Patents

Literature

60results about How to "Small porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cluster ion exchange membrane and electrolyte membrane electrode connection body

InactiveUS20050095486A1High mechanical strengthImprove ionic conductivityIon-exchange process apparatusSolid electrolytesIon-exchange membranesMembrane configuration

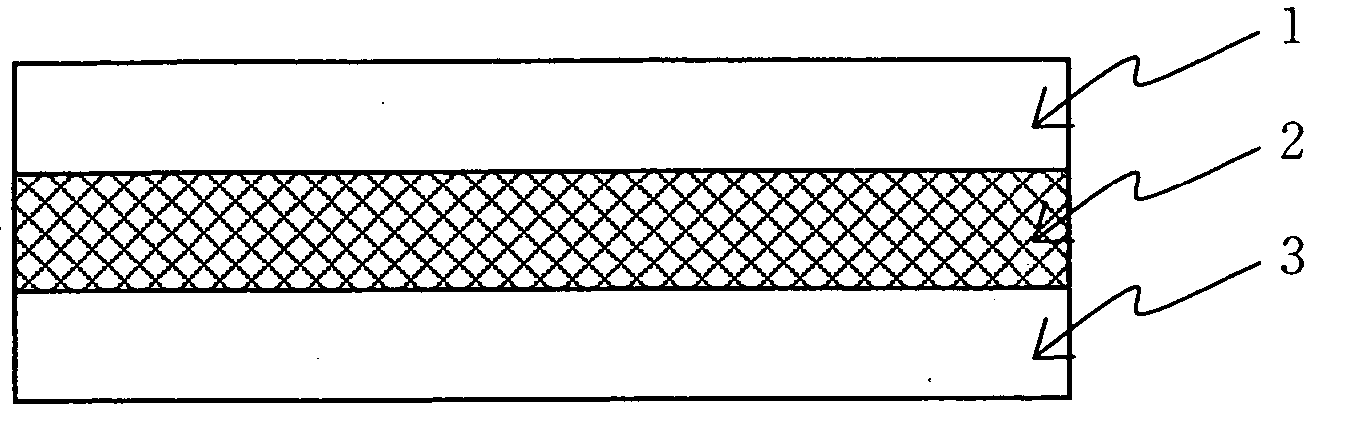

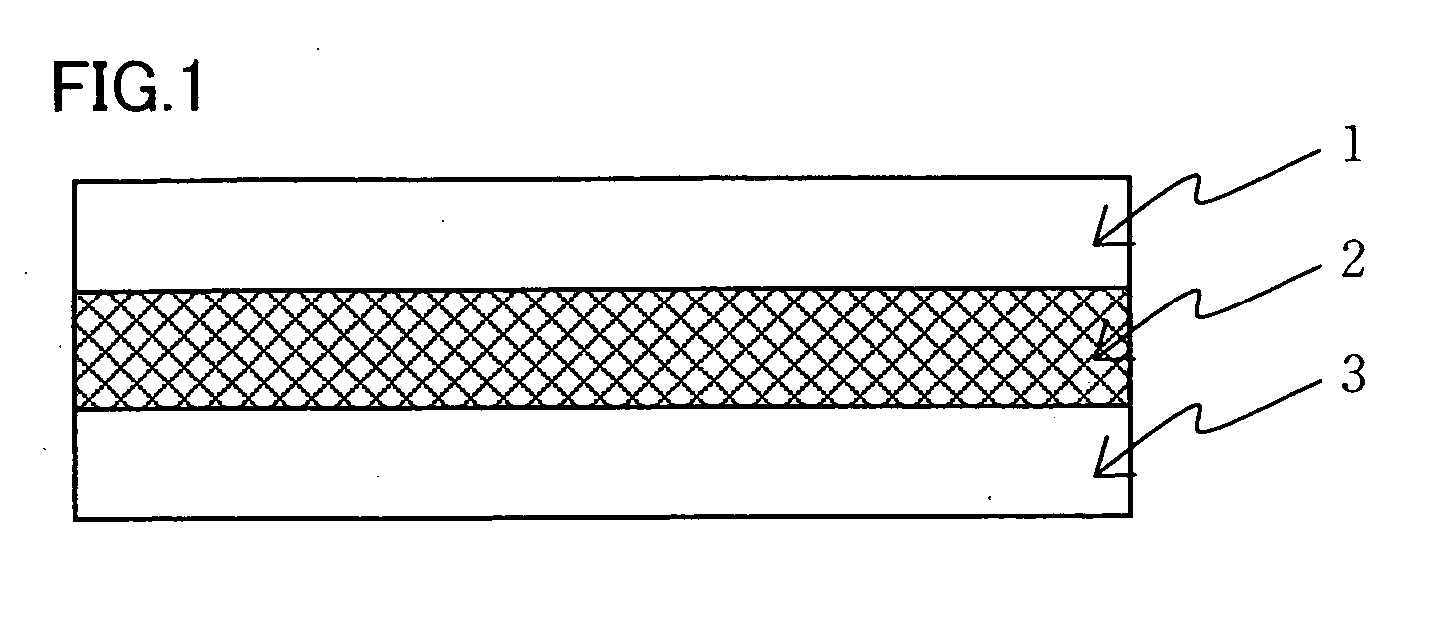

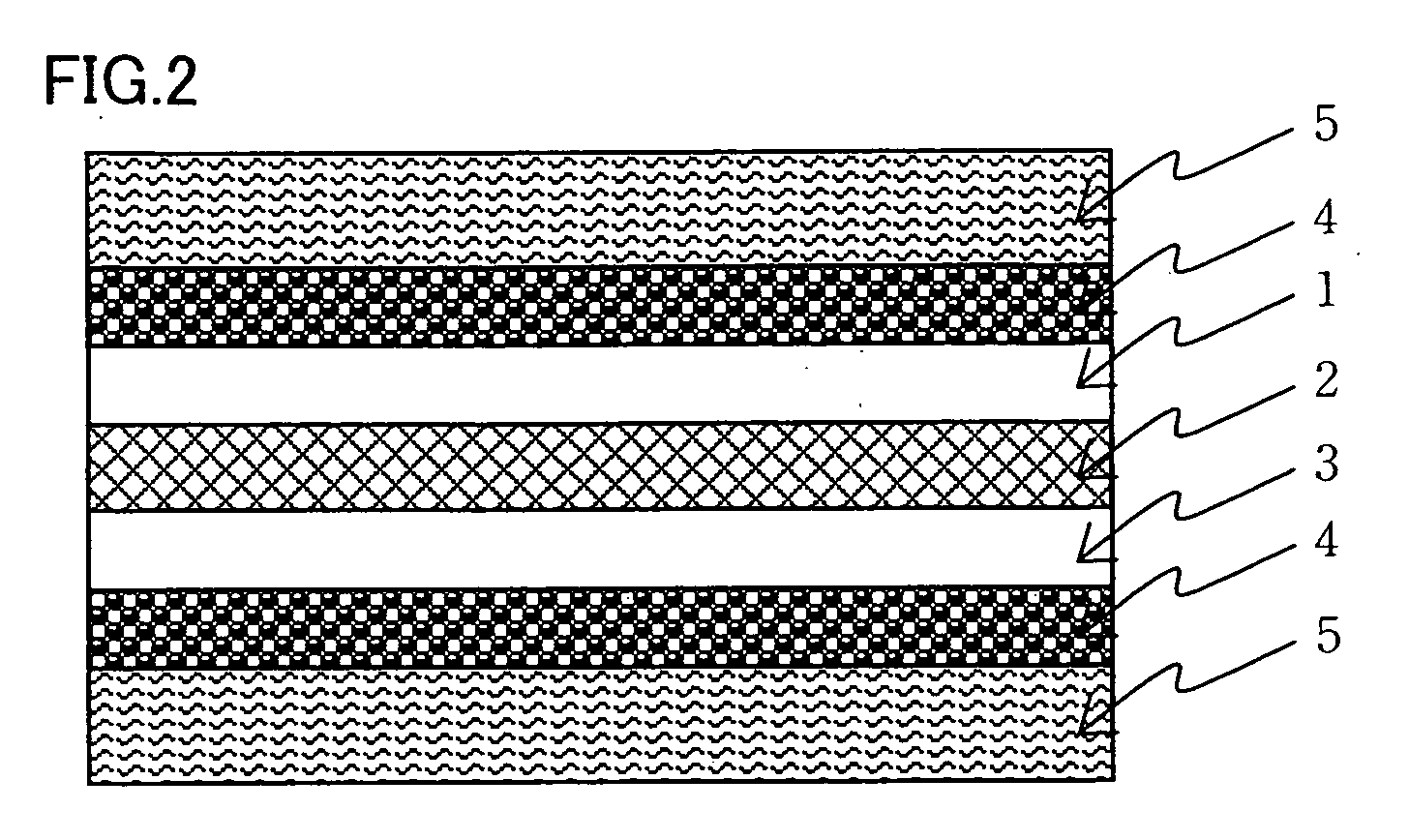

The present invention provides a composite ion exchange membrane which has high mechanical strength and is suitable for use as a solid polymer electrolyte membrane excellent in ionic conductivity and a method for its production. The invention is achieved by a composite ion exchange membrane including a composite layer comprising a support membrane with continuous voids formed of polybenzazole polymer, the support membrane being impregnated with ion exchange resin, and surface layers formed of ion exchange resin free of support membranes, the surface layers being formed on both surfaces of the composite layer so as to sandwich the composite layer therebetween.

