Method of improving performance of iron-based powder metallurgy parts prepared by high velocity compaction

A technology of iron-based powder metallurgy and high-speed pressing, applied in the field of powder metallurgy, can solve the problems of insufficient mechanical properties and unattainable mechanical properties, and achieve the effects of remarkable strengthening effect, high production efficiency and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

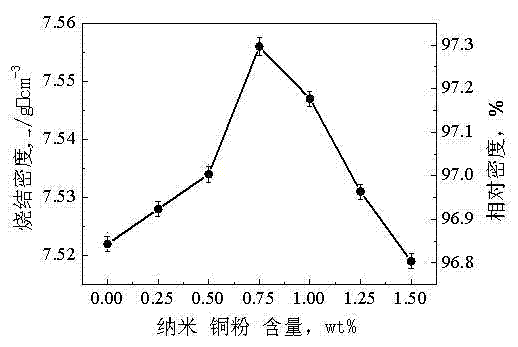

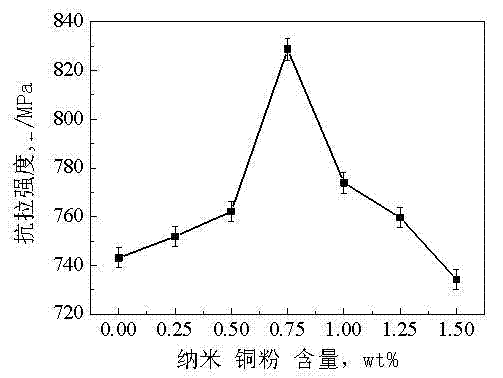

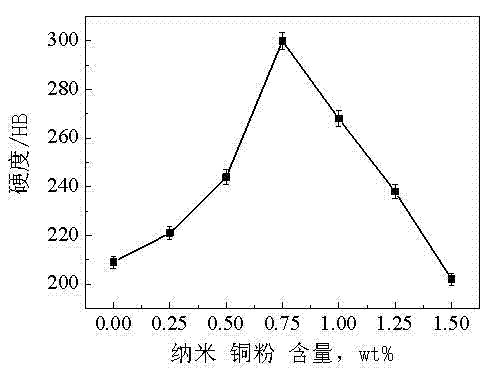

[0018] Embodiment 1: Nano copper powder replaces the common copper powder of 0.25wt%

[0019] Using water atomized iron powder and 1.25wt% ordinary copper powder, 0.25wt% nano-copper powder, 2wt% carbonyl nickel powder, 0.83wt% molybdenum iron powder, and 0.8wt% graphite powder, a total of 1Kg is filled with high-purity argon Prepared in a gas-filled glove box, put it into a mixing barrel and sealed it, and kneaded on a heart-type drum machine to obtain a uniform iron-based mixed powder. Then the iron-based green part is prepared by three-time pressing method of high-speed pressing technology. Finally, the prepared iron-based green parts were sintered at 1150-1280°C for 1-2 hours under a hydrogen protective atmosphere. The obtained iron-based parts had a density of 7.528 / g cm-3, a tensile strength of 751.9 MPa, and a hardness of 97.9 HRB, equivalent to 221HB.

Embodiment 2

[0020] Embodiment 2: Nano copper powder replaces 0.5wt% common copper powder

[0021] Using water atomized iron powder and 1wt% common copper powder, 0.5wt% nano-copper powder, 2wt% carbonyl nickel powder, 0.83wt% molybdenum iron powder, and 0.8wt% graphite powder, a total of 1Kg is filled with high-purity argon Prepare it in a glove box, put it into a mixing barrel and seal it, and knead it on a heart-type drum machine to obtain a uniform iron-based mixed powder. Then the iron-based green part is prepared by three-time pressing method of high-speed pressing technology. Finally, the prepared iron-based green parts were sintered at 1150-1280°C for 1-2 hours under a hydrogen protective atmosphere. The obtained iron-based parts had a density of 7.534 / g cm-3, a tensile strength of 762.1 MPa, and a hardness of 24.6 HRC, equivalent to 244HB.

Embodiment 3

[0022] Embodiment 3: Nano copper powder replaces the common copper powder of 0.75wt%

[0023] Using water atomized iron powder and 0.75wt% ordinary copper powder, 0.75wt% nano-copper powder, 2wt% carbonyl nickel powder, 0.83wt% molybdenum iron powder, and 0.8wt% graphite powder, a total of 1Kg is filled with high-purity argon Prepared in a gas-filled glove box, put it into a mixing barrel and sealed it, and kneaded on a heart-type drum machine to obtain a uniform iron-based mixed powder. Then the iron-based green part is prepared by three-time pressing method of high-speed pressing technology. Finally, the prepared iron-based green parts were sintered at 1150-1280°C for 1-2 hours under a hydrogen protective atmosphere. The obtained iron-based parts had a density of 7.556 / g cm-3, a tensile strength of 828.7 MPa, and a hardness of 32.3 HRC, equivalent to 300HB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com