Inner support hollow fibrous membrane and preparation method and application thereof

A fiber membrane and hollow technology, which is applied to the inner support hollow fiber membrane and its preparation and application fields, achieves the effect of reducing the possibility of broken wires and fouling, good elasticity, and improving water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

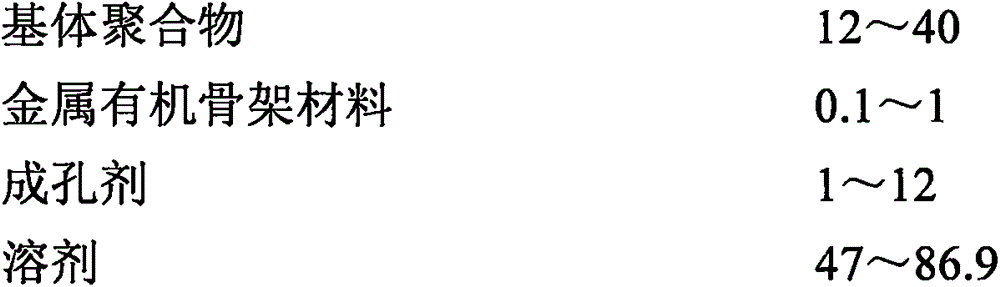

[0036] 1) Weigh 0.09g of MIL-101 and uniformly disperse it in 74.91g of dimethylacetamide under ultrasonic conditions, mix 7g of polyvinylpyrrolidone (K30) and 18g of polyvinyl chloride with a degree of polymerization of 3000 at 70°C under stirring conditions Dissolve the resin in the mixed solution of MIL-101 / dimethylacetamide for 3 hours, filter, stand for defoaming to obtain 18% polyvinyl chloride casting solution for use;

[0037] 2) Soak a polyethylene hollow braided rope with a length of 50 cm, an inner diameter of 0.5 mm, and an outer diameter of 1.2 mm with a 10% sodium hydroxide aqueous solution at 40°C for 1 hour, take it out, wash it and dry it in the air;

[0038] 3) Under the condition of 70°C, evenly coat the polyvinyl chloride casting solution prepared in step 1) on the outer surface of the hollow braided rope prepared in step 2), at a temperature of 10°C and a relative humidity of 99%RH After being placed in a cool environment for 30s, it was solidified by etha...

Embodiment 2

[0040] 1) Weigh 0.04g of MOF-177 and uniformly disperse it in 47.96g of dimethylformamide under ultrasonic conditions, mix 10g of polyethylene glycol (molecular weight 2000), 2g of alumina and 40g of weight-average A polyvinylidene fluoride resin with a molecular weight of 700,000 was dissolved in a mixed solution of MOF-177 / dimethylformamide for 5 hours, filtered, and defoamed to obtain a 40% polyvinylidene fluoride casting solution for use;

[0041] 2) Soak a polyester hollow braided rope with a length of 50 cm, an inner diameter of 2.2 mm, and an outer diameter of 3.2 mm with a 20% sodium hydroxide aqueous solution at 40°C for 1 hour, take it out, wash it and dry it in the air;

[0042] 3) At 50°C, apply the polyvinylidene fluoride casting solution prepared in step 1) on the outer surface of the polyester braided rope prepared in step 2), and immediately solidify in acetone at 30°C for 300s, Soak in deionized water at 20°C for 24 hours, and dry to obtain the inner-supported...

Embodiment 3

[0044] 1) Weigh 0.15g ZIF-8-NH 2 Uniformly dispersed in 69.85g dimethyl sulfoxide under ultrasonic conditions, 5g polyethylene glycol (molecular weight 600) and 25g polyethersulfone resin in ZIF-8-NH 2 Dissolve in the mixed solution of dimethyl sulfoxide / dimethyl sulfoxide for 5 hours, filter and stand for defoaming to obtain 25% polyethersulfone casting solution for later use;

[0045] 2) Soak a polypropylene hollow braided rope with a length of 50 cm, an inner diameter of 1.8 mm, and an outer diameter of 2.8 mm in 30% sodium hydroxide aqueous solution at 40° C. for 1 hour, take it out, wash it and dry it in the air;

[0046] 3) At 40°C, apply the polyethersulfone casting solution prepared in step 1) on the outer surface of the polypropylene braided rope prepared in step 2), at a temperature of 40°C and a relative humidity of 50% After being placed in an RH environment for 200s, it was solidified by ethanol at 20°C for 20s, then soaked in deionized water at 35°C for 15h, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com