Bird-nest catalyst carrier

A technology of catalyst carrier and bird's nest, which is applied in the field of catalyst carrier, can solve problems that cannot meet the development of new technologies and processes, and achieve the effect of increasing the total amount of effective contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

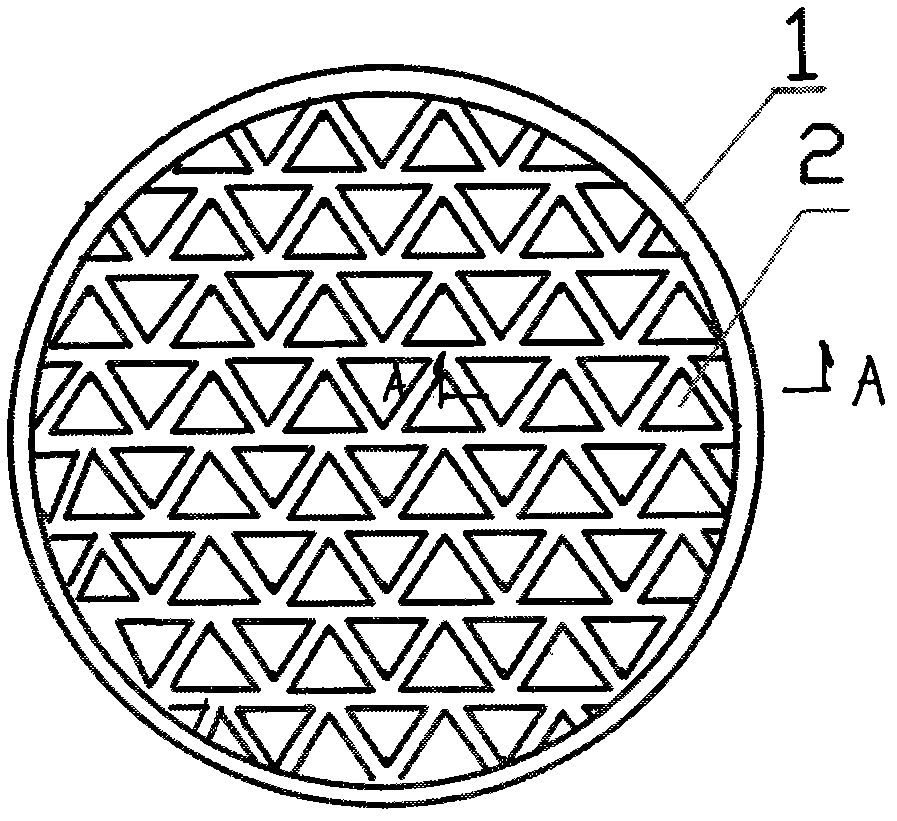

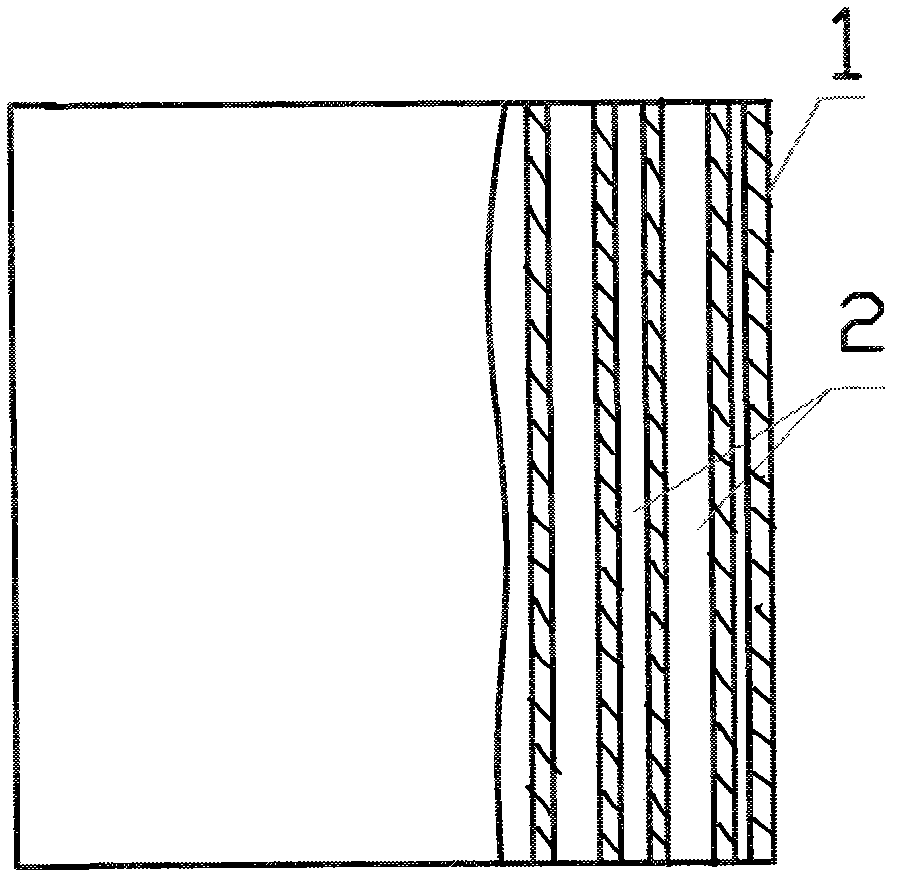

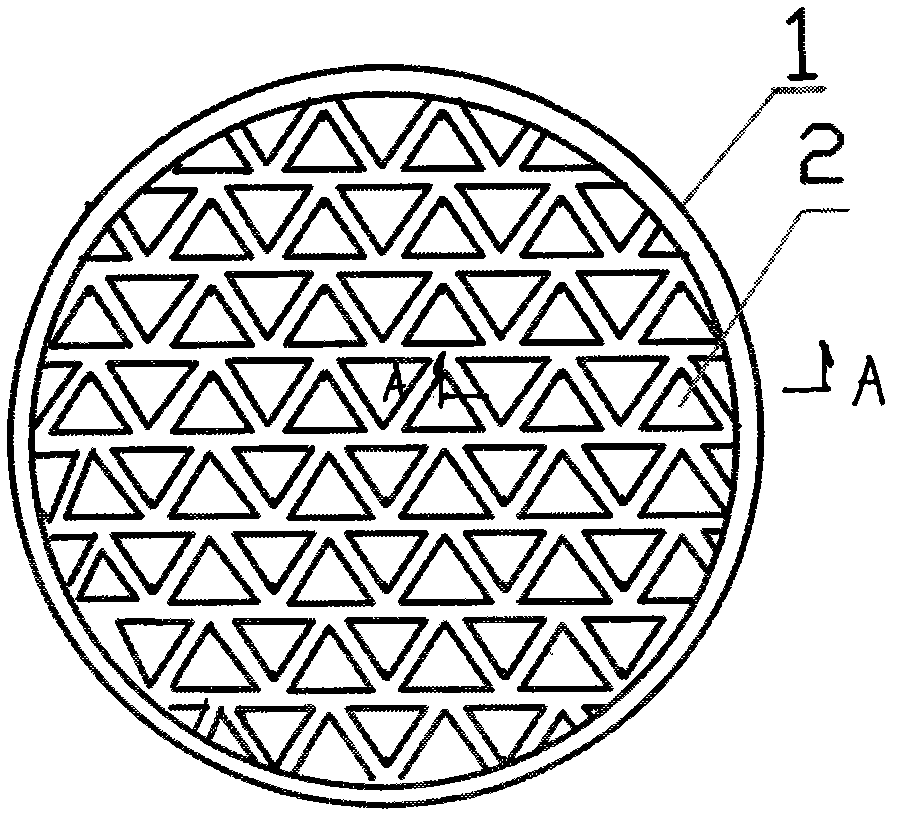

[0014] Example 1, in figure 1 and figure 2 Among them, the bird's nest catalyst carrier is φ30±3, which includes a body 1, and the inner cavity of the body is formed with honeycomb holes 2 that are uniform in size, parallel up and down, and staggered left and right. The cross section of the honeycomb holes is triangular. Specific surface area of the bird's nest catalyst carrier: 380m2 / g, pore volume: 0.55ml / g, porosity: 65%, honeycomb hole diameter: 1.6mm, honeycomb hole density: 300 mesh, the bird's nest catalyst carrier adopts the activity of 85%wt The mixture formed by mixing aluminum oxide, 10%wt silicon carbide, and 5%wt titanium dioxide is the main raw material, and then add tung oil in an amount of 5% of the total weight of the main raw materials and feldspar of 2% of the total weight of the main raw materials. After 20 hours Ball milling, kneading, aging for 24 hours, mud refining, molding, drying at 120°C to shape, cutting and firing at a low temperature of 600-90...

