Surface wear-resisting layer of gas turbine compressor blade and blade root and manufacturing method thereof

A gas turbine and wear-resistant layer technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of high production cost, coating peeling, complex process flow, etc., to enhance the performance of anti-fretting fatigue, The effect of improving the service life and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

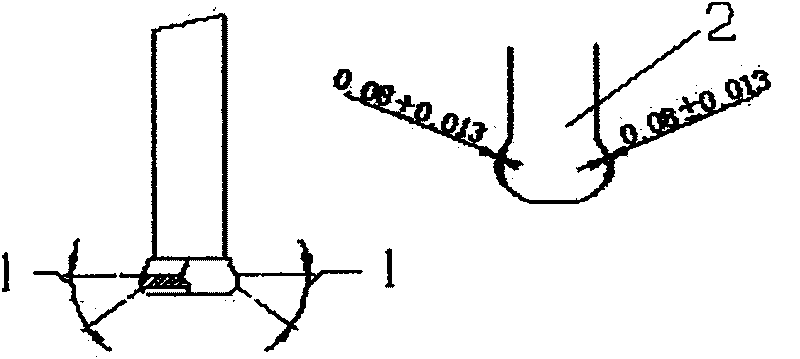

[0026] figure 1 One embodiment of the present invention is shown. The components of this embodiment are 58% by weight of copper powder, 37% by weight of nickel powder, and 5% by weight of indium powder, which is Cu-37Ni-5In alloy powder. The surface wear-resistant layer 1 sprayed by the alloy powder is located at the bottom of the gas turbine compressor blade root 2 and on the outer surface of the contact surface with the impeller. The Cu-37Ni-5In surface wear-resistant layer 1 is sprayed on the surface of the blade root 2 by a supersonic flame spraying (AC-HVAF) method, with a thickness of about 0.08mm.

