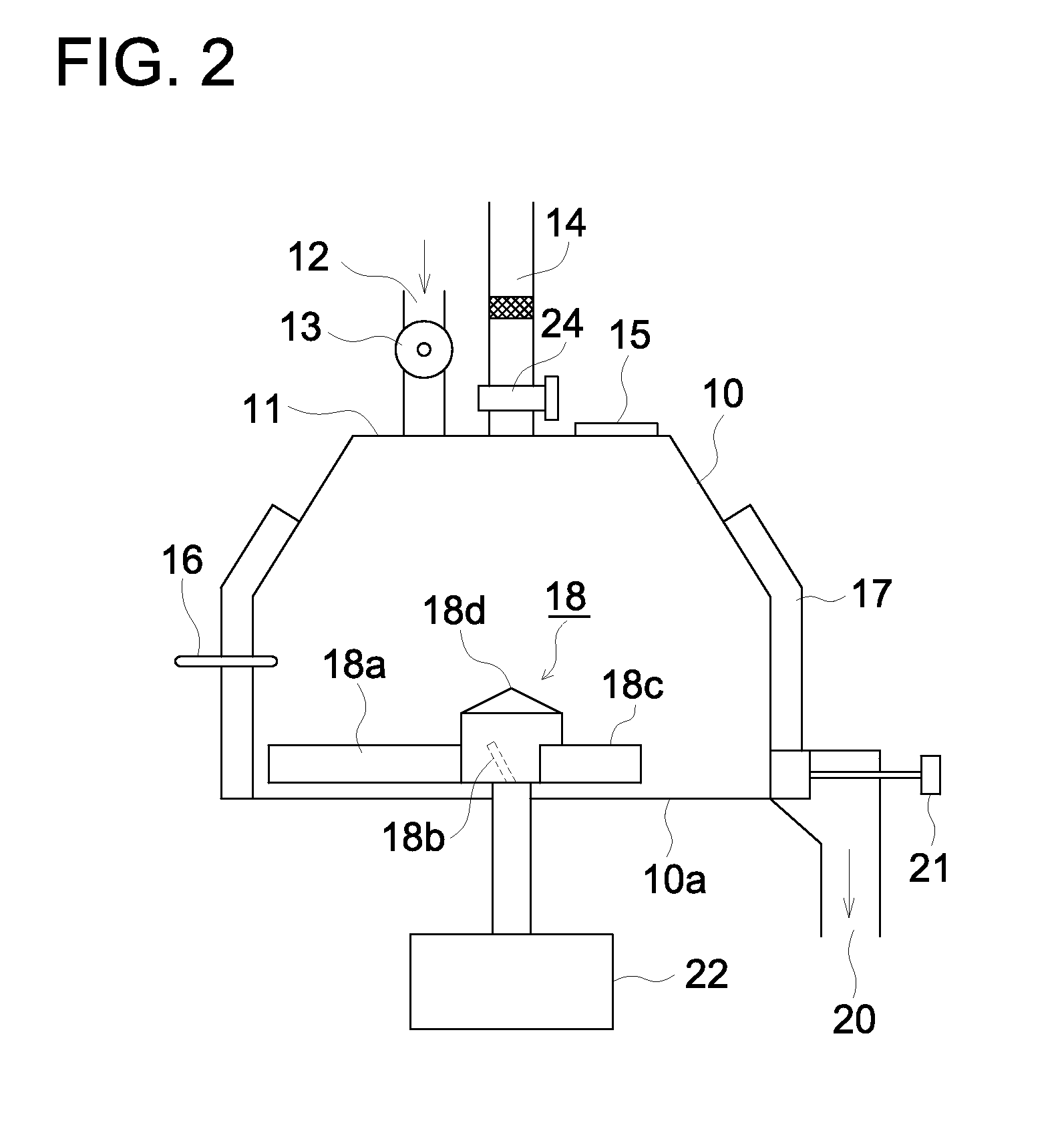

InactiveCN102430334AUniform growthEvenly distributedDispersed particle separationAir quality improvementVoid ratioBiological filter