Owner:TOYO TOYOBO CO LTD

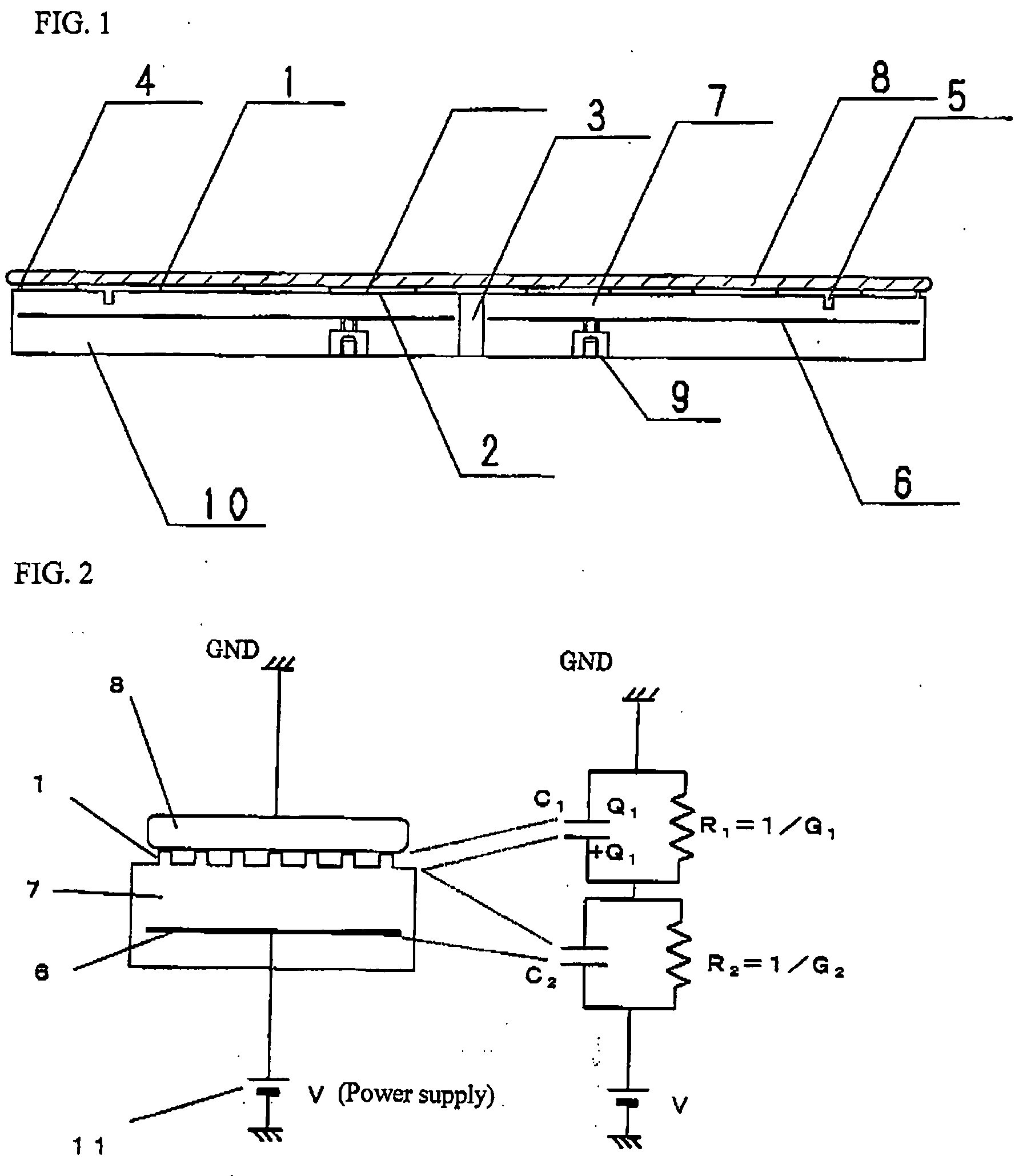

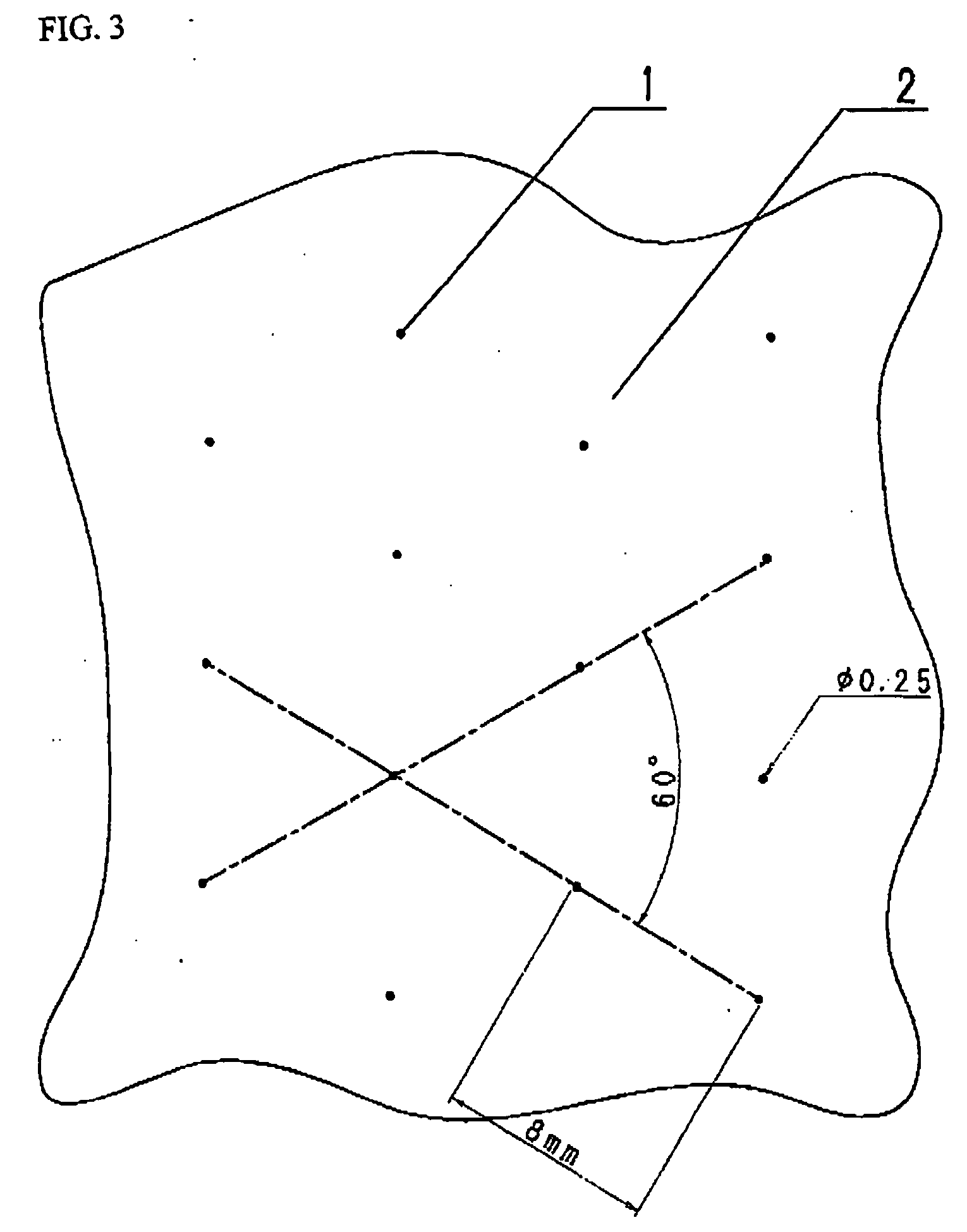

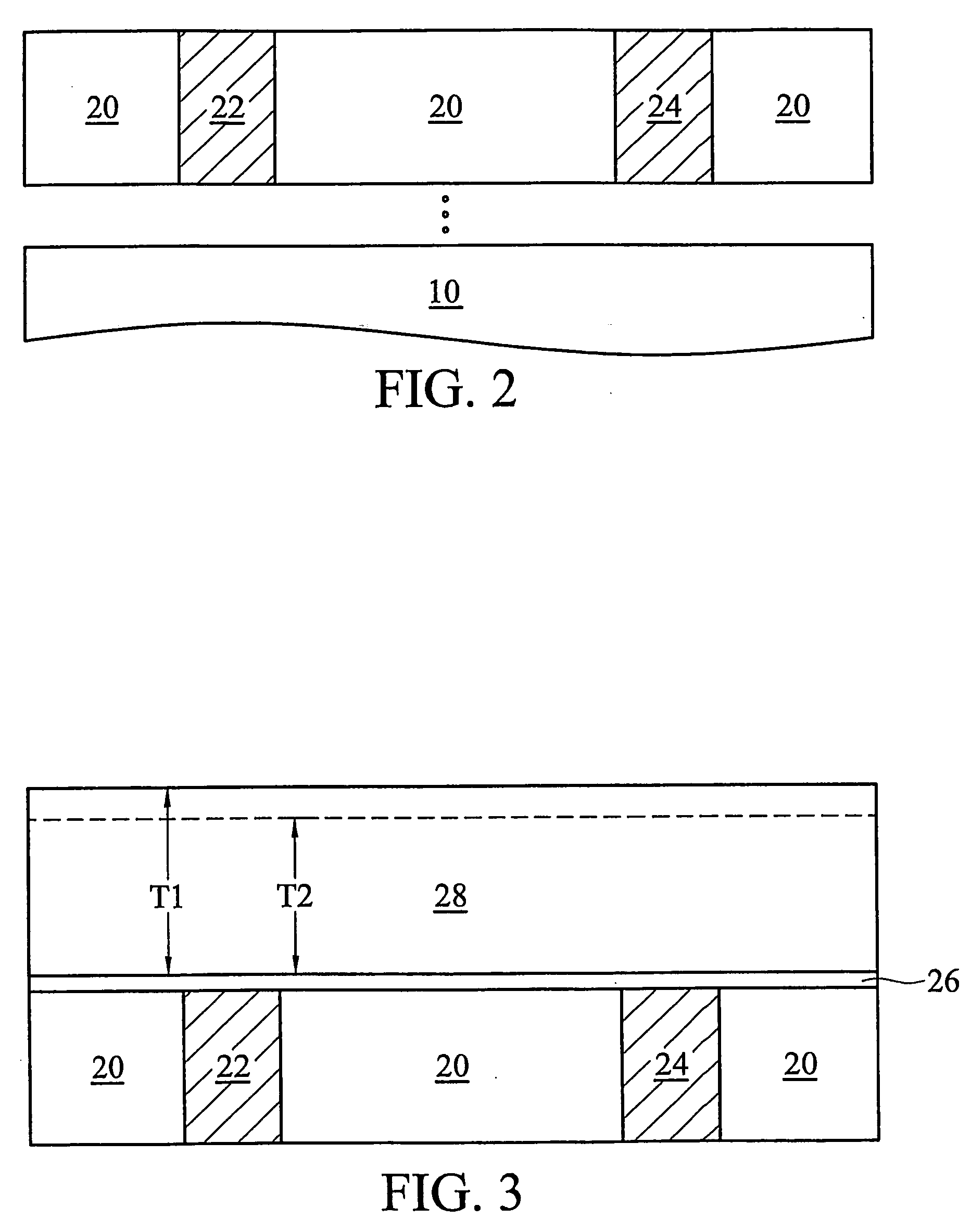

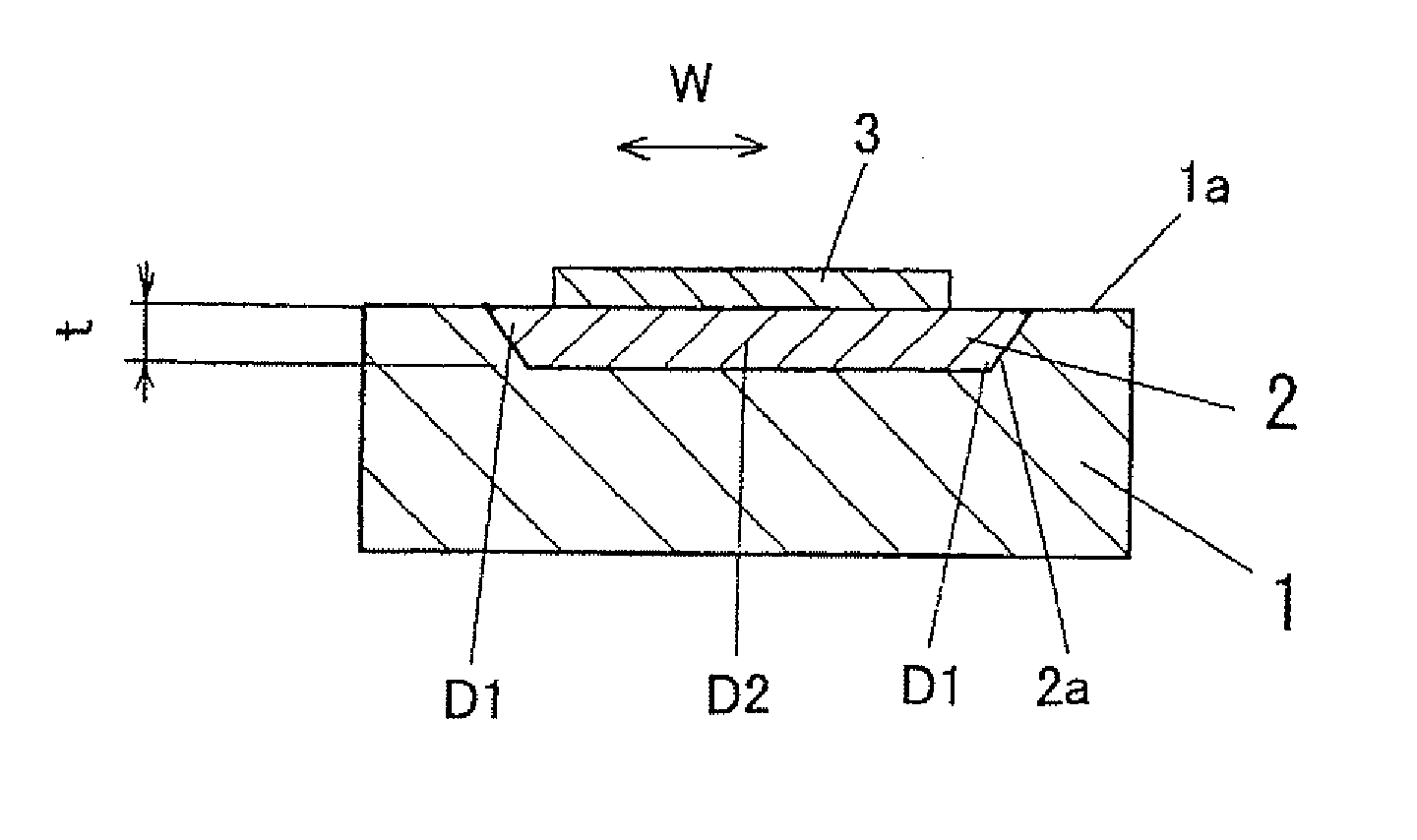

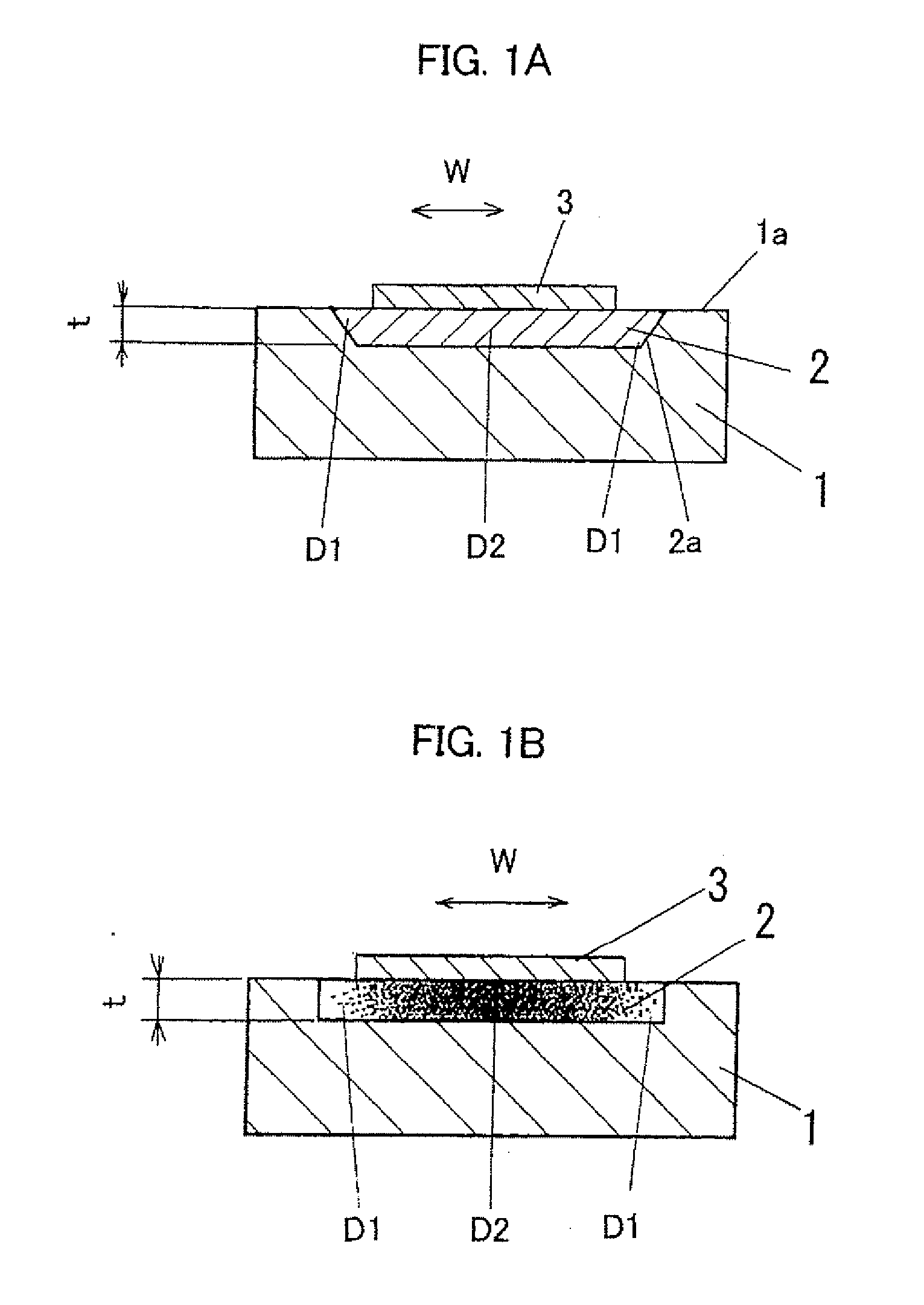

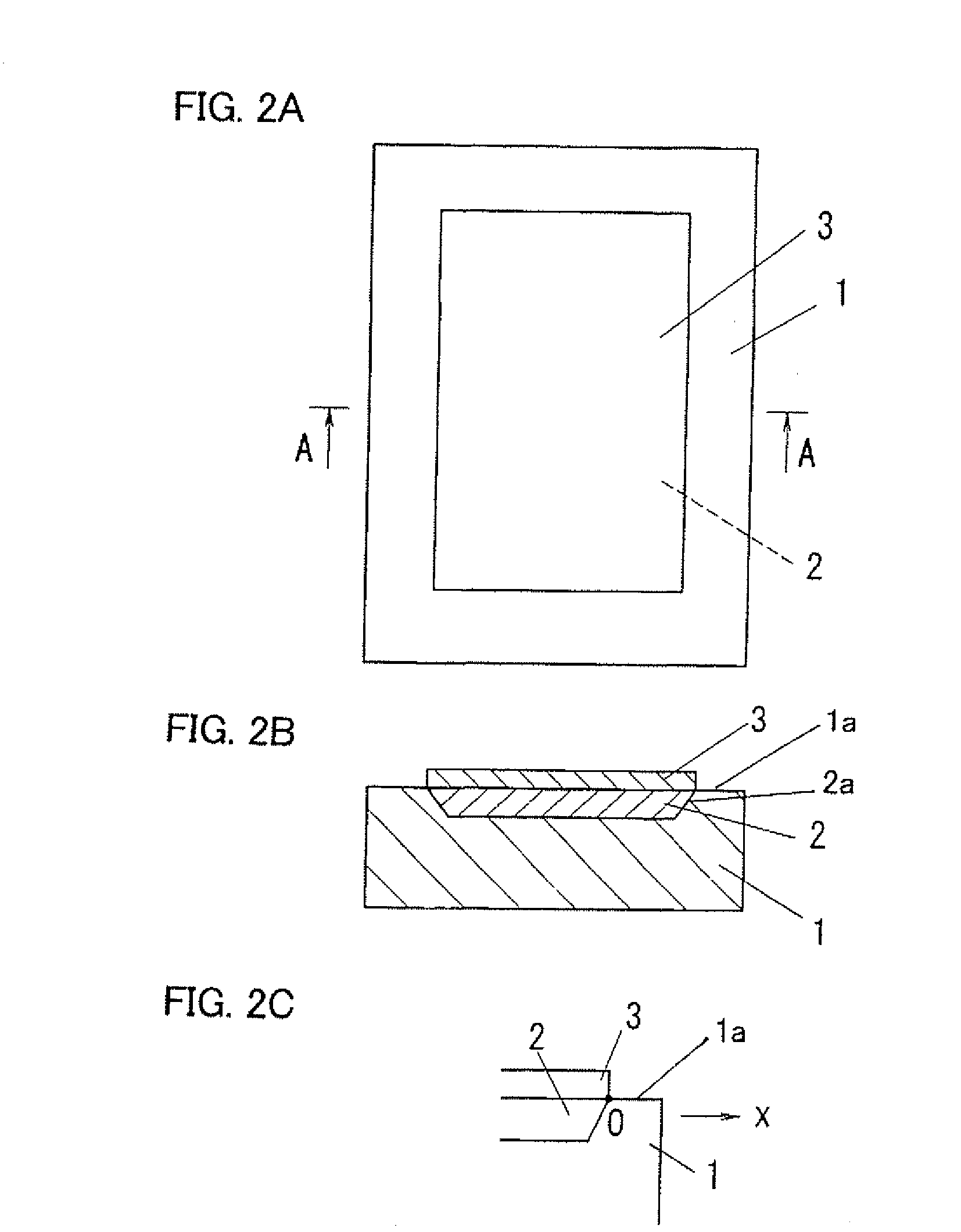

Pressure wave generator and process for manufacturing the same

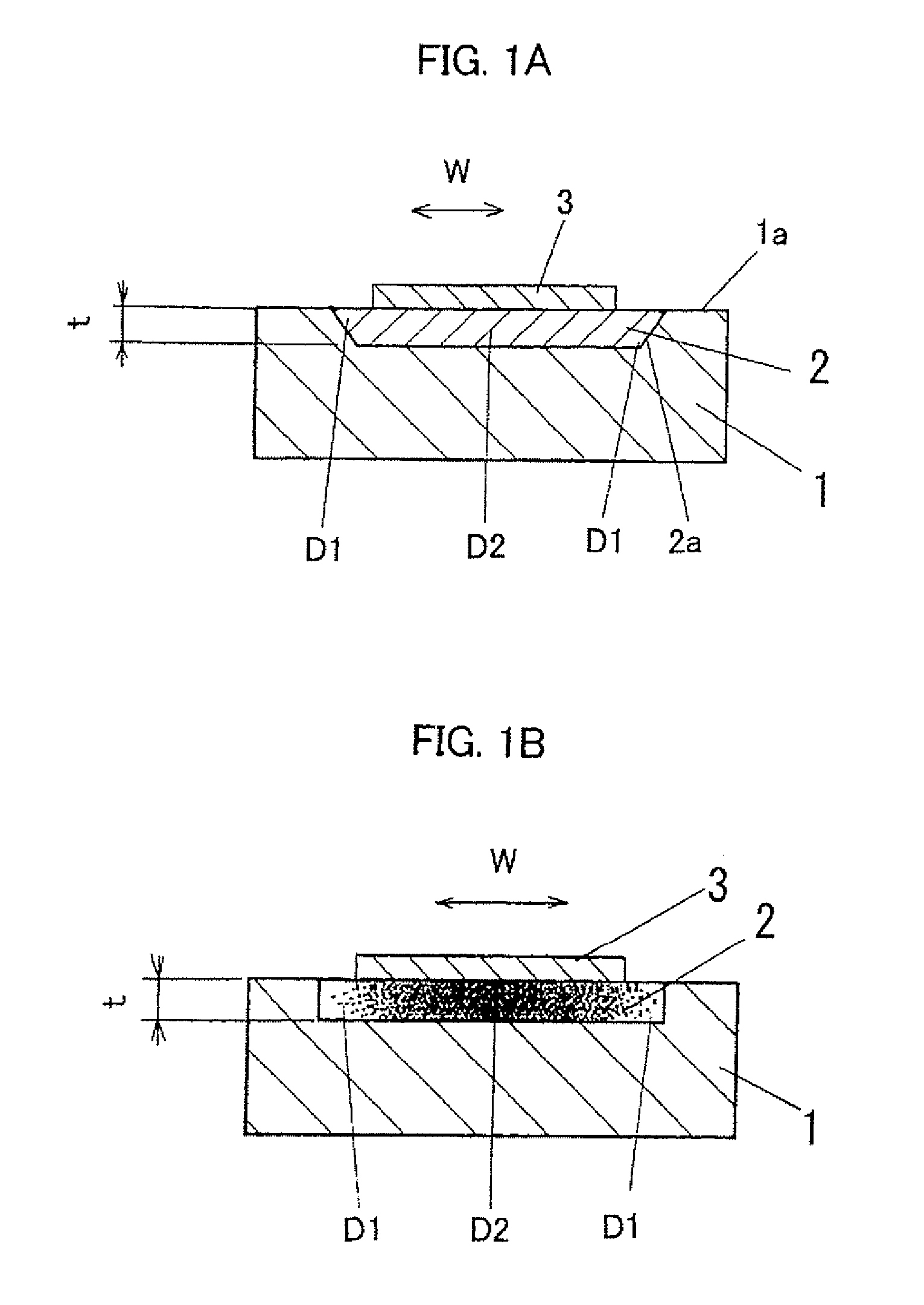

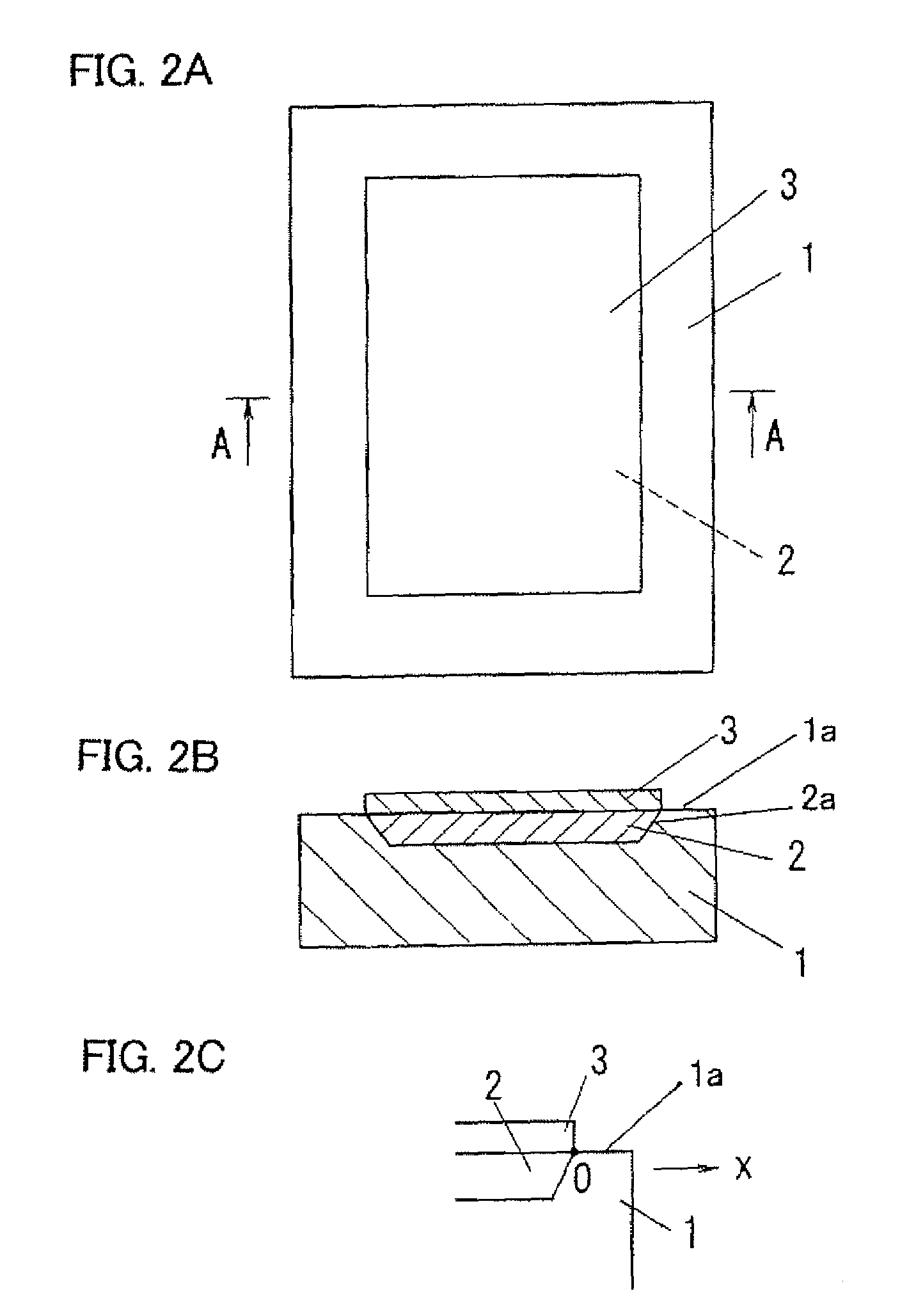

InactiveUS7474590B2Reduce the likelihood of occurrenceMade smallMicrophonesElectrothermic-effect transistorPorosityElectrical conductor

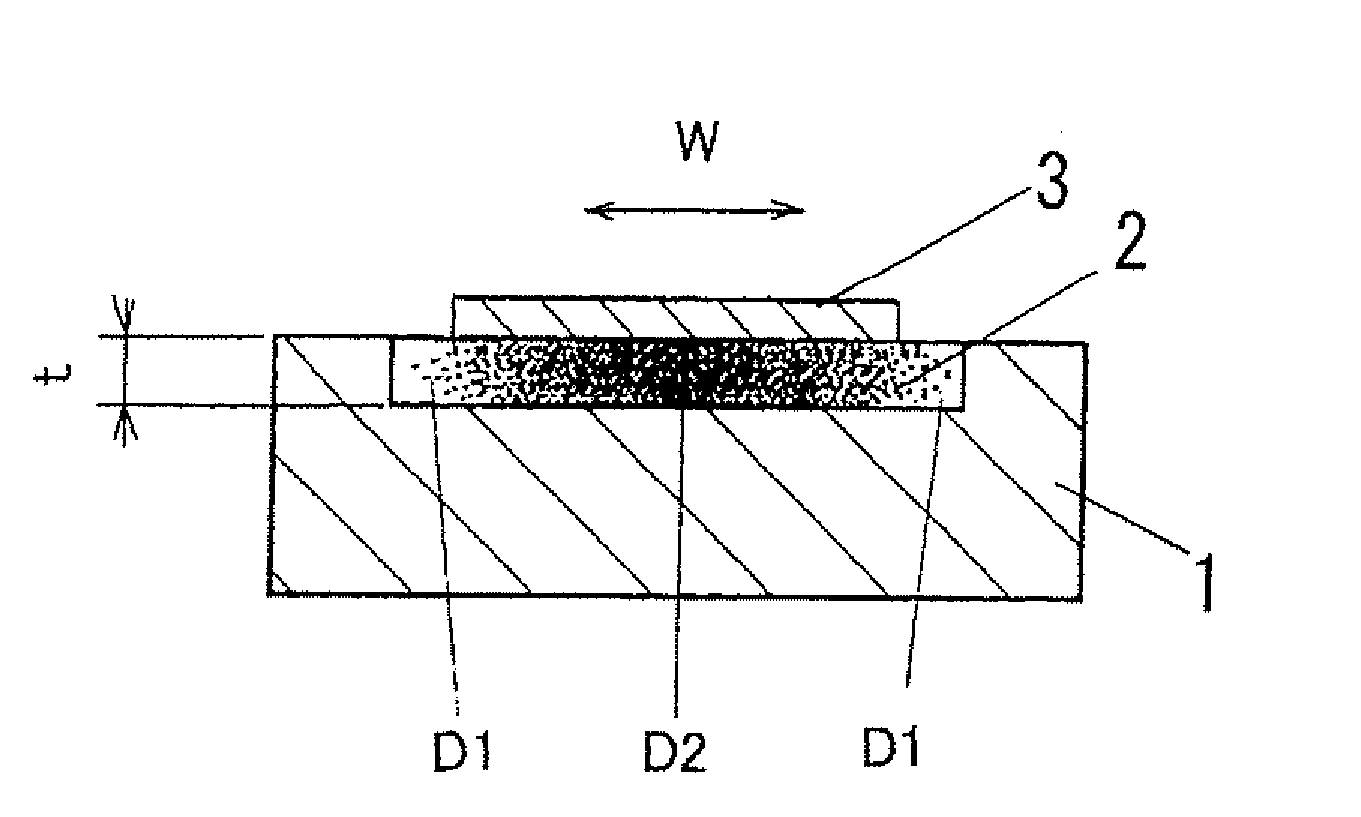

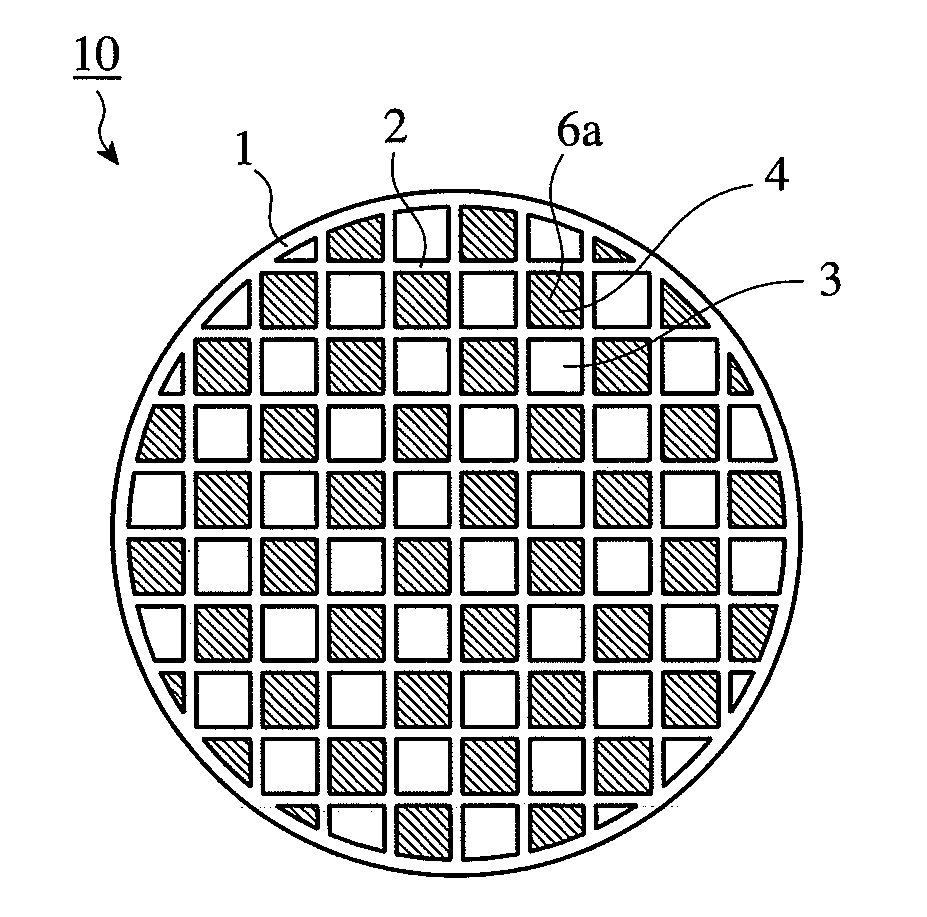

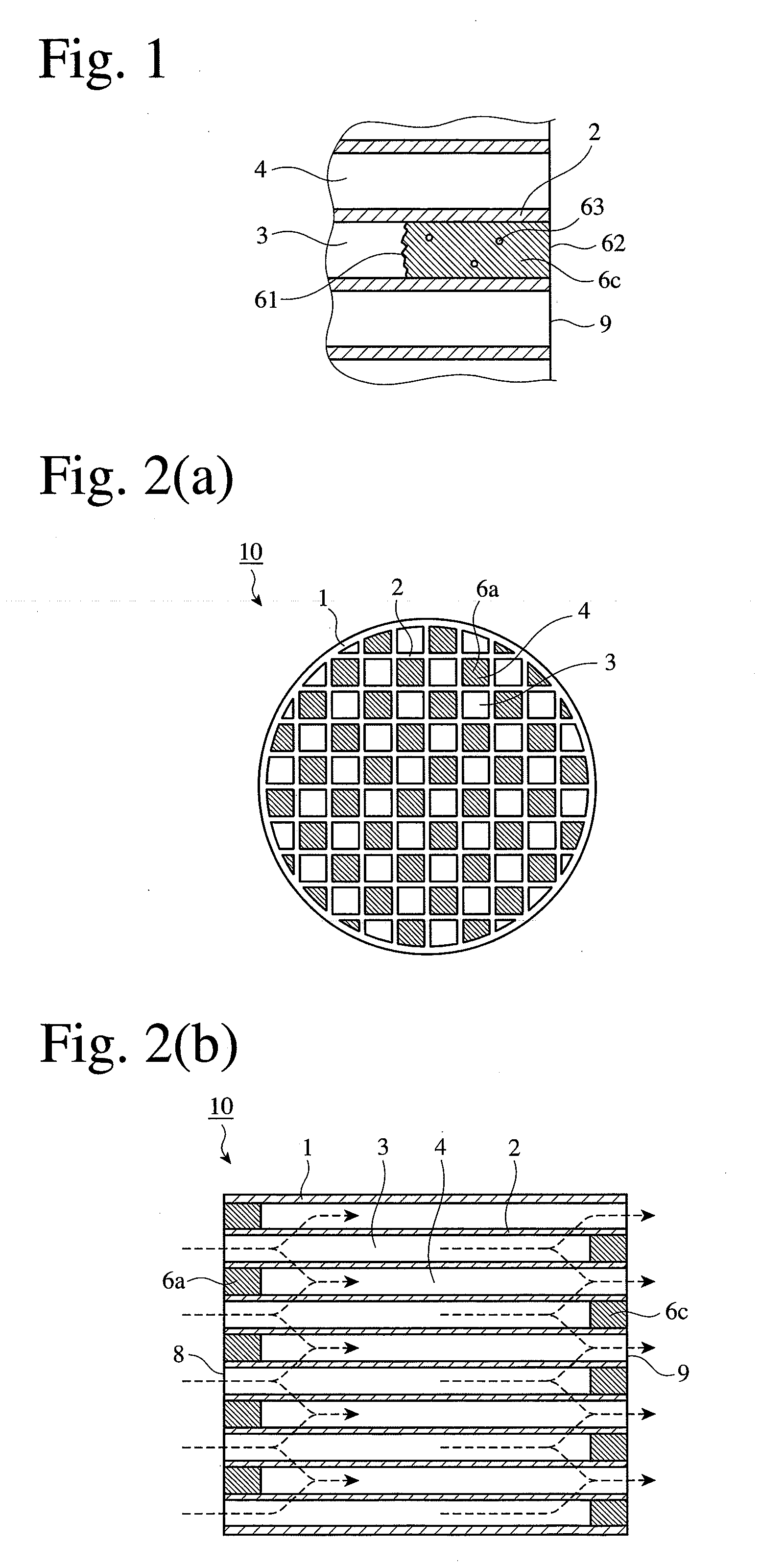

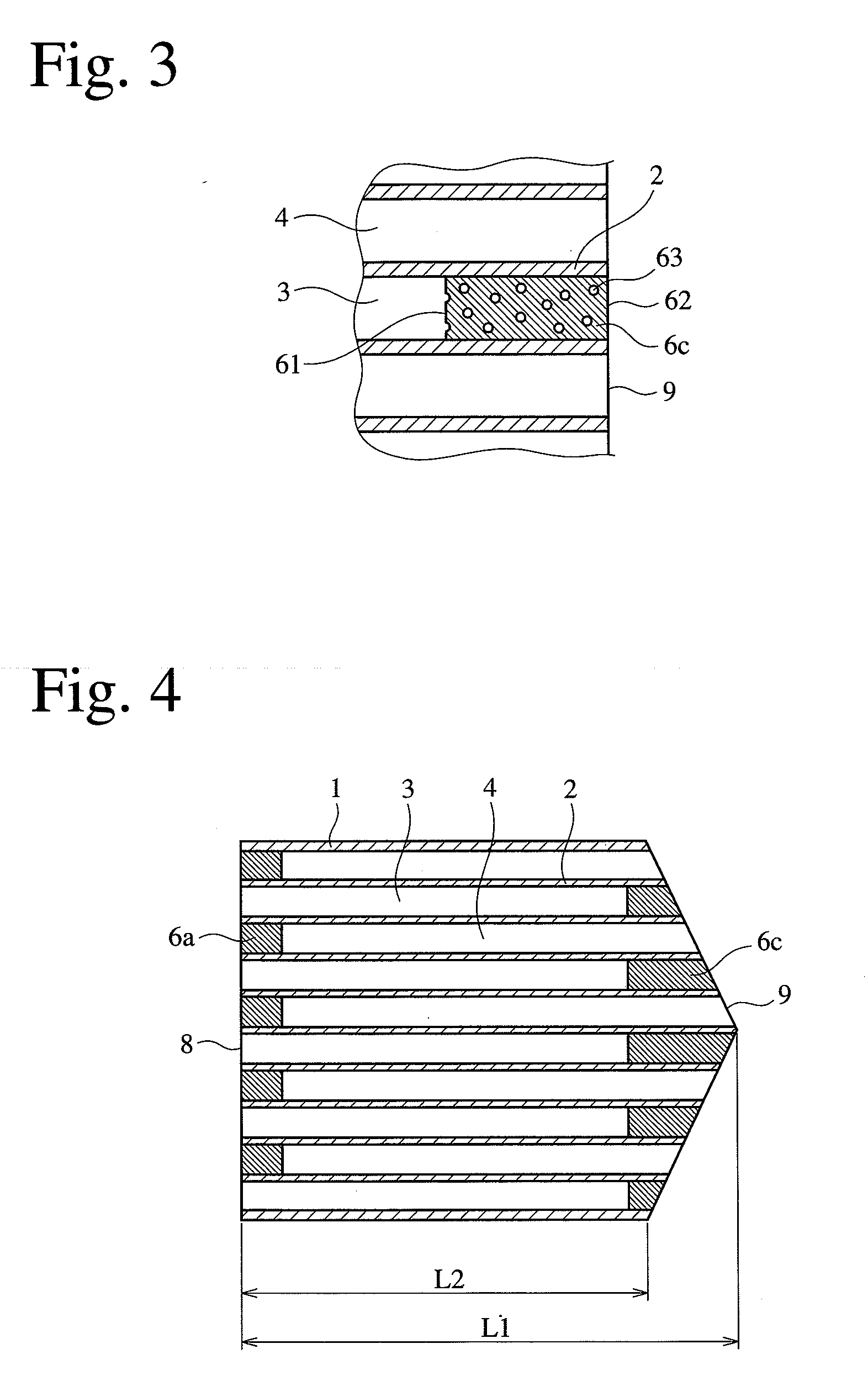

Even when compression stress is generated because a volume of a thermal insulation layer 2 is expanded due to oxidized by oxygen in the air, occurrence of cracks and fractures of the thermal insulation layer and a heating conductor 3 caused by the cracks are prevented by dispersing the compression stress. A pressure wave generator comprises a substrate 1, the thermal insulation layer 2 of porous material which is formed on a surface of the substrate 1 in thickness direction, and the heating conductor 3 of thin film formed on the thermal insulation layer 2, and generates pressure waves by heat exchange between the heating conductor 3 and a medium. When a thickness at the center of the thermal insulation layer 2 in width direction W is used as a reference thickness, and it is assumed that distribution of thickness of thermal insulation layer in the width direction is averaged with the reference thickness, porosity in an outer peripheral portion of the thermal insulation layer is made smaller than porosity in the center portion. By making the porosity in the outer peripheral portion of the thermal insulation layer 2 smaller, a number of immovable points on the outer periphery of the thermal insulation layer 2 restricted by the substrate 1 is increased and the positions of them are dispersed, so that the compression stress compressed in the outer peripheral portion of the thermal insulation layer 2 can be dispersed.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Lithium ion conductive solid electrolyte and method for producing the same

InactiveUS8431287B2Easy to getLow moisture permeabilityNon-metal conductorsActive material electrodesLithiumPorosity

In a solid electrolyte obtained by sintering a powder, high ionic conductivity and remarkably low moisture permeation applicable to a lithium ion secondary battery or a lithium primary battery are realized. A method for producing a solid electrolyte including the steps of preparing a green sheet containing a lithium ion conductive inorganic material powder; and firing the green sheet, wherein in the step of firing the green sheet, at least one surface of the green sheet is covered by a setter having a porosity of not more than 10% by volume, is disclosed.

Owner:OHARA

Method for the production of a sandwich component having a honeycomb core and the sandwich component obtained in this way

InactiveUS20090252921A1Improve adhesionEnhance layeringLamination ancillary operationsSynthetic resin layered productsShell moldingAdhesive

The invention relates to a method for the production of a fiber reinforced sandwich component (10) having a honeycomb core (12), the honeycombs of which are closed on both sides. The honeycomb core is closed at least on one side by a cover layer (14) made of fiber material, which is embedded in matrix material. The method comprises the following steps: —Producing a fabric comprising the honeycomb core and at least on one side of the honeycomb core, disposed from the inside to the outside, a curable adhesive layer (20), a barrier layer (16) and a fiber layer (14); —Locking the fabric on a one-sided molding tool (30) in a gastight chamber, which is formed up by a vacuum foil (48) on the one-sided molding tool; —Creating a vacuum in this gastight chamber, —After creating the vacuum, hardening or partial hardening of the adhesive layer between the honeycomb core and barrier layer in this vacuum such that the honeycomb cells (18) are evacuated at least partially before they are closed off by the barrier layer; —After hardening or partially hardening of the adhesive layer, infusion of the fiber layer in a vacuum with a matrix material; and —Hardening of the matrix material in a vacuum.

