Method for separating CO2 from CO2/CH4 mixed gas

A technology of mixed gas and separation method, applied in separation method, gas treatment, dispersed particle separation, etc., can solve the problems of high cost, poor mixed gas separation effect, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] a CO 2 / CH 4 CO in the mixed gas 2 The separation method comprises the following steps:

[0064] Step 1, under vacuum conditions, the mass m w Dry 6.30g of activated carbon at 120°C for 24 hours, cool to normal temperature after drying, and obtain dry activated carbon with a mass m of 3.30g;

[0065] Step 2, the mass m mIm 1.01g of 2-methylimidazole, mass m glycol 1.64g of ethylene glycol and 10g of ethanol are mixed uniformly to obtain a mixed solution;

[0066] 3.30g dry activated carbon obtained in step 1 is mixed with 12.65g mixed solution to obtain a solid-liquid mixture;

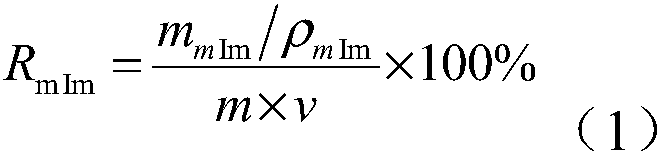

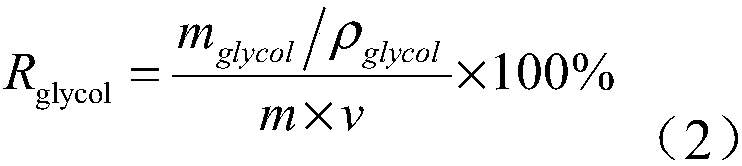

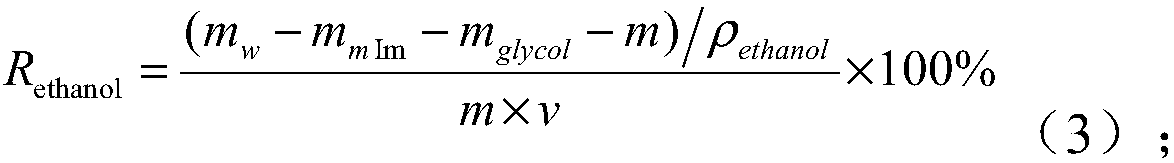

[0067] Step 3, put the solid-liquid mixture in step 2 under vacuum for one week, then dry at 80°C, and monitor the pore volume occupancy of ethanol in the activated carbon during the drying process, when the pore volume occupancy of ethanol in the activated carbon is monitored When the drying rate reaches 10.20%, the drying is finished and the modified activated carbon is obtained;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com