Variable-flow-path parallel flow heat exchanger

A parallel flow heat exchanger and process technology, applied in evaporators/condensers, lighting and heating equipment, refrigeration components, etc., can solve the problem of reduced air-conditioning energy consumption ratio, large refrigerant flow resistance, low heat exchanger efficiency, etc. problem, to achieve the effect of improving performance and optimizing distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

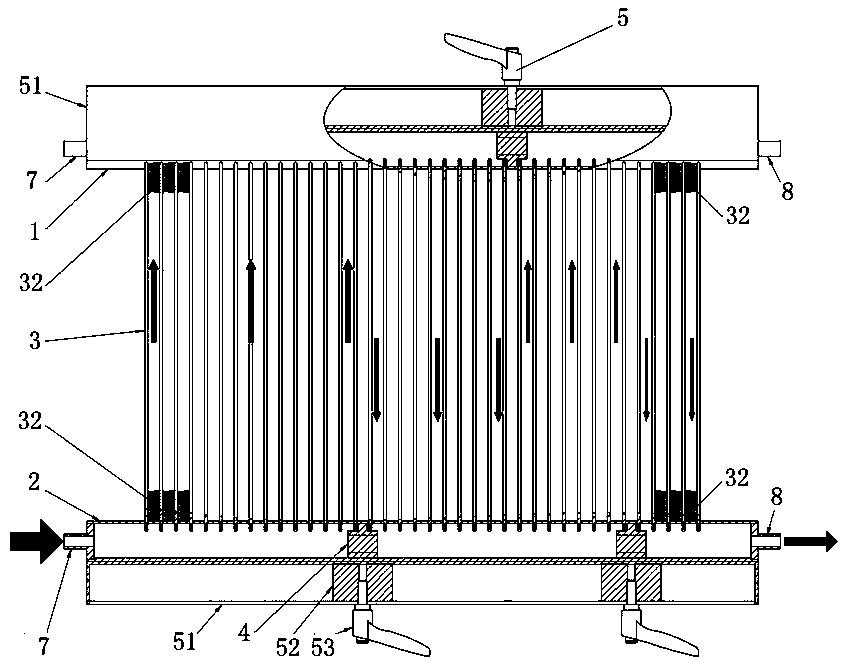

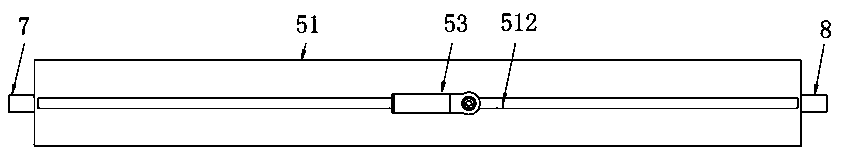

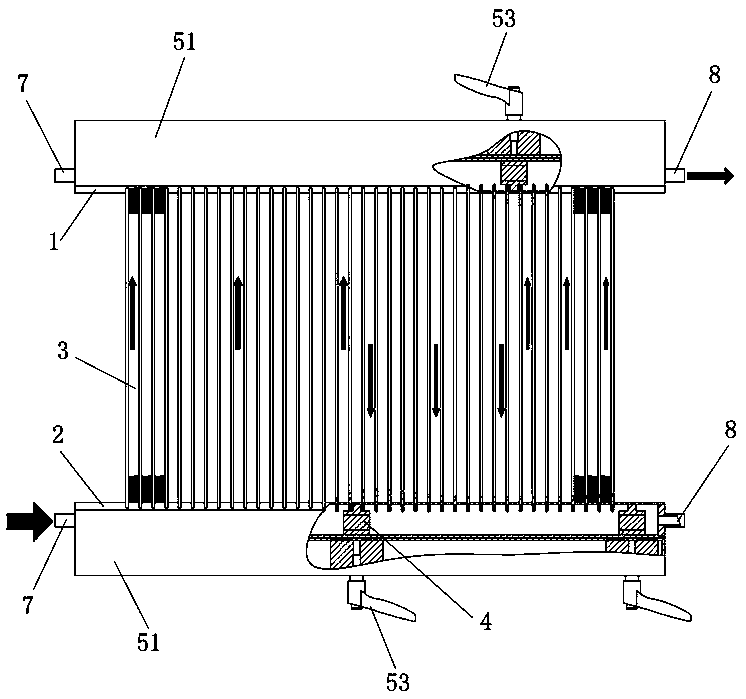

[0030] Figure 1 to Figure 9 It shows an embodiment of the variable flow parallel flow heat exchanger of the present invention, including an upper header 1, a lower header 2 and an upper header 1 and a lower header 2 inserted between the header and the In the flat tube group 3 connected by the two, the upper header 1 and the lower header 2 are equipped with flow-blocking pistons 4 that can move in the axial direction, and the upper header 1 and the lower header 2 are equipped with There is an adjustment mechanism 5 for driving the corresponding blocking piston 4 to a predetermined position. In this structure, the refrigerant enters from the upper header 1 or the lower header 2, and conducts heat exchange through the flat tube group 3, and the position of the cooling flow isolation can be adjusted actively by the adjustment mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com