Back channel etched oxide semiconductor tft substrate and method of making the same

A technology of oxide semiconductors and production methods, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, transistors, etc., can solve the problems of complex preparation process of IGZOTFT, low reliability of TFT devices, and easy damage to the channel region, so as to save The effect of etching barrier mask, low production cost, and small number of film defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

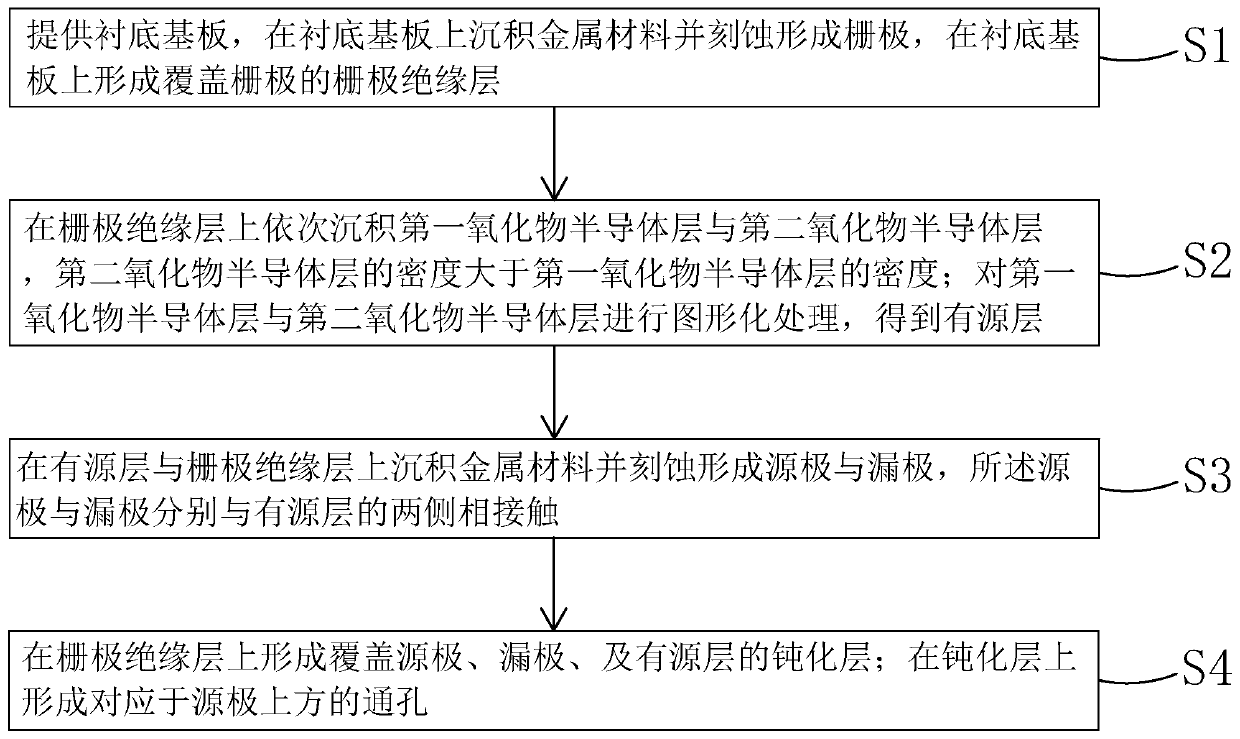

[0041] see figure 1 , the present invention provides a method for fabricating a back channel etched oxide semiconductor TFT substrate, comprising the following steps:

