Resin ball capable of swelling and adsorbing aromatic hydrocarbon in hydrocarbon mixture and preparation method of resin ball

A technology of hydrocarbon mixture and resin balls, applied in chemical instruments and methods, refined hydrocarbon oil, other chemical processes, etc., to achieve the effect of enhancing adsorption capacity, improving separation process and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of cross-linked polystyrene resin balls by suspension polymerization:

[0040] The oil phase is composed of initiator BPO, styrene and crosslinking agent divinylbenzene, wherein BPO accounts for 1% of the mass of styrene, the amount of styrene is 15.623g, and the molar ratio of styrene to divinylbenzene is 50: 3. The aqueous phase contains 114mL of PVA dispersant, 3.42g of common salt and 0.5mL of an aqueous solution of 2% methylene blue in mass fraction. The oil phase and water phase were mixed evenly and then poured into the N 2 Into the three-necked flask of the introduction tube, reflux condenser, and mechanical stirrer, pass N 2 After 0.5h, put it into a constant temperature water bath preheated to 70°C, adjust the speed to 220rpm, react for 1.5h, then raise the temperature to 85°C for 4h, and continue to raise the temperature to 90°C for 5h. After the reaction, use a filter cloth to filter at room temperature to obtain cross-linked polystyrene re...

Embodiment 2

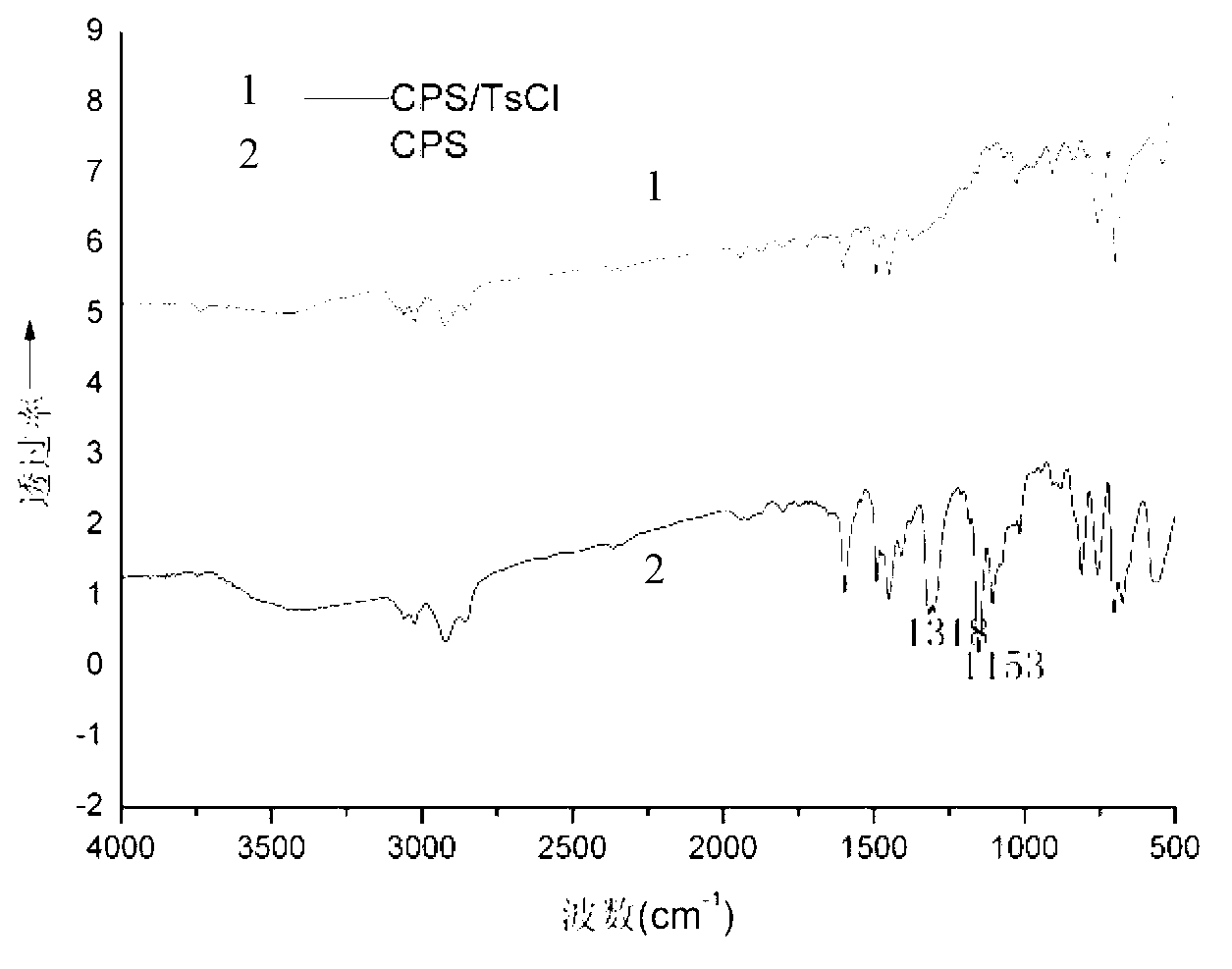

[0055] Embodiment 2: the resin ball of different p-toluenesulfonyl chloride adding amount

