Preparation method for aerogel particle in cavity structure

A technology of airgel and microparticles, which is applied in the preparation of microspheres and microcapsule preparations. It can solve the problems of low drug loading, easy separation and drop of microparticles, and low porosity, so as to prolong the release time and improve the preparation method. Simple, controllable, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

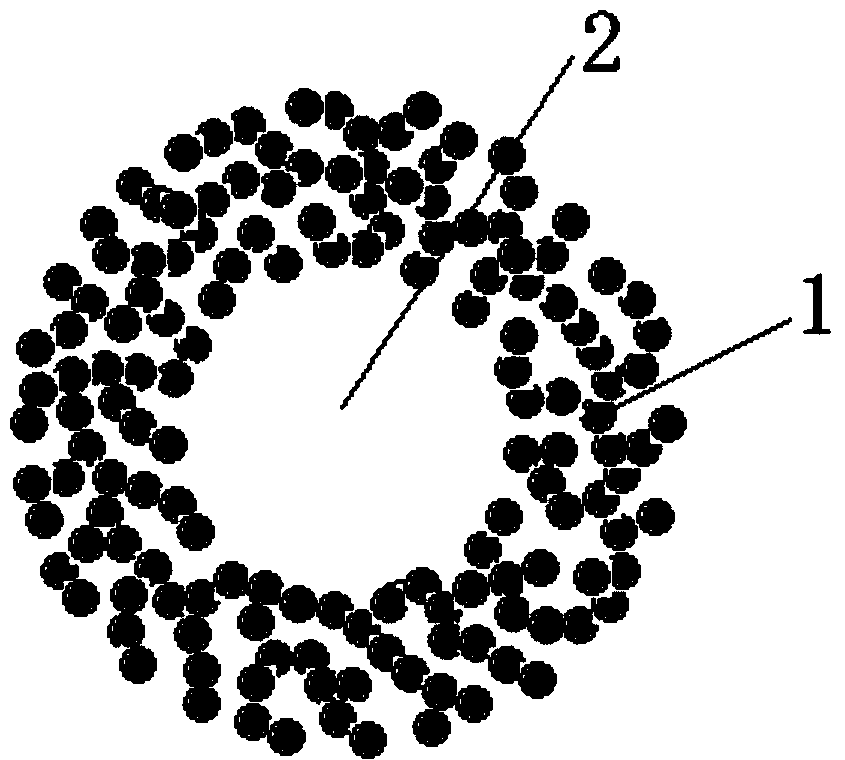

[0052] (Example 1, SiO with cavity structure 2 Preparation method of airgel particles)

[0053] The preparation of SiO with a cavity structure in this embodiment 2 The method of airgel particles comprises the following steps:

[0054] ① SiO 2 Preparation of Wet Gels.

[0055] Stir and mix alkoxysilane, alcohol solvent and pure water under a water bath at 25°C to 60°C for 10min to 60min, add an acidic catalyst dropwise to the above mixture, and stir for 30min to 80min to fully hydrolyze the alkoxysilane to obtain a precursor Then add a basic catalyst dropwise to the acid-catalyzed hydrolyzed material to adjust the pH value of the material to 6-8, so that the precursor sol undergoes a rapid polycondensation reaction, and a colorless and transparent wet gel is obtained after the polycondensation reaction is completed. SiO obtained after static aging for 2h to 15h (6h in this example) 2 Wet gel is ready for use.

[0056] The ratio of the amount of the above-mentioned alkoxysil...

Embodiment 2

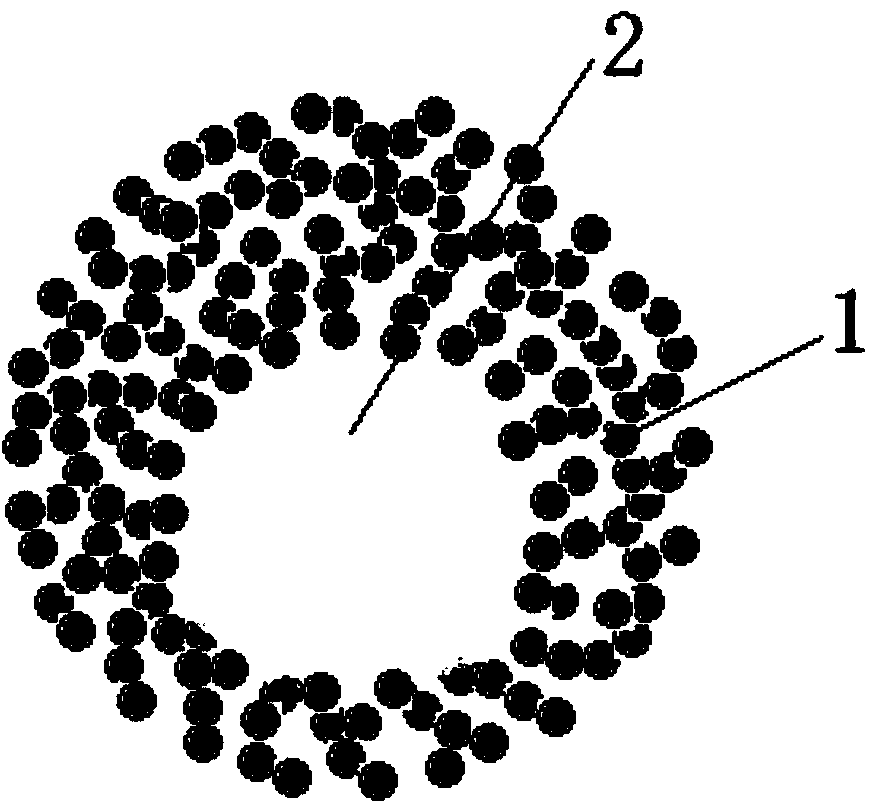

[0088] (Example 2, Fe with cavity structure 2 o 3 / SiO 2 Preparation method of airgel particles)

