Composited cast member, iron-based porous substance for composited cast members, and pressure casing processes for producing the same, constituent member of compressors provided with composited cast members and the compressors

a composited cast and iron-based porous technology, applied in the direction of machines/engines, positive displacement liquid engines, transportation and packaging, etc., can solve the problems of poor adhesiveness at the interface between cast-steel sleeves, inability to say that the weight saving of cylinder blocks is fully achieved, and difficult to secure strength, rigidity, slidability, wear resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

(Example No. 1)

(Outline)

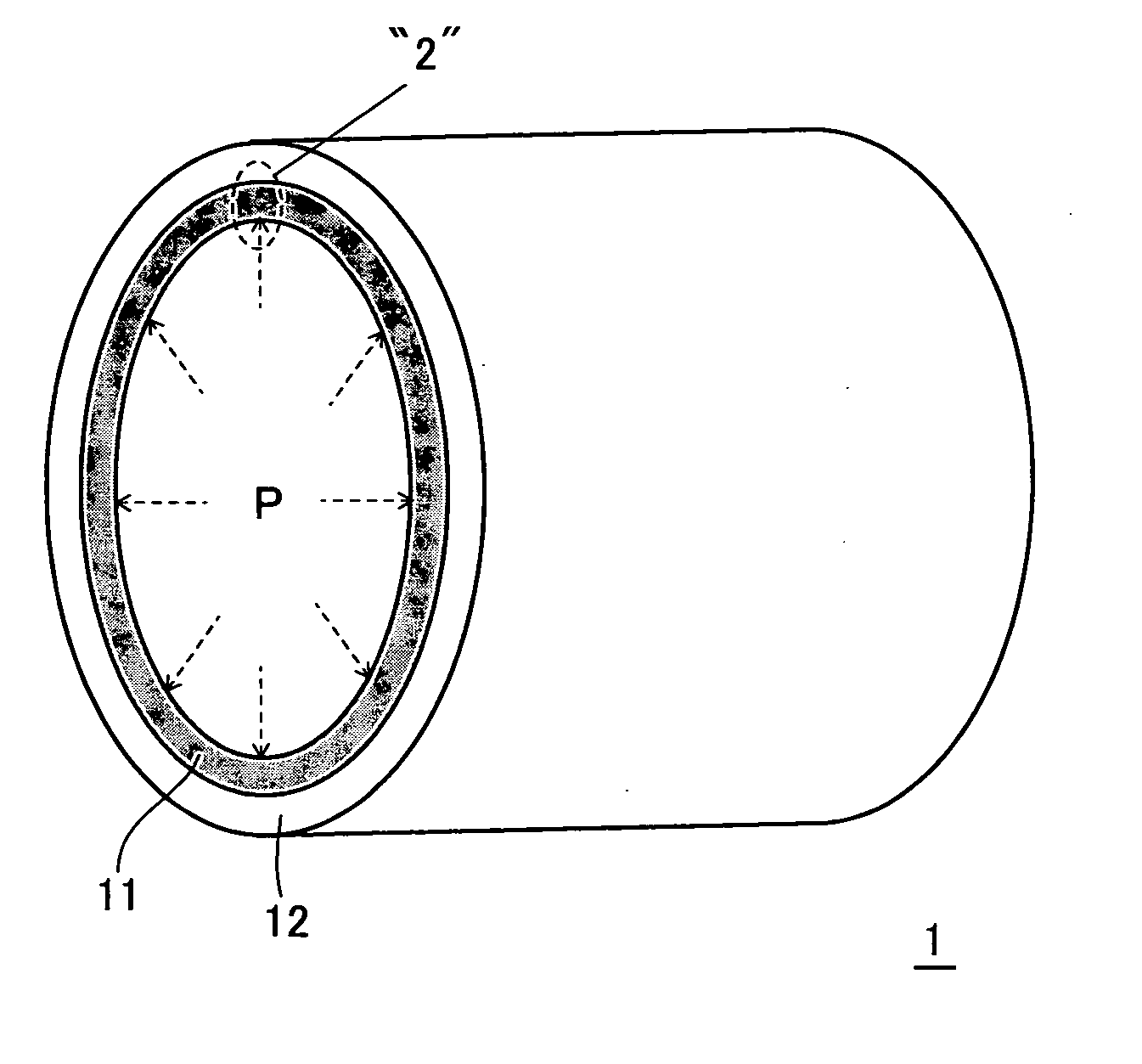

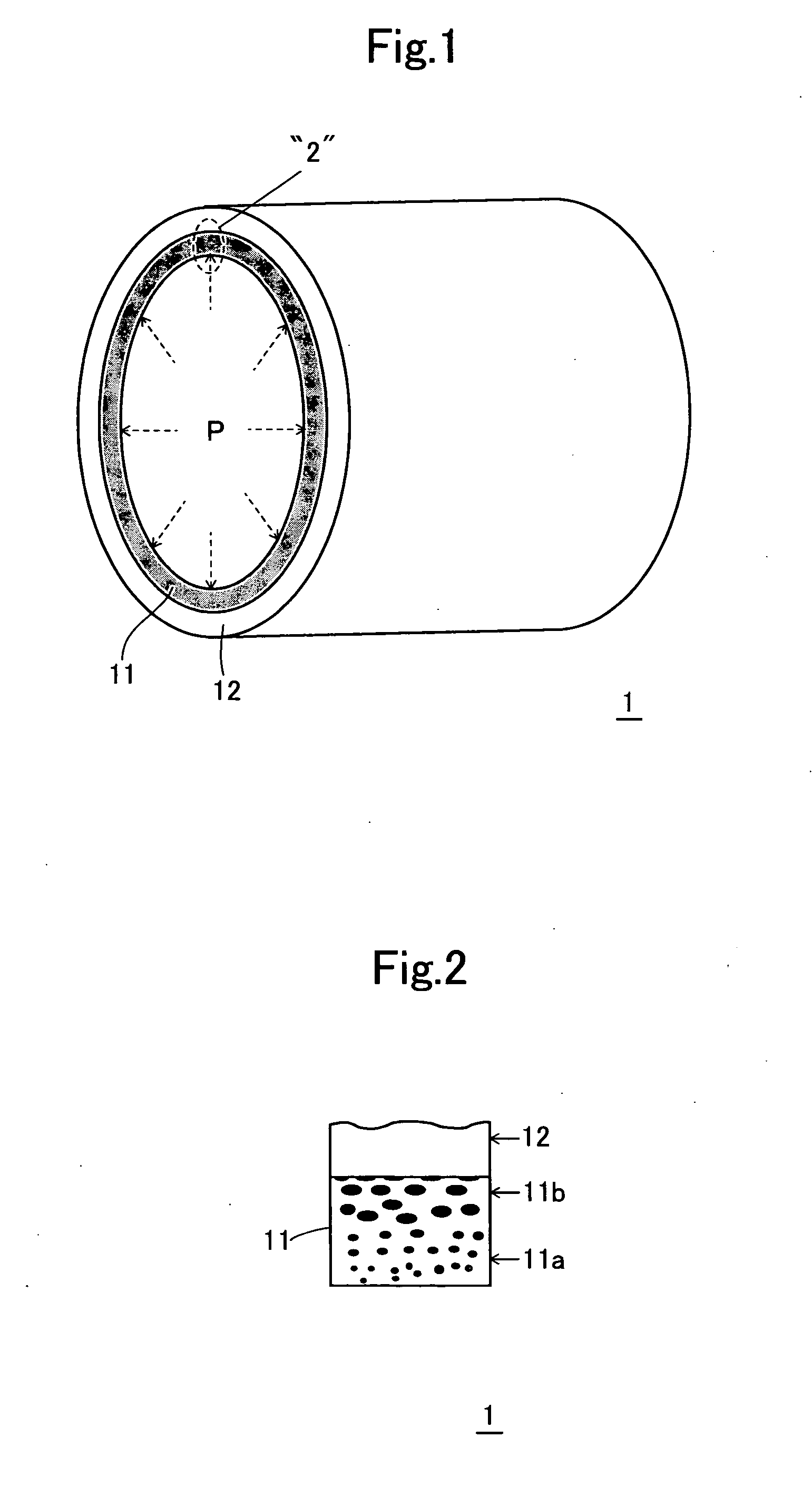

[0096]FIGS. 1 and 2 illustrate a cylinder-shaped housing 1 for compressors, Example No. 1 of the present invention. Note that the present composited cast member, constituent members of compressors or pressure casing include the cylinder-shaped housing 1. FIG. 2 is an enlarged view of an opposite end surface of the cylinder-shaped housing 1 designated at “2” in FIG. 1. Moreover, as illustrated in FIG. 1, the cylinder-shaped housing 1 is made on the assumption that an internal pressure “P” resulting from a working fluid acts outward from the inner peripheral side.