Owner:EURO COMPOSITES

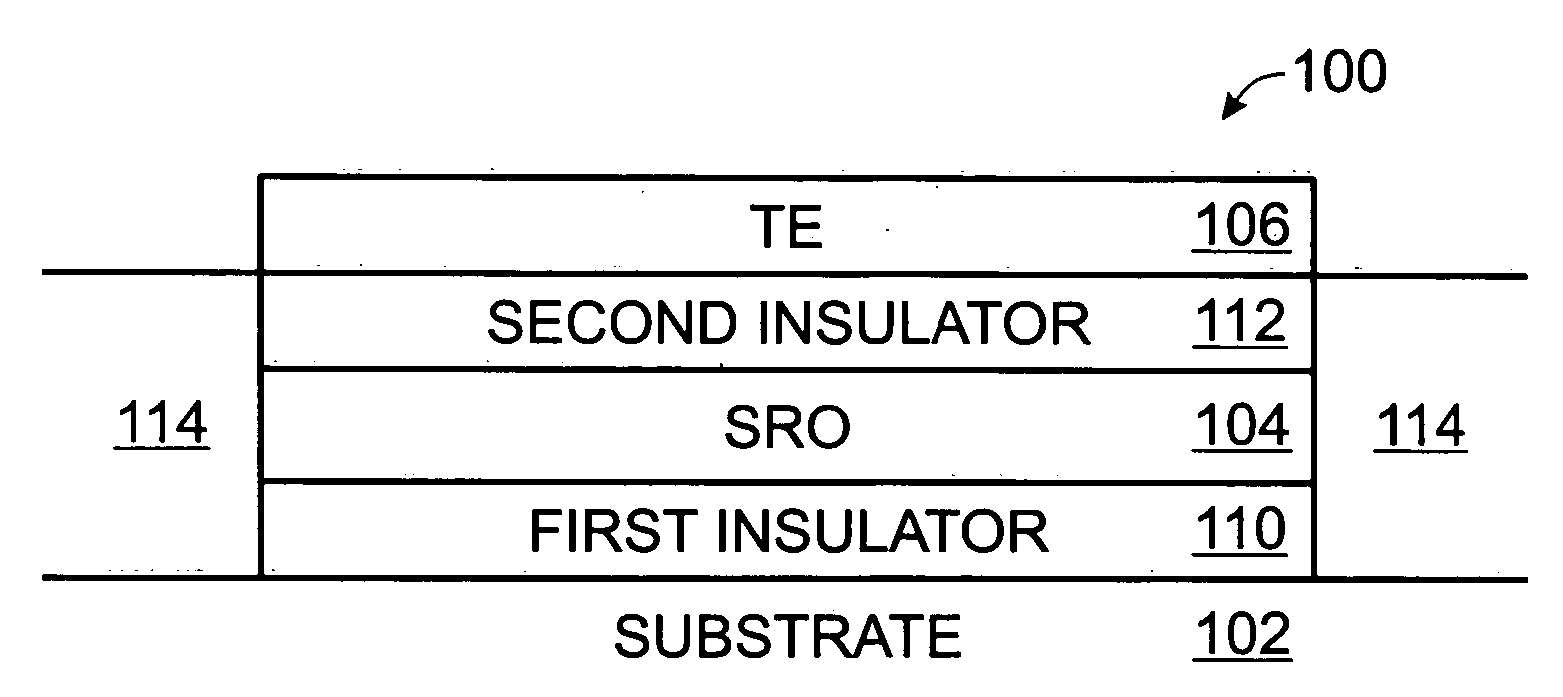

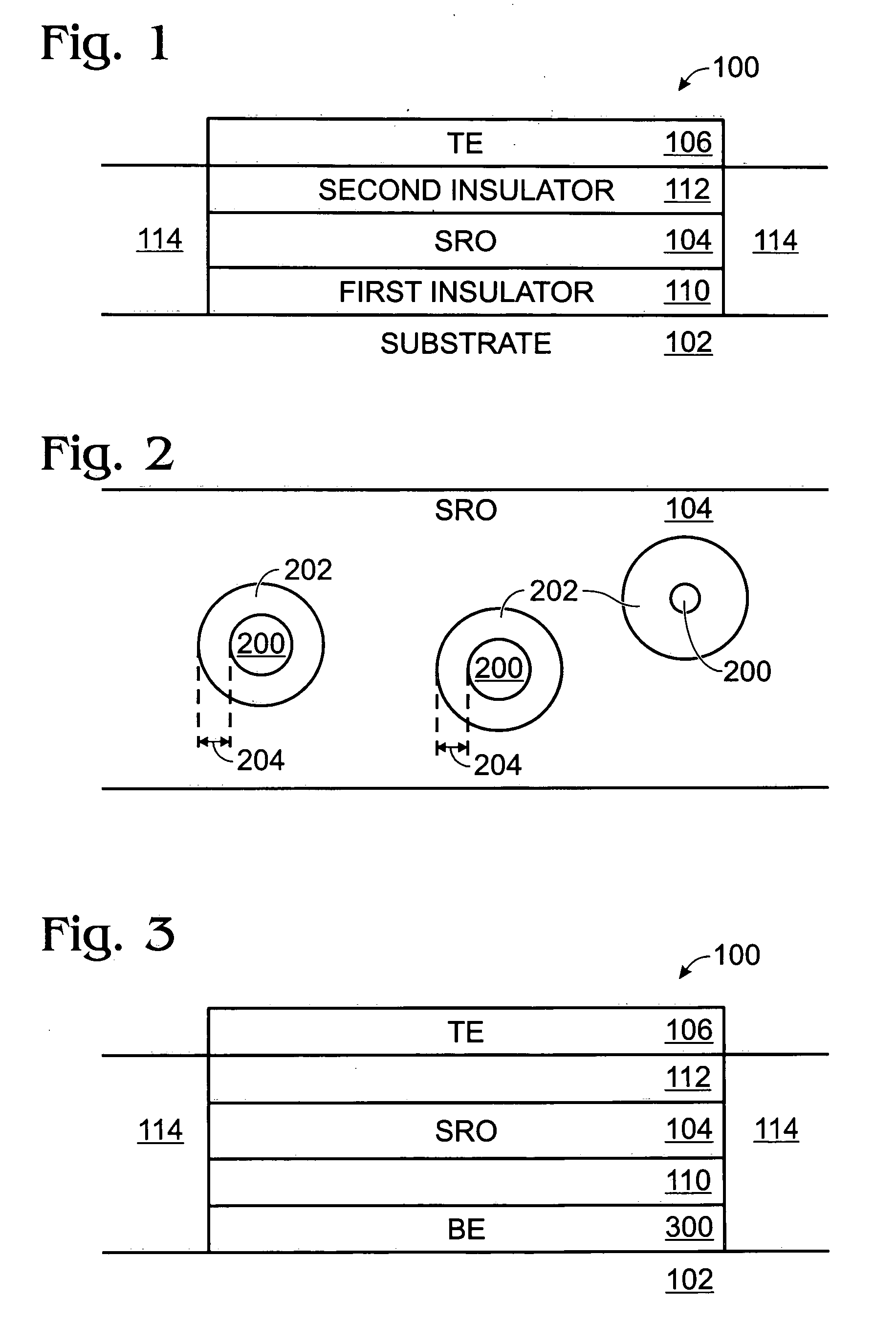

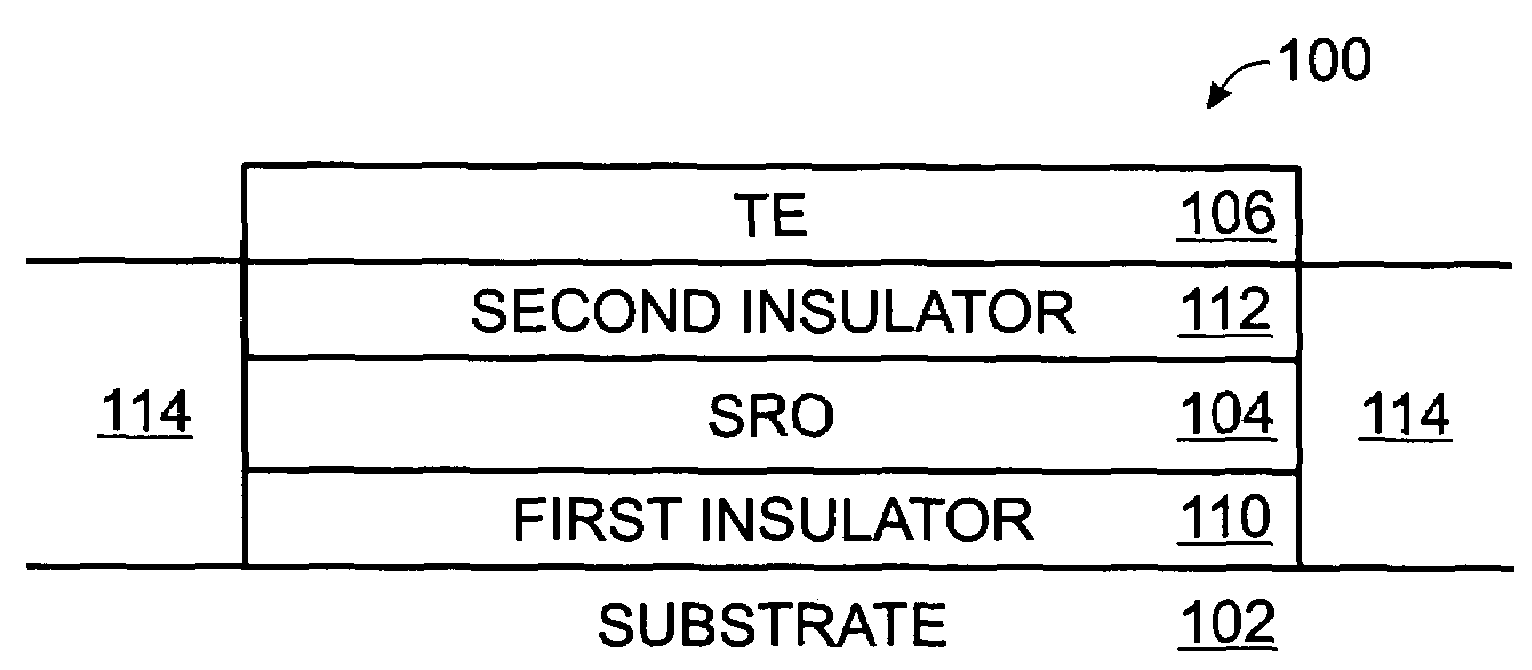

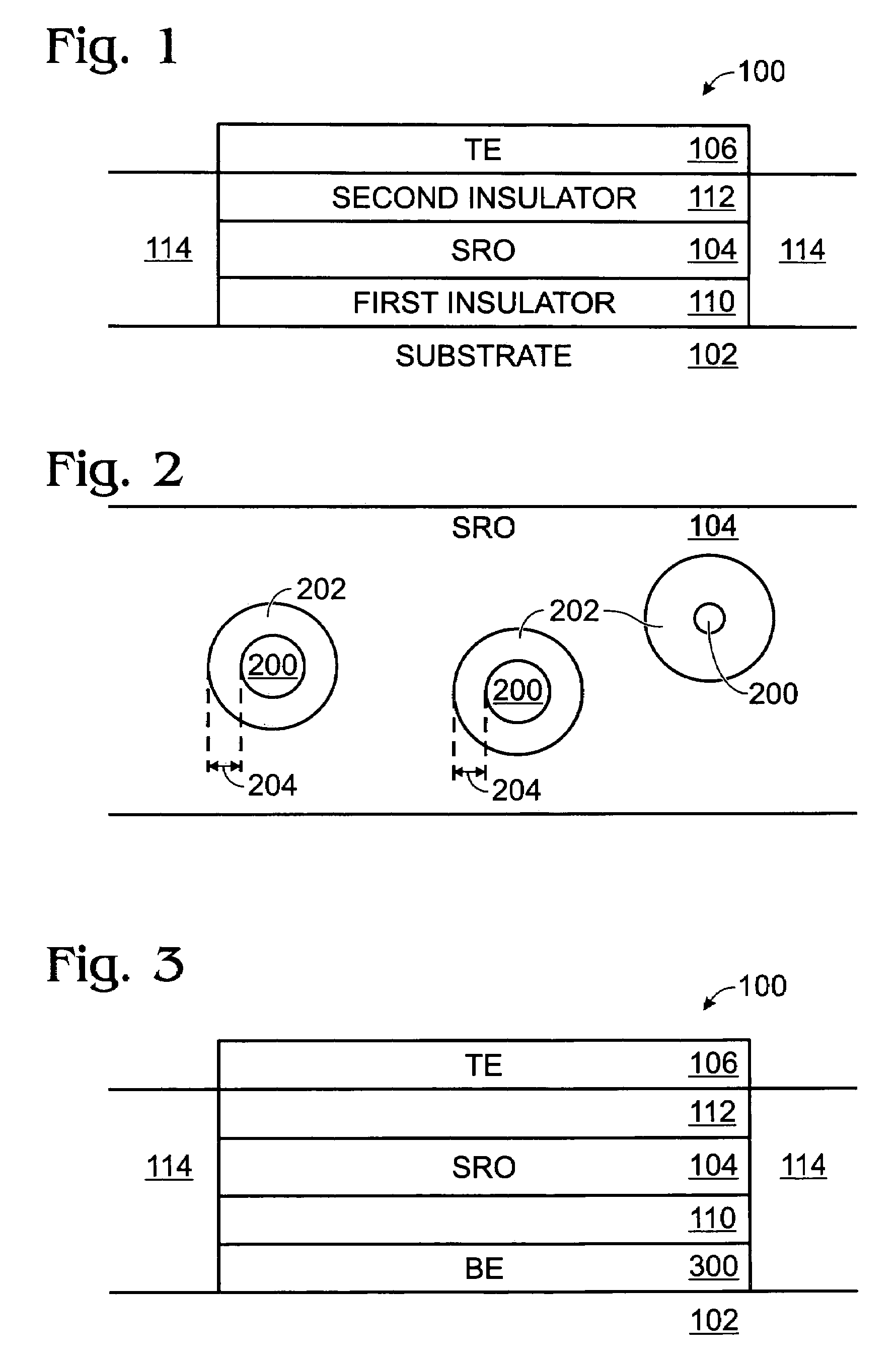

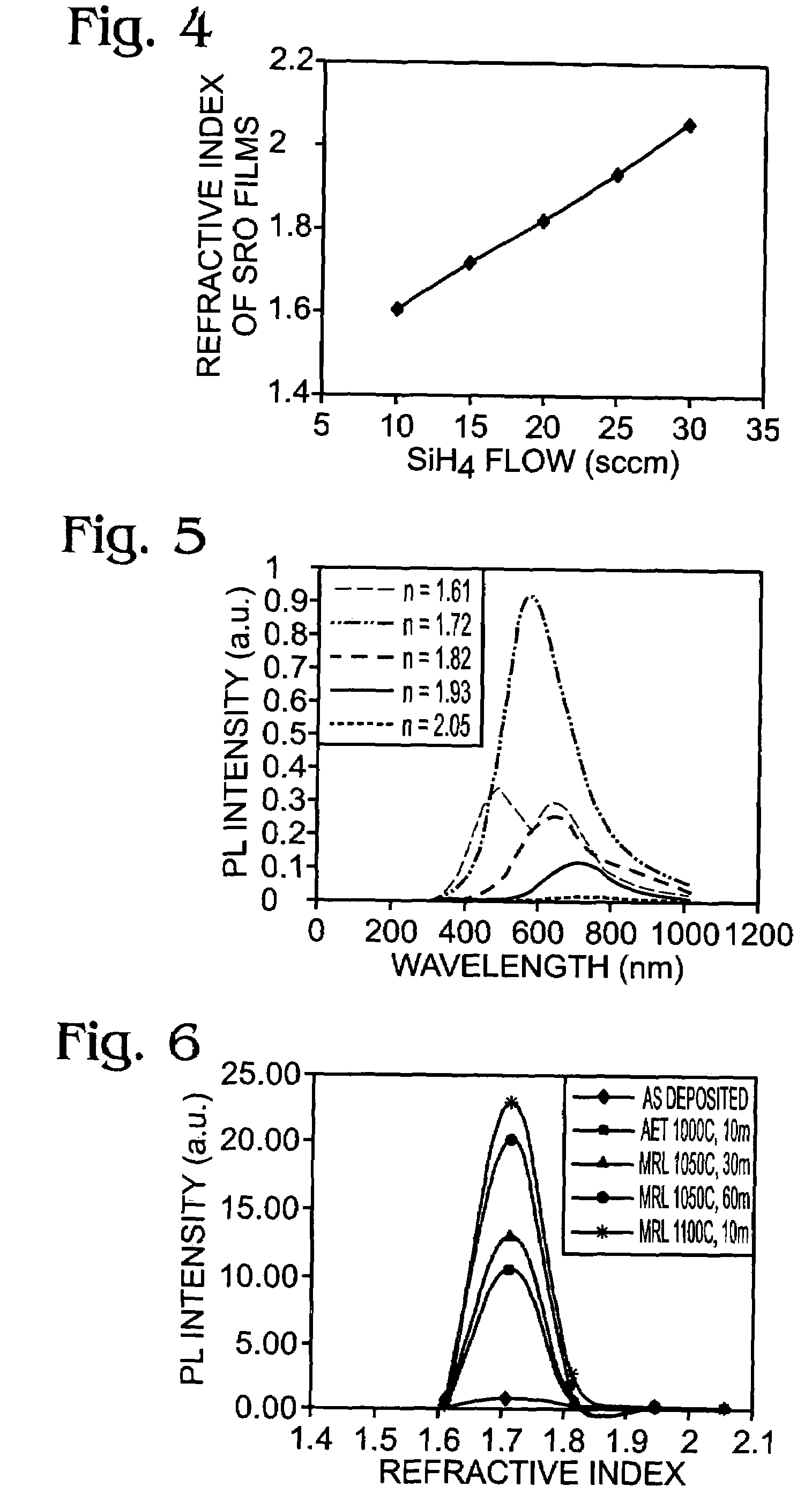

High-luminescence silicon electroluminescence device

InactiveUS20060189014A1Enhance homogeneous oxidation of nano-SiFacilitated DiffusionFinal product manufactureSemiconductor/solid-state device detailsPorosityRefractive index

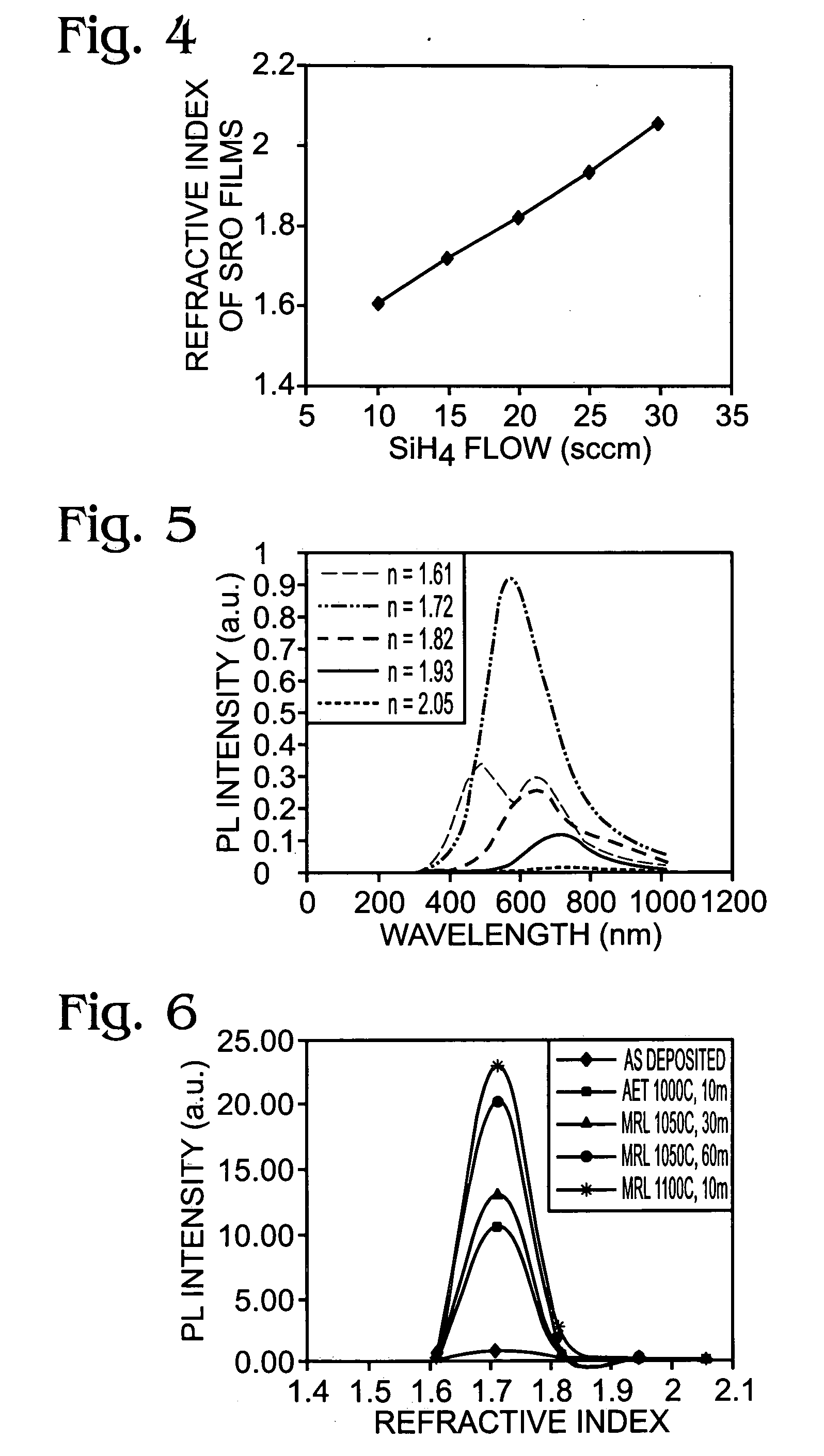

A method for forming a high-luminescence Si electroluminescence (EL) phosphor is provided, with an EL device made from the Si phosphor. The method comprises: depositing a silicon-rich oxide (SRO) film, with Si nanocrystals, having a refractive index in the range of 1.5 to 2.1, and a porosity in the range of 5 to 20%; and, post-annealing the SRO film in an oxygen atmosphere. DC-sputtering or PECVD processes can be used to deposit the SRO film. In one aspect the method further comprises: HF buffered oxide etching (BOE) the SRO film; and, re-oxidizing the SRO film, to form a SiO2 layer around the Si nanocrystals in the SRO film. In one aspect, the SRO film is re-oxidized by annealing in an oxygen atmosphere. In this manner, a layer of SiO2 is formed around the Si nanocrystals having a thickness in the range of 1 to 5 nanometers (nm).

Owner:SHARP KK

Lithium ion conductive solid electrolyte and method for producing the same

In a solid electrolyte obtained by sintering a powder, high ionic conductivity and remarkably low moisture permeation applicable to a lithium ion secondary battery or a lithium primary battery are realized. A method for producing a solid electrolyte including the steps of preparing a green sheet containing a lithium ion conductive inorganic material powder; and firing the green sheet, wherein in the step of firing the green sheet, at least one surface of the green sheet is covered by a setter having a porosity of not more than 10% by volume, is disclosed.

Owner:OHARA

Ceramic honeycomb filter and its production method

ActiveUS20100058725A1Effective absorptionReduce erosionDispersed particle filtrationExhaust apparatusPorositySurface roughness

A ceramic honeycomb filter comprising a honeycomb structure having large numbers of flow paths partitioned by porous cell walls, and plugs alternately formed in the flow paths on the exhaust-gas-inlet and outlet sides, the outlet-side plugs having porosity of 65% or less, and the upstream-side end surfaces of the outlet-side plugs having surface roughness Ra of 13-50 μm.