[0089] The preparation of the present embodiment has Fe with cavity structure 2 o 3 / SiO 2 The method of airgel particles comprises the following steps:

[0090] ①O / W emulsion preparation. Dissolve the iron salt in deionized water to prepare an iron salt solution with a concentration of 0.05 mol / L to 3 mol / L and use it as the water phase; stir and mix the alkoxysilane and the iron salt solution as the oil phase in a water bath, An O / W emulsion is formed. The temperature of the water bath is 20°C to 60°C.

[0091] The iron salt is one of ferric chloride, ferric nitrate, ferric sulfate or a combination of any two or three, in this embodiment it is FeCl 3 ·6H 2 O.

[0092] The ratio of the amount of alkoxysilane to the iron salt is (5-50): (1-10).

[0093] The alkoxysilane is one of ethyl silicate, methyl silicate, propyl silicate and polysiloxane E40, E32, E28 or a comb...

Embodiment 3

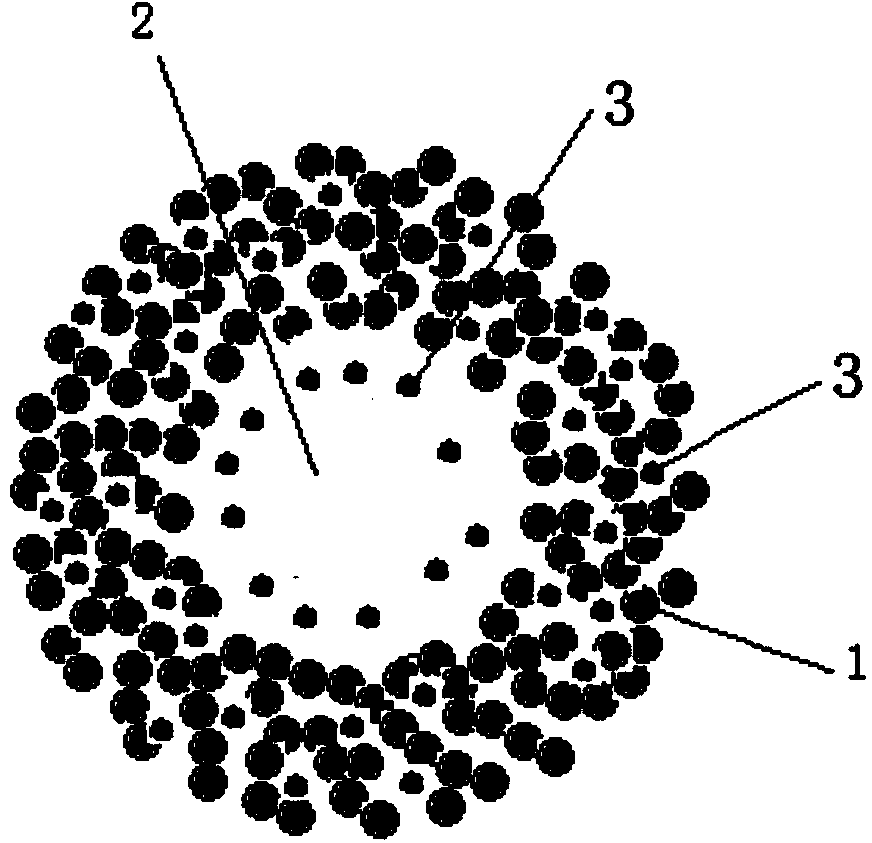

[0110] (embodiment 3, hollow Fe 2 o 3 / SiO 2 Preparation method of airgel microspheres)

[0111] The preparation of the present embodiment hollow Fe 2 o 3 / SiO 2 The method all the other of airgel microsphere is identical with embodiment 2, difference is:

[0112] In step ①, FeCl with a molar ratio of 1:1 3 ·6H 2 O and FeCl 2 4H 2 O was dissolved in deionized water, and the concentration of iron ions in the solution was 1mol / L. Stir and mix TEOS and iron ion solution in a water bath to form an O / W emulsion. The mass ratio of TEOS to iron ions was 50:5.

[0113] The molar ratio of TEOS to sodium hydroxide in step ③ is 50:0.5.

[0114] In step ④, add hexadecyltrimethylammonium chloride and deionized water to the material after the alkali-catalyzed reaction in step ③, continue to stir for 2 hours, leave it to stand for aging for 1d; then carry out solid-liquid separation, and use deionized water, acetone washing.

[0115] In step ⑤, soak the gel washed in step ④ in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com