The invention relates to the field of filler and aims at providing biological filler with a self-rotating function for waste gas treatment. The biological filter comprises a spherical support frame and a hollow multi-surface sphere, wherein the spherical support frame is formed by the abutting joint of two semispherical surfaces, each semispherical surface is formed by a plurality of longitudinal bars and transverse bars which are staggered; the hollow multi-surface sphere comprises a rotating shaft and a plurality of semi-circular blades which are fixed on the rotating shaft through straight sides; the two ends of the rotating shaft are arranged in a rotating shaft sleeve of the spherical support frame; and the hollow multi-surface sphere can freely rotate in the spherical support frame. The biological filler has the advantages of being beneficial to the uniform growing and distribution of microorganisms on the surface of the filler, further being beneficial to the increasing of microorganism charge capacity of the filler in unit volume, the purification efficiency of waste gas and load, being capable of promoting aged biological membranes to timely fall off and be taken away from gaps of the filter along with circulating water so as to avoid short-circuiting and blocking of a filler layer and having large enough specific surface area and void ratio, thereby ensuring the surface and space required for the growth of the microorganisms.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of water-soluble ceramic core

InactiveCN105777114AImprove high temperature strengthLarge porosityCeramicwareEthyl esterPolyethylene glycol

The invention discloses a preparation method of a water-soluble ceramic core.The water-soluble ceramic core is prepared from, by mass, 20-60% of sodium chloride powder, 40-80% of zircon powder, ethyl silicate, 15-20% of plasticizer, 30% of baking soda and 10% of talcum powder, wherein the total weight parts of the sodium chloride powder and the zircon powder sum up to 100%, ethyl silicate accounts for 0.5-1% of the total weight parts of the sodium chloride powder and the zircon powder, and the plasticizer is polyethylene glycol with the concentration being 50%.The preparation method of the water-soluble ceramic core comprises the steps of powder preparation and mixing, slurry preparation, compression formation, dewaxing and sintering.The core prepared through the preparation method is high in wet strength, good in compression flowability, small in shrinking percentage, high in surface polishness, the core complex in shape can be made, and the core formed through sintering is high in high temperature strength, large in porosity and quick in depoling.

Owner:JIANGSU JINHUI PRECISION CASTING CERAMIC CO LTD

High dust holding filter material for filter bag

ActiveCN103638747AImprove breathabilityEasy to processDispersed particle filtrationSynthetic resin layered productsPorosityCarding

The invention discloses a high dust holding filter material for a filter bag. The high dust holding filter material is in a three-layer overlap structure formed by clamping a middle dust holding layer clamped by an upper protective layer and a lower protective layer, wherein the three layers are compounded into a whole by adopting a punching or ultrasonic welding process; the total gram weight of the high dust holding filter material is 50-200g / m<2>; the upper protective layer and the lower protective layer are made of polypropylene spunbond nonwoven fabrics with the gram weight of 10-30g / m<2>. The invention aims to give a certain strength to the high dust holding filter material, the dust holding layer is clamped, and the effects of fixing fibers and preventing the fibers from dropping are achieved. Moreover, the dust holding layer is a key layer of the high dust holding filter material, has the gram weight of 30-140 g / m<2> and is made of a polypropylene short fiber raw material, and a high-bulk high-porosity three-dimensional stereoscopic structure is manufactured by utilizing the mechanical carding and mechanical wet forming technology. The high dust holding filter material has the characteristics of high dust holding capacity, high processing performance and the like.

Owner:桐乡市朗裕净化科技股份有限公司

Production method of two-component developer

ActiveUS20120028186A1Increased added amount of resinReduce yieldDevelopersDry mixingMethods of production

Disclosed is a production method of a two-component developer for developing an electrostatic image comprising a toner and a resin coated carrier having a porous magnetic core particle and a resin coated layer, wherein the porous magnetic core particle are composed of a porous ferrite material and have pit apertures on a surface of the particle, and the method comprises steps of blocking the pit apertures of the porous magnetic core particle with rubber particles by dry mixing of the porous magnetic core particle and the rubber particles, forming the resin coated carrier by forming a resin layer on the porous magnetic core particle whose pore openings have been blocked, and mixing the resin coated carrier and the toner.

Owner:KONICA MINOLTA BUSINESS TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com