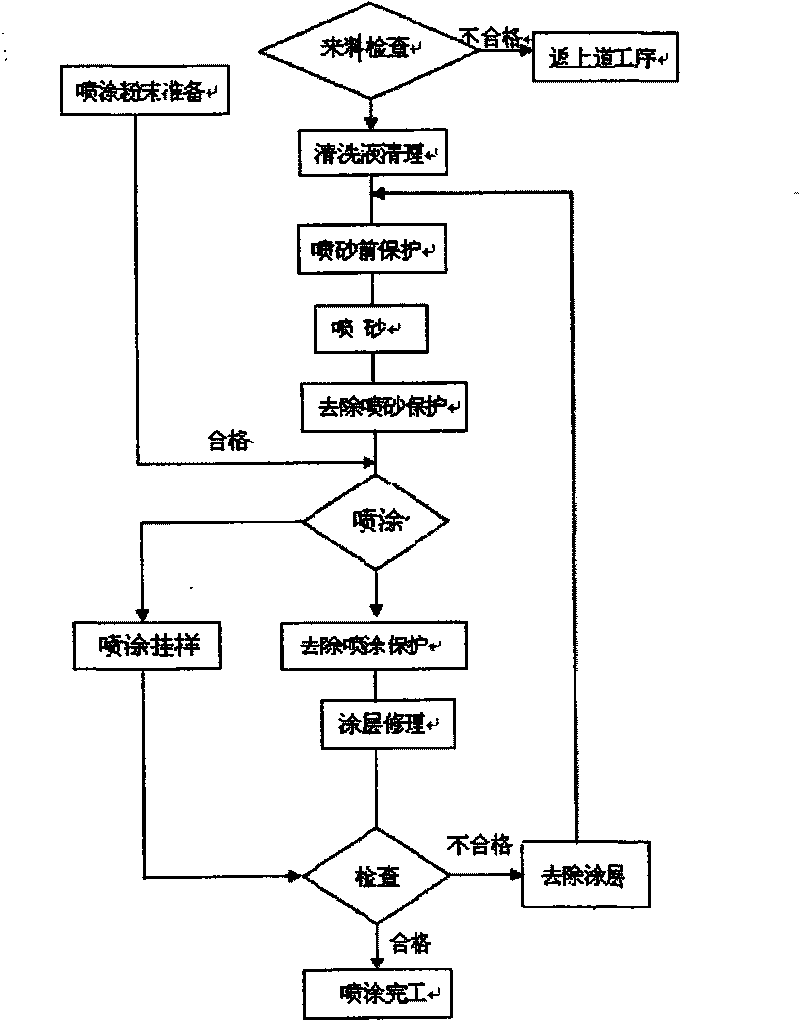

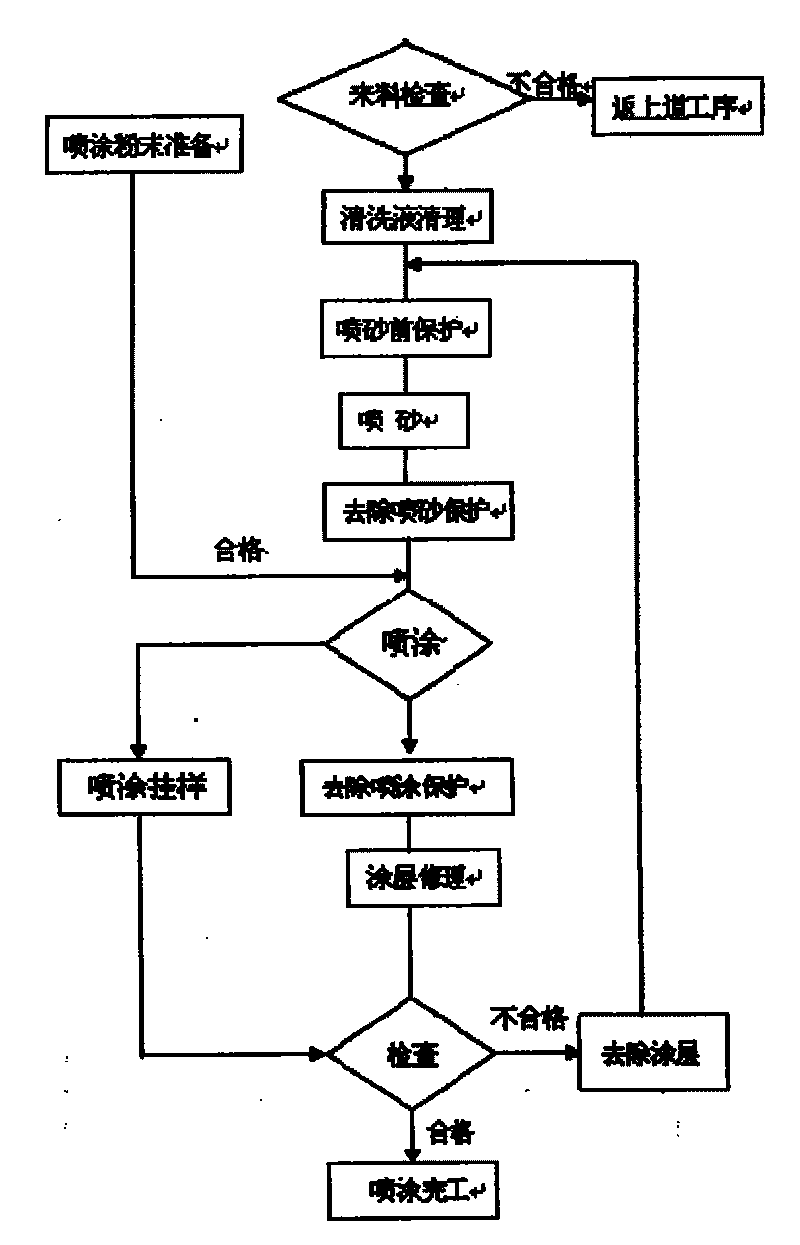

[0027] The preparation method of the surface wear-resistant layer 1 of the gas turbine compressor moving blade root 2 of the present invention, see figure 2 , including the following steps:

[0028] 1. Check the incoming materials to be sprayed, and then enter the next process after passing the inspection.

[0029] 2. Use a cleaning solution, such as acetone, to clean t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com