Owner:HITACHI METALS LTD

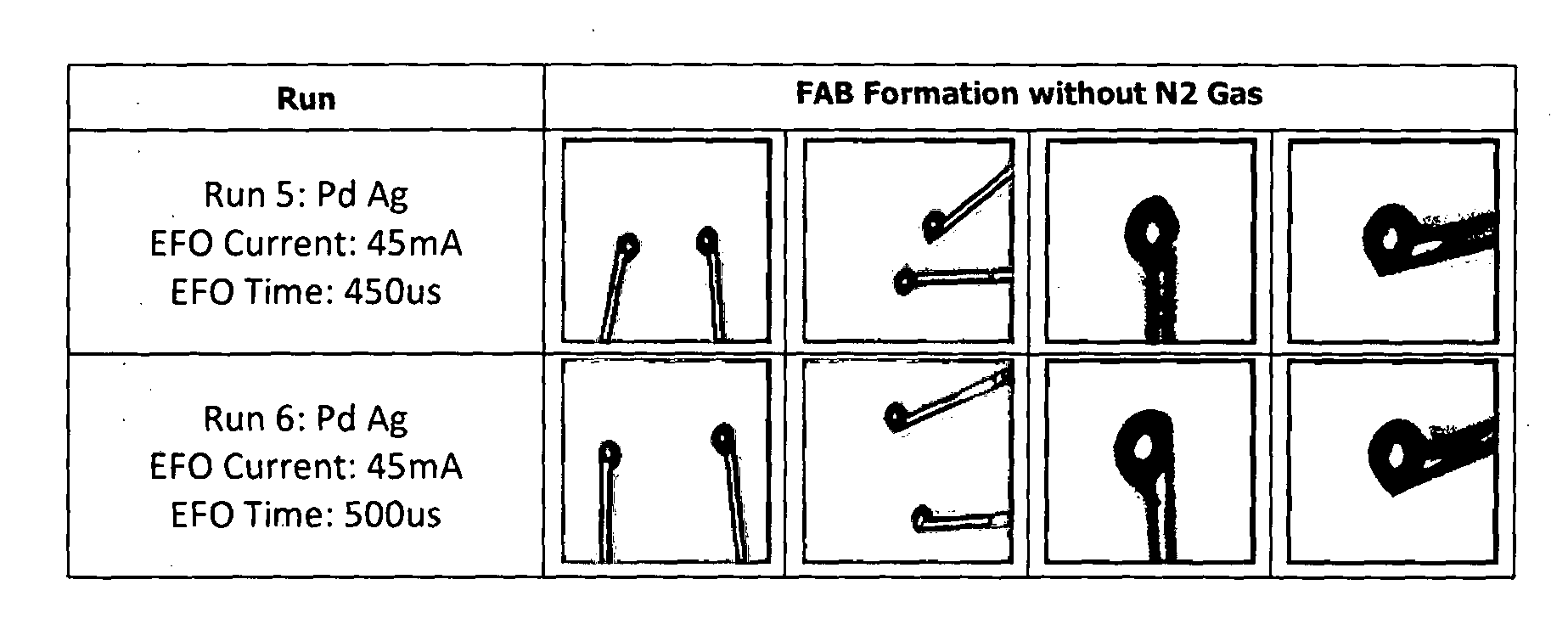

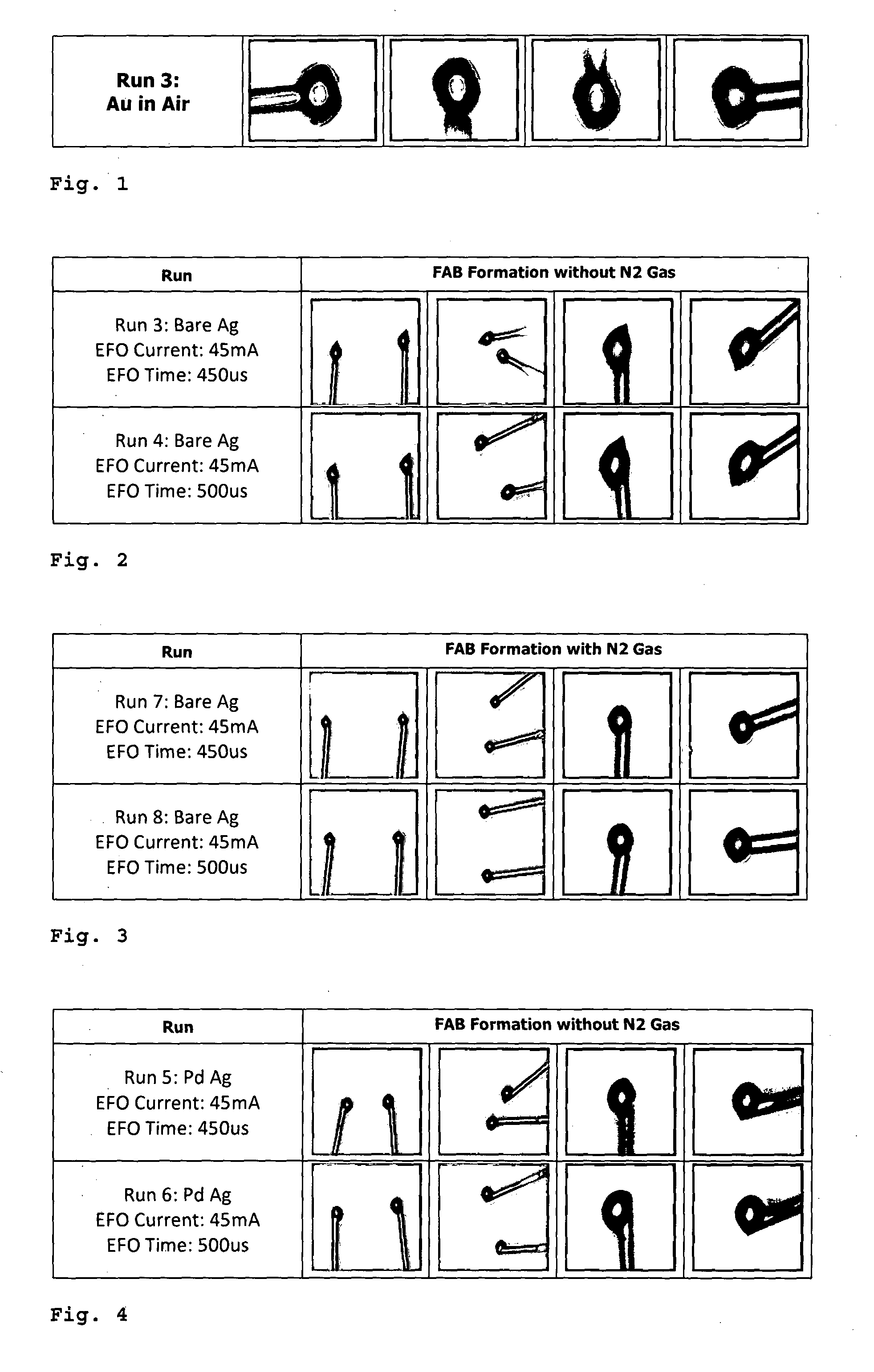

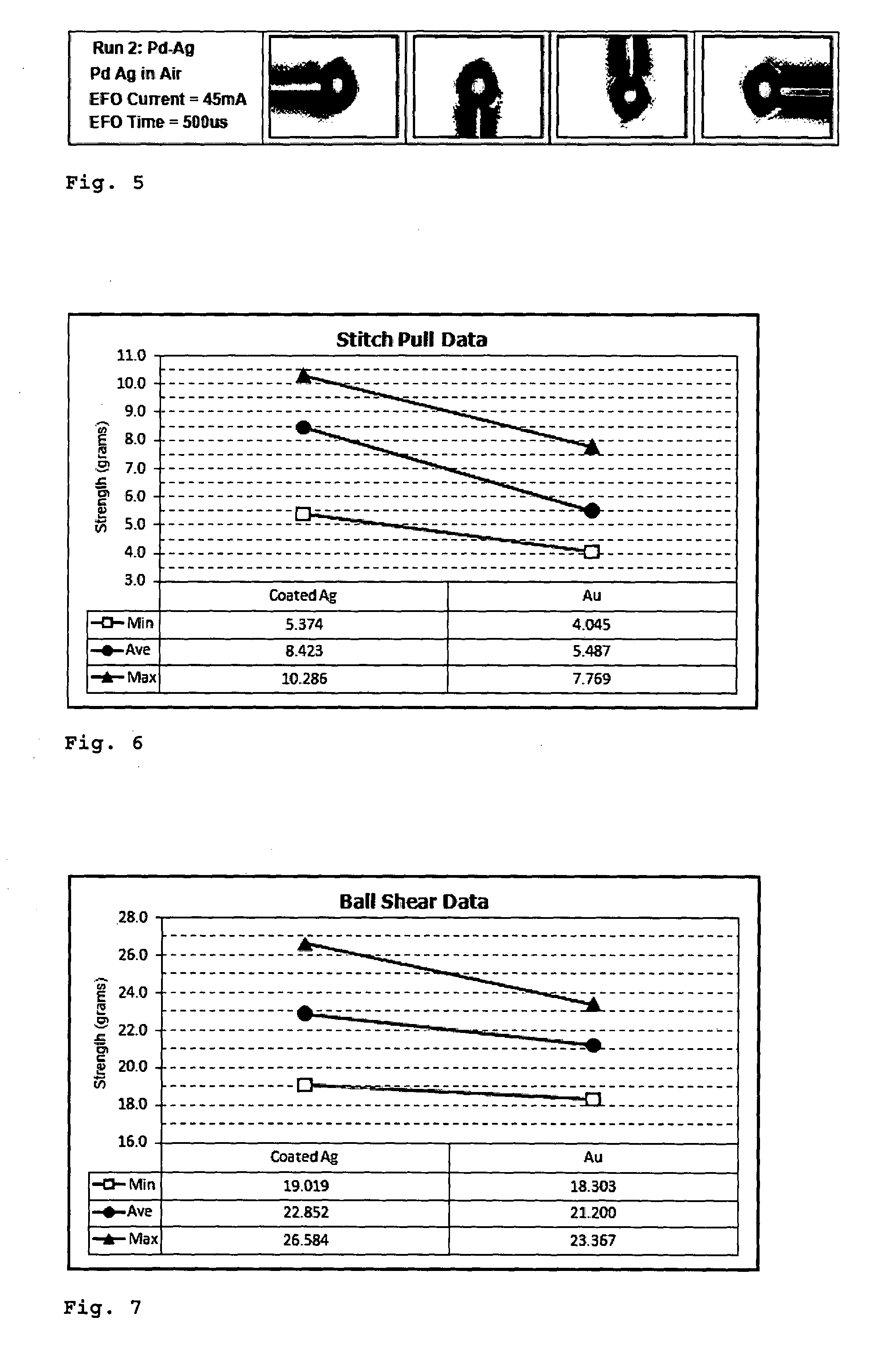

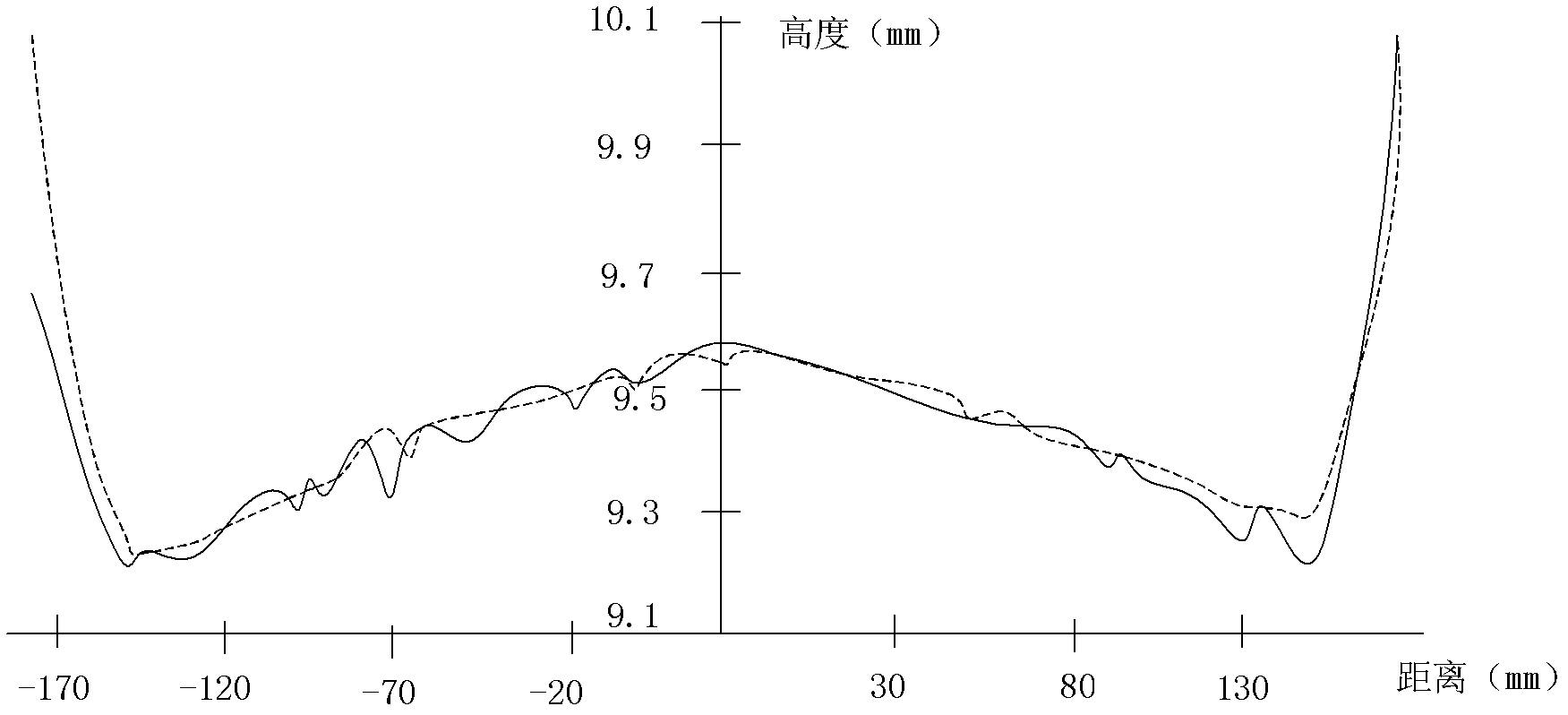

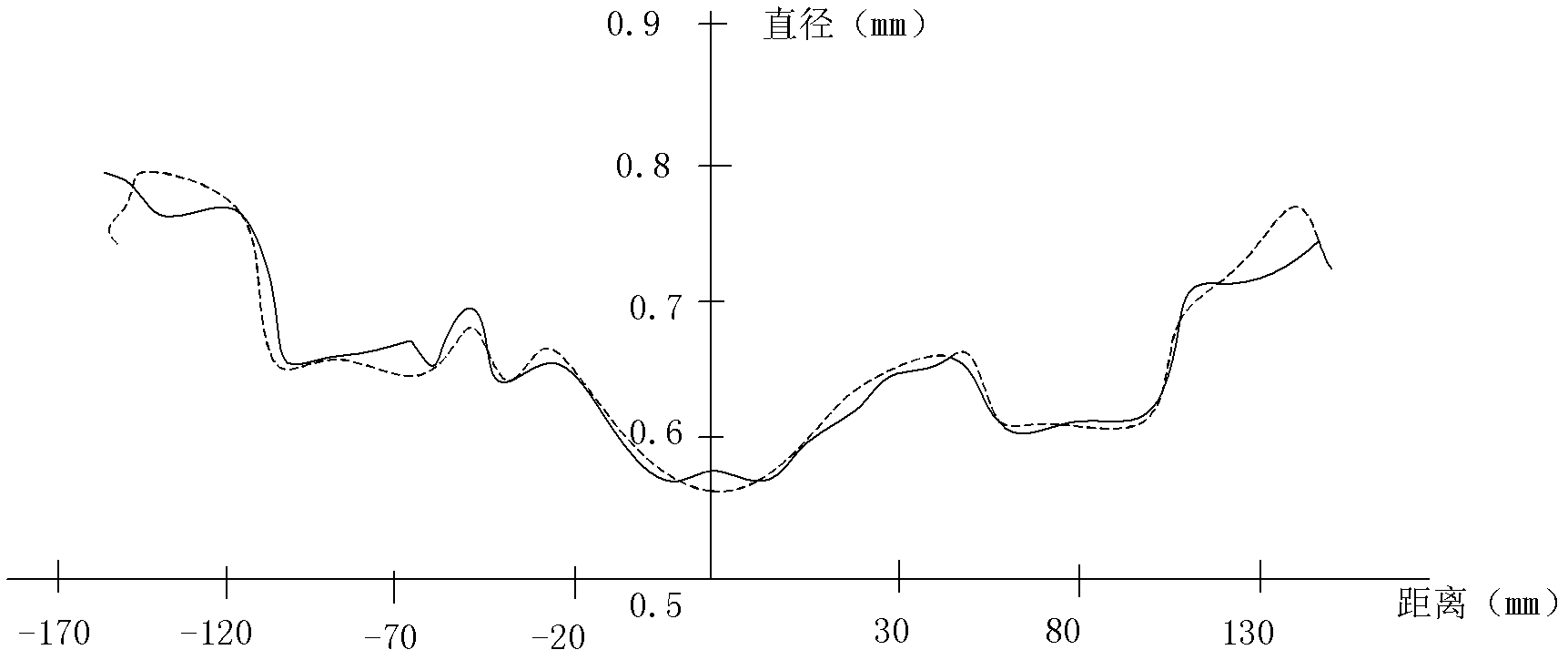

Bonding wire and process for manufacturing a bonding wire

InactiveUS20150322586A1Improve consistencyAvoid large deviationMolten spray coatingSingle bars/rods/wires/strips conductorsIridiumPlatinum

A bonding wire comprises a core wire generally made of silver or a silver alloy, and the coating material is selected from one or more of: gold, palladium, platinum, rhodium. Alternatively, the core wire is generally made of copper or a copper alloy, and the coating material is selected from one or more of: palladium, platinum, rhodium, iridium, ruthenium. For both core wires, the coating material can be selected from a group of materials with the following characteristics: (1) the materials' melting temperature is higher than the melting temperature of the core wire material, respectively; (2) the materials' molten surface tension is higher than that of the core wire material, respectively; (3) the materials show a high resistance to oxide formation between the melting temperature of the core wire material and the melting temperature of the respective material itself; and (4) the coating material has the additional characteristic that the material's melting temperature is lower than the boiling temperature of the core wire material.

Owner:MICROBONDS INC

Method of forming high-luminescence silicon electroluminescence device

InactiveUS7259055B2Enhance homogeneous oxidation of nano-SiFacilitated DiffusionFinal product manufactureSemiconductor/solid-state device detailsPorosityRefractive index

A method for forming a high-luminescence Si electroluminescence (EL) phosphor is provided, with an EL device made from the Si phosphor. The method comprises: depositing a silicon-rich oxide (SRO) film, with Si nanocrystals, having a refractive index in the range of 1.5 to 2.1, and a porosity in the range of 5 to 20%; and, post-annealing the SRO film in an oxygen atmosphere. DC-sputtering or PECVD processes can be used to deposit the SRO film. In one aspect the method further comprises: HF buffered oxide etching (BOE) the SRO film; and, re-oxidizing the SRO film, to form a SiO2 layer around the Si nanocrystals in the SRO film. In one aspect, the SRO film is re-oxidized by annealing in an oxygen atmosphere. In this manner, a layer of SiO2 is formed around the Si nanocrystals having a thickness in the range of 1 to 5 nanometers (nm).

Owner:SHARP KK

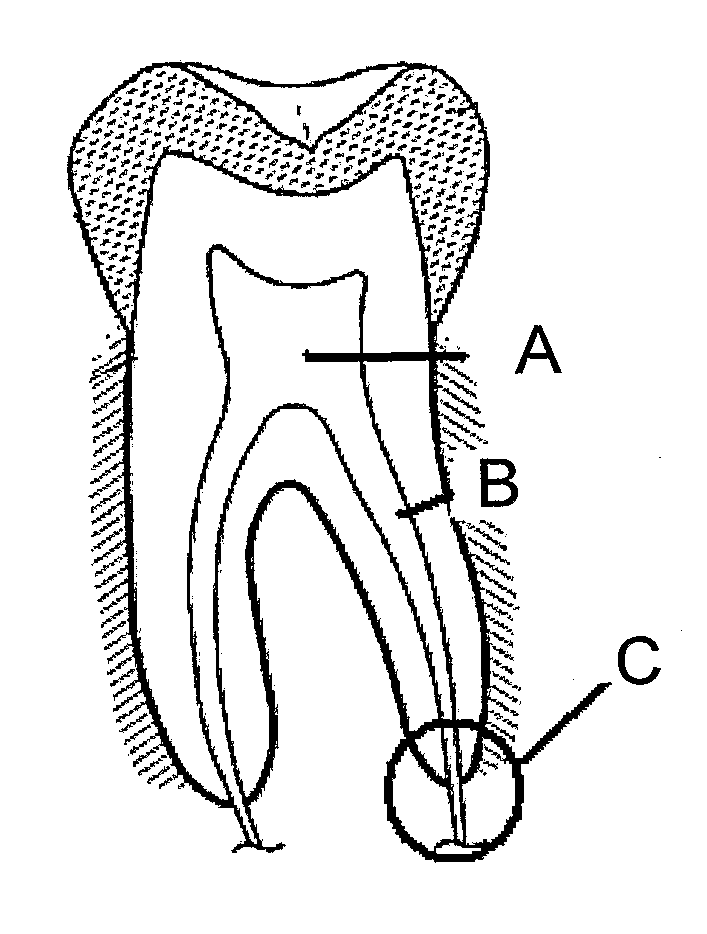

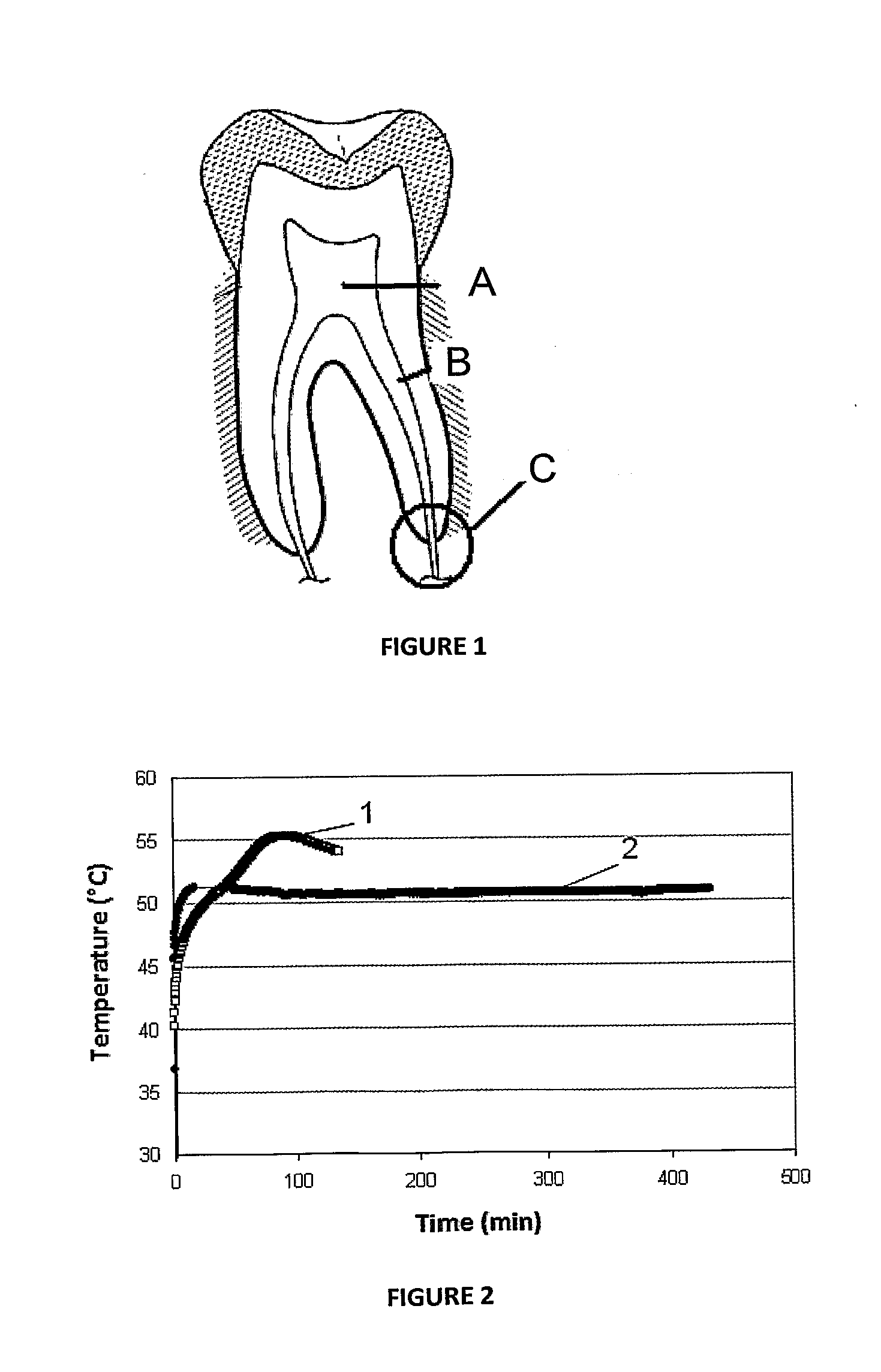

Aluminous cement-based composition for application in endodontics and cementitious product obtained thereof

InactiveUS20110281241A1Improve rheologyImprove workabilityCosmetic preparationsImpression capsRadiopaque agentPlasticizer

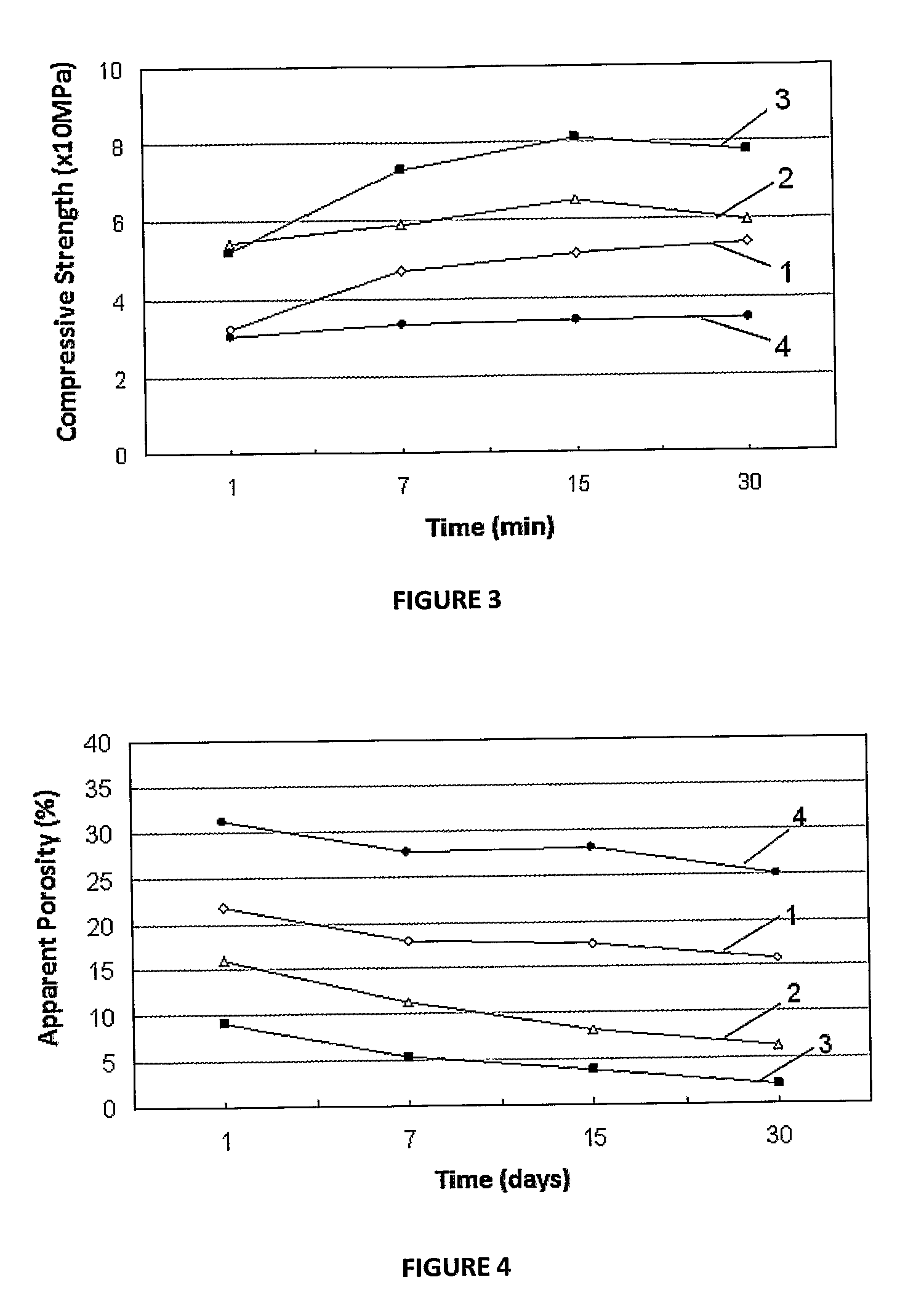

The present invention provides a composition based on calcium aluminate cement (CAC) for application in endodontics, comprising: (a) a cement—Al2O3 (>68.5 wt %), CaO (<31 wt %), SiO2 (0.3-0.8 wt %), MgO (0.4-0.5 wt %), and Fe2O3 (<0.3 wt %); (b) additives: dispersant at a content of 0.4 to 0.8% by weight of the cement, a plasticizer at a content of 2.0 to 4.0% by weight of the cement, and a radiopaque agent at a content of 20 to 35% by weight of the cement; and (c) water, wherein water / cement ratio lies in the range of 0.19-0.24 in the presence of additives. Cementitious product obtained thereof, after setting time, is also disclosed and characterized by enhanced properties when compared to the most used commercial repair cement, MTA.

Owner:UNIVE FEDERAL DE SAO CARLOS

Environment protection type efficient aerating powder for shield construction

ActiveCN101462844AHigh foaming ratioEasy to operateTransportation and packagingMixingFoaming agentSlag

The invention discloses an environmental protection high efficiency foaming agent for shield construction. The foaming agent comprises the following components in percentage by weight: 5 to 20 percent of aliphatic alcohol polyethenoxy ether sulfate, 1 to 8 percent of alcohol amide, 0.5 to 8 percent of alcohol ether, and 64 to 93.5 percent of water. The foaming agent for shield construction has a high foaming ratio and produces abundant and fine foams with even diameter distribution. The produced bubbles have small pores, good lubricity and stability, simple production operation, and lower cost. The foaming agent can better meet the requirements of the slag soil improvement during the process of earth pressure balanced shield.

Owner:GUANGZHOU AORUN SYNTHETIC MATERIAL

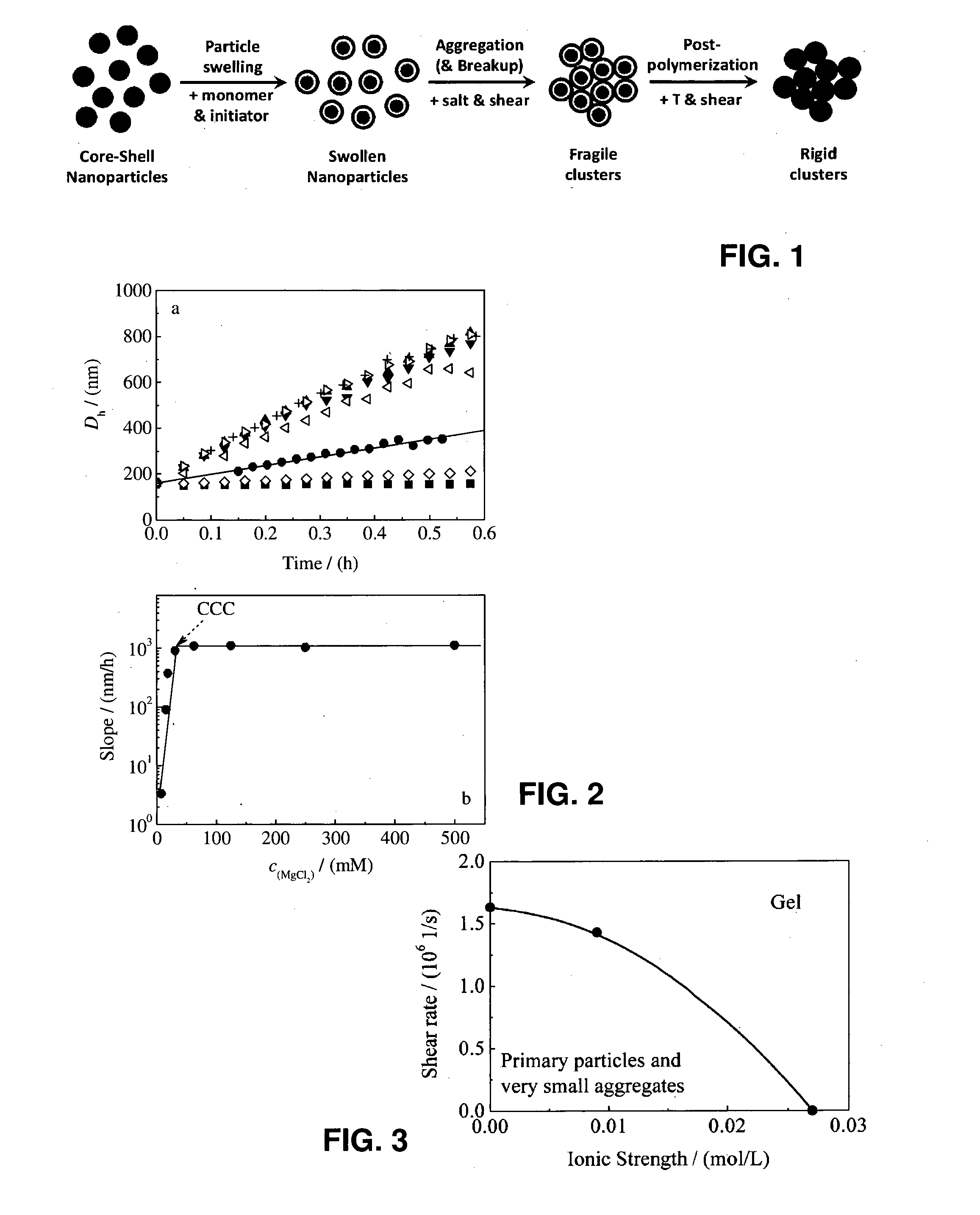

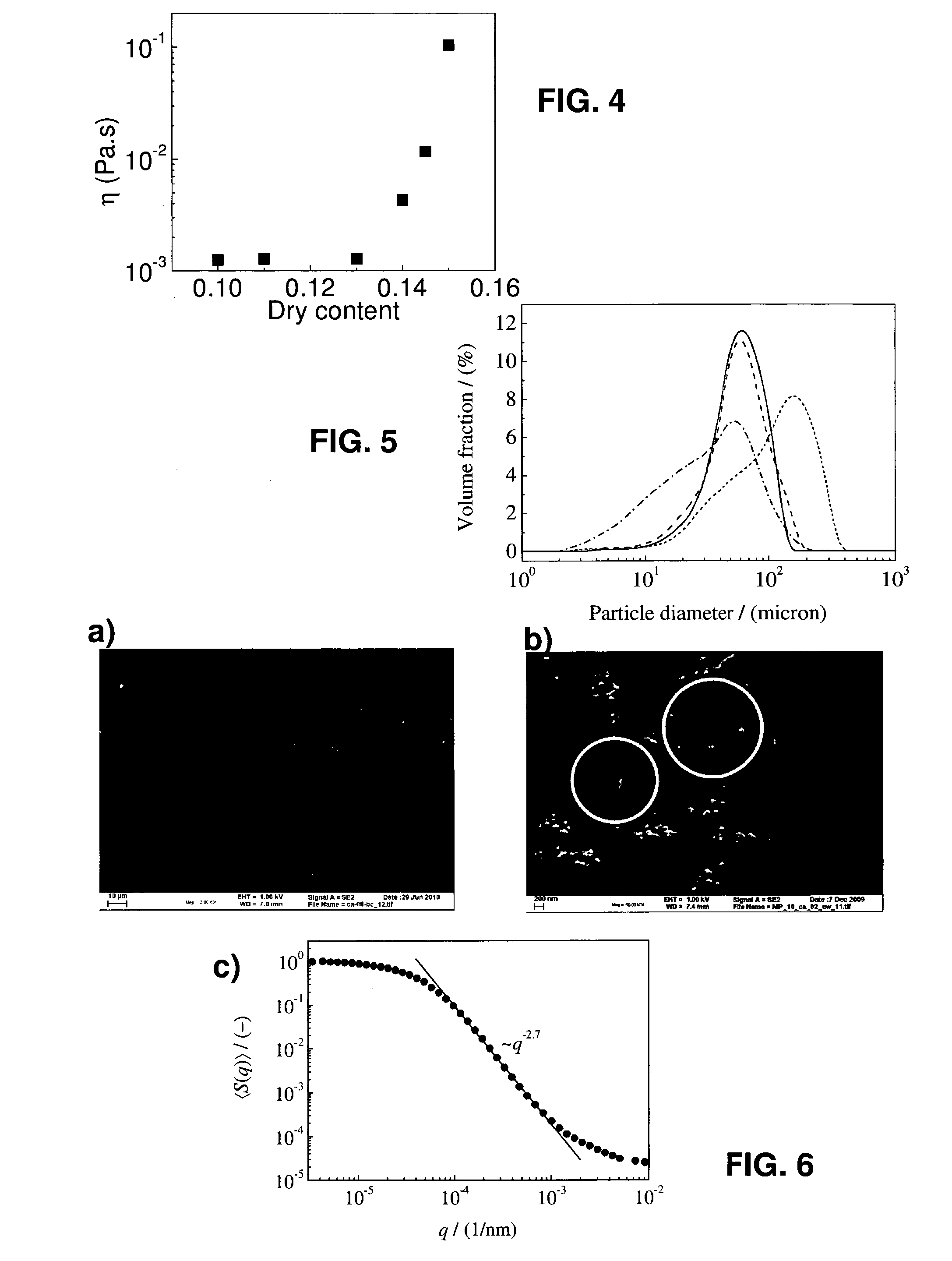

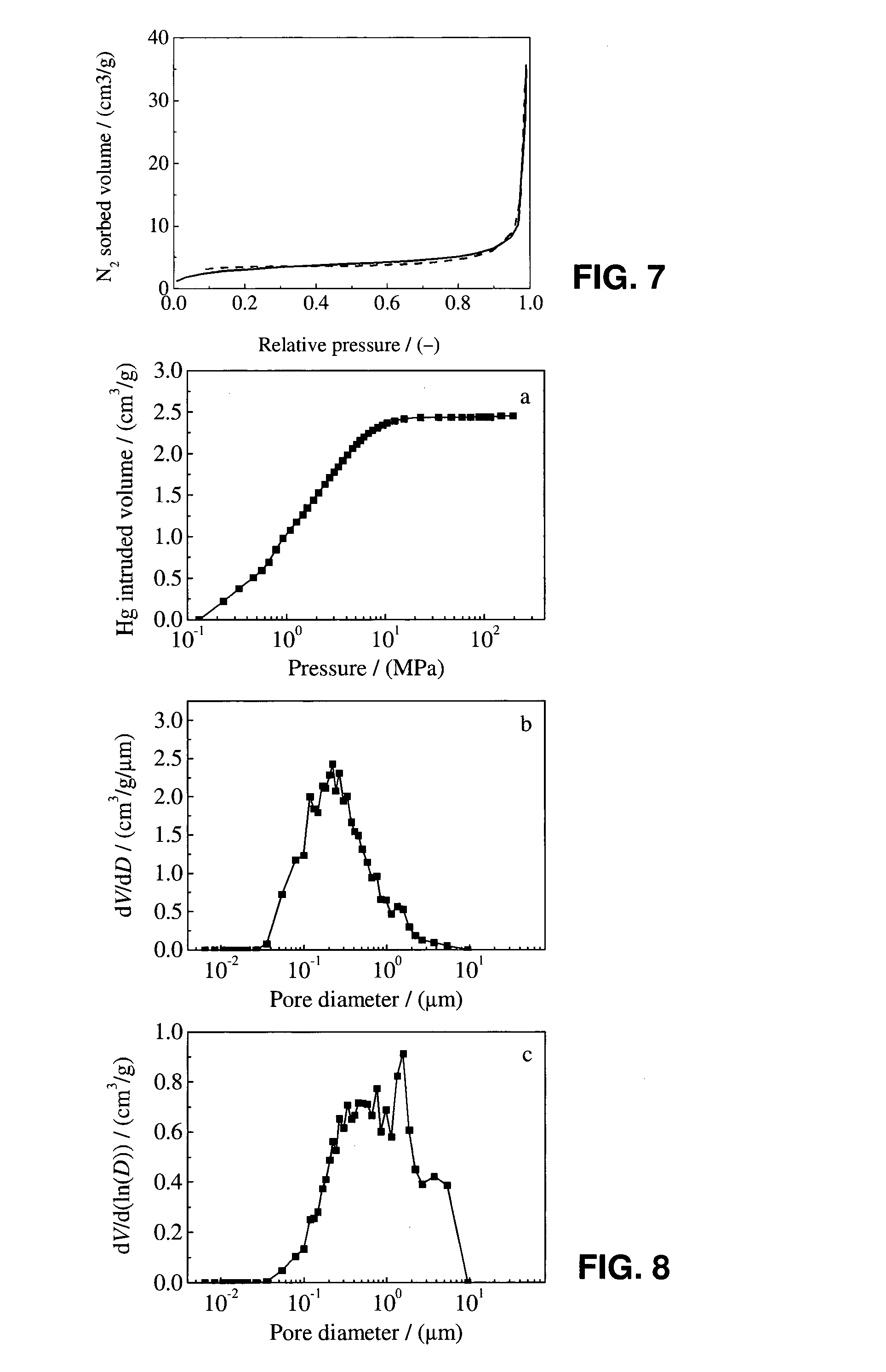

Method for the preparation of macroporous particles and macroporous microclusters

