Composite filtering material for activating and regenerating coal ash and production method thereof

A composite filter material and manufacturing method technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of fly ash environmental pollution and high cost of filter materials, and achieve low raw material costs, wide sources, and reduced operation cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

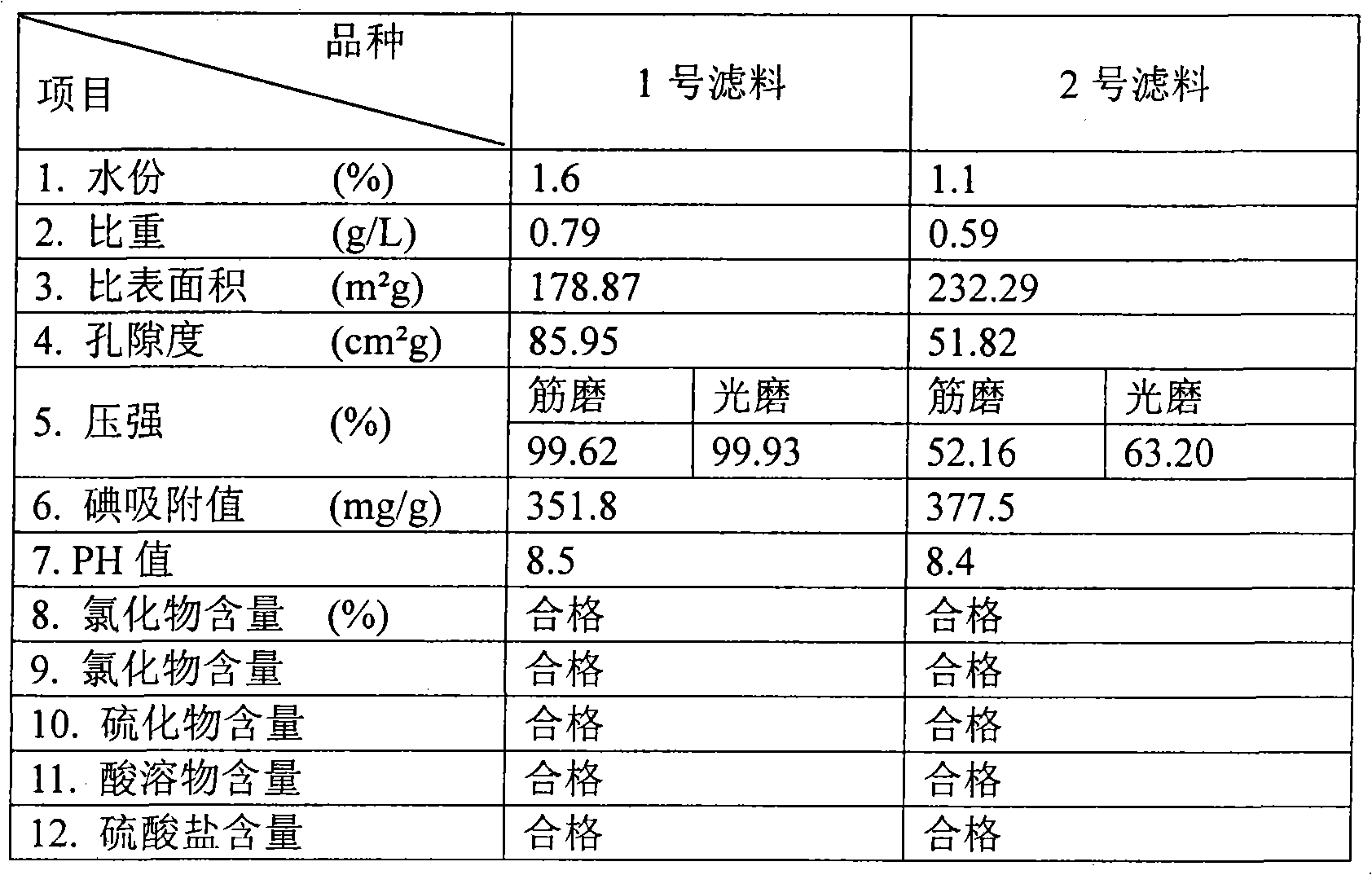

Image

Examples

Embodiment 1

[0047] A fly ash activated regeneration composite filter material is manufactured by the following method.

[0048] First, remove the fly ash or furnace ash from the sedimentation tank, drain and dry, and take the weight 800kg. The fly ash or furnace ash is preferentially used for flue recovery type and settled in the sedimentation tank. The particle size should be ≥ 80 mesh, the smaller the particle size during actual manufacturing, the better;

[0049] Secondly, add a binder to the above-mentioned drained and cool-dried fly ash or furnace ash, mix and stir evenly. The binder can be soaked alkali flower (ie water glass) with a concentration of about 5%. The granulation requirements are appropriate;

[0050] Third, put the processed small core into the granulator. The small core can be either the small core commonly used in the granulator or the small core prefabricated with 70% kaolin, 30% attapulgite and binder. Its function is to serve as the basis of granulation. The final fly ...

Embodiment 2

[0056] A fly ash activated regeneration composite filter material is manufactured by the following method.

[0057] First, remove the fly ash or furnace ash from the sedimentation tank, drain and dry, and take the weight 900kg. The fly ash or furnace ash is preferentially used for flue recovery and settled in the sedimentation tank. The particle size should be ≥ 80 mesh, the smaller the particle size during actual manufacturing, the better;

[0058] Secondly, add a binder to the above-mentioned drained and cool-dried fly ash or furnace ash, mix and stir evenly. The binder can be soaked alkali flower (ie water glass) with a concentration of about 5%. The granulation requirements are appropriate;

[0059] Third, put the processed small nuclei into the granulator;

[0060] Fourth, send the above-mentioned fly ash or furnace ash with the binder added and uniformly stirred into a granulator for granulation to obtain fly ash particles;

[0061] Fifth, continue to add 100kg of porous alu...

Embodiment 3

[0065] A fly ash activated regeneration composite filter material is manufactured by the following method.

[0066] First, remove the fly ash or furnace ash from the sedimentation tank, drain and dry, and take the weight of 850kg. The fly ash or furnace ash is preferentially used for flue recovery type and settled in the sedimentation tank. The particle size should be ≥ 80 mesh, the smaller the particle size during actual manufacturing, the better;

[0067] Secondly, add a binder to the above-mentioned drained and cool-dried fly ash or furnace ash, mix and stir evenly. The binder can be soaked alkali flower (ie water glass) with a concentration of about 5%. The granulation requirements are appropriate;

[0068] Third, put the processed small nuclei into the granulator;

[0069] Fourth, send the above-mentioned fly ash or furnace ash with the binder added and uniformly stirred into a granulator for granulation to obtain fly ash particles;

[0070] Fifth, continue to add 150kg of po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com