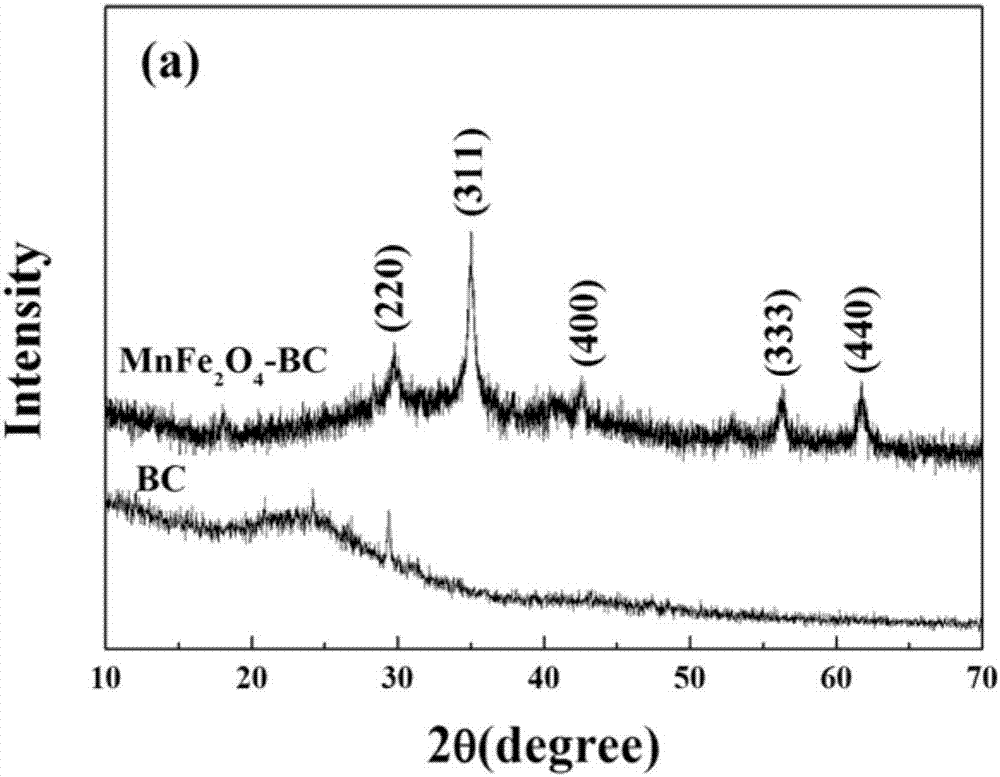

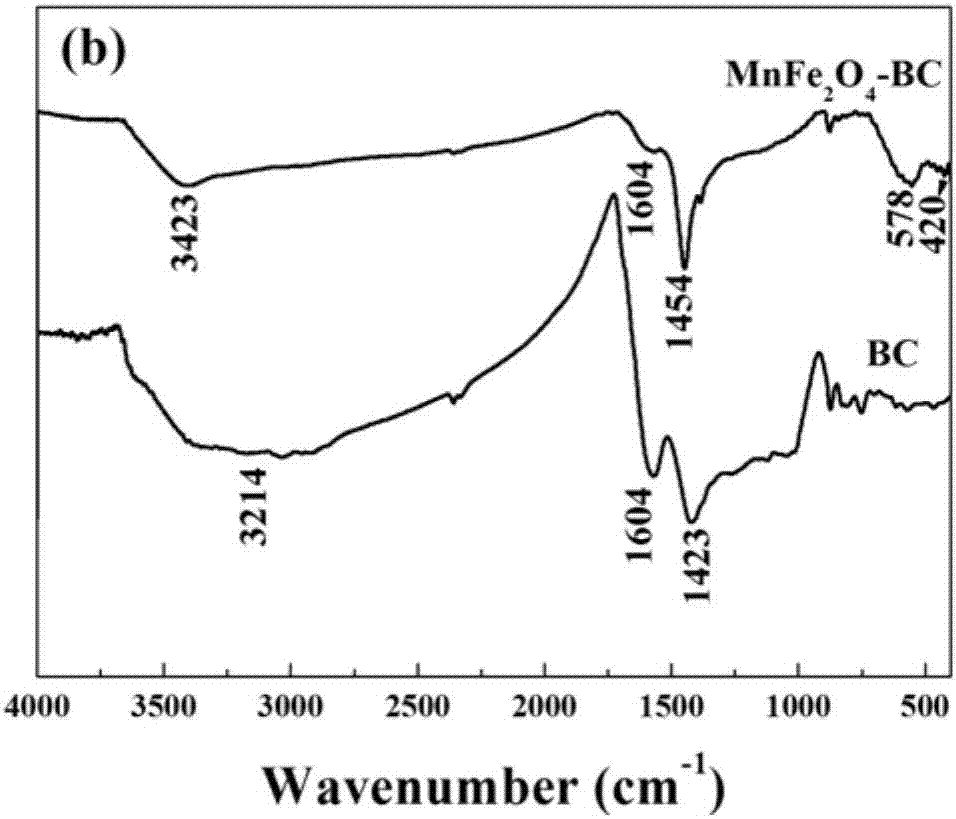

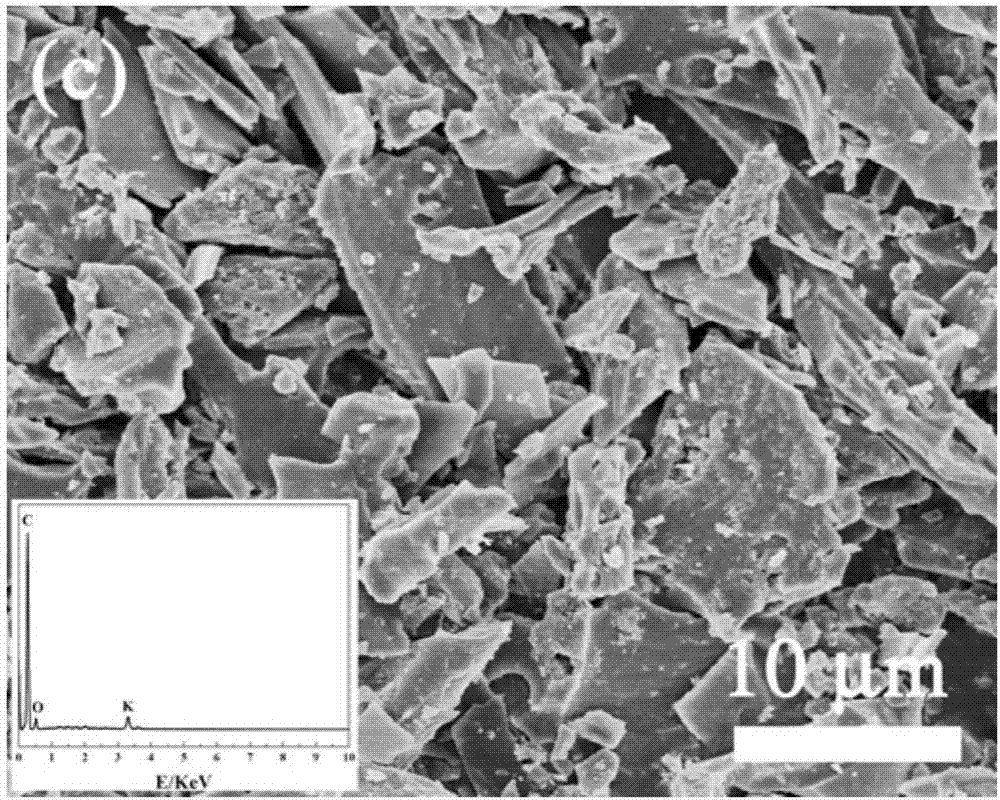

Biochar, iron and manganese spinel composite material for adsorbing heavy metal antimony and cadmium

A technology for adsorbing heavy metals and composite materials, which is applied in the field of biochar ferromanganese spinel composite materials, to achieve high-efficiency adsorption, good adsorption, and favorable adsorption effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A biochar ferromanganese spinel composite material for adsorbing heavy metal antimony and cadmium, which is dripped from solution B into suspension A at a constant speed, then stirred for 2.5 hours, and then centrifuged, washed and dried to obtain biochar iron Manganese spinel composite material, adjust the pH value of solution B and suspension A to 10 before dropping, the weight ratio of suspension A and solution B is 1:0.92; solution B is 0.1mol / L high manganese Suspension A consists of water, ferrous sulfate heptahydrate and tea branch biochar in a weight ratio of 100:8.0:0.8;

[0040] Tea branch biochar is prepared by the following method:

[0041] a) drying the tea leaves after cleaning;

[0042] b) Wash and dry the tea leaves first in an air atmosphere at 200°C for 20 minutes, then heat at 600°C without oxygen for 70 minutes, and cool to obtain a charred product;

[0043] c) drying the charred product at 70° C. for 12 hours, and grinding it to 50 mesh to prepare...

Embodiment 2

[0046] A biochar ferromanganese spinel composite material for adsorbing heavy metal antimony and cadmium, which is dripped from solution B into suspension A at a constant speed, then stirred for 3 hours, and then centrifuged, washed and dried to obtain biochar iron Manganese spinel composite material, adjust the pH value of solution B and suspension A to 10 before dropping, the weight ratio of suspension A and solution B is 1:0.929; solution B is 0.1mol / L high manganese Suspension A consists of water, ferrous sulfate heptahydrate and tea branch biochar in a weight ratio of 100:8.34:1;

[0047] Tea branch biochar is prepared by the following method:

[0048] a) drying the tea leaves after cleaning;

[0049] b) Wash and dry the tea leaves first in an air atmosphere at 250°C for 25 minutes, then heat at 500°C without oxygen for 90 minutes, and cool to obtain a charred product;

[0050] c) drying the charred product at 80° C. for 14 hours, and grinding it to 60 mesh to prepare t...

Embodiment 3

[0053] A biochar ferromanganese spinel composite material for adsorbing heavy metal antimony and cadmium, which is dripped from solution B into suspension A at a constant speed, then stirred for 3.5 hours, and then centrifuged, washed and dried to obtain biochar iron Manganese spinel composite material, adjust the pH value of solution B and suspension A to 10 before dropping, the weight ratio of suspension A and solution B is 1:0.94; solution B is 0.1mol / L high manganese Potassium acid potassium solution, suspension A is made up of water, ferrous sulfate heptahydrate and tea branch biochar by weight ratio 100:8.5:1.2;

[0054] Tea branch biochar is prepared by the following method:

[0055] a) drying the tea leaves after cleaning;

[0056] b) Wash and dry the tea leaves first in an air atmosphere at 300°C for 30 minutes, then heat at 700°C without oxygen for 110 minutes, and cool to obtain a charred product;

[0057] c) drying the charred product at 90° C. for 16 hours, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com