InactiveUS9938390B2Firmly connectedIncrease the number ofCation exchanger materialsOrganic anion exchangersOligomerCross linker

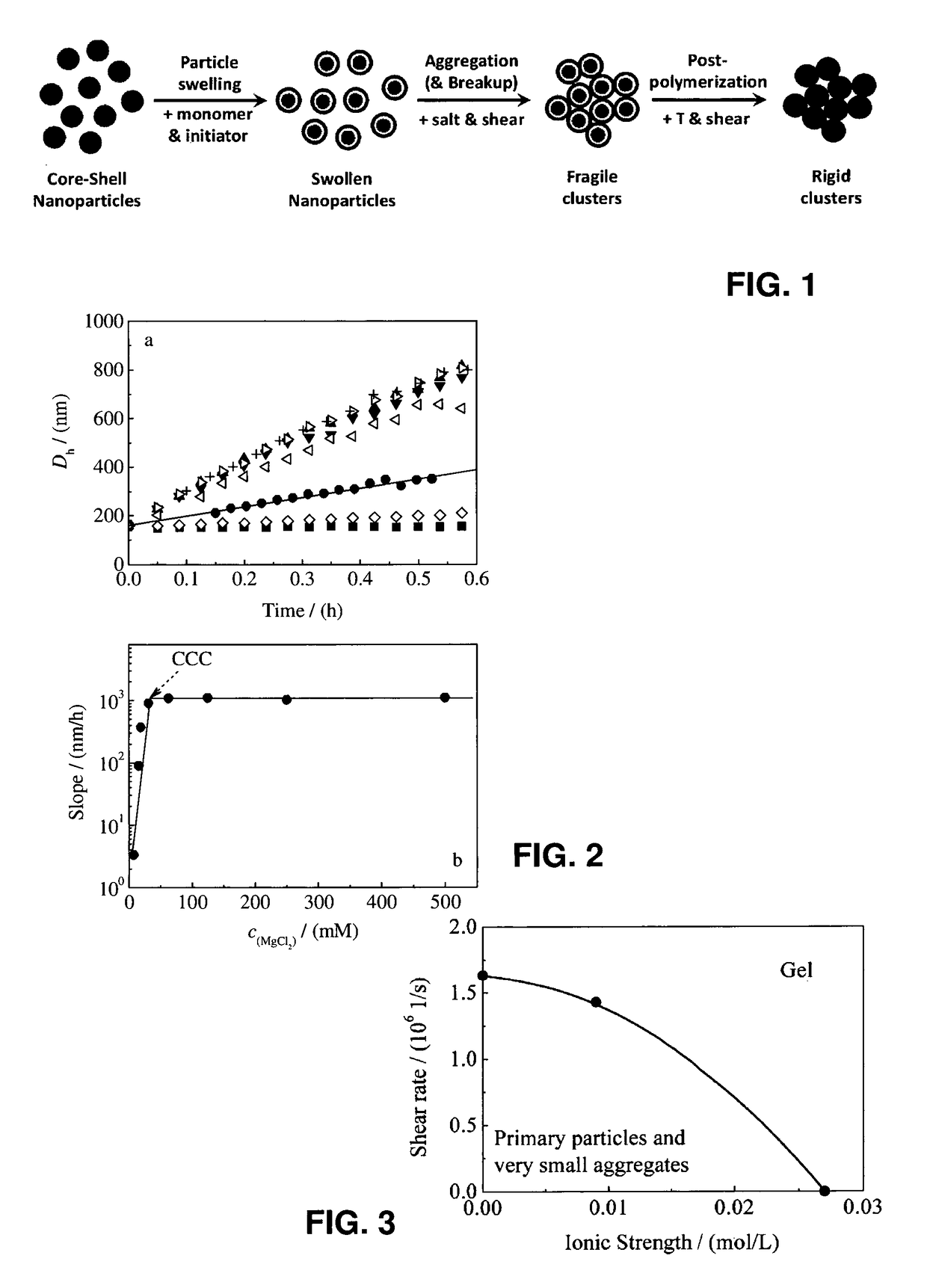

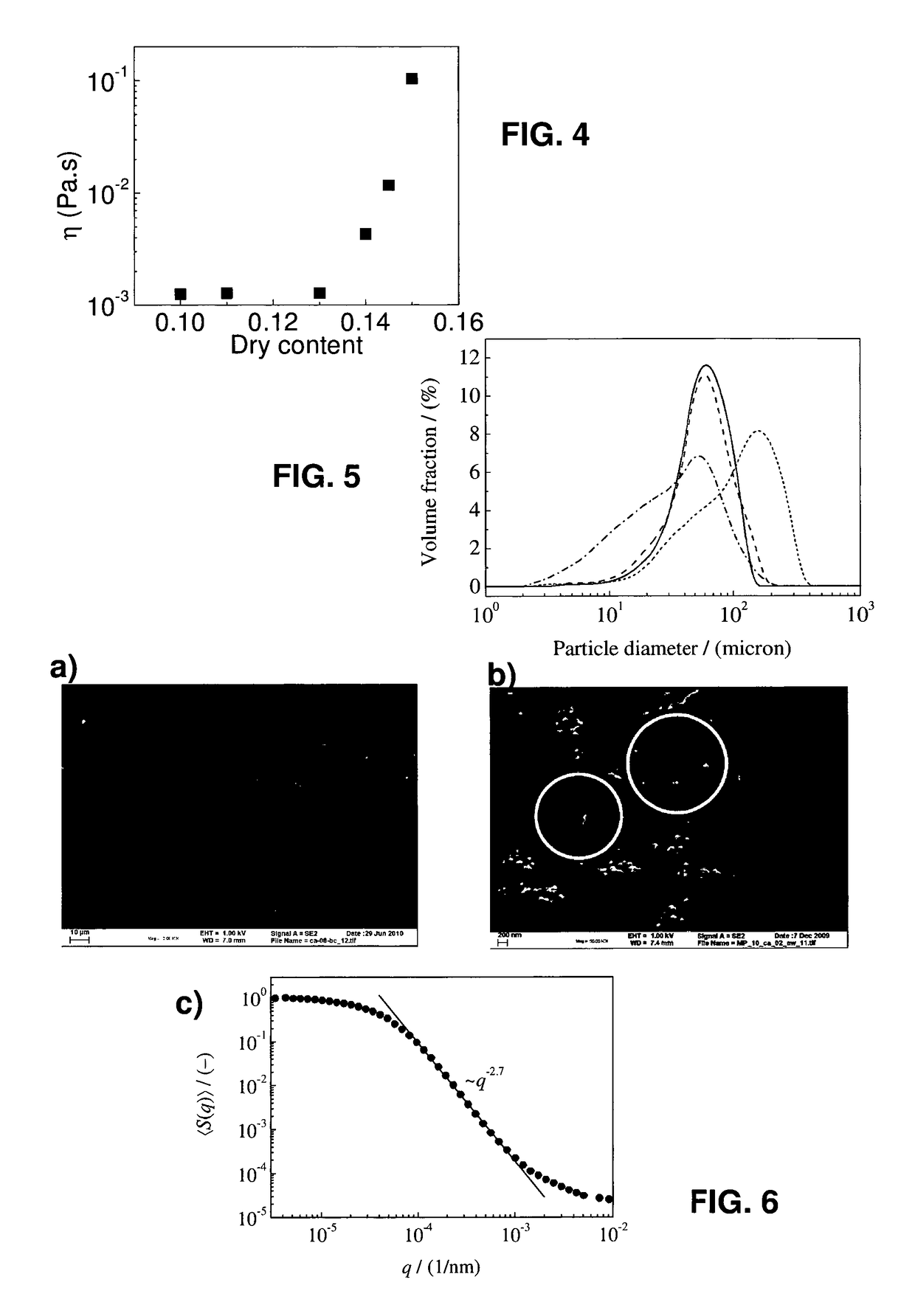

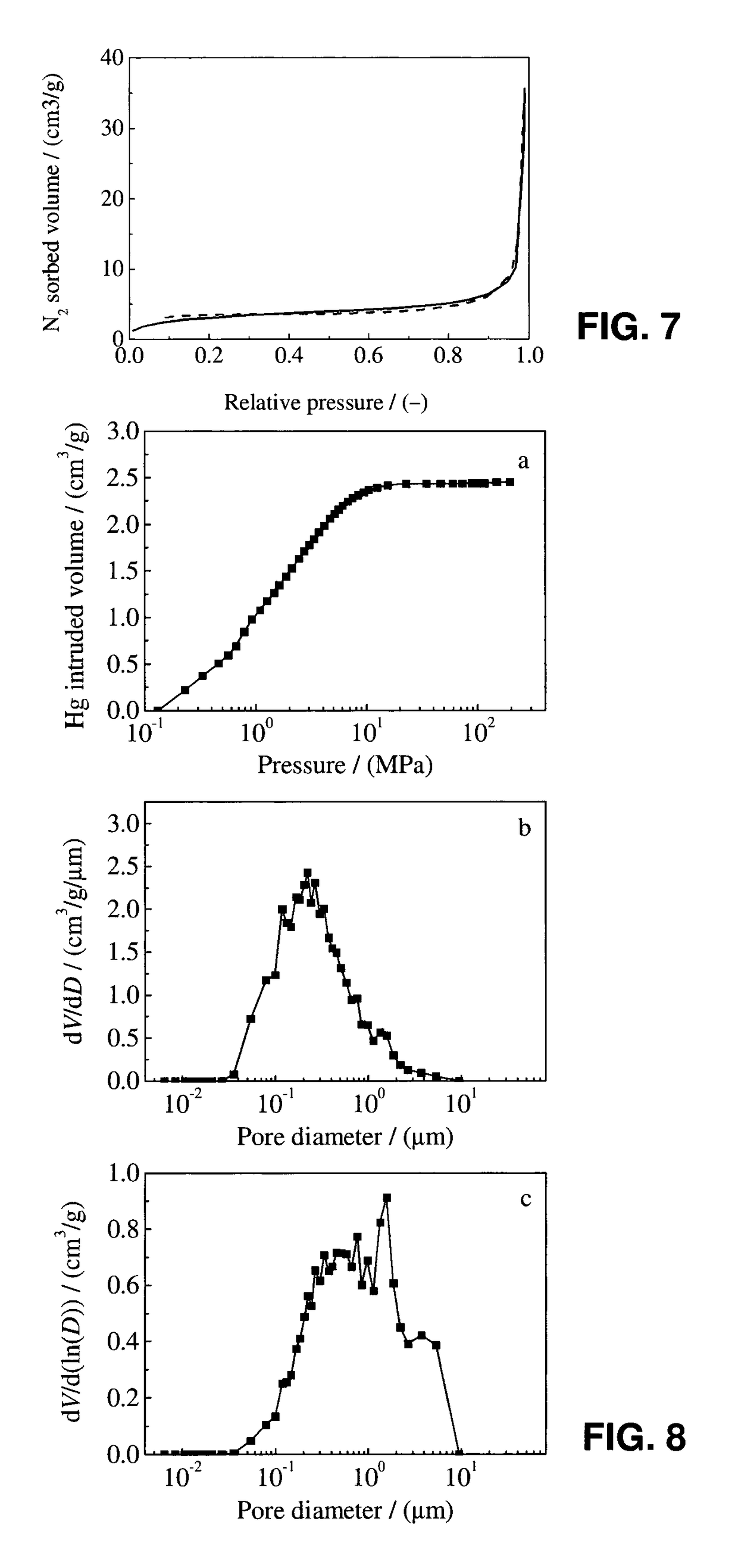

A method for producing macro porous micro-clusters is proposed comprising at least the following individual steps in given order: a) synthesis of dispersed cross-linked polymeric latex primary particles starting from at least one monomer or oligomer using emulsion polymerization; b) swelling of the primary particles with a liquid comprising at least an additional charge of monomer and / or oligomer and a cross-linker, optionally further comprising functionalization agents; c) destabilization by increase of ionic strength (by adding a salt and / or acid and / or base) in a combination with application of shear, both being above the gel formation boundary of the phase diagram, until agglomerates composed of primary particles of the desired size are formed; d) polymerization of the agglomerates to form the macro porous micro-clusters. Furthermore the invention to relates to correspondingly produced micro-clusters and uses of such micro-clusters in particular for chromatographic purposes.