[0056] Put cross-linked polystyrene (CPS) balls into a three-necked flask according to the formula in Table 1, add dichloroethane, and add anhydrous aluminum trichloride under nitrogen protection after swelling for 10 hours. Slowly add the mixed solution of prefabricated p-toluenesulfonyl chloride and dichloroethane dropwise into the three-necked flask, keep the temperature of the system at 40-50°C, and release a large amount of gas at the same time. After the dropwise addition, the reaction temperature was maintained at 60°C until no gas evolved. The filtered resin balls were washed with a mixture of ice and hydrochloric acid and ethanol, respectively, and then dried and set aside.

[0057] Table 1: Raw material ratio of different p-toluenesulfonyl chloride resin balls

[0058]

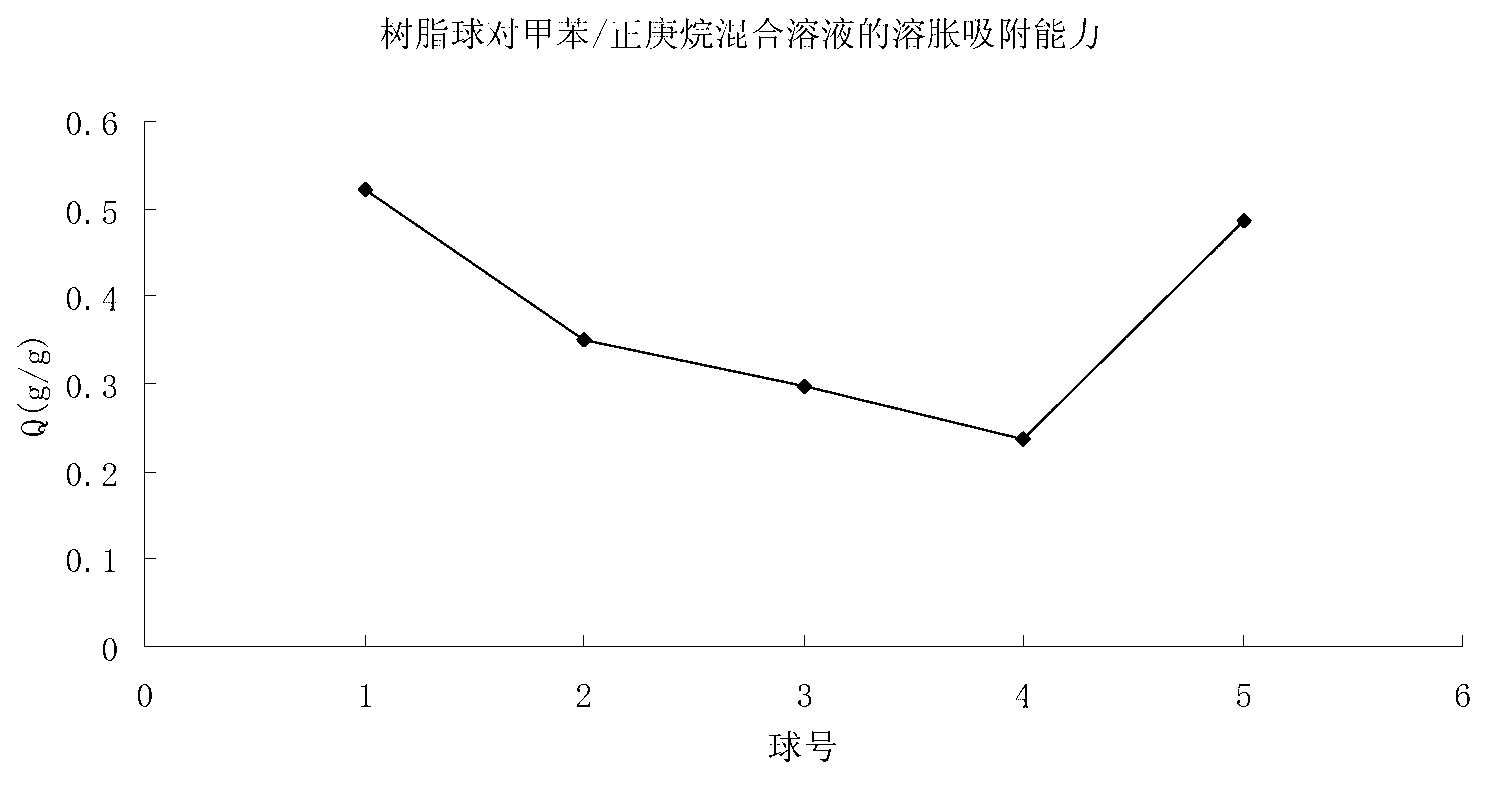

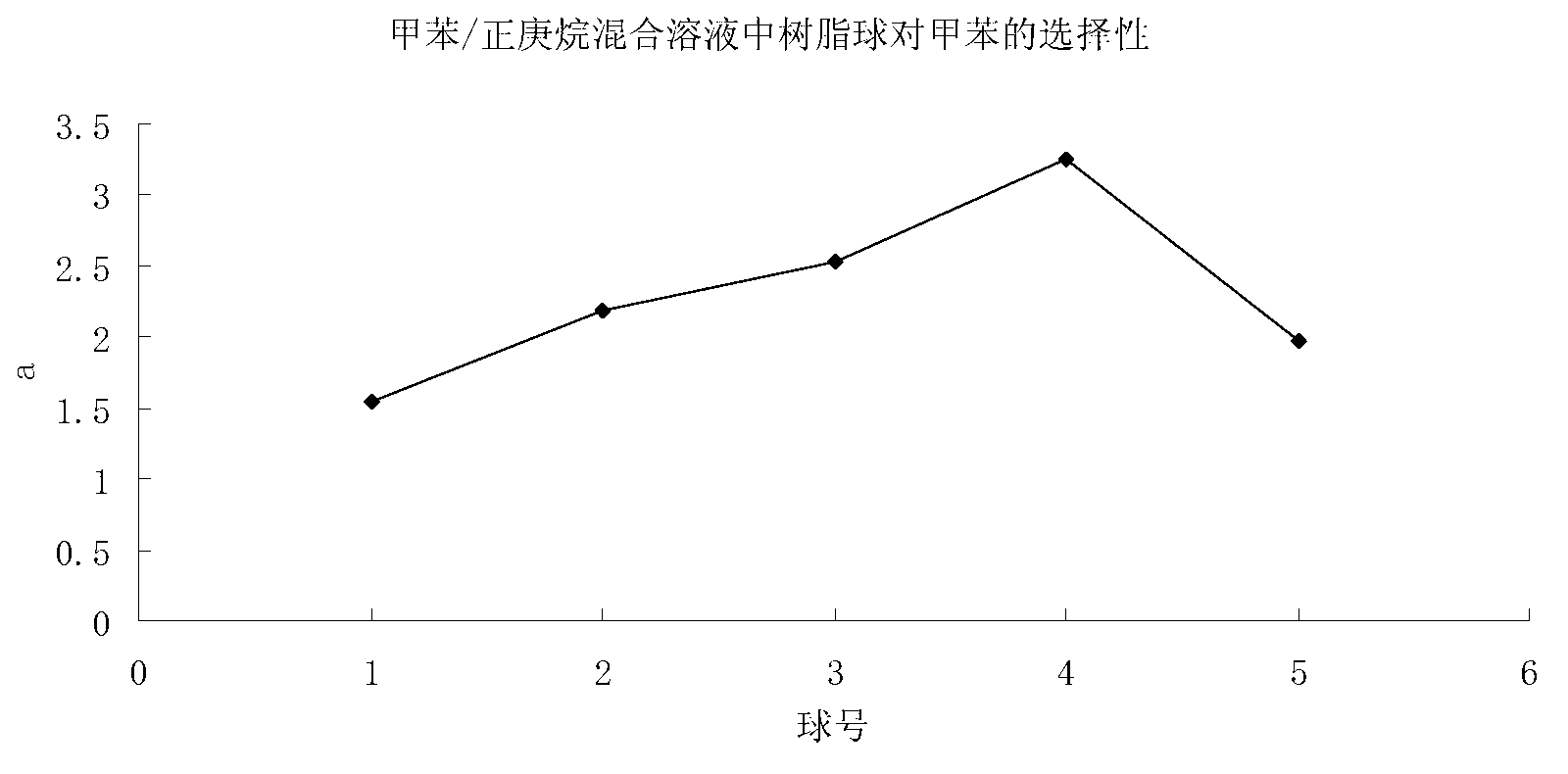

[0059] The swelling adsorption capacity of resin balls to toluene / n-heptane mixed solution figure 2 ...

Embodiment 3

[0061] Example 3: Comparison of the swelling ability of resin balls to various aromatic hydrocarbons and paraffins

[0062] Take 5g of resin balls, bake them at 70°C for 5 hours, put them in a desiccator and cool them down to room temperature, and set them aside. Weigh 2g of resin balls in eight 50mL Erlenmeyer flasks, add 10mL of benzene, n-heptane, cyclohexane, p-xylene, n-octane, toluene, n-heptane and vinylbenzene respectively, seal and shake at constant temperature In a water bath, shake and adsorb for 48 hours at 50°C and a frequency of 100 rpm. Weigh the mass of the adsorbed solution before and after swelling adsorption. According to the formula (1), calculate the swelling adsorption capacity Q of resin balls for various aromatic hydrocarbons and paraffins.

[0063] Q=(Q 1 -Q 0 ) / m 0 (1)

[0064] Q 1 is the mass of the adsorbed solution before adsorption swelling, Q 0 is the mass of the adsorbed solution after adsorption swelling, m 0 is the mass of dry re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com