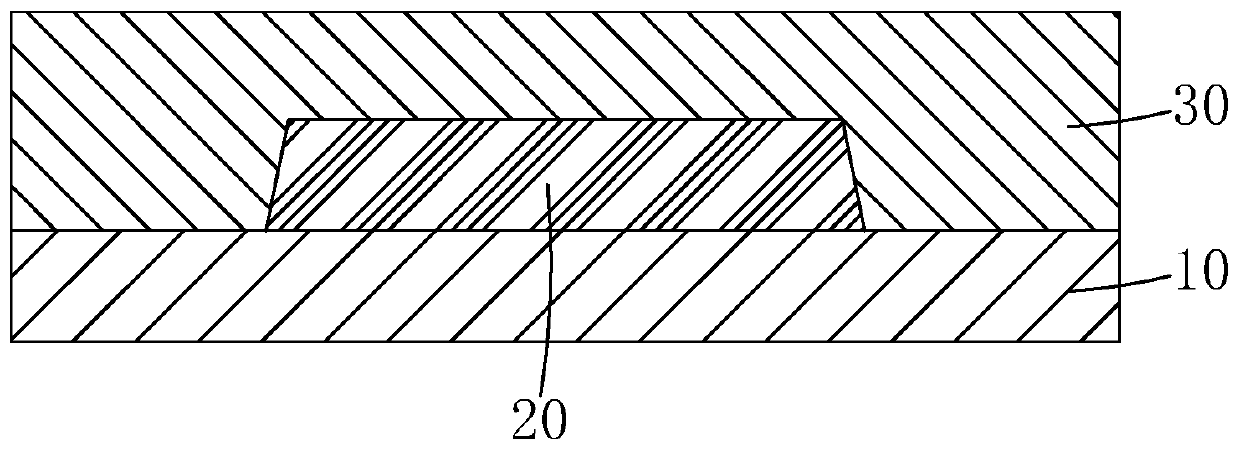

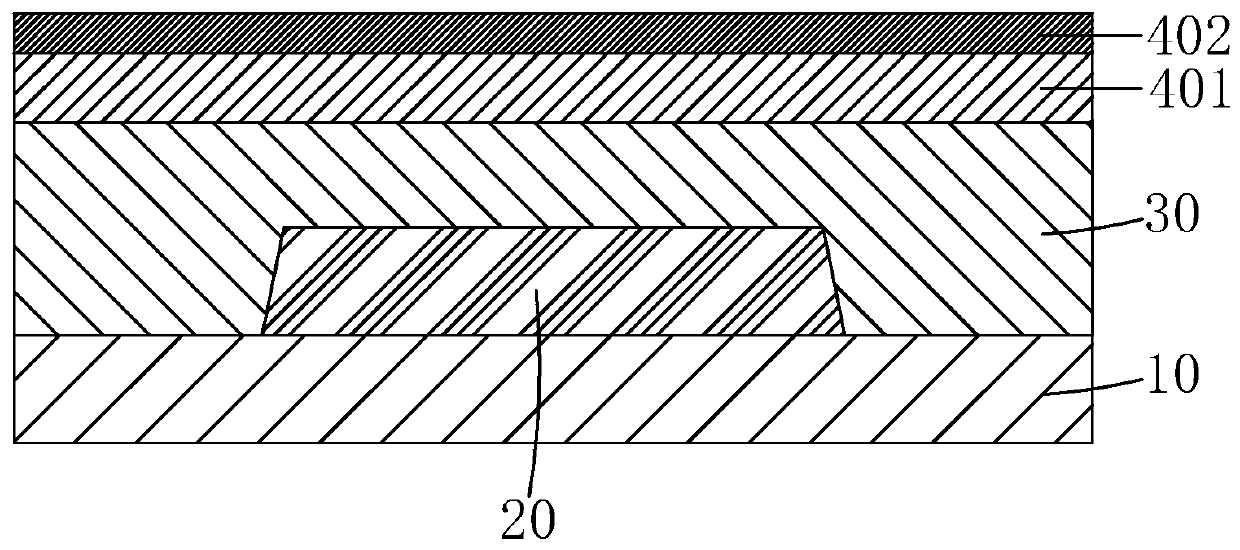

[0042] Step 1, such as figure 2 As shown, a base substrate 10 is provided, a metal material is deposited on the base substrate 10 and etched to form a gate 20 , and a gate insulating layer 30 covering the gate 20 is formed on the base substrate 10 .

[0043] Specifically, the base substrate 10 is a glass substrate.

[0044] Specifically, the step 1 further includes: cleaning and baking the base substrate 10 before forming the gate 20 on the base substrate 10 .

[0045] Specifically, the material of the gate 20 includes one or more of molybdenum (Mo), aluminum (Al), and copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com