Owner:ETH ZZURICH

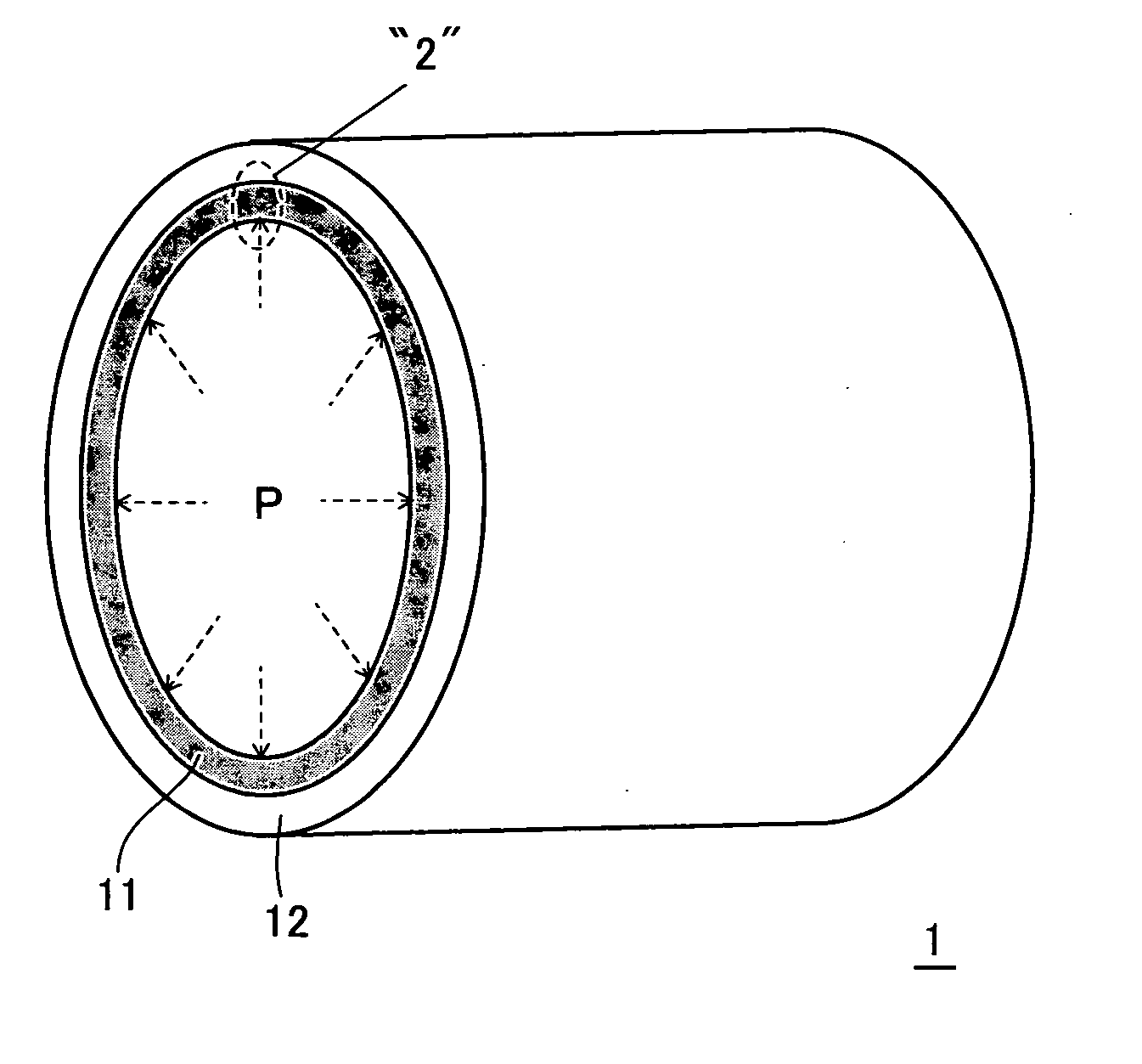

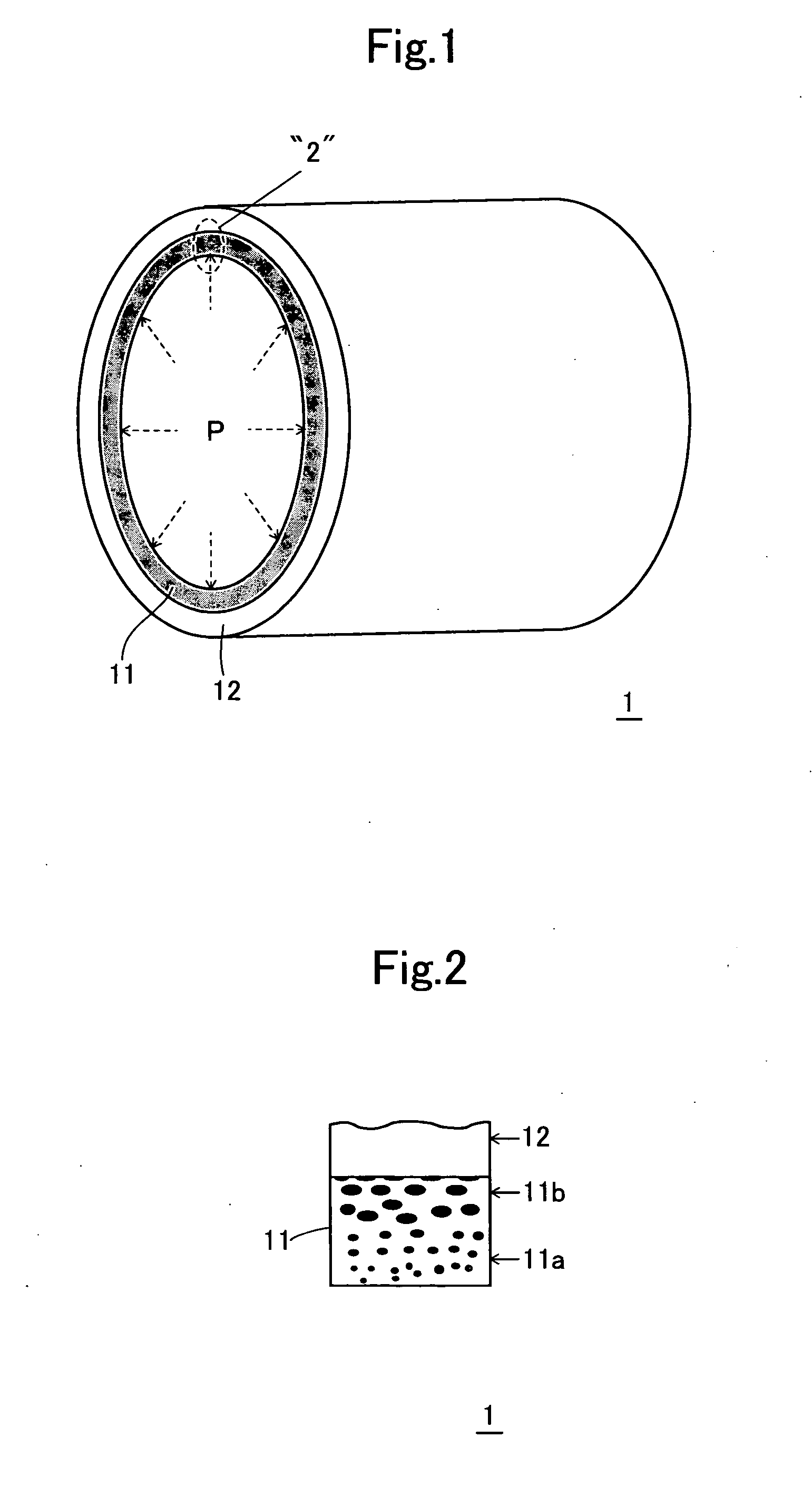

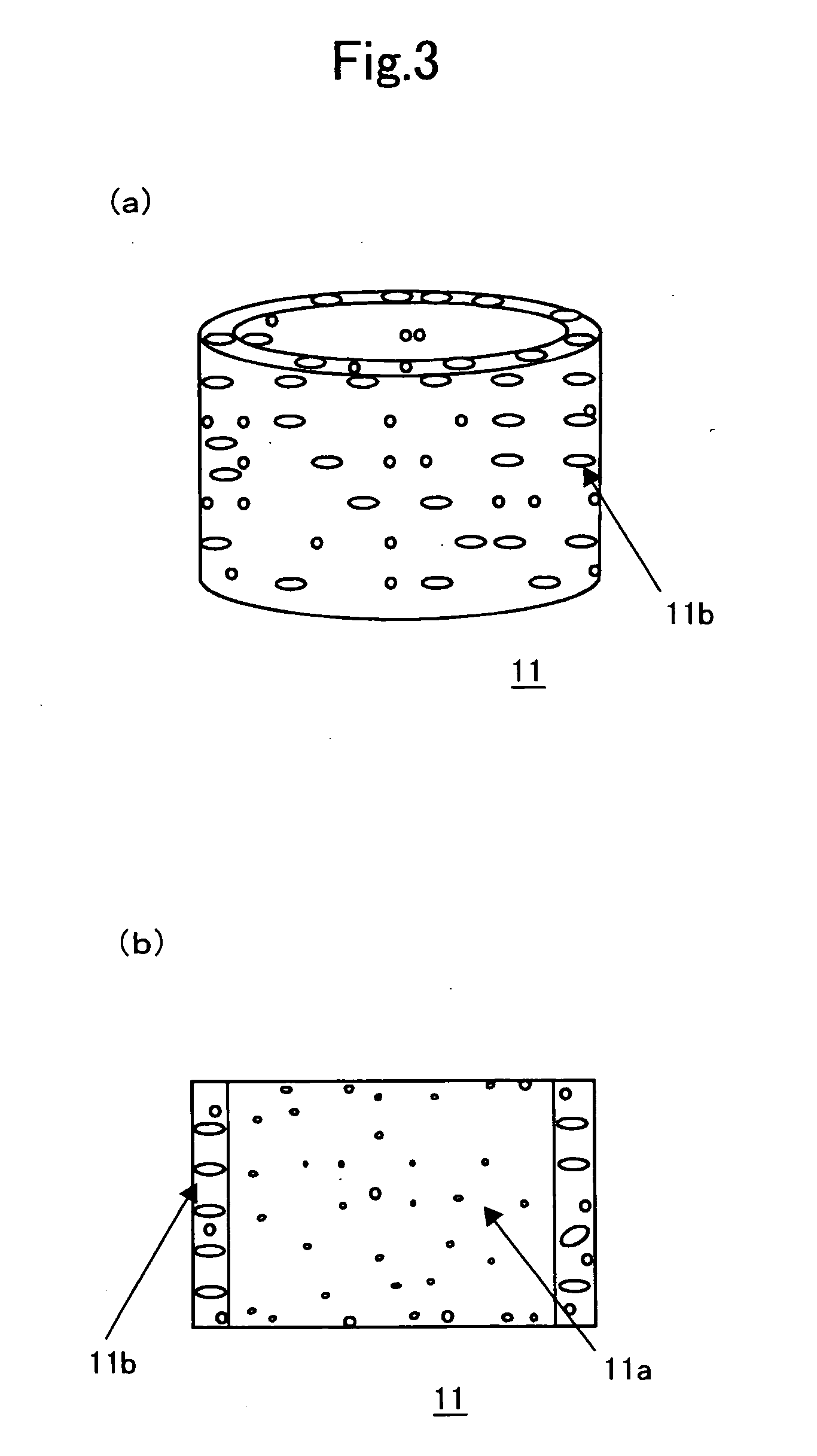

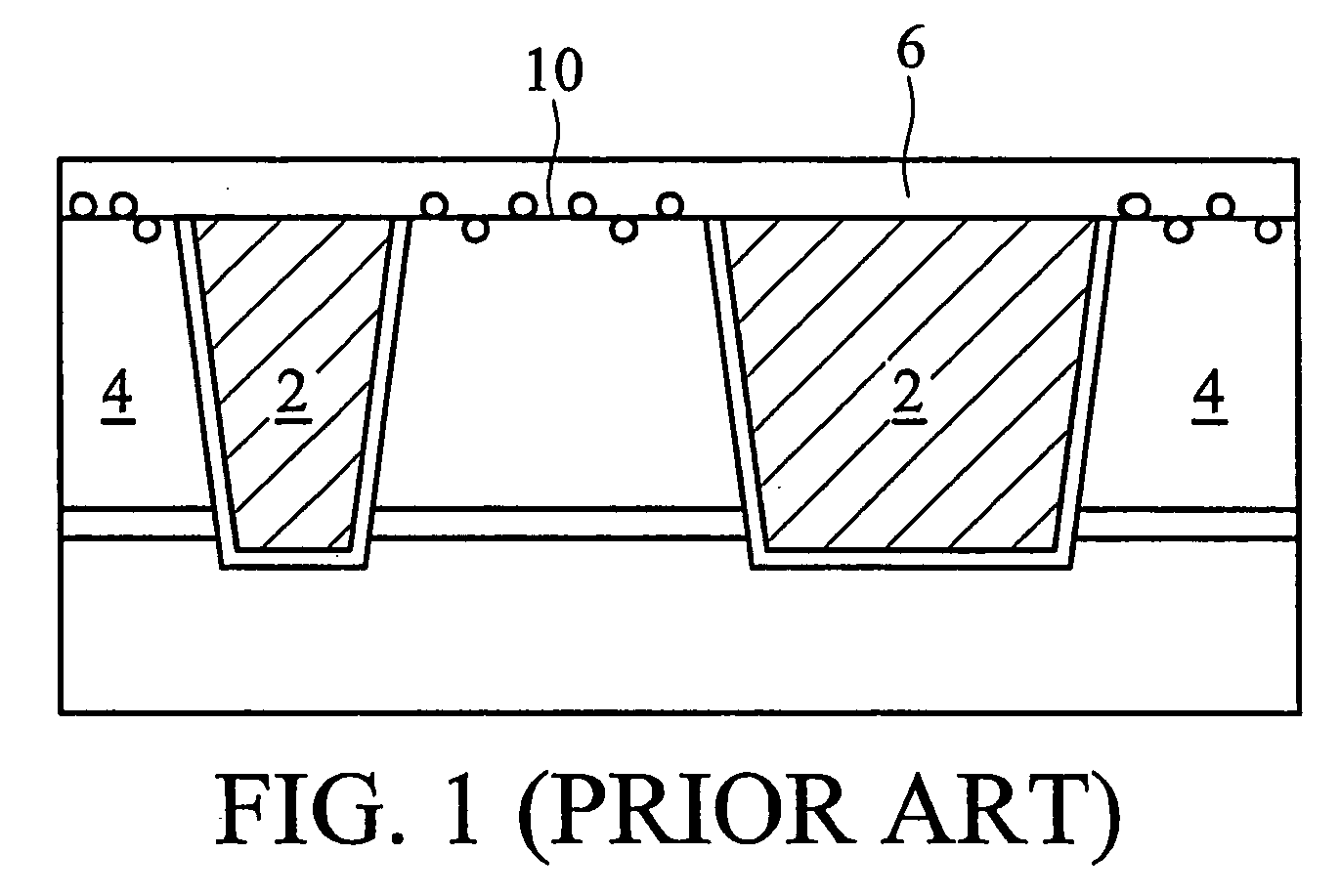

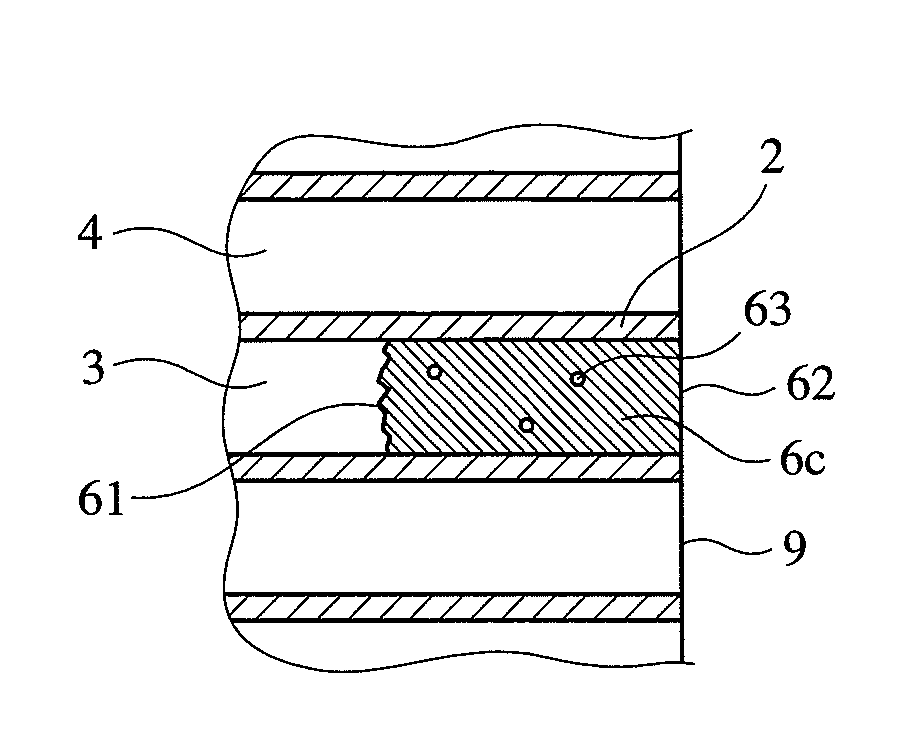

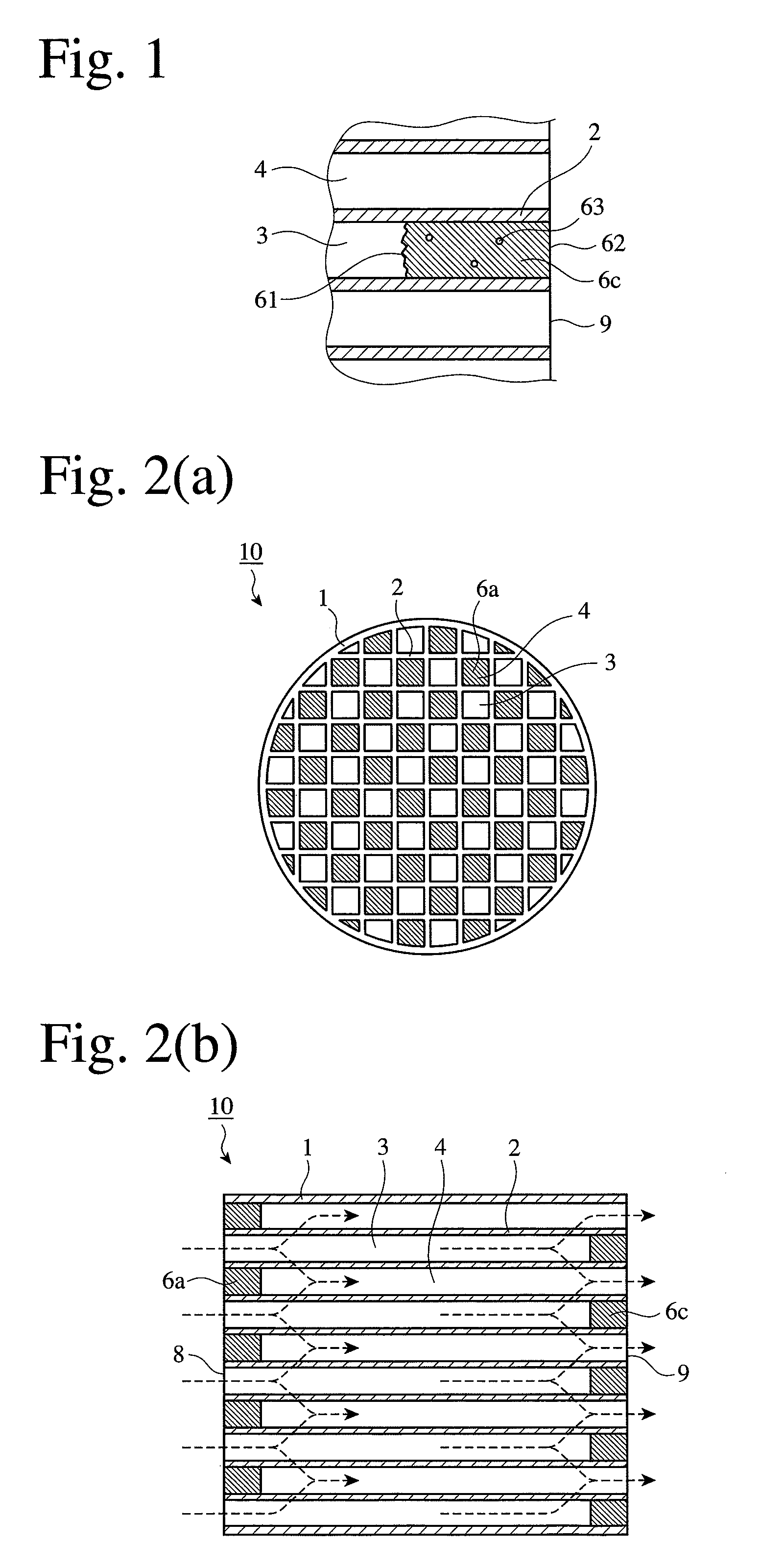

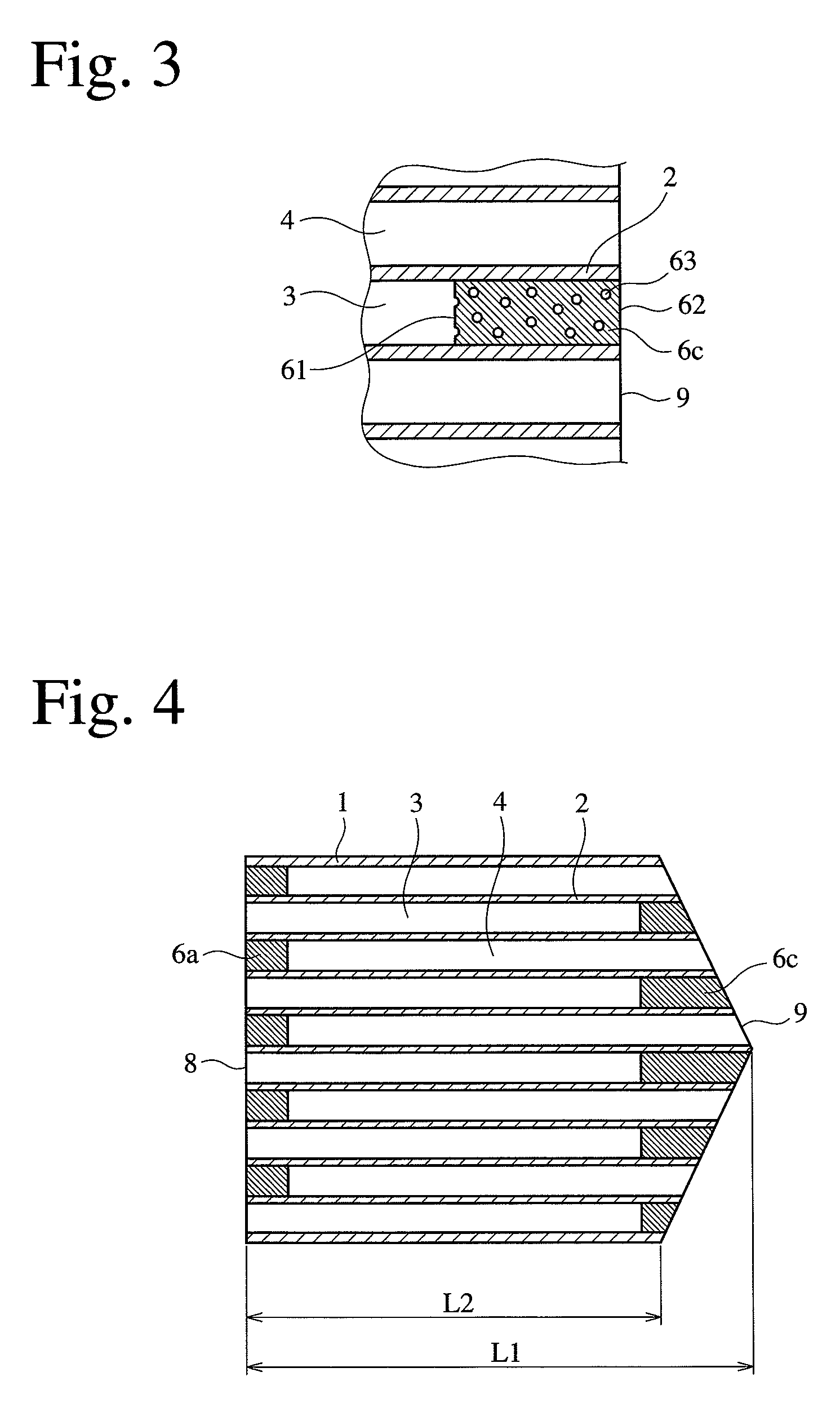

Composited cast member, iron-based porous substance for composited cast members, and pressure casing processes for producing the same, constituent member of compressors provided with composited cast members and the compressors

InactiveUS20050153156A1High strengthSmall porosityPositive displacement pump componentsLayered productsPorosityHigh intensity

A pressure casing includes a composited cast member. The composited cast member includes an iron-based porous substance whose major component is Fe and which has a large number of pores, and a cast-wrapping member whose major component is a light metal and which cast-wraps a part of the iron-based porous substance at least. The iron-based porous substance includes a connector disposed adjacent to a boundary between the iron-based porous substance and the cast-wrapping member and exhibiting a larger porosity, and a high-strength reinforcer disposed in the iron-based porous substance free from the connector and exhibiting a smaller porosity. The connector is impregnated with the cast-wrapping member, and solidifies therewith, thereby firmly bonding the iron-based porous substance and the cast-wrapping member in the composited cast member. The pressure casing secures strength with the reinforcer, and secures adhesiveness with the connector.

Owner:TOYOTA IND CORP

Electrostatic chuck

ActiveUS20070109713A1Improve plasma resistanceImprovement of fundamental functionSemiconductor/solid-state device manufacturingElectrostatic holding devicesMetallurgyRoom temperature

The object of the present invention is to provide an electrostatic chuck in which the surface can be kept smooth after being exposed to plasma, so as to protect a material to be clamped such as a silicon wafer from being contaminated with particles, and which is excellent in clamping and releasing a material to be clamped. According to the present invention, there is provided an electrostatic chuck comprising a dielectric material in which alumina is 99.4 wt % or more, titanium oxide is more than 0.2 wt % and equal to or less than 0.6 wt %, whose average particle diameter is 2 μm or less, and whose volume resistivity is 108-1011 Ωcm in room temperature, wherein the electrostatic chuck is used in a low temperature of 100° C. or less.

Owner:TOTO LTD

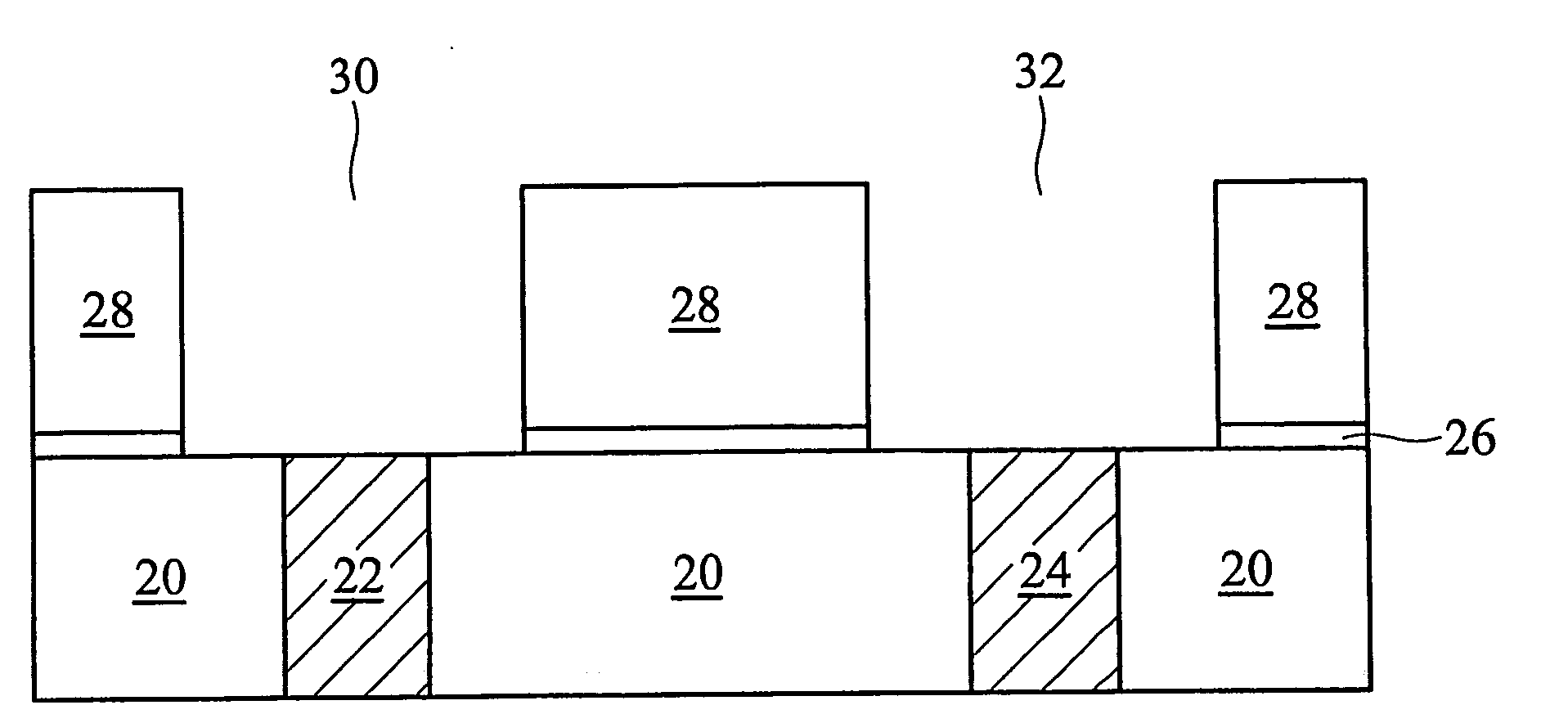

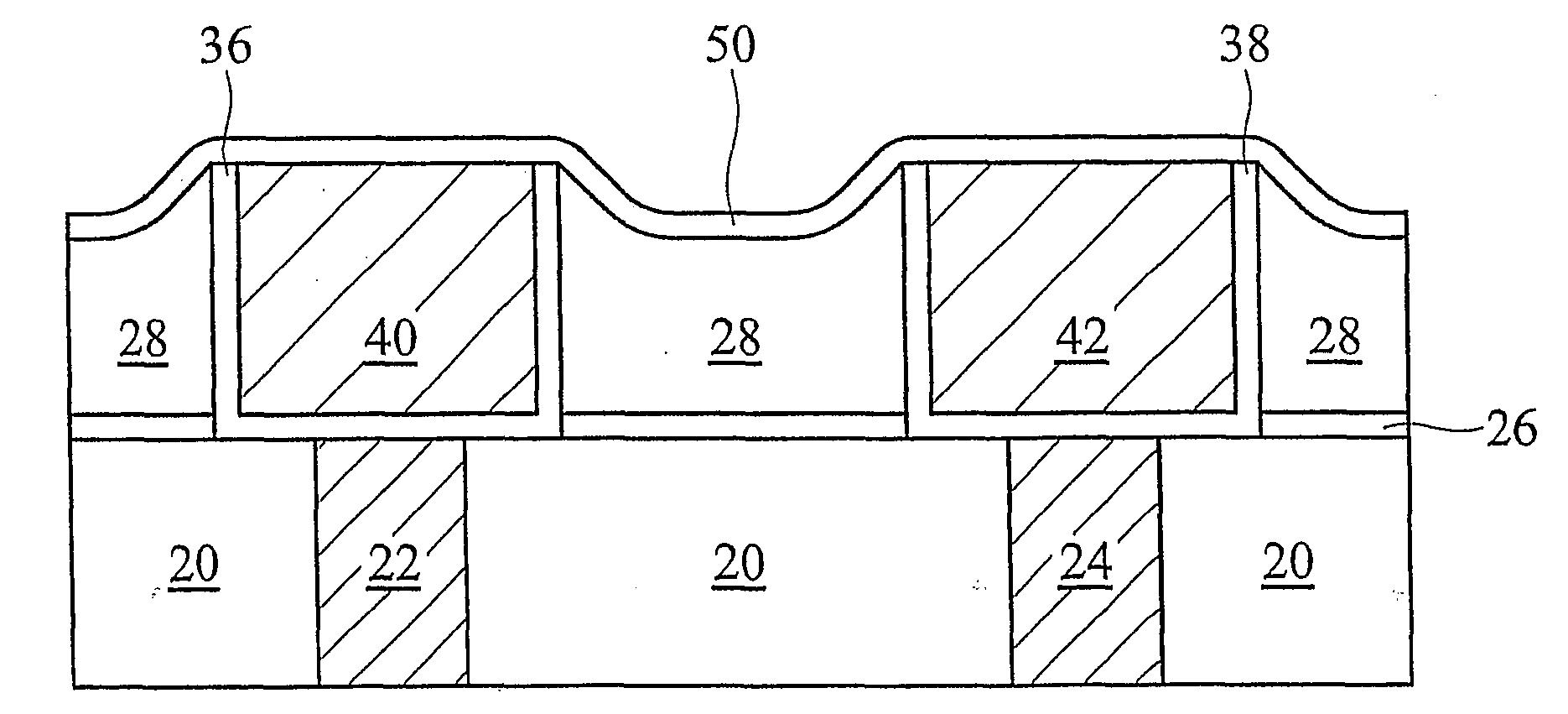

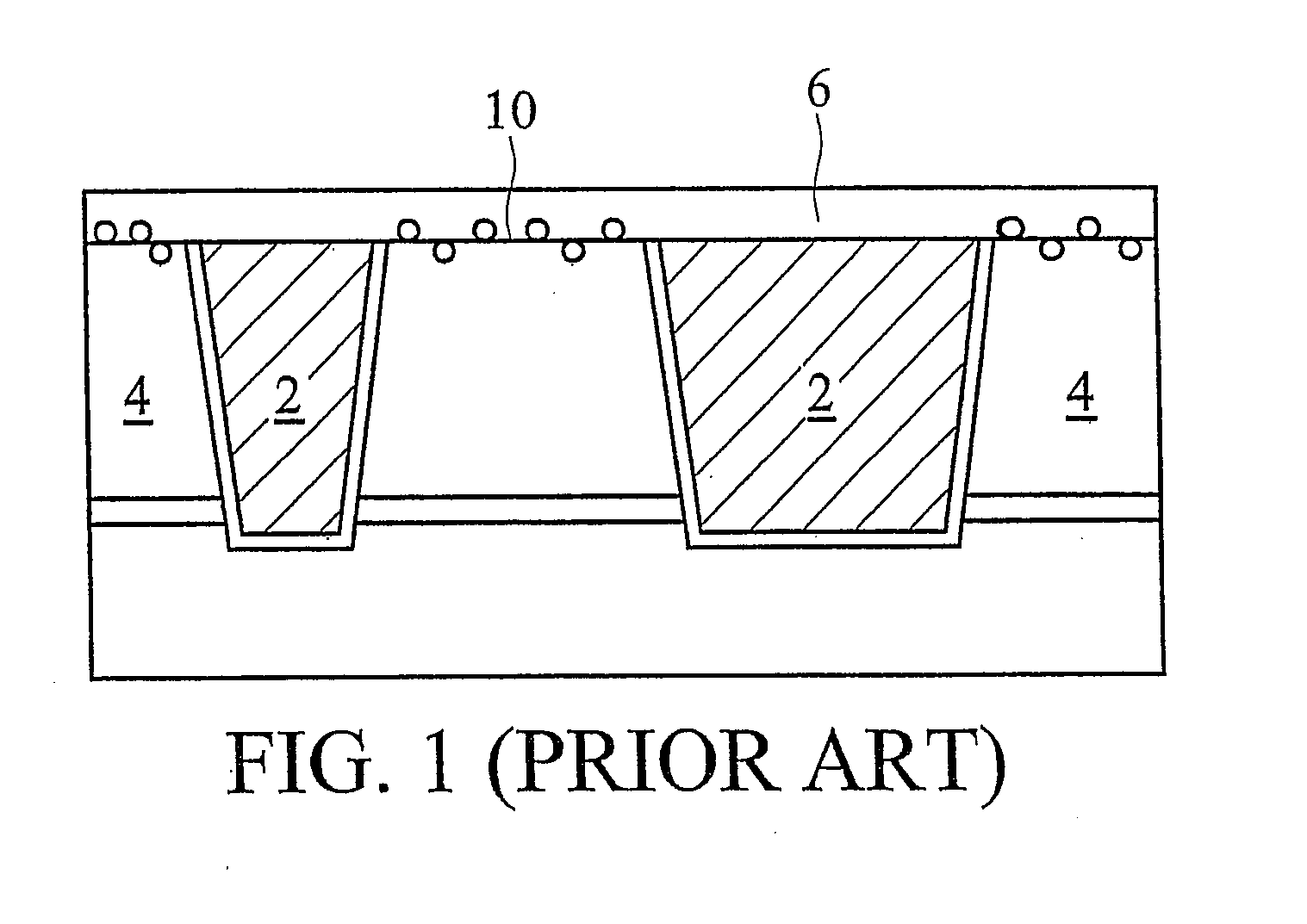

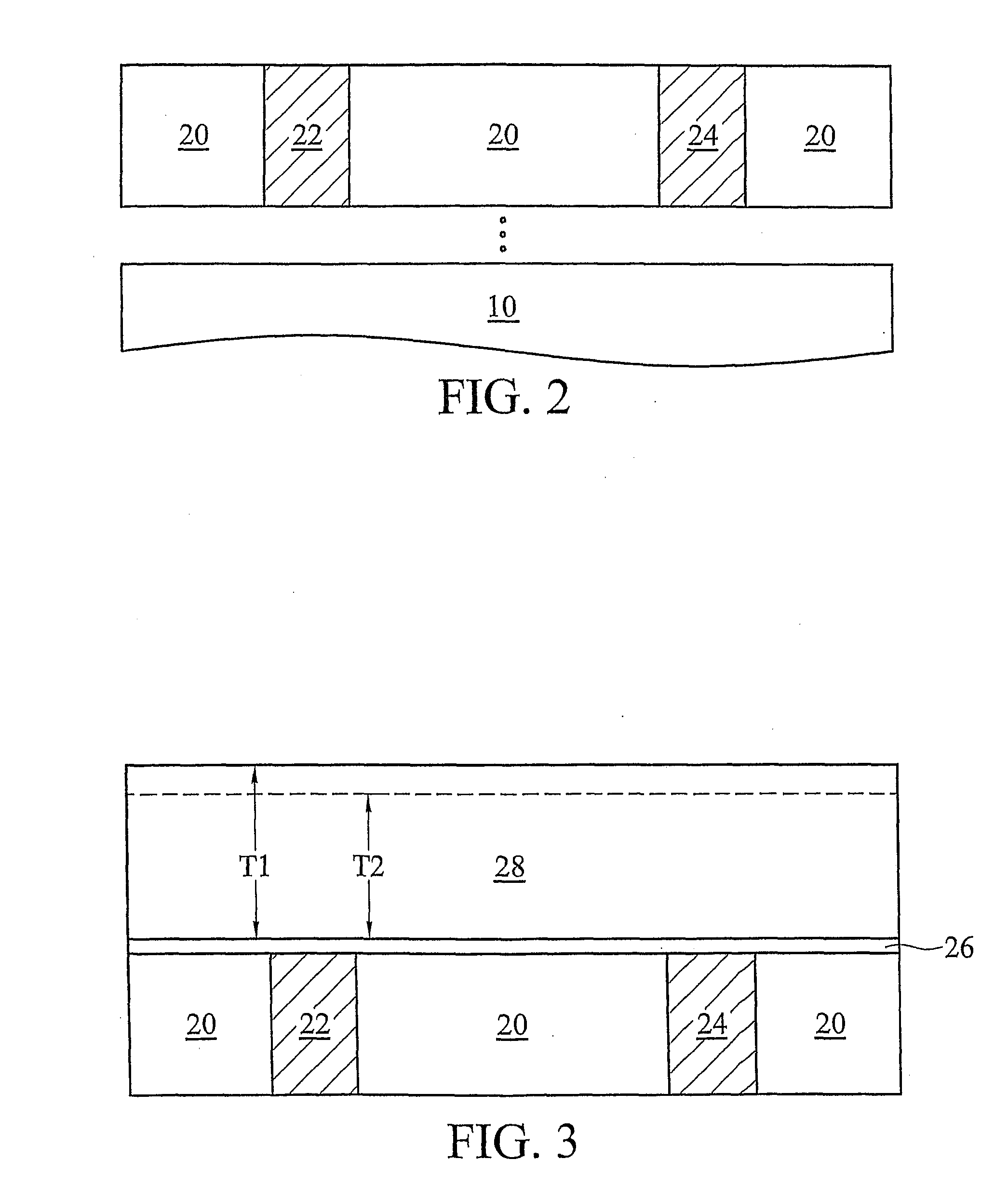

Process for improving the reliability of interconnect structures and resulting structure

InactiveUS20080014741A1Improved diffusion barrier layerSmall porositySolid-state devicesSemiconductor/solid-state device manufacturingShrinkage rateDielectric layer

An interconnect structure of an integrated circuit having improved reliability and a method for forming the same are provided. The method includes providing a substrate, forming a dielectric layer overlying the substrate, performing a first shrinking process, wherein the dielectric layer shrinks and has a first shrinkage rate, forming a conductive feature in the dielectric layer after the step of performing the first shrinking process, and performing a second shrinking process after the step of forming the conductive feature, wherein the dielectric layer substantially shrinks and has a second shrinkage rate.