Embodiment 2

[0015] Embodiment 2, described bird's nest catalyst carrier adopts the mixture that the active alumina of 65%wt, 10%wt silicon carbide, the titanium dioxide of 5%wt, the natural clay of 20%wt are mixed as main raw material, add above-mentioned main raw material total again 7% tung oil by weight and 3% feldspar by weight of the above-mentioned main raw materials, ball milled for 20 hours, kneaded, aged for 24 hours, smelted, shaped, dried at 120°C for setting, cut and kept at a low temperature of 600-900°C Fired for 6 hours, the specific surface area of the bird's nest catalyst carrier: 250m2 / g, pore volume: 0.45ml / g, porosity: 55%, honeycomb hole diameter: 1.2mm, honeycomb hole density: 600 mesh,

Embodiment 3

[0016] Embodiment 3, described bird's nest catalyst carrier adopts the active alumina of 100%wt as main raw material, adds the tung oil of 3% of above-mentioned main raw material gross weight and the feldspar of above-mentioned main raw material gross weight 1%, through ball milling in 20 hours, It is kneaded, aged for 24 hours, smelted, shaped, dried at 120°C to set the shape, cut and fired at a low temperature of 600-900°C for 6 hours. The specific surface area of the bird's nest catalyst carrier: 160m2 / g, pore volume: 0.42 ml / g, porosity: 70%, honeycomb hole diameter: 0.4mm, honeycomb hole density: 680 mesh,

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com