Biological filler with self-rotating function for waste gas treatment

A technology for waste gas treatment and biological fillers, which is applied in the directions of air quality improvement, dispersed particle separation, chemical instruments and methods, etc. It can solve the problems of short circuit or blockage, and the filler cannot be fully wetted, so as to avoid short circuit or blockage, large porosity, The effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

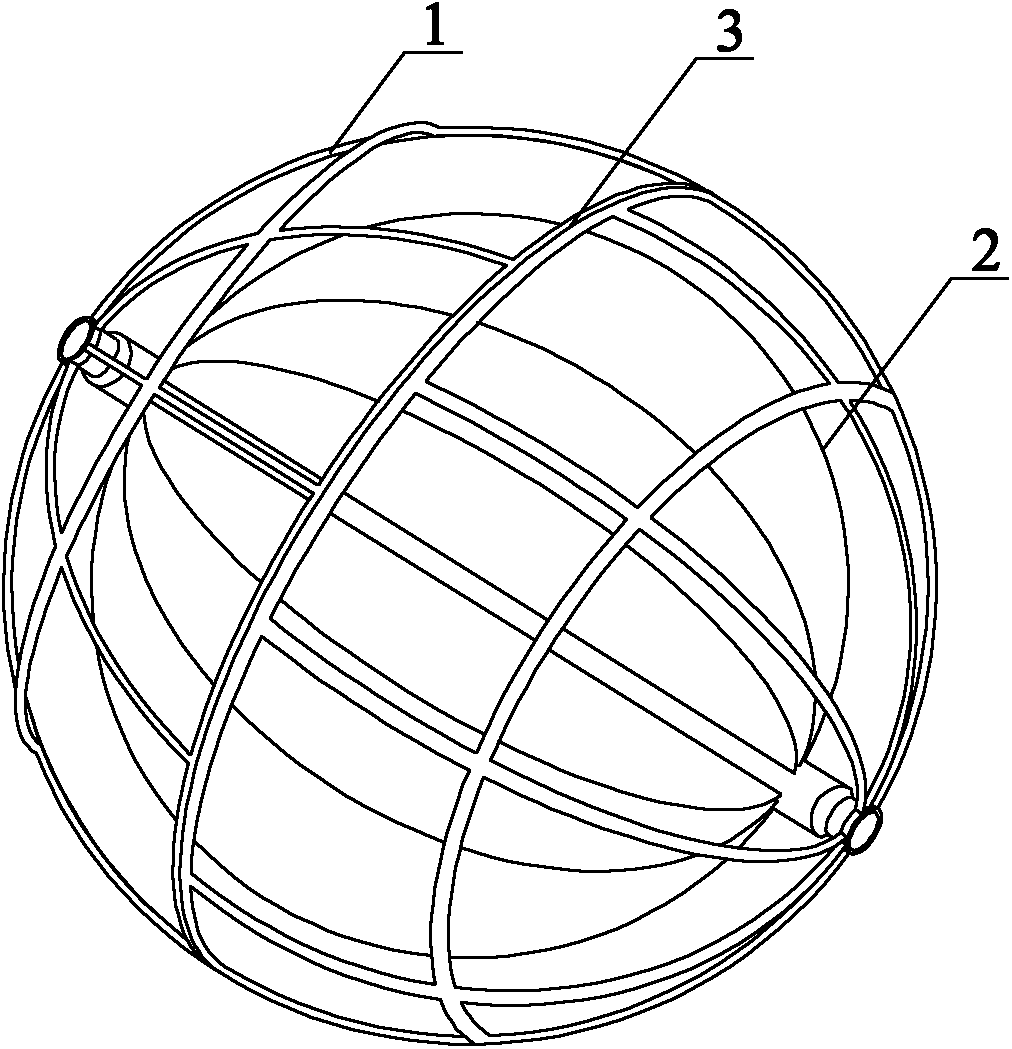

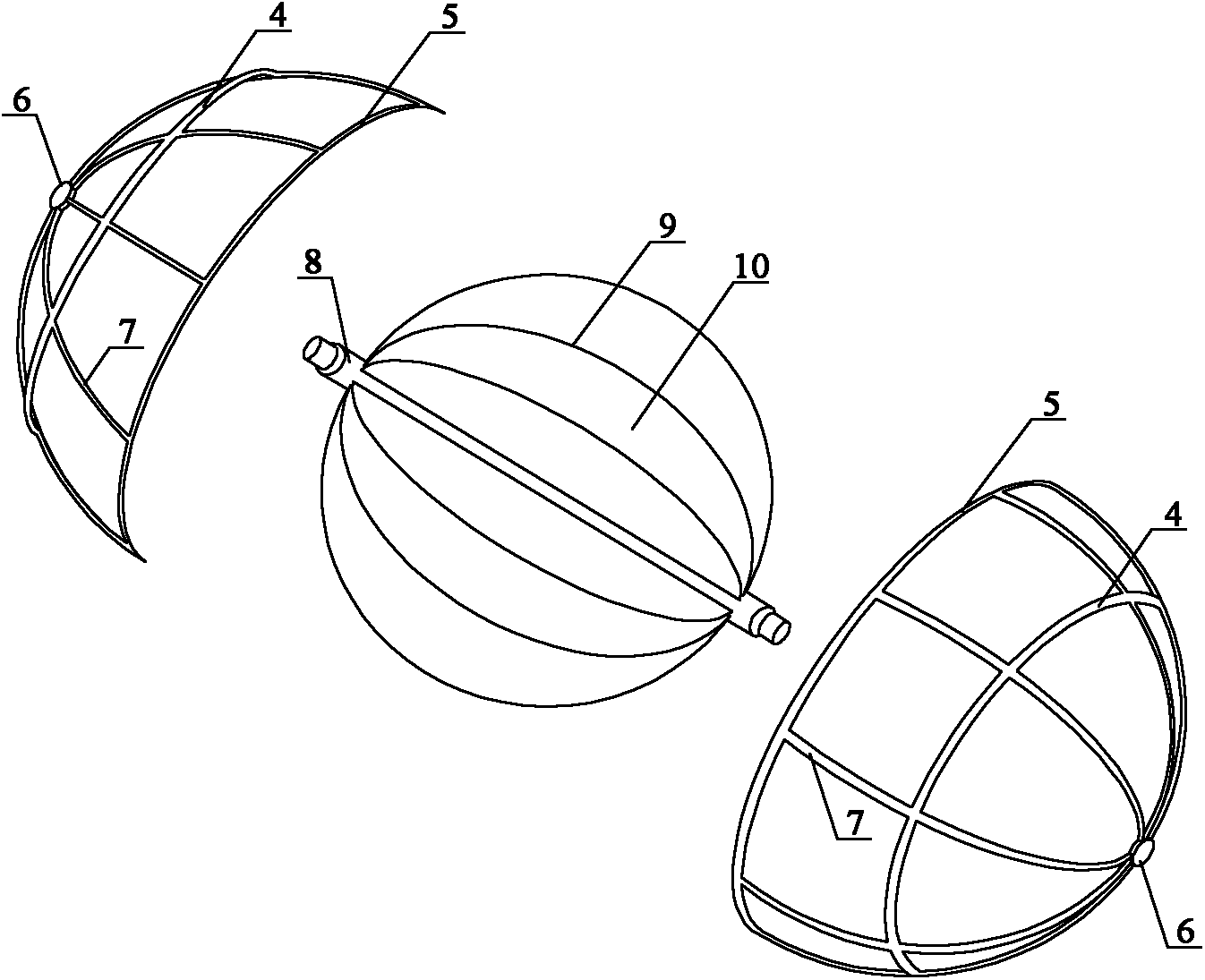

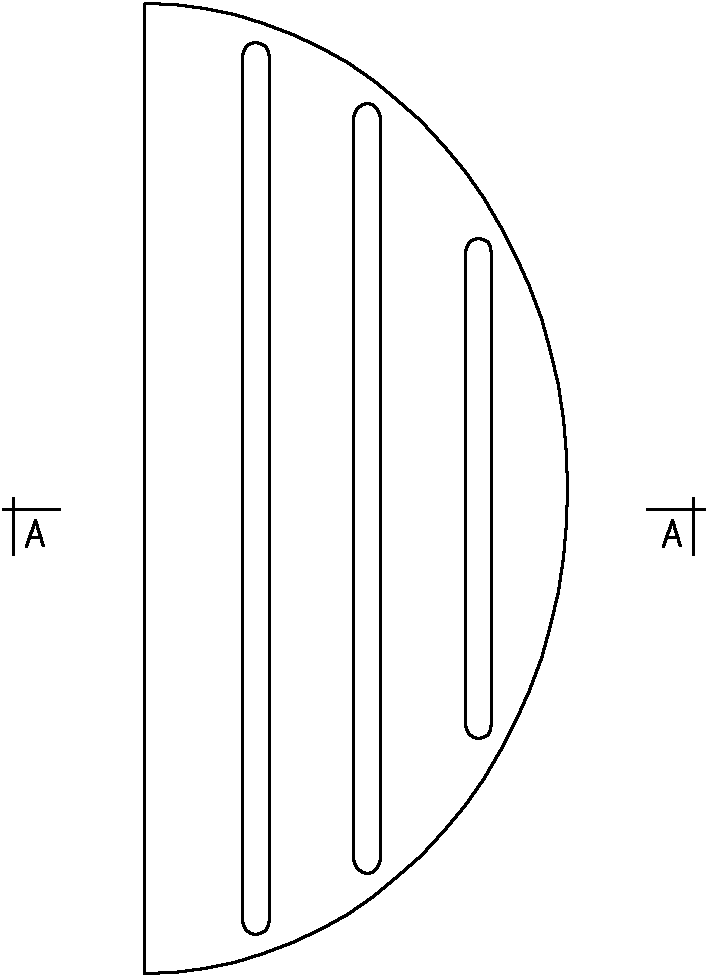

[0033] The waste gas treatment biological filler with spin function in the present invention is composed of a spherical support frame 1 and a hollow polyhedral sphere 2 , and the hollow polyhedral sphere 2 can freely rotate in the spherical support frame 1 . The spherical support frame 1 is formed by joining two identical several interlaced ribs to form a hemispherical surface, and the butt joint forms a spherical equatorial rib 3 . The connection of the two hemispherical surfaces can be bonded, welded or pierced, and the meridian bars on the two hemispherical surfaces are arranged alternately after the butt joint. A number of meridian ribs 7 are evenly distributed on the hemispherical surface, one end of the meridian ribs 7 is connected to the equator rib 3, and the apex of the other end meets the weft rib at the apex of the sphere. The sphere apex parallel rib constitute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com