High dust holding filter material for filter bag

A filter material and filter bag technology, applied in the fields of filtration and separation, dispersed particle filtration, layered products, etc., can solve the problems of limited dust holding layer and difficult to increase dust holding capacity, and achieve easy unwinding and traction, good machinery The effect of high performance and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

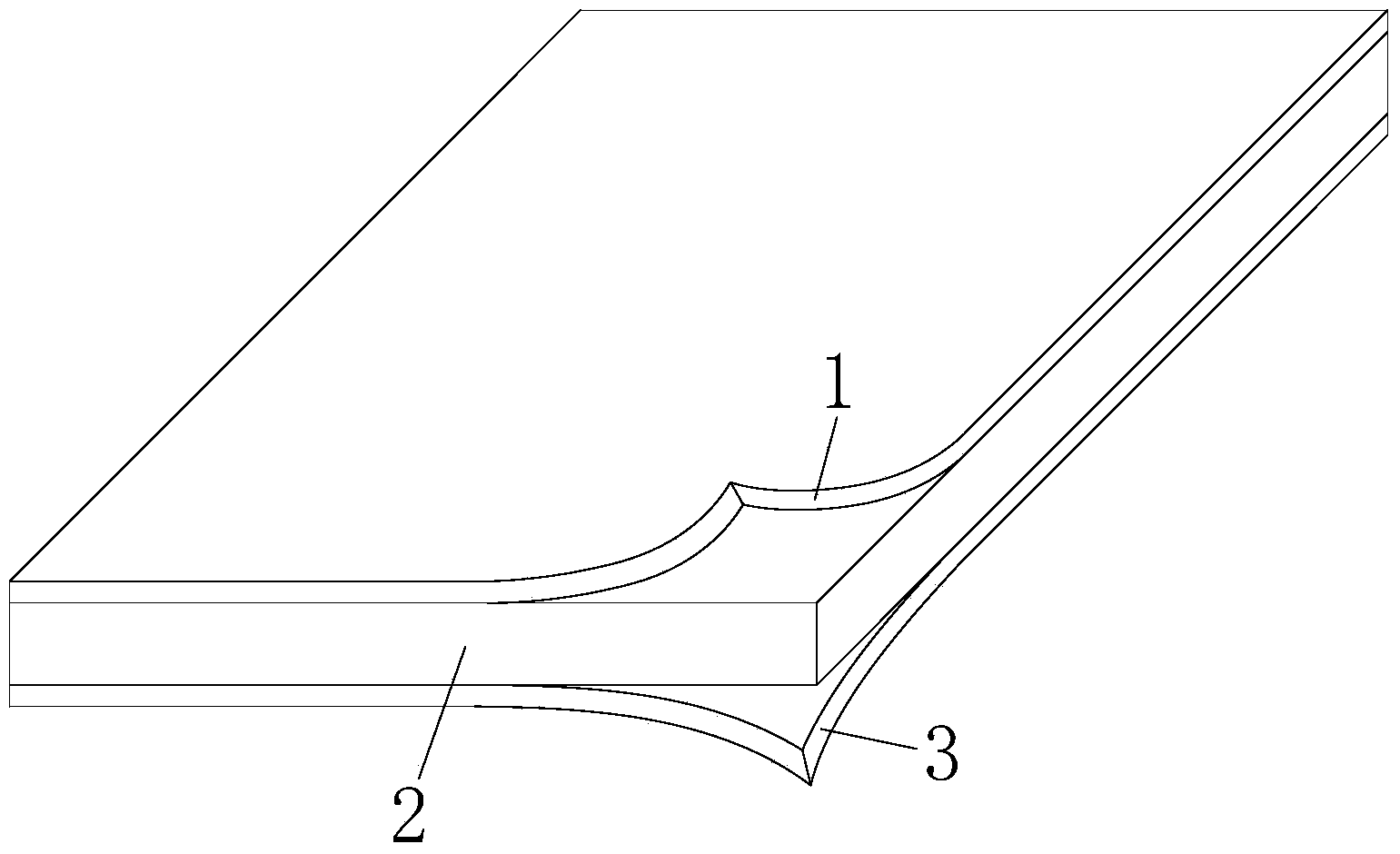

[0010] Example: see figure 1 , the present invention has a three-layer laminated structure in which the upper protective layer 1 and the lower protective layer 3 sandwich the middle dust-holding layer 2, and the three layers are combined into one by acupuncture or ultrasonic welding technology, and the total grammage of the high-dust-holding filter material is 50- 200g / m 2 , where the upper and lower protective layers adopt a grammage of 10-30g / m 2 Made of polypropylene spunbonded non-woven fabric, the purpose is to give the high dust holding filter material a certain strength, and at the same time clamp the dust holding layer to fix the fibers and prevent the fibers from falling off; the dust holding layer is the key layer of the high dust holding filter material. The weight is 30-140g / m 2 , using polypropylene staple fiber raw materials, using mechanical carding and mechanical web forming technology to make a three-dimensional structure with high fluffy and high porosity, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com