Owner:TAIWAN SEMICON MFG CO LTD

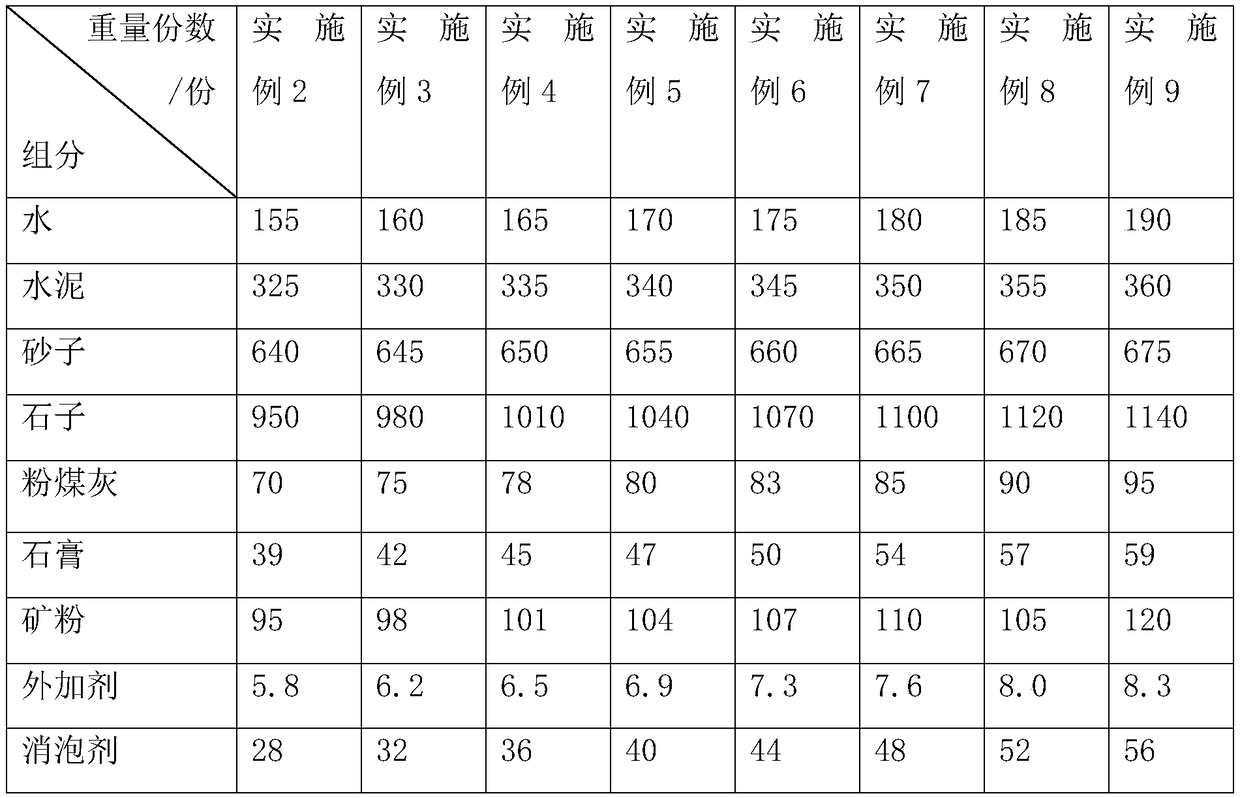

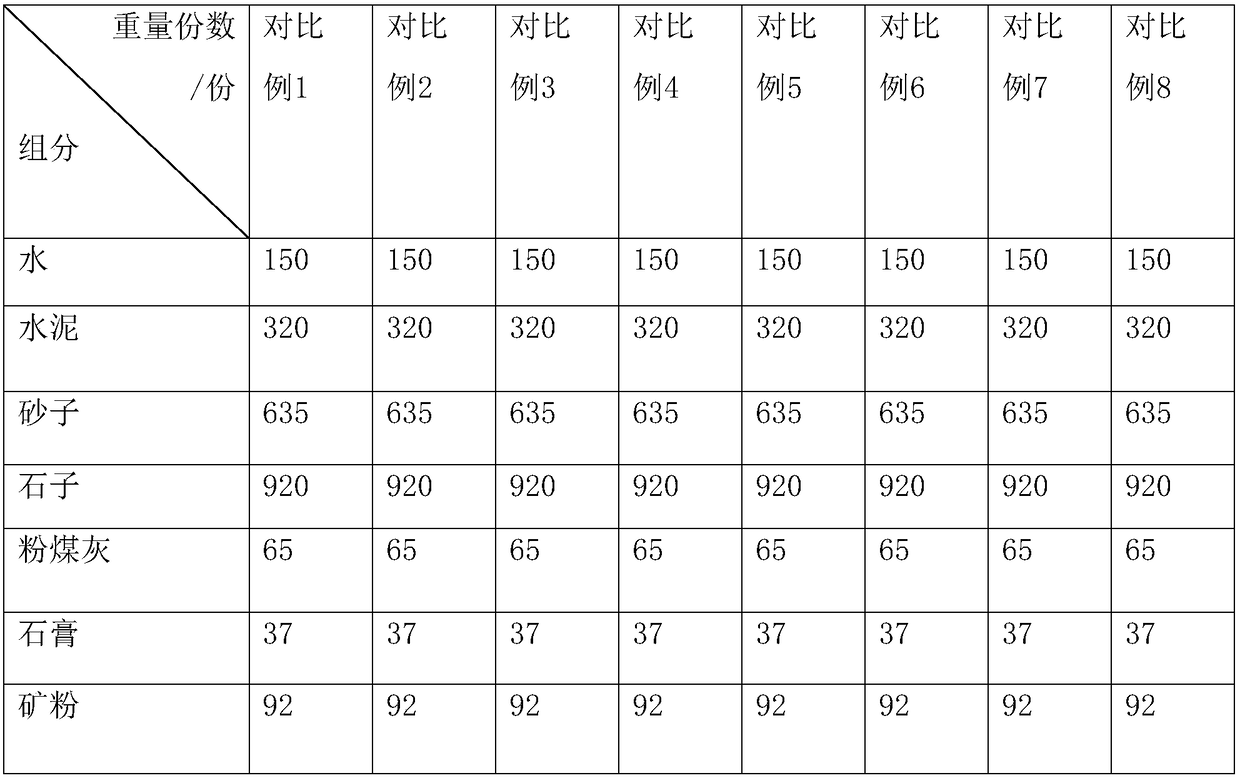

Super-retarding concrete and preparation method thereof

The invention discloses super-retarding concrete and relates to the technical field of building materials. According to the key pint of the technical scheme, the super-retarding concrete comprises thefollowing ingredients (by weight): 150-190 parts of water, 320-360 parts of cement, 635-675 parts of sand, 920-1140 parts of cobblestone, 65-95 parts of an admixture A, 92-120 parts of an admixture B, 37-59 parts of gypsum, and 5.5-8.3 parts of an additive. The additive comprises the following ingredients (by weight): 12-16 parts of a retarder and 38-52 parts of a polycarboxylate superplasticizer. The admixture A comprises fly ash, and the admixture B comprises mineral powder. The retarder is composed of sodium thiosulfate, glycerol and sodium tripolyphosphate according to the mass ratio of 1-3: 2.4-3.5: 2.3-3.2. The problem that concrete's short setting time and low long-term strength are hard to meet the requirement of prolonging the setting time of concrete and guaranteeing long-term strength is solved. By using the retarder and the polycarboxylate superplasticizer cooperatively, the setting time of concrete can be prolonged, and the concrete can have high long-term strength.

Owner:上海石化安东混凝土有限公司

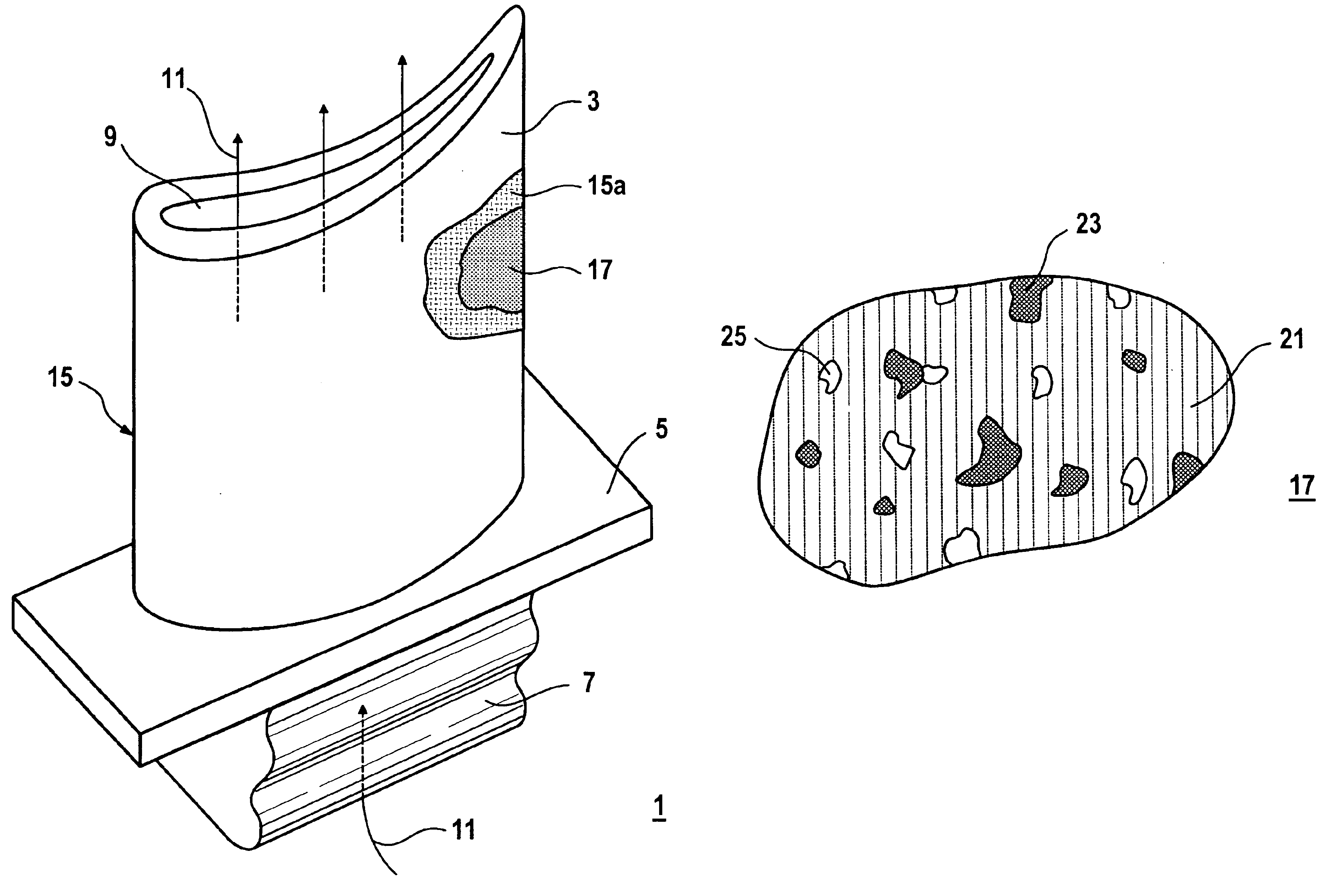

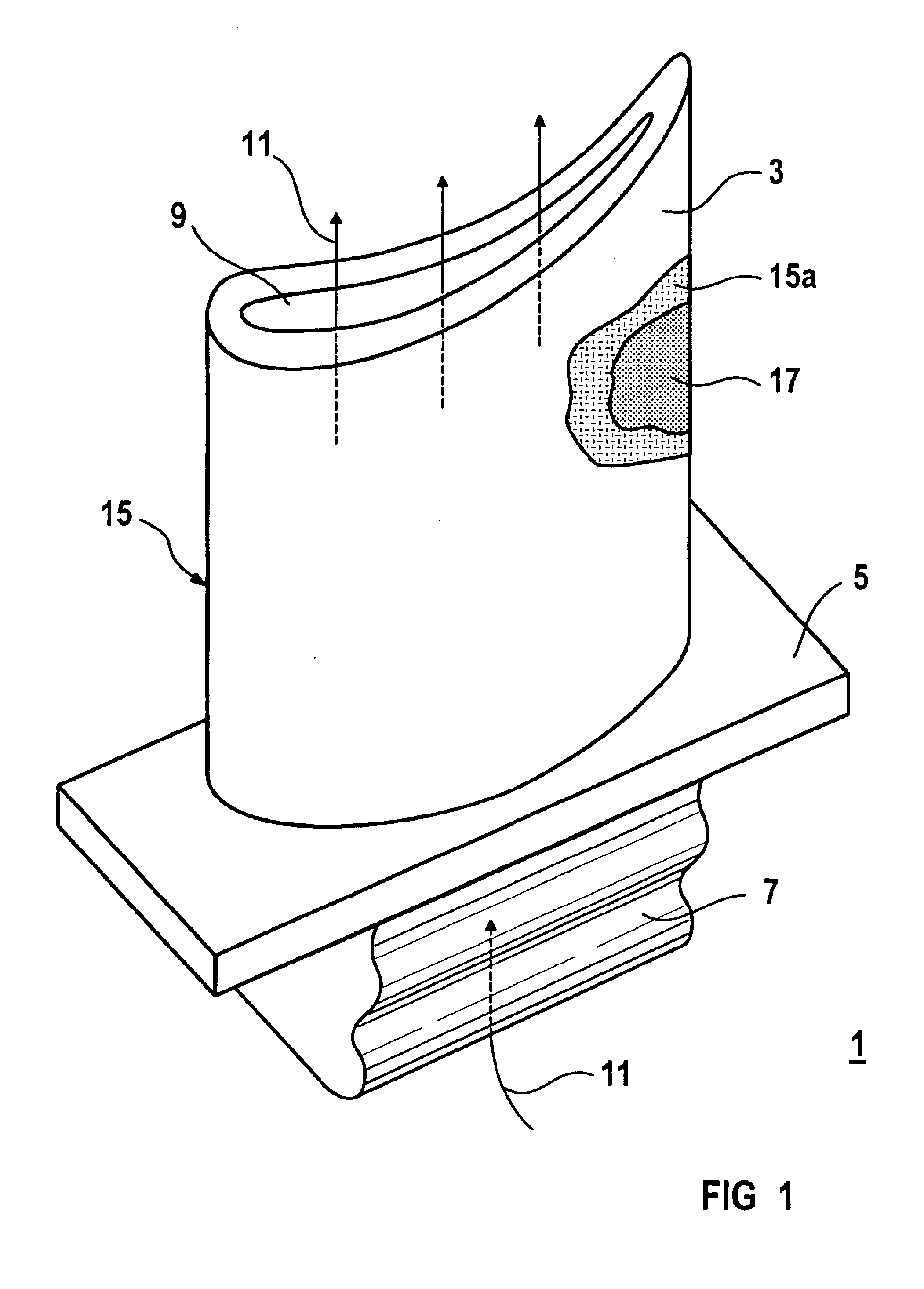

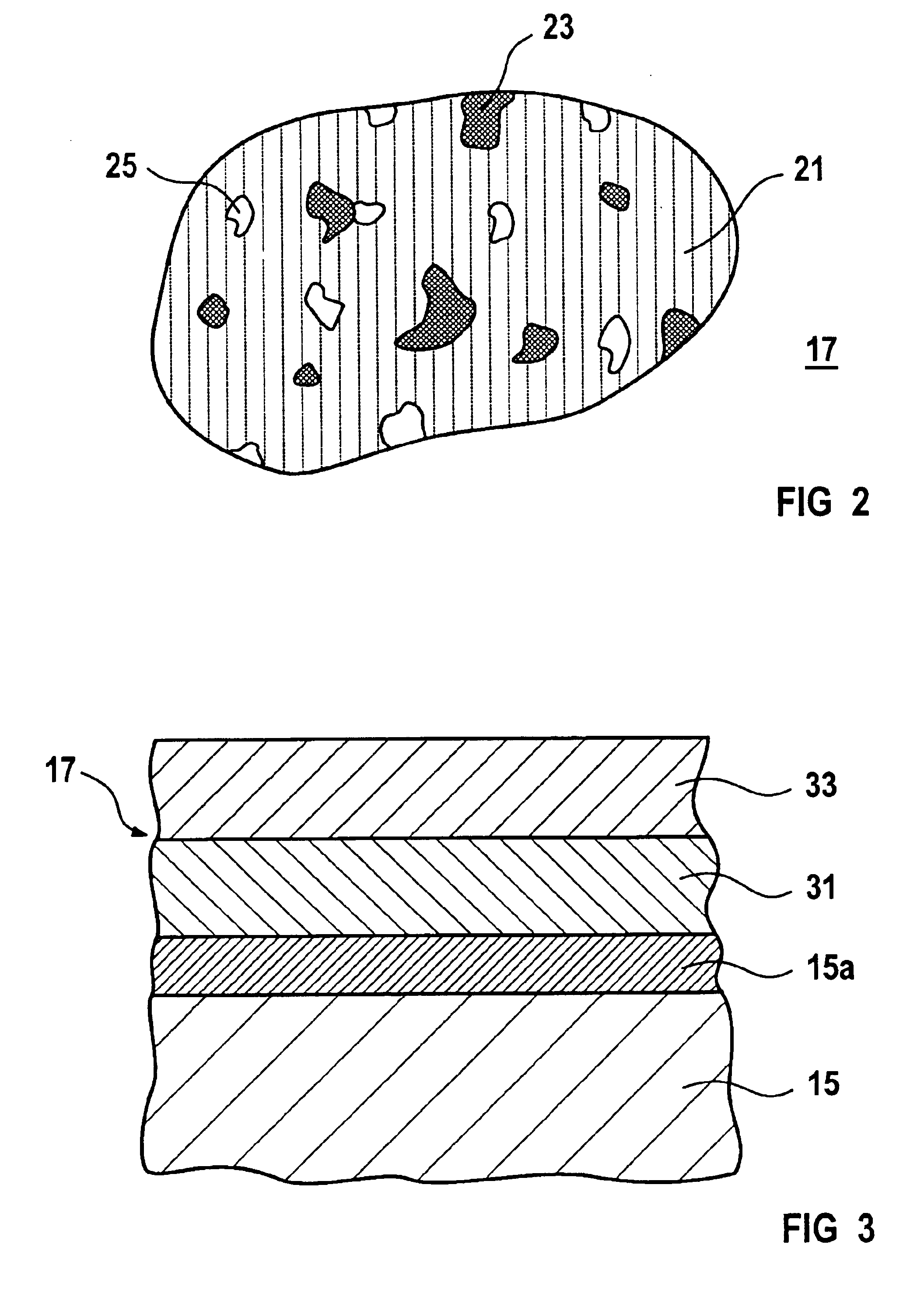

Gas turbine blade

Disclosed is a gas turbine blade (1) having a ceramic heat-insulating layer (17). The ceramic heat-insulating layer (17) consists of 10-95% wt. % magnesium aluminate, 5-90 wt. % magnesium oxide and 0-20 wt. % aluminum oxide. Magnesium oxide particles are incorporated into a matrix made of spindle-shaped magnesium aluminate, enabling the thermal expansion coefficient of the ceramic heat-insulating layer (17) to be adapted in a particularly suitable manner to a metallic base body (15) of the gas turbine blade (1). The ceramic heat-insulating layer (17) also has a porosity which is greater that 3 vol. %, thereby guaranteeing sufficiently low heat conductivity.

Owner:SIEMENS AG

Process for Improving the Reliability of Interconnect Structures and Resulting Structure

ActiveUS20100327456A1Enhance layeringSmall porositySemiconductor/solid-state device detailsSolid-state devicesStructural reliabilityShrinkage rate

An interconnect structure of an integrated circuit having improved reliability and a method for forming the same are provided. The method includes providing a substrate, forming a dielectric layer overlying the substrate, performing a first shrinking process, wherein the dielectric layer shrinks and has a first shrinkage rate, forming a conductive feature in the dielectric layer after the step of performing the first shrinking process, and performing a second shrinking process after the step of forming the conductive feature, wherein the dielectric layer substantially shrinks and has a second shrinkage rate.

Owner:TAIWAN SEMICON MFG CO LTD

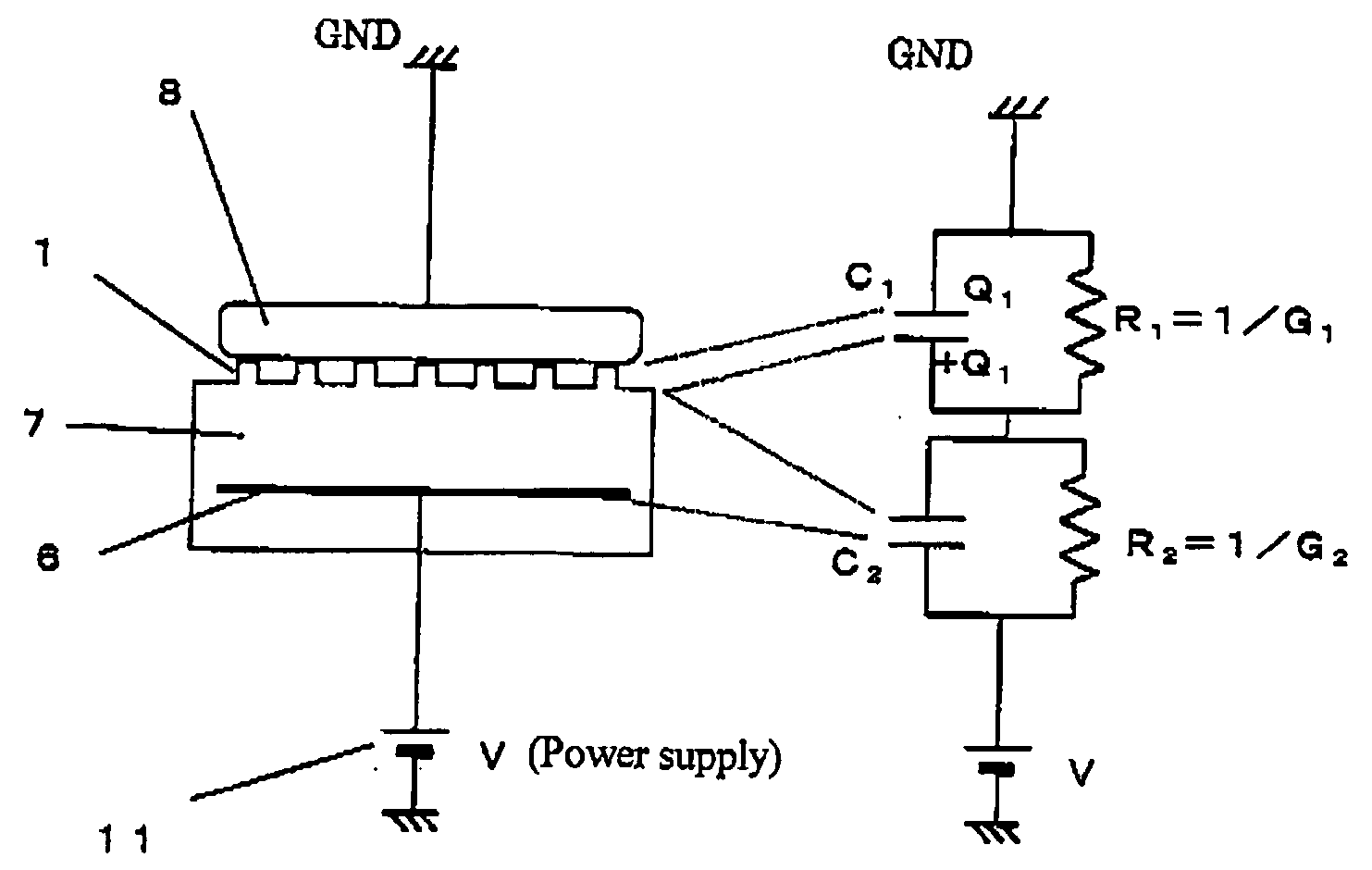

Pressure Wave Generator and Process for Manufacturing the Same

InactiveUS20070217289A1Increased operating lifeReduce thermal stressMicrophonesElectrothermic-effect transistorPorosityElectrical conductor

Even when compression stress is generated because a volume of a thermal insulation layer 2 is expanded due to oxidized by oxygen in the air, occurrence of cracks and fractures of the thermal insulation layer and a heating conductor 3 caused by the cracks are prevented by dispersing the compression stress. A pressure wave generator comprises a substrate 1, the thermal insulation layer 2 of porous material which is formed on a surface of the substrate 1 in thickness direction, and the heating conductor 3 of thin film formed on the thermal insulation layer 2, and generates pressure waves by heat exchange between the heating conductor 3 and a medium. When a thickness at the center of the thermal insulation layer 2 in width direction W is used as a reference thickness, and it is assumed that distribution of thickness of thermal insulation layer in the width direction is averaged with the reference thickness, porosity in an outer peripheral portion of the thermal insulation layer is made smaller than porosity in the center portion. By making the porosity in the outer peripheral portion of the thermal insulation layer 2 smaller, a number of immovable points on the outer periphery of the thermal insulation layer 2 restricted by the substrate 1 is increased and the positions of them are dispersed, so that the compression stress compressed in the outer peripheral portion of the thermal insulation layer 2 can be dispersed.

Owner:MATSUSHITA ELECTRIC WORKS LTD

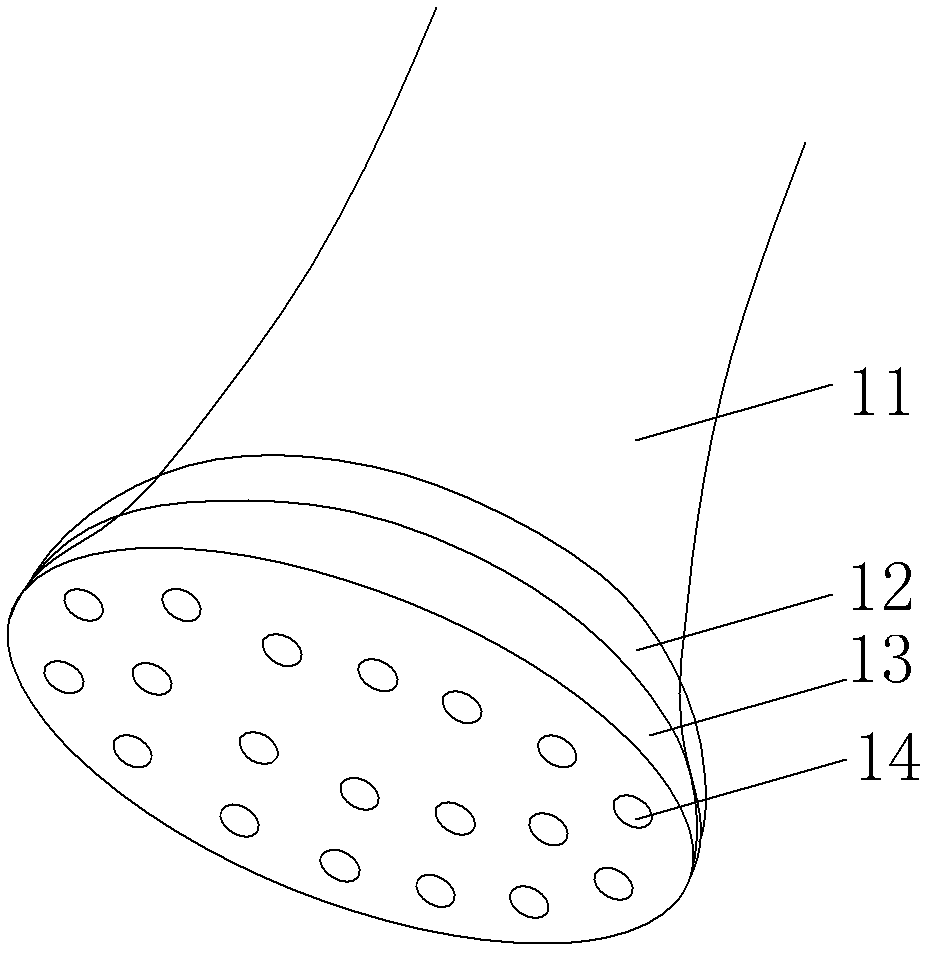

Spray head

InactiveCN102522306AStrong etching resistanceExtended service lifeElectric discharge tubesYttriumMaterials science

The invention provides a spray head which comprises a spray head matrix. A silicon or silicon carbide layer is covered on the spray head matrix, wherein an yttrium oxide layer is covered on the surface of the silicon or silicon carbide layer. The spray head provided by the invention has strong etching resistance capability and long service life.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Ceramic honeycomb filter and its production method

ActiveUS8092568B2Effective absorptionReduce erosionDispersed particle filtrationExhaust apparatusPorositySurface roughness

A ceramic honeycomb filter comprising a honeycomb structure having large numbers of flow paths partitioned by porous cell walls, and plugs alternately formed in the flow paths on the exhaust-gas-inlet and outlet sides, the outlet-side plugs having porosity of 65% or less, and the upstream-side end surfaces of the outlet-side plugs having surface roughness Ra of 13-50 μm.

Owner:HITACHI METALS LTD

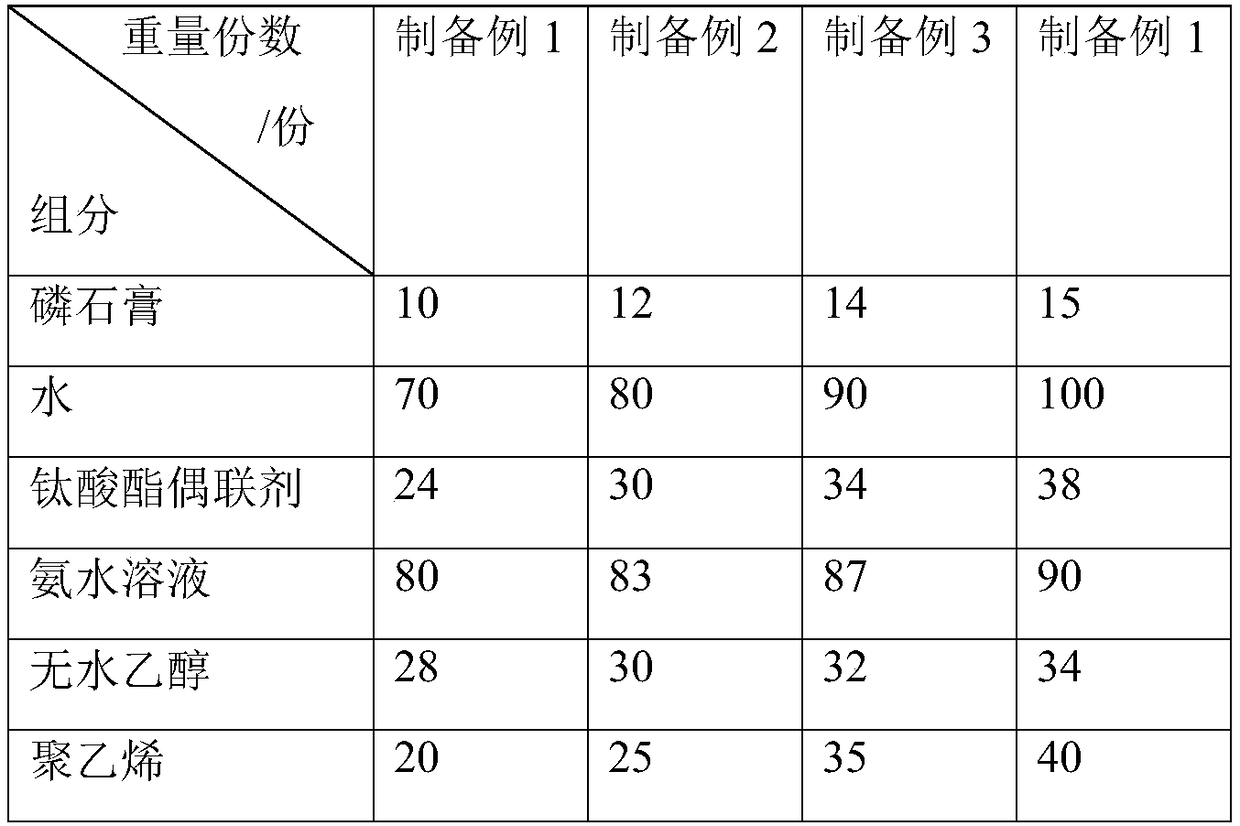

Super-retarded concrete and preparation method thereof

The invention discloses super-retarded concrete and a preparation method thereof. The super-retarded concrete is prepared from the following raw materials in parts by weight: 165-180 parts of water, 280-335 parts of cement, 565-620 parts of sand, 990-1200 parts of stone, 70-85 parts of flyash, 85-110 parts of mineral powder and 7.8-9.4 parts of an additive, wherein the additive is prepared from aretarder and a water reducer according to a mass ratio of 1 to (3.5-4.1). The retarder is prepared from the following components in parts by weight: 10-15 parts of phosphogypsum, 70-100 parts of water, 26-38 parts of a titanate coupling agent, 80-90 parts of an ammonium hydroxide solution with a mass fraction of 15-20%, 28-34 parts of absolute ethyl alcohol with a mass fraction of 20-35% and 20-40parts of polypropylene. The preparation method of the super-retarded concrete comprises the following steps: S1, adding the water reducer and a defoamer into water and fully mixing to obtain a firstmixture; S2, fully mixing corresponding parts by weigh of cement, stone, sand, flyash and mineral powder to form a second mixture; and S3, adding the first mixture into the second mixture, uniformly stirring, then adding the retarder and fully mixing to form the super-retarded concrete. The super-retarded concrete has the advantages of long setting time and high later-stage strength.

Owner:青岛康兴混凝土有限公司

Method for the preparation of macroporous particles and macroporous

InactiveUS20150291760A1Eliminate formationFirmly connectedCation exchanger materialsOrganic anion exchangersIonChemistry

A method for producing macro porous micro-clusters is proposed comprising at least the following individual steps in given order: a) synthesis of dispersed cross-linked polymeric latex primary particles starting from at least one monomer or oligomer using emulsion polymerization; b) swelling of the primary particles with a liquid comprising at least an additional charge of monomer and / or oligomer and a cross-linker, optionally further comprising functionalization agents; c) destabilization by increase of ionic strength (by adding a salt and / or acid and / or base) in a combination with application of shear, both being above the gel formation boundary of the phase diagram, until agglomerates composed of primary particles of the desired size are formed; d) polymerization of the agglomerates to form the macro porous micro-clusters. Furthermore the invention to relates to correspondingly produced micro-clusters and uses of such micro-clusters in particular for chromatographic purposes.

Owner:ETH ZZURICH

Acid-resistant shield foaming agent

ActiveCN106433679AHigh foaming rateEvenly distributedBuilding constructionsOrganic fertilisersFoaming agentBetaine

The invention discloses an earth pressure balance type shield foaming agent. The foaming agent comprises the following components by weight percent: 2.5-10.0% of fatty alcohol polyoxyethylene ether (AEO-9), 2.0-8.0% of alkyl glucoside (APG), 2-6.5% of dodecyl betaine, 1.0-3.0% of polyethylene glycol (PEG4000), 2-4.5% of ammonium sulfate and 32.0-90.5% of water. Through the earth pressure balance type shield foaming agent disclosed by the invention, high-rate foaming can be realized even in an acid condition, and the generated foam is fine while the stabilization time is long; and the product can perfectly meet the requirements of modified acid residue soil in a tunneling process of an earth pressure balance shield machine.

Owner:DALIAN RES & DESIGN INST OF CHEM IND +1

Amorphous refractory and corrosion resistant material for inert anode aluminum cells and manufacturing method thereof

The invention relates to an amorphous refractory and corrosion resistant material for inert anode aluminum cells and a manufacturing method thereof. The preparation of the material is characterized by employing sintered tabular corundum particles as the aggregate, powder selected from several of sintered tabular corundum fine powder, magnesia-alumina spinel fine powder, multi-peak sintered alumina micropowder with different particle size distributions, activated alumina micropowder, activated Rho-Al2O3 micropowder, dispersion alumina micropowder and pure calcium aluminate cement as the substrate, fiber as the reinforcing and toughening agent for mixing. Able to well resist electrolyte atmosphere corrosion, the amorphous refractory and corrosion resistant material of the invention has the advantages of high hot strength, good thermal shock resistance, easy implementation, long service period, relative low cost, etc. The material provided in the invention is suitable for heat preservation and sealing of industrial inert anode aluminum cells, especially the upper parts of cells, and can be used to directly face a fused electrolyte liquid surface and areas with invaded by an electrolyte atmosphere.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Artificial mudstone core and preparation method and application thereof

PendingCN108593385AReduce porosityReduce penetrationPreparing sample for investigationSaline waterClay minerals

The invention relates to an artificial mudstone core and a preparation method and application thereof. The artificial mudstone core comprises, by mass, 10-60 parts of clay mineral material, 30-80 parts of cementing agent, 10-40 parts of inorganic nano-material and 30-160 parts of quartz sand. The artificial mudstone core is obtained by mixing the clay mineral material, the cementing agent, the inorganic nano-material, the quartz sand and saline water and then performing solidification reaction and curing treatment. The artificial mudstone core has a perfect appearance and the composition characteristics of a natural mudstone core, the lithological characters and physical property parameters of the artificial mudstone core are close to those of natural mudstone, and thus the artificial mudstone core can replace the natural mudstone core for indoor simulation experiments of various drilling engineering measures, can provide technological support for oilfield exploration and development production, and has good economic benefits and application prospects.

Owner:李战伟 +1

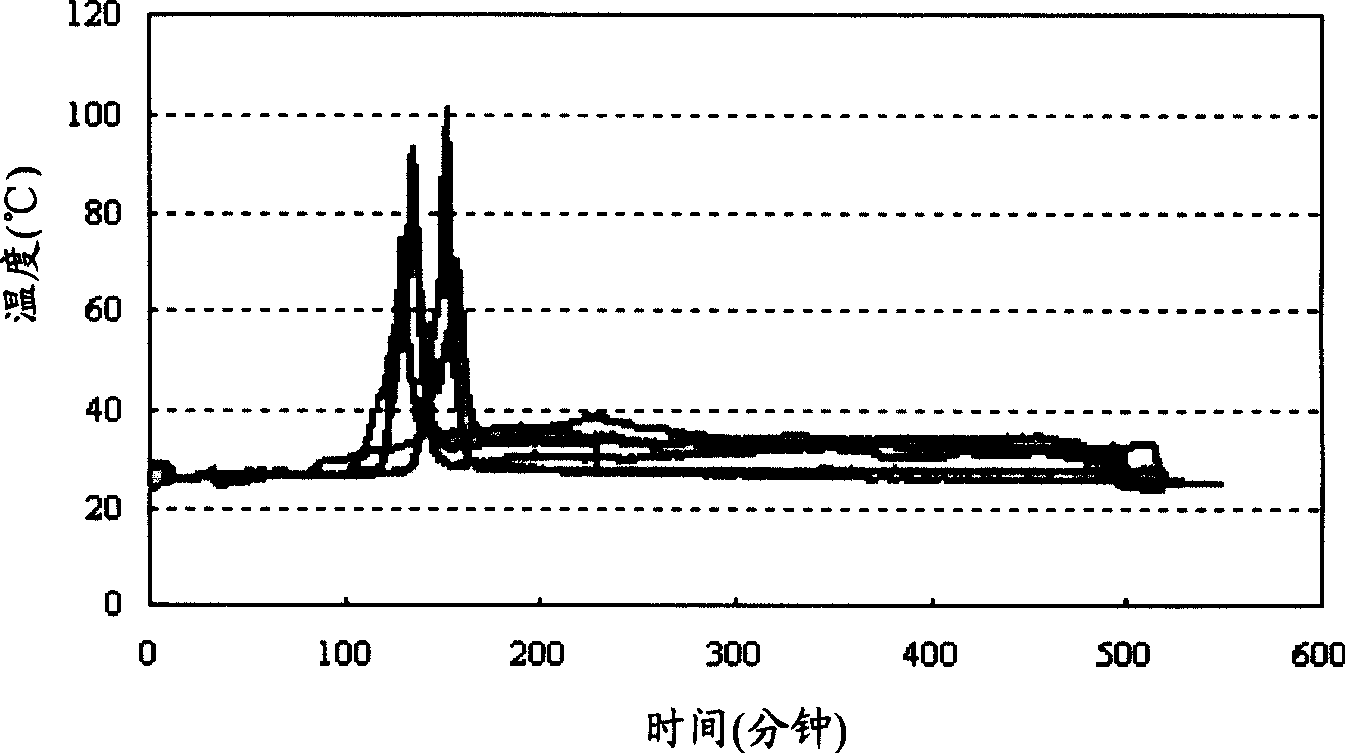

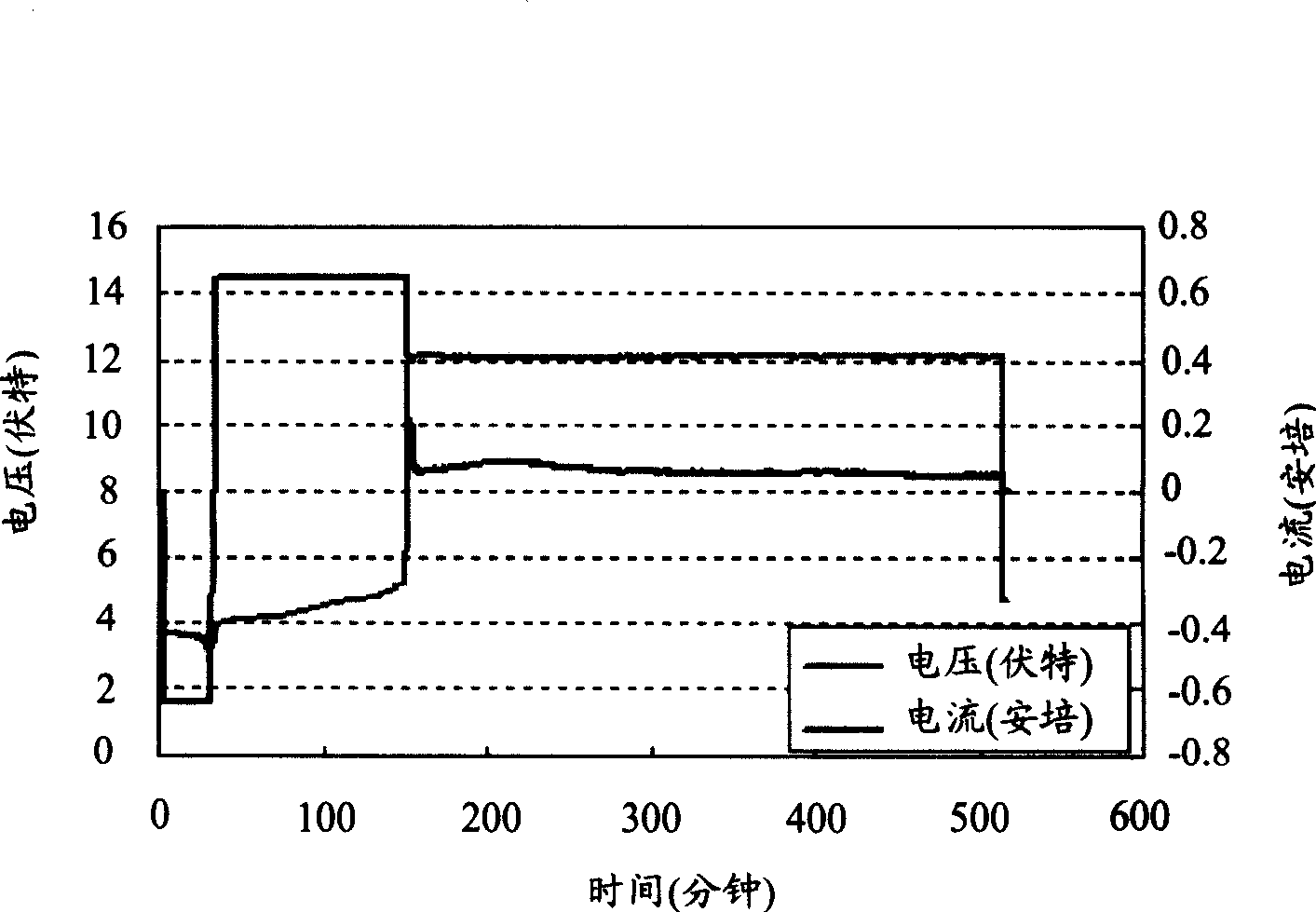

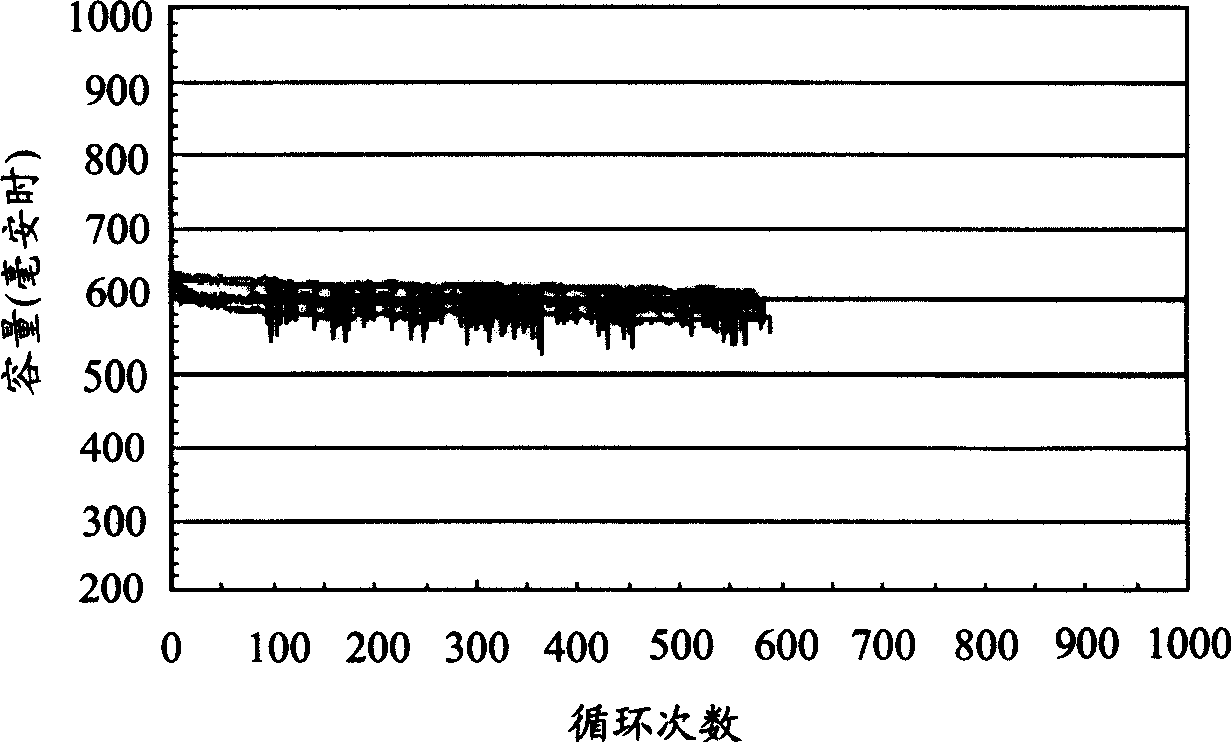

Lithium ion battery and isolating film

InactiveCN101510597ASmall porositySmall apertureCell seperators/membranes/diaphragms/spacersSecondary cellsPorosityEngineering

The invention provides an isolating membrane for a Li-ion battery and the thickness d, the porosity Rho r and the aperture Rho s thereof respectively meet the following conditions: d is more than or equal to 5 microns and less than or equal to 50 microns, Rho r is more than or equal to 15 percent and less than or equal to 35 percent, and Rho s is more than or equal to 0.05 micron and less than or equal to 0.08 micron. The isolating membrane for the Li-ion battery has smaller porosity and aperture. When the Li-ion battery is fully charged and the short circuit happens, the isolating membrane is capable of reducing the discharging current and decreasing the continuous discharge capacity of the battery, thus controlling the magnitude of the short circuit current and the continuous time of the current and improving the safety; and when the battery is overcharged, has high temperature, or suffers improper use such as poking of a nail, squeezing and the like, the isolating membrane can rapidly shut off a micropore at fusion temperature, cut off an ion path, cause the Li to stop migrating from the anode to the cathode so as to stop the lattice collapse of anode materials and the oxidation of an electrolytic solution, thus protecting a battery cell from burning or exploding.

Owner:DONGGUAN AMPEREX TECH

Neutral lining refractory material for electric induction furnace and manufacturing method thereof

The invention discloses a neutral lining refractory material for an electric induction furnace and a manufacturing method thereof, which belongs to the technical field of linings of electric induction furnaces. The neutral lining refractory material for the electric induction furnace comprises the following raw materials by weight: 50 to 75% of high bauxite clinker, 20 to 30% of high purity quartz sand, 1 to 3% of alumina and 5 to 15% of an adhesive. The weight percentages of high bauxite clinker with different particle sizes are as follows: high bauxite clinker with a particle size of 0 to 3 mm, 15 to 25%; high bauxite clinker with a particle size of more than 3 mm and no more than 5 mm, 40 to 70%; and high bauxite clinker with a particle size of 6 to 8 mm, 15 to 25%. According to then invention, through usage of the high bauxite clinker as aggregate, reasonable proportion of the high bauxite clinker with different particle sizes and cooperative usage of high purity quartz sand and a small amount of alumina, the neutral lining refractory material has good compactness and a prepared lining has small porosity, great volume density, high uniformity, good sinterability and good resistance to chilling and intense heating.

Owner:安徽中建材开源新材料科技有限公司

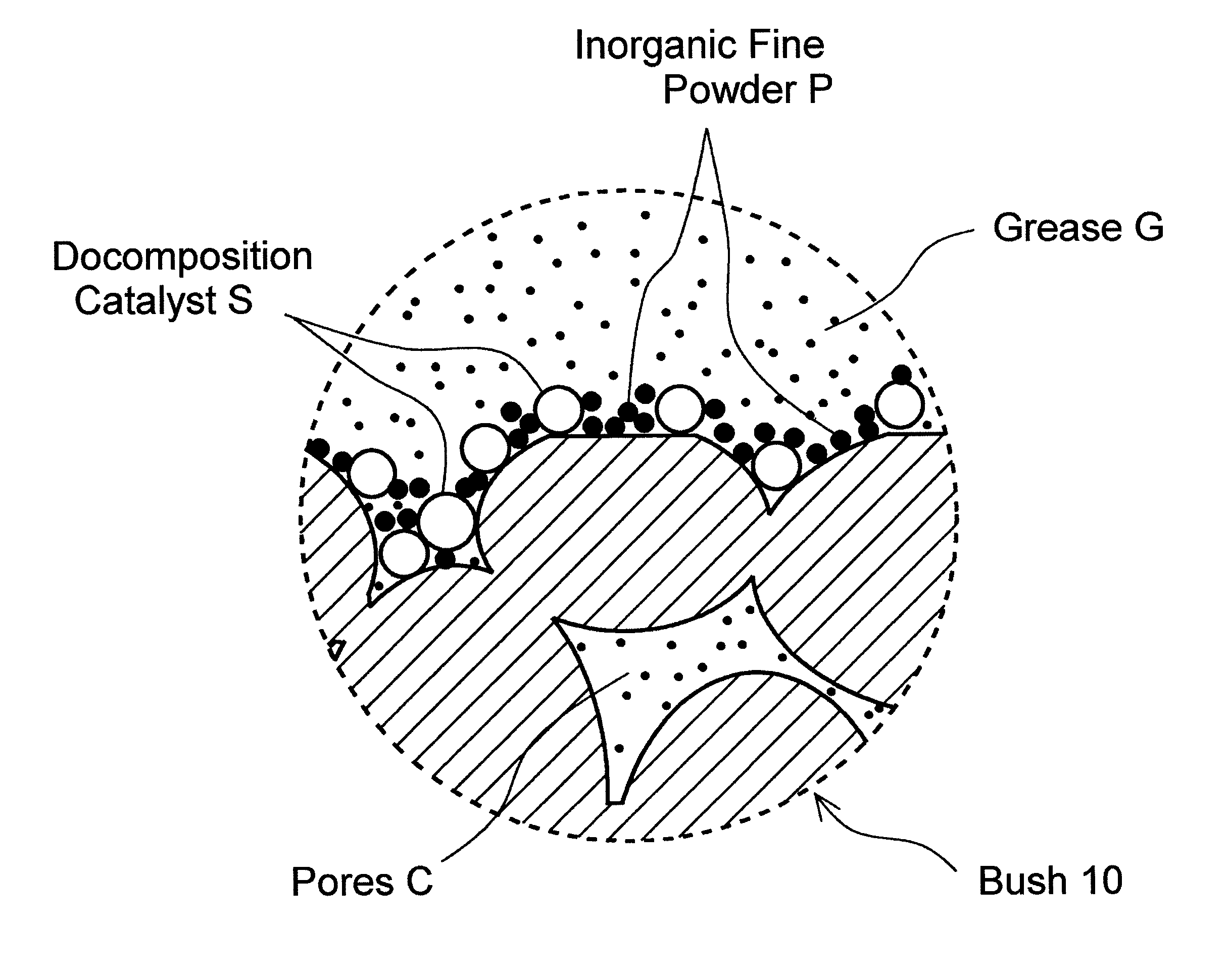

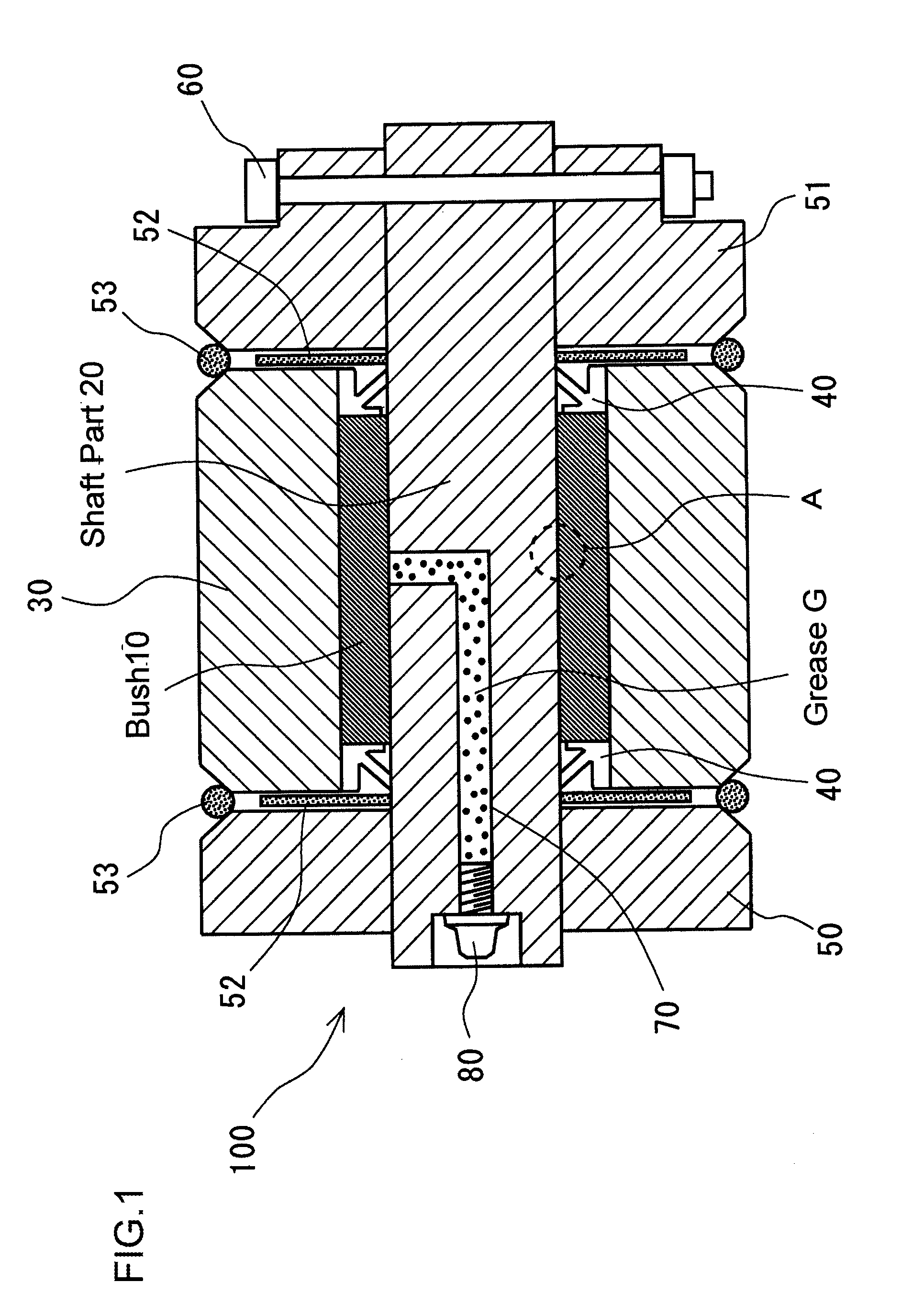

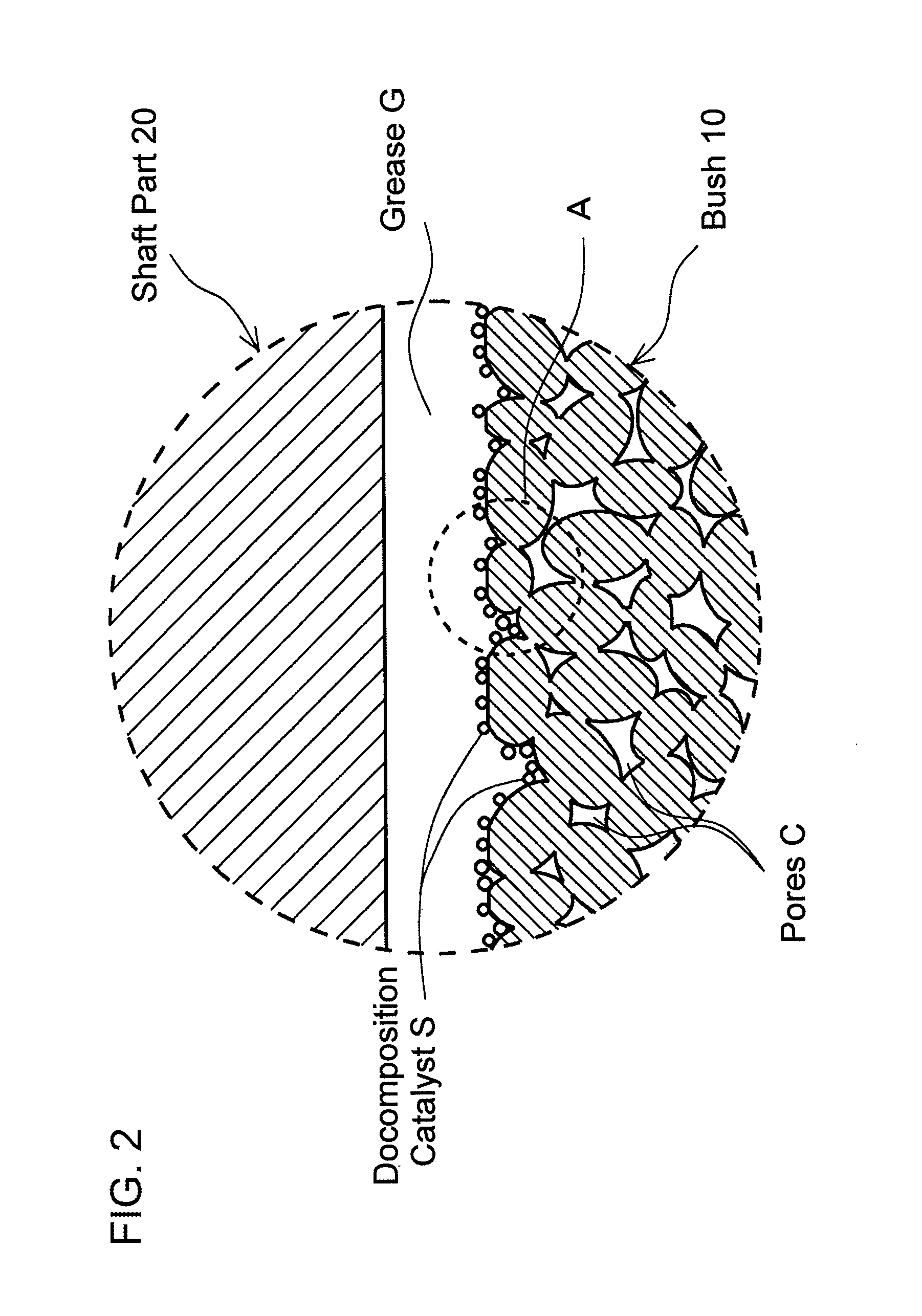

Sliding bearing and construction machine provided with same

InactiveUS8821022B2High strengthImprove the lubrication effectShaftsBearing componentsMechanical engineeringPlain bearing

Provided are a novel sliding bearing and a construction machine provided with same, the sliding bearing being capable of maintaining an excellent sliding performance over a long period of time and exhibiting an excellent strength. A sliding bearing includes at least a brush and a shaft part, the shaft part being provided with a grease feeding pathway for feeding grease from the exterior to the sliding surfaces of the shaft part and the bush, the bush being formed from a porous sintered metal, and a decomposition catalyst being adhered to the sliding surface of the bush.

Owner:NIHON KENKI CO LTD

Surface wear-resisting layer of gas turbine compressor blade and blade root and manufacturing method thereof

InactiveCN101737352AEnhanced performance against fretting fatigueQuality improvementMolten spray coatingPump componentsPorosityIndium

The invention provides a surface wear-resisting layer of gas turbine compressor blade and blade root and a manufacturing method thereof. The surface wear-resisting layer is positioned on the contact surface of blade bottom and an impeller, and is a coating which is made of copper-nickel indium alloy powder; the copper-nickel indium alloy powder comprises the following components: 50-60 wt% of copper powder, 30-40 wt% of nickel powder, 3-10 wt% of indium powder; and a supersonic speed flame spraying method is used to spray the copper-nickel indium alloy powder on the surface of the blade root. The thickness of the coating is 0.07-0.09 mm. The surface wear-resisting layer of the invention is a fretting wear-resisting layer, which enhances blade fretting fatigue resistance, and prolongs the service life of products. the supersonic speed flame spraying (AC-HVAF) process method is adopted to prepare the copper-nickel-indium coating with lower porosity and high bonding strength; the method simplifies process flow, reduces production cost, plays a positive social benefit for the improvement of gas turbine product quality and the popularization of new technology and new process of the products, and greatly facilitates localization progress of heavy gas turbine products in China.

Owner:DONGFANG TURBINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com