Spray head

A technology of shower head and yttrium oxide, applied in the field of shower head, can solve problems such as aluminum corrosion, thinning of shower head thickness, pollution, etc., and achieve the effect of enhancing service life and strong anti-etching ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention uses yttrium oxide, a material with strong etching resistance, to cover the surface of silicon or silicon carbide, thereby enhancing the service life of the shower head.

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. Since the emphasis is placed upon illustrating the principles of the invention, the drawings are not drawn to scale.

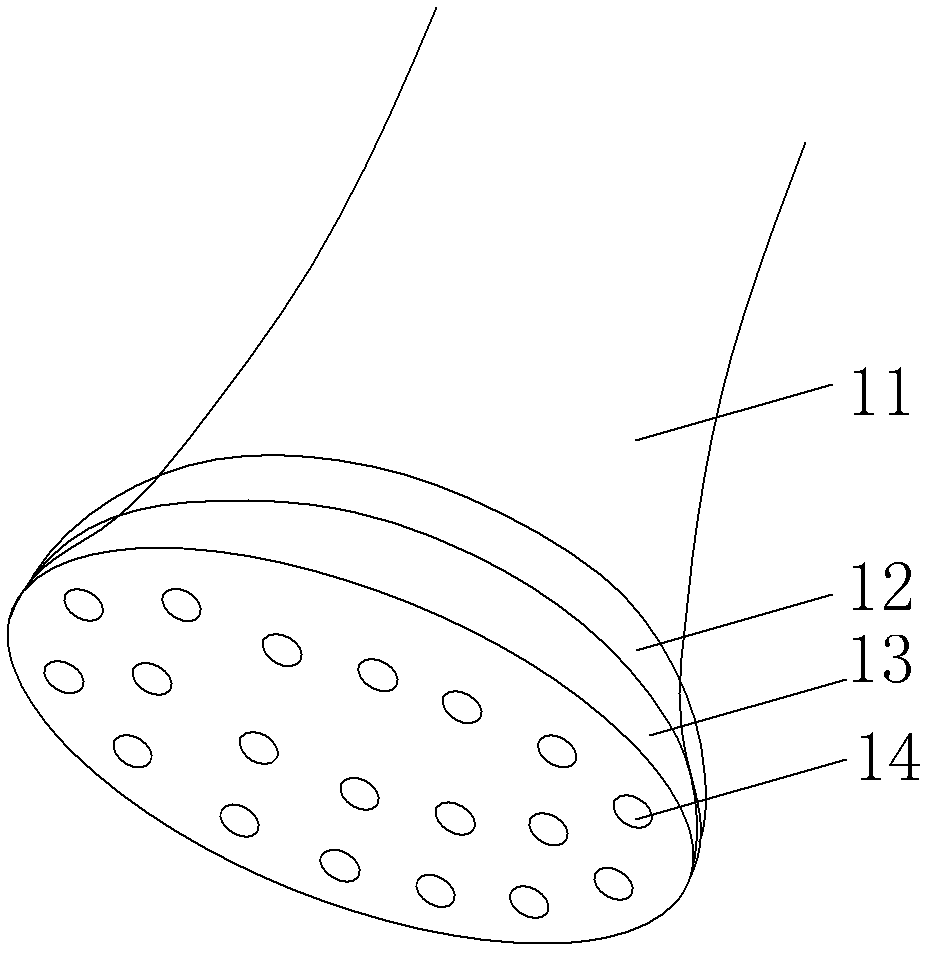

[0026] figure 1 Shown is a schematic diagram of the shower head provided in this embodiment. This sprinkler includes:

[0027] Spray head substrate 11;

[0028] The shower head substrate 11 is covered with a silicon or silicon carbide layer 12;

[0029] The surface of the silicon or silicon carbide layer 12 is covered with an yttrium oxide layer 13 .

[0030] The material of the shower head substrate 11 is generally me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness range | aaaaa | aaaaa |

| Thickness range | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com