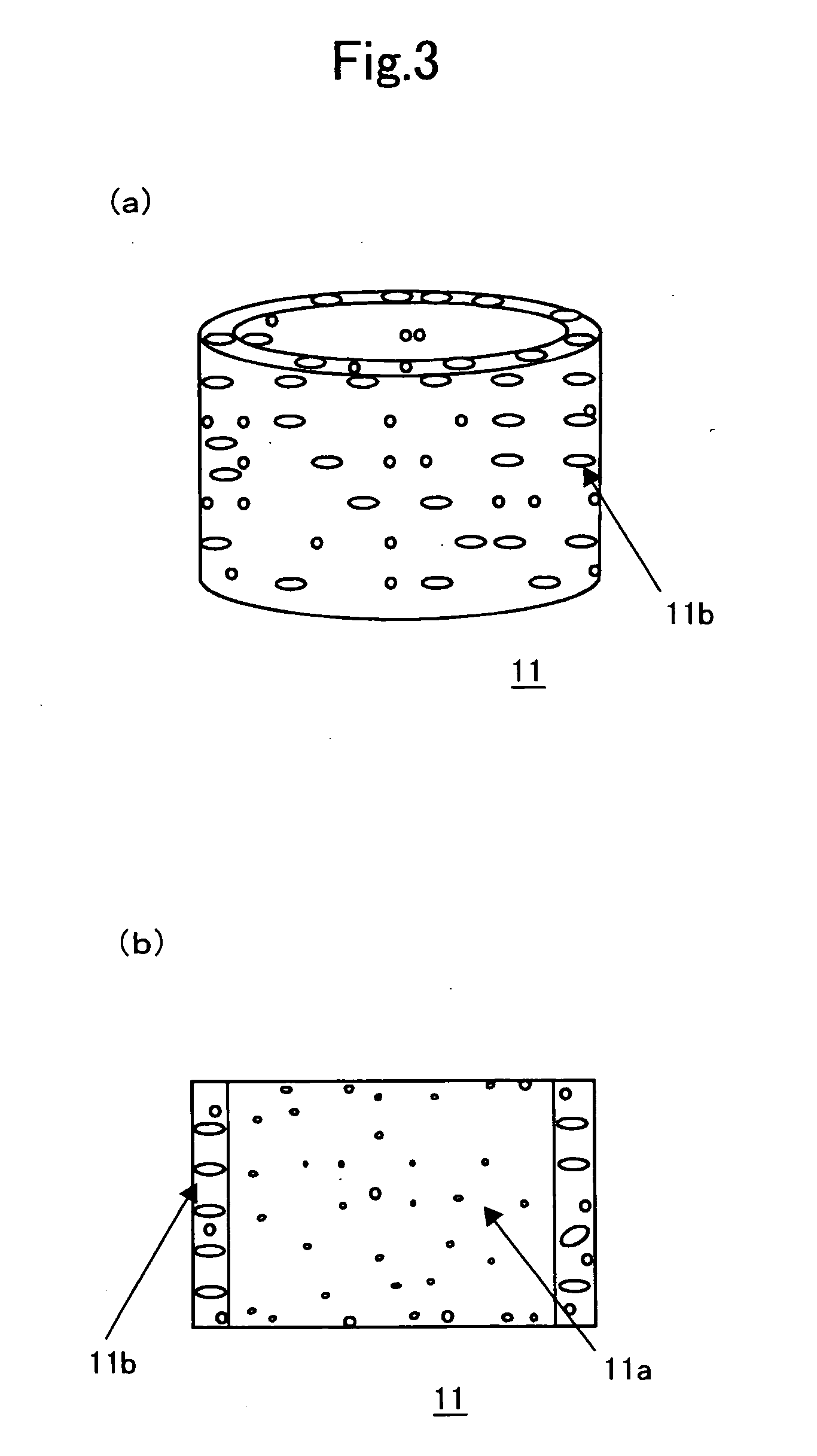

[0097] The housing 1 is a composited cast member which comprises a cylinder-shaped iron-based porous sintered substance 11, and a cast-wrapping member 12. The cast-wrapping member 12 is made by casting a casting aluminum alloy around the outer peripheral surface of the iron-based porous sintered substance 11. As illustrated in FIG. 2, the iron-based porous sintered substance 11 comprises a reinforce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com