Super-retarded concrete and preparation method thereof

A concrete and ultra-retarding technology, which is applied in the field of ultra-retarding concrete and its preparation, can solve the problems of small increase of concrete compressive strength, prolonged concrete setting time, short retardation time, etc. Densification, prolonged setting time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-4

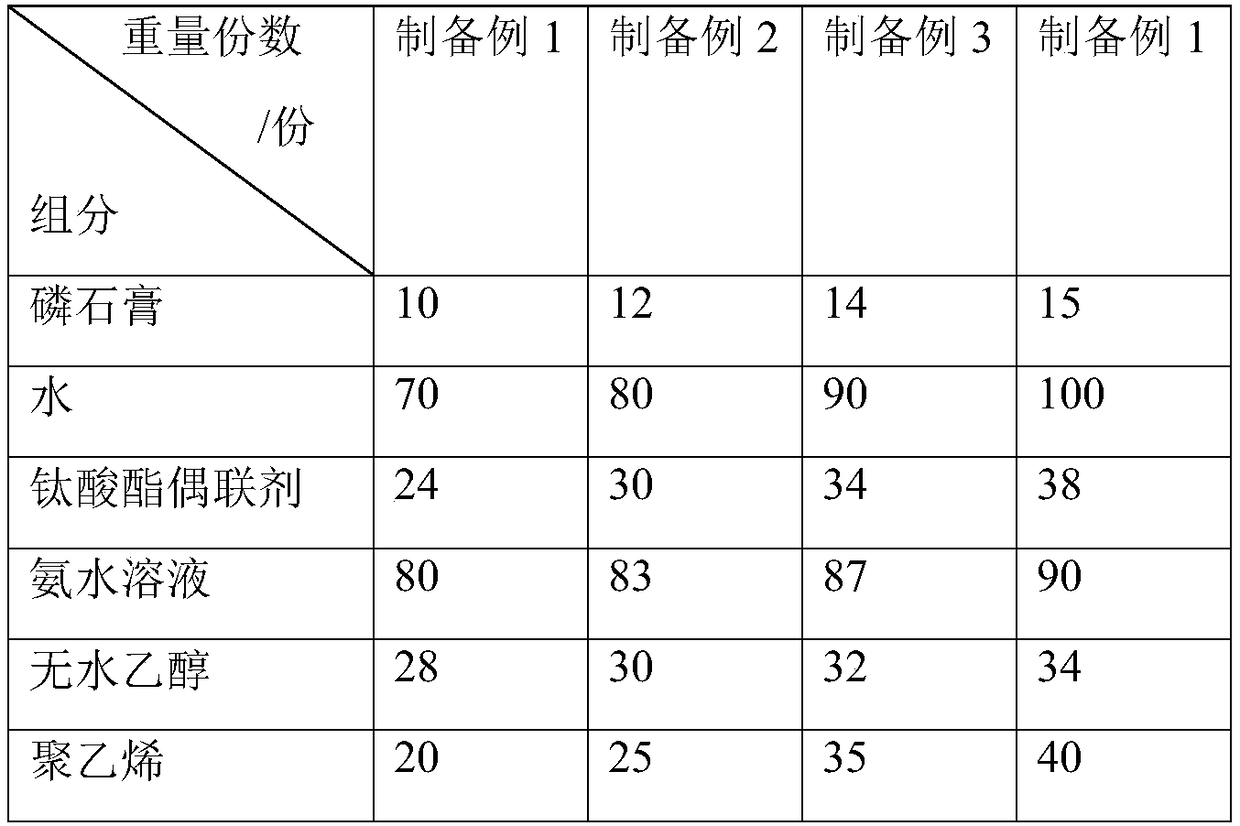

[0045] The composition and proportioning of the retarder in Preparation Examples 1-4 are shown in Table 1, and "parts" represent parts by weight.

preparation example 1

[0048] Preparation example 1: the preparation method of retarder comprises the following steps: (1) according to the proportioning in table 1, after 10 parts of phosphogypsum are rinsed with 70 parts of clear water, pulverize and sieve, make the dry powder that diameter is 40um, then in Dry at 45°C;

[0049] (2) Place the dried phosphogypsum powder in a mixed solution of 26 parts of titanate coupling agent and 28 parts of absolute ethanol with a mass fraction of 20%, adjust the pH of the solution to 6.8, and stir while heating , heated to 60°C, and left for 50 minutes; the titanate coupling agent is TCA-105;

[0050] (3) Suction filter the product obtained in step (2), rinse the filter cake with 80 parts of ammonia water with a mass fraction of 15%, then dry at 65°C for 30 minutes, blend with 20 parts of polypropylene, and extrude to granulate .

preparation example 2

[0051] Preparation example 2: the preparation method of retarder comprises the following steps: (1) according to the proportioning in table 1, after 12 parts of phosphogypsum are washed with 80 parts of clear water, pulverize and sieve, make the dry powder that diameter is 42um, then in Dry at 50°C;

[0052] (2) Place the dried phosphogypsum powder in a mixed solution of 30 parts of titanate coupling agent and 30 parts of absolute ethanol with a mass fraction of 25%, adjust the pH of the solution to 6.9, and stir while heating , heated to 65°C, and left for 52 minutes; the titanate coupling agent is TCA-105;

[0053] (3) Suction filter the product obtained in step (2), rinse the filter cake with 83 parts of ammonia water with a mass fraction of 16%, then dry at 66°C for 34 minutes, blend with 25 parts of polypropylene, and extrude to granulate .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com