Multielement modified bentonite adsorption material and preparation method thereof

An adsorption material, bentonite technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as rare research, and achieve the effect of reducing residual concentration, high thermal stability, and improving adsorption selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

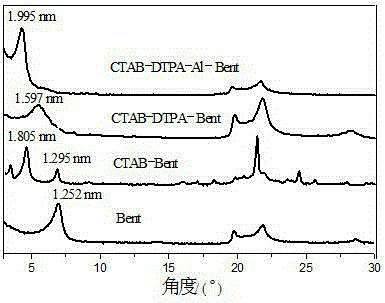

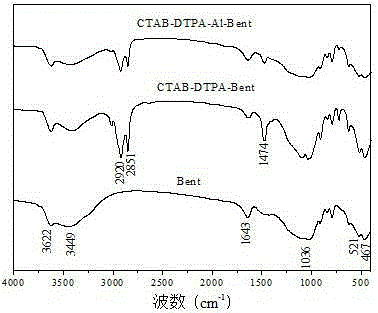

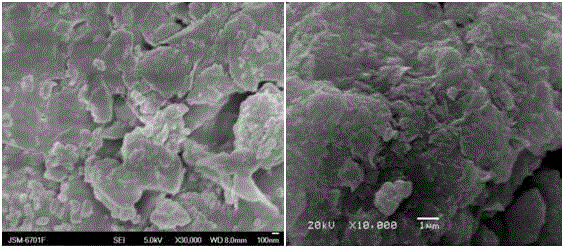

Image

Examples

Embodiment 1

[0026] (1) Preparation of inorganic polymeric hydroxyaluminum cation propping agent: Slowly add 0.4mol / L NaOH solution to 6 times the volume of 1.0mol / LAlCl at 60°C under constant stirring within 3 hours 3 solution, so that OH in the mixed solution - with Al 3+ The molar ratio of the solution is 1:2.4; after the dropwise addition, continue to stir for 3 hours, and then age the resulting solution at 60°C for 24 hours to obtain the inorganic polymeric hydroxyaluminum cationic proppant;

[0027] (2) Preparation of multi-component composite pillaring agent: mix CTAB, DTPA and inorganic polymeric hydroxyl aluminum cationic pillaring agent (the molar ratio of DTPA to CTAB is 1:1, and the total amount of DTPA and CTAB is 0.85mmol / g bentonite ; The dosage of the inorganic polymerized hydroxyl aluminum cationic propping agent is: 6mmol / g bentonite), stirring for 2 hours, to obtain a multi-component composite propping agent;

[0028] (3) Preparation of multi-component modified bentoni...

Embodiment 2

[0030] (1) Preparation of inorganic polymerized hydroxyaluminum cationic propping agent: firstly, 0.5mol / L Na 2 CO 3 Slowly add 3 times the volume of 1.0mol / LAlCl to the solution 3 solution, so that OH in the mixed solution - with Al 3+ The molar ratio is 2.4:1, after the dropwise addition is completed; after continuing to stir for 4 hours, age at 80°C for 36 hours to obtain an inorganic polymeric hydroxyaluminum cationic proppant;

[0031] (2) Preparation of multi-component composite pillaring agent: mix CTAB, DTPA and inorganic polymeric hydroxyl aluminum cationic pillaring agent (the molar ratio of DTPA and CTAB is 1:1.5, and the total amount of DTPA and CTAB is 0.85mmol / g bentonite ; The dosage of the inorganic polymerized hydroxyl aluminum cationic propping agent is: 6mmol / g bentonite), stirring for 2 hours, to obtain a multi-component composite propping agent;

[0032] 3. Preparation of multi-component modified bentonite adsorption material: Weigh 3.0 g of sodium-bas...

Embodiment 3

[0034] (1) Preparation of inorganic polymeric hydroxyaluminum cationic propping agent: Slowly add 0.4mol / L NaOH solution to 6 times the volume of 1.0mol / LAlCl at 60°C under constant stirring within 3 hours 3 solution, so that OH in the mixed solution - with Al 3+ The molar ratio is 1:2.4. After the dropwise addition, continue to stir for 3 hours, and then age the resulting solution at 60°C for 24 hours to obtain the inorganic polymeric hydroxyl metal cation propping agent;

[0035] (2) Preparation of multi-component composite pillaring agent: mix CTAB, DTPA and inorganic polymeric hydroxyl aluminum cationic pillaring agent (the molar ratio of DTPA and CTAB is 1:0.35, and the total amount of DTPA and CTAB is 1.03mmol / g bentonite ; The dosage of the inorganic polymerized hydroxyl aluminum cationic propping agent is: 6mmol / g bentonite), stirring for 2 hours, to obtain a multi-component composite propping agent;

[0036] (3) Preparation of multi-component modified